Experimental Investigation of Wall Confluent Jets on Transparent Large-Space Building Envelopes: Part 1—Application in Heating Greenhouses

Abstract

1. Introduction

2. Materials and Methods

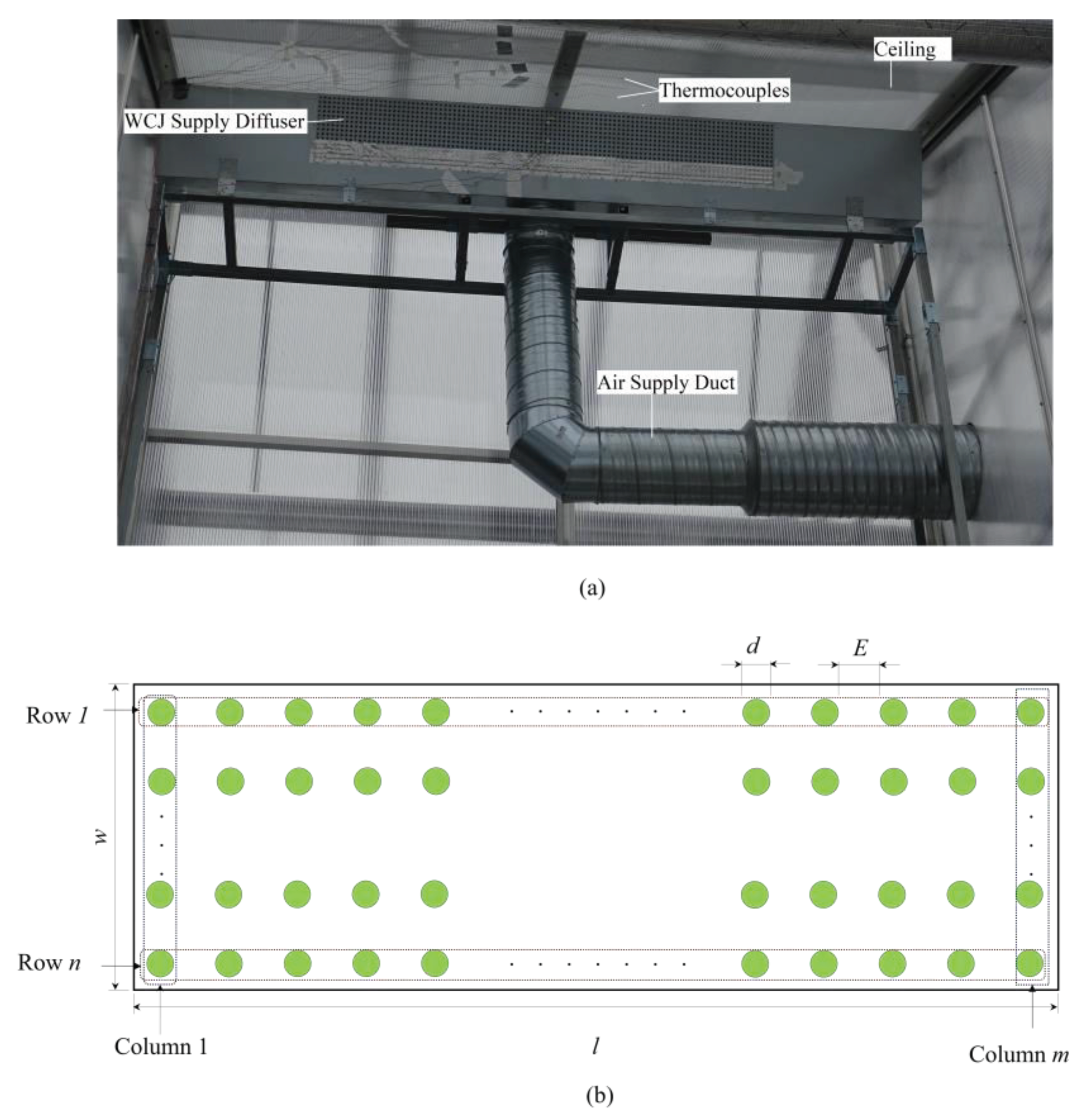

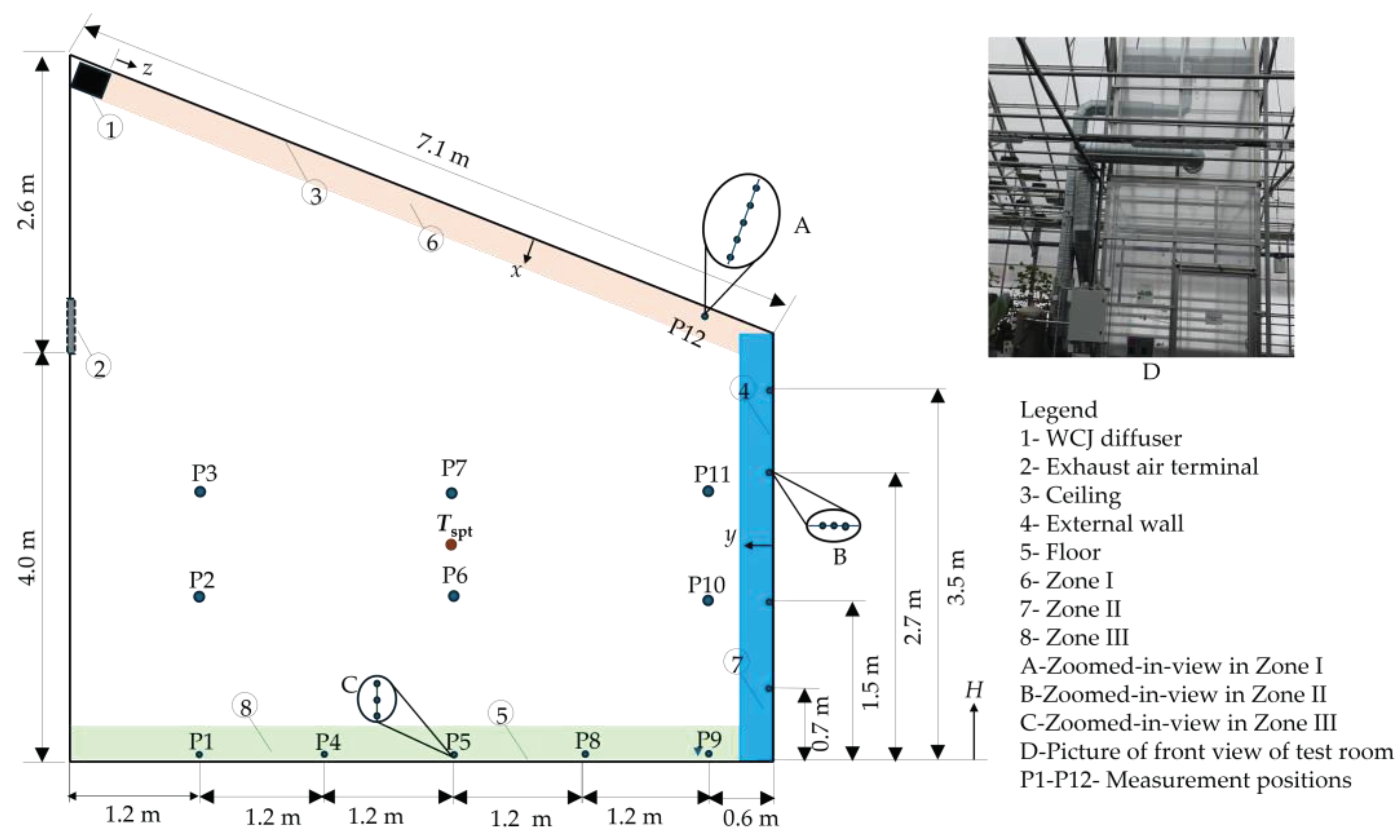

2.1. Research and Measurement Facility

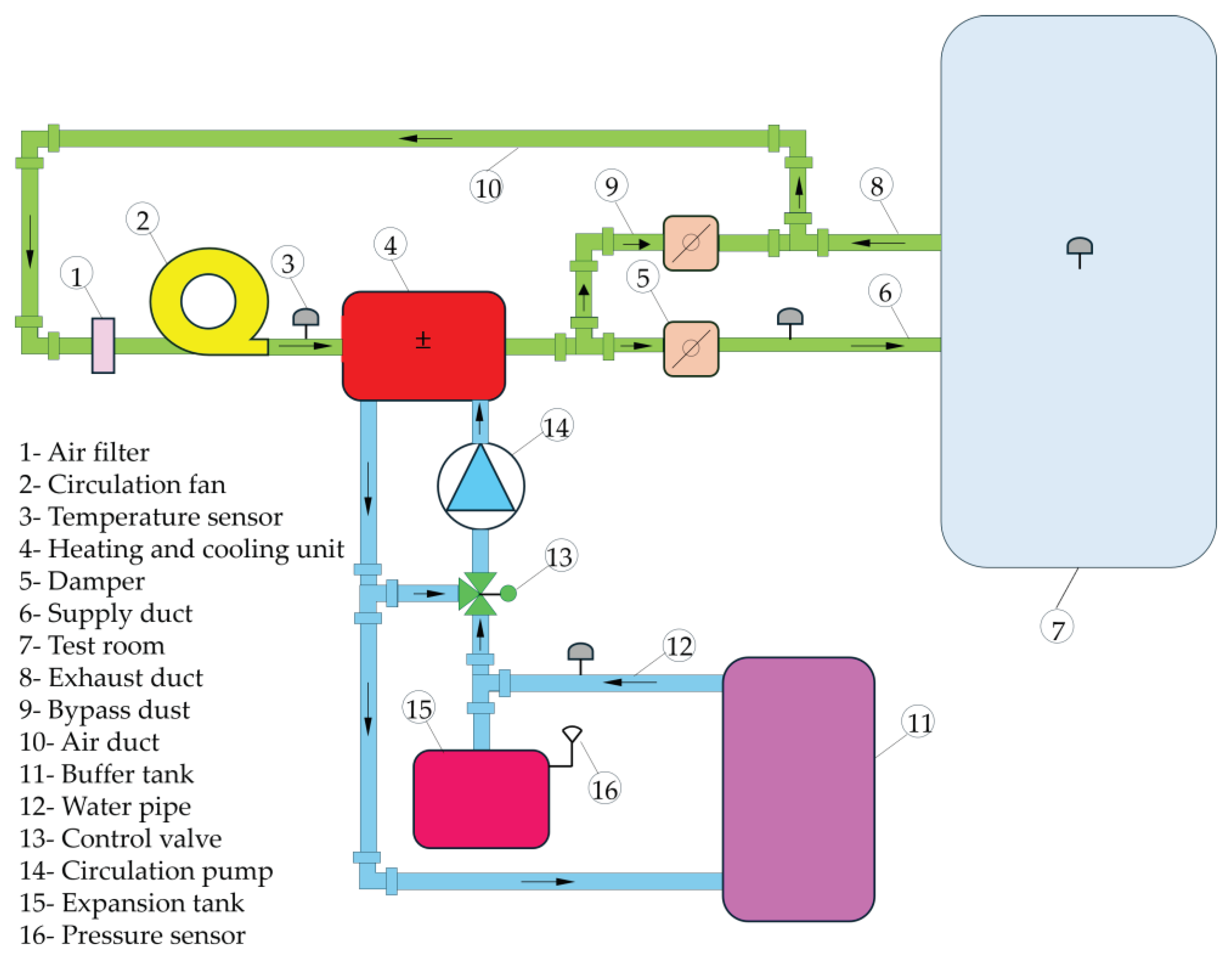

2.2. HVAC System for the Test Room

2.3. Experimental Design

2.4. Response Surface Methodology (RSM)

2.5. Air Velocity and Temperature Measurement

2.5.1. Measurements with Constant Current Anemometers (CCAs)

2.5.2. Measurements with Thermocouples

2.6. Approach and Analysis

2.6.1. The Dimensionless Ceiling Surface Temperature (TCST*)

2.6.2. The Dimensionless Inner Surface Temperature of the External Wall (TEWT*)

2.6.3. The Dimensionless Supply Air Temperature (TSAT*)

2.6.4. The Dimensionless Room Air Temperature (TRAT*)

3. Results and Discussion

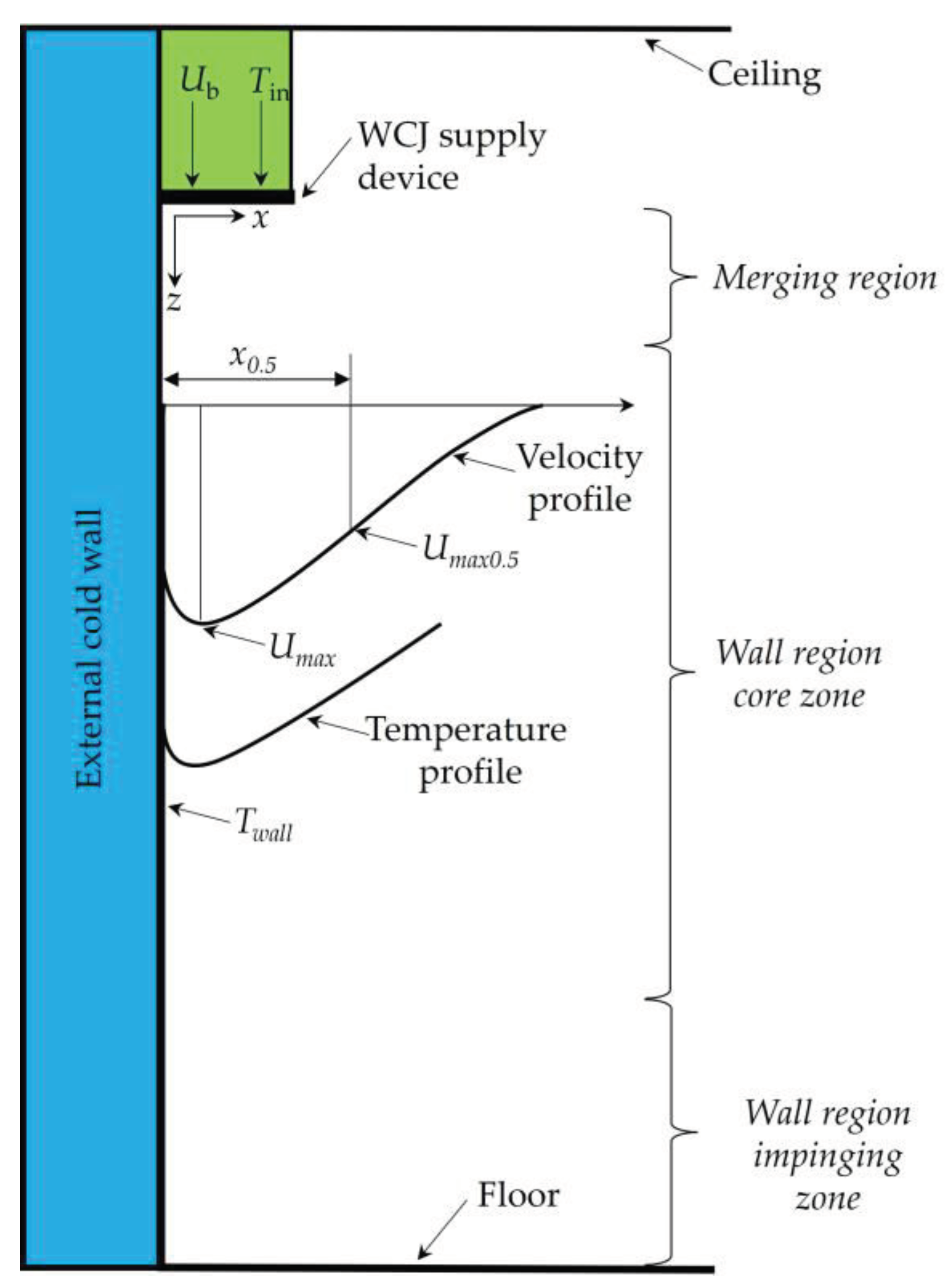

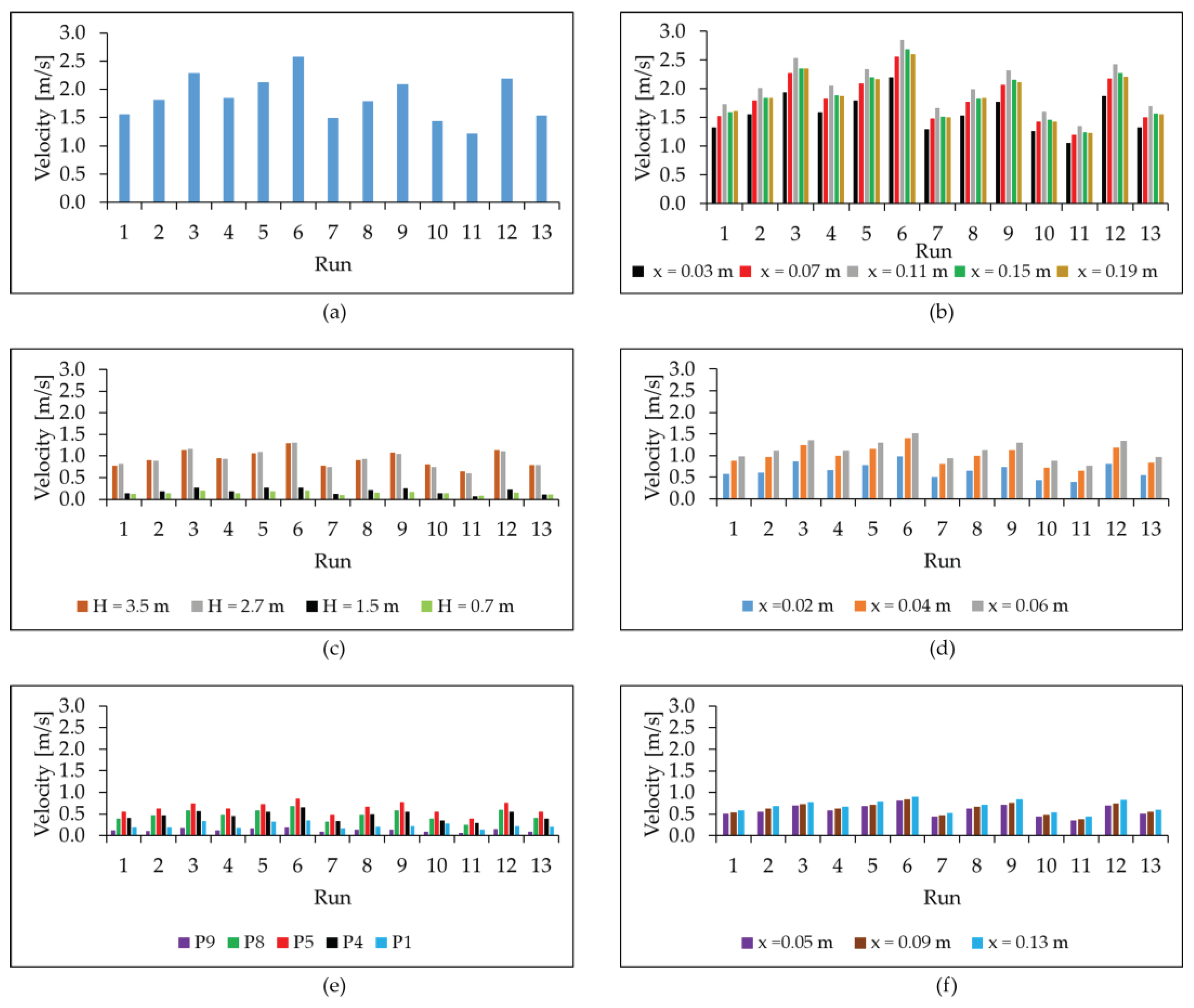

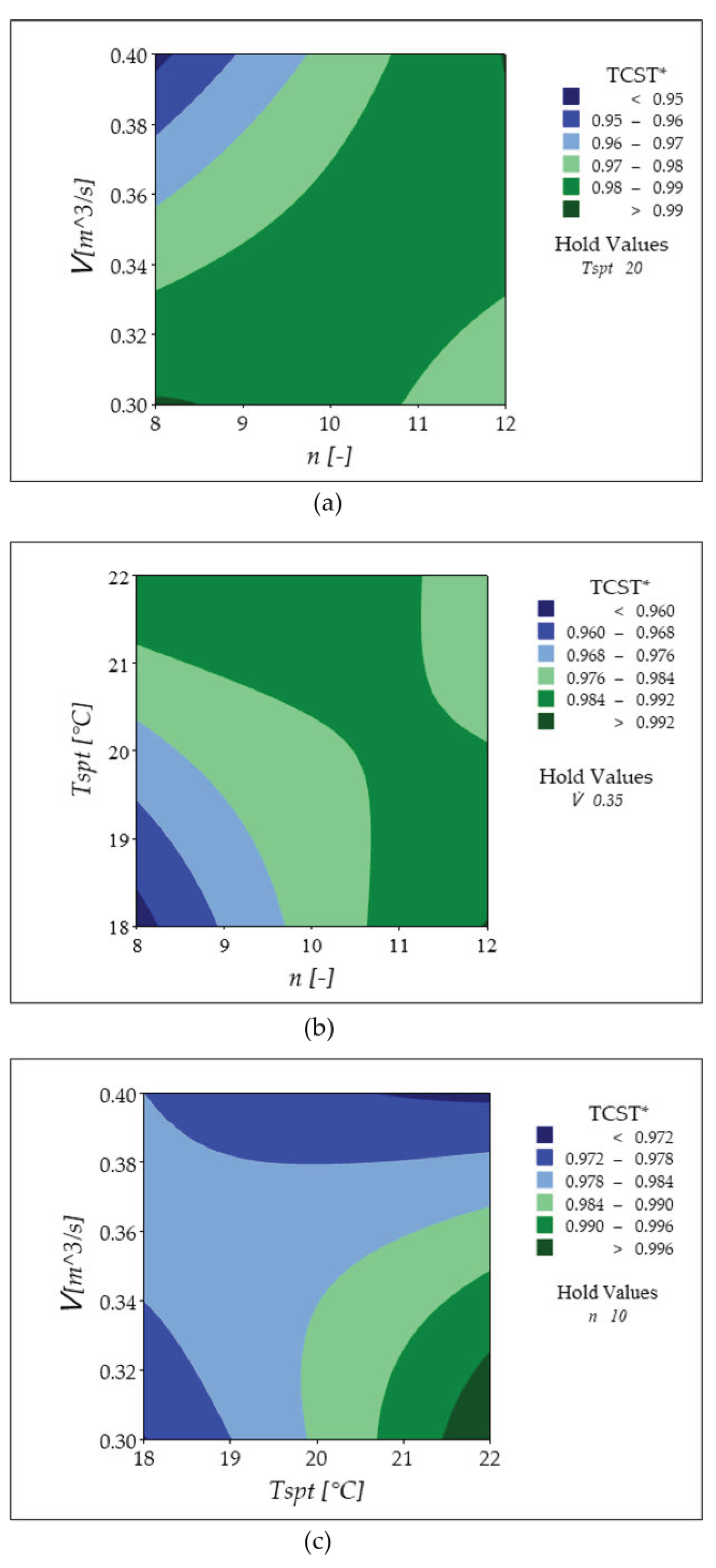

3.1. WCJ Velocity

3.2. WCJ Temperature

3.3. Effect of Warm WCJ on the Ceiling Surface

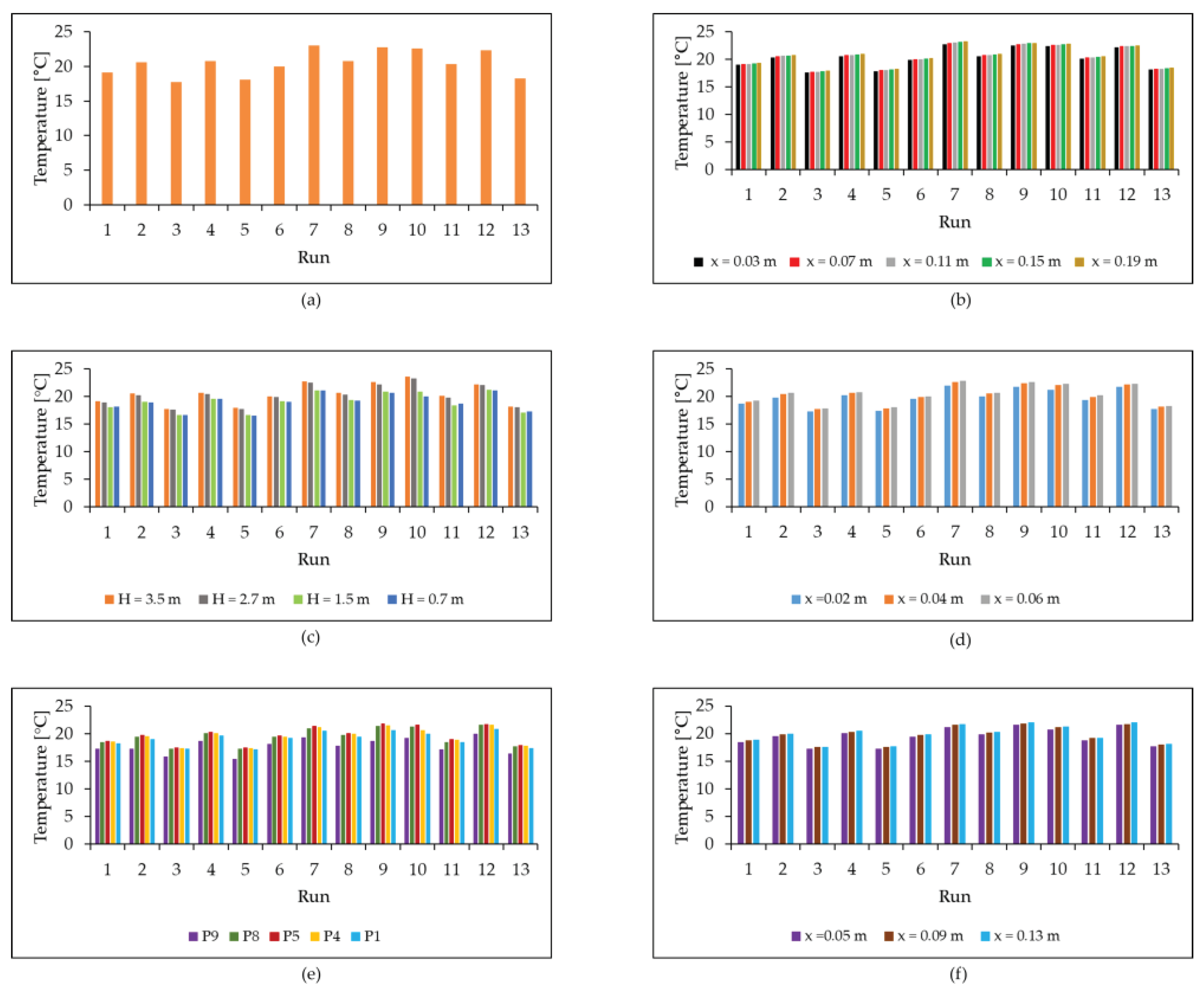

3.3.1. Dynamic Dimensionless Ceiling Surface Temperature (TCST*) Profiles

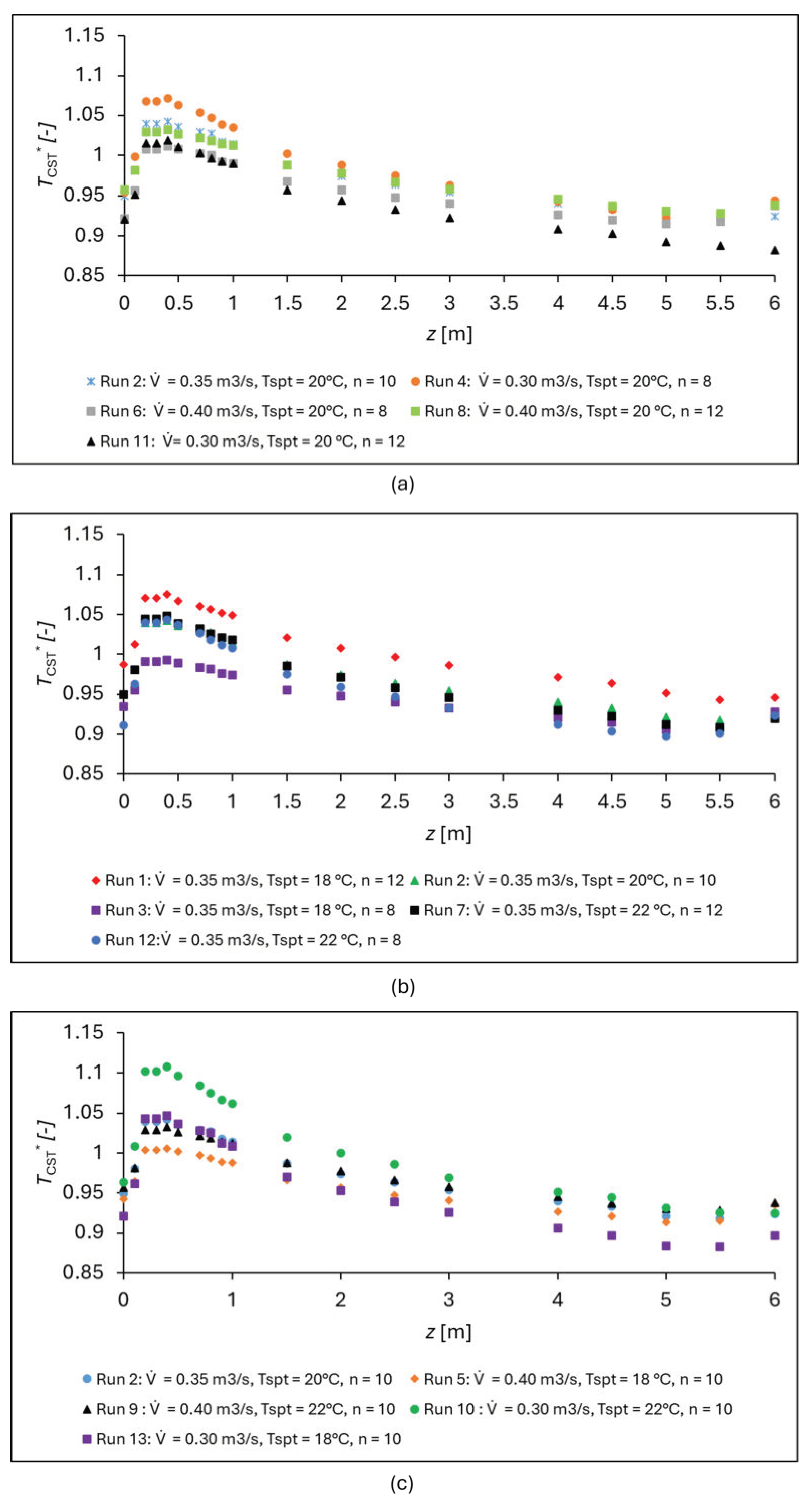

3.3.2. Contour Plots of Dimensionless Ceiling Surface Temperatures

3.3.3. Response Surface Model for Dimensionless Ceiling Surface Temperature (TCST*)

3.4. Effect of the Warm WCJ on the External Wall

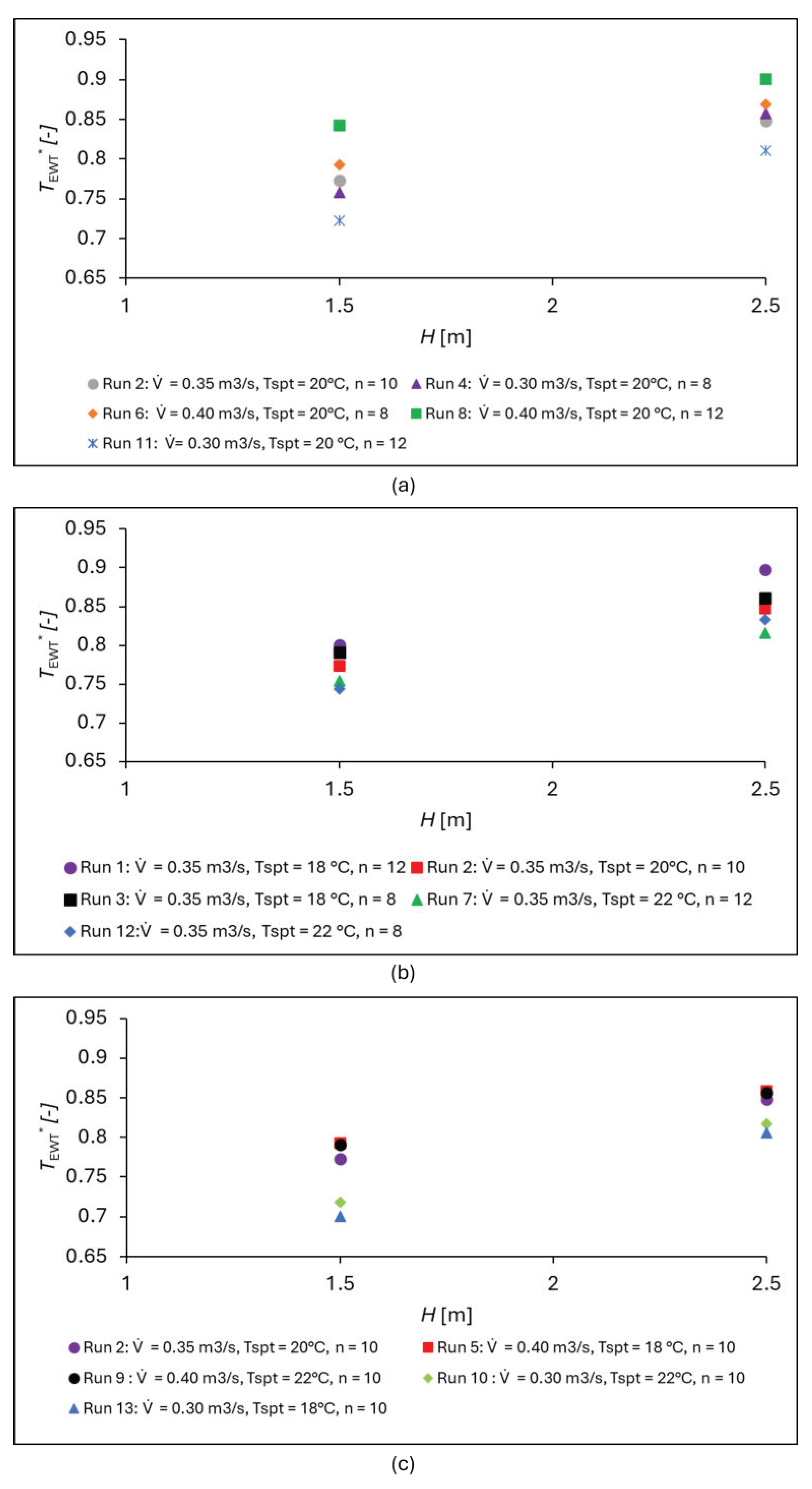

3.4.1. The Dynamic Dimensionless Inner Surface Temperature of the External Wall (TEWT*)

3.4.2. Contour Plots for the Dimensionless Inner Surface Temperature of the External Wall (TEWT*)

3.4.3. Response Surface for the Dimensionless Inner Surface Temperature of the External Wall (TEWT*)

3.5. WCJ Supply Temperature

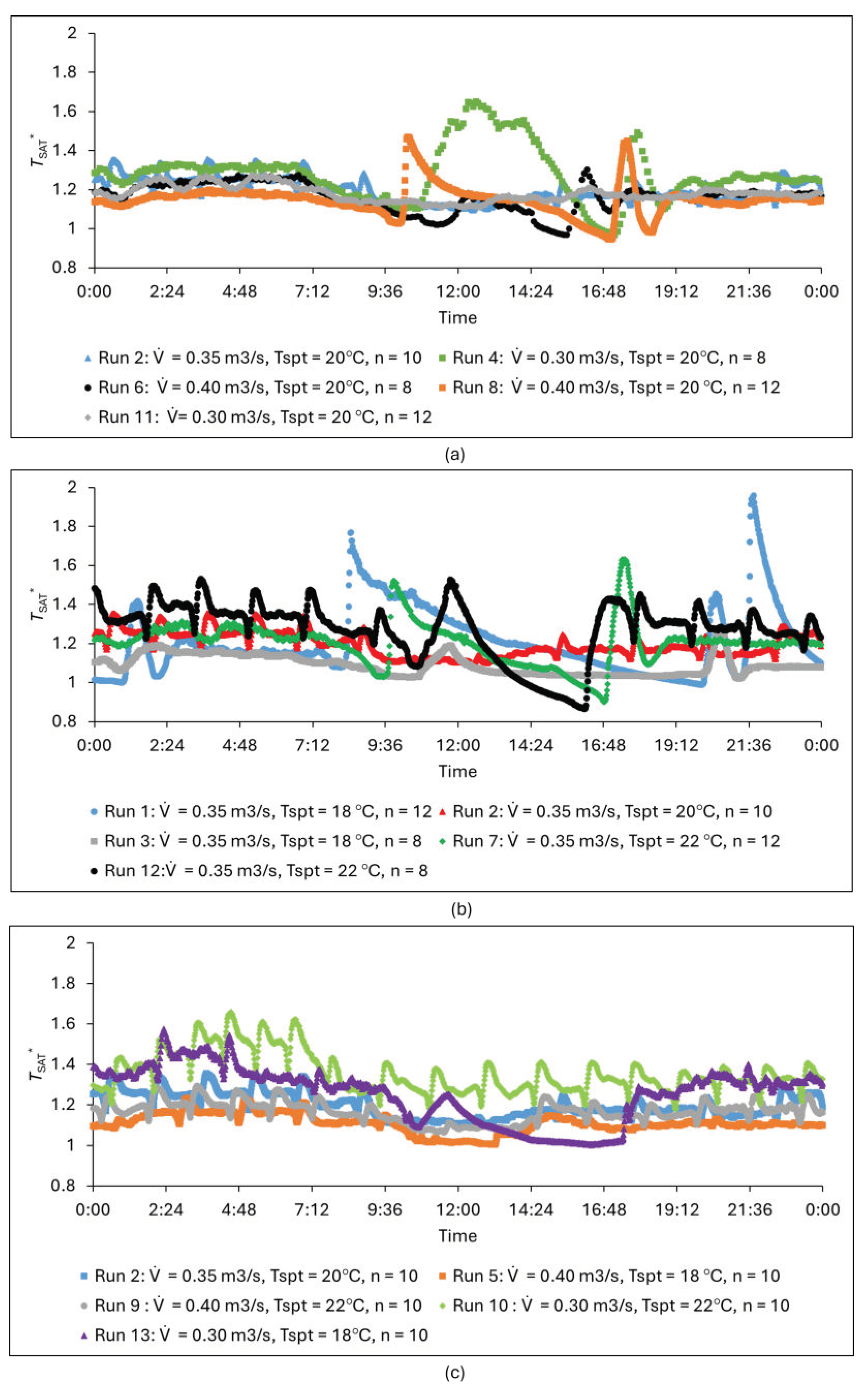

3.5.1. Dynamic Dimensionless Supply Air Temperature (TSAT*)

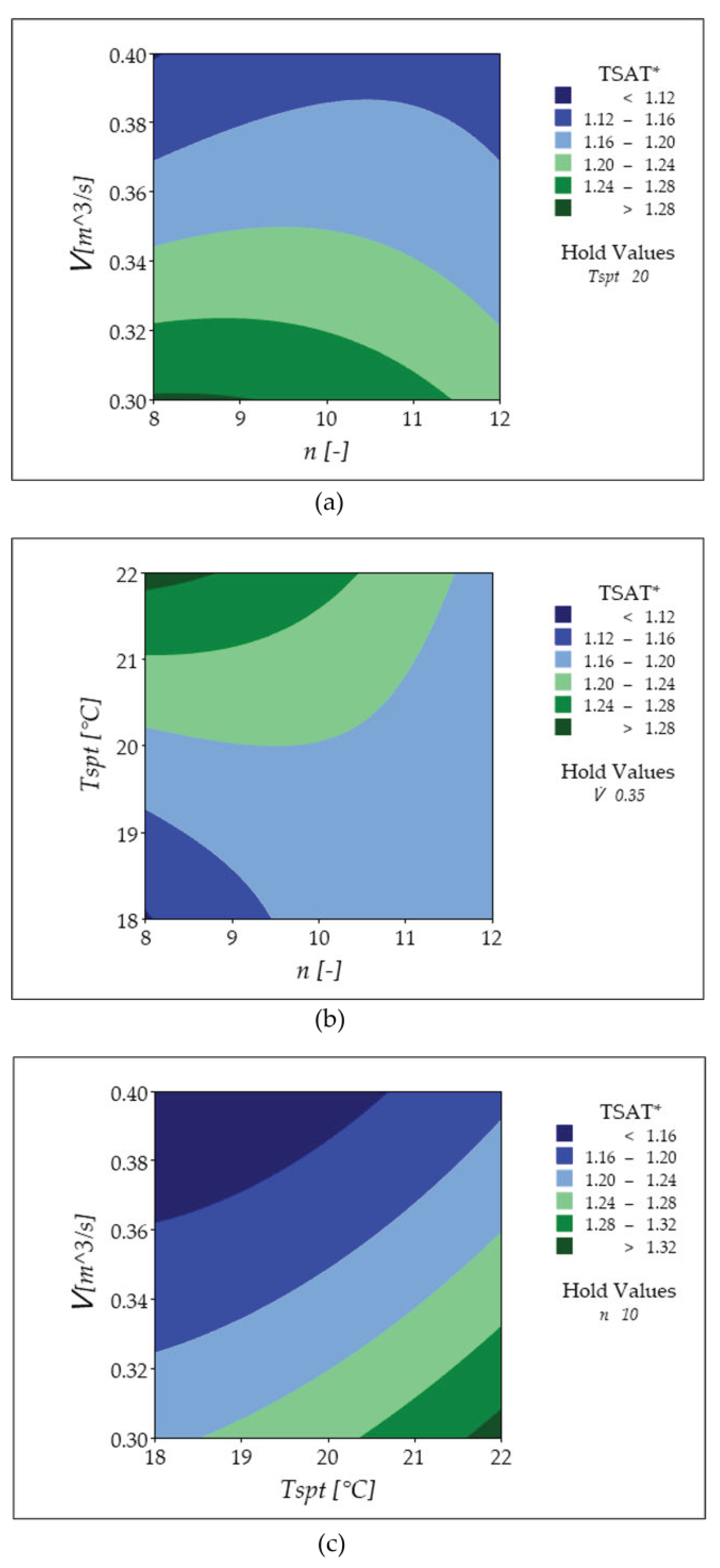

3.5.2. Contour Plots for Supply Air Temperature (TSAT*)

3.5.3. Response Surface for Dimensionless Supply Air Temperature (TSAT*)

3.6. Room Air Temperature

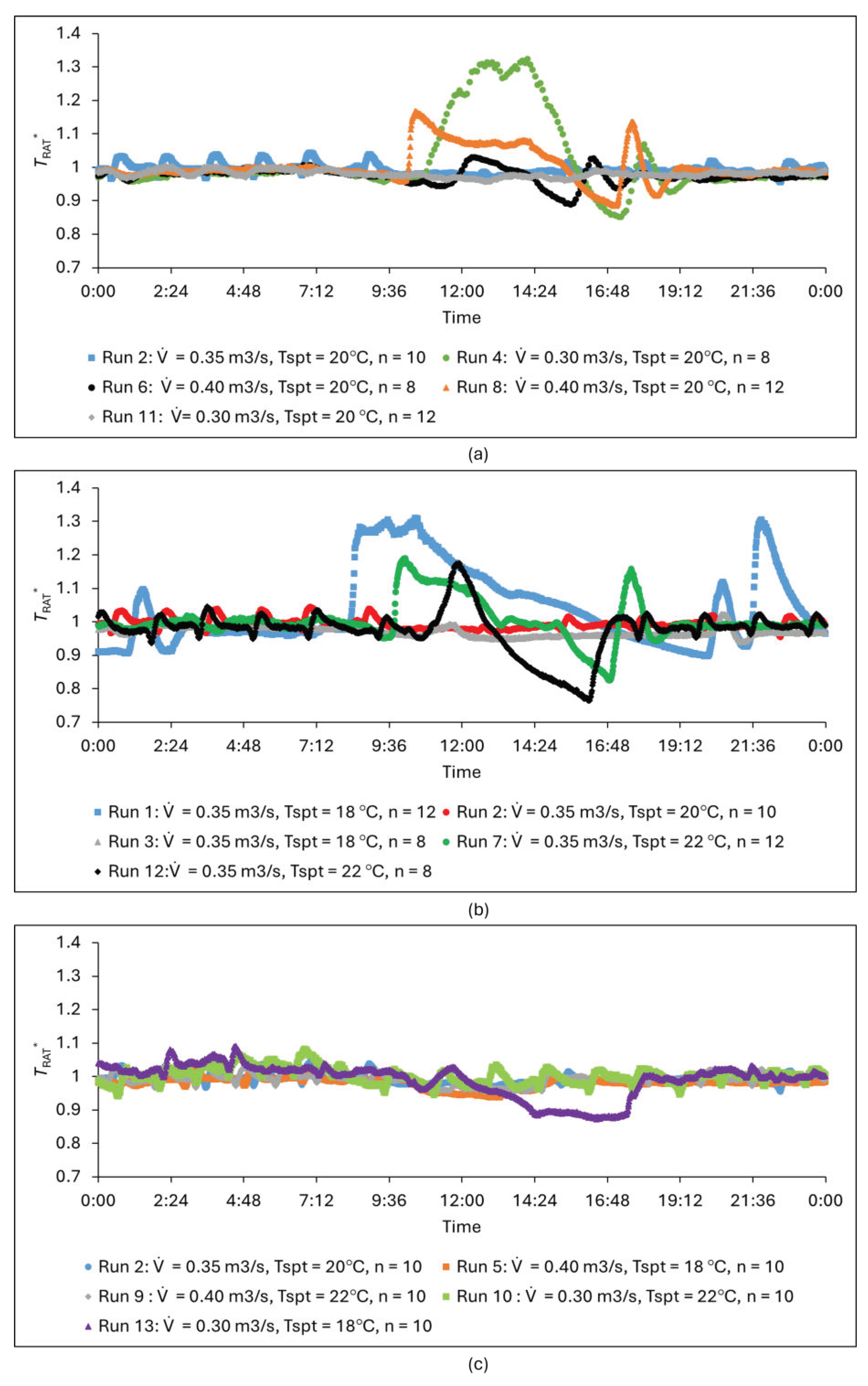

3.6.1. Dynamic Dimensionless Room Air Temperature (TRAT*) Profiles

3.6.2. Contour Plots for Dimensionless Room Air Temperature (TRAT*)

3.6.3. Response Surface Model for Dimensionless Room Air Temperature Correlations (TRAT*)

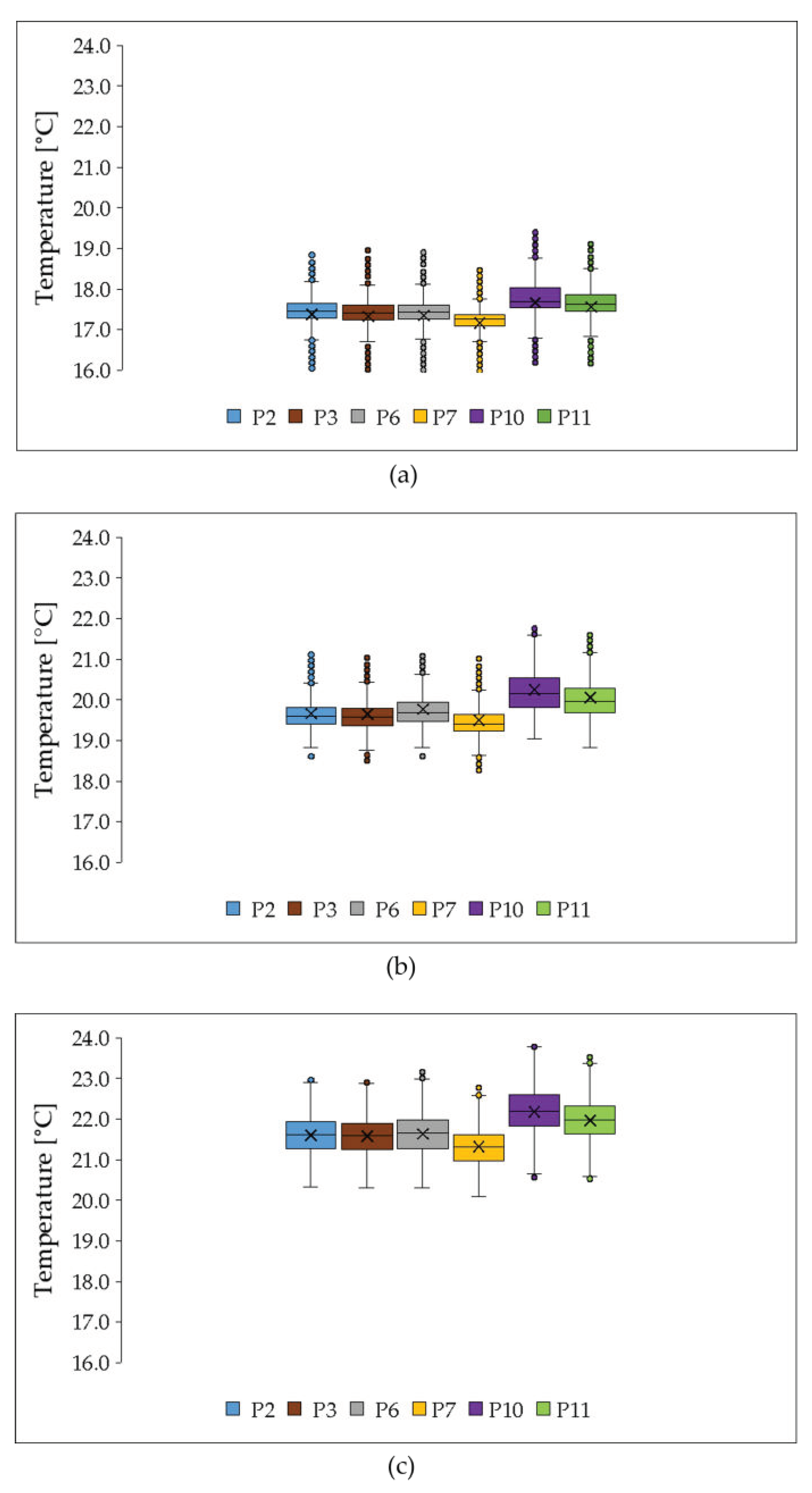

3.6.4. Room Air Temperature Distribution

4. Further Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| d | inside diameter of nozzle [m] |

| E | space between two adjacent nozzles [m] |

| n | number of nozzle rows in the wall confluent jet diffuser [-] |

| m | number of nozzle columns in the wall confluent jet diffuser [-] |

| w | width of the wall confluent jet diffuser [m] |

| l | length of the wall confluent jet diffuser [m] |

| airflow rate [m3/s] | |

| Q | heat transmission [W/°C] |

| Ps | electrical power to the sensor [W] |

| Ts | temperature of velocity thermistor [°C] |

| Ta | air temperature in the proximity of velocity thermistor [°C] |

| Tsat | supply air temperature [°C] |

| Tcst | ceiling surface temperature [°C] |

| Tewt | inner surface temperature of the external wall [°C] |

| Trat | room air temperature [°C] |

| Tout | outdoor air temperature [°C] |

| Tspt | room air temperature setpoint [°C] |

| TSAT* | dimensionless supply air temperature [-] |

| TCST* | dimensionless ceiling surface temperature [-] |

| TEWT* | dimensionless inner surface temperature of the external wall [-] |

| TRAT* | dimensionless room air temperature [-] |

| Abbreviations | |

| CJs | confluent jets |

| CJV | confluent jet ventilation |

| WCJs | wall confluent jets |

| WCJ | wall confluent jet ventilation |

| RSM | response surface methodology |

| RS | response surface |

| HVAC | heating, ventilation, and air conditioning system |

| CCA | constant current anemometer |

| BBD | Box–Behnken design |

| PC | polycarbonate |

References

- Oral, G.K.; Yilmaz, Z. Building form for cold climatic zones related to building envelope from heating energy conservation point of view. Energy Build. 2003, 35, 383–388. [Google Scholar] [CrossRef]

- Pacheco, R.; Ordóñez, J.; Martínez, G. Energy efficient design of building: A review. Renew. Sustain. Energy Rev. 2012, 16, 3559–3573. [Google Scholar] [CrossRef]

- Liu, X.; Lin, L.; Liu, X.; Zhang, T.; Rong, X.; Yang, L.; Xiong, D. Evaluation of air infiltration in a hub airport terminal: On-site measurement and numerical simulation. Build. Environ. 2018, 143, 163–177. [Google Scholar] [CrossRef]

- Balaras, C.A.; Dascalaki, E.; Gaglia, A.; Droutsa, K. Energy conservation potential, HVAC installations and operational issues in Hellenic airports. Energy Build. 2003, 35, 1105–1120. [Google Scholar] [CrossRef]

- Caruso, G.; De Santoli, L.; Mariotti, M. Ventilation Design in Large Enclosures for Sports Events using CFD: The Halls of the “Città dello Sport” in Rome. In Proceedings of the Clima 2007 WellBeing Indoors, Helsinki, Finland, 10–14 June 2007; pp. 1–10. [Google Scholar]

- Calay, R.K.; Borresen, B.A.; Holdø, A.E. Selective ventilation in large enclosures. Energy Build. 2000, 32, 281–289. [Google Scholar] [CrossRef]

- Von Elsner, B.; Briassoulis, D.; Waaijenberg, D.; Mistriotis, A.; Von Zabeltitz, C.; Gratraud, J.; Russo, G.; Suay-Cortes, R. Review of structural and functional characteristics of greenhouses in European Union countries: Part I, design requirements. J. Agric. Eng. Res. 2000, 75, 1–16. [Google Scholar] [CrossRef]

- Briassoulis, D.; Waaijenberg, D.; Gratraud, J.; Von Eslner, B. Mechanical properties of covering materials for greenhouses: Part 1, general overview. J. Agric. Eng. Res. 1997, 67, 81–96. [Google Scholar] [CrossRef]

- Badji, A.; Benseddik, A.; Bensaha, H.; Boukhelifa, A.; Hasrane, I. Design, technology, and management of greenhouse: A review. J. Clean. Prod. 2022, 373, 133753. [Google Scholar] [CrossRef]

- Von Elsner, B.; Briassoulis, D.; Waaijenberg, D.; Mistriotis, A.; Von Zabeltitz, C.; Gratraud, J.; Russo, G.; Suay-Cortes, R. Review of structural and functional characteristics of greenhouses in European Union countries, part II: Typical designs. J. Agric. Eng. Res. 2000, 75, 111–126. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, J.; Ham, Y. Quantifying the impact of building envelope condition on energy use. Build. Res. Inf. 2019, 47, 404–420. [Google Scholar] [CrossRef]

- Sozer, H. Improving energy efficiency through the design of the building envelope. Build. Environ. 2010, 45, 2581–2593. [Google Scholar] [CrossRef]

- Manioğlu, G.; Yılmaz, Z. Economic evaluation of the building envelope and operation period of heating system in terms of thermal comfort. Energy Build. 2006, 38, 266–272. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F.; Al-Hussain, S.N. Effect of thermal mass on performance of insulated building walls and the concept of energy savings potential. Appl. Energy 2012, 89, 430–442. [Google Scholar] [CrossRef]

- Reilly, A.; Kinnane, O. The impact of thermal mass on building energy consumption. Appl. Energy 2017, 198, 108–121. [Google Scholar] [CrossRef]

- Feng, G.; Sha, S.; Xu, X. Analysis of the building envelope influence to building energy consumption in the cold regions. Procedia Eng. 2016, 146, 244–250. [Google Scholar] [CrossRef]

- Soytas, U.; Sari, R. Energy consumption, economic growth, and carbon emissions: Challenges faced by an EU candidate member. Ecol. Econ. 2009, 68, 1667–1675. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Yang, L.; Yan, H.; Lam, J.C. Thermal comfort and building energy consumption implications—A review. Appl. Energy 2014, 115, 164–173. [Google Scholar] [CrossRef]

- Ortega Alba, S.; Manana, M. Energy research in airports: A review. Energies 2016, 9, 349. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, J.; Liu, J. Zonal modelling for thermal and energy performance of large space buildings: A review. Renew. Sustain. Energy Rev. 2020, 133, 110241. [Google Scholar] [CrossRef]

- Palmowska, A.; Miczka, G. Research on the thermal conditions in ventilated large space building. ACEE J. 2018, 11, 169–178. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Coronel, J.F.; Maestre, I.R. A review of HVAC systems requirements in building energy regulations. Energy Build. 2011, 43, 255–268. [Google Scholar] [CrossRef]

- Barozzi, M.; Lienhard, J.; Zanelli, A.; Monticelli, C. The sustainability of adaptive envelopes: Developments of kinetic architecture. Procedia Eng. 2016, 155, 275–284. [Google Scholar] [CrossRef]

- Kim, J.-J.; Moon, J.W. Impact of Insulation on Building Energy Consumption. In Proceedings of the Building Simulation, Glasgow, UK, 27–30 July 2009; Available online: https://www.aivc.org/resource/impact-insulation-building-energy-consumption (accessed on 13 October 2024).

- Oral, G.K.; Yilmaz, Z. The limit U values for building envelope related to building form in temperate and cold climatic zones. Build. Environ. 2002, 37, 1173–1180. [Google Scholar] [CrossRef]

- Elghamry, R.; Hassan, H. Impact of window parameters on the building envelope on the thermal comfort, energy consumption and cost and environment. Int. J. Vent. 2020, 19, 233–259. [Google Scholar] [CrossRef]

- Asphaug, S.K.; Kvande, T.; Time, B.; Peuhkuri, R.H.; Kalamees, T.; Johansson, P.; Berardi, U.; Lohne, J. Moisture control strategies of habitable basements in cold climates. Build. Environ. 2020, 169, 106572. [Google Scholar] [CrossRef]

- Ngirubiu, I.I. Circular Economy and Its Governance in Dutch Agri-Food Greenhouse Horticulture. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2023. Available online: https://essay.utwente.nl/96769/ (accessed on 12 May 2024).

- Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; García-Arca, D.; López-Felices, B. Identification of opportunities for applying the circular economy to intensive agriculture in Almería (South-East Spain). Agronomy 2020, 10, 1499. [Google Scholar] [CrossRef]

- Van Tuyll, A.; Boedijn, A.; Brunsting, M.; Barbagli, T.; Blok, C.; Stanghellini, C. Quantification of material flows: A first step towards integrating tomato greenhouse horticulture into a circular economy. J. Clean. Prod. 2022, 379, 134665. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; Ruijs, M.; Victoria, N.G.; Stanghellini, C.; Montero, J.I. Environmental and economic assessment of protected crops in four European scenarios. J. Clean. Prod. 2012, 28, 45–55. [Google Scholar] [CrossRef]

- Martin, M.; Brandão, M. Evaluating the environmental consequences of Swedish food consumption and dietary choices. Sustainability 2017, 9, 2227. [Google Scholar] [CrossRef]

- Critten, D.L.; Bailey, B.J. A review of greenhouse engineering developments during the 1990s. Agric. For. Meteorol. 2002, 112, 1–22. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Energy management strategies for commercial greenhouses. Appl. Energy 2014, 114, 880–888. [Google Scholar] [CrossRef]

- Janbakhsh, S.; Moshfegh, B. Experimental investigation of a ventilation system based on wall confluent jets. Build. Environ. 2014, 80, 18–31. [Google Scholar] [CrossRef]

- Awbi, H.B. Ventilation of Buildings; Routledge: London, UK, 2002. [Google Scholar]

- Svensson, K. Experimental and Numerical Investigations of Confluent Round Jets; Linköping University Electronic Press: Linköping, Sweden, 2015; Available online: https://www.diva-portal.org/smash/record.jsf?dswid=667&pid=diva2%3A805327 (accessed on 24 January 2020).

- Svensson, K.; Rohdin, P.; Moshfegh, B.; Tummers, M.J. Numerical and experimental investigation of the near zone flow field in an array of confluent round jets. Int. J. Heat Fluid Flow 2014, 46, 127–146. [Google Scholar] [CrossRef]

- Ghahremanian, S. A Near-Field Study of Multiple Interacting Jets: Confluent Jets; Linkopings Universitet (Sweden): Linköping, Sweden, 2014. [Google Scholar] [CrossRef]

- Karimipanah, T.; Awbi, H.B.; Blomqvist, C.; Sandberg, M.; Fresh, A.B. Effectiveness of confluent jets ventilation system for classrooms. In Proceedings of the 10th International Conference in Indoor Air Quality and Climate-Indoor Air, Beijing, China, 4–9 September 2005; Volume 5, pp. 3271–3277. [Google Scholar]

- Andersson, H. Optimization of Confluent Jets Ventilation with Variable Airflow; Gävle University Press: Gävle, Sweden, 2022; Available online: https://www.diva-portal.org/smash/record.jsf?dswid=667&pid=diva2%3A1702356 (accessed on 3 June 2023).

- Janbakhsh, S. A Ventilation Strategy Based on Confluent Jets: An Experimental and Numerical Study; Linköping University Electronic Press: Linköping, Sweden, 2015; Available online: https://www.diva-portal.org/smash/get/diva2:808188/FULLTEXT02.pdf (accessed on 23 September 2021).

- Chen, H.; Janbakhsh, S.; Larsson, U.; Moshfegh, B. Numerical investigation of ventilation performance of different air supply devices in an office environment. Build. Environ. 2015, 90, 37–50. [Google Scholar] [CrossRef]

- Choonya, G.; Larsson, U.; Moshfegh, B. Experimental investigations of flow and thermal behavior of wall confluent jets as a heating device for large-space enclosures. Build. Environ. 2023, 236, 110282. [Google Scholar] [CrossRef]

- Arghand, T.; Karimipanah, T.; Awbi, H.B.; Cehlin, M.; Larsson, U.; Linden, E. An experimental investigation of the flow and comfort parameters forunder-floor, confluent jets and mixing ventilation systems in an open-plan office. Build. Environ. 2015, 92, 48–60. [Google Scholar] [CrossRef]

- Karimipanah, T.; HB, A.; Moshfegh, B. The air distribution index as an indicator for energy consumption and performance of ventilation systems. J. Hum.-Environ. Syst. 2008, 11, 77–84. [Google Scholar] [CrossRef]

- Janbakhsh, S.; Moshfegh, B. Numerical study of a ventilation system based on wall confluent jets. HVAC&R Res. 2014, 20, 846–861. [Google Scholar]

- Cho, Y.; Awbi, H.B.; Karimipanah, T. Theoretical and experimental investigation of wall confluent jets ventilation and comparison with wall displacement ventilation. Build. Environ. 2008, 43, 1091–1100. [Google Scholar] [CrossRef]

- Swedish Meteorological and Hydrological Institute. Climate Indicator-Temperature|SMHI. SMHI. Available online: https://www.smhi.se/en/climate/climate-indicators/climate-indicators-temperature-1.91472 (accessed on 5 December 2024).

- Hoforsbacken, D.; Observation, S. LÄGSTA UPPMÄTTA TEMPERATURER, HOFORS. Available online: https://www.vackertvader.se/väderstation/hoforsbacken (accessed on 4 December 2024).

- Fatnassi, H.; Boulard, T.; Benamara, H.; Roy, J.C.; Suay, R.; Poncet, C. Increasing the height and multiplying the number of spans of greenhouse: How far can we go? Acta Hortic. 2017, 1170, 137–143. [Google Scholar] [CrossRef]

- EN 60751; Industrial Platinum Resistance Thermometers and Platinum Temperature Sensors. European Committee for Standardization (CEN)/CENELEC: Brussels, Belgium, 2008.

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Box, G.E.P.; Behnken, D.W. Some new three level designs for the study of quantitative variables. Technometrics 1960, 2, 455–475. [Google Scholar] [CrossRef]

- Box, G.E.P.; Behnken, D.W. Simplex-sum designs: A class of second order rotatable designs derivable from those of first order. Ann. Math. Stat. 1960, 31, 838–864. [Google Scholar] [CrossRef]

- Svensson, K.; Rohdin, P.; Moshfegh, B. A computational parametric study on the development of confluent round jet arrays. Eur. J. Mech. 2015, 53, 129–147. [Google Scholar] [CrossRef]

- Andersson, H.; Cehlin, M.; Moshfegh, B. An investigation concerning optimal design of confluent jets ventilation with variable air volume. Int. J. Vent. 2023, 23, 183–203. [Google Scholar] [CrossRef]

- Abad, M.; Monteiro, A.A. The use of auxins for the production of greenhouse tomatoes in mild-winter conditions: A review. Sci. Hortic. 1989, 38, 167–192. [Google Scholar] [CrossRef]

- Peet, M.M.; Welles, G.W.H. Greenhouse tomato production. Crop Prod. Sci. Hortic. 2005, 13, 257. [Google Scholar]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Khuri, A.I.; Mukhopadhyay, S. Response surface methodology. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 128–149. [Google Scholar] [CrossRef]

- Khuri, A.I.; Cornell, J.A. Response Surfaces: Designs and Analyses: Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Mäkelä, M. Experimental design and response surface methodology in energy applications: A tutorial review. Energy Convers. Manag. 2017, 151, 630–640. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Vining, G.G.; Borror, C.M.; Kowalski, S.M. Response surface methodology: A retrospective and literature survey. J. Qual. Technol. 2004, 36, 53–77. [Google Scholar] [CrossRef]

- Blackburn, T.D. Six Sigma: A Case Study Approach Using Minitab®; Springer Nature: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Gupta, B.C. Statistical Quality Control: Using MINITAB, R, JMP and Python; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Evans, M. Minitab Manual; University of Toronto: Toronto, ON, Canada, 2009; ISBN 0-7167-2994-6. [Google Scholar]

- Eldeeb, A. Adoption of Lean Six Sigma Using Minitab Software to Improve Industries Performance. Ph.D. Thesis, Hochschule für Technik und Wirtschaft Berlin, Berlin, Germany, 2023. [Google Scholar]

- Bruun, H.H. Hot-wire anemometry: Principles and signal analysis. Meas. Sci. Technol. 1996, 7, 24. [Google Scholar] [CrossRef]

- Lomas, C.G. Fundamentals of Hot Wire Anemometry; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Duff, M.; Towey, J. Two ways to measure temperature using thermocouples feature simplicity, accuracy, and flexibility. Analog Dialogue 2010, 44, 1–6. [Google Scholar]

- Choonya, G.; Larsson, U.; Moshfegh, B. Heating of Cold Wall with Confluent Jets in Large Space Enclosures: Application in Greenhouse Premises. In Proceedings of the International Conference on Building Energy and Environment; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1925–1933. [Google Scholar]

- Wheeler, E.F.; Both, A.J. Evaluating Greenhouse Mechanical Ventilation System Performance, Part 3 of 3; The State University of New Jersey Rutgers Cooperative Extension: New Brunswick, NJ, USA, 2002. [Google Scholar] [CrossRef]

- Holder, R.; Cockshull, K.E. Effects of humidity on the growth and yield of glasshouse tomatoes. J. Hortic. Sci. 1990, 65, 31–39. [Google Scholar] [CrossRef]

- Tan, D.; Li, B.; Cheng, Y.; Liu, H.; Chen, J. Airflow pattern and performance of wall confluent jets ventilation for heating in a typical office space. Indoor Built Environ. 2020, 29, 67–83. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I.; Kanoglu, M. Role of exergy in increasing efficiency and sustainability and reducing environmental impact. Energy Policy 2008, 36, 128–137. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Energy, environment and sustainable development. Appl. Energy 1999, 64, 427–440. [Google Scholar] [CrossRef]

- Schmidt, D. Low exergy systems for high-performance buildings and communities. Energy Build. 2009, 41, 331–336. [Google Scholar] [CrossRef]

- Hepbasli, A. A comparative investigation of various greenhouse heating options using exergy analysis method. Appl. Energy 2011, 88, 4411–4423. [Google Scholar] [CrossRef]

- Sethi, V.P.; Sharma, S.K. Survey and evaluation of heating technologies for worldwide agricultural greenhouse applications. Sol. Energy 2008, 82, 832–859. [Google Scholar] [CrossRef]

- Esen, M.; Yuksel, T. Experimental evaluation of using various renewable energy sources for heating a greenhouse. Energy Build. 2013, 65, 340–351. [Google Scholar] [CrossRef]

| Run | Coded Values | Actual Values | ||||

|---|---|---|---|---|---|---|

| n [-] | Tspt [°C] | [m3/s] | n [-] | Tspt [°C] | [m3/s] | |

| 1 | 1 | −1 | 0 | 12 | 18 | 0.35 |

| 2 | 0 | 0 | 0 | 10 | 20 | 0.35 |

| 3 | −1 | −1 | 0 | 8 | 18 | 0.35 |

| 4 | −1 | 0 | −1 | 8 | 20 | 0.30 |

| 5 | 0 | −1 | 1 | 10 | 18 | 0.40 |

| 6 | −1 | 0 | 1 | 8 | 20 | 0.40 |

| 7 | 1 | 1 | 0 | 12 | 22 | 0.35 |

| 8 | 1 | 0 | 1 | 12 | 20 | 0.40 |

| 9 | 0 | 1 | 1 | 10 | 22 | 0.40 |

| 10 | 0 | 1 | −1 | 10 | 22 | 0.30 |

| 11 | 1 | 0 | −1 | 12 | 20 | 0.30 |

| 12 | −1 | 1 | 0 | 8 | 22 | 0.35 |

| 13 | 0 | −1 | −1 | 10 | 18 | 0.30 |

| Term | TCST* | TEWT* | TSAT* | TRAT* |

|---|---|---|---|---|

| Linear terms | ||||

| n | V | IX | VI | II |

| Tspt | VI | II | II | V |

| IV | I | I | IV | |

| Quadratic terms | ||||

| n × n | VII | V | V | VI |

| Tspt × Tspt | IX | VI | VIII | VIII |

| × | VIII | IV | IX | VII |

| Two-way interactions terms | ||||

| n × Tspt | II | VIII | III | III |

| n × | I | III | IV | I |

| Tspt × | III | VII | VII | IX |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choonya, G.; Kabanshi, A.; Moshfegh, B. Experimental Investigation of Wall Confluent Jets on Transparent Large-Space Building Envelopes: Part 1—Application in Heating Greenhouses. Energies 2024, 17, 6217. https://doi.org/10.3390/en17246217

Choonya G, Kabanshi A, Moshfegh B. Experimental Investigation of Wall Confluent Jets on Transparent Large-Space Building Envelopes: Part 1—Application in Heating Greenhouses. Energies. 2024; 17(24):6217. https://doi.org/10.3390/en17246217

Chicago/Turabian StyleChoonya, Gasper, Alan Kabanshi, and Bahram Moshfegh. 2024. "Experimental Investigation of Wall Confluent Jets on Transparent Large-Space Building Envelopes: Part 1—Application in Heating Greenhouses" Energies 17, no. 24: 6217. https://doi.org/10.3390/en17246217

APA StyleChoonya, G., Kabanshi, A., & Moshfegh, B. (2024). Experimental Investigation of Wall Confluent Jets on Transparent Large-Space Building Envelopes: Part 1—Application in Heating Greenhouses. Energies, 17(24), 6217. https://doi.org/10.3390/en17246217