The Generation Methods and Applications of Cavitating Jet by Using Bubble Collapse Energy

Abstract

1. Introduction

2. Generation Methods of Cavitating Jets

2.1. Cavitation Formation, Growth and Collapse

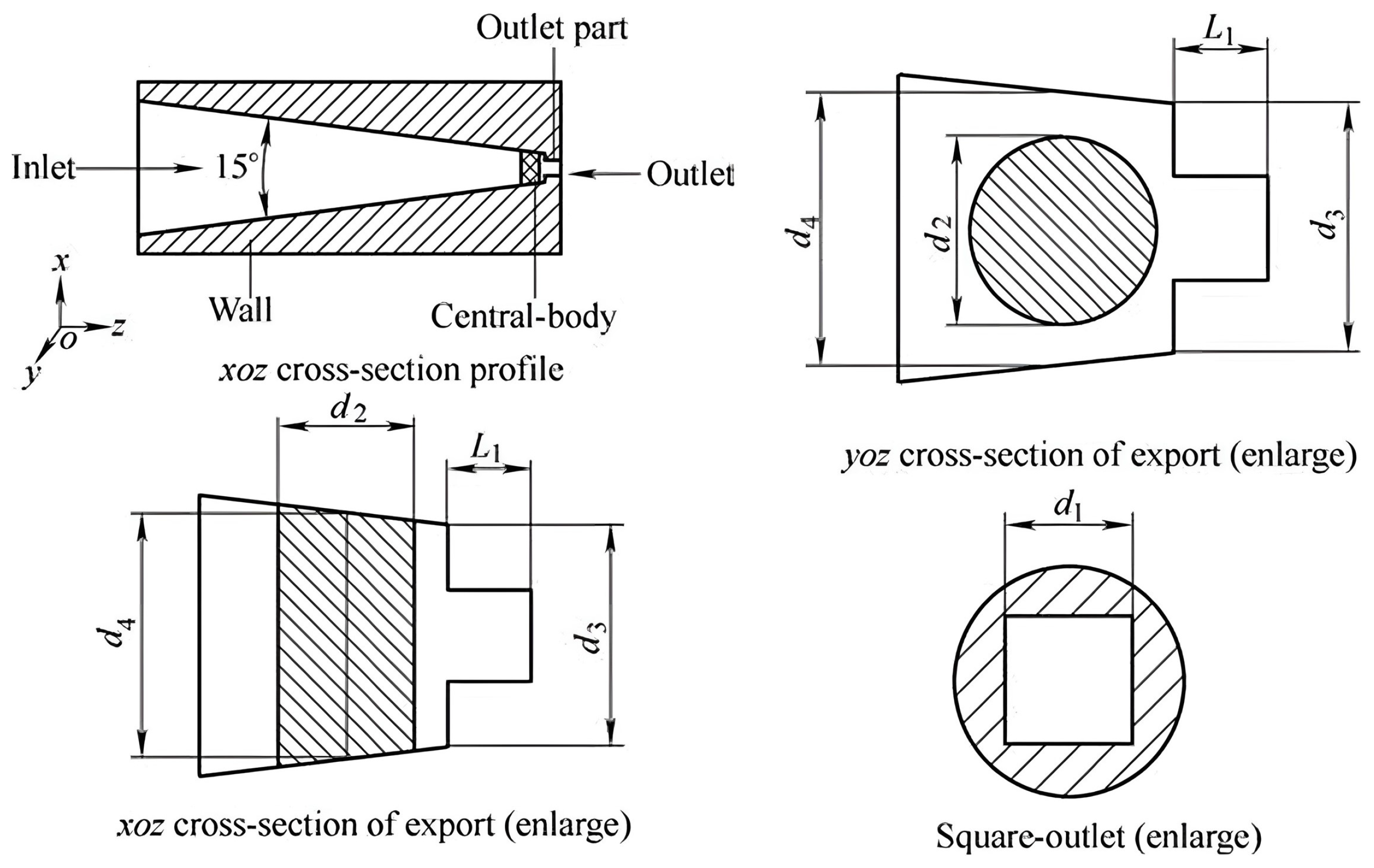

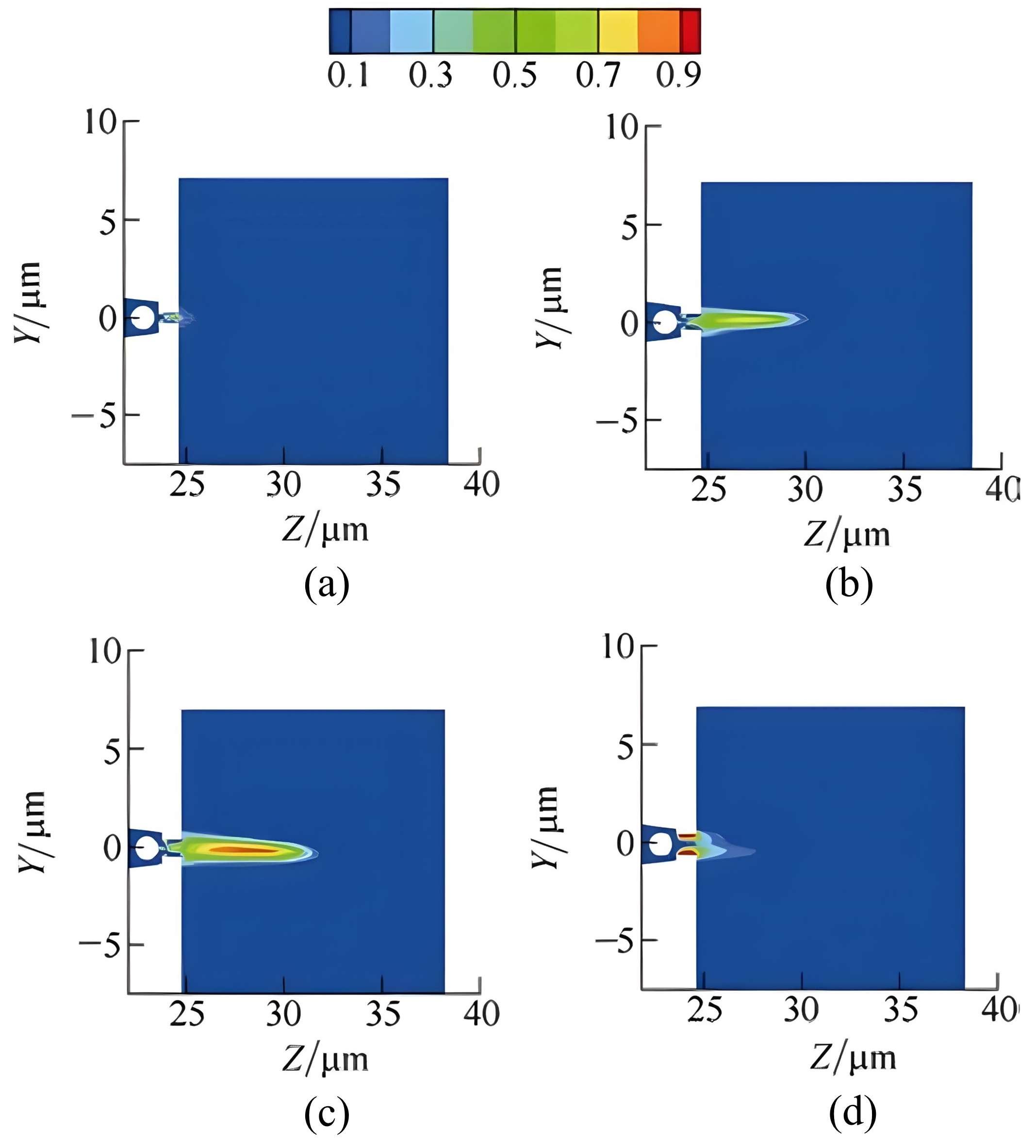

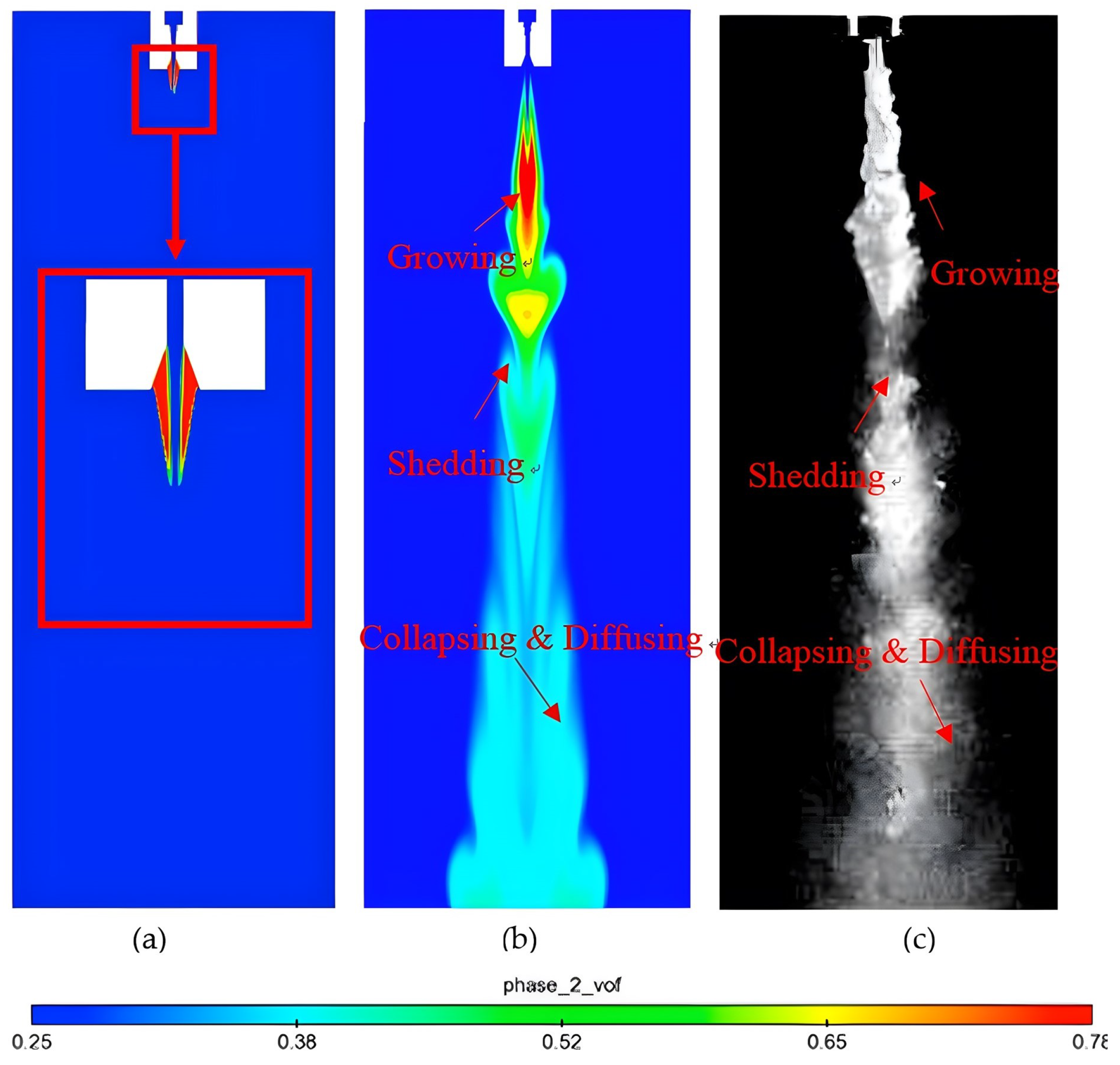

2.2. Central Body Cavitation

2.3. Oscillatory Cavitation

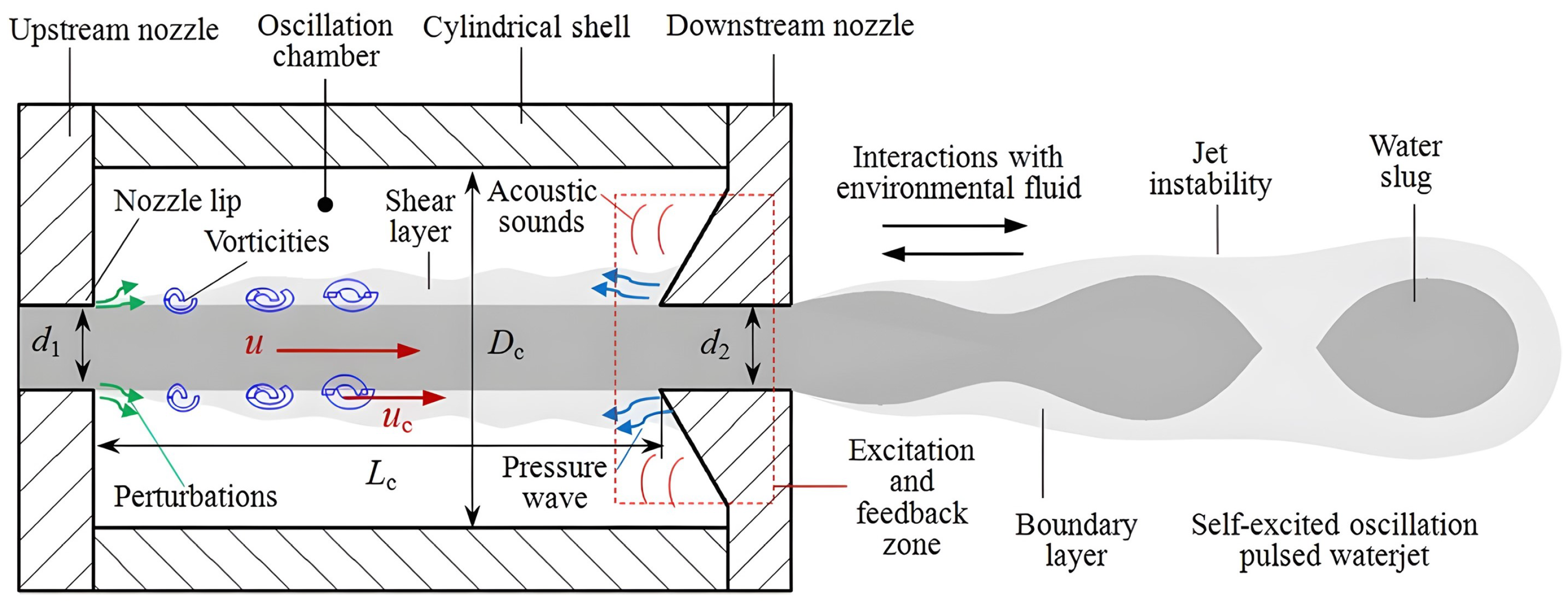

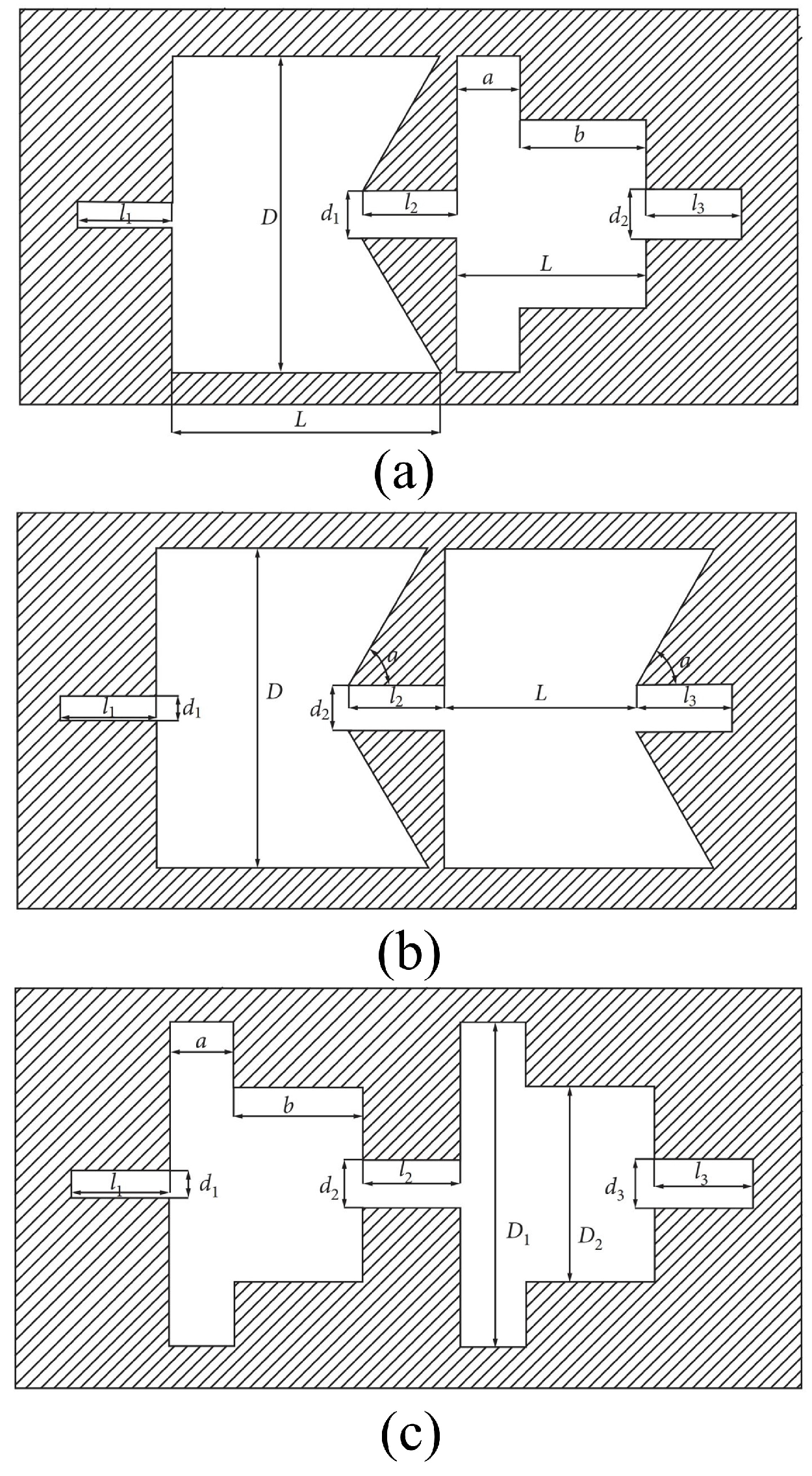

2.3.1. Helmholtz Type Self-Excited Cavitating Jet

2.3.2. Organ Pipe Type Self-Excited Cavitating Jet

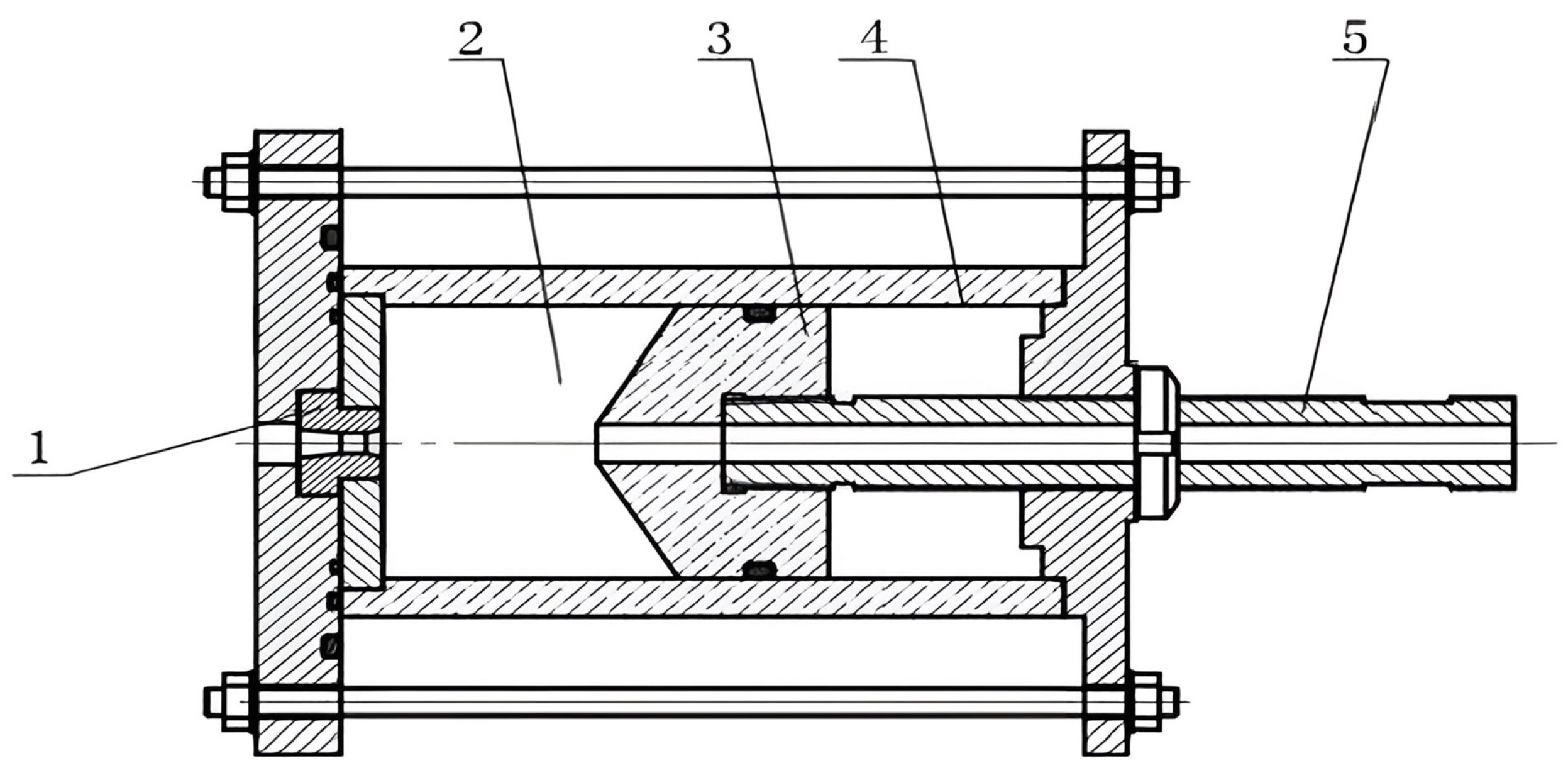

2.3.3. Dual-Chamber Self-Excited Oscillating Pulsed Nozzles

2.3.4. Factors Influencing the Strength of Self-Excited Cavitating Jet

2.3.5. Erosion Patterns of Self-Excited Cavitating Jet

2.4. Shear Cavitation

2.5. Other Methods of Cavitating Jet Generation

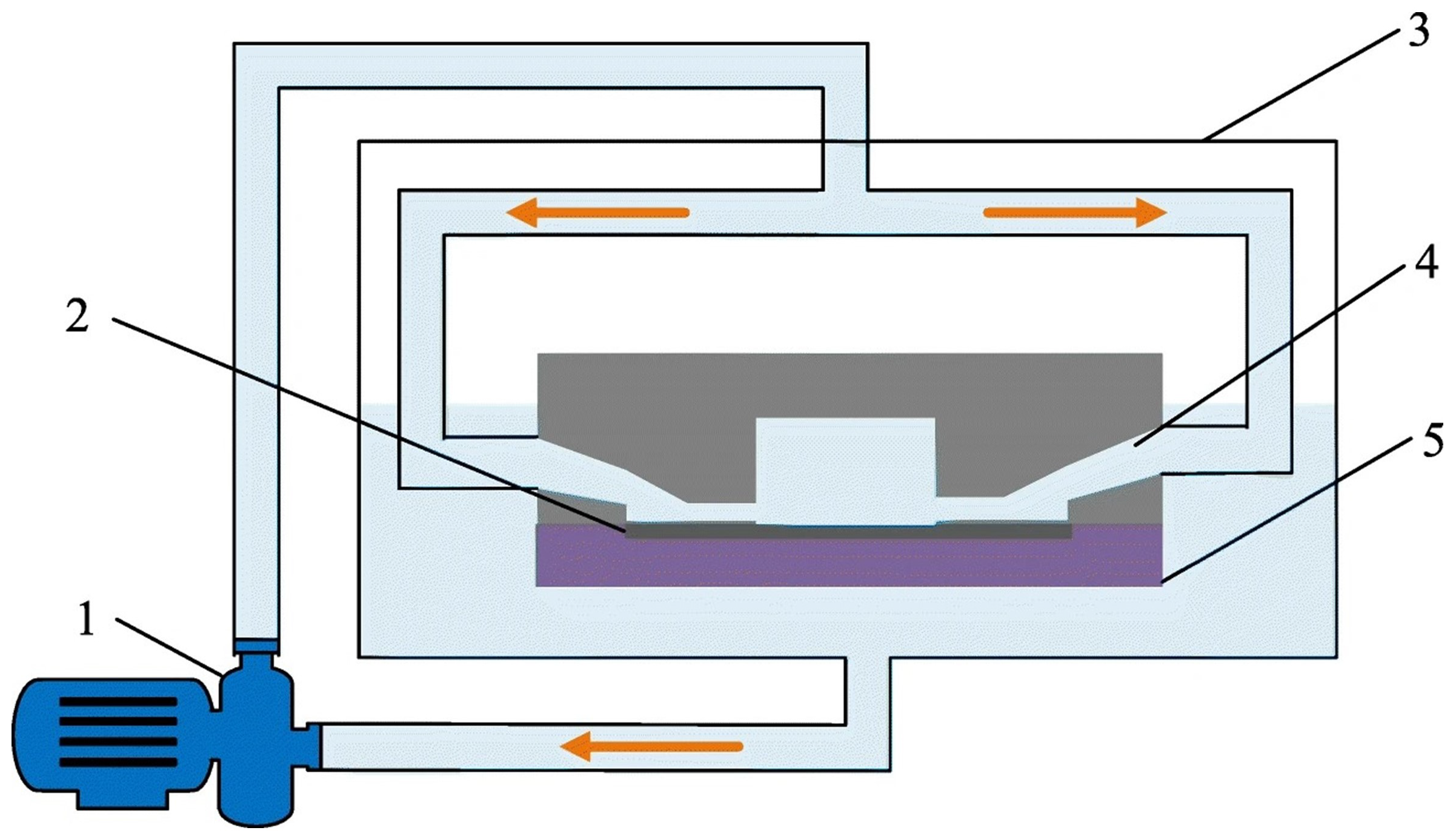

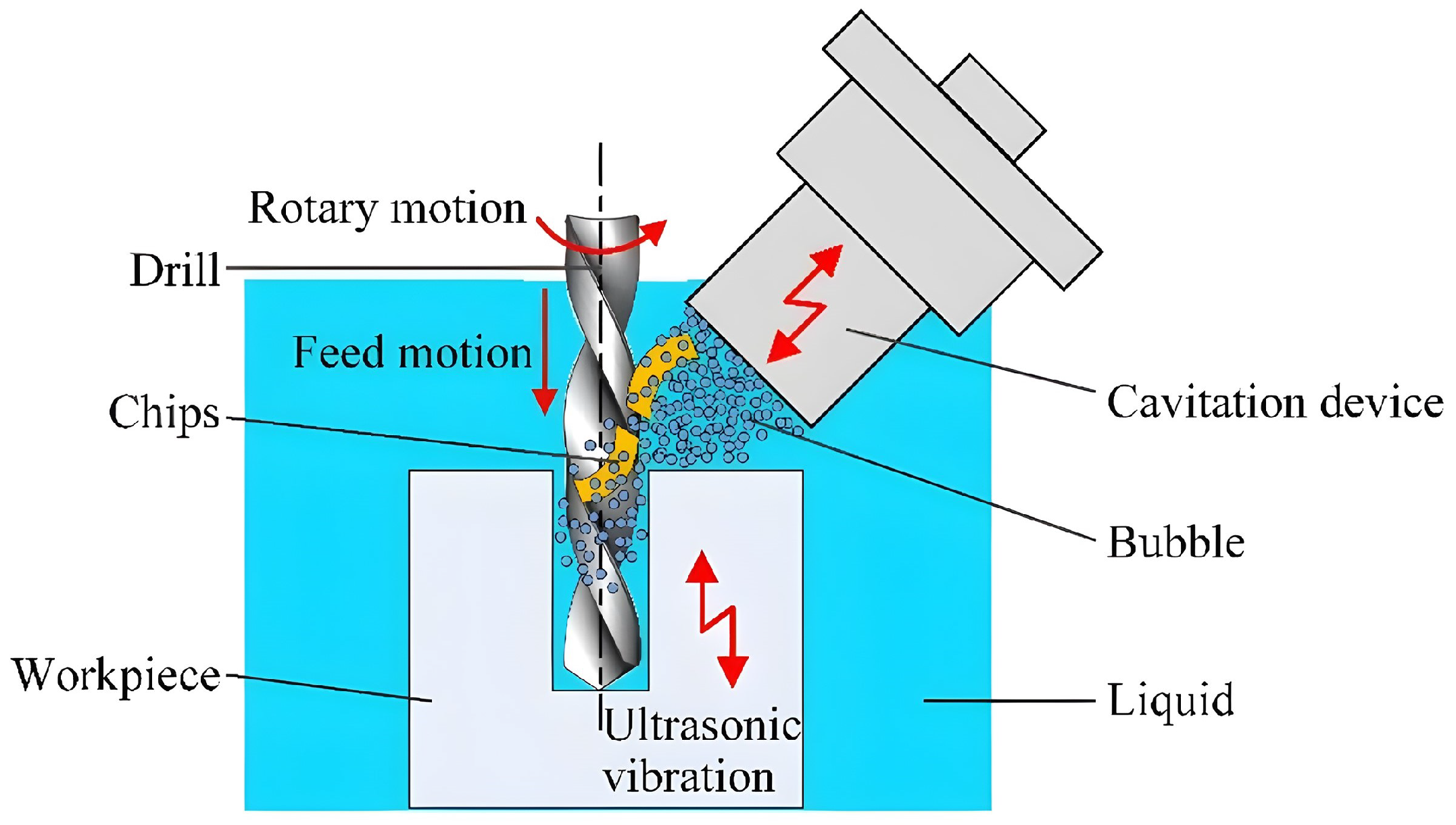

2.5.1. Ultrasonic Cavitation

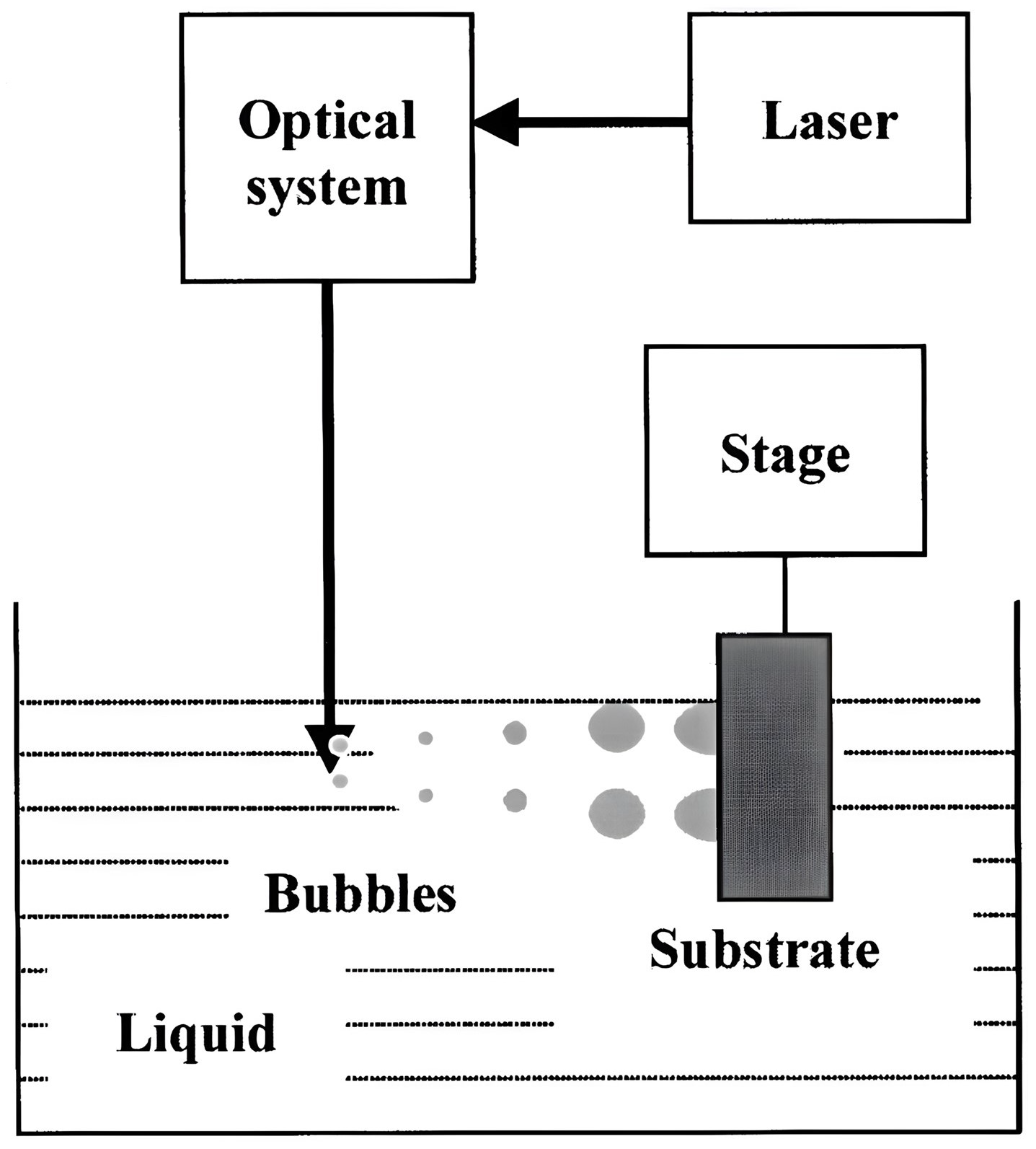

2.5.2. Laser Induced Cavitation

3. Applications of Cavitating Jets

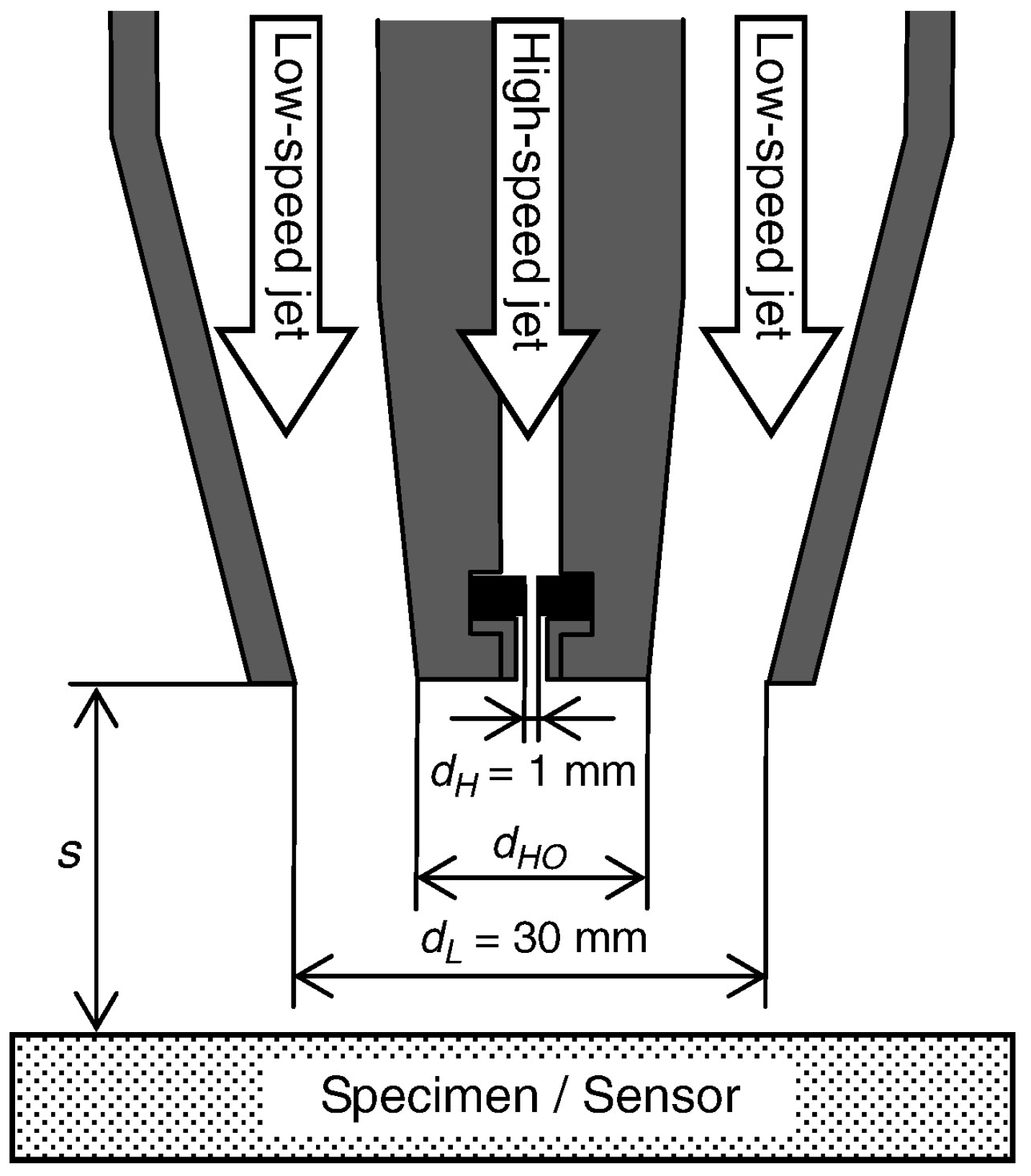

3.1. Application in Improving the Surface Performance of Materials

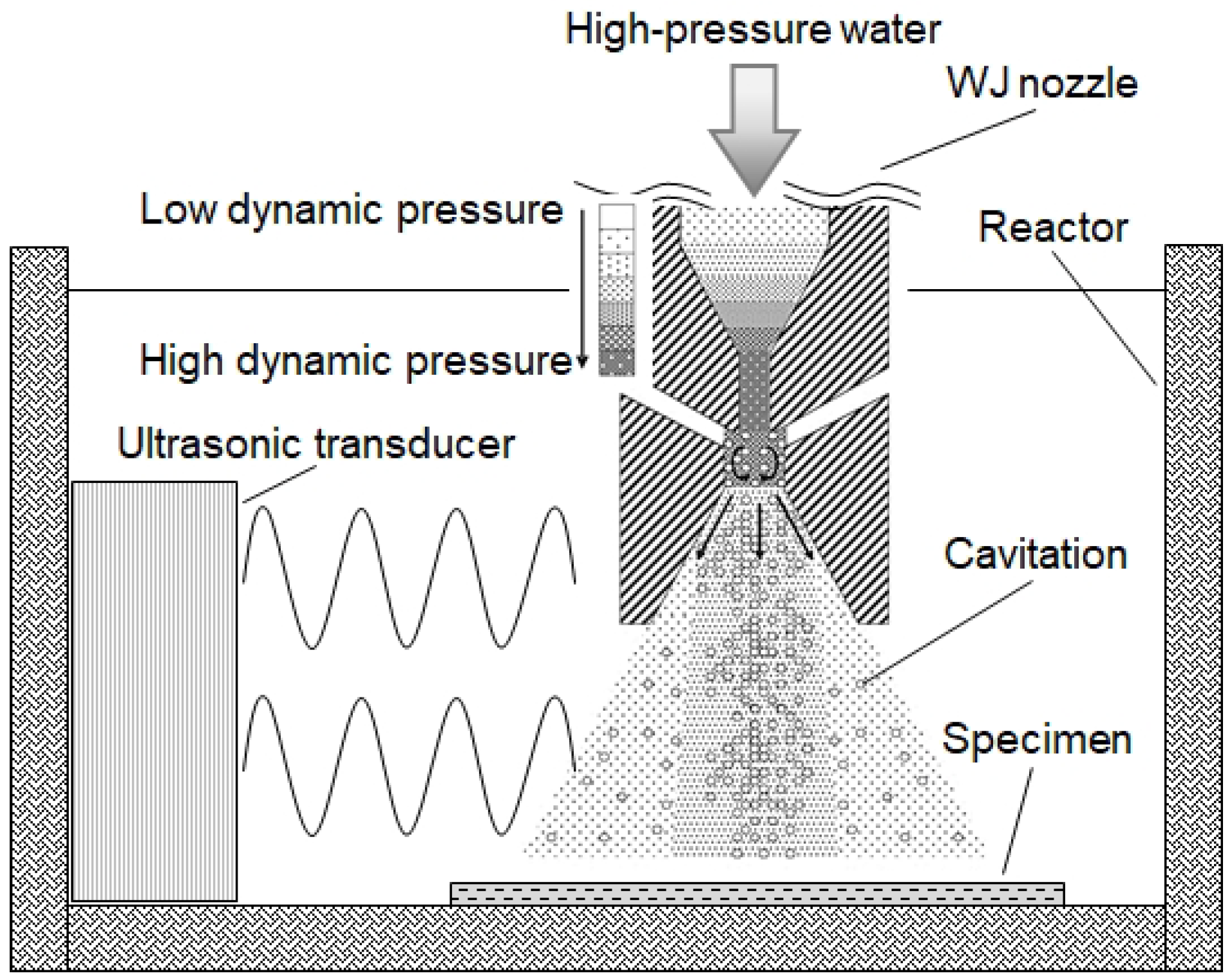

3.1.1. Surface Material Strengthening

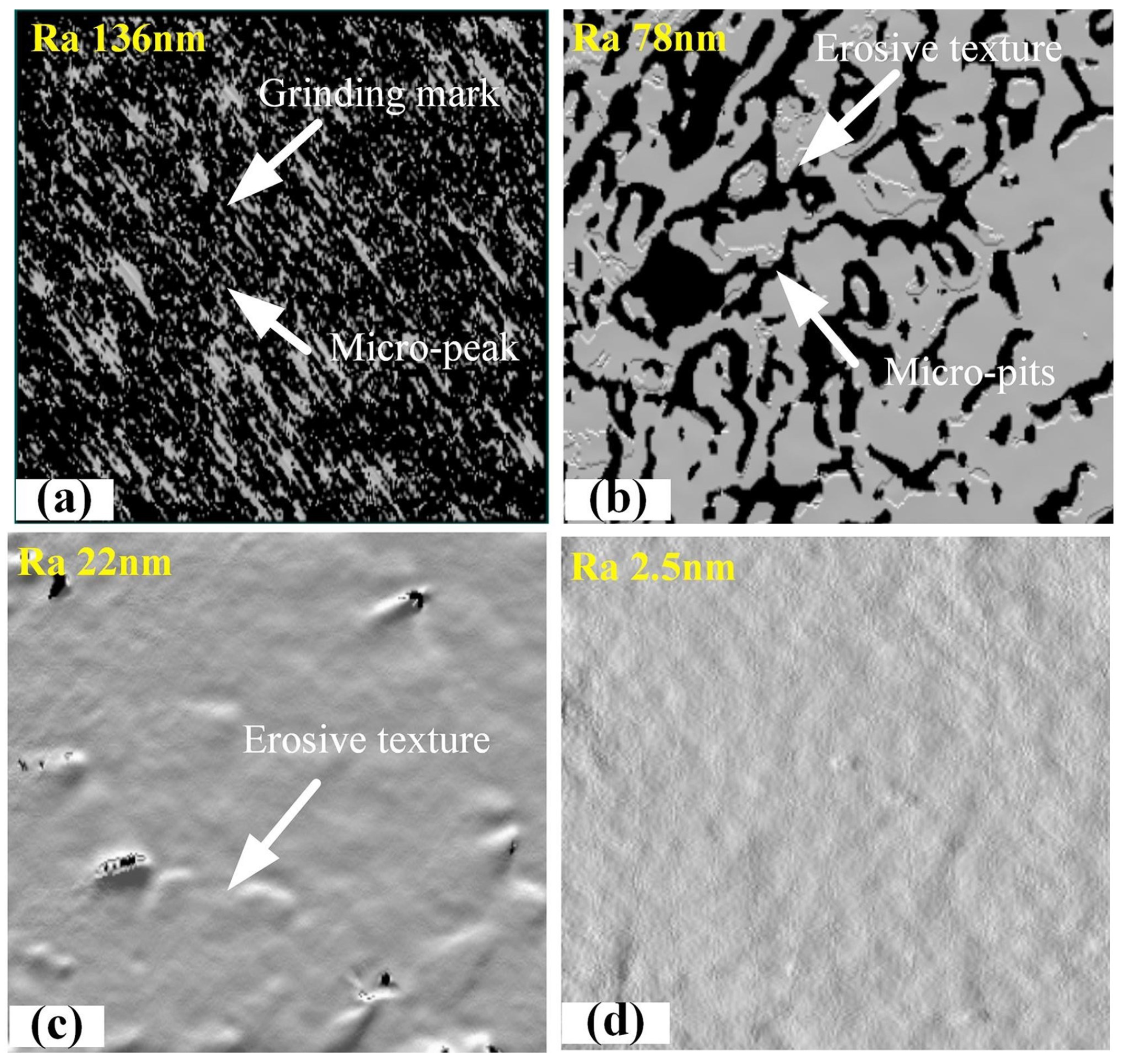

3.1.2. Surface Polishing

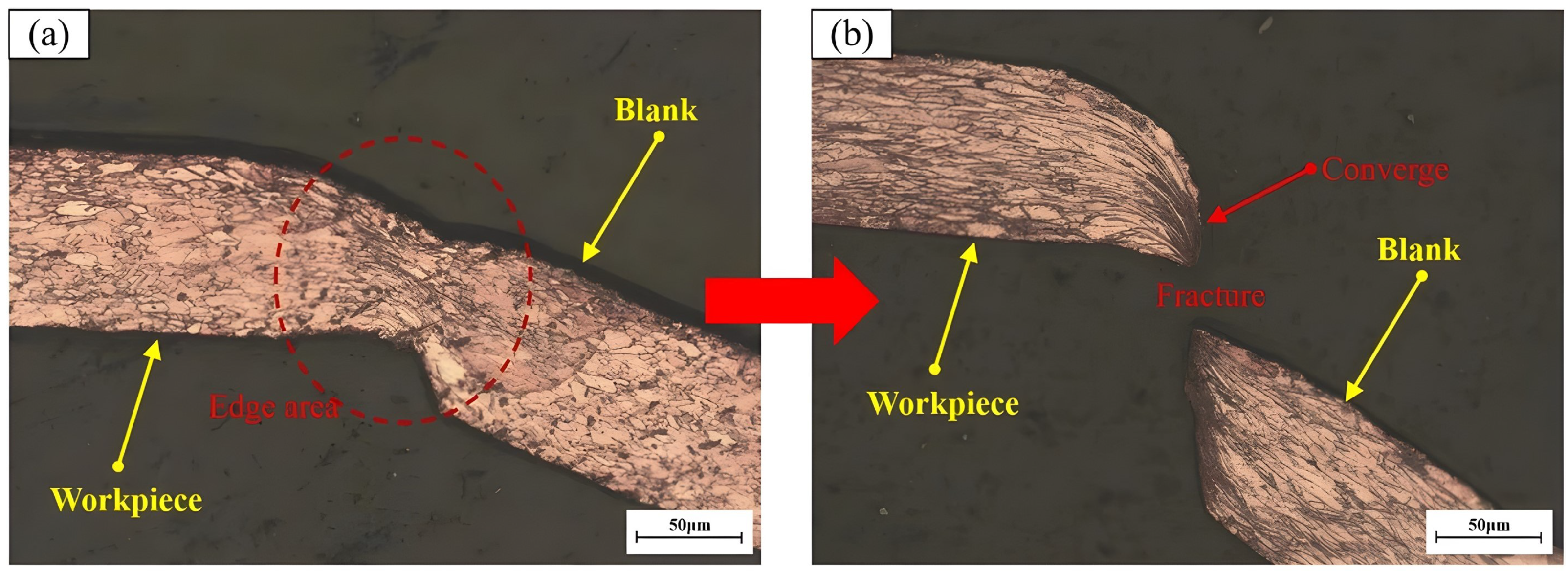

3.1.3. Surface Material Micro-Forming

3.2. Application in Crushing and Cutting

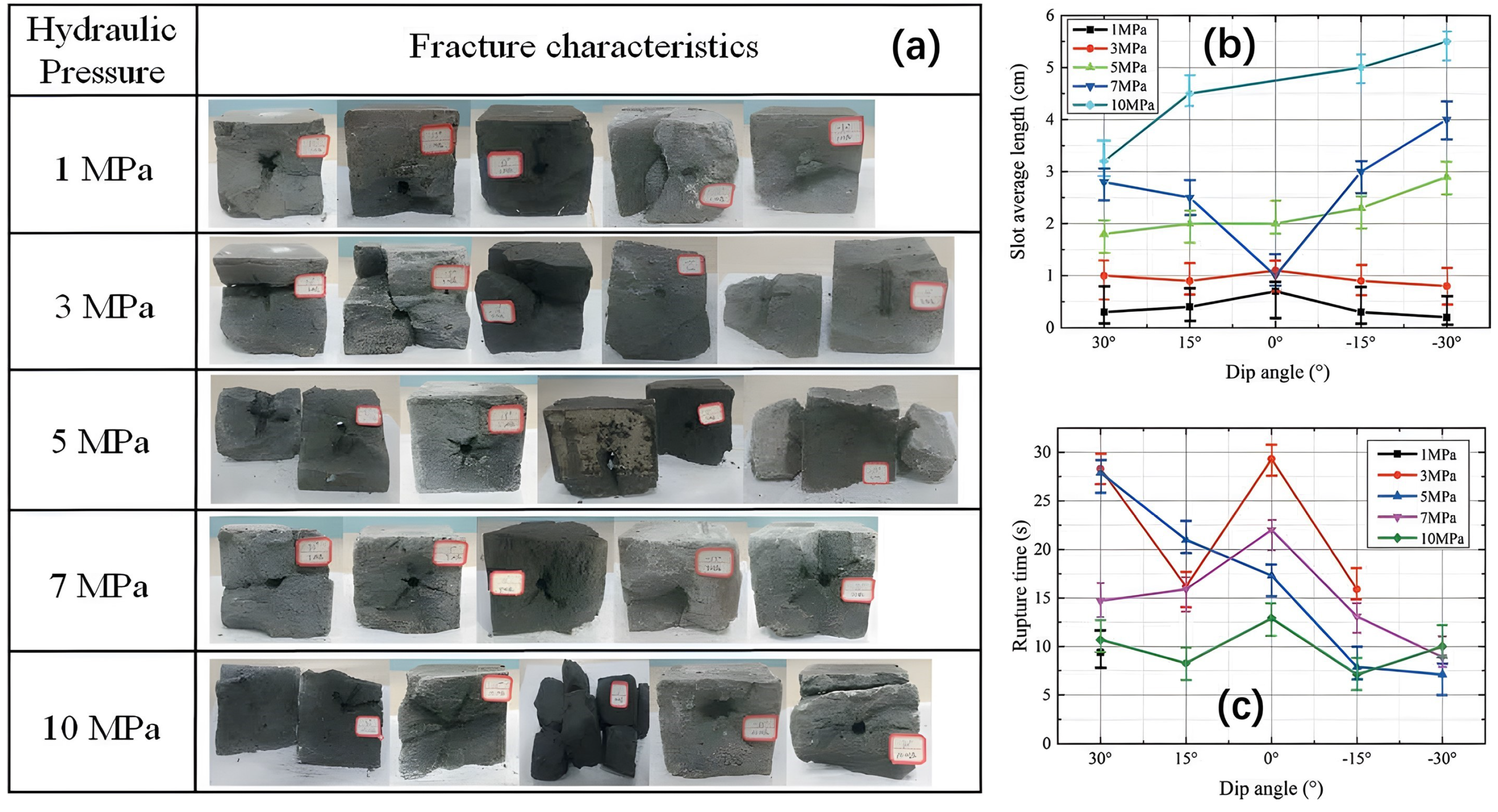

3.3. Application in Energy Exploration

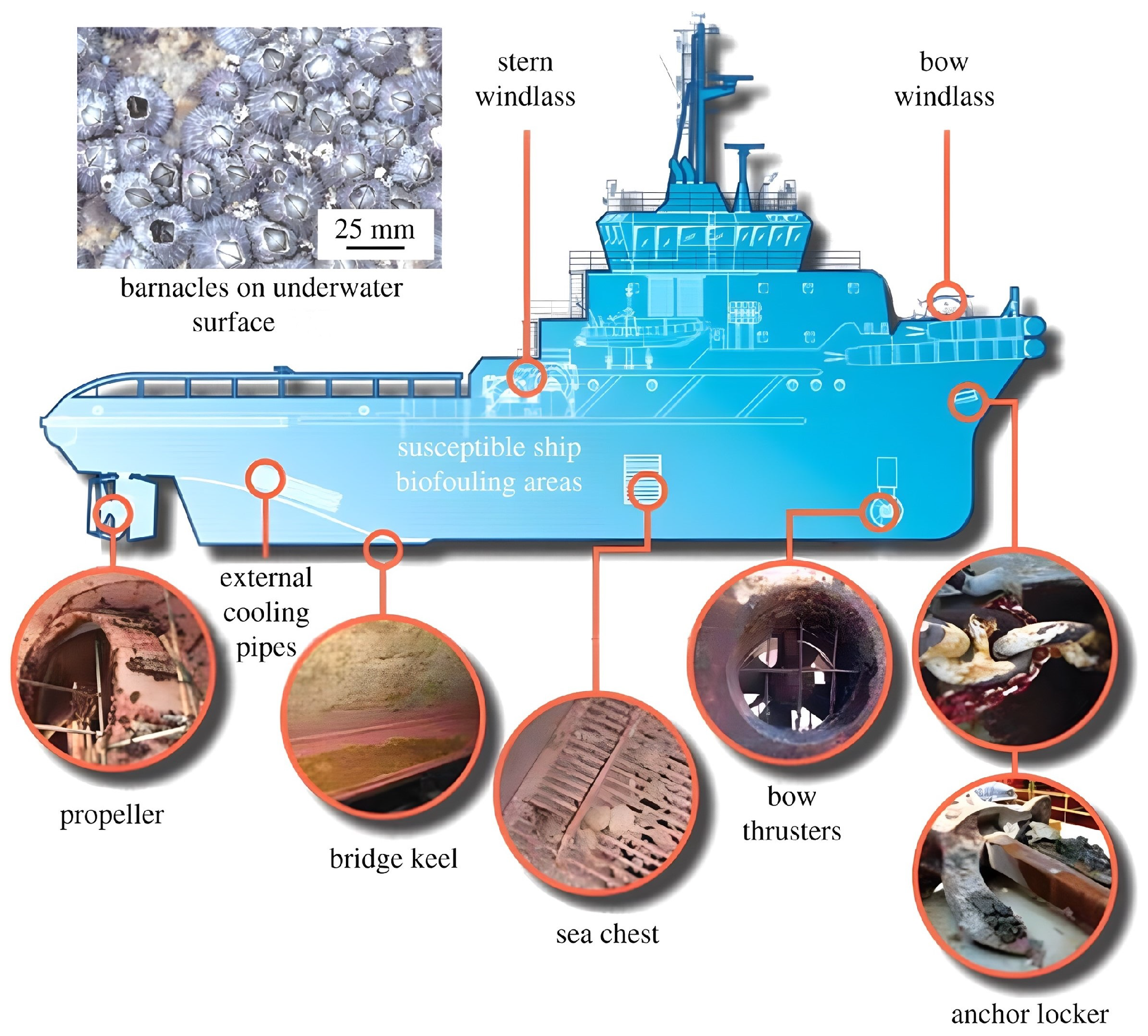

3.4. Application in Cleaning

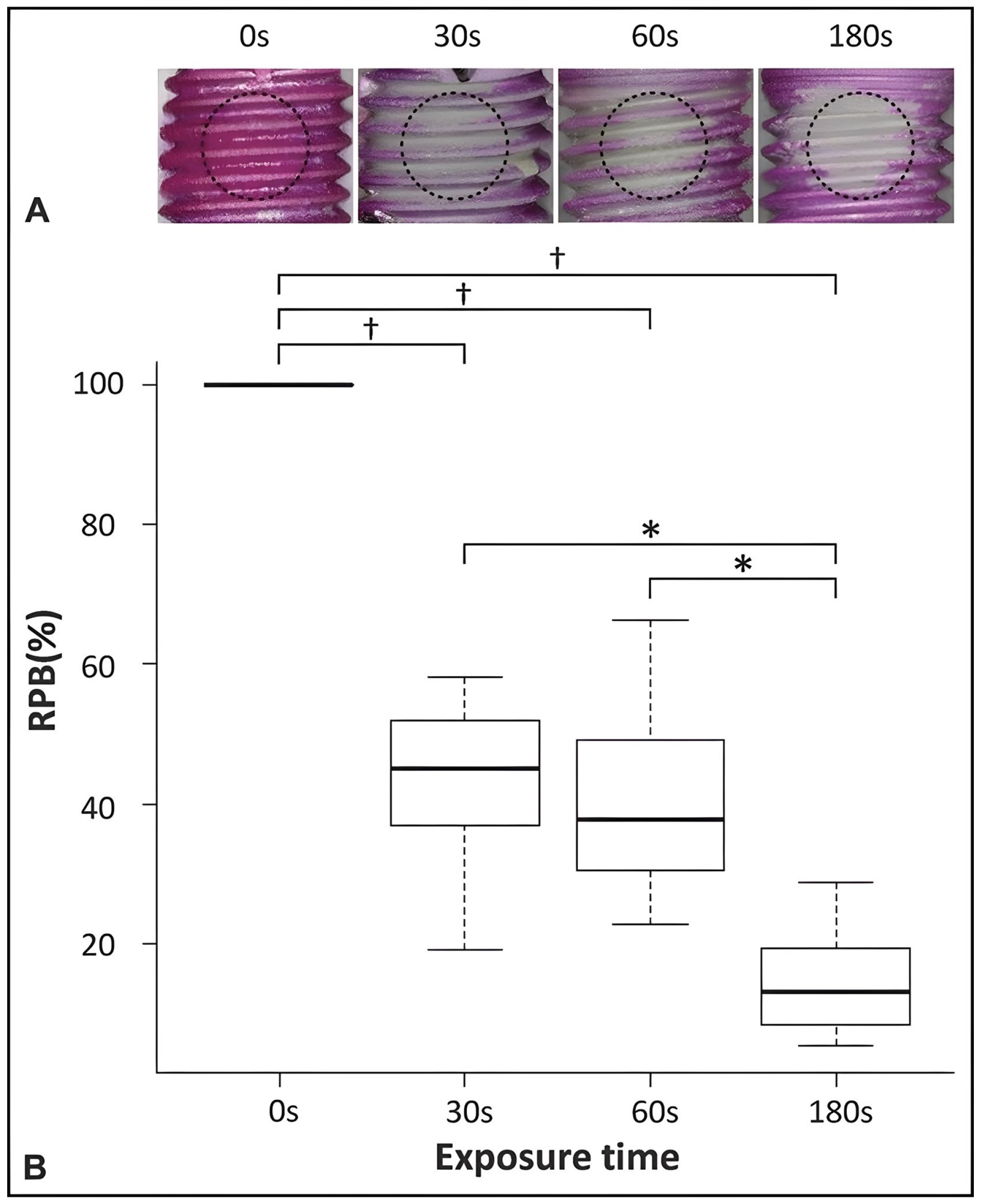

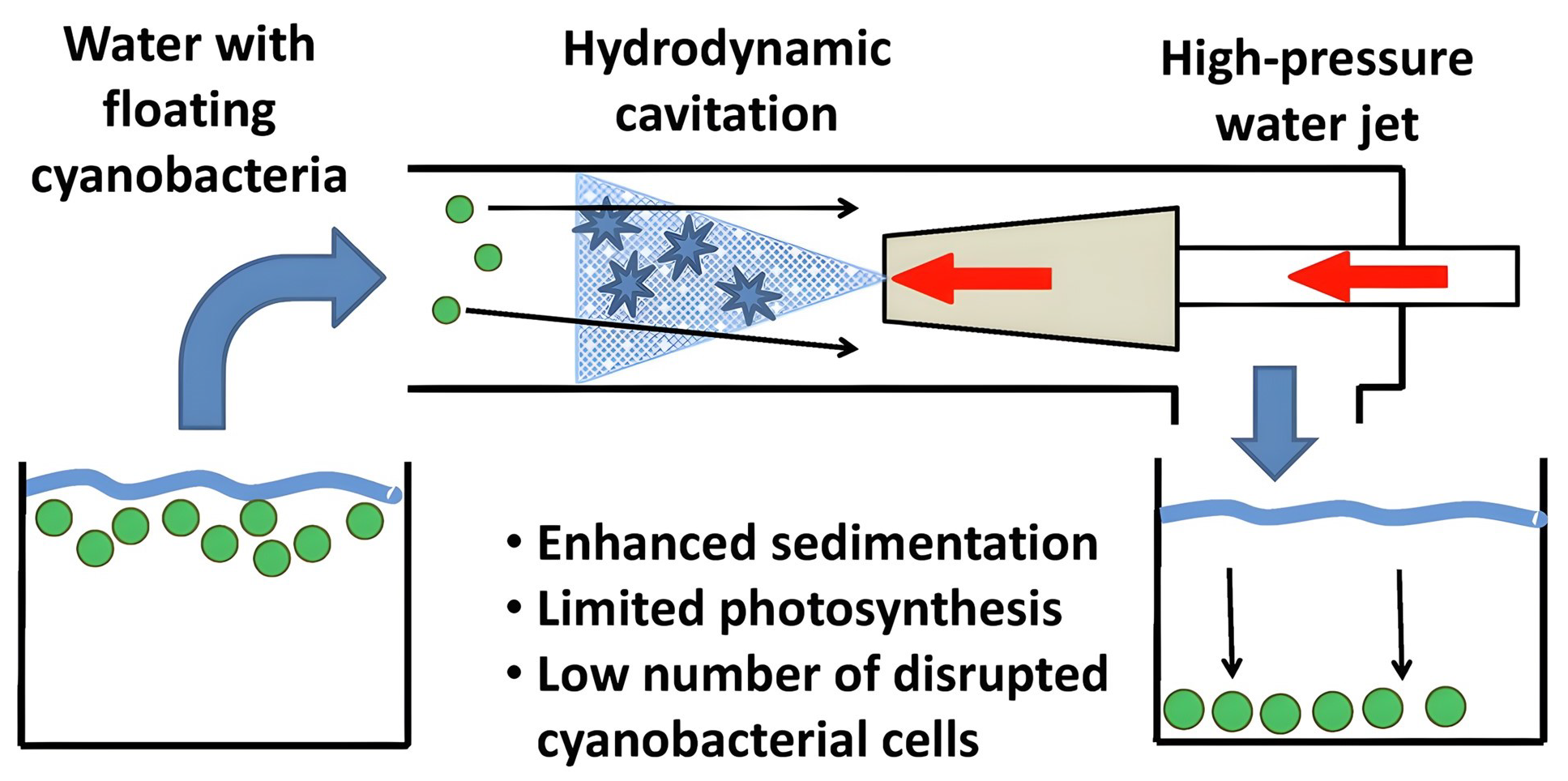

3.5. Application in Biological Treatment and Waste Treatment

4. Conclusions

- The study categorizes three primary methods for generating cavitating jets: central body, oscillatory, and shear cavitation. Central body cavitation uses a physical obstruction to create intense, localized cavitation, ideal for high-impact applications. Oscillatory cavitation leverages resonance to produce controlled bubble formation and collapse, suited for precision needs. Shear cavitation, driven by velocity gradients and boundary interactions, supports broad-area applications and continuous-flow processes. Each method’s unique characteristics—cavitation intensity, stability, and control—make them adaptable for specific industrial uses, underscoring the importance of tailored method selection for diverse operational requirements.

- Cavitating jets show significant potential across industries, including surface treatment, pollutant removal, material processing, and energy extraction. The intense impact force of bubble collapse enables effective applications such as surface peening, pollutant breakdown, precision cutting, and hydraulic fracturing. Adjustable cavitation parameters allow these jets to address varying application demands, from enhancing surface durability to processing confined materials. The flexibility offered by cavitating jets, with tailored generation methods for specific needs, allows for targeted industrial use, fostering innovation and efficiency in both established and emerging fields.

- Despite advancements, challenges limit cavitating jet technology’s full implementation. Achieving efficient cavitation under high-pressure and low-energy conditions remains difficult, particularly for applications requiring prolonged stability and consistent intensity. Central body cavitation struggles with maintaining stability over large areas, while shear cavitation faces concentration issues along boundary layers. Optimizing nozzle designs and integrating hybrid methods (e.g., ultrasonic or laser assistance) could enhance performance, though such integrations introduce complexity. Addressing these issues will be crucial for maximizing cavitating jets’ versatility and effectiveness across industrial applications.

- Further research should focus on optimizing nozzle designs that enhance cavitation efficiency under varying pressure conditions. Developing nozzles capable of maintaining cavitation at lower energy inputs, while still achieving high-impact forces, would broaden the applicability of cavitating jets across industries. Coaxial and multi-orifice designs, which improve stability and cavitation intensity, offer promising avenues. Experimentation with materials and structural configurations could lead to more durable and adaptable nozzles, addressing issues such as wear and efficiency loss in high-intensity applications. Such innovations are essential for expanding the use of cavitating jets in industrial settings.

- Hybrid methods, such as combining cavitating jets with ultrasonic or laser assistance, present a significant potential to amplify cavitation effects for specialized applications. These hybrid approaches could enhance the precision and energy concentration of cavitation, making them suitable for areas like precision cleaning, biomedical treatments, and environmental remediation. Further studies should examine the optimal parameters for synchronization and energy distribution in hybrid systems. Additionally, research into the interactions between different energy sources and cavitation mechanisms will be vital for fully leveraging hybrid techniques’ advantages while minimizing operational complexity.

- Advancing computational fluid dynamics (CFD) models to more accurately simulate cavitation dynamics is crucial for optimizing cavitating jet design and application. Enhanced modeling would enable precise control over cavitation parameters and predict performance in diverse operational conditions. Coupling these models with experimental validation can provide a robust framework for understanding cavitation behavior and refining jet designs accordingly. Future research should focus on creating models that incorporate variables such as fluid properties, nozzle geometry, and hybrid cavitation effects to predict outcomes with higher accuracy, ultimately streamlining the design and implementation of cavitating jet technologies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burrill, L.C. The phenomenon of cavitation. Int. Shipbuild. Prog. 1955, 2, 503–511. [Google Scholar] [CrossRef]

- Johnson, V.; Kohl, R.; Thiruvengadam, A.; Conn, A. Tunneling, fracturing, drilling and mining with high speed water jets utilizing cavitation damage. In Proceedings of the 1st International Symposium on Jet Cutting Technology, Bedford, UK, 1 October 1972; British Hydromechanics Research Association: Cranfield, UK, 1972; p. A3-37. [Google Scholar]

- Conn, A.; Rudy, S. Cutting coal with the CAVIJET cavitating water jet method. In Proceedings of the 3rd International Symposium on Jet Cutting Technology, Chicago, IL, USA, 11 May 1976; pp. 11–13. [Google Scholar]

- Senshen, P. Modern Research on the Mechanism of Cavitation. Adv. Mech. 1979, 23, 4. [Google Scholar]

- Cui, M.; Sun, J. Higher Education Textbook: High-Pressure Water Jet Technology; China Coal Industry Publishing House: Beijing, China, 1993. [Google Scholar]

- Johnson, V.; Lindenmuth, W.; Conn, A. Feasibility Study of Tuned-Resonator, Pulsating Cavitating Water Jet for Deep-Hole Drilling; Petroleum; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA; Hydronautics, Inc.: Laurel, MD, USA, 1981. [Google Scholar]

- Johnson, V.; Conn, A.; Lindenmuth, W.; Chahine, G.; Frederick, G. Self-resonating cavitating jets. In Proceedings of the 6th International Symposium on Jet Cutting Technology, BHRA, Cranfield, UK, 6–8 April 1982; pp. 1–26. [Google Scholar]

- Lichtarowicz, A.; Sakkejha, M. Cutting with cavitating jets. In Proceedings of the 1st International Symposium on Jet Cutting Technology, BHRA, Coventry, UK, 5–7 April 1972; Paper G6. Volume 26. [Google Scholar]

- Tavoularis, S.; Remisz, J.; Hu, S. A Study of the Practicality of Cavitating Water Jets; Springer: Dordrecht, The Netherlands, 1992. [Google Scholar]

- Soyama, H. Introduction of Compressive Residual Stress Using a Cavitating Jet in Air. J. Eng. Mater. Technol. 2004, 126, 123–128. [Google Scholar] [CrossRef]

- Soyama, H. High-Speed Observation of a Cavitating Jet in Air. J. Fluids Eng. 2005, 127, 1095–1101. [Google Scholar] [CrossRef]

- Soyama, H. Improvement of fatigue strength by using cavitating jets in air and water. J. Mater. Sci. 2007, 42, 6638–6641. [Google Scholar] [CrossRef]

- Li, Z. Criteria and erosion mechanism of cavitation jet formation. Eng. Mech. 2007, 24, 185–188. (In Chinese) [Google Scholar]

- Plesset, M.S.; Chapman, R.B. Collapse of an initially spherical vapour cavity in the neighbourhood of a solid boundary. J. Fluid Mech. 1971, 47, 283–290. [Google Scholar] [CrossRef]

- Lauterborn, W.; Bolle, H. Experimental investigations of cavitation-bubble collapse in the neighbourhood of a solid boundary. J. Fluid Mech. 1975, 72, 391–399. [Google Scholar] [CrossRef]

- Tomita, Y.; Shima, A. Mechanisms of impulsive pressure generation and damage pit formation by bubble collapse. J. Fluid Mech. 1986, 169, 535–564. [Google Scholar] [CrossRef]

- Vogel, A.; Lauterborn, W.; Timm, R. Optical and acoustic investigations of the dynamics of laser-produced cavitation bubbles near a solid boundary. J. Fluid Mech. 1989, 206, 299–338. [Google Scholar] [CrossRef]

- Isselin, J.C.; Alloncle, A.P.; Autric, M. On laser induced single bubble near a solid boundary: Contribution to the understanding of erosion phenomena. J. Appl. Phys. 1998, 84, 5766–5771. [Google Scholar] [CrossRef]

- Dular, M.; Bachert, B.; Stoffel, B.; Širok, B. Relationship between cavitation structures and cavitation damage. Wear 2004, 257, 1176–1184. [Google Scholar] [CrossRef]

- Johnsen, E.; Colonius, T. Numerical simulations of non-spherical bubble collapse. J. Fluid Mech. 2009, 629, 231–262. [Google Scholar] [CrossRef] [PubMed]

- Jin, W. Cavitation generation and inhibition. I. Dominant mechanism of turbulent kinetic energy for cavitation evolution. AIP Adv. 2021, 11, 065028. [Google Scholar] [CrossRef]

- Fortes-Patella, R.; Challier, G.; Reboud, J.L.; Archer, A. Energy balance in cavitation erosion: From bubble collapse to indentation of material surface. J. Fluids Eng. 2013, 135, 011303. [Google Scholar] [CrossRef]

- Leighton, T.; Farhat, M.; Field, J.; Avellan, F. Cavitation luminescence from flow over a hydrofoil in a cavitation tunnel. J. Fluid Mech. 2003, 480, 43–60. [Google Scholar] [CrossRef]

- Lavigne, S. Measurement of the aggressivity of erosive cavitating flows by a technique of pit analysis. Application to a method of prediction of erosion. In Proceedings of the International Symposium on Cavitation, CAV’95, Deauville, France, 2–5 May 1995; pp. 241–248. [Google Scholar]

- Escaler, X.; Farhat, M.; Avellan, F.; Egusquiza, E. Cavitation erosion tests on a 2D hydrofoil using surface-mounted obstacles. Wear 2003, 254, 441–449. [Google Scholar] [CrossRef]

- Fujisawa, N.; Fujita, Y.; Yanagisawa, K.; Fujisawa, K.; Yamagata, T. Simultaneous observation of cavitation collapse and shock wave formation in cavitating jet. Exp. Therm. Fluid Sci. 2018, 94, 159–167. [Google Scholar] [CrossRef]

- Shima, A.; Takayama, K.; Tomita, Y.; Miura, N. An experimental study on effects of a solid wall on the motion of bubbles and shock waves in bubble collapse. Acta Acust. United Acust. 1981, 48, 293–301. [Google Scholar]

- Tsuda, Y.; Ueki, H.; Hirose, T.; Kimoto, H. Experimental study of the shock generation at the collapse of cavitation bubble. Bull. JSME 1982, 25, 1890–1897. [Google Scholar] [CrossRef]

- Arabnejad, M.H.; Svennberg, U.; Bensow, R.E. Numerical assessment of cavitation erosion risk using incompressible simulation of cavitating flows. Wear 2021, 464, 203529. [Google Scholar] [CrossRef]

- Liu, H.; Kang, C.; Zhang, W.; Zhang, T. Flow structures and cavitation in submerged waterjet at high jet pressure. Exp. Therm. Fluid Sci. 2017, 88, 504–512. [Google Scholar] [CrossRef]

- Peng, C.; Tian, S.; Li, G. Joint experiments of cavitation jet: High-speed visualization and erosion test. Ocean Eng. 2018, 149, 1–13. [Google Scholar] [CrossRef]

- Nishimura, S.; Takakuwa, O.; Soyama, H. Similarity law on shedding frequency of cavitation cloud induced by a cavitating jet. J. Fluid Sci. Technol. 2012, 7, 405–420. [Google Scholar] [CrossRef][Green Version]

- Sato, K.; Taguchi, Y.; Hayashi, S. High speed observation of periodic cavity behavior in a convergent-divergent nozzle for cavitating water jet. J. Flow Control. Meas. Vis. 2013, 2013, 102–107. [Google Scholar] [CrossRef]

- Hutli, E.; Nedeljkovic, M.; Bonyár, A. Dynamic behaviour of cavitation clouds: Visualization and statistical analysis. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 281. [Google Scholar] [CrossRef]

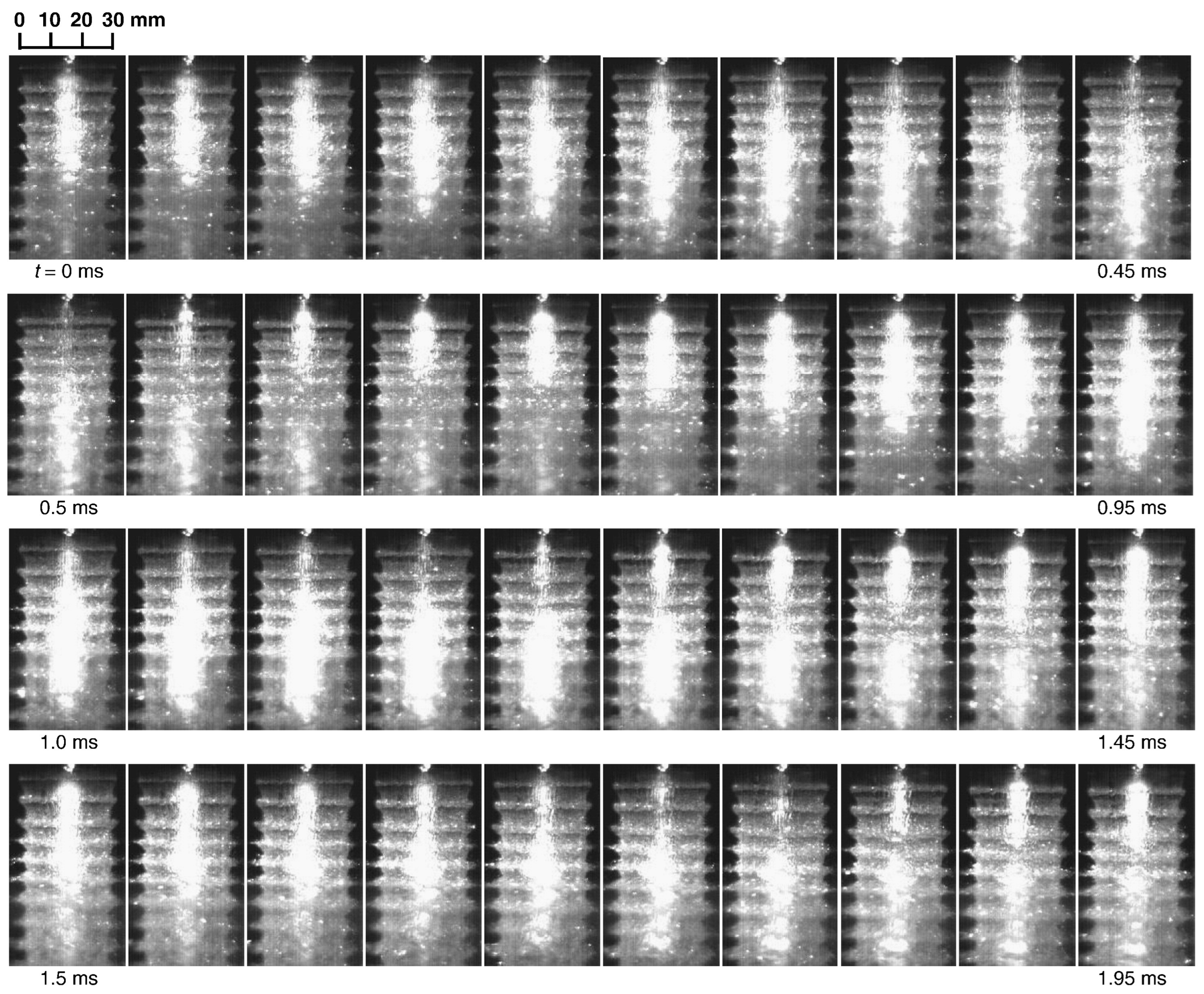

- Wu, Q.; Wei, W.; Deng, B.; Jiang, P.; Li, D.; Zhang, M.; Fang, Z. Dynamic characteristics of the cavitation clouds of submerged Helmholtz self-sustained oscillation jets from high-speed photography. J. Mech. Sci. Technol. 2019, 33, 621–630. [Google Scholar] [CrossRef]

- Liu, B.; Pan, Y.; Ma, F. Pulse pressure loading and erosion pattern of cavitating jet. Eng. Appl. Comput. Fluid Mech. 2020, 14, 136–150. [Google Scholar] [CrossRef]

- Hutli, E.; Nedeljkovic, M.S.; Radovic, N.A.; Bonyar, A. The relation between the high speed submerged cavitating jet behaviour and the cavitation erosion process. Int. J. Multiph. Flow 2016, 83, 27–38. [Google Scholar] [CrossRef]

- Soyama, H. Enhancing the aggressive intensity of a cavitating jet by introducing a cavitator and a guide pipe. J. Fluid Sci. Technol. 2014, 9, JFST0001. [Google Scholar] [CrossRef]

- Mishra, A.; Yadav, H.; Djenidi, L.; Agrawal, A. Effect of pulsation on the wall jet flow in the near region of an impinging jet. Exp. Fluids 2021, 62, 157. [Google Scholar] [CrossRef]

- Soyama, H. Cavitating jet: A review. Appl. Sci. 2020, 10, 7280. [Google Scholar] [CrossRef]

- Zhu, R.; Zhu, H.; Zhang, X. Numerical investigation about the unsteady behavior of a free submerged cavitation jet using the SBES approach. Ocean Eng. 2023, 281, 115010. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, G.; Huang, B. A cavitation model for computations of unsteady cavitating flows. Acta Mech. Sin. 2016, 32, 273–283. [Google Scholar] [CrossRef]

- Soyama, H.; Lichtarowicz, A.; Momma, T. Vortex cavitation in a submerged jet. Am. Soc. Mech. Eng. Fluids Eng. Div. (Publ.) FED 1996, 236, 415–422. [Google Scholar]

- Kang, C.; Zhou, L.; Yang, M.; Wang, Y. Experiment Study on Cavitating Waterjet Induced by a Central Body in the Nozzle. J. Eng. Thermophys. 2013, 34, 2275–2278. (In Chinese) [Google Scholar]

- Liu, L.; Deng, S.; Guan, J.; Li, G.; Yao, S.; Jiang, Y. Numerical Simulation and Structural Optimization of New Central Body Nozzle Flow Field. Nat. Gas Oil 2019, 37, 106–111. (In Chinese) [Google Scholar]

- Liao, Z. Theoretical study and application of self-oscillating pulsed jet nozzle. High Press. Water Jet 1993, 1, 1–14. [Google Scholar]

- Wang, Y.; Zhu, C.; Li, F.; Yu, C.; Chen, S.; Wu, J. Processing characteristics and loading principle on micro blanking of cavitation jet. Int. J. Adv. Manuf. Technol. 2024, 133, 1317–1329. [Google Scholar] [CrossRef]

- Takakuwa, O.; Soyama, H. Preventing hydrogen embrittlement in stainless steel by means of compressive stress induced by cavitation peening. J. Eng. 2015, 2015, 106–109. [Google Scholar] [CrossRef]

- Feng, R. Ultrasound Cavitation and Ultrasound Medicine. Nat. J. 2004, 25, 35–38. (In Chinese) [Google Scholar]

- Ramirez-Cadavid, D.A.; Kozyuk, O.; Lyle, P.; Michel, F.C., Jr. Effects of hydrodynamic cavitation on dry mill corn ethanol production. Process Biochem. 2016, 51, 500–508. [Google Scholar] [CrossRef]

- Brujan, E.A.; Nahen, K.; Schmidt, P.; Vogel, A. Dynamics of laser-induced cavitation bubbles near an elastic boundary. J. Fluid Mech. 2001, 433, 251–281. [Google Scholar] [CrossRef]

- Zhang, J. Research on the Effect of Nozzle Structure on Water Jet Velocity and Cavitation Capacity. Ph.D. Thesis, China University of Petroleum (East China), Dongying, China, 2019. (In Chinese). [Google Scholar]

- Deng, S.; Liao, S.; Yu, Y.; Guan, J. Study on Numerical Simulation of Cavitation Water Jet Induced by Abnormal Central-body. Fluid Mach. 2017, 45, 21–25. (In Chinese) [Google Scholar]

- Yang, M.; Xiao, S.; Kang, C. Influence of Outlet Profile on Performance of Central-body Nozzle. Fluid Mach. 2011, 39, 13–19. (In Chinese) [Google Scholar]

- Yang, M.; Xiao, S.; Kang, C.; Wang, Y. Effect of Geometrical Parameters on Submerged Cavitation Jet Discharged from Profiled Central-body Nozzle. Chin. J. Mech. Eng. 2013, 26, 476–482. (In Chinese) [Google Scholar] [CrossRef]

- Johnson, V.E., Jr.; Chahine, G.L.; Lindenmuth, W.T.; Conn, A.F.; Frederick, G.S.; Giacchino, G.J., Jr. The development of structured cavitating jets for deep-hole bits. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 26–29 September 1982; p. SPE–11060. [Google Scholar]

- Wang, Z.; Shen, Z. Mathematical model and experimental study of the jet excited oscillator. J. Pet. Univ. 1989, 13, 22–30. [Google Scholar]

- Peng, K.; Tian, S.; Li, G. Bubble dynamics characteristics and influencing factors on the cavitation collapse intensity for self-resonating cavitating jets. Pet. Explor. Dev. 2018, 45, 343–350. [Google Scholar] [CrossRef]

- Chahine, G.; Johnson, V. Mechanics and applications of self-excited cavitating jets. In Proceedings of the International Symposium on Jets and Cavities, ASME, WAM, Miami Beach, FL, USA, 17–22 November 1985; pp. 21–33. [Google Scholar]

- Qu, Y.; Chen, S. Orthogonal experimental research on the structural parameters of a self-excited pulsed cavitation nozzle. Eur. J. Mech.-B/Fluids 2017, 65, 179–183. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Wang, X.; Fang, Z. Effects of area discontinuity at nozzle inlet on the characteristics of high speed self-excited oscillation pulsed waterjets. Exp. Therm. Fluid Sci. 2016, 79, 254–265. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, B.; Liu, B.; Li, B. Investigation on the influence of the frequency of pulsed water jet on the rock-breaking effect. Powder Technol. 2024, 431, 119054. [Google Scholar] [CrossRef]

- Tomita, Y.; Sato, K. Pulsed jets driven by two interacting cavitation bubbles produced at different times. J. Fluid Mech. 2017, 819, 465–493. [Google Scholar] [CrossRef]

- Cai, T.; Pan, Y.; Ma, F.; Xu, P. Effects of organ-pipe chamber geometry on the frequency and erosion characteristics of the self-excited cavitating waterjet. Energies 2020, 13, 978. [Google Scholar] [CrossRef]

- Hlaváč, L.M. System of chambers for activation of modulation or pulsation in water jets. In Proceedings of the 2007 American WJTA Conference and Expo, Houston, TX, USA, 19–21 August 2007; pp. 19–21. [Google Scholar]

- Zuzana Šimonovská, M. Device to Create and Intensify Modulation of Liquid Flow Velocity. Patent 302595, 27 July 2011. [Google Scholar]

- Wang, X.; Li, Y.; Hu, Y.; Ding, X.; Xiang, M.; Li, D. An experimental study on the jet pressure performance of Organ–Helmholtz (OH), self-excited oscillating nozzles. Energies 2020, 13, 367. [Google Scholar] [CrossRef]

- Shi, D.; Xing, Y.; Wang, L.; Chen, Z. Numerical Simulation and Experimental Research of Cavitation Jets in Dual-Chamber Self-Excited Oscillating Pulsed Nozzles. Shock Vib. 2022, 2022, 1268288. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Guan, K.; Ma, T. Experimental study on the effect of multi frequency pulse of self-excited nozzle. J. Eng. Thermos-Phys. 2013, 34, 458–461. [Google Scholar]

- Pan, Y.; Cai, T.; Ma, F.; Qiu, L.; Cui, L. Self-excited Frequency Estimation Model of Organ-pipe Waterjet under Confining Pressure. J. Mech. Eng. 2018, 54, 220–225. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, X. Effect of pulse duration and pulse repetition frequency of cavitation histotripsy on erosion at the surface of soft material. Ultrasonics 2018, 84, 296–309. [Google Scholar] [CrossRef]

- Suo, D.; Govind, B.; Zhang, S.; Jing, Y. Numerical investigation of the inertial cavitation threshold under multi-frequency ultrasound. Ultrason. Sonochem. 2018, 41, 419–426. [Google Scholar] [CrossRef]

- Soyama, H. Effect of nozzle geometry on a standard cavitation erosion test using a cavitating jet. Wear 2013, 297, 895–902. [Google Scholar] [CrossRef]

- Zhang, S.; Fu, B.; Sun, L. Investigation of the jet characteristics and pulse mechanism of self-excited oscillating pulsed jet nozzle. Processes 2021, 9, 1423. [Google Scholar] [CrossRef]

- Xiang, L.; Wei, X.; Chen, S. Experimental study on the frequency characteristics of self-excited pulsed cavitation jet. Eur. J. Mech./B Fluids 2020, 83, 66–72. [Google Scholar] [CrossRef]

- Thaker, A.H.; Madane, K.R.; Ranade, V.V. Influence of viscosity and device scale on pressure drop and cavitation inception: Vortex based cavitation devices. Chem. Eng. J. 2023, 474, 145943. [Google Scholar] [CrossRef]

- Zeng, Q.; An, H.; Ohl, C.D. Wall shear stress from jetting cavitation bubbles: Influence of the stand-off distance and liquid viscosity. J. Fluid Mech. 2022, 932, A14. [Google Scholar] [CrossRef]

- Iwai, Y.; Li, S. Cavitation erosion in waters having different surface tensions. Wear 2003, 254, 1–9. [Google Scholar] [CrossRef]

- Krothapalli, A.; Venkatakrishnan, L.; Lourenco, L.; Greska, B.; Elavarasan, R. Turbulence and noise suppression of a high-speed jet by water injection. J. Fluid Mech. 2003, 491, 131–159. [Google Scholar] [CrossRef]

- Hu, H.; Zheng, Y.; Qin, C. Comparison of Inconel 625 and Inconel 600 in Resistance to Cavitation Erosion and Jet Impingement Erosion. Nucl. Eng. Des. 2010, 240, 2721–2730. [Google Scholar] [CrossRef]

- Pan, Y.; Ma, F. Cavitation intensity and erosion pattern of a self-excited cavitating jet. J. Mater. Process. Tech. 2020, 282, 116668. [Google Scholar] [CrossRef]

- O’hern, T. An experimental investigation of turbulent shear flow cavitation. J. Fluid Mech. 1990, 215, 365–391. [Google Scholar] [CrossRef]

- Katz, J.; O’Hern, T.J. Cavitation in Large Scale Shear Flows. J. Fluids Eng. 1986, 108, 373–376. [Google Scholar] [CrossRef]

- Iyer, C.O.; Ceccio, S.L. The influence of developed cavitation on the flow of a turbulent shear layer. Phys. Fluids 2002, 14, 3414–3431. [Google Scholar] [CrossRef]

- Yang, Y.; Li, W.; Shi, W.; Zhang, W.; El-Emam, M.A. Numerical investigation of a high-pressure submerged jet using a cavitation model considering effects of shear stress. Processes 2019, 7, 541. [Google Scholar] [CrossRef]

- Soyama, H.; Kikuchi, T.; Nishikawa, M. Introduction of compressive residual stress into stainless steel by employing a cavitating jet in air. Surf. Coatings Technol. 2011, 205, 3167–3174. [Google Scholar] [CrossRef]

- Fan, C.X.; Li, D.; Kang, Y.; Zhang, H.T. Effect of low-speed waterjet pressure on the rock-breaking performance of unsubmerged cavitating abrasive waterjet. Pet. Sci. 2024, 21, 2638–2649. [Google Scholar] [CrossRef]

- Liu, H.; Cao, Z.; Xie, C.; Chen, G.; Li, D.; Wang, J. Research on erosion characteristics of a novel cavitation nozzle under nonsubmerged condition. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 988–998. [Google Scholar] [CrossRef]

- Fujisawa, N.; Kikuchi, T.; Fujisawa, K.; Yamagata, T. Time-resolved observations of pit formation and cloud behavior in cavitating jet. Wear 2017, 386–387, 99–105. [Google Scholar] [CrossRef]

- Yang, Y.; Li, W.; Shi, W.; Zhou, L.; Zhang, W. Experimental study on the unsteady characteristics and the impact performance of a high-pressure submerged cavitation jet. Shock Vib. 2020, 2020, 1701843. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, Y.; Zhang, S. Structure optimization of submerged water jet cavitating nozzle with a hybrid algorithm. Eng. Appl. Comput. Fluid Mech. 2019, 13, 591–608. [Google Scholar] [CrossRef]

- Luo, Y.; Zang, J.; Zheng, H. Flow Field and Gas Field Distribution of Non-Submerged Cavitation Water Jet Based on Dual-Nozzle with Concentric Configuration. Water 2023, 15, 2904. [Google Scholar] [CrossRef]

- Xu, K.; Wang, G.; Wang, L.; Yun, F.; Sun, W.; Wang, X.; Chen, X. CFD-based study of nozzle section geometry effects on the performance of an annular multi-nozzle jet pump. Processes 2020, 8, 133. [Google Scholar] [CrossRef]

- Dong, W.; Yao, L.; Luo, W. Numerical simulation of flow field of submerged angular cavitation nozzle. Appl. Sci. 2023, 13, 613. [Google Scholar] [CrossRef]

- Marcon, A.; Melkote, S.N.; Yoda, M. Effect of nozzle size scaling in co-flow water cavitation jet peening. J. Manuf. Process. 2018, 31, 372–381. [Google Scholar] [CrossRef]

- Yamamoto, T.; Komarov, S.V. Dynamic behavior of acoustic cavitation bubble originated from heterogeneous nucleation. J. Appl. Phys. 2020, 128, 044702. [Google Scholar] [CrossRef]

- Lv, Z.; Hou, R.; Zhang, Y.; Chen, X. Investigation on the effect of cavitation in ultrasonic-assisted AWJ. Int. J. Adv. Manuf. Technol. 2020, 106, 3823–3830. [Google Scholar] [CrossRef]

- Lv, Z.; Hou, R.; Wang, T.; Huang, C.; Zhu, H. Research on cavitation involved in ultrasonic-assisted abrasive waterjet machining. Int. J. Adv. Manuf. Technol. 2019, 101, 1879–1886. [Google Scholar] [CrossRef]

- Sun, X.; Xuan, X.; Ji, L.; Chen, S.; Liu, J.; Zhao, S.; Park, S.; Yoon, J.Y.; Om, A.S. A novel continuous hydrodynamic cavitation technology for the inactivation of pathogens in milk. Ultrason. Sonochem. 2021, 71, 105382. [Google Scholar]

- Jain, P.; Bhandari, V.M.; Balapure, K.; Jena, J.; Ranade, V.V.; Killedar, D.J. Hydrodynamic cavitation using vortex diode: An efficient approach for elimination of pathogenic bacteria from water. J. Environ. Manag. 2019, 242, 210–219. [Google Scholar] [CrossRef]

- Yusof, N.S.M.; Babgi, B.; Alghamdi, Y.; Aksu, M.; Madhavan, J.; Ashokkumar, M. Physical and chemical effects of acoustic cavitation in selected ultrasonic cleaning applications. Ultrason. Sonochem. 2016, 29, 568–576. [Google Scholar] [CrossRef]

- Bai, F.; Wang, L.; Yang, K.; He, Z.; Liu, C.; Twiefel, J. A novel inner surface enhancement method for holes utilizing ultrasonic cavitation. Ultrasonics 2021, 115, 106453. [Google Scholar] [CrossRef]

- Soyama, H.; Iga, Y. Laser cavitation peening: A review. Appl. Sci. 2023, 13, 6702. [Google Scholar] [CrossRef]

- Akhatov, I.; Lindau, O.; Topolnikov, A.; Mettin, R.; Vakhitova, N.; Lauterborn, W. Collapse and rebound of a laser-induced cavitation bubble. Phys. Fluids 2001, 13, 2805–2819. [Google Scholar] [CrossRef]

- Gu, J.; Luo, C.; Lu, Z.; Ma, P.; Xu, X.; Ren, X. Bubble dynamic evolution, material strengthening and chemical effect induced by laser cavitation peening. Ultrason. Sonochem. 2021, 72, 105441. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Xie, X.; Zhang, Y.; Zhang, Y.; Du, X. Experimental study of influences of a particle on the collapsing dynamics of a laser-induced cavitation bubble near a solid wall. Exp. Therm. Fluid Sci. 2019, 105, 289–306. [Google Scholar] [CrossRef]

- Brujan, A.; Noda, T.; Ishigami, A.; Ogasawara, T.; Takahira, H. Dynamics of laser-induced cavitation bubbles near two perpendicular rigid walls. J. Fluid Mech. 2018, 841, 28–49. [Google Scholar] [CrossRef]

- Zhou, J.; Andersson, M. An analysis of surface breakup induced by laser generated cavitation bubbles in a turbulent liquid jet. Exp. Fluids 2020, 61, 242. [Google Scholar] [CrossRef]

- Benjamin, T.B.; Ellis, A.T. The collapse of cavitation bubbles and the pressures thereby produced against solid boundaries. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1966, 260, 221–240. [Google Scholar]

- van Wijngaarden, L. Mechanics of collapsing cavitation bubbles. Ultrason. Sonochem. 2016, 29, 524–527. [Google Scholar] [CrossRef]

- Soyama, H.; Kumagai, N.; Takakuwa, O.; Takeo, F. Suppression of Fatigue Crack Propagation of Duralumin by Cavitation Peening. J. Eng. 2015, 2014, 135–139. [Google Scholar] [CrossRef]

- Marcon, A.; Melkote, S.N.; Castle, J.; Sanders, D.G.; Yoda, M. Effect of jet velocity in co-flow water cavitation jet peening. Wear 2016, 360, 38–50. [Google Scholar] [CrossRef]

- Takakuwa, O.; Nakai, M.; Narita, K.; Niinomi, M.; Hasegawa, K.; Soyama, H. Enhancing the Durability of Spinal Implant Fixture Applications Made of Ti-6Al-4V ELI by Means of Cavitation Peening. Int. J. Fatigue 2016, 92, 360–367. [Google Scholar] [CrossRef]

- Latchoumi, T.; Balamurugan, K.; Dinesh, K.; Ezhilarasi, T. Particle swarm optimization approach for waterjet cavitation peening. Measurement 2019, 141, 184–189. [Google Scholar] [CrossRef]

- Soyama, H.; Takeo, F. Comparison between cavitation peening and shot peening for extending the fatigue life of a duralumin plate with a hole. J. Mater. Process. Technol. 2016, 227, 80–87. [Google Scholar] [CrossRef]

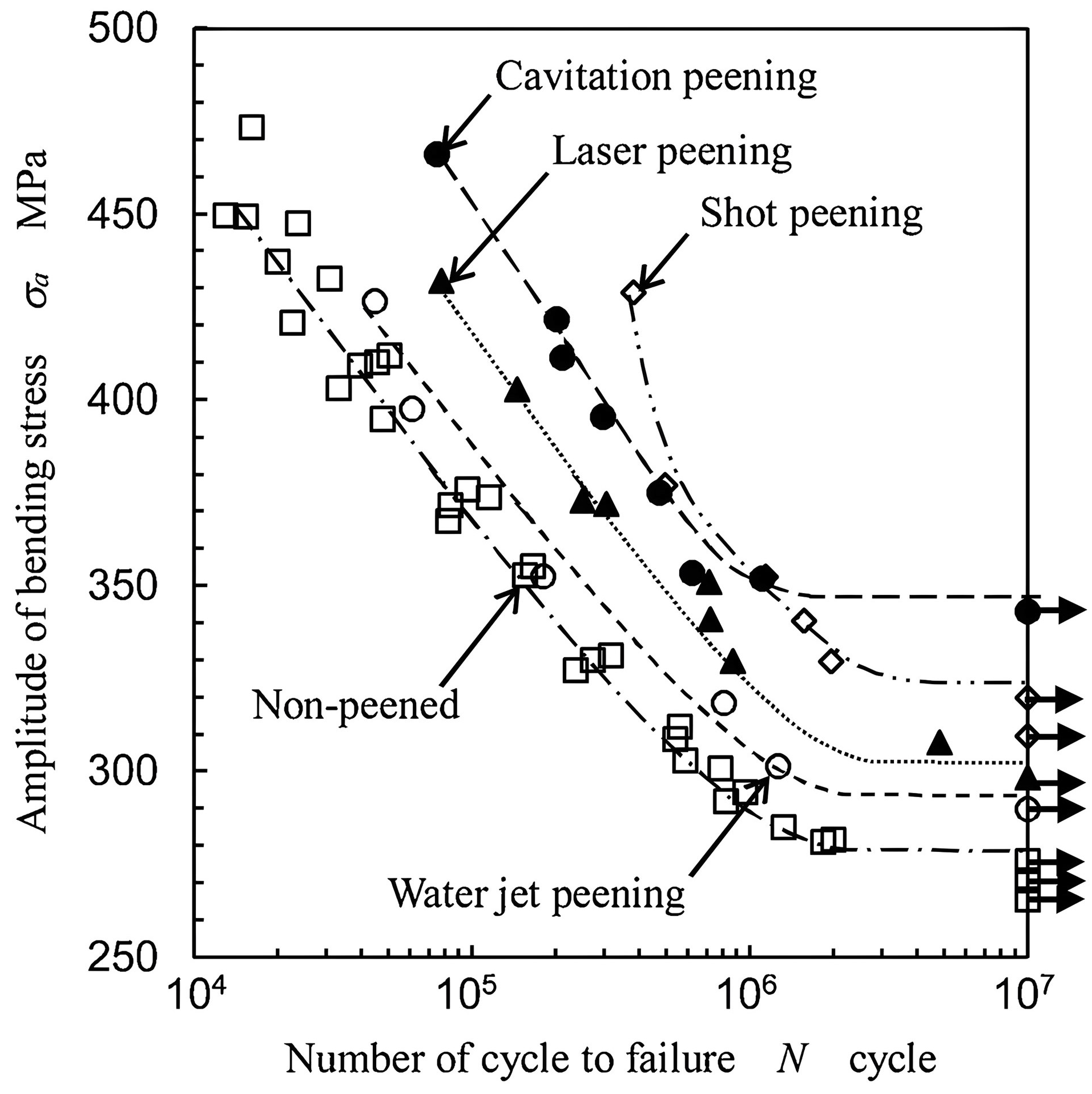

- Soyama, H. Comparison between Shot Peening, Cavitation Peening, and Laser Peening by Observation of Crack Initiation and Crack Growth in Stainless Steel. Met.-Open Access Metall. J. 2019, 10, 63. [Google Scholar] [CrossRef]

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Technol. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- Ijiri, M.; Yoshimura, T. Evolution of surface to interior microstructure of SCM435 steel after ultra-high-temperature and ultra-high-pressure cavitation processing. J. Mater. Process. Technol. 2018, 251, 160–167. [Google Scholar] [CrossRef]

- Chen, F.; Du, J.; Huang, S. Fabrication of repairable anti-corrosive superhydrophobic surfaces with micro-nano structures by ultrasonic cavitation. Appl. Surf. Sci. 2021, 541, 148605. [Google Scholar] [CrossRef]

- Ijiri, M.; Okada, N.; Kanetou, S.; Yamamoto, M.; Nakagawa, D.; Tanaka, K.; Yoshimura, T. Thermal Stress Relaxation and High-Temperature Corrosion of Cr-Mo Steel Processed Using Multifunction Cavitation. Materials 2018, 11, 2291. [Google Scholar] [CrossRef]

- Ijiri, M.; Ogi, T.; Yoshimura, T. High-temperature corrosion behavior of high-temperature and high-pressure cavitation processed Cr–Mo steel surface. Heliyon 2020, 6, e04698. [Google Scholar] [CrossRef]

- Gu, J.; Luo, C.; Ma, P.; Xu, X.; Wu, Y.; Ren, X. Study on processing and strengthening mechanisms of mild steel subjected to laser cavitation peening. Appl. Surf. Sci. 2021, 562, 150242. [Google Scholar] [CrossRef]

- Ijiri, M.; Yoshimura, T. Improvement of corrosion resistance of low-alloy steels by resurfacing using multifunction cavitation in water. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 307, p. 012040. [Google Scholar]

- Bai, F.; Wang, L.; Saalbach, K.; Twiefel, J. A novel ultrasonic cavitation peening approach assisted by water jet. Appl. Sci. 2018, 8, 2218. [Google Scholar] [CrossRef]

- Beaucamp, A.; Katsuura, T.; Takata, K. Process mechanism in ultrasonic cavitation assisted fluid jet polishing. CIRP Ann. 2018, 67, 361–364. [Google Scholar] [CrossRef]

- Ge, J.; Ren, Y.; Xu, X.; Li, C.; Li, Z.; Xiang, W. Numerical and experimental study on the ultrasonic-assisted soft abrasive flow polishing characteristics. Int. J. Adv. Manuf. Technol. 2021, 112, 3215–3233. [Google Scholar] [CrossRef]

- Chen, F.; Wang, H.; Yin, S.; Huang, S.; Tang, Q.; Luo, H. Cavitation water-suction polishing of metallic materials under negative-pressure effect. J. Mater. Process. Technol. 2019, 273, 116257. [Google Scholar] [CrossRef]

- Chen, F.; Wang, H.; Tang, Y.; Yin, S.; Huang, S.; Zhang, G. Novel Cavitation Fluid Jet Polishing Process Based on Negative Pressure Effects. Ultrason. Sonochem. 2018, 42, 339–346. [Google Scholar] [CrossRef] [PubMed]

- Ge, M.; Ji, S.; Tan, D.; Cao, H. Erosion analysis and experimental research of gas-liquid–solid soft abrasive flow polishing based on cavitation effects. Int. J. Adv. Manuf. Technol. 2021, 114, 3419–3436. [Google Scholar] [CrossRef]

- Beaucamp, A.; Katsuura, T.; Kawara, Z. A novel ultrasonic cavitation assisted fluid jet polishing system. Cirp Ann. 2017, 66, 301–304. [Google Scholar] [CrossRef]

- Hutli, E.; Nedeljkovic, M.; Bonyar, A. Controlled Modification of the Surface Morphology and Roughness of Stainless Steel 316 by a High Speed Submerged Cavitating Water Jet. Appl. Surf. Sci. 2018, 458, 293–304. [Google Scholar] [CrossRef]

- Lu, Z.; Gu, J.; Zhang, P. Investigation on laser cavitation micro-forming process: Deformation behavior of 1060 aluminum foil and bubble evolution in a gap. J. Manuf. Process. 2021, 67, 619–627. [Google Scholar] [CrossRef]

- Li, F.; Fan, H.; Guo, Y.; Chen, Z.; Wang, X.; Li, R.; Liu, H.; Wang, Y. Water-Jet cavitation shock bulging as novel microforming technique. Chin. J. Mech. Eng. 2021, 34, 4. [Google Scholar] [CrossRef]

- Li, F.; He, P.; Chen, Z.; Chen, S.; Guo, J.; Xue, S.; Guo, Y.; Wang, Y. Water-jet cavitation shocking as a novel array micro-forming technique. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 987–994. [Google Scholar] [CrossRef]

- Whipple, K.X.; Hancock, G.S.; Anderson, R.S. River incision into bedrock: Mechanics and relative efficacy of plucking, abrasion, and cavitation. Geol. Soc. Am. Bull. 2000, 112, 490–503. [Google Scholar] [CrossRef]

- Jurewicz, E.; Gireń, B.; Steller, J. Cavitation erosion–a possible cause of the mass loss within thrust zones in the Tatra Mts., Poland. Acta Geol. Pol. 2007, 57, 305–323. [Google Scholar]

- Lopez-Sanchez, M.A.; Llana-Fúnez, S. A cavitation-seal mechanism for ultramylonite formation in quartzofeldspathic rocks within the semi-brittle field (Vivero fault, NW Spain). Tectonophysics 2018, 745, 132–153. [Google Scholar] [CrossRef]

- Patehebieke, Y.; Zhao, Z.R.; Wang, S.; Xu, H.X.; Chen, Q.Q.; Wang, X. Cavitation as a plausible driving force for the prebiotic formation of N9 purine nucleosides. Cell Rep. Phys. Sci. 2021, 2, 100375. [Google Scholar] [CrossRef]

- Su, H.; Zhou, W. Mechanism of accelerated dissolution of mineral crystals by cavitation erosion. Acta Geochim. 2020, 39, 11–42. [Google Scholar] [CrossRef]

- Carling, P.A.; Perillo, M.; Best, J.; Garcia, M.H. The bubble bursts for cavitation in natural rivers: Laboratory experiments reveal minor role in bedrock erosion. Earth Surf. Process. Landforms 2017, 42, 1308–1316. [Google Scholar] [CrossRef]

- Chi, P.; Chaoyue, Z.; Qinfeng, L.; Shilong, Z.; Yu, S.; Hairui, L.; Jianhong, F. Erosion characteristics and failure mechanism of reservoir rocks under the synergistic effect of ultrasonic cavitation and micro-abrasives. Adv. Powder Technol. 2021, 32, 4391–4407. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, Z.; Xiong, T.; Hou, W.; Zhang, Z.; Shi, R. An experimental study on the erosion of sandstone by self-excited oscillation cavitation waterjet in submerged environment. Ocean Eng. 2023, 279, 114546. [Google Scholar] [CrossRef]

- Apte, D.; Ge, M.; Coutier-Delgosha, O. Numerical investigation of a cavitating nozzle for jetting and rock erosion based on different turbulence models. Geoenergy Sci. Eng. 2023, 231, 212300. [Google Scholar] [CrossRef]

- Guo, C.; Lin, B.; Yao, H.; Yang, K.; Zhu, C. Characteristics of breaking coal-rock by submerged jet and its application on enhanced coal bed methane recovery. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 42, 2249–2260. [Google Scholar] [CrossRef]

- Jasper, S.; Gradzki, D.; Bracke, R.; Hussong, J.; Petermann, M.; Lindken, R. Nozzle Cavitation and Rock Erosion Experiments Reveal Insight into the Jet Drilling Process. Chem. Ing. Tech. 2021, 93, 1610–1618. [Google Scholar] [CrossRef]

- Fan, C.; Zhang, H.; Kang, Y.; Shi, H.; Li, D. Rock breaking performance of the newly proposed unsubmerged cavitating abrasive waterjet. Int. J. Min. Sci. Technol. 2023, 33, 843–853. [Google Scholar] [CrossRef]

- Liang, Z.; Ma, Y.; Nie, Q.; Wang, X.; Zhou, T.; Guo, H.; Sun, X.; Jiang, L. Ultrasonic cavitation and vibration hybrid-assisted micro-drilling of stainless steel. Int. J. Adv. Manuf. Technol. 2019, 104, 3073–3082. [Google Scholar] [CrossRef]

- Tinne, N.; Schumacher, S.; Nuzzo, V.; Ripken, T.; Lubatschowski, H. Dynamic and interaction of fs-laser induced cavitation bubbles for analyzing the cutting effect. In Proceedings of the European Conference on Biomedical Optics, Munich, Germany, 14–18 June 2009; Optica Publishing Group: Washington, DC, USA, 2009; p. 7373_0L. [Google Scholar]

- Arba-Mosquera, S.; Naubereit, P.; Sobutas, S.; Verma, S. Analytical optimization of the cutting efficiency for generic cavitation bubbles. Biomed. Opt. Express 2021, 12, 3819–3835. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Cai, J.; Kang, Y.; Wang, X.; Lai, Q.; Li, D. Generation of effective pulsed waterjets by ultrasonic nozzle used for energy exploration. Energy 2024, 294, 130868. [Google Scholar] [CrossRef]

- Al-Jubori, A.; Johnston, S.; Boyer, C.; Lambert, S.; Bustos, O.; Pashin, J.; Wray, A. Coalbed methane: Clean energy for the world. Oilfield Rev. 2009, 21, 4–13. [Google Scholar]

- Ji, X.; Song, D.; Zhao, H.; Li, Y.; He, K. Experimental analysis of pore and permeability characteristics of coal by low-field NMR. Appl. Sci. 2018, 8, 1374. [Google Scholar] [CrossRef]

- Wang, H.; Xia, B.; Lu, Y.; Ge, Z.; Tang, J. Experimental study on sonic vibrating effects of cavitation water jets and its promotion effects on coalbed methane desorption. Fuel 2016, 185, 468–477. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, Y.; Liu, Q.; Yuan, L.; Dong, J.; Wang, L.; Qi, Y.; Wang, W. A novel in-seam borehole hydraulic flushing gas extraction technology in the heading face: Enhanced permeability mechanism, gas flow characteristics, and application. J. Nat. Gas Sci. Eng. 2017, 46, 498–514. [Google Scholar] [CrossRef]

- Zou, Q.; Lin, B. Fluid–solid coupling characteristics of gas-bearing coal subject to hydraulic slotting: An experimental investigation. Energy Fuels 2018, 32, 1047–1060. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, K.; Wu, X.; Tian, S.; Shi, H.; Wang, W.; Zhang, P. An innovative experimental apparatus for the analysis of natural gas hydrate erosion process using cavitating jet. Rev. Sci. Instrum. 2020, 91, 095107. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Zhang, Y.; Wu, X.; Hui, C.; Tan, Y.; Li, G. Study on the Decomposition of Natural Gas Hydrate Induced by Cavitation Damage. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Atlanta, GA, USA, 25–28 June 2023; p. ARMA-2023-0366. [Google Scholar]

- Wu, X.Y.; Zhang, Y.Q.; Xu, Z.Q.; Zhao, S.; Li, G.S.; Tian, S.C.; Tan, Y.W.; Peng, K.W. Structure optimization of the organ-pipe cavitating nozzle and its erosion ability test on hydrate-bearing sediments. Pet. Sci. 2023, 20, 1104–1118. [Google Scholar] [CrossRef]

- Song, X.; Li, G.; Yuan, J.; Tian, Z.; Shen, R.; Yuan, G.; Huang, Z. Mechanisms and field test of solution mining by self-resonating cavitating water jets. Pet. Sci. 2010, 7, 385–389. [Google Scholar] [CrossRef]

- Vijay, M. Comparison of the performance of high-speed abrasive-entrained, cavitating and plain water jets for selective mining applications. Int. J. Surf. Mining Reclam. Environ. 1992, 6, 1–9. [Google Scholar] [CrossRef]

- Fang, Z.; Gao, X.; Tao, X.; Li, D.; Zhang, M.; Xiong, T.; Jiang, P. Impact performance of Helmholtz self-excited oscillation waterjets used for underground mining. Appl. Sci. 2019, 9, 3235. [Google Scholar] [CrossRef]

- Prosperetti, A. Bubbles. Phys. Fluids 2004, 16, 1852. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, H.; Fang, Z.; Li, D.; Wang, B. Experimental study and prediction model of the cleaning effect induced by self-resonating cavitating waterjet. J. Mech. Sci. Technol. 2022, 36, 5097–5106. [Google Scholar] [CrossRef]

- Liu, C.; Liu, G.; Yan, Z. Study on Cleaning Effect of Different Water Flows on the Pulsed Cavitating Jet Nozzle. Shock Vib. 2019, 2019, 1496594. [Google Scholar] [CrossRef]

- Song, W. Laser-induced cavitation bubbles for cleaning of solid surfaces. J. Appl. Phys. 2004, 95, 2952–2956. [Google Scholar] [CrossRef]

- Ohl, C.; Arora, M.; Dijkink, R.; Janve, V.; Lohse, D. Surface cleaning from laser-induced cavitation bubbles. Appl. Phys. Lett. 2006, 89, 074102. [Google Scholar] [CrossRef]

- Ralys, A.; Mokin, V. Numerical Simulation of a Cavitating Pulsating Water Jet Used for Removing Contaminants from Metal Surfaces. Trans. FAMENA 2020, 43, 69–80. [Google Scholar] [CrossRef]

- Verhaagen, B.; Rivas, D.F. Measuring cavitation and its cleaning effect. Ultrason. Sonochem. 2016, 29, 619–628. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Cui, W. Review of Underwater Ship Hull Cleaning Technologies. J. Mar. Sci. Appl. 2020, 19, 415–429. [Google Scholar] [CrossRef]

- Vickers, G.; Houlston, R. Modelling the erosion efficiency of cavitation cleaning jets. Appl. Sci. Res. 1983, 40, 377–391. [Google Scholar] [CrossRef]

- Yamada, J.; Takiguchi, T.; Saito, A.; Odanaka, H.; Soyama, H.; Yamamoto, M. Removal of Oral Biofilm on an Implant Fixture by a Cavitating Jet. Implant Dent. 2017, 26, 904. [Google Scholar] [CrossRef]

- Bixler, G.D.; Bhushan, B. Biofouling: Lessons from nature. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2012, 370, 2381–2417. [Google Scholar] [CrossRef]

- Kwon, G.S.; Kataoka, K. Block copolymer micelles as long-circulating drug vehicles. Adv. Drug Deliv. Rev. 1995, 16, 295–309. [Google Scholar] [CrossRef]

- Franc, J.P.; Michel, J.M. Fundamentals of Cavitation; Springer Science & Business Media: Dordrecht, The Netherlands, 2006; Volume 76. [Google Scholar]

- Doulah, M. Mechanism of disintegration of biological cells in ultrasonic cavitation. Biotechnol. Bioeng. 1977, 19, 649–660. [Google Scholar] [CrossRef]

- Storey, B.D.; Szeri, A.J. Water vapour, sonoluminescence and sonochemistry. Proc. R. Soc. London. Ser. A Math. Phys. Eng. Sci. 2000, 456, 1685–1709. [Google Scholar] [CrossRef]

- Wang, X.; Yao, Z.; Wang, J.; Guo, W.; Li, G. Degradation of reactive brilliant red in aqueous solution by ultrasonic cavitation. Ultrason. Sonochem. 2008, 15, 43–48. [Google Scholar] [CrossRef]

- Sivakumar, M.; Senthilkumar, P.; Majumdar, S.; Pandit, A.B. Ultrasound mediated alkaline hydrolysis of methyl benzoate—Reinvestigation with crucial parameters. Ultrason. Sonochem. 2002, 9, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Mishra, K.P.; Gogate, P.R. Intensification of degradation of Rhodamine B using hydrodynamic cavitation in the presence of additives. Sep. Purif. Technol. 2010, 75, 385–391. [Google Scholar] [CrossRef]

- Wang, J.; Cao, Y.; Sun, B.; Wang, C.; Mo, Y. Effect of ultrasound on the activity of alliinase from fresh garlic. Ultrason. Sonochem. 2011, 18, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wu, Y.; Huang, W.; Yang, F. Degradation of chitosan by hydrodynamic cavitation. Polym. Degrad. Stab. 2013, 98, 37–43. [Google Scholar] [CrossRef]

- Zezulka, S.; Marsalkova, E.; Pochylý, F.; Rudolf, P.; Hudec, M.; Maršálek, B. High-pressure jet-induced hydrodynamic cavitation as a pre-treatment step for avoiding cyanobacterial contamination during water purification. J. Environ. Manag. 2020, 255, 109862. [Google Scholar] [CrossRef]

- Tao, Y.; Cai, J.; Huai, X.; Liu, B. A novel antibiotic wastewater degradation technique combining cavitating jets impingement with multiple synergetic methods. Ultrason. Sonochem. 2018, 44, 36–44. [Google Scholar] [CrossRef]

- Badmus, K.O.; Irakoze, N.; Adeniyi, O.R.; Petrik, L. Synergistic Advance Fenton Oxidation and Hydrodynamic Cavitation treatment of persistent organic dyes in textile wastewater. J. Environ. Chem. Eng. 2019, 8, 103521. [Google Scholar] [CrossRef]

- Mancuso, G.; Langone, M.; Andreottola, G. A swirling jet-induced cavitation to increase activated sludge solubilisation and aerobic sludge biodegradability. Ultrason. Sonochem. 2017, 35, 489–501. [Google Scholar] [CrossRef]

- Ferrentino, R.; Andreottola, G. Investigation of sludge solubilization and phosphorous release in anaerobic side-stream reactor with a low pressure swirling jet hydrodynamic cavitation treatment. J. Environ. Chem. Eng. 2020, 8, 104389. [Google Scholar] [CrossRef]

- Patil, P.N.; Gogate, P.R.; Csoka, L.; Dregelyi-Kiss, A.; Horvath, M. Intensification of biogas production using pretreatment based on hydrodynamic cavitation. Ultrason. Sonochem. 2016, 30, 79–86. [Google Scholar] [CrossRef]

- He, M.; Wu, C.; Li, L.; Zheng, L.; Tian, T.; Jiang, L.; Li, Y.; Teng, F. Effects of Cavitation Jet Treatment on the Structure and Emulsification Properties of Oxidized Soy Protein Isolate. Foods 2021, 10, 2. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; He, M.; Zheng, L.; Tian, T.; Teng, F.; Li, Y. Effect of cavitation jets on the physicochemical properties and structural characteristics of the okara protein. J. Food Sci. 2021, 86, 4566–4576. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Teng, F.; McClements, D.J.; Zhang, S.; Li, Y.; Wang, Z. Effect of cavitation jet processing on the physicochemical properties and structural characteristics of okara dietary fiber. Food Res. Int. 2020, 134, 109251. [Google Scholar] [CrossRef] [PubMed]

| Cavitation Method | Features | Applications |

|---|---|---|

| Central Body Cavitation [44,45] |

|

|

| Oscillatory Cavitation [46,47] |

|

|

| Shear Cavitation [48] |

|

|

| Ultrasonic Cavitation [49,50] |

|

|

| Laser Induced Cavitation [51] |

|

|

| Nozzle Design | Cavitation Intensity | Jet Velocity | Stability |

|---|---|---|---|

| Flat-Headed | High | Moderate | Low |

| Conical | Moderate | High | High |

| Hemispherical | Low | Moderate | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Fan, C.; Wang, L.; Lu, W.; Li, D. The Generation Methods and Applications of Cavitating Jet by Using Bubble Collapse Energy. Energies 2024, 17, 5902. https://doi.org/10.3390/en17235902

Zhang H, Fan C, Wang L, Lu W, Li D. The Generation Methods and Applications of Cavitating Jet by Using Bubble Collapse Energy. Energies. 2024; 17(23):5902. https://doi.org/10.3390/en17235902

Chicago/Turabian StyleZhang, Haida, Chenxing Fan, Luyao Wang, Wenjun Lu, and Deng Li. 2024. "The Generation Methods and Applications of Cavitating Jet by Using Bubble Collapse Energy" Energies 17, no. 23: 5902. https://doi.org/10.3390/en17235902

APA StyleZhang, H., Fan, C., Wang, L., Lu, W., & Li, D. (2024). The Generation Methods and Applications of Cavitating Jet by Using Bubble Collapse Energy. Energies, 17(23), 5902. https://doi.org/10.3390/en17235902