1. Introduction

The design solutions of modern automobiles definitely go beyond the basic tasks of road transportation means. Advances in technical solutions and expectations from users set further goals for the designers of modern cars. Oftentimes, they can only be achieved through some compromise between technical possibilities and the expectations of their users.

Electric cars are the answer to society’s expectations for green transportation. For them to become an acceptable mobility solution, certain barriers must be overcome. One of these barriers is the range of the car. Two groups of factors influence the range of electric cars traveling in urban environments. The first group of factors includes road conditions, travel time, and the driver’s driving style [

1,

2], while the second group, called internal factors, is formed by technical solutions [

2]. The range of self-driving cars can be increased by, among other things, adopting an energy-efficient driving style, increasing battery capacity, reducing aerodynamic drag, and reducing the energy consumption of other components, which can include, for example, the air conditioning system [

3,

4].

Driving style has a very significant impact on car range. The effects of car movement parameters on energy consumption and car range were analyzed by [

5,

6,

7,

8]. Research and energy analyses of acceleration and braking maneuvers were conducted by [

3,

7]. Energy losses associated with cornering in urban driving were analyzed by [

5]. The authors of this work developed and analyzed an energy-efficient cornering model based on vehicle and road geometry. The tire parameters in this model were ignored. Energy losses associated with cornering by city buses, however, were analyzed by [

8]. The model built by the authors takes into account energy losses associated with cornering as well as wheel slippage. In addition, the model allows for the simulation of different types of trucks.

A review of the literature shows that energy losses associated with cornering range from 3–5.8% of total energy demand and should not be overlooked. In most works that analyze the energy demand of electric vehicles, cornering losses are ignored or estimated as part of rolling resistance losses. The literature lacks information on energy intensity for typical maneuvers associated with traffic situations. These maneuvers include the double lane change maneuver or the curve entry maneuver, among others. The lack of information on the energy intensity of the double lane change maneuver inspired a study, the results of which are presented in this article. This maneuver is executed by the driver with the help of the steering system, which is the key system of any car. In order to reduce the steering force in cars, power steering systems are used. Three main types of power steering systems can be distinguished: hydraulic power steering (HPS), electro-hydraulic, and electric power steering (EPS). In hydraulic power steering systems, the pump pumping hydraulic oil to the power steering gear actuator is driven by the car’s internal combustion engine. In this type of (conventional) system, the power of the power steering does not depend on the speed of the car being steered. Hydraulic power steering systems are increasingly being replaced by electrohydraulic power steering (EHPS) systems. In electrohydraulic power steering systems, the hydraulic pump is driven by an electric motor. EHPS systems allow the torque on the steering wheel to be adjusted smoothly depending on the car’s movement parameters and steering angle. Adaptation of the electro-hydraulic power steering system to different driving situations is provided by an electronic module that controls the speed of the hydraulic pump. The pump’s operating speed depends on the car’s speed and the steering wheel’s rotation speed, among other factors. In addition, the advantage of this system is that it offers quite a lot of freedom in terms of where it is installed. Another type of power steering is the electric power steering (EPS) system. Its advantage is that there is no hydraulic pump, which has a positive effect on the weight of the vehicle, fuel consumption, and the level of noise generated. An additional important advantage of electric power steering is the use of electricity only during the turning maneuver, which significantly reduces energy consumption [

9]. The above advantages as well as the fact that these systems operate with variable power characteristics have made them very popular [

10,

11,

12,

13,

14,

15]. The control system of a classic EPS system takes into account the speed of the car and the torque applied to the steering wheel. The ESP control concept, which additionally takes into account the car’s front axle load and wheel traction coefficient, was proposed by Yaohua Li et al. [

16].

Advances in the development of highly automated cars have made the Steer-by-Wire (SbW) system increasingly important. The SbW system allows the steering wheel to be completely mechanically disconnected from the wheels of the car [

17,

18,

19]. The installation of such systems, in currently manufactured cars, is prevented by current regulations.

The main objectives of the use of power steering systems are to reduce steering effort while guaranteeing the driver an adequate sense of traffic conditions and driving satisfaction (pleasure) [

20,

21]. The design solutions for steering and power steering systems are a certain compromise between maneuverability, vehicle stability, and comfort (driver effort). Achieving the aforementioned compromises is associated with extensive research on the steering system and its support in terms of objective evaluation as well as subjective evaluation [

22]. It often turns out that steering systems that meet the guidelines of ECE Regulation No. 97 [

23], which specifies how to conduct steering system tests, do not meet drivers’ expectations. Research on subjective evaluation of steering systems is carried out by many researchers. This research is performed using driving simulators [

24,

25] as well as in real cars [

26,

27]. A review of ongoing research on the subjective and objective evaluation of steering systems was made in [

28]. In the future, it will probably be possible to adjust the steering system to the individual characteristics of the car driver. Drivers living on different continents may also have different expectations of steering systems. A study of the steering effort preferences of Chinese drivers was conducted by C. Zong et al. They showed that the steering effort expectations of Chinese drivers increase with increasing vehicle speed as well as lateral acceleration. These expectations do not differ from those of European drivers [

29].

In-service testing for steering evaluation is significantly hampered. This is due to restrictions on the movement of a test vehicle with additional measuring apparatuses on public roads.

Steering effort plays an important role in steering evaluation. In most cases, it is defined as torque on the steering wheel [

30,

31]. A more complex definition of the steering effort index was given by F. Jaksch [

32]. Its determination requires measuring the torque on the steering wheel, the transverse acceleration of the car, and the steering wheel steering angle during the execution of typical road maneuvers.

From the research conducted so far by the authors, it appears that the energy effort of steering can be significantly affected by the energy intensity of the tire. The energy intensity of the tire structure [

33], manifested by its heating [

34], depends on the value of tire pressure. The value of tire pressure also affects the tire’s lateral stiffness, drift resistance, and steerability (lateral stability) of the car. The lateral stability of the car was dealt with by [

35,

36], who conducted their research in a driving simulation. Changing the trajectory due to lateral drift of the car forces the driver to make corrections to the trajectory, and this can consequently result in higher energy consumption.

The purpose of this article is to determine the effect of tire pressure on steering energy effort and energy intensity of the steering assist system during the execution of a double lane change maneuver. To evaluate the energy intensity of the steering system, the authors used the steering effort index. Its determination requires measuring the torque on the steering wheel, the car’s post-acceleration acceleration, and the steering wheel’s steering angle during the execution of typical road maneuvers.

The measurements, the results of which are presented in this paper, were carried out for the double lane change maneuver. The studies were conducted in the ranges of low speeds at which cars travel in built-up areas. These studies were a certain fragment of the broader research conducted by the authors of this paper and will serve them to develop certain relationships on the basis of which it will be possible to evaluate the steering system in real (operational) road conditions.

This article consists of four chapters. The second chapter describes the course of the tests carried out as well as the test object and measuring apparatus. The next chapter presents and analyzes the results of the tests of the tire wheels and steering effort. Finally, chapter four presents a summary.

3. Test Results and Analysis

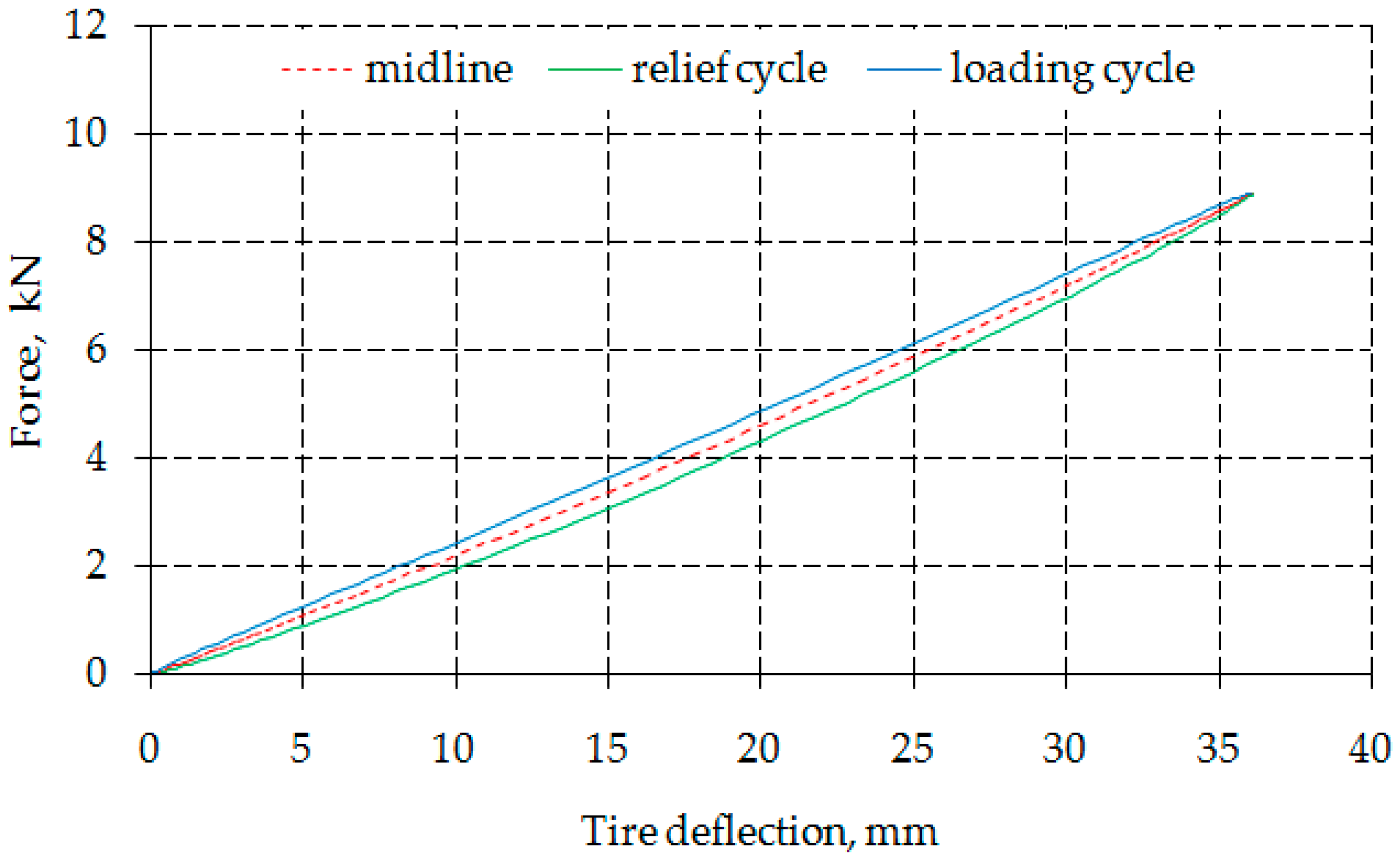

The research carried out as part of the first stage of the experiment made it possible to determine the stiffness and damping coefficients of the test cars’ tires wheels. The methodology for determining these coefficients was described in detail in [

33]. These coefficients were identified on the basis of the work diagrams determined for the tire wheels (

Figure 3).

From each characteristic of the wheel depicted as a hysteresis loop

, the elastic component

(

Figure 4) and the damping

were extracted (

Figure 5).

The elastic characteristics (

Figure 4) were characterized by negligibly small nonlinearity, so their form was assumed to be linear. The directional coefficients of the linear regression lines thus obtained gave the directional coefficients, which were also the stiffness coefficients of the tested wheel.

The directional coefficients of the axes of the skeletal damping characteristics were also the damping coefficients of the tested wheel. The values of the determined stiffness (k) and damping (c) coefficients of the tires of the tested cars are summarized in

Table 4.

The analysis shows that an increase in the pressure value caused a clear and obvious increase in the stiffness coefficient. This was confirmed by the correlation coefficient between these quantities, which for the E-segment car was at the level of 1, and for the D-segment car was at the level of 0.99, which shows a very strong relationship. In contrast, the increase in tire pressure values did not cause significant changes in the values of damping coefficients (c). The observed changes in the damping coefficient did not exceed 5%.

The polygon tests made it possible to determine, for each test, the courses of change in the torque on the steering wheel (M

H), the angle of rotation of the steering wheel (δ

H), and the lateral acceleration of the car (a

y) (

Figure 6).

Presented in

Figure 6, the waveforms of the recorded quantities are characterized by high variability in the different stages of lane changes.

According to F. Jaksch, steering effort is the product of increments of steering wheel rotation angle relative to normalized transverse acceleration (

Figure 7) and increments of torque on the steering wheel relative to normalized transverse acceleration (

Figure 8). Therefore, to determine the steering effort, it is necessary to examine the torque on the steering wheel as well as the steering wheel rotation angle (1).

where:

—increase in steering angle,

—increment of transverse acceleration normalized,

—increase in steering wheel torque.

3.1. Test Results and Their Analysis—D-Segment Passenger Car

The results of the road tests conducted for the D-segment passenger car are summarized in

Table 5 and

Table 6. Based on the analysis, it should be noted that a decrease in the speed of the car caused a clear increase in the increment of the steering angle relative to the normalized acceleration, while there was no clear change in the increment of the torque on the steering wheel. Steering effort is considered favorable if it is in the range of 1050–26,250 Nm° [

32]. The higher the effort, the more energy is consumed by the power steering system. For the case under review, the steering effort values determined for a car traveling at 20 and 30 km/h fell within this range. Reducing the speed of the car to 10 km/h resulted in a significant increase in the value of the steering effort index. The values of the steering effort index for this speed exceeded the values of the range considered favorable several times and, depending on the tire pressure, amounted to 107,322.5 Nm°, 98,127.67 Nm°, 90,026.52 Nm°, and 81,188.84 Nm° (

Table 6,

Figure 9).

The correlation coefficients between tire wheel stiffness coefficients and steering effort coefficients, determined for a D-segment car traveling at speeds of 10, 20, and 30 km/h, were −0.99, −0.67, and −0.47, respectively. The first of these values indicates a very high correlation and a very certain relationship, while the other two indicate moderate correlations and significant relationships (

Table 7). Slightly lower correlations of 1, 0.64, and 0.41, respectively, were observed between steering effort and the load cycle damping factor (

Table 7). The first of these values signifies a very high correlation and a very certain relationship, while the other two (0.64 and 0.41) signify moderate correlations and significant relationships (

Table 7).

3.2. Test Results and Their Analysis—E-Segment Passenger Car

The results of the road tests carried out for the E-segment car are summarized in

Table 8 and

Table 9. Based on their analysis, it should be noted that a decrease in the speed of the car causes a clear increase in the increase in the steering wheel angle relative to the normalized acceleration, while it did not cause a clear increase in the torque of the steering wheel relative to the normalized acceleration. For low speeds, the values of the steering effort index (

Table 9,

Figure 10) were within the range that is considered favorable (1050–26,250 Nm°) [

32].

At a car speed of 40 km/h, a 15% increase in tire pressure caused a 7% decrease in steering effort index, while a 50% decrease in pressure caused a 25% increase in steering effort index. Steering effort at a car speed of 20 km/h changed to a greater extent as a result of changes in tire pressure and increased by 30% due to a 50% decrease in pressure and decreased by 9% due to a 15% increase in pressure (

Table 9).

The correlation coefficients between the tire wheel stiffness coefficients and steering effort indices, determined for an E-segment car traveling at 20, 30, and 40 km/h, were at a very high level and were −1.0, −0.95, and −1.0, respectively. They testify to a very high correlation and a very reliable relationship (

Table 10). On the other hand, the correlations between the damping coefficients of the tire wheel, determined for load cycles, and the steering effort indexes were slightly lower, at 0.89, 0.88, and 0.89, respectively. These values indicate a high correlation and a significant dependence. On the other hand, an even lower but still significant correlation was observed between steering effort and the damping coefficient of the load cycle (

Table 10).

According to this study, it appears that the energy effort of steering can be significantly affected by the energy intensity of the tire. The energy intensity of the tire structure, manifested by its heating, depends on the value of the tire pressure. The value of tire pressure also affects the tire’s lateral stiffness, drift resistance, and steerability (lateral stability) of the car. A change in trajectory, caused by the lateral drift of the car, forces the need to make corrections to the trajectory, and this, consequently, causes greater energy consumption. The corrections to the driving track may be so small that they are not visible on the graph of the course of the change in steering angle. Identification of these corrections can be made on the basis of analysis of the derivative of the steering angle against time. To better understand the problem, it is desirable to continue research in the context of a detailed analysis of the physical phenomena occurring in the area of interaction between the wheel and the road surface. For this purpose, it is necessary to verify the parameters characterizing the interaction of the test car wheel with the road surface (lateral drift angle) and tire temperature. Tire temperature significantly affects the actual tire pressure value.

4. Conclusions

The authors of this article attempted to determine the effect of the low-speed movement of the car and the elastic-damping properties of the tire wheel of a motor vehicle on the value of the index characterizing “steering effort” and the energy intensity of the steering assistance system.

The experiment carried out by the authors made it possible to show that changing the elastic properties of the tire wheels affected the “effort” and energy intensity of steering. This impact was greater the lower the speed of the car. However, for the E’-segment car, it does not result in exceeding the permissible load level of 1050–26,250 Nm°, and an increase in energy consumption is noticeable.

A clear impact on “steering effort” was noted for the D-segment car, as it was observed to exceed the upper limit of the 26,250 Nm° range considered acceptable.

The correlation between the coefficients of the stiffness of the tire wheels and the energy intensity of the steering system increased as the speed of the self-driving car decreased. At the lowest speeds, they were −0.99 for the D-segment car and −1 for the E-segment car. This indicates a very high correlation and a very reliable relationship. At the same speeds, the correlation coefficients between steering energy intensity and load cycle damping coefficients were 1 for the D-segment car and 0.89 for the E-segment car.

The authors also performed a study of the energy expenditure of a car’s steering assistance system in traffic, which confirmed the relationships noted here. The results of in-service testing of the steering effort in traffic will be presented in future publications.