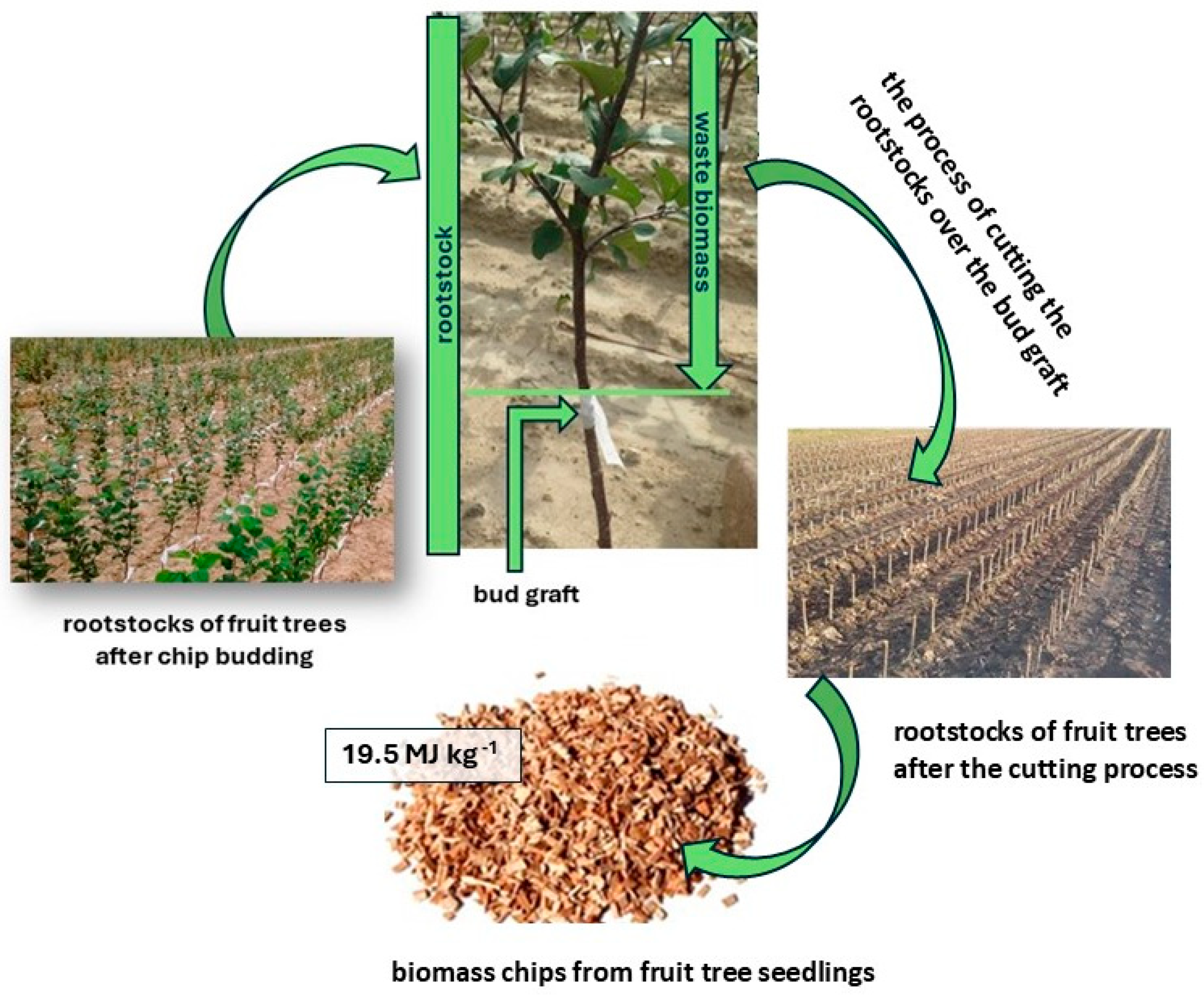

Analysis of the Energy Potential of Waste Biomass Generated from Fruit Tree Seedling Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Material

- ▪

- R1: Peach ‘Rakoniewicka’ (Prunus persica ‘Rakoniewicka’)

- ▪

- R2: Colt (Prunus avium X Prunus pseudocerasus)

- ▪

- R3: Wild Cherry (Prunus avium L.)

- ▪

- R4: Caucasian Pear (Pyrus communis var. caucasica Fed.)

- ▪

- R5: Quince S1 (Cydonia oblonga)

- ▪

- R6: Apple M9

- ▪

- R7: Apple M26

- ▪

- R8: Apple M7

- ▪

- R9: Apple A2

- ▪

- R10: Apple P60

- ▪

- R11: Apple P14

- ▪

- R12: Cherry Plum (Prunus cerasifera)

- ▪

- R13: Mahaleb Cherry (Prunus mahaleb)

2.2. Determination of Dry Matter Content

2.3. Calorific Value Determination

2.4. Moisture, Volatile Matter, and Ash Content Determination

2.5. Determination of C, H, N, and S Content

2.6. Determination of Inorganic Anions

2.7. Statistical Analysis

3. Results and Discussion

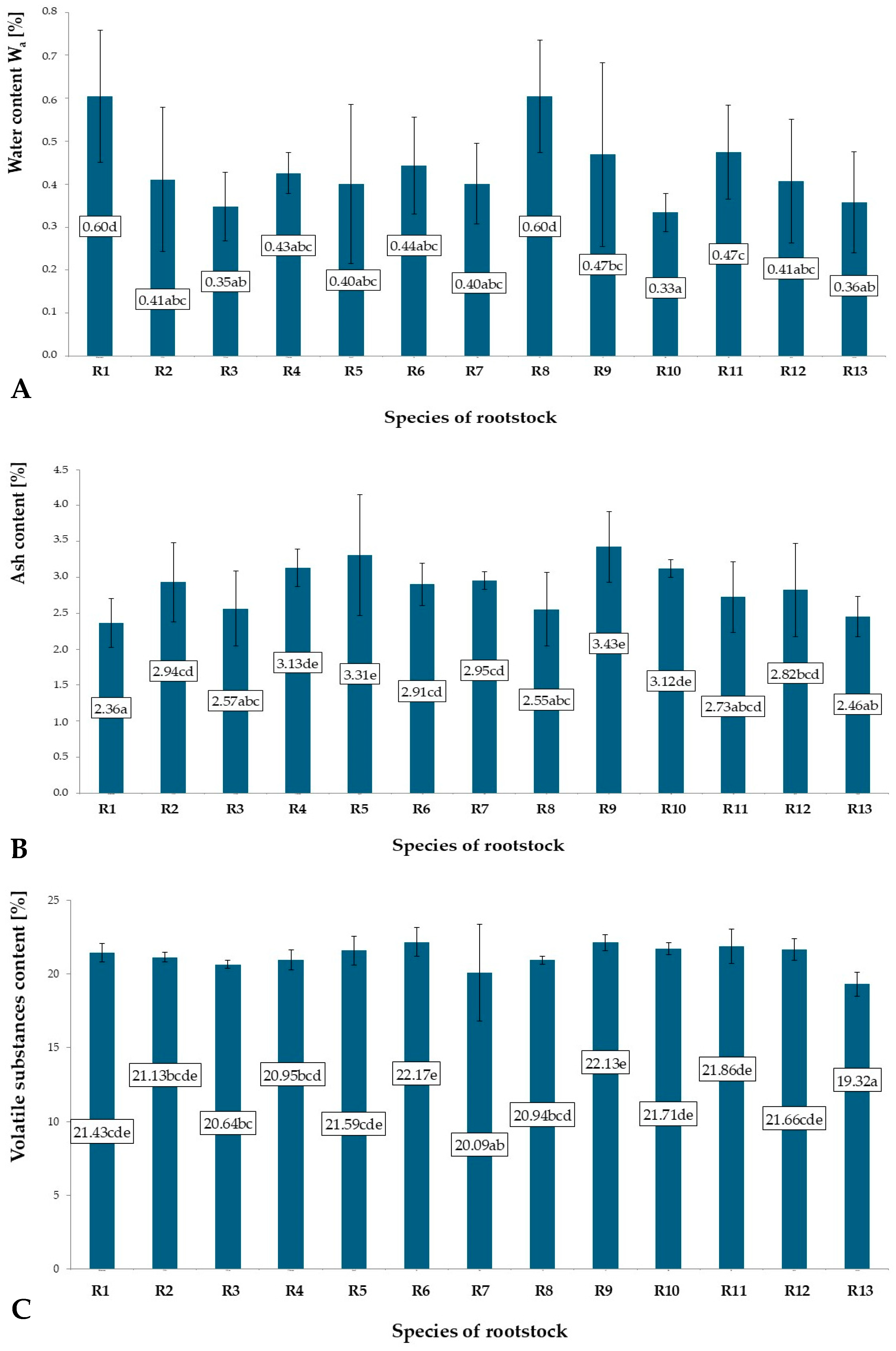

3.1. Moisture, Ash Content, and Volatile Matter

3.2. Calorific Value

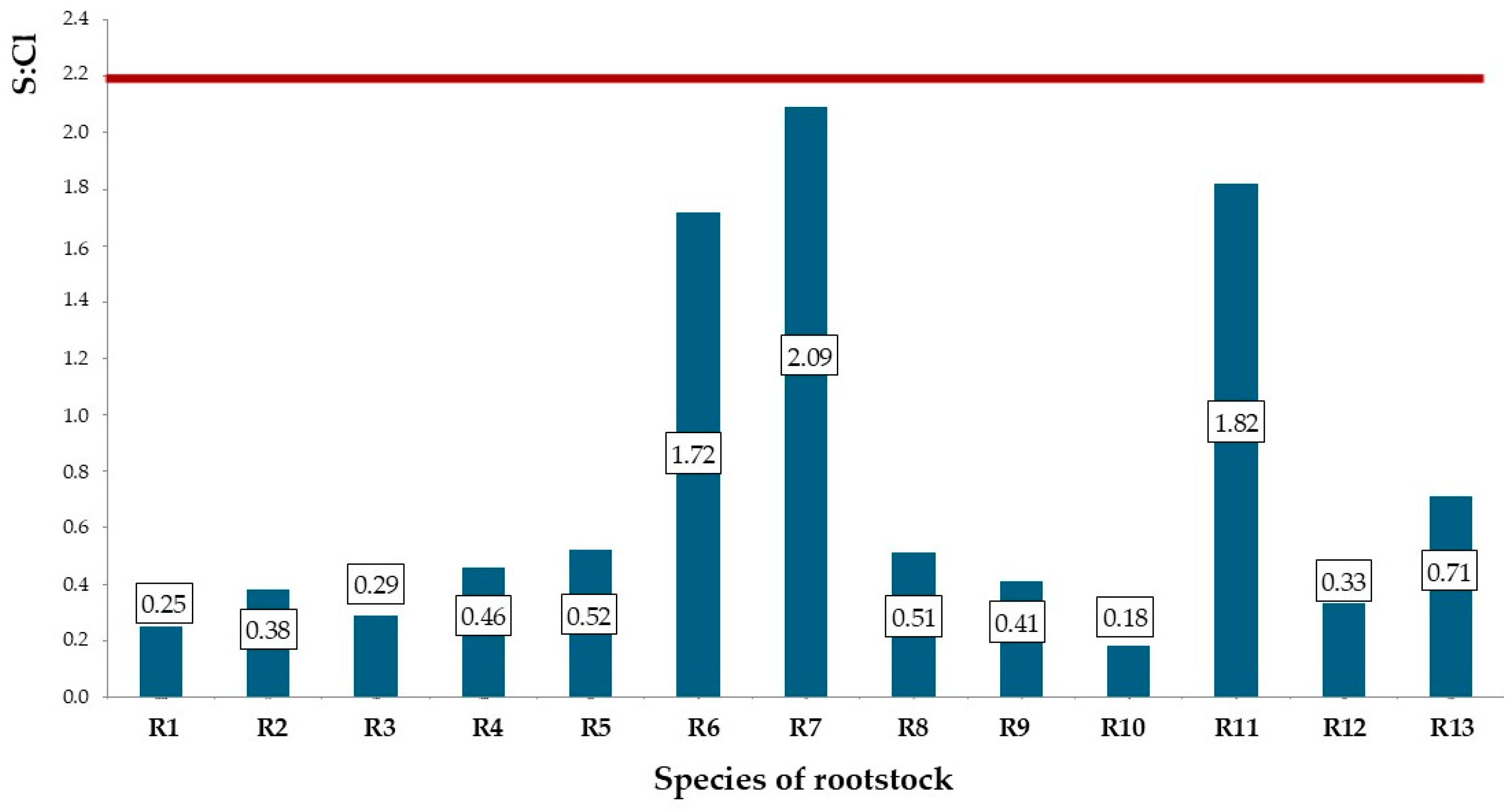

3.3. Elementary Composition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.; Zeng, B.; Zhao, X.; Zeng, S.; Jiang, S. Impact of green finance on green energy efficiency: A pathway to sustainable development in China. J. Clean. Prod. 2024, 450, 141943. [Google Scholar] [CrossRef]

- Janiszewska, D.; Ossowska, L. The Role of Agricultural Biomass as a Renewable Energy Source in European Union Countries. Energies 2022, 15, 6756. [Google Scholar] [CrossRef]

- Juliszewski, T.; Kwaśniewski, D.; Mudryk, K.; Wróbel, M. Assessment of selected parameters of biomass obtained from fast-growing tree plantations. Agric. Eng. 2012, 16, 189–197. [Google Scholar]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and co-combustion of biomass: Fundamentals, technologies, and primary measures for emission reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Demirbas, A. Relationships between lignin contents and heating values of biomass. Energy Convers. Manag. 2001, 42, 183–188. [Google Scholar] [CrossRef]

- Petersen, J.E. Umweltfreundliche Bioenergie Produktion: Analysen und Strategien auf EU-Ebene; Elsevier Science: Berlin, Germany, 2007; p. 10. [Google Scholar]

- Klugmann-Radziemska, E. Renewable Energy Sources-Computational Examples; Wydawnictwo Politechniki Gdańskiej: Gdańsk, Poland, 2009; ISBN 8373482555. [Google Scholar]

- Romański, L.; Dyjakon, A.; Adamczyk, F.; Frąckowiak, P. Problems with deriving the fruit tree pruned biomass for energy use. Agric. Eng. 2014, 3, 157–167. [Google Scholar] [CrossRef]

- Bilandzija, N.; Voca, N.; Kricka, T.; Matin, A.; Jurisic, V. Energy potential of fruit tree pruned biomass in Croatia. SJAR 2012, 10, 292–298. [Google Scholar] [CrossRef]

- Gong, Y.; Ren, L.; Han, X.; Gao, A.; Jing, S.; Feng, C.; Song, Y. Analysis of Operating Conditions for Vibration of a Self-Propelled Monorail Branch Chipper. Agriculture 2023, 13, 101. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Krawiec, P.; Wieczorek, B. Impact of Number of Operators and Distance to Branch Piles on Woodchipper Operation. Forests 2020, 11, 598. [Google Scholar] [CrossRef]

- Gorzelany, J.; Matłok, N. Development of producing nursery material in the area of the present voivodeship of Podkarpackie. Acta Carpathica 2013, 7, 57–63. [Google Scholar]

- Kamperidou, V.; Lykidis, C.; Barmpoutis, P. Assessment of the thermal characteristics of pellets made of agricultural crop residues mixed with wood. BioResources 2017, 12, 9263–9272. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, S.; Weng, W.; He, Y.; Aldén, M.; Li, Z. Alkali metal release in thermochemical conversion of biomass and coal: Optical measurements and modelling. PECS 2024, 100, 101131. [Google Scholar] [CrossRef]

- He, Z.; Liu, S.; Wang, S.; Liu, W.; Li, Y.; Feng, X. Reduced Pollutant Emissions and Slagging Rate of Biomass Pellet Combustion by Optimizing the Multilayer Distribution of Secondary Air. ACS Omega 2022, 7, 33. [Google Scholar] [CrossRef]

- Kalak, T. Potential Use of Industrial Biomass Waste as a Sustainable Energy Source in the Future. Energies 2023, 16, 1783. [Google Scholar] [CrossRef]

- Bošković, G.; Cvetanović, A.M.; Jovičić, N.; Jovanović, A.; Jovičić, M.; Milojević, S.L. Digital Technologies for Advancing Future Municipal Solid Waste Collection Services. In Futuristic e-Governance Security with Deep Learning Applications; IGI Global: Hershey, PA, USA, 2024; pp. 167–192. [Google Scholar]

- Clarke, S.; Eng, P.; Preto, F. Biomass Densification for Energy Production; Order No. 11-035; Ontario Ministry of Agriculture, Food and Rural Affairs: Toronto, ON, Canada, 2011; ISSN 1198-712X.

- Carneiro, P.; Ferreira, P. The economic, environmental and strategic value of biomass. Renew. Energy 2012, 44, 17–22. [Google Scholar] [CrossRef]

- Singh, A.K.; Sinha, O.P.; Singh, R. A Review on Use of Biomass as An Alternative to Coal for Sustainable Ironmaking. In Proceedings of the International Conference on Metallurgical Engineering and Centenary Celebration, Varanasi, India, 26–28 October 2023; pp. 375–393. [Google Scholar] [CrossRef]

- PN-EN 14918:2010; Colorimetric Method, Calorific Value. Polish Committee for Standardization: Warsaw, Poland, 2010.

- Bajcar, M.; Zardzewiały, M.; Saletnik, B.; Zaguła, G.; Puchalski, C.; Gorzelany, J. Torrefaction as a Way to Remove Chlorine and Improve the Energy Properties of Plant Biomass. Energies 2023, 16, 7365. [Google Scholar] [CrossRef]

- Gautam, A.K.; Verma, B. Char Reduction for Pyrolysis of Lignocellulosic Biomass. Anal. Chem. Lett. 2018, 8, 475–485. [Google Scholar] [CrossRef]

- PN-EN 15104:2011; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen—Instrumental Methods. Polish Committee for Standardization: Warsaw, Poland, 2011.

- Szostek, M.; Szpunar-Krok, E.; Jańczak-Pieniążek, M.; Ilek, A. Short-Term Effect of Fly Ash from Biomass Combustion on Spring Rape Plants Growth, Nutrient, and Trace Elements Accumulation, and Soil Properties. Int. J. Environ. Res. Public Health 2023, 20, 455. [Google Scholar] [CrossRef]

- Siol, C.; Thrän, D.; Majer, S. Utilizing residual biomasses from agriculture and forestry: Different approaches to set system boundaries in environmental and economic life-cycle assessments. Biomass Bioenergy 2023, 174, 106839. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, J.; Preto, F.; Zhu, J.; Xu, C. Ash Deposition in Biomass Combustion or Co-Firing for Power/Heat Generation. Energies 2012, 5, 5171–5189. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.C.; Loha, C.; Akinlabi, E.T. An overview of biomass solid fuels: Biomass sources, processing methods, and morphological and microstructural properties. J. Bioresour. Bioprod. 2023, 8, 333–360. [Google Scholar] [CrossRef]

- Matłok, N.; Szostek, M.; Balawejder, M. Soil Recycling of Waste Biomass in the Production of Malus domestica Fruit Tree Seedlings. Agriculture 2024, 14, 1806. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyńska, M.; Szefner, W. The Use of Waste Biomass from the Wood Industry and Municipal Sources for Energy Production. Sustainability 2019, 11, 3083. [Google Scholar] [CrossRef]

- Yildiz, C.; Richter, M.; Ströhle, J.; Epple, B. Release of Sulfur and Chlorine Gas Species during Combustion and Pyrolysis of Walnut Shells in an Entrained Flow Reactor. Energies 2023, 16, 5684. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Moskalik, T.; Nowacka, W.; Sadowski, J.; Zastocki, D. The energy wood market in Poland as an element of regional development. Stud. Mater. CEPL Rogowie 2012, 32, 222–230. (In Polish) [Google Scholar]

- Szczukowski, S.; Tworkowski, J.; Stolarski, M.; Krzyżaniak, M. The Energy Efficiency Of Willow Biomass Production In Poland—A Comparative Study. Pap. Glob. Chang. IGBP 2015, 22, 123–130. [Google Scholar] [CrossRef][Green Version]

- Kajda-Szcześniak, M. Evaluation of the basic properties of the wood waste and wood based wastes. Arch. J. Waste Manag. Environ. Prot. 2013, 15, 2–10. [Google Scholar]

- Wieruszewski, M.; Górna, A.; Stanula, Z.; Adamowicz, K. Energy Use of Woody Biomass in Poland: Its Resources and Harvesting Form. Energies 2022, 15, 6812. [Google Scholar] [CrossRef]

- Ju, Y.R.; Baek, Y.C.; Jang, S.S.; Oh, Y.K.; Lee, S.S.; Kim, Y.S.; Park, K.K. Nutritional value and in situ degradability of oak wood roughage and its feeding effects on growth performance and behavior of Hanwoo steers during the early fattening period. Asian-Australas J. Anim. Sci. 2020, 33, 930–940. [Google Scholar] [CrossRef] [PubMed]

- Bube, B.; Bullerdiek, N.; Voß, S.; Kaltschmitt, M. Kerosene production from power-based syngas—A technical comparison of the Fischer-Tropsch and methanol pathway. Fuel 2024, 366, 131269. [Google Scholar] [CrossRef]

- Zi, J.; Ma, D.; Wang, X.; Rahman, Z.; Li, H.; Liao, S. Slagging behavior and mechanism of high-sodium–chlorine coal combustion in a full-scale circulating fluidized bed boiler. J. Energy Inst. 2020, 93, 2264–2270. [Google Scholar] [CrossRef]

- Wisz, J.; Matwiejew, A. Biomass—Laboratory tests in terms of suitability for energetic combustion. Energetyka 2005, 9, 615, 631–637. (In Polish) [Google Scholar]

- Warmiński, K.; Stolarski, M.J.; Gil, Ł.; Krzyżaniak, M. Willow bark and wood as a source of bioactive compounds and bioenergy feedstock. Ind. Crop. Prod. 2021, 171, 113976. [Google Scholar] [CrossRef]

- Tillman, D.A. Annual Report on Biomass Cofiring Program; Report 1004601; EPRI: Palo Alto, CA, USA, 2001. [Google Scholar]

- Růžičková, J.; Raclavská, H.; Šafář, M.; Kucbel, M.; Raclavský, K.; Grobelak, A.; Svédová, B.; Juchelková, D. The occurrence of pesticides and their residues in char produced by the combustion of wood pellets in domestic boilers. Fuel 2021, 293, 120452. [Google Scholar] [CrossRef]

- Uusitalo, M.A.; Vuoristo, P.M.J.; Mantyla, T.A. High temperature corrosion of coatings and boiler steels in oxidizing chlorine-containing atmosphere. Mater. Sci. Eng. 2003, 346, 168–177. [Google Scholar] [CrossRef]

- Zapałowska, A.; Puchalski, C.; Hury, G.; Makarewicz, A. Influence of fertilization with the use of biomass ash and sewage sludge on the chemical composition of Jerusalem artichoke used for energy-related purposes. J. Ecol. Eng. 2017, 18, 235–245. [Google Scholar] [CrossRef]

- Haneklaus, S.; Bloem, E.; Schung, E. Sulphur in agroecosystems. Folia Univ. Agric. Stetin. Agric. 2000, 81, 17–32. [Google Scholar]

- Pronobis, M.; Krupa, M.; Wojnar, W. Threat to the durability of the heating surfaces of boilers with supercritical steam parameters resulting from restrictions on gas emissions. Arch. Energetyki 2008, 2, 165–174. [Google Scholar]

- Aho, M.; Ferrer, E. Importance of coal ash composition in protecting the boiler against chlorine deposition during combustion of chlorine rich biomass. Fuel 2005, 84, 201–212. [Google Scholar] [CrossRef]

- Born, M. Cause and risk evaluation for high-temperature chlorine corrosion. VGB Power Tech. 2005, 5, 107–111. [Google Scholar]

| Species of Rootstock | Calorific Value CV (MJ kg−1); n = 12 | |||

|---|---|---|---|---|

| I Year | II Year | III Year | Average | |

| Prunus persica ‘Rakoniewicka’ | 18.22 ± 0.04 | 18.30 ± 0.00 | 18.21 ± 0.02 | 18.25 cd ± 0.05 |

| Colt (Prunus avium X Prunus pseudocerasus) | 18.22 ± 0.03 | 18.55 ± 0.02 | 18.27 ± 0.08 | 18.35 de ± 0.16 |

| Wild Cherry (Prunus avium L.) | 18.11 ± 0.06 | 18.03 ± 0.11 | 18.15 ± 0.06 | 18.10 abc ± 0.09 |

| Caucasian Pear (Pyrus communis var. caucasica Fed.) | 18.45 ± 0.04 | 18.45 ± 0.03 | 18.44 ± 0.13 | 18.45 e ± 0.07 |

| Quince S1 (Cydonia oblonga) | 17.98 ± 0.02 | 18.03 ± 0.00 | 18.11 ± 0.09 | 18.04 ab ± 0.07 |

| M9 | 18.04 ± 0.08 | 18.05 ± 0.03 | 18.04 ± 0.05 | 18.07 ab ± 0.06 |

| M26 | 18.01 ± 0.13 | 17.97 ± 0.06 | 18.04 ± 0.05 | 18.01 a ± 0.09 |

| M7 | 18.07 ± 0.00 | 18.15 ± 0.01 | 18.08 ± 0.03 | 18.10 abc ± 0.04 |

| A2 | 18.03 ± 0.05 | 18.45 ± 0.01 | 18.13 ± 0.09 | 18.20 bcd ± 0.20 |

| P60 | 18.12 ± 0.03 | 18.14 ± 0.02 | 18.16 ± 0.04 | 18.14 abc ± 0.04 |

| P14 | 18.04 ± 0.01 | 17.96 ± 0.06 | 18.09 ± 0.02 | 18.03 a ± 0.07 |

| Cherry Plum (Prunus cerasifera) | 18.14 ± 0.08 | 18.17 ± 0.14 | 18.21 ± 0.02 | 18.17 abc ± 0.09 |

| Mahaleb Cherry (Prunus mahaleb) | 19.51 ± 0.06 | 18.39 ± 0.00 | 18.46 ± 0.04 | 18.79 f ± 0.54 |

| Average | 18.23 B ± 0.40 | 18.21 AB ± 0.31 | 18.19 A ± 0.14 | 18.21 ± 0.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matłok, N.; Zaguła, G.; Gorzelany, J.; Balawejder, M. Analysis of the Energy Potential of Waste Biomass Generated from Fruit Tree Seedling Production. Energies 2024, 17, 5964. https://doi.org/10.3390/en17235964

Matłok N, Zaguła G, Gorzelany J, Balawejder M. Analysis of the Energy Potential of Waste Biomass Generated from Fruit Tree Seedling Production. Energies. 2024; 17(23):5964. https://doi.org/10.3390/en17235964

Chicago/Turabian StyleMatłok, Natalia, Grzegorz Zaguła, Józef Gorzelany, and Maciej Balawejder. 2024. "Analysis of the Energy Potential of Waste Biomass Generated from Fruit Tree Seedling Production" Energies 17, no. 23: 5964. https://doi.org/10.3390/en17235964

APA StyleMatłok, N., Zaguła, G., Gorzelany, J., & Balawejder, M. (2024). Analysis of the Energy Potential of Waste Biomass Generated from Fruit Tree Seedling Production. Energies, 17(23), 5964. https://doi.org/10.3390/en17235964