Abstract

In the context of the growing share of renewable energy and the impending decommission of a large number of coal-fired units, nuclear energy is the only green energy that can replace coal power for a stable, clean, efficient, and large-scale power supply. This article compares the differences between coal power and nuclear power in terms of thermal system, thermal cycle, turbine parameters, and safety. It discusses the possibility of replacing the boiler of a coal power plant with nuclear power, that is, replacing the boiler of a coal power plant with a nuclear reactor for generation/heating/cogeneration. For coal-fired units with similar capacity that do not use a reheat cycle (at or below high pressure) and nuclear power units (such as a high-temperature gas-cooled reactor), as well as coal-fired units with a reheat cycle (ultra-high pressure and above) and nuclear power units (such as pressurized water reactors), there are great differences in steam parameters. In terms of steam turbines, the size of nuclear power units is relatively larger, requiring additional dehumidification measures. In addition, the safety factors and management methods considered in the site selection, construction, and operation of nuclear power plants are more stringent and complex, and comprehensive analysis and evaluation are needed in aspects such as waste treatment and accident emergency response. Except for the relevant provisions of the American Society of Mechanical Engineers code for pressure vessels, nuclear power units are not compatible with coal-fired units in terms of safety standards. Therefore, considering comprehensively, it is believed that the scheme of nuclear power replacing coal-fired units for power generation/heating/cogeneration program is not feasible at present.

1. Introduction

Coal accounts for the largest share of China’s energy structure, about 61% [1], and coal-fired power generation will remain the front-runner in power supply for a certain period in the future. By the end of 2023, China’s installed capacity of coal power is about 1.17 billion kW, accounting for about 40% of the country’s total installed power capacity [2]. However, most coal-fired units operate at loads between 65% and 75% for a long time [3], and the operation efficiency of high-capacity coal-fired units will decline during deep peak regulation. For example, the coal loss rate of a coal-fired power unit of 1100 MW at 60% load is about 25 kg/h higher than that at full load [4]. Incomplete combustion of fuel at low load will cause significant changes in parameters such as carbon monoxide, carbon dioxide, sulfur dioxide, nitrogen oxides, etc., resulting in a sharp rise in carbon emissions. The carbon emissions of coal-fired units account for about 40% of the total carbon emissions in the country [5], which has a great deal of negative impact on environmental protection.

The Chinese government has carried out a lot of exploration in the low-carbon transformation of coal power to promote the realization of low-carbon transformation and carbon neutrality [6,7,8,9]. In the context of continuous innovation on the supply side of electric power energy, the rapid rise of new energy sources, the continuous emergence of new models and new forms such as multi-energy complementarity, and considering the shortage of fossil energy sources, new energy sources such as solar energy and wind power cannot continuously ensure a stable power generation volume, being characterized by volatility and discontinuity. Although water energy is a good regulating energy in the whole power grid, its resources are limited and affected by seasons [10,11]. Nuclear power generation, with its low carbon emissions and stability superior to coal power generation, is the only alternative to thermal power generation in the future, and provides a stable, clean, economic and effective mode of large-scale power supply, which is a stable, reliable, safe and efficient green energy, and plays an important role in building a modern energy system and promoting the energy revolution [12,13,14].

China is the second largest nuclear power country in the world, with 56 nuclear power units in commercial operation, with a total installed capacity of 58.22 million kW. In 2023, the power generation of China’s nuclear power units was 433.4 billion kWh, accounting for 4.86% of the country’s power generation capacity with an annual equivalent emission reduction of about 340 million tons of carbon dioxide [15,16,17,18]. It is expected that by 2035, the share of nuclear power generation in China’s electricity mix will reach about 10% [19], which is comparable to the current global average, with a corresponding reduction of about 900 million tons of carbon dioxide. By 2060, the share of nuclear power generation will reach about 18%, which is comparable to the current average level of the OECD (Organization for Economic Co-operation and Development) countries [20,21]. Therefore, in the long run, the development of nuclear power is an inevitable choice; China has formulated a national strategy to revitalize and expand the nuclear energy industry, and has taken many measures to actively promote the development of nuclear energy. According to the overall deployment of China’s energy structure adjustment in the “13th Five-Year Plan”, the construction of nuclear power units will steadily increase, and a large number of coal-fired units will be suspended or postponed. The proportion of clean energy will be greatly increased, and a number of personnel in the electric power construction industry will inevitably be transferred from coal power construction to nuclear power engineering and construction.

If nuclear power can be used to replace part of the “major part” of carbon emissions, it will solve the problem of high carbon emissions in the coal power industry, promote green development and build a beautiful China. Therefore, some scholars have proposed to use nuclear reactors to replace boilers of coal power plants that are about to be decommissioned [22,23,24], that is, to use “non-smoking boilers” for power generation/heating/cogeneration. Building nuclear reactors in coal-fired power plants while providing an available site for nuclear power development also helps to reduce the cost of nuclear power, promote the development of nuclear power and reduce carbon emissions. At the same time, it can also reduce the negative social and economic impacts of the closure of coal-fired power plants, and promote the transformation from traditional fossil energy power generation to low-carbon electricity. However, its specific feasibility is highly controversial, and scholars and engineers have different opinions on safety, technical feasibility, and other aspects [25,26,27,28,29,30]. Coal-fired units with steam parameters at or below high pressure do not use a reheat cycle, while for coal-fired units at ultra-high pressure and above, a reheat cycle is adopted to improve steam dryness and cycle thermal efficiency. In the pressurized water reactor in a nuclear power plant, a steam–water separation reheat device is used between the high- and low-pressure cylinders. The high-temperature gas-cooled reactor ensures the safety of the steam turbine by increasing the initial temperature of steam and does not use a reheat cycle. However, no matter whether the high-temperature gas-cooled reactor without reheat cycle or the pressurized water reactor with a reheat cycle, there are significant differences in steam parameters compared to coal-fired units of similar capacity. When one makes nuclear energy substitutions, the steam temperature meets the requirement, but the steam pressure parameter differs significantly. This article focuses on the key factors of the feasibility of coal-fired boilers in China substitution with nuclear reactors, including the matching of thermal systems, steam parameters, and relevant safety standards of nuclear power plants and coal power plants to conduct a literature review of the existing relevant studies. Taking a typical pressurized water reactor (PWR) NHR200-II and high-temperature gas-cooled reactor (HTGR) HTR-PM as examples, this article summarizes and analyzes the feasibility of nuclear energy substitution from the aspects of thermal system, steam parameters, equipment difference and safety matching in order to provide valuable reference for future research and engineering practice.

2. Comparison of Thermal Systems

2.1. Thermal System of Coal-Fired Units

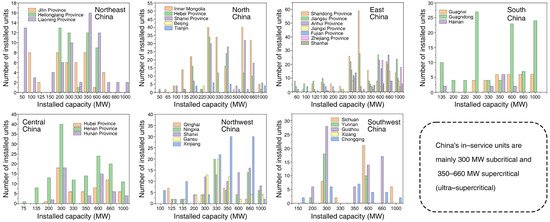

Coal-fired units occupy an important position in modern energy supply and are the “ballast stone” of the power system. This article investigates the parameter distribution of existing coal-fired units in different regions of China by the end of 2022 [31,32,33,34], and the results are shown in Figure 1. Among them, in the northeast region, due to the heating demand, the units are mainly 200 MW (ultra-high pressure)–300 MW (subcritical) cogeneration units and 350–600 MW supercritical generating units. The units in north China are mainly concentrated in 300 MW sub-critical units, 350–600 MW supercritical units and 660 MW ultra-supercritical units. The units in east China are mainly concentrated in 300 MW sub-critical units and 600–1000 MW supercritical (ultra-supercritical) critical units. The units in south China are mainly concentrated in 350–600 MW supercritical (ultra-supercritical) units. The units in central China are mainly concentrated in 300 MW subcritical units and 600–660 MW supercritical (ultra-supercritical) units. The units in northwest China are mainly concentrated in sub-critical units of 300 MW and supercritical (ultra-supercritical) units of 350–660 MW. The units in southwest China are mainly concentrated in 300 MW subcritical units and 600 MW supercritical units. In general, China’s in-service units are mainly 300 MW subcritical and 350–660 MW supercritical units. According to the classification of thermal systems, it can be divided into high-pressure units without a reheat cycle, and ultra-high pressure and above parameters units with a reheat cycle.

Figure 1.

Technical parameters and regional distribution of existing coal-fired units in China (2022) [31,32,33,34].

2.1.1. Coal-Fired Units with Steam Parameters of High Pressure and Below

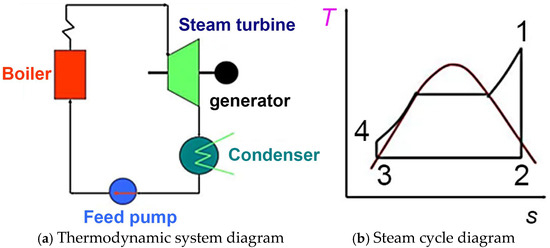

Figure 2 is a schematic diagram of the thermodynamic cycle of a high-pressure unit. It can be seen that the water is compressed and pressurized by the feed pump, it is heated into superheated steam in the boiler, and then it enters the steam turbine to expand and do work. After the work, the low-pressure steam enters the condenser to be cooled and condensed into water, and then returns to the pump to complete a cycle. As can be seen in Table 1, for high-pressure units, the saturation pressure of water is relatively low, so the finished exhaust gas still has a high dryness, which can make the turbine operate safely. Therefore, the a reheat cycle is not used for units below 50 MW class [35,36].

Figure 2.

Schematic diagram of the thermodynamic cycle of a high-pressure coal-fired power generator unit.

Table 1.

Steam parameters of high-pressure unit.

2.1.2. Coal-Fired Units with Ultra-High Pressure and Above Steam Parameters

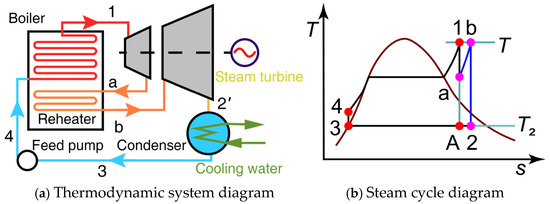

According to Rankine cycle law, increasing steam initial parameters of steam can improve the cycle thermal efficiency. Figure 3 is a schematic diagram of the thermodynamic cycle of the coal-fired units with ultra-high pressure and above steam parameters. Due to the constraints of the material technology development at that time, it was difficult to improve the steam parameters, so the method of increasing to ultra-high pressure was adopted to improve the cycle thermal efficiency. The higher pressure reduces the dryness of the steam and increases the wet steam content, and the steam needs to be reheated to ensure the safety of the turbine and avoid the occurrence of water corrosion. Therefore, for units above the ultra-high-pressure level, that is, units above the 135 MW level, in order to improve the steam dryness at the last stage of the steam turbine and the thermal efficiency of the unit, the reheat cycle is adopted [37,38]. At the same time, by properly designing steam parameters, the thermal efficiency of the unit is also improved.

Figure 3.

Schematic diagram of the thermodynamic cycle of coal-fired power generator unit with ultra-high pressure and above steam parameters.

The main coal-fired units in service in China are 300 MW subcritical and 350–660 MW supercritical (ultra-supercritical). Table 2 summarizes the steam parameters of different ultra-high pressure and above units. The main steam pressure of the supercritical boiler is 25 MPa, the temperature is 560 °C, and the steam enters the high-pressure cylinder of the turbine through the main steam valve and regulating valve. The steam entering the high-pressure cylinder passes through the double-flow controlling stage, flows to the regulating end through the impulse pressure stage, and is discharged into the reheater by the high-pressure steam exhaust port after doing work. After reheating, the steam t, with a pressure of 4.75 MPa and a temperature of 560 °C, returns to the medium-pressure cylinder of the double shunt of the turbine. After the work is done through the impulse medium pressure stage, the steam flows into the two double-flow low-pressure cylinders through the medium–low-pressure connecting pipe. After passing through the impulse low-pressure stage, the steam is discharged down to the condenser.

Table 2.

Steam parameters of ultra-high-pressure and above grade coal-fired units.

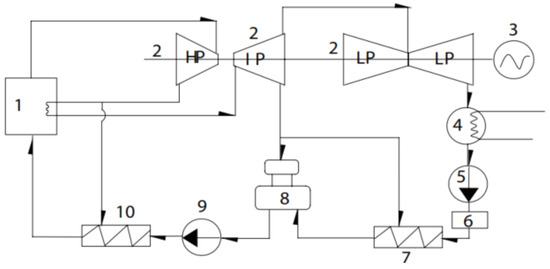

After being cooled by the circulating water, it is pressurized by the condensate pump and then passes through the low-pressure heater, deaerator, and high-pressure heater. There are a total of 8 stages in the entire feed water regenerative system. The system diagram is shown in Figure 4.

Figure 4.

Thermodynamic system diagram of a typical coal power plant (1. boiler; 2. steam turbine; 3. generator; 4. condenser; 5. condensate pump; 6. purifier; 7. low-pressure heater; 8. deaerator; 9. feed pump; 10. high-pressure heater).

2.2. Thermal System of Nuclear Power Units

There are about 440 nuclear power units in operation worldwide, of which about 70% are pressurized water reactors (PWR) [39], and the vast majority of nuclear power plants in operation in China are PWR types. High-temperature gas-cooled reactor (HTGR) is the latest generation of nuclear reactors. Two typical thermal systems of nuclear power plants are investigated in this article.

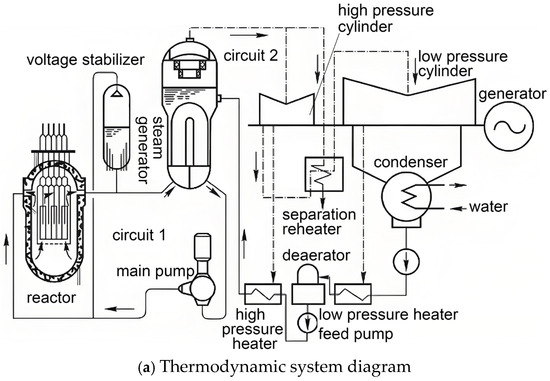

2.2.1. Thermal Systems for PWR

The thermodynamic cycle of a PWR is shown in Figure 5, where water is heated to a saturated steam state in a steam generator, and the steam temperature is typically between 280 °C and 310 °C. Table 3 shows the main parameters of the nuclear reactor (model NHR200-II) designed by Tsinghua University. The initial parameters are saturated steam. In order to improve the dryness of steam and reduce the occurrence of water hammer, a steam–water separation and reheating device is used between the high-pressure and low-pressure cylinders, with the high-pressure cylinder extracting steam for the first stage reheat, and the new steam used to reheat the exhaust steam for the second stage to reduce the humidity of the final stage of the turbine.

Figure 5.

Thermodynamic cycle diagram of PWR.

Table 3.

Main design parameters of NHR200-II.

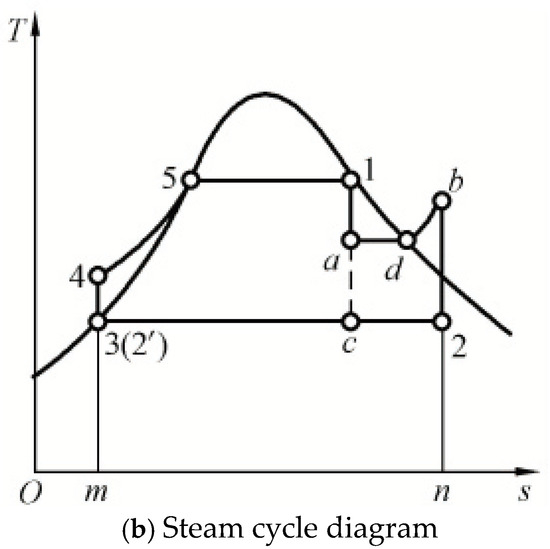

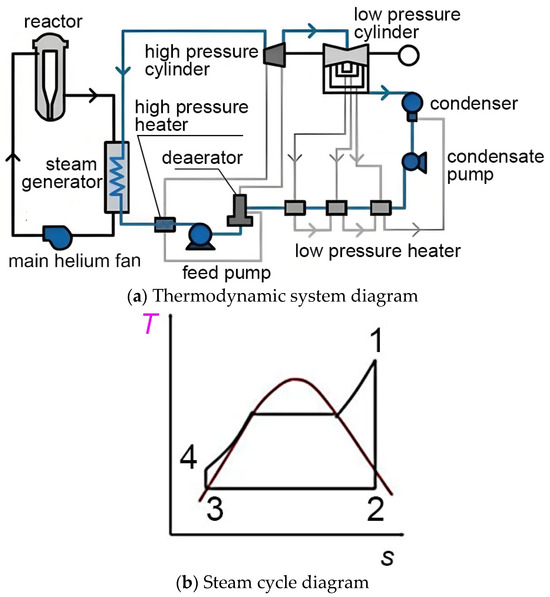

2.2.2. Thermal Systems for HTGR

HTGR is the latest generation of nuclear reactors. The thermodynamic cycle is shown in Figure 6. With gas (usually helium) as the coolant, the heat of the circuit 1 is transferred to circuit 2 through the heat exchanger, which has the characteristics of high temperature, high efficiency and inherent safety. According to the difference of the intermediate heat exchanger (IHX), this can be divided into He–steam type and He–He type [40,41,42]. The He–steam type can use the latent heat of steam to transfer more heat at the same temperature difference, which is suitable for power generation; the He–He type relies primarily on sensible heat for heat transfer, and is suitable for industrial applications with large thermal energy requirements and hydrogen energy production. The presence of steam requires more corrosion-resistant materials, as well as more sophisticated control systems and safety equipment, taking into account the effects of high-pressure steam. The He–He-type system is relatively simple, with relatively low system operation and maintenance costs. Table 4 shows the main design parameters of a HTGR (Model: HTR-PM). The operating temperature of a HTGR is usually above 600 °C, which is much higher than that of traditional PWR, so it has higher thermal efficiency. The HTGR ensures the safety of the final blade of the steam engine by increasing the initial steam temperature, without using a reheat cycle. The main reasons for this are the steam traveling to and from the steam generator, and that the steam turbine needs to cross the pressure boundary of the reactor’s first circuit. The use of new steam reheat does not provide much of an efficiency gain: at a steam temperature of 540 °C, new steam reheat increases the cycle efficiency from 44.9% to 45.2%; at a steam temperature of 570 °C, new steam reheat increases the cycle efficiency from 45.6% to 46.1%.

Figure 6.

Thermodynamic cycle diagram of HTGR.

Table 4.

Main design parameters of HTR-PM.

2.3. Comparative Analysis of Thermal System

For coal-fired units, the reheat cycle is not used for units below 50 MW class. In order to improve the dryness of steam in the final stage and the thermal efficiency of the unit, the units above 135 MW grade all adopt a reheat cycle. For the nuclear power unit, the steam–water separation and reheating device is used between the high- and low-pressure cylinders, with high-pressure cylinders pumping steam for the first stage reheat, and the new steam used to reheat the exhaust steam for the second stage to reduce the humidity of the final stage of the turbine. The HTGR can ensure the safety of the final stage blade by increasing the initial steam temperature, instead of using a reheat cycle. Therefore, there are significant differences in the thermal systems of nuclear and coal-fired units; the problem of reheating device must be considered when making nuclear power substitutions.

When carrying out nuclear energy substitution, there are also some difficulties in the calculation compatibility of the thermal system: the nuclear power system contains a steam–water separator and a reheater, which uses new steam and high-pressure-extraction steam to heat the steam, and its drain water is introduced into the regenerative heater, making it impossible to directly apply the current thermal calculation method. In nuclear power systems, additional items such as steam generator sewage expansion, pipeline leakage, pipeline heat dissipation, door rod leakage, shaft seal leakage and small steam turbine increase the complexity of thermal calculation.

3. Steam Parameters and Equipment Difference Analysis

3.1. Comparative Analysis of Steam Parameters

In the process of nuclear energy replacement, the first thing to consider is the capacity of the unit. Table 5 and Table 6 summarize the system parameters with similar capacities of coal-fired units without reheat and with a reheat system and nuclear power with similar capacity. It can be seen that no matter whether an HTGR without reheat cycle or the PWR with a reheat cycle is used, the steam parameters are significantly different from coal-fired units with a similar capacity. As can be seen from Table 6, if the coal-fired unit with a reheat cycle is replaced by a nuclear power unit with the same capacity, it is difficult for the steam temperature to meet the requirements. Coal power plants can achieve higher cycle efficiency by increasing steam temperature and pressure, while nuclear reactors have some technical limitations in this regard. In addition, boilers in coal power plants can adjust steam parameters faster to respond to changes in grid load, while nuclear reactors have a relatively slow start–stop process and regulation capacity, which is not conducive to a quick response to changes in demand. Therefore, from the point of view of steam parameters, it is difficult for nuclear reactors to directly replace the boilers of coal power plants, and detailed evaluation and design adjustment should be carried out according to various technical indicators and practical application environment.

Table 5.

Comparison of parameters between coal-fired units and nuclear power units without reheat cycle.

Table 6.

Comparison of parameters between coal-fired units and nuclear power units with a reheat cycle.

By comparing the steam turbine parameters of a 600 MW a nuclear power unit and a coal-fired unit, it is found that the first circuit of the nuclear power unit maintains a pressure of about 16 MPa, and the coolant temperature at the reactor outlet usually does not exceed 330 °C. Under such coolant temperature, saturated steam with a pressure of about 6 MPa is generated in the steam generator. In contrast, the boiler in the coal power plant heats the main steam in the superheater, and the steam is in a superheated state. From the high pressure to the sub-critical unit, the main steam temperature can reach 540 °C, and the pressure is higher than the saturated steam pressure of the nuclear power plant, which makes the main steam parameters of the steam turbine in the second circle of the nuclear power plant much lower than that of the coal power plant.

The steam pressure produced by PWR is 6~7 MPa. Because the steam turbine of nuclear power plant uses saturated steam, the parameters are lower than that of the coal-fired units, and the effective enthalpy drop is smaller. The effective enthalpy drop is about 66% of that of the coal power unit with the same power. And the steam flow rate is larger, which is 2.15 times of that of the coal-fired power unit. Therefore, although the steam turbine, condenser, heater and other equipment of nuclear power plants are basically the same as those of coal power plants, due to the differences in main steam parameters, there are big differences in the turbine parameters, thermal system and operation mode between the nuclear power plant and the coal power plant.

3.2. Differences in Turbine Equipment

Due to the difference of thermal system and steam parameters, there are great differences in turbine structure, which is also a problem that must be considered in substitution. Taking PWR as an example, the number of stages of nuclear power turbine is lower, there is no medium pressure cylinder, and the proportion of low-pressure cylinder power to the total power increases to about 50~60%. When the power increases to 500~800 MW, the high-pressure cylinder must be made into a double flow. The influence of steam exhaust loss, separation reheater and pressure loss of steam inlet and exhaust pipeline on the economy of the turbine increases. The turbine outlet steam volume flow is larger, which makes the final stage blades increase in height, thus increasing the radial size of the turbine, and adopting the structure of multiple steam discharge ports, which makes the turbine size increase and weight increase. Nuclear power steam turbine works in a wet steam environment. The influence of large and small water droplets on the turbine is mainly manifested in the erosion and destructive effect on the flow parts. Therefore, measures to remove moisture should be taken on the inner wall of the cylinder, including increasing the axial clearance and external separator, etc. Most nuclear power turbines operate at constant pressure, so reducing the speed of the turbine can significantly increase the ultimate power of the turbine unit under the condition that the initial and final steam parameters are unchanged.

4. Safety Matching Analysis

4.1. Comparative Analysis of Site Selection

Since the risks of nuclear energy are radiation-related, nuclear safety also needs to consider building and maintaining effective defenses against radiation hazards compared to coal power generation. In the selection and design of nuclear power plant sites, consideration should be given to the most severe natural disasters such as earthquakes, tsunamis, tropical storms and floods that may occur in the local area [43]. It must be ensured that reactors can be safely shut down even in the event of the most severe natural disaster.

4.1.1. Site Selection for Nuclear Power Plants

From the point of view of nuclear safety, the main purpose of choosing a site for a nuclear power plant is to protect the public and the environment from excessive radiation caused by a radioactive accident, and the normal release of radioactive materials from a nuclear power plant should also be taken into account. In evaluating the suitability of a site for a nuclear power plant, the following factors must be considered [44]:

- (1)

- The effect of external natural or man-made events on the nuclear power plant that may occur in the area of a particular site.

- (2)

- Site characteristics and environmental characteristics that may affect the transfer of released radioactive materials to human bodies.

- (3)

- Population density, distribution, and other characteristics of the relevant peripheral zones relevant to the possibility of implementing emergency measures and to the evaluation of individual and group risks required.

- (4)

- Social factors such as the level of public awareness, understanding and support for nuclear safety.

- (5)

- The need for adequate cooling water sources for nuclear power plants, usually in close proximity to large bodies of water.

4.1.2. Site Selection for Coal Power Plants

The geological requirements of coal power plants are relatively loose, and the basic principles are as follows [45]:

- (1)

- Coal power plants are close to raw materials, fuel and consumption areas, while ensuring convenient transportation and hence continuous fuel supply.

- (2)

- The amount of ash discharged from coal power plants accounts for about 15% to 20% of the amount of coal, while the coal power plant can reduce water dependence through the circulating water-cooling system.

- (3)

- Water supply problem: the site area should have a reliable water source and backup water source, and the coal power plant can reduce the dependence on water resources through its circulating water-cooling system.

- (4)

- Social factors such as public concern about air pollution and greenhouse gas emissions.

4.2. Comparative Analysis of the Construction of Nuclear and Coal-Fired Power Plants

The construction period of a nuclear power plant is generally longer. Taking the same 1000 MW unit as an example, the construction period of the conventional island plant of a nuclear power plant is 39 to 43 months from the pouring of the first tank of concrete (the First Concrete Date) to the availability of the steam turbine being ready for steam admission, and it is often completed behind schedule due to a variety of factors in the actual construction. The construction period of the steam turbine of the conventional 1000 MW coal power plant is 23 months from the pouring of the first tank of concrete to the turbine with steam admission conditions, and the actual construction can often be completed 2 to 3 months in advance. The direct cause of the huge difference in construction period is mainly the difference in the amount of work and the strictness of management requirements, but at the root, the deepest fundamental reason is the difference in the design concepts of the two types of power plants.

Compared with coal plants, nuclear power plants place an overriding importance on safe operation. Once a nuclear leakage accident occurs, its impact is long-term and the scope of the impact is also worldwide; therefore, nuclear power plants must be designed and built to ensure strict safety. Coal power plants, on the other hand, need to integrate economic considerations to a certain extent.

Under the guidance of the design concept of ensuring safety, the design redundancy of nuclear power plants has increased greatly, which is mainly reflected in various aspects such as steam parameters, equipment selection, plant layout, plant structure, construction management requirements, etc. Steam turbine equipment needs to consider the safety and durability of related equipment inside the nuclear island, and the seismic grade of plant structure needs to be considered. All these have increased the construction workload to varying degrees [46].

4.3. Matching of Safety Standards

A 600 MW HTGR nuclear power unit would not have a core meltdown, would meet the most stringent nuclear safety standards and meet the most stringent radiation dose limitations around the site under accident conditions, and would not technically require an off-site emergency response [47]. Therefore, HTGR nuclear power units can be built on some coal power plant sites that are facing retirement, and the existing infrastructure and equipment such as coal power turbine and cooling tower can be fully utilized. However, because nuclear safety requirements are higher than those of coal power plants, additional consideration of nuclear-related safety standards and requirements is needed when utilizing HTGR to replace decommissioned coal power units.

Safety analysis is of great importance for the safety and economy of nuclear power plant design and operation.

Relevant International Atomic Energy Agency standards include the following:

- (1)

- SSR-2/1 Safety of Nuclear Power Plants: Design (2016): This safety requirement specifies the requirements to be met in the design of safety-important structures, systems, and components of nuclear power plants, as well as procedures and organizational processes.

- (2)

- SSG-2 Deterministic Safety Analysis for Nuclear Power Plants (2019): This safety guideline specifies the overall considerations for determining safety analysis, plant state classification, calculation procedures, safety margins, and other aspects.

- (3)

- TECDOC-1791 Considerations on the Application of the IAEA Safety Requirements for Design of Nuclear Power Plants (2016): This technical document is a supplement to the specific requirements set out in standard SSR-2/1 [48] and its implementation.

- (4)

- SSG-3 Development and Application of Leve l Probabilistic Safety Assessment for Nu-clear Power Plants (2010): This safety guideline specifies the contents related to the level 1 probabilistic safety analysis of nuclear power plants, including Level 1 PSA for internal events of power operation, Level 1 PSA for low power and shutdown conditions, etc.

- (5)

- SSG-4 Development and Application of Level 2 Probabilistic Safety Assessment for Nuclear Power Plants (2010): This safety guideline specifies the content related to level 2 probabilistic safety analysis of nuclear power plants, including interface with Level 1 PSA, containment response to severe accidents, and source term analysis.

In the standard review guidelines with which the safety regulatory department of nuclear power plants in the United States reviews the safety analysis reports of nuclear power plants, Chapter 6 (Containment Design), Chapter 15 (Deterministic Accident Analysis), and Chapter 19 (Severe Accidents) are related to accident analysis. Some contents of this standard refer to Chapter 15 of the SRP. This chapter, for different types of design basis accidents and some beyond design basis accidents, in accordance with the chapter arrangement of Chapter 15 of the safety analysis report, provides detailed regulations on the analysis methods, evaluation contents and acceptance criteria for different types of events or accidents.

The French nuclear safety regulatory system consists of three components: the decrees and regulations issued by the government working section, the basic rules issued by the nuclear safety authority, and the Code for the Design and Construction of nuclear power stations (RCC) prepared by the nuclear industry. RCC rules are based on the industrial specifications of the United States as the main reference, based on the actual situation of domestic industry, formed a special standard system of PWR mainly based on the engineering model. The French standard system is simple in structure, narrow in application, focused on engineering design and construction, and other aspects have relatively little involvement.

China’s nuclear power plant-related standard system has a relatively clear hierarchical structure. The first level is the national law level, for the analysis of nuclear power plant accidents, this level involves the Nuclear Safety Law and the Radioactive Pollution Prevention Law. The second layer is the administrative regulations and guidelines issued by relevant government departments, such as HAF, HAD and other regulations and guidelines. The third layer is the national standard, industry standard, or related technical specification system formulated by the industry. The last layer is the nuclear power enterprise standard developed by the enterprise. It includes 2 regulations, 10 guidelines, 7 national standards and 18 row standards.

By comparing the safety standards of nuclear power plants and coal power units, it can be found that nuclear reactors require very complex and redundant safety systems to control nuclear reactions and prevent radioactive material from escaping, while coal-fired boilers are primarily concerned with combustion control and emissions. Nuclear reactors involve radioactive materials, and there is a potential risk of radioactive leakage. Therefore, specially designed containment and cooling systems are required to prevent the occurrence and spread of accidents, which are not required in coal-fired power plants. Radioactive waste generated by nuclear reactors requires long-term management and storage, which requires not only specialized facilities, but also safety measures for thousands of years to ensure safety for the environment and humans, which are not available in coal-fired power plants. Nuclear power plants require sophisticated emergency response plans, including evacuation planning, incident control and coordination with government and public safety authorities, the kind of complex emergency systems that are missing in coal-fired power plants. In addition to the relevant provisions of the American Society of Mechanical Engineers code for pressure vessels, nuclear power units are not compatible with coal power units in terms of safety standards.

5. Discussion

Utilizing nuclear reactors to replace coal power in decommissioned coal power plants for generation/heat/cogeneration at decommissioned coal plants can reduce the negative impact of coal power plant shutdowns and promote the transition to green and low-carbon energy sources. However, nuclear power and coal power units have great differences in technical parameters and safety standards, so the current substitution is not feasible.

First of all, there are great differences between nuclear power and coal power units in terms of thermal system. Coal power units below 50 MW class do not use a reheat cycle. China’s in-service coal power units are mainly 300 MW subcritical and 350–660 MW supercritical (ultra-supercritical). In order to improve the dryness of steam in the final stage and the thermal efficiency of the unit, the reheat cycle is adopted. Pressurized water nuclear reactor adopts a steam–water separation and reheating device between high- and low-pressure cylinders, using the high-pressure cylinder to extract steam for the first stage to reheat, and using the new steam to reheat the exhaust steam for the second stage to reduce the humidity of the final stage of the turbine. The high-temperature gas-cooled reactor ensures the safety of the final stage blades of the turbine by raising the initial temperature of the steam, and does not use the reheat cycle.

When making nuclear energy substitutions of similar capacity, both the high-temperature gas-cooled reactor without reheat cycle and the pressurized water reactor with a reheat cycle have great differences in steam parameters and thermal system of coal power units with similar capacity. Nuclear reactors have some technical limitations in increasing steam temperature and pressure, and their start–stop process and regulation capacity are relatively slow, which is not conducive to responding quickly to changes in demand.

In terms of steam turbine, nuclear power units and coal power units also have a big difference: nuclear power turbines have fewer stages without medium-pressure cylinders, while low-pressure cylinder power account for a higher proportion of the total power, about 50~60%. The larger steam volume flow at the outlet of nuclear power turbine makes the turbine larger in size and weight. Since the nuclear power turbine works in the environment of wet steam, the inner wall of the cylinder has to take dehumidification measures.

Nuclear power plants are more stringent in terms of site selection, requiring more safety considerations, nuclear power units require a longer construction cycle, in addition to sufficient cooling water sources and social factors, which also limit the substitution of nuclear power for coal power. In terms of safety standards, although different countries have developed more safety standards and norms, in addition to the relevant provisions of the pressure vessel in the American Society of Mechanical Engineers specification, nuclear power units are not compatible with coal power units in terms of safety standards.

6. Conclusions

Replacing the original coal-fired power plant boiler with a nuclear reactor will arouse widespread concern in industry and society. When nuclear power replaces coal-fired units, high-temperature gas-cooled reactors without a reheat cycle and pressurized water reactors with a reheat cycle have significant differences in steam parameters and thermal system compared to coal power units with similar capacity. The main steam parameters of nuclear power units and coal power units are distinctly different, and the steam turbine of nuclear power units is larger, so the problem of dehumidification needs to be considered. Under the premise of ensuring safety, what kind of nuclear reactor specifications should be selected to replace various standardized and systematic boiler systems, and the current safety standards do not match. In addition, it is also necessary to address the universality problem of steam turbines, generators and their auxiliary equipment, and formulate relevant nuclear reactor replacement specifications and standards to be complemented with the existing turbines and generators. It is currently considered that nuclear energy substitution for power generation/heat supply/cogeneration at decommissioned coal power units is not feasible at present.

Author Contributions

Conceptualization and data curation, D.Z.; investigation and writing—original draft, Z.L.; methodology, T.Z.; project administration, H.Y.; writing—review and editing, R.B. and M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This research is supported by China Carbon Neutrality Initiative of Tsinghua University.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- National Bureau of Statistics. China Statistical Yearbook—2022; National Bureau of Statistics, China Statistics Press: Beijing, China, 2022.

- Department of Industry, National Bureau of Statistics. Annual Economic Operation Report of Energy Industry 2023; IEA: Paris, France, 2024.

- Henderson, C. Increasing the Flexibility of Coal-Fired Power Plants; IEA Clean Coal Centre: Paris, France, 2014; Volume 15, p. 15. [Google Scholar]

- Yu, X.; Zheng, D.; Yang, K.; Kong, J.; Zhang, T. Opportunities and challenges of energy and power industry under the goal of carbon peak carbon neutrality. Huadian Technol. 2019, 43, 21–32. [Google Scholar]

- Fan, J.L.; Li, Z.; Huang, X.; Li, K.; Zhang, X.; Lu, X.; Shen, B. A net-zero emissions strategy for China’s power sector using carbon-capture utilization and storage. Nat. Commun. 2023, 14, 5972. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Wang, L.; Zhong, S.; Xiang, N.; Qu, Q. Low-carbon transformation of electric system against power shortage in China: Policy optimization. Energies 2022, 15, 1574. [Google Scholar] [CrossRef]

- Zhang, X.; Cui, X.; Li, B.; Hidalgo-Gonzalez, P.; Kammen, D.M.; Zou, J.; Wang, K. Immediate actions on coal phaseout enable a just low-carbon transition in China’s power sector. Appl. Energy 2022, 308, 118401. [Google Scholar] [CrossRef]

- Wei, F.; Li, L. Research and practice on development path of low-carbon, zero-carbon and negative carbon transformation of coal-fired power units under “double carbon” targets. Power Gener. Technol. 2022, 43, 452. [Google Scholar]

- Qu, X.; Yuan, Z.; Peng, T.; Sun, Z.; Zhou, S. The low-carbon transition toward sustainability of regional coal-dominated energy consumption structure: A case of Hebei province in China. Sustainability 2017, 9, 1184. [Google Scholar] [CrossRef]

- Gaudard, L.; Avanzi, F.; De, M. Seasonal aspects of the energy-water nexus: The case of a run-of-the-river hydropower plant. Appl. Energy 2018, 210, 604–612. [Google Scholar] [CrossRef]

- Converse, A. Seasonal energy storage in a renewable energy system. Proc. IEEE 2011, 100, 401–409. [Google Scholar] [CrossRef]

- Bodansky, D. Nuclear Energy: Principles, Practices, and Prospects; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Lenzen, M. Life cycle energy and greenhouse gas emissions of nuclear energy: A review. Energy Convers. Manag. 2008, 49, 2178–2199. [Google Scholar] [CrossRef]

- Dittmar, M. Nuclear energy: Status and future limitations. Energy 2012, 37, 35–40. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, X. Nuclear energy development in China: A study of opportunities and challenges. Energy 2010, 35, 4282–4288. [Google Scholar] [CrossRef]

- Chen, Y.; Martin, G.; Chabert, C.; Eschbach, R.; He, H.; Ye, G.A. Prospects in China for nuclear development up to 2050. Prog. Nucl. Energy 2018, 103, 81–90. [Google Scholar] [CrossRef]

- Yu, S.; Yarlagadda, B.; Siegel, J. The role of nuclear in China’s energy future: Insights from integrated assessment. Energy Policy 2020, 139, 111344. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Power Reactor Information System (PRIS) [EB/OL]. Available online: https://www.iaea.org/PRIS/home.aspx (accessed on 1 August 2020).

- Lu, H.; Gao, B.; Li, L.; Cheng, G.S. China’s Nuclear Energy Development and Prospects (2023); China Nuclear Energy Association: Beijing, China, 2023.

- China Nuclear Energy Industry Association. Blue Book of Nuclear Energy Development: Report on China’s Nuclear Energy Development (2024); Social Sciences Academic Press: Beijing, China, 2024.

- China Nuclear Power Development Center, State Grid Energy Research Institute Co. Ltd. Research on Nuclear Power Development Planning in China; China Atomic Energy Press: Beijing, China, 2019.

- Griffith, G. Transitioning Coal Power Plants to Nuclear Power; Idaho National Laboratory (INL): Idaho Falls, ID, USA, 2021.

- Hansen, J.; Jenson, W.; Wrobel, A.; Biegel, K.; Kim, T. Investigating Benefits and Challenges of Converting Retiring Coal Plants into Nuclear Plants; Idaho National Laboratory (INL): Idaho Falls, ID, USA, 2022.

- Ochmann, J.; Niewiński, G.; Łukowicz, H.; Bartela, Ł. Potential for Repowering Inland Coal-Fired Power Plants Using Nuclear Reactors According to the Coal-to-Nuclear Concept. Energies 2024, 17, 3545. [Google Scholar] [CrossRef]

- Weng, T.; Zhang, G.; Wang, H.; Qi, M.; Qvist, S.; Zhang, Y. The impact of coal to nuclear on regional energy system. Energy 2024, 302, 131765. [Google Scholar] [CrossRef]

- Virdis, M.R.; Rieber, M. The cost of switching electricity generation from coal to nuclear fuel. Energy J. 1991, 12, 109–134. [Google Scholar] [CrossRef]

- Hou, Y. High temperature gas cooled reactor: A replacement for small and medium-sized thermal power. Energy 2020, 1, 83–86. [Google Scholar]

- Sun, J. The United States plans to convert coal power plants into nuclear power plants. Therm. Energy Power Eng. 2024, 39, 37. [Google Scholar]

- Kasperson, R.E.; Berk, G.; Pijawka, D.; Sharaf, A.B.; Wood, J. Public opposition to nuclear energy: Retrospect and prospect. Sci. Technol. Hum. Values 1980, 5, 11–23. [Google Scholar] [CrossRef]

- De, G.; Steg, L.; Poortinga, W. Values, perceived risks and benefits, and acceptability of nuclear energy. Risk Anal. Int. J. 2013, 33, 307–317. [Google Scholar]

- The Global Coal Plant Tracker. Global Coal Plant Tracker [EB/OL]. 2021 [2022-01-12]. Available online: https://globalenergymonitor.org/projects/global-coal-plant-tracker/ (accessed on 7 October 2022).

- Global Power Plant Database. Global Power Plant Database v1.3.0 [EB/OL]. 2018 [2022-01-06]. Available online: https://datasets.wri.org/dataset/globalpowerplantdatabase (accessed on 6 January 2022).

- Cui, R.; Hultman, N.; Cui, D.; McJeon, H.; Yu, S.; Edwards, M.R.; Sen, A.; Song, K. A plant-by-plant strategy for high-ambition coal power phaseout in China. Nat. Commun. 2021, 12, 1468. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Tong, D.; Zheng, Y.; Liu, Y.; Chen, S.; Qin, X.; Chen, C.; Xu, R.; Cheng, J.; Shi, Q. Cost-effectiveness uncertainty may bias the decision of coal power transitions in China. Nat. Commun. 2024, 15, 2272. [Google Scholar] [CrossRef] [PubMed]

- Liu, C. Supercritical Carbon Dioxide Coal-Fired Power Generation System of Boiler and Regenerator Research. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2022. [Google Scholar] [CrossRef]

- Yang, W.; Liu, X. Natural gas distributed energy station host scheme selection. Constr. Shanxi Prov. 2012, 38, 158–160. [Google Scholar] [CrossRef]

- Geng, J.; Zheng, D.; Zhang, C.; Yi, S. Discussion on Host Parameter selection of 600MW thermal power Unit. Power Plant Syst. Eng. 2011, 27, 8–10. [Google Scholar]

- Wu, X. Research on Parameters and Structure Selection of Ultra-supercritical Units in China. Electr. Power Sci. Eng. 2008, 24, 45–50. [Google Scholar]

- International Atomic Energy Agency (IAEA). World Nuclear Power Reactors (2023 Edition); International Atomic Energy Agency: Vienna, Austria, 2023. [Google Scholar]

- Nagatsuka, K.; Noguchi, H.; Nagasumi, S.; Nomoto, Y.; Shimizu, A.; Sato, H.; Nishihara, T.; Sakaba, N. Current status of high temperature gas-cooled reactor development in Japan. Nucl. Eng. Des. 2024, 425, 113338. [Google Scholar] [CrossRef]

- McDonald, C. The key role of heat exchangers in advanced gas-cooled reactor plants. Heat Recovery Syst. CHP 1994, 14, 7–28. [Google Scholar] [CrossRef]

- Bolfo, L.; Devia, F.; Lomonaco, G. Nuclear hydrogen production: Modeling and preliminary optimization of a helical tube heat exchanger. Energies 2021, 14, 3113. [Google Scholar] [CrossRef]

- Radar. Comparison between nuclear power plant and conventional thermal power plant. J. Wuhan Univ. Eng. Technol. 2009, 42, 85–89. [Google Scholar]

- Sheng, W. A brief about code on the safety of nuclear power plants (Rev. 1). Nucl. Power Eng. 1994, 15, 181–186. [Google Scholar]

- Lu, B. Research on Site Selection of a Large Thermal Power Plant. Master’s Thesis, Jilin University, Changchun, China, 2014. [Google Scholar]

- Zhao, Y. Plant ci compared with power plant turbine plant construction time limit for a project. J. Eng. Constr. Des. 2016, 14, 23–24+29. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Z.; Wang, D.; Tong, J. Research on development strategy of high temperature gas cooled reactor in China. Eng. Sci. 2019, 21, 12–19. [Google Scholar]

- International Atomic Energy Agency. Safety of Nuclear Power Plants: Design; IAEA Safety Standards Series No: SSR-2/1 (Rev.1); IAEA: Vienna, Austria, 2016. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).