Degradation Diagnosis and Control Strategy for a Diesel Hybrid Powertrain Considering State of Health

Abstract

1. Introduction

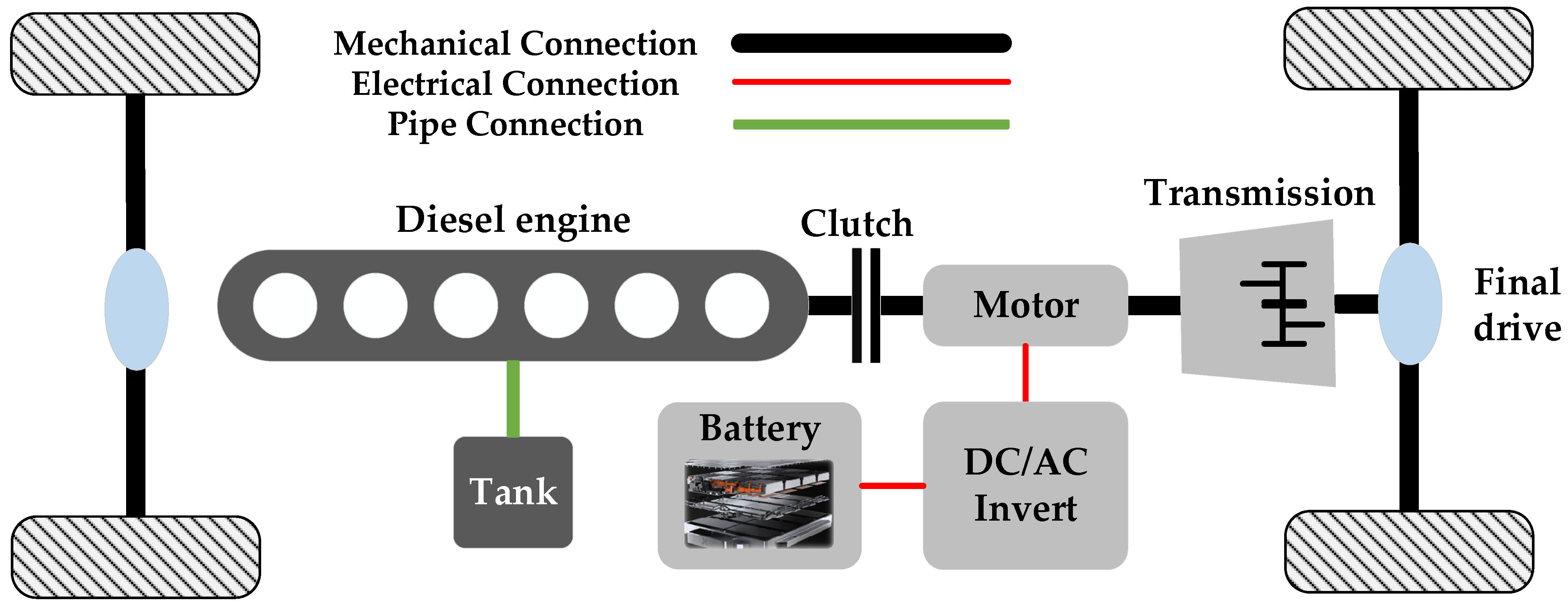

2. P2 HEV Modelling with NN Engine Model Simplification

2.1. Vehicle Model

2.2. Traction Motor Model

2.3. Battery Model

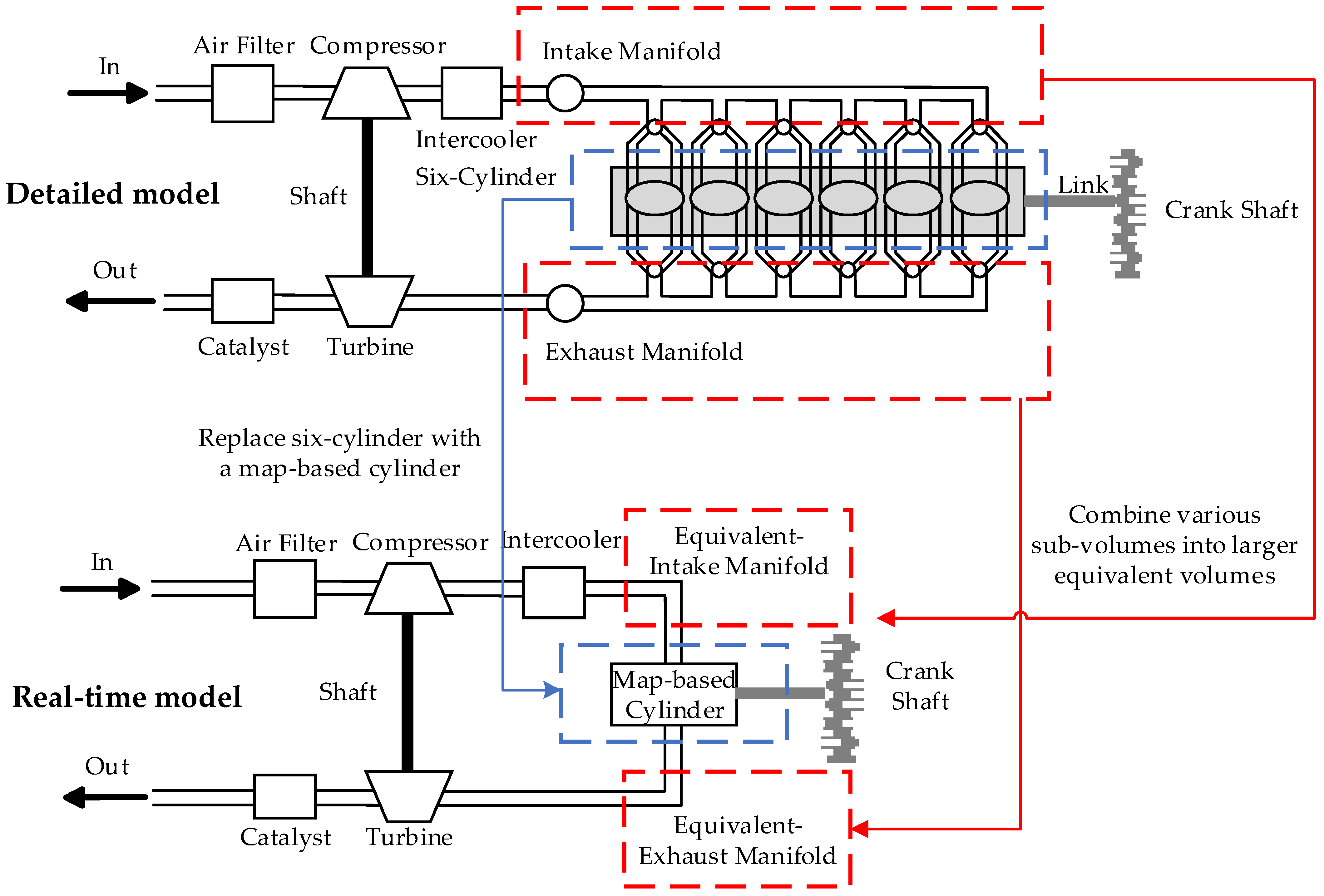

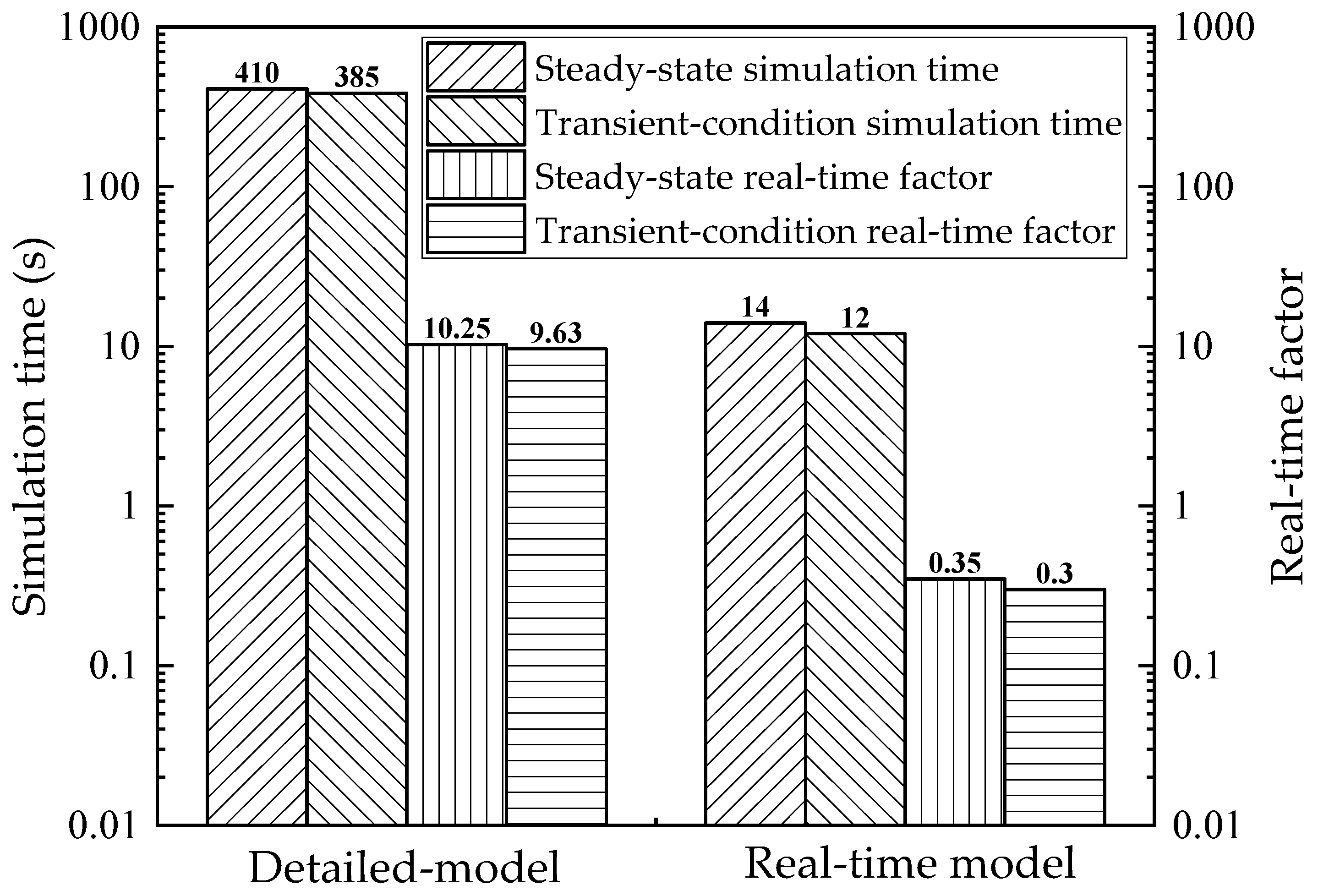

2.4. Diesel Engine Model

2.4.1. Model Building

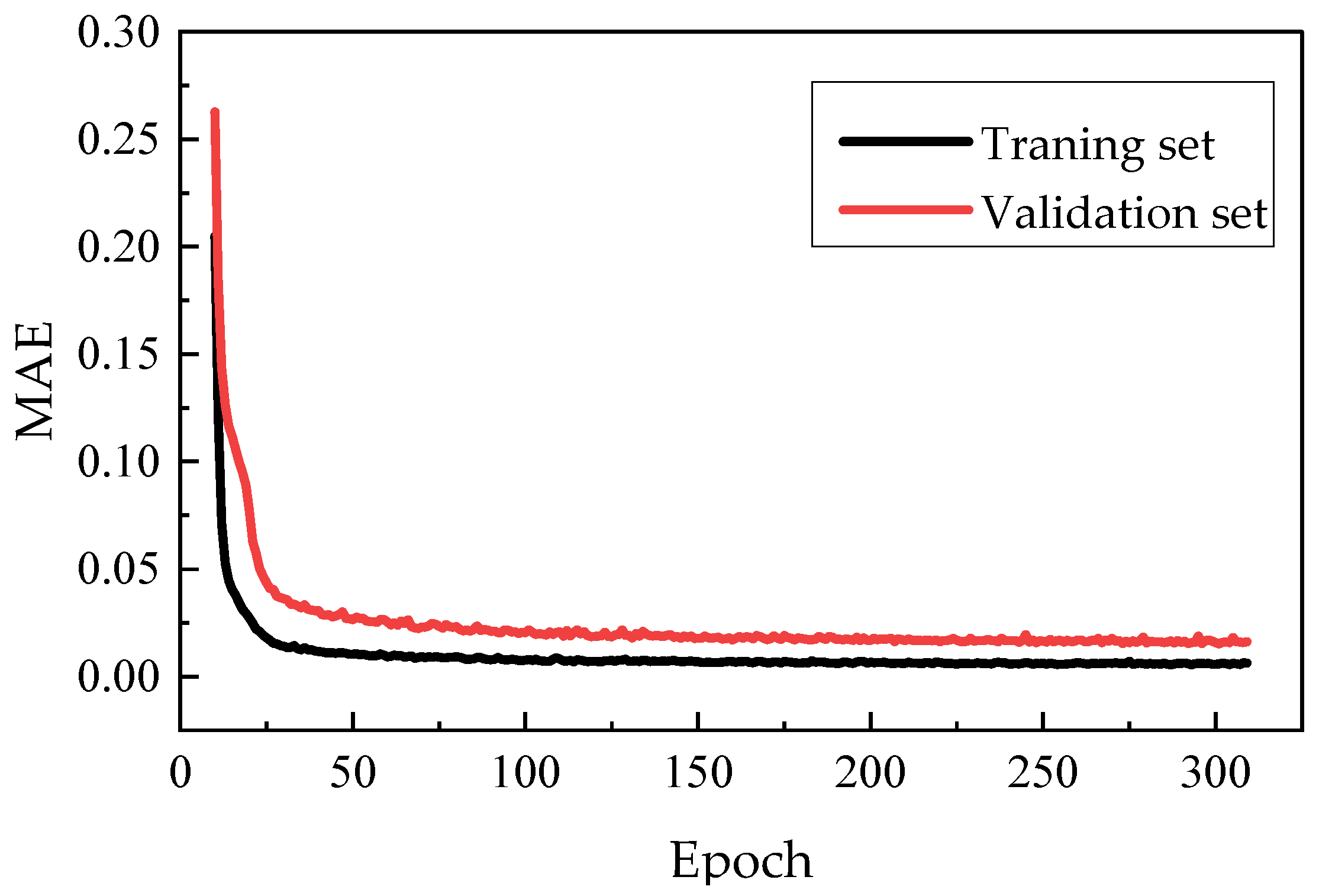

2.4.2. Model Verification

2.5. Rule-Based Hybrid System Operation Mode

3. HEV Degradation Prognostic Method

3.1. GRA

- Set up a matrix of m × n data series to construct the evaluation index system, where n represents the number of samples and m represents the number of features;

- Use the sequence from normal operation as the reference sequence and comparison standard;

- Different feature signals often have different dimensions. Use normalization to scale the data to a uniform range, enabling easier comparison and processing across different features.

- Calculate gray correlation coefficients one by one using Equation (5):

- 5.

- Calculate the correlation degree one by one using Equation (6):

3.2. Feature Signals Selection

3.3. Weight Determination Based on PCA

- Form a matrix from the raw data using Equation (7):

- 2.

- Normalize the original data matrix to obtained a new data matrix A using Equation (8):

- 3.

- Then, the correlation coefficient matrix C of the original data is calculated, which is the covariance matrix of the normalized data, as shown in Equation (9):

- 4.

- Compute the eigenvalues λj using Equation (10):

- 5.

- The cumulative contribution rate M is calculated by Equation (11) and the number of principal components k will be determined by it, such that the cumulative contribution M reaches the predetermined value

- 6.

- Sort the eigenvalues in descending order, and select the eigenvector corresponding to the largest eigenvalue as the weight.

3.4. Count-Based Degradation Confirmation

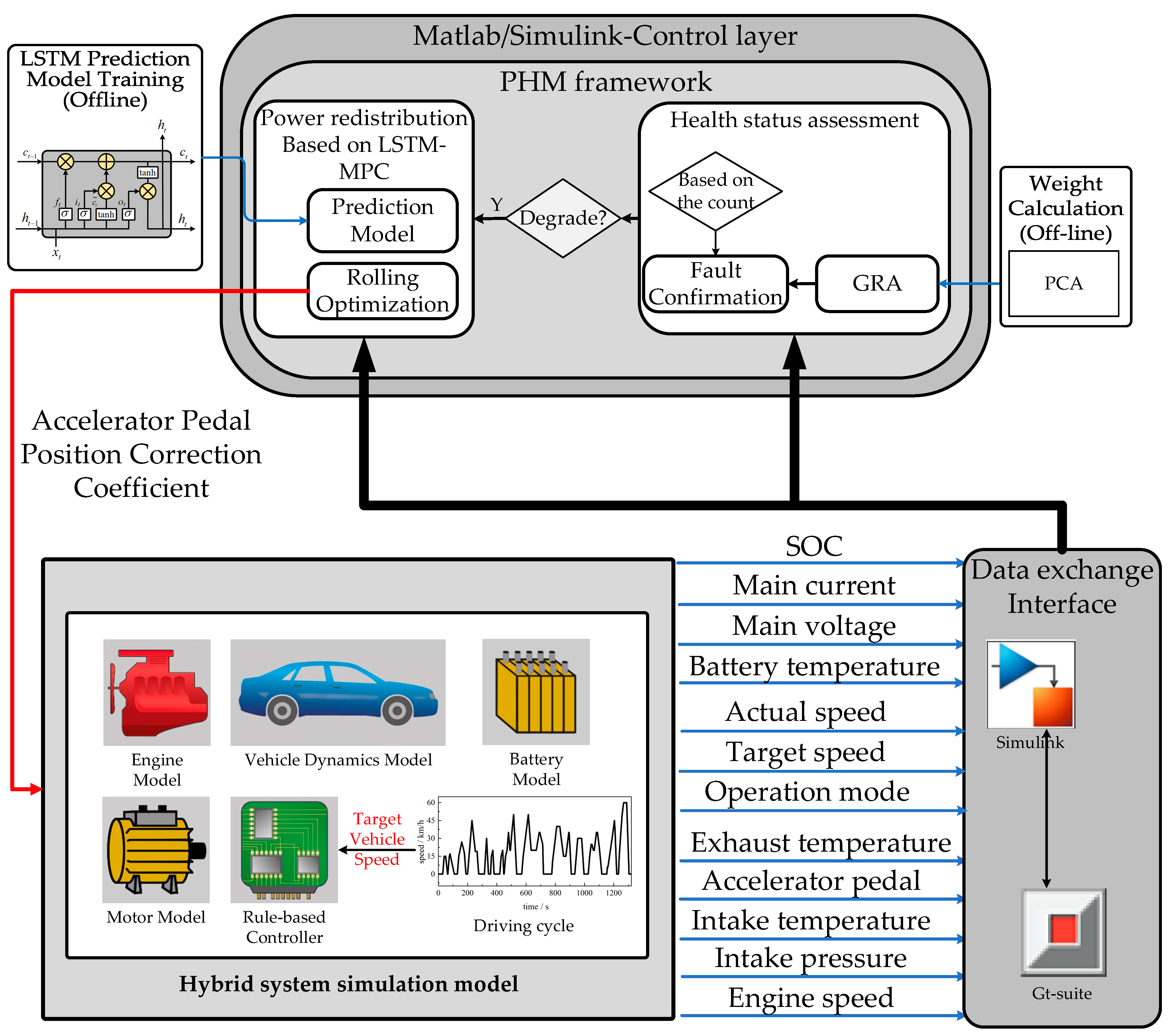

4. PHM Strategy Study

4.1. MPC

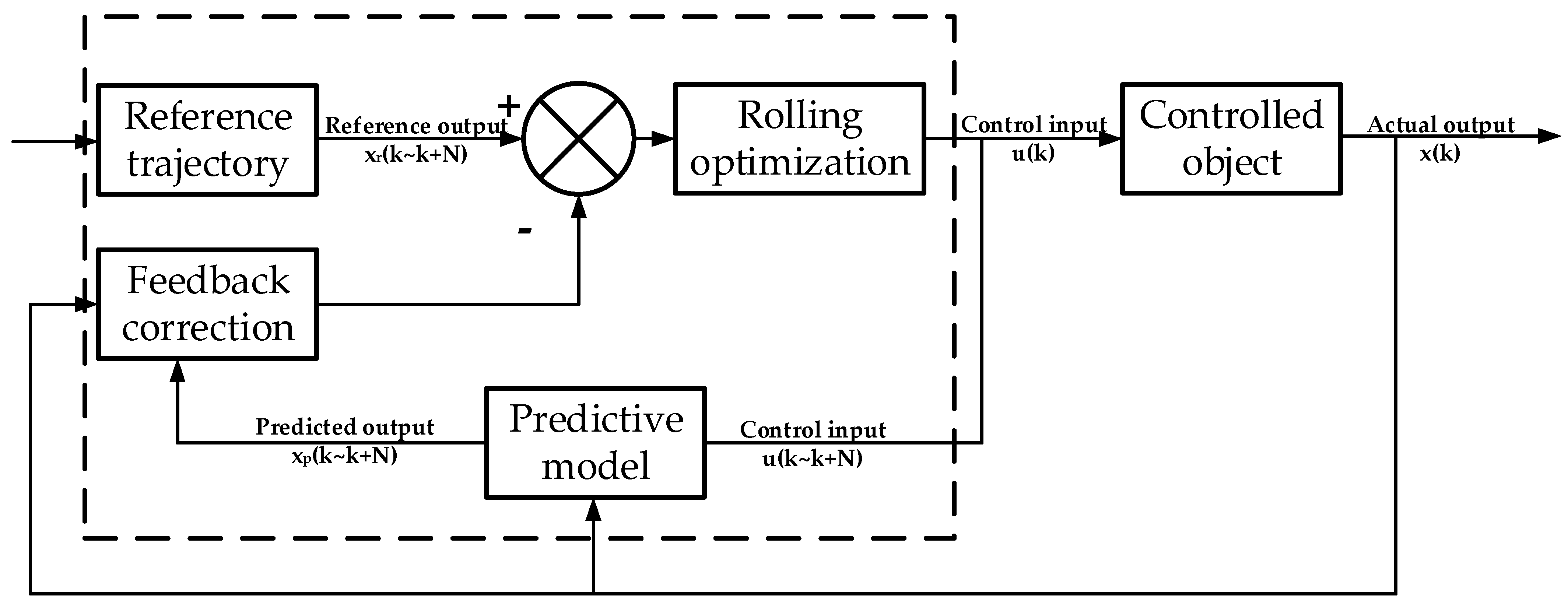

4.1.1. Principle

- Reference trajectory: The desired output value of the controlled object, that is, the target value;

- Predictive model: Changes in the system in a relatively short time domain can be predicted, making the control system prospective. The dynamic characteristics of the controlled object can be retained to reduce sharp changes in the output of the controlled object in the control process, reduce overshoot, and ensure the subsequent effect of the target.

- Rolling optimization: Within a limited prediction horizon, the optimal control sequence is obtained that minimizes the objective function while satisfying constraints. Only the first step is applied, then the horizon shifts forward by one step, repeating the process for rolling optimization.

- Feedback correction: To reduce the impact of prediction errors and other disturbances, corrections are made by comparing the actual values with the predicted values, improving the system’s robustness.

4.1.2. Problem Construction

4.2. Prediction Model Based on LSTM

4.3. Simulation of PHM

Simulation Process

- The control layer first receives feature signals from the model. It continuously calculates the system’s health index to assess the system state. Degradation is identified using a counting-based method, where a degradation label is generated: 0 indicates no degradation, and 1 indicates a degradation;

- When the system health index starts to decline, the LSTM-MPC-based power redistribution strategy kicks in. It receives feature signals and pre-calculates the accelerator pedal position correction coefficient. Upon degradation confirmation, this correction coefficient is used to adjust the accelerator pedal position, allowing the system to operate with the degradation;

- If no degradation is detected, the system continues to operate using the rule-based control strategy.

5. Result and Discussion

5.1. Degradation Case Setup

5.2. Weight Calculation (Off-Line)

5.3. Performance Under Different Degradation Cases

5.3.1. Battery Degradation

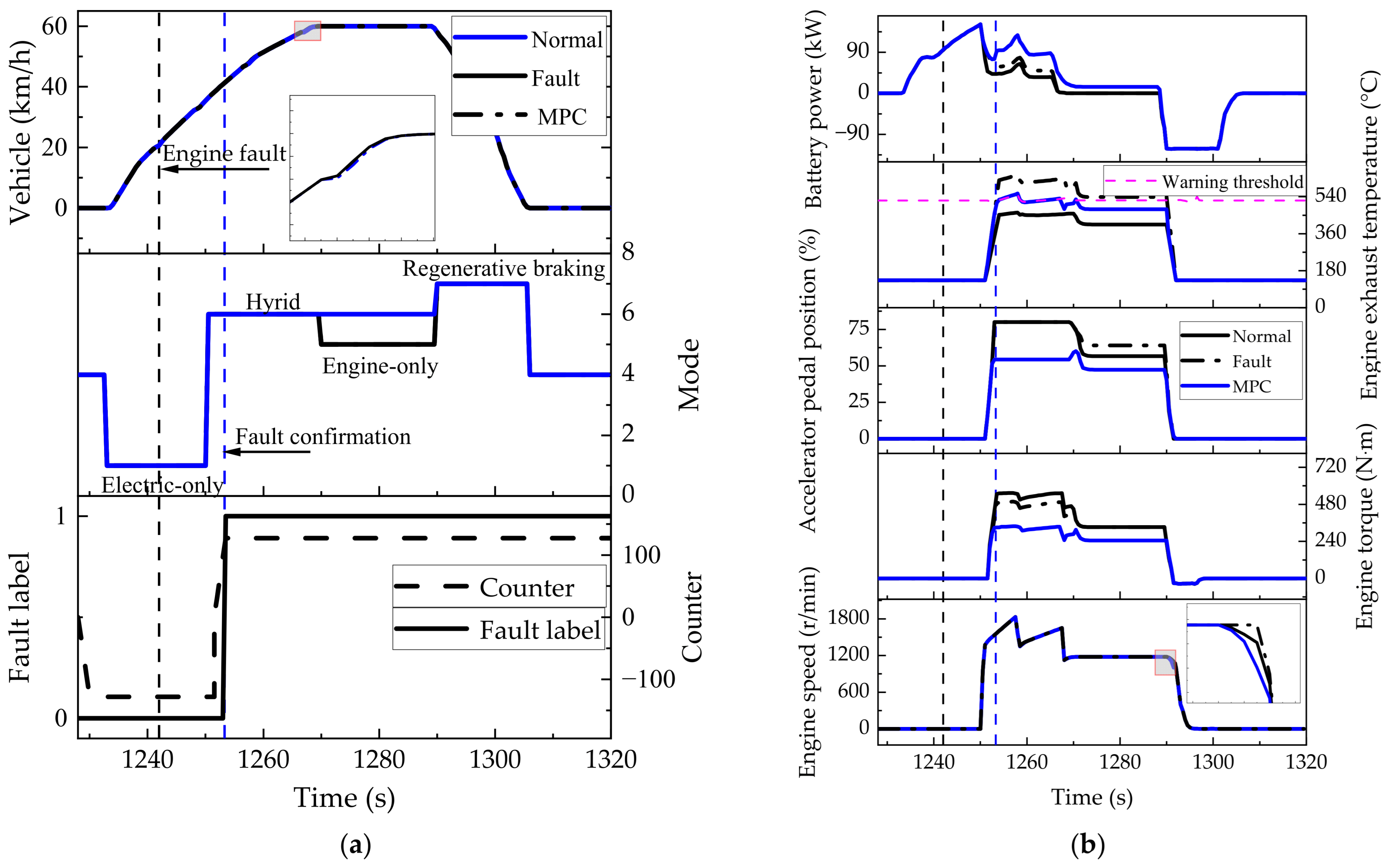

5.3.2. Engine Degradation

5.3.3. Combined Case

6. Conclusions

- A physical P2 HEV model with a rule-based controller was built. The diesel engine sub-model was simplified by using NN to meet the requirement of real-time performance for degradation prognostics.

- Considering real-world HEV sensor data, the GRA-PCA-based algorithm for degradation prognostics was used. The method showed good anti-noise ability and fast responsibility with 2s triggered by the health index.

- PHM case studies were performed and LSTM-MPC-based degradation tolerance strategies were validated. The optimization targets were the best vehicle speed tracing with less degradation in energy consumption.

- The result shows that the energy consumption remained nearly unchanged for the engine degradation case. For the battery degradation case, the tracing error was reduced by 11.7% with 4.3% more energy consumption. For combined degradation, the strategy achieved a 12.3% tracing error reduction with 3.7% more energy consumption. The suggested PHM method guaranteed vehicle power performance under degradation situations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations and Symbols

| Abbreviations | Meaning | Symbols | Meaning |

| HEV | Hybrid electric vehicles | Exhaust temperature | |

| DD | Degradation diagnosis | Accelerator pedal position | |

| PHM | Prognostics and Health Management | Intake temperature | |

| NN | Neural network | Intake pressure | |

| GRA | Gray relation analysis | Main Voltage | |

| PCA | Principal component analysis | Main Current | |

| LSTM | Long short-term memory | Battery temperature | |

| MPC | Model predictive control | Vehicle speed | |

| SOC | State of charge |

References

- Eikenberry, S.E. Hybrids are an effective transitional technology for limiting US passenger fleet carbon emissions. AIMS Environ. Sci. 2020, 7, 117–139. [Google Scholar] [CrossRef]

- Qadir, S.A.; Ahmad, F.; Al-Wahedi, A.M.A.B.; Iqbal, A.; Ali, A. Navigating the complex realities of electric vehicle adoption: A comprehensive study of government strategies, policies, and incentives. Energy Strategy Rev. 2024, 53, 101379. [Google Scholar] [CrossRef]

- Zaino, R.; Ahmed, V.; Alhammadi, A.M.; Alghoush, M. Electric vehicle adoption: A comprehensive systematic review of technological, environmental, organizational and policy impacts. World Electr. Veh. J. 2024, 15, 375. [Google Scholar] [CrossRef]

- Lü, X.; Li, S.; He, X.; Xie, C.; He, S.; Xu, Y.; Fang, J.; Zhang, M.; Yang, X. Hybrid electric vehicles: A review of energy management strategies based on model predictive control. J. Energy Storage 2022, 56, 106112. [Google Scholar] [CrossRef]

- Milojević, S.; Glišović, J.; Savić, S.; Bošković, G.; Bukvić, M.; Stojanović, B. Analysis of Urban Air Quality Based on Remote Sensing and Machine Learning. Atmosphere 2024, 15, 184. [Google Scholar] [CrossRef]

- Ehsani, M. Conventional fuel/hybrid electric vehicles. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance; Woodhead Publishing: Sawston, UK, 2014; pp. 632–654. [Google Scholar]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Wei, Z.; Goehring, T.; Mioduszewski, M.; Luo, L.; Kotrba, A.; Rybarz, M.; Ellinghaus, K.; Pieszkalla, M. Failure mechanisms and modes analysis of vehicle exhaust components and systems. In Handbook of Materials Failure Analysis with Case Studies from the Aerospace and Automotive Industries; Butterworth–Heinemann: Oxford, UK, 2016; pp. 393–432. [Google Scholar]

- Huang, T.; Pan, H.; Sun, W. A sensor fault detection, isolation, and estimation method for intelligent vehicles. Control Eng. Pract. 2023, 139, 105620. [Google Scholar] [CrossRef]

- Rimpas, D.; Papadakis, A.; Samarakou, M. OBD-II sensor diagnostics for monitoring vehicle operation and consumption. Energy Rep. 2020, 6, 55–63. [Google Scholar] [CrossRef]

- Li, Y.; Duan, X.; Fu, J.; Liu, J.; Wang, S.; Dong, H.; Xie, Y. Development of a method for on board measurement of instant engine torque and fuel consumption rate based on direct signal measurement and RGF modelling under vehicle transient operating conditions. Energy 2019, 189, 116218. [Google Scholar] [CrossRef]

- Yao, L.; Xiao, Y.; Gong, X.; Hou, J.; Chen, X. A novel intelligent method for fault diagnosis of electric vehicle battery system based on wavelet neural network. J. Power Sources 2020, 453, 227870. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Lin, H.; Riaz, S.; Elahi, H. Real-time fault diagnosis and fault-tolerant control strategy for Hall sensors in permanent magnet brushless DC motor drives. Electronics 2021, 10, 1268. [Google Scholar] [CrossRef]

- Krishna, K.S.; Kumar, K.S. A review on hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2015, 52, 907–916. [Google Scholar] [CrossRef]

- Zio, E. Prognostics and Health Management (PHM): Where are we and where do we (need to) go in theory and practice. Reliab. Eng. Syst. Saf. 2022, 218, 108119. [Google Scholar] [CrossRef]

- Meng, H.; Li, Y. A review on prognostics and health management (PHM) methods of lithium-ion batteries. Renew. Sustain. Energy Rev. 2019, 116, 109405. [Google Scholar] [CrossRef]

- Khan, S.; Tsutsumi, S.; Yairi, T.; Nakasuka, S. Robustness of AI-based prognostic and systems health management. Annu. Rev. Control 2021, 51, 130–152. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A.Y. Digital twin driven prognostics and health management for complex equipment. CIRP Ann. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Nor, A.K.; Pedapati, S.R.; Muhammad, M. Reliability engineering applications in electronic, software, nuclear and aerospace industries: A 20 year review (2000–2020). Ain Shams Eng. J. 2021, 12, 3009–3019. [Google Scholar] [CrossRef]

- Che, C.; Wang, H.; Fu, Q.; Ni, X. Combining multiple deep learning algorithms for prognostic and health management of aircraft. Aerosp. Sci. Technol. 2019, 94, 105423. [Google Scholar] [CrossRef]

- Sun, Y.; Lu, Y.; Bao, J.; Tao, F. Prognostics and health management via long short-term digital twins. J. Manuf. Syst. 2023, 68, 560–575. [Google Scholar] [CrossRef]

- Milićević, S.; Blagojević, I.; Milojević, S.; Bukvić, M.; Stojanović, B. Numerical Analysis of Optimal Hybridization in Parallel Hybrid Electric Powertrains for Tracked Vehicles. Energies 2024, 17, 3531. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Guo, P.; Guo, S.; Yang, Z.; Pei, P. Bibliometric analysis of prognostics and health management (PHM) in hydrogen fuel cell engines. Int. J. Hydrogen Energy 2022, 47, 34216–34243. [Google Scholar] [CrossRef]

- Sujesh, G.; Ramesh, S. Modeling and control of diesel engines: A systematic review. Alex. Eng. J. 2018, 57, 4033–4048. [Google Scholar] [CrossRef]

- Banta, N.J.I.; Njionou, P.; Offole, F.; Mouangue, R. Machine learning models for the prediction of turbulent combustion speed for hydrogen-natural gas spark ignition engines. Heliyon 2024, 10, e30497. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhang, K.; Deng, K.; Cui, Y. Real-time engine model development based on time complexity analysis. Int. J. Engine Res. 2022, 23, 2094–2104. [Google Scholar] [CrossRef]

- Lu, N.; Liu, S.; Du, J.; Fang, Z.; Dong, W.; Tao, L.; Yang, Y. Grey relational analysis model with cross-sequences and its application in evaluating air quality index. Expert Syst. Appl. 2023, 233, 120910. [Google Scholar] [CrossRef]

- Geum, Y.; Cho, Y.; Park, Y. A systematic approach for diagnosing service failure: Service-specific FMEA and grey relational analysis approach. Math. Comput. Model. 2011, 54, 3126–3142. [Google Scholar] [CrossRef]

- Balu Mahandiran, S.; Sekar, P. Multi-objective optimization of process parameters in dry sliding wear characteristics of Al/sic composites using Taguchi grey relation analysis. Mater. Today Proc. 2021, 45, 1882–1886. [Google Scholar]

- Sarwar, U.; Muhammad, M.; Mokhtar, A.A.; Khan, R.; Behrani, P.; Kaka, S. Hybrid intelligence for enhanced fault detection and diagnosis for industrial gas turbine engine. Results Eng. 2024, 21, 101841. [Google Scholar] [CrossRef]

- Peng, Y. Research on Fault Diagnosis Algorithms for Hybrid Power Systems. Ph.D. Dissertation, Jilin University, Changchun, China, 2015. [Google Scholar]

- ISO 26262; Road Vehicles—Functional Safety. International Organization for Standardization: Geneva, Switzerland, 2018.

- Liu, Z.; Chang, G.; Yuan, H.; Tang, W.; Xie, J.; Wei, X.; Dai, H. Adaptive look-ahead model predictive control strategy of vehicular PEMFC thermal management. Energy 2023, 285, 129176. [Google Scholar] [CrossRef]

- Yan, F.J.; Wang, J.M.; Huang, K.S. Hybrid electric vehicle model predictive control torque-split strategy incorporating engine transient characteristics. IEEE Trans. Veh. Technol. 2012, 61, 2458–2467. [Google Scholar] [CrossRef]

- Morari, M.; Garcia, C.E.; Prett, D.M. Model predictive control: Theory and practice. Automatica 1989, 25, 335–348. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Li, J.; Sun, Q.; Wang, H. NGCU: A new RNN model for time-series data prediction. Big Data Res. 2022, 27, 100296. [Google Scholar] [CrossRef]

- Sundermeyer, M.; Hermann, N.; Schluter, R. From feedforward to recurrent LSTM neural networks for language modeling. IEEE/ACM Trans. Audio Speech Lang. Process. 2015, 23, 517–529. [Google Scholar] [CrossRef]

- Xu, D.; Yao, C.; Ma, C.; Song, E. Comprehensive performance prediction and optimization of marine dual-fuel engines. J. Intern. Combust. Engine 2022, 40, 403–411. [Google Scholar]

- Lv, Y.; Yang, X.; Li, Y.; Liu, J.; Li, S. Fault detection and diagnosis of marine diesel engines: A systematic review. Ocean Eng. 2024, 294, 116798. [Google Scholar] [CrossRef]

- Xiong, R.; Pan, Y.; Shen, W.; Li, H.; Sun, F. Lithium-ion battery aging mechanisms and diagnosis method for automotive applications: Recent advances and perspectives. Renew. Sustain. Energy Rev. 2020, 131, 110048. [Google Scholar] [CrossRef]

- Machlev, R. EV battery fault diagnostics and prognostics using deep learning: Review, challenges & opportunities. J. Energy Storage 2024, 83, 110614. [Google Scholar]

| Parameter | Value |

|---|---|

| Curb weight (kg) | 18,000 |

| Drag coefficient (-) | 0.55 |

| Rolling resistance coefficient (-) | 0.0095 |

| Windward area (m2) | 6.6 |

| Tire radius (m) | 0.473 |

| Final drive ratio | 7.5 |

| Maximum engine speed (r/min) | 2500 |

| Motor rated power (kW) | 60 |

| Motor peak power (kW) | 168 |

| Motor maximum torque (N·m) | 2000 |

| Battery rated voltage (V) | 400 |

| Battery rated capacity (Ah) | 60 |

| Diesel engine maximum power (kW) | 147 |

| Diesel engine maximum torque (N·m) | 692 |

| Mode | Battery | ICE | Switching Condition |

|---|---|---|---|

| Electric-only | discharge | Off | |

| Diesel-only | Off | On | |

| Hybrid | discharge | On | |

| In-motion charging | charge | On | |

| Regenerative braking | charge | Off |

| Component | Feature Signal | Unit | |

|---|---|---|---|

| Diesel engine | Exhaust temperature | °C | |

| Accelerator pedal position | % | ||

| Intake temperature | °C | ||

| Intake pressure | kPa | ||

| Battery | Main voltage | V | |

| Main current | A | ||

| Battery temperature | °C | ||

| Vehicle | Vehicle speed | Km/h | |

| Normal | Battery Degradation | ||

|---|---|---|---|

| Rule-Based | LSTM-MPC | ||

| Battery energy consumption (kW·h) | 0.59 | 0.59 | 0.28 |

| Fuel consumption (g) | 138.80 | 142.30 | 191.30 |

| Overall energy consumption (L/100 km) | 27.51 | 29.55 | 30.81 |

| Normal | Battery Degradation | ||

|---|---|---|---|

| Rule-Based | LSTM-MPC | ||

| Battery energy consumption (kW·h) | 0.59 | 0.68 | 1.00 |

| Fuel consumption (g) | 138.80 | 144.40 | 103.97 |

| Overall energy consumption (L/100 km) | 27.51 | 29.56 | 28.27 |

| Normal | Battery Degradation | ||

|---|---|---|---|

| Rule-Based | LSTM-MPC | ||

| Battery energy consumption (kW·h) | 0.59 | 0.65 | 0.52 |

| Fuel consumption (g) | 138.80 | 150.13 | 172.88 |

| Overall energy consumption (L/100 km) | 27.51 | 31.73 | 32.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.; Liu, B.; Fan, W.; Zhong, D.; Liu, L. Degradation Diagnosis and Control Strategy for a Diesel Hybrid Powertrain Considering State of Health. Energies 2024, 17, 5413. https://doi.org/10.3390/en17215413

Tang J, Liu B, Fan W, Zhong D, Liu L. Degradation Diagnosis and Control Strategy for a Diesel Hybrid Powertrain Considering State of Health. Energies. 2024; 17(21):5413. https://doi.org/10.3390/en17215413

Chicago/Turabian StyleTang, Jingxian, Bolan Liu, Wenhao Fan, Dawei Zhong, and Liang Liu. 2024. "Degradation Diagnosis and Control Strategy for a Diesel Hybrid Powertrain Considering State of Health" Energies 17, no. 21: 5413. https://doi.org/10.3390/en17215413

APA StyleTang, J., Liu, B., Fan, W., Zhong, D., & Liu, L. (2024). Degradation Diagnosis and Control Strategy for a Diesel Hybrid Powertrain Considering State of Health. Energies, 17(21), 5413. https://doi.org/10.3390/en17215413