Numerical Simulation and Analysis of Semi-Industrial Retrofit for Tangentially Fired Boilers with Slag-Tap Technology

Abstract

1. Introduction

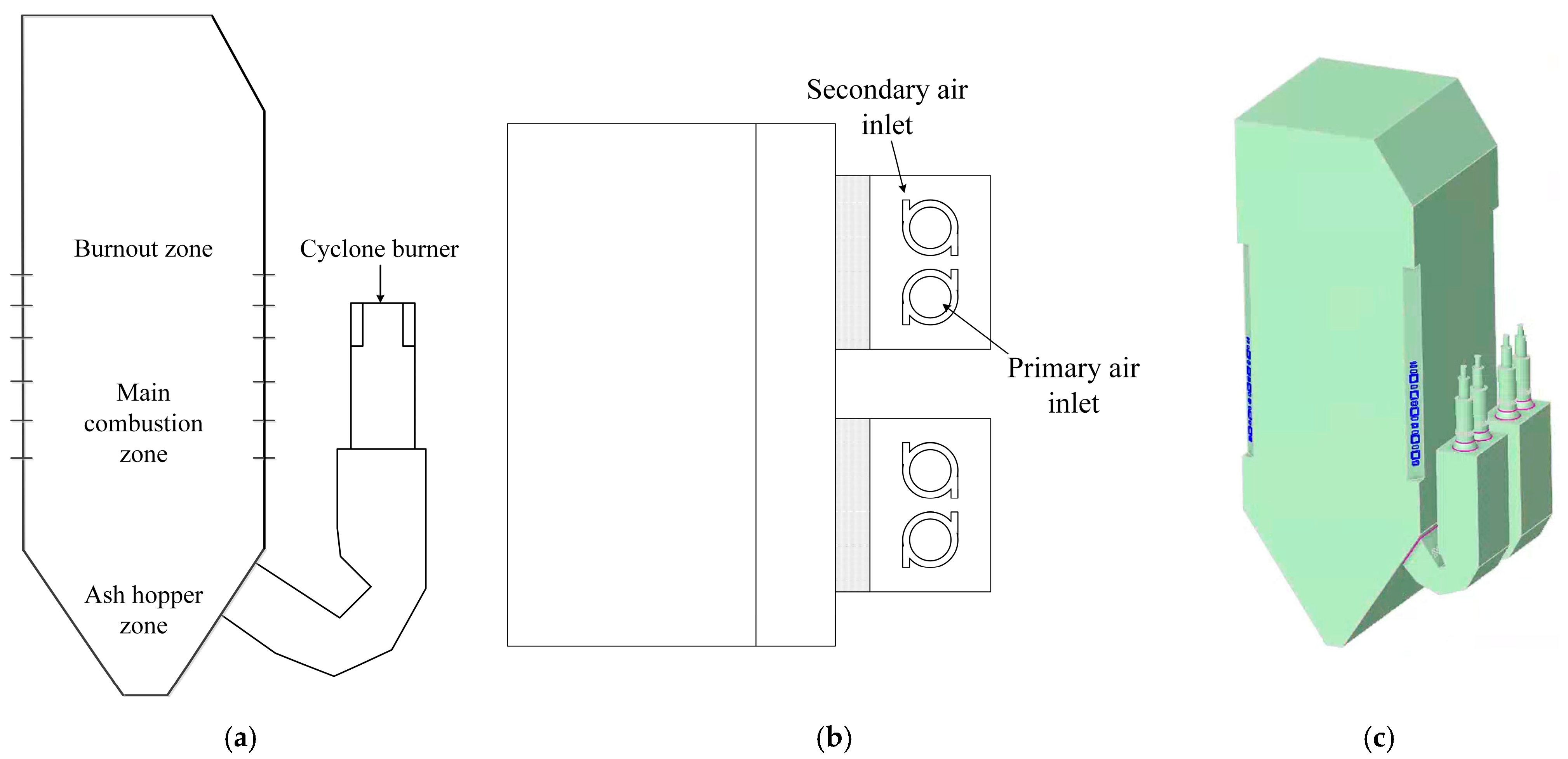

2. Boiler Structure and Geometry

2.1. Original Model of the Boiler

2.2. Modified Model of the Boiler

3. Numerical Simulation

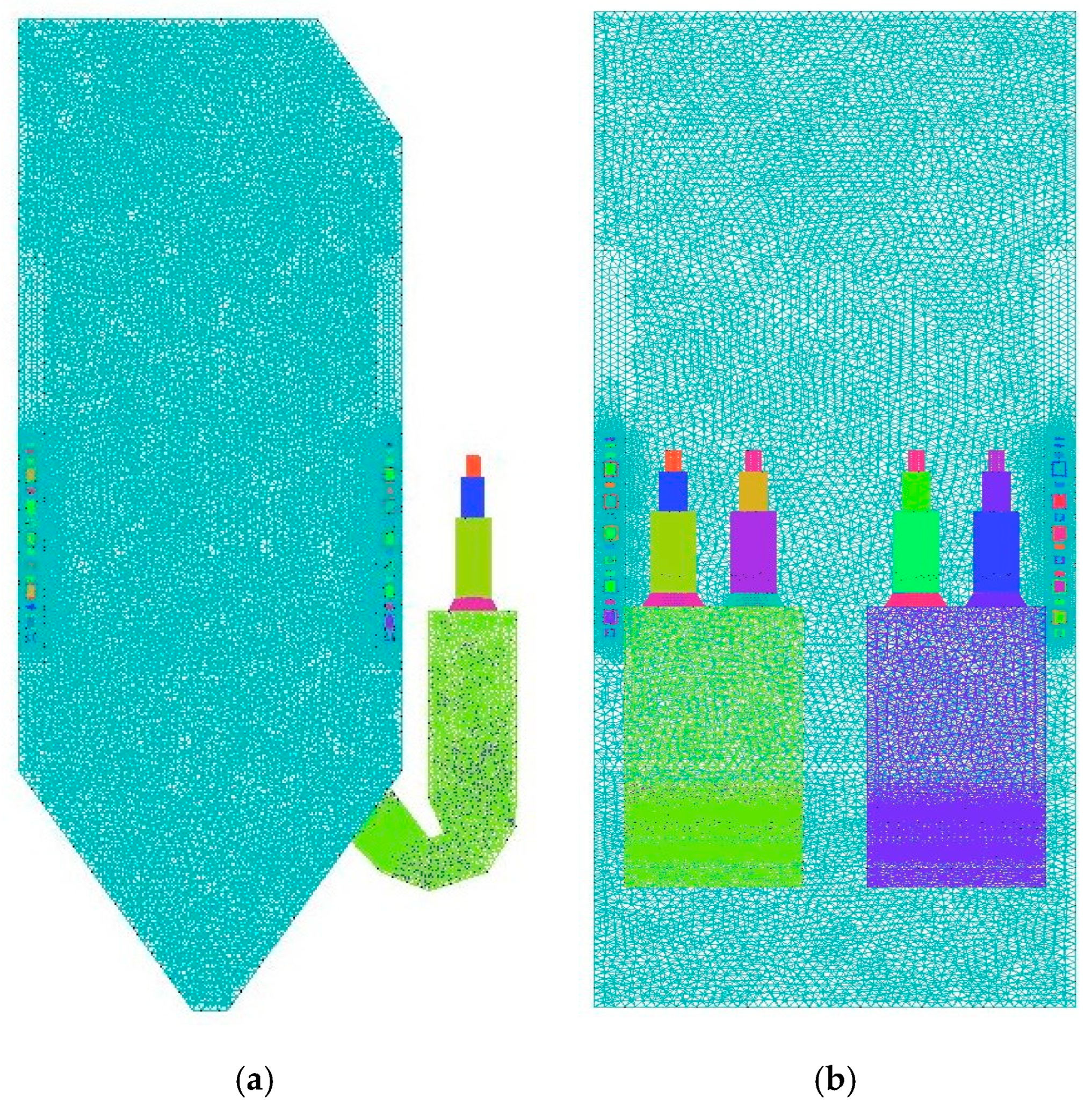

3.1. Grid Generation

3.2. Basic Equations for CFD Simulation

3.3. Numerical Methods

3.4. Boundary Conditions

3.5. Working Conditions

4. Results and Discussion

4.1. Simulation Model Validation

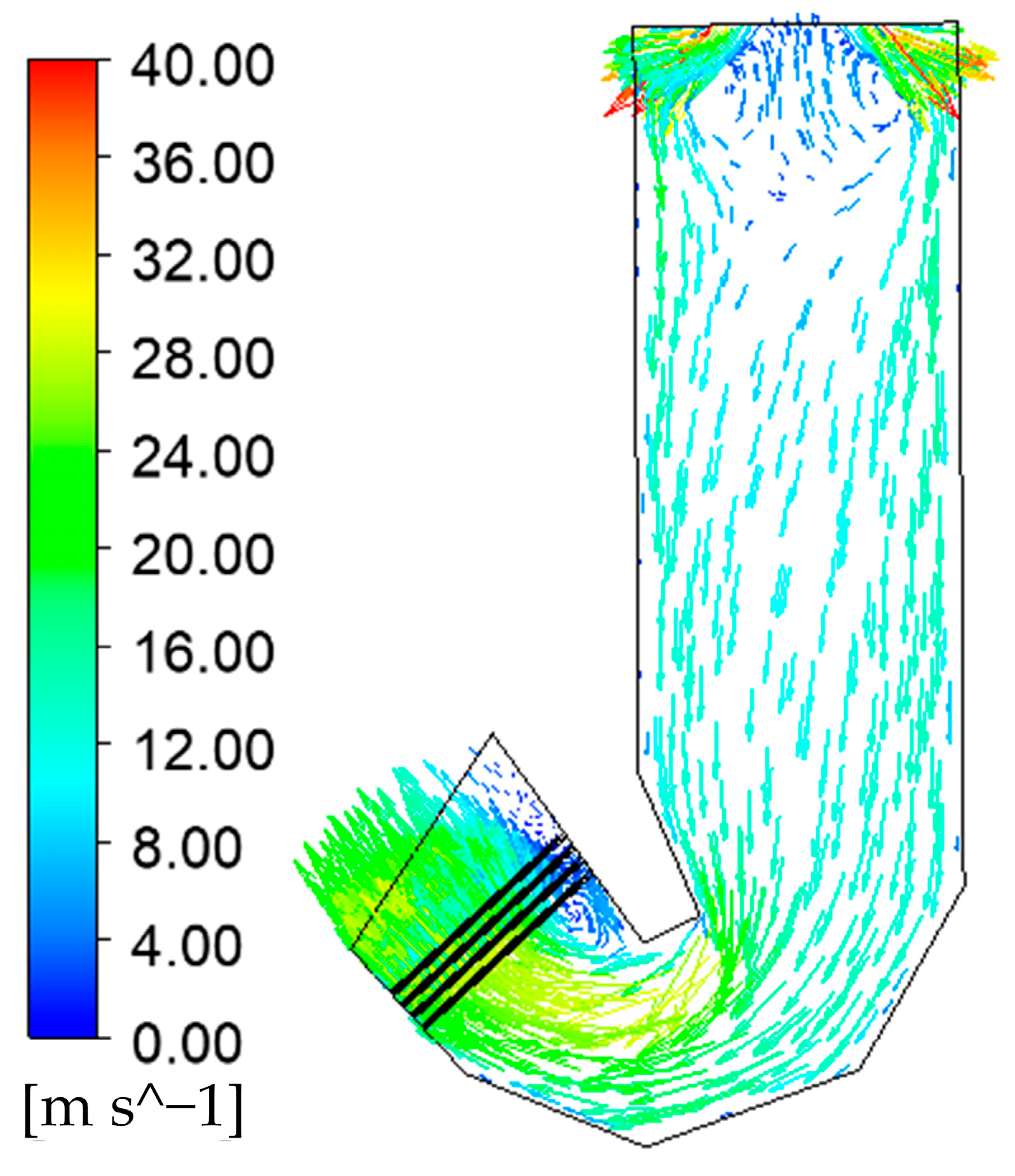

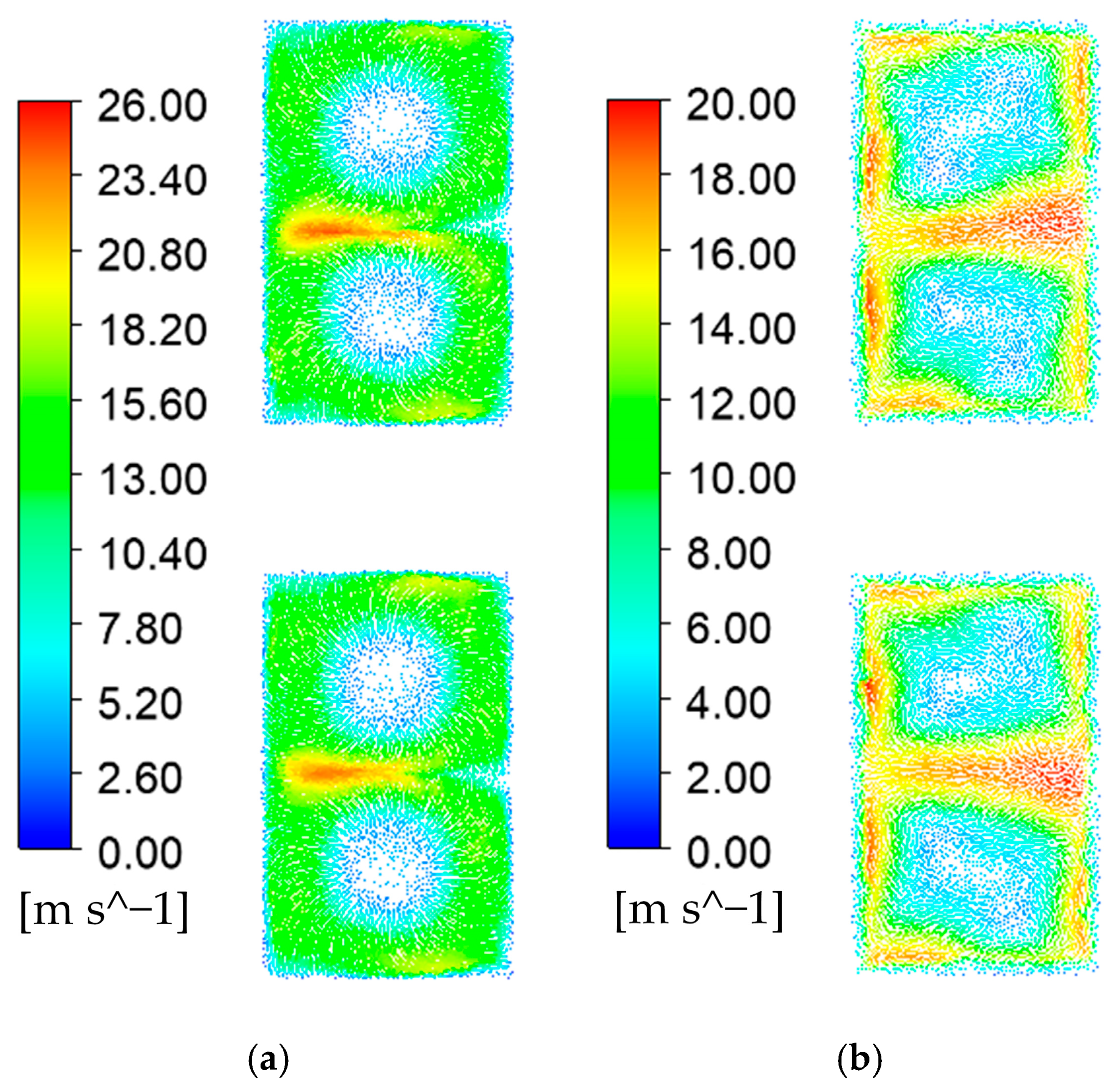

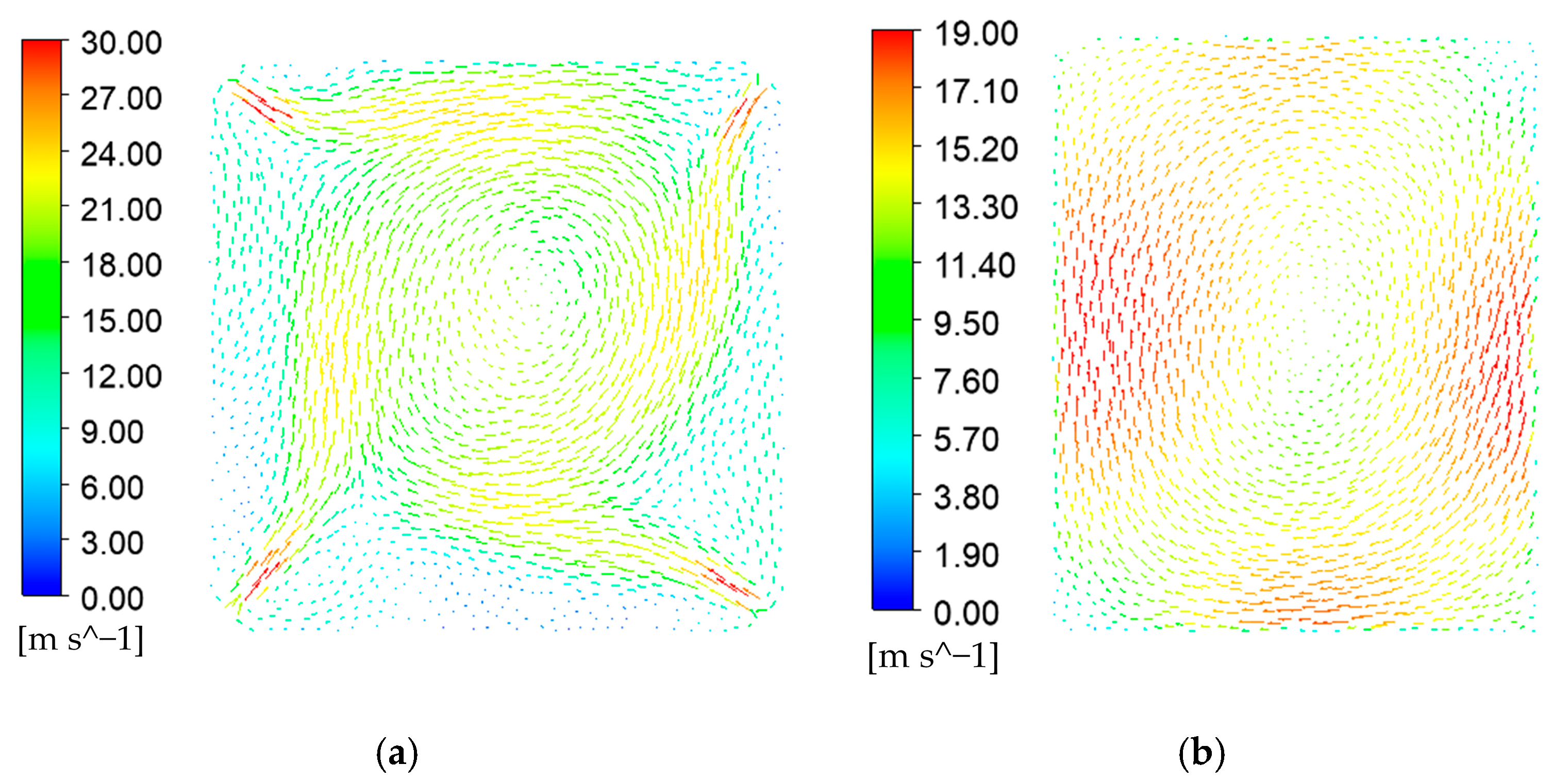

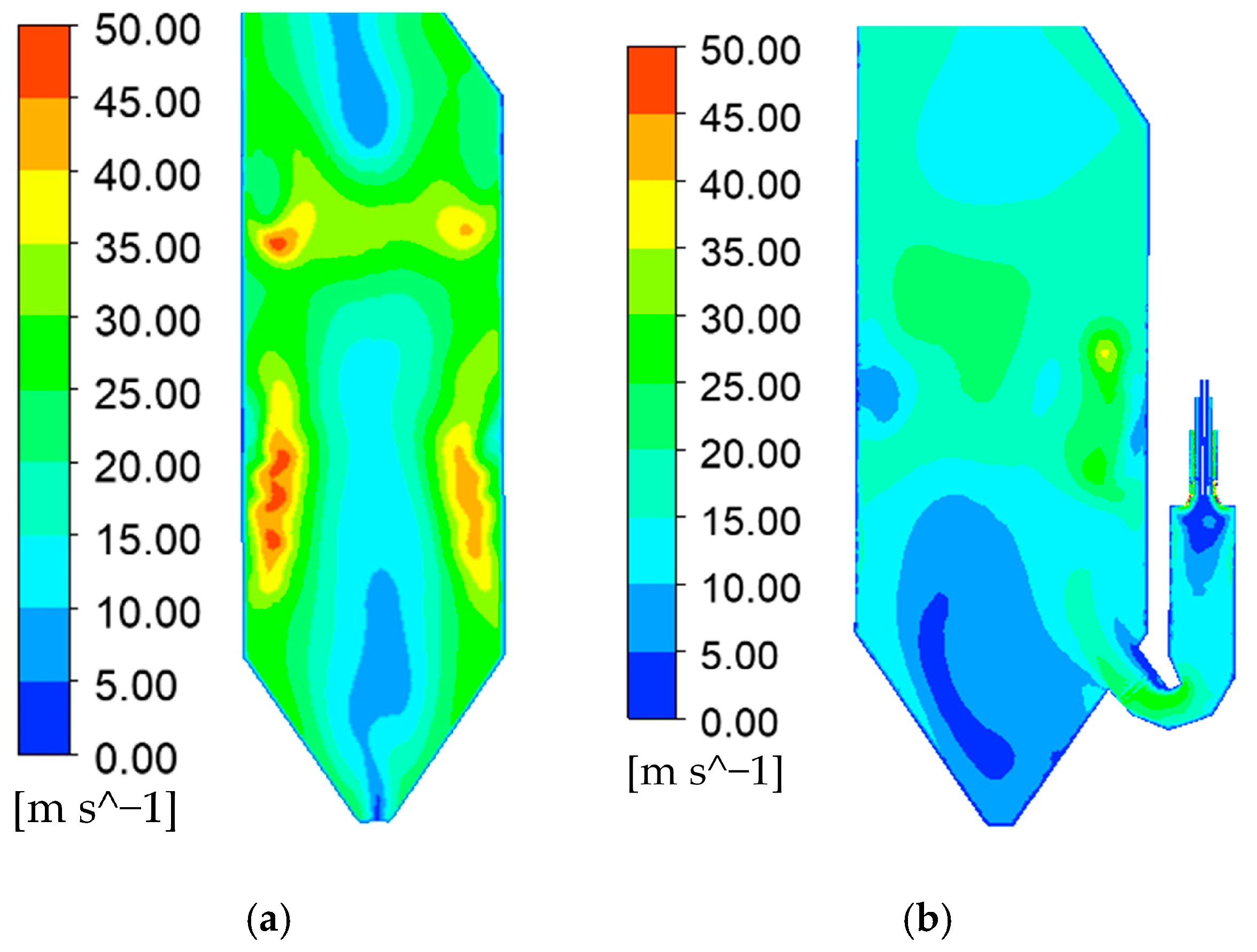

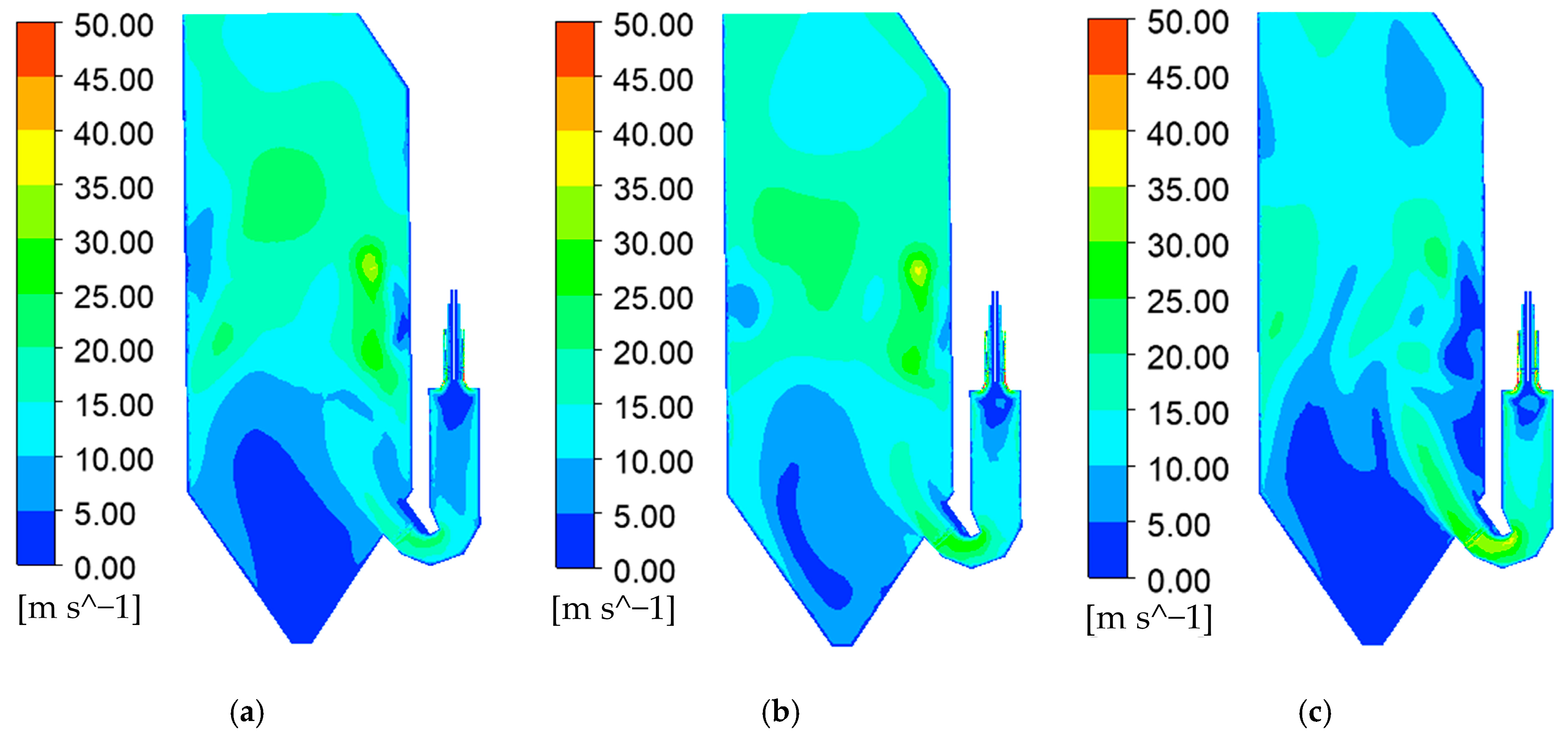

4.2. Analysis of the Aerodynamic Field in the Retrofit Furnace

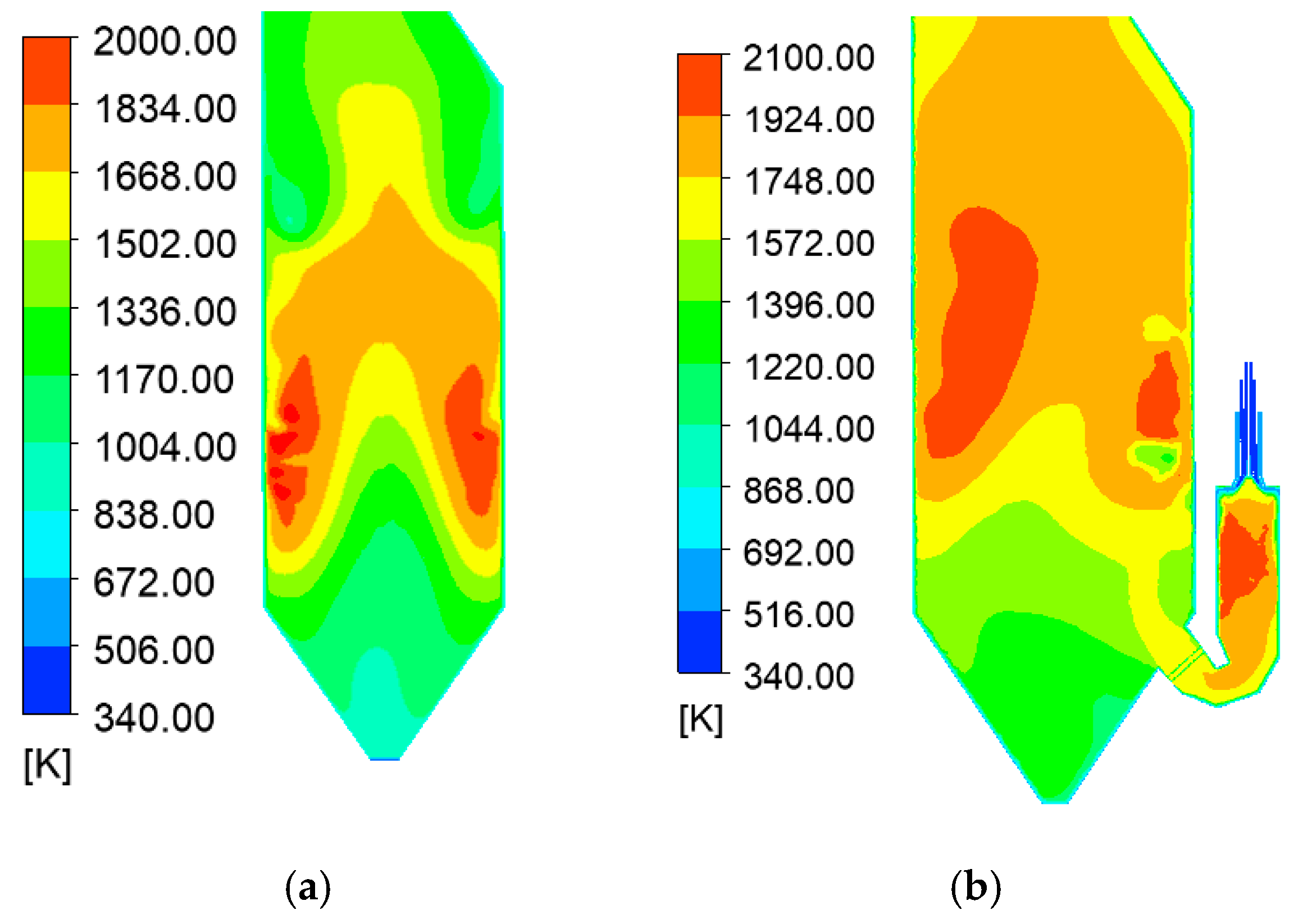

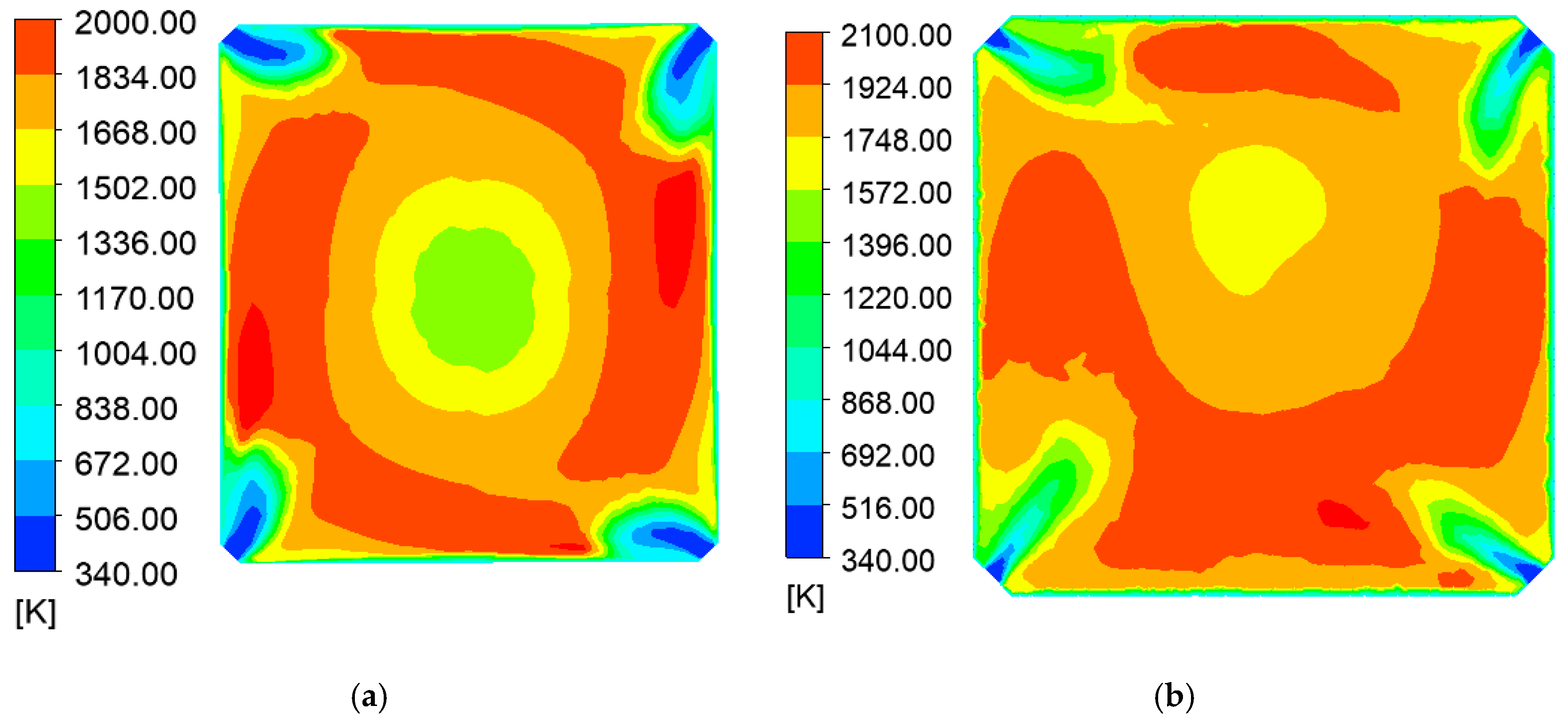

4.3. Analysis of the Temperature Field in the Retrofit Furnace

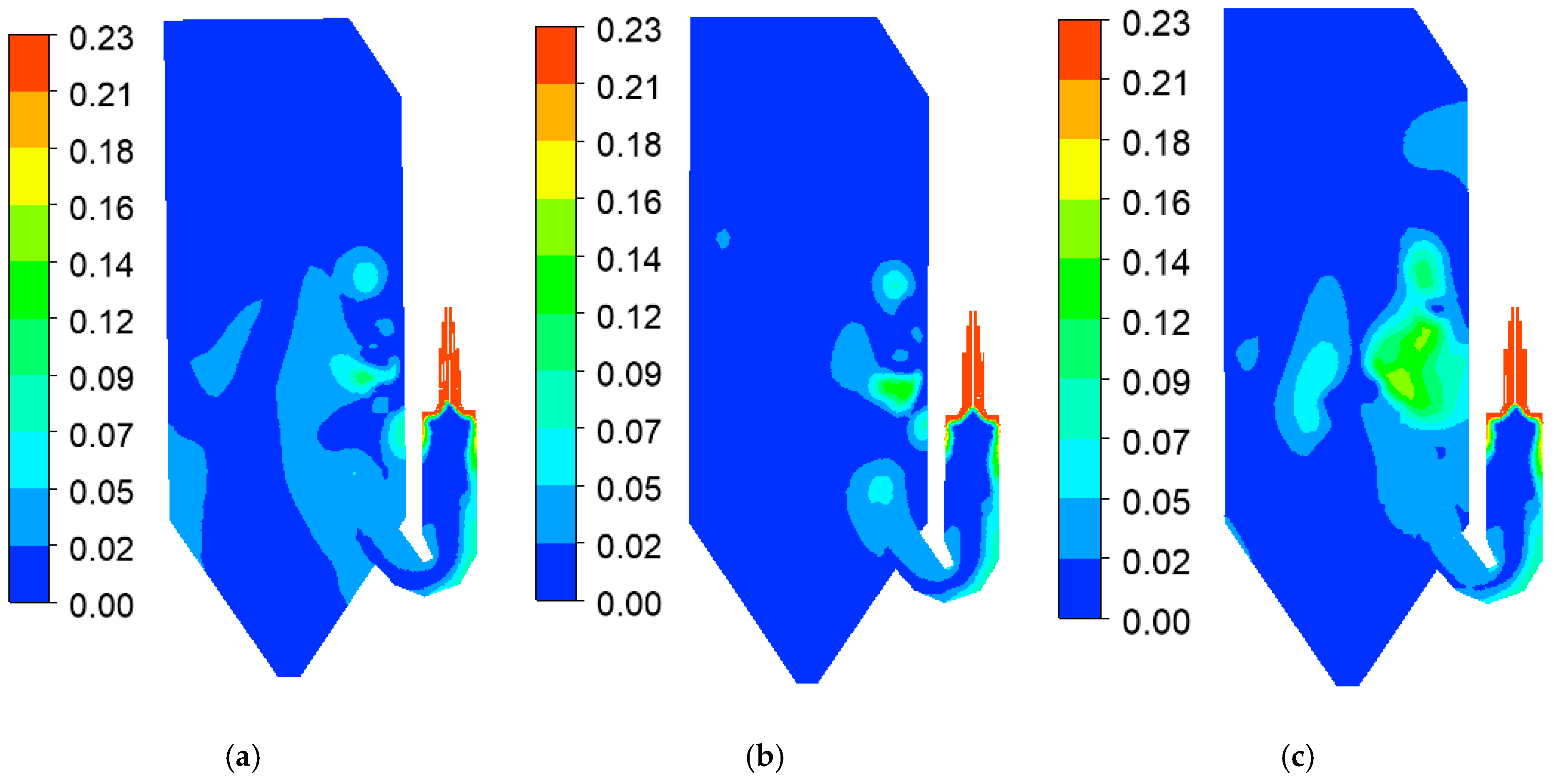

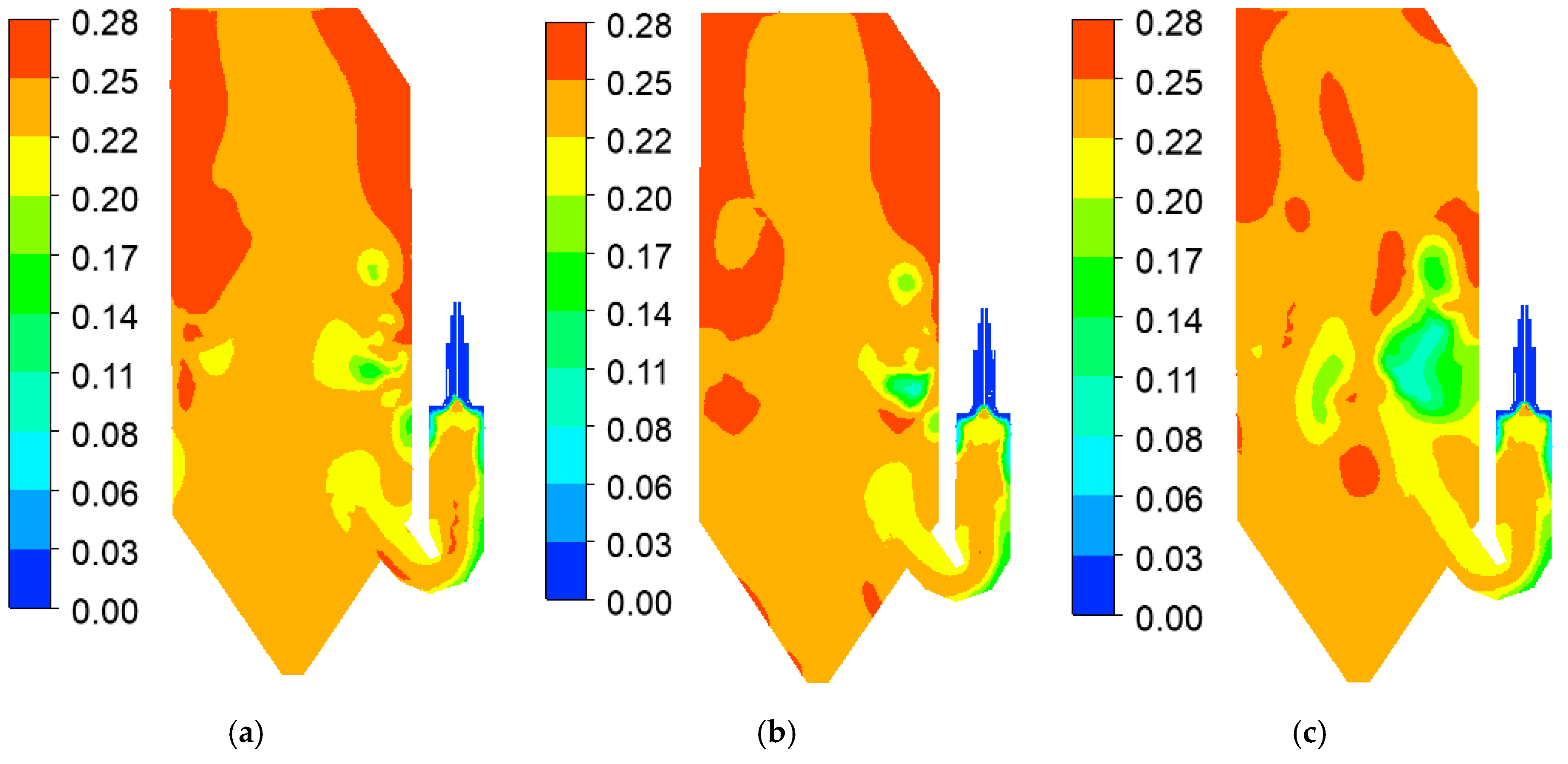

4.4. Analysis of the Component Concentrations in the Retrofit Furnace

4.5. Influence of the Zhundong Coal Ratio on Heat and Mass Transfer Characteristics in the Furnace

5. Conclusions

- The combustion chamber exhibits a peak temperature of approximately 2080 K in the upper central region, with a peripheral-to-center gradient driven by cyclonic flow. As the flue gas exits, the temperature drops to around 1650 K, due to the slag catcher’s cooling. Meanwhile, furnace regions reach a peak temperature of 2180 K during coal combustion, displaying a periphery–high, center–low temperature distribution. This modification significantly stabilizes combustion and reduces slag formation. These findings demonstrate the retrofit’s potential to improve operational reliability when burning high-alkali coal.

- The retrofit effectively regulates O2 and CO2 distributions throughout the furnace, enhancing oxygen availability and CO2 formation in critical regions. This optimization improves the combustion efficiency and reduces the risk of slagging. Such improvements are critical for industrial applications where high combustion efficiency and reduced fouling are key operational objectives.

- Higher blending ratios of Zhundong coal induce specific shifts in O2 and CO2 concentrations, particularly near the bottom burner region, indicating improved air–fuel mixing, facilitated by the retrofit. As the Zhundong coal ratio increases to 30%, the combustion chamber temperature rises by 3%, reaching approximately 2080 K, while the flow velocity in the upper and middle furnace sections decreases by up to 15%, thereby enhancing the overall combustion intensity. From an engineering perspective, this finding supports the adaptability of the retrofit for various coal blending scenarios, which is crucial for operational flexibility.

- The temperature distribution within the furnace displays higher values at the periphery, with a peak temperature of around 2180 K in the combustion chamber center, aligning with cyclone combustion characteristics. Additionally, the O2 and CO2 mass fraction distributions confirm that the retrofit effectively manages oxygen consumption and combustion product formation, with notable changes in concentrations influenced by disturbances from the combustion chamber’s exit jet.

- Higher blending ratios reduce the flow velocity in the upper and middle furnace sections, thereby decreasing cyclonic flow intensity. However, the exit jet from the combustion chamber significantly impacts flow dynamics, causing local temperature fluctuations of ± 5% that ultimately influence combustion efficiency. Addressing these dynamics in future designs could further optimize furnace performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Li, J.; Wu, G.G.; Bai, Z.Q.; Li, W. Clean and efficient utilization of sodium-rich Zhundong coals in China: Behaviors of sodium species during thermal conversion processes. Fuel 2018, 218, 162–173. [Google Scholar] [CrossRef]

- Lei, Y.; Fu, P.; Tang, S.; Yue, F.; Bie, K.; Liu, Y. Occurrence form of sodium in Zhundong coal and its evaporation and condensation characteristics. J. Combust. Sci. Technol. 2019, 25, 124–130. [Google Scholar]

- Wang, C.A.; Li, G.Y.; Du, Y.B.; Yan, Y.; Li, H.; Che, D.F. Ash deposition and sodium migration behaviors during combustion of Zhundong coals in a drop tube furnace. J. Energy Inst. 2018, 91, 251–261. [Google Scholar] [CrossRef]

- Jing, X.H.; Pu, Y.; Li, Z.Y.; Tang, Q.L.; Yao, B.; Fu, P.F.; Lou, C.; Lim, M. Experimental Investigation of Gaseous Sodium Release in Slag-Tapping Coal-Fired Furnaces by Spontaneous Emission Spectroscopy. Energies 2022, 15, 4165. [Google Scholar] [CrossRef]

- Hariana; Prismantoko, A.; Prabowo; Hilmawan, E.; Darmawan, A.; Aziz, M. Effectiveness of different additives on slagging and fouling tendencies of blended coal. J. Energy Inst. 2023, 107, 101192. [Google Scholar] [CrossRef]

- Zhu, L. Analysis and optimization of high alkali coal boiler. Boil. Technol. 2020, 51, 37–44. [Google Scholar]

- Guo, Y.; Bai, X.; Zhang, X.; Gao, G.; Wang, G.; Yao, W. Study on techniques for slagging prevention and ash deposition control in existing boilers burning high-alkali coal. Therm. Power Gener. 2022, 51, 131–140. [Google Scholar]

- Zhang, P.; Lyu, J.; Wang, H.; Xin, S.; Liang, J.; Wu, W.; Qiu, Z.; Du, J. Study kaolin on operation characteristics of a 300 MW CFB boiler burning Zhundong high-alkali coal. Boil. Technol. 2020, 51, 29–32+54. [Google Scholar]

- Yang, Y.; Wang, D.; Chen, X.; Yao, B. Study on comprehensive evaluation of slagging characteristics of high-alkali coal blending combustion from Hami Area. Coal Sci. Technol. 2020, 48, 207–213. [Google Scholar]

- Yang, Y.; Chen, C.; Chen, X.; Wang, D.; Yao, B. Experimental study on fouling characteristics for blending ratio of high alkali coal in Hami area. Coal Sci. Technol. 2019, 47, 214–219. [Google Scholar]

- Meng, Y.; Li, Y.; Yang, Z.; Qi, Q.; Jiang, T.; Zhao, X.; Nie, M. Adaptability research of different types of boiler burning Naomaohu high-alkali coal in one power plant. Therm. Power Gener. 2023, 52, 142–149. [Google Scholar]

- Huang, S.; Zhang, L.; Yan, J.; Wang, Z.; Lei, Z.; Li, Z.; Ren, S.; Wang, Z.; Shui, H. Investigation on cofiring high-alkali coal with coal gangues: SO2, NO reduction and ash slagging inhibition. CIESC J. 2022, 73, 5581–5591. [Google Scholar]

- Wang, Y.A.; Zou, L.; Shao, H.S.; Bai, Y.Y.; Liu, Y.; Zhao, Q.X.; Li, F.X. Co-combustion of high alkali coal with municipal sludge: Thermal behaviour, kinetic analysis, and micro characteristic. Sci. Total Environ. 2022, 838, 156489. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.D.; Yang, D.; Zhou, X.H.; Dong, L.; Suo, L.H.; Sun, W.B. Heavy metal migration characteristics of co-combustion between sewage sludge and high alkaline coal on circulating fluidized bed. J. Therm. Sci. 2022, 31, 2178–2188. [Google Scholar] [CrossRef]

- Tang, C.W.; Pan, W.G.; Zhang, J.K.; Wang, W.H.; Sun, X.L. A comprehensive review on efficient utilization methods of High-alkali coals combustion in boilers. Fuel 2022, 316, 123269. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Cheng, L.M.; Ji, J.Q.; Zhang, W.G. Ash deposition behavior in co-combusting high-alkali coal and bituminous coal in a circulating fluidized bed. Appl. Therm. Eng. 2019, 149, 520–527. [Google Scholar] [CrossRef]

- Wang, Y.G.; Bai, Y.Y.; Zou, L.; Liu, Y.; Li, F.X.; Zhao, Q.X. Co-combustion characteristics and ash melting behavior of sludge/high-alkali coal blends. Combust. Sci. Technol. 2024, 196, 177–194. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, S.; Liu, J.; Zhang, Y.; Li, H.; Zhou, H. Slagging and element migration characteristics of Zhundong coal in horizontal liquid slag cyclone furnace. Clean Coal Technol. 2024, 30, 27–35. [Google Scholar]

- Gong, Y.; Fu, P.; Liu, Y.; Bie, K. Sintering characteristics of Zhundong coal ash and refractory material of slag tap pulverized coal boiler. J. Combust. Sci. Technol. 2021, 27, 67–73. [Google Scholar]

- Ren, Z.; Fan, J.; Chen, S. Numerical simulation of combustion characteristics of horizontal cyclone burner. Power Syst. Eng. 2021, 37, 25–28+32. [Google Scholar]

- Lan, D.; Fan, J.; Zhang, Z.; Hu, X.; Chen, S. Experimental study on combustion of high alkali coal in horizontal liquid slag cyclone furnace. Clean Coal Technol. 2020, 26, 119–126. [Google Scholar]

- Hu, S.H.; Ni, Y.G.; Yin, Q.; Wang, J.K.; Lv, L.Q.; Cen, K.F.; Zhou, H. Research on element migration and ash deposition characteristics of high-alkali coal in horizontal liquid slagging cyclone furnace. Fuel 2022, 308, 121962. [Google Scholar] [CrossRef]

- Zhu, M.X.; Lu, H.; Zhao, W.J.; Huang, S.W.; Chang, X.Q.; Dong, L.J.; Kong, D.; Jing, X.H. A numerical study of ash deposition characteristics in a 660MW supercritical tangential boiler. Adv. Theory Simul. 2023, 6, 2300133. [Google Scholar] [CrossRef]

- Zhong, Y.X.; Wang, X.; Xu, G.; Ning, X.Y.; Zhou, L.; Tang, W.; Wang, M.H.; Wang, T.; Xu, J.; Jiang, L.; et al. Investigation on slagging and high-temperature corrosion prevention and control of a 1000 MW ultra supercritical double tangentially fired boiler. Energy 2023, 275, 127455. [Google Scholar] [CrossRef]

- Liao, X.; Zhang, Q.; Yang, W.H.; Qiu, Z.Z.; Guo, R.T.; Liu, J.Q.; Li, F.Q.; Li, Y. The role of pulverized coal drying temperature in fly ash carbon content and slagging of a tangentially coal-fired boiler. Fuel 2019, 257, 115951. [Google Scholar] [CrossRef]

- Pei, J.J.; Zhang, Z.; You, C.F. Optimizing the combustion of low-quality coal by the wall wind auxiliary combustion method in a tangentially fired utility boiler. Combust. Sci. Technol. 2019, 191, 570–589. [Google Scholar] [CrossRef]

- ASTM D388-19; Standard Classification of Coals by Rank. ASTM International: West Conshohocken, PA, USA, 2019.

- GB/T 5751-2009; Classification of Coals in China. National Standard of the People’s Republic of China: Beijing, China, 2009.

- Wang, H.; Ma, X.; Deng, L.; Bai, P.; Wang, Y. Double-U-Shaped Low-Nitrogen Combustion System of Liquid Slag Discharging Boiler Containing Classified Furnace Smoke. CN112325276A, 5 February 2021. [Google Scholar]

- Hidki, R.; El Moutaouakil, L.; Boukendil, M.; Charqui, Z.; Jamal, B. Analysis of mixed convection and surface radiation in a horizontal channel containing different finned heat-generating blocks. Therm. Sci. Eng. Prog. 2024, 48, 102370. [Google Scholar] [CrossRef]

- Ma, Q.L.; Zhong, W.Q.; Chen, X.; Li, J.H.; Zhang, H. Numerical Simulation of the Effects of Oil Gun Location and Oil Feed Rate on Coal Ignition and Burner Wall Temperature in a Tiny Oil Ignition Burner. Energies 2021, 14, 7597. [Google Scholar] [CrossRef]

- Rachele, L.; Cristiana, B.; Marco, F.; Leonardo, T.; Chiara, G. Impact of H2-enriched natural gas on pollutant emissions from domestic condensing boilers: Numerical simulations of the combustion chamber. Int. J. Hydrog. Energy 2023, 48, 19686–19699. [Google Scholar]

- Nakamura, H.; Zhang, J.W.; Hirose, K.; Shimoyama, K.; Ito, T.; Kanaumi, T. Generating simplified ammonia reaction model using genetic algorithm and its integration into numerical combustion simulation of 1 MW test facility. Appl. Energy Combust. Sci. 2023, 15, 100187. [Google Scholar] [CrossRef]

- Zhu, B.; Shang, B.C.; Guo, X.; Wu, C.; Chen, X.Q.; Zhao, L.L. Study on Combustion Characteristics and NOx Formation in 600 MW Coal-Fired Boiler Based on Numerical Simulation. Energies 2023, 16, 262. [Google Scholar] [CrossRef]

- Li, Z.X.; Miao, Z.Q.; Shen, X.S.; Li, J.T. Effects of momentum ratio and velocity difference on combustion performance in lignite-fired pulverized boiler. Energy 2018, 165, 825–839. [Google Scholar] [CrossRef]

- Zhu, M.; Chen, L.; Zhou, L.A.; Jiang, L.; Su, S.; Hu, S.; Xu, K.; Wang, C.; Li, A.S.; Qing, H.R.; et al. Experimental test, numerical analysis and thermal calculation modeling of hundreds kWth-class supercritical CO2 fossil-fired boiler system. Energy 2023, 284, 128523. [Google Scholar] [CrossRef]

- Zhou, J.; Zhu, M.; Su, S.; Chen, L.; Xu, J.; Hu, S.; Wang, Y.; Jiang, L.; Zhong, W.Q.; Xiang, J. Numerical analysis and modified thermodynamic calculation methods for the furnace in the 1000 MW supercritical CO2 coal-fired boiler. Energy 2020, 212, 118735. [Google Scholar] [CrossRef]

- Wang, W.S.; Sun, Y.Z.; Huang, Z.H.; Liao, Y.H.; Fang, F. Numerical simulation of NOx emission characteristics of a cyclone boiler with slag-tap furnace. Acs Omega 2020, 5, 29978–29987. [Google Scholar] [CrossRef]

- Li, X.Y.; Li, G.Y.; Cao, Z.D.; Xu, S.S. Research on flow characteristics of slag film in a slag tapping gasifier. Energy Fuels 2010, 24, 5109–5115. [Google Scholar] [CrossRef]

- Karampinis, E.; Nikolopoulos, N.; Nikolopoulos, A.; Grammelis, P.; Kakaras, E. Numerical investigation Greek lignite/cardoon co-firing in a tangentially fired furnace. Appl. Energy 2012, 97, 514–524. [Google Scholar] [CrossRef]

- Chen, S.N.; He, B.S.; He, D.; Cao, Y.; Ding, G.C.; Liu, X.; Duan, Z.P.; Zhang, X.; Song, J.G.; Li, X.Z. Numerical investigations on different tangential arrangements of burners for a 600 MW utility boiler. Energy 2017, 122, 287–300. [Google Scholar] [CrossRef]

- Wang, W.; Huang, Z.; Fang, F.; Liao, Y. Effect of primary air blade inclination angle on combustion and NOx emission of a cyclone boiler with slag-tap furnace. J. Chin. Soc. Power Eng. 2021, 41, 8–13. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Ma, X.; Deng, L.; Da, Y.; Che, D. Thermal calculation and numerical simulation on double-U flame slag-tap boiler that fully burning high-alkali coal. Therm. Power Gener. 2024, 53, 38–45. [Google Scholar]

- Ran, J.; Liu, L.; Li, C. Study on combustion and deposition characteristics of coal particles in a cyclone burner. J. Power Eng. 2012, 32, 836–840. [Google Scholar]

- Zhu, T.; Tang, C.L.; Ning, X.; Wang, L.M.; Deng, L.; Che, D.F. Experimental study on NOx emission characteristics of Zhundong coal in cyclone furnace. Fuel 2022, 311, 122536. [Google Scholar] [CrossRef]

- Qin, S.; Du, J.; Li, C.; Zhou, Y. Numerical investigations on the aerodynamics and flue gas recirculation optimization of cyclone-fired coal boiler. Therm. Power Gener. 2024, 53, 53–63. [Google Scholar]

- You, M.; Chen, L.; Shang, Y.; Gao, A.; Su, S.; Xiang, J. Low load combustion characteristics of supercritical wall type tangentially fired boiler. Clean Coal Technol. 2023, 29, 145–152. [Google Scholar]

- Xu, C.; Shao, Y.; Lu, P.; Song, T. Numerical simulation of low NOx swirl combustor with inverse diffusion flame. J. Eng. Therm. Energy Power 2023, 38, 170–178. [Google Scholar]

- Wang, W.; Luo, X.; Yang, Z.; Liao, Y. Effect of excess air coefficient on combustion and NOx emission of cyclone boiler with pure high alkali coal. J. Eng. Therm. Energy Power 2021, 36, 73–79. [Google Scholar]

- Lv, H.; Tong, J.; Qi, X.; Hua, G. Numerical simulation on air flow distribution characteristics for 1 000 MW swirl burners. J. Eng. Therm. Energy Power 2017, 32, 86–90. [Google Scholar]

| Parameter | Superheated Steam Flow Rate (t h−1) | Superheated Steam Temperature (K) | Superheated Steam Pressure (MPa) | Feed Water Temperature (K) | Reheated Steam Flow Rate (t h−1) | Excess Air Ratio |

|---|---|---|---|---|---|---|

| Value | 1025.0 | 814.0 | 17.5 | 555.3 | 846.1 | 1.25 |

| Proximate Analysis (%) | Ultimate Analysis (%) | Qnet,ar (MJ⋅kg−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Vdaf | FCar | Car | Har | Oar | Nar | Sar | |

| 18.40 | 15.89 | 23.02 | 42.69 | 51.93 | 2.65 | 9.59 | 0.56 | 0.98 | 19.98 |

| Parameters | Boundary Conditions |

|---|---|

| Inlet | Mass flow rate |

| Outlet | Outflow |

| Wall motion | Stationary wall |

| Wall shear condition | No slip |

| Wall thermal condition | Isothermal |

| Proximate Analysis (%) | Ultimate Analysis (%) | Qnet,ar (MJ⋅kg−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Vdaf | FCar | Car | Har | Oar | Nar | Sar | |

| 22.60 | 11.02 | 30.15 | 36.23 | 50.46 | 3.32 | 11.46 | 0.67 | 0.47 | 18.80 |

| Working Conditions | 1 | 2 | 3 |

|---|---|---|---|

| Coal blending ratios (%) | 20 | 25 | 30 |

| Parameter | Thermal Calculation Results | CFD Results |

|---|---|---|

| Maximum combustion temperature (K) | 2193.2 | 2224.7 |

| Gas temperature at the bottom of the platen (K) | 1438.4 | 1468.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Fang, F.; Guan, J.; Zhu, L.; Chen, Y.; Deng, L. Numerical Simulation and Analysis of Semi-Industrial Retrofit for Tangentially Fired Boilers with Slag-Tap Technology. Energies 2024, 17, 6331. https://doi.org/10.3390/en17246331

Wu Q, Fang F, Guan J, Zhu L, Chen Y, Deng L. Numerical Simulation and Analysis of Semi-Industrial Retrofit for Tangentially Fired Boilers with Slag-Tap Technology. Energies. 2024; 17(24):6331. https://doi.org/10.3390/en17246331

Chicago/Turabian StyleWu, Qinglong, Fan Fang, Jingyu Guan, Lingkun Zhu, Yang Chen, and Lei Deng. 2024. "Numerical Simulation and Analysis of Semi-Industrial Retrofit for Tangentially Fired Boilers with Slag-Tap Technology" Energies 17, no. 24: 6331. https://doi.org/10.3390/en17246331

APA StyleWu, Q., Fang, F., Guan, J., Zhu, L., Chen, Y., & Deng, L. (2024). Numerical Simulation and Analysis of Semi-Industrial Retrofit for Tangentially Fired Boilers with Slag-Tap Technology. Energies, 17(24), 6331. https://doi.org/10.3390/en17246331