The Impact of Post-Furnace Steel Processing Equipment on Reducing Voltage Fluctuations Caused by Arc Furnaces

Abstract

1. Introduction

- Pstn corresponds to the flicker level induced by the n-th disrupting receiver.

- m = 4: Used only for the summation of voltage changes due to arc furnaces specifically run to avoid coincident melts;

- m = 3.2: This choice matches the slope of the straight part of the Pst = 1 curve;

- m = 3: This is used for most types of voltage changes where the risk of coincident voltage occurring is small. The vast majority of studies combining unrelated disturbances will fall into this category, and it should be used where there is any doubt over the magnitude of the risk of coincident voltage changes occurring;

- m = 2: This is used where coincident stochastic noise is likely to occur, e.g., coincident melts on arc furnaces;

- m = 1: The resultant Pst will approach the value given by this coefficient when there are very high occurrences of coincident voltage changes.

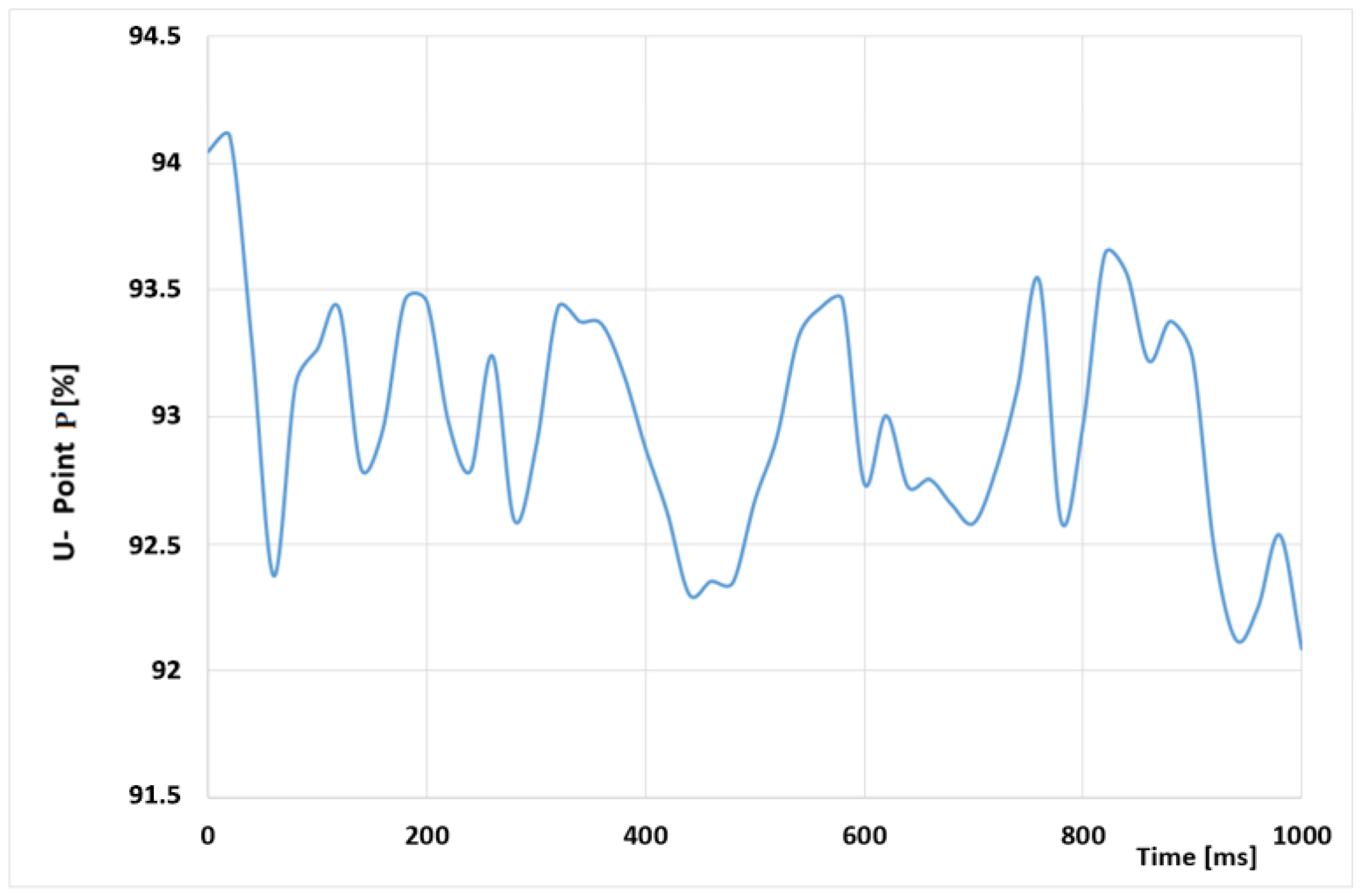

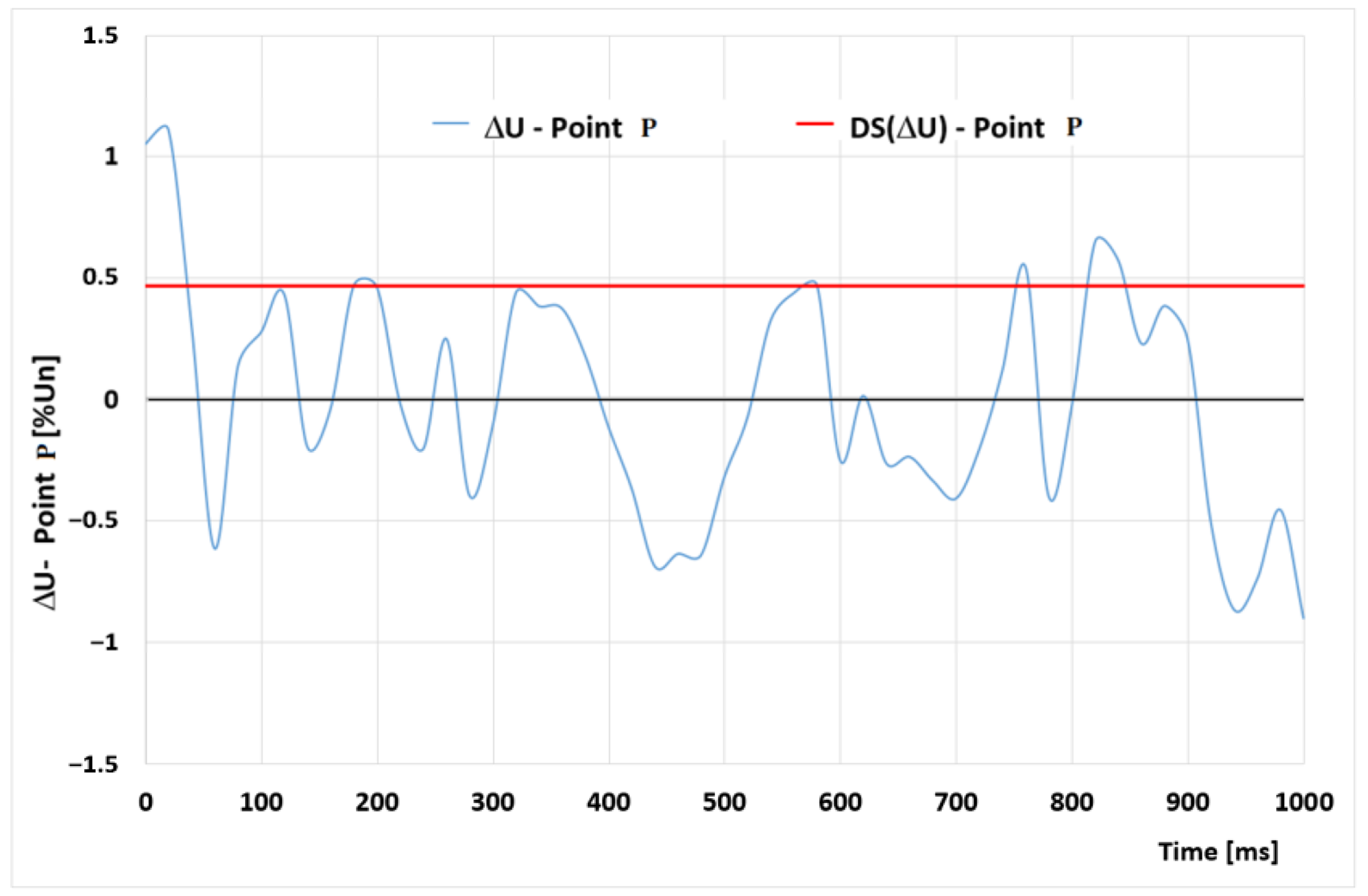

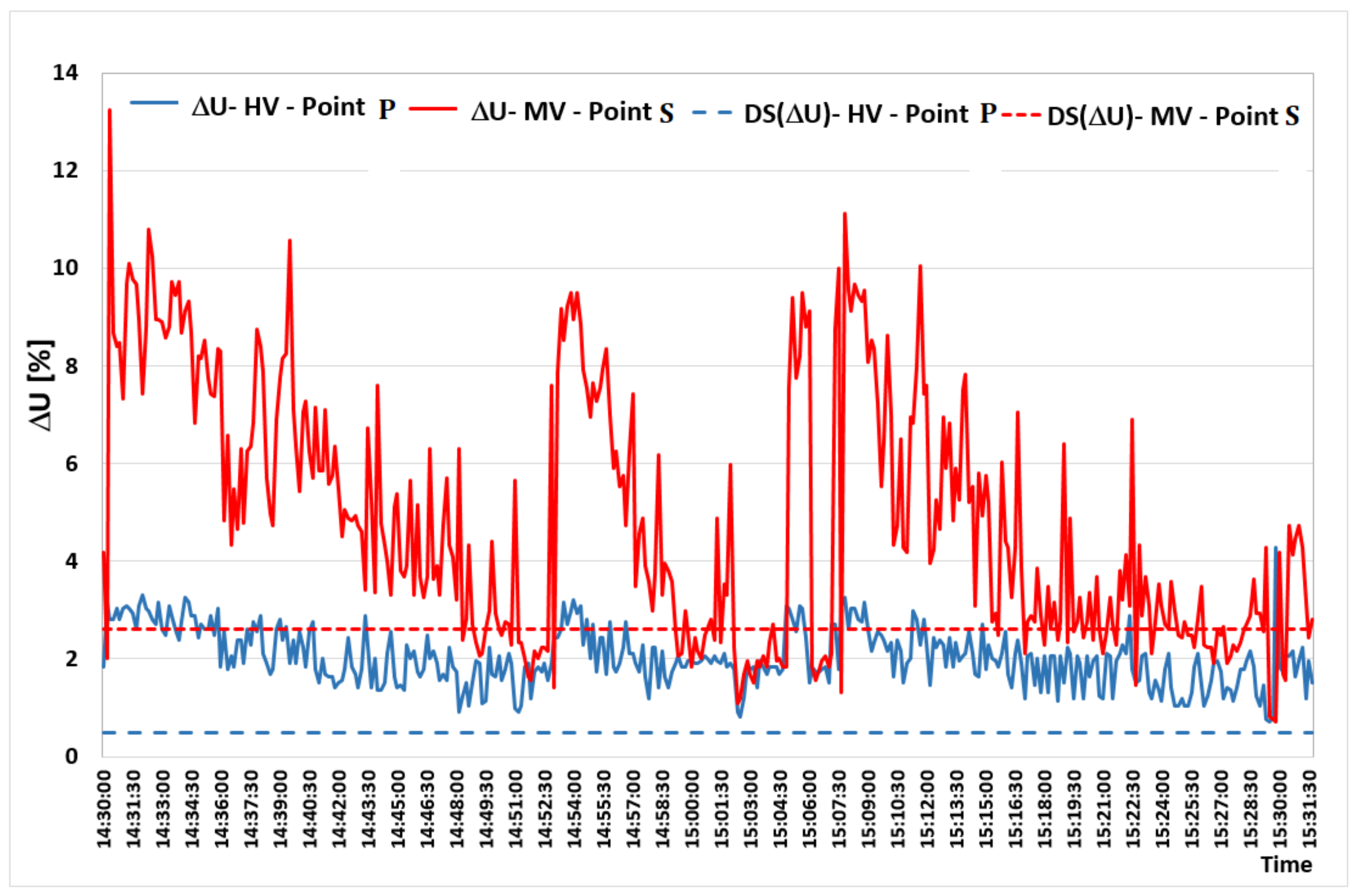

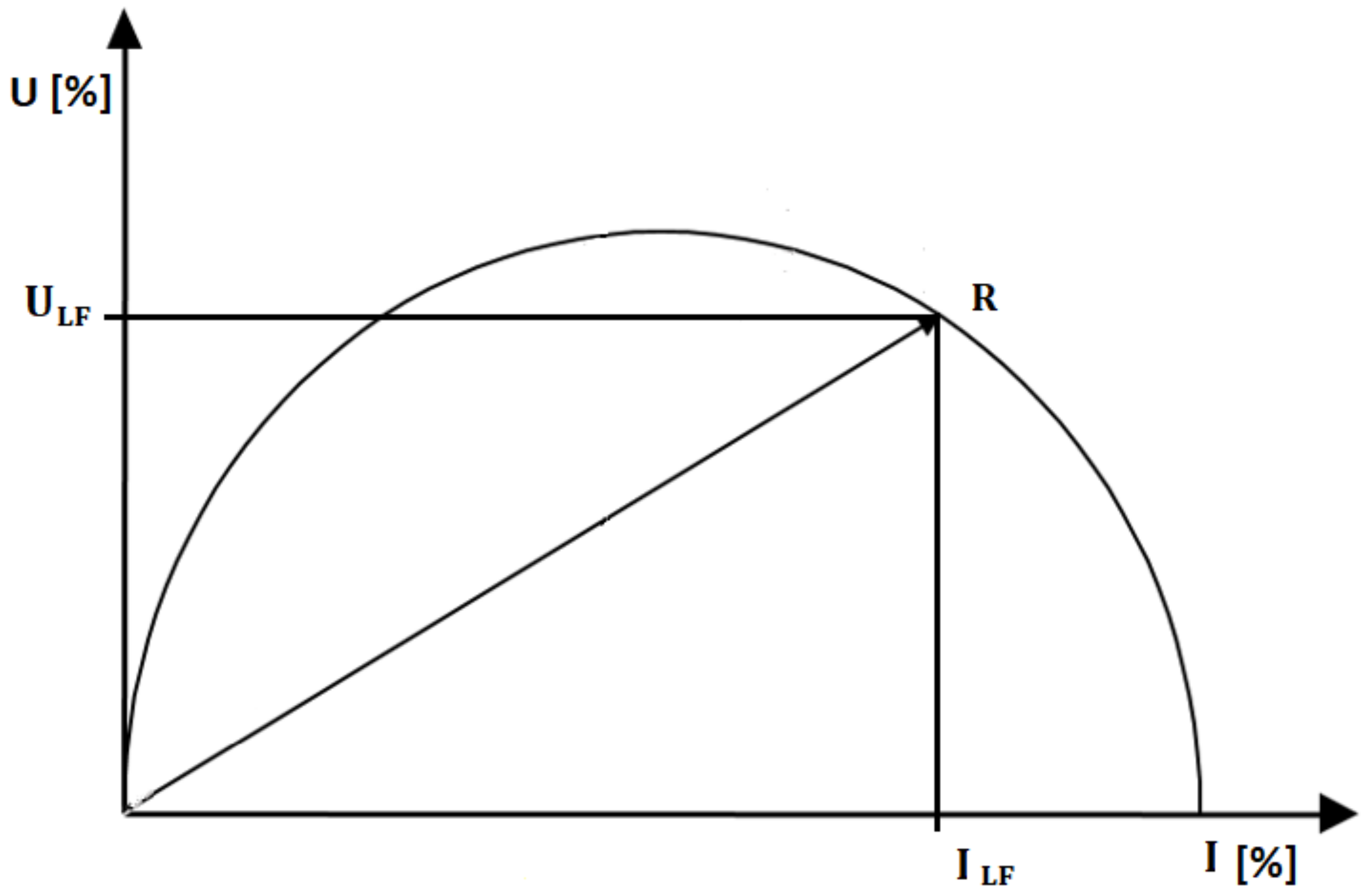

2. Voltage Fluctuations Generated by an Arc Device During Scrap Melting

- SD(U)—standard deviation of voltage

- Ui—value for the i-th rms voltage sample

- Umean—RMS voltage mean for n samples

- n—number of voltage samples.

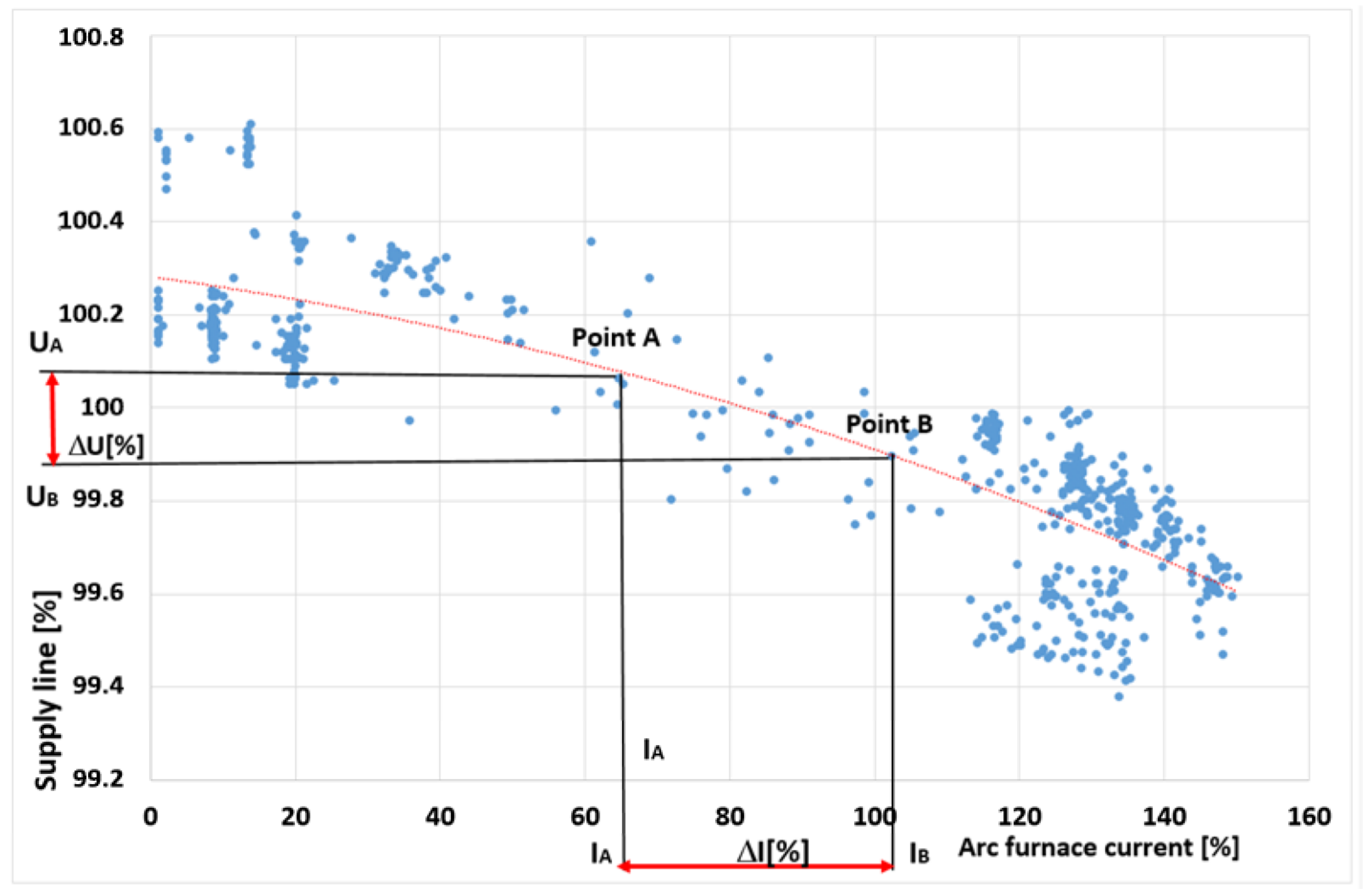

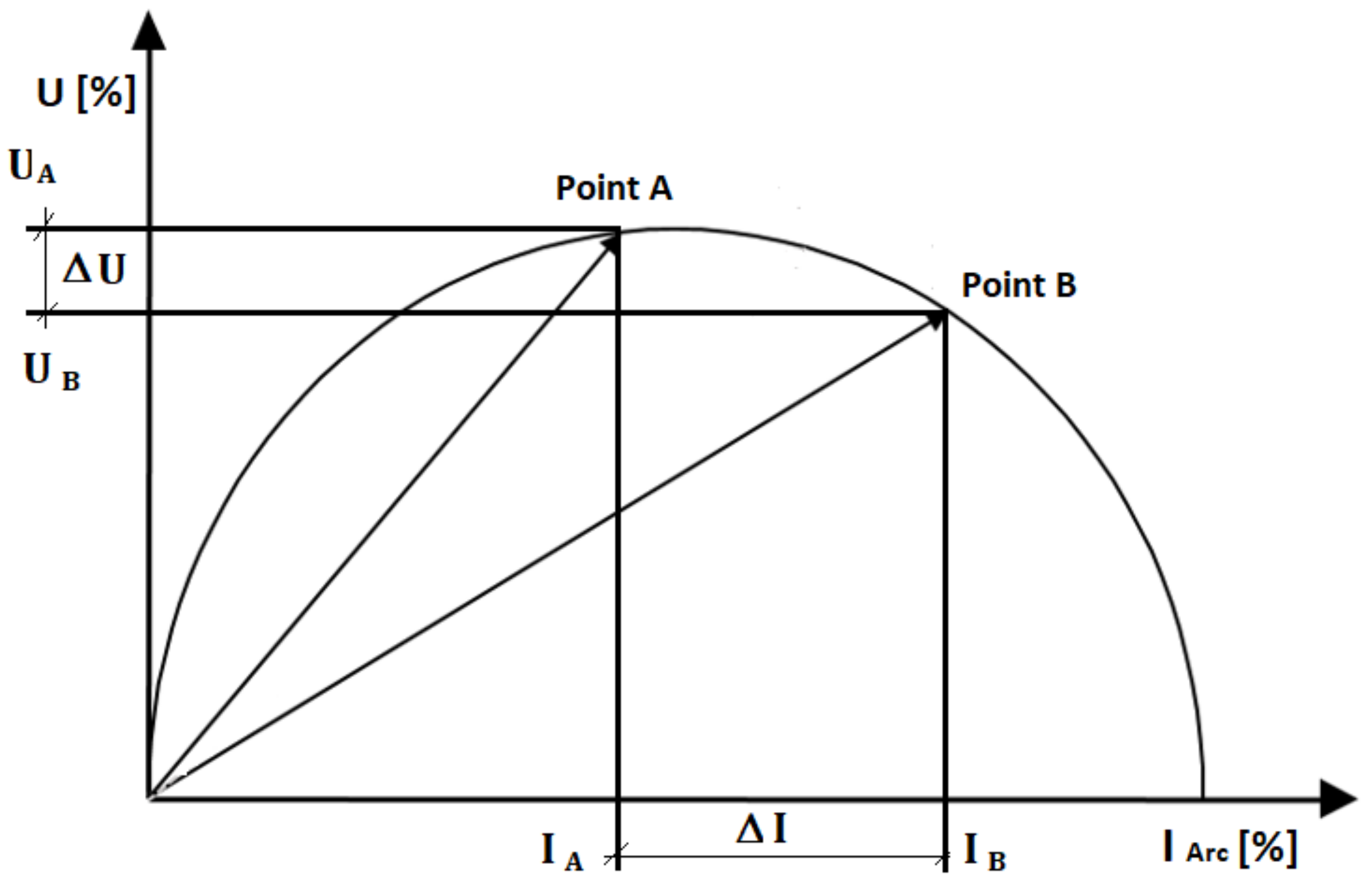

3. Voltage Fluctuations Generated by a Single Arc Furnace—Modeling Studies

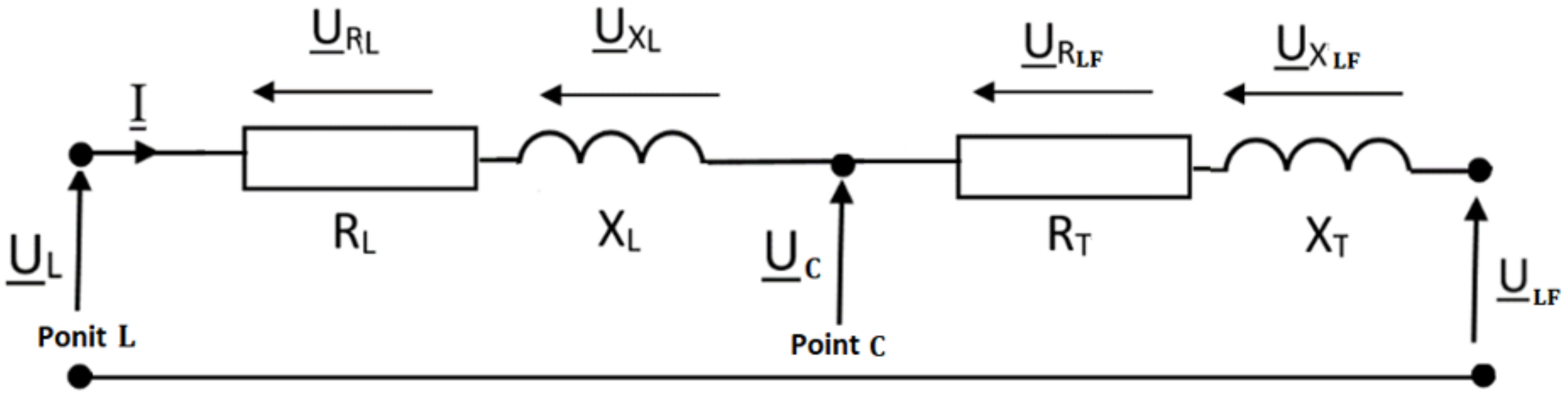

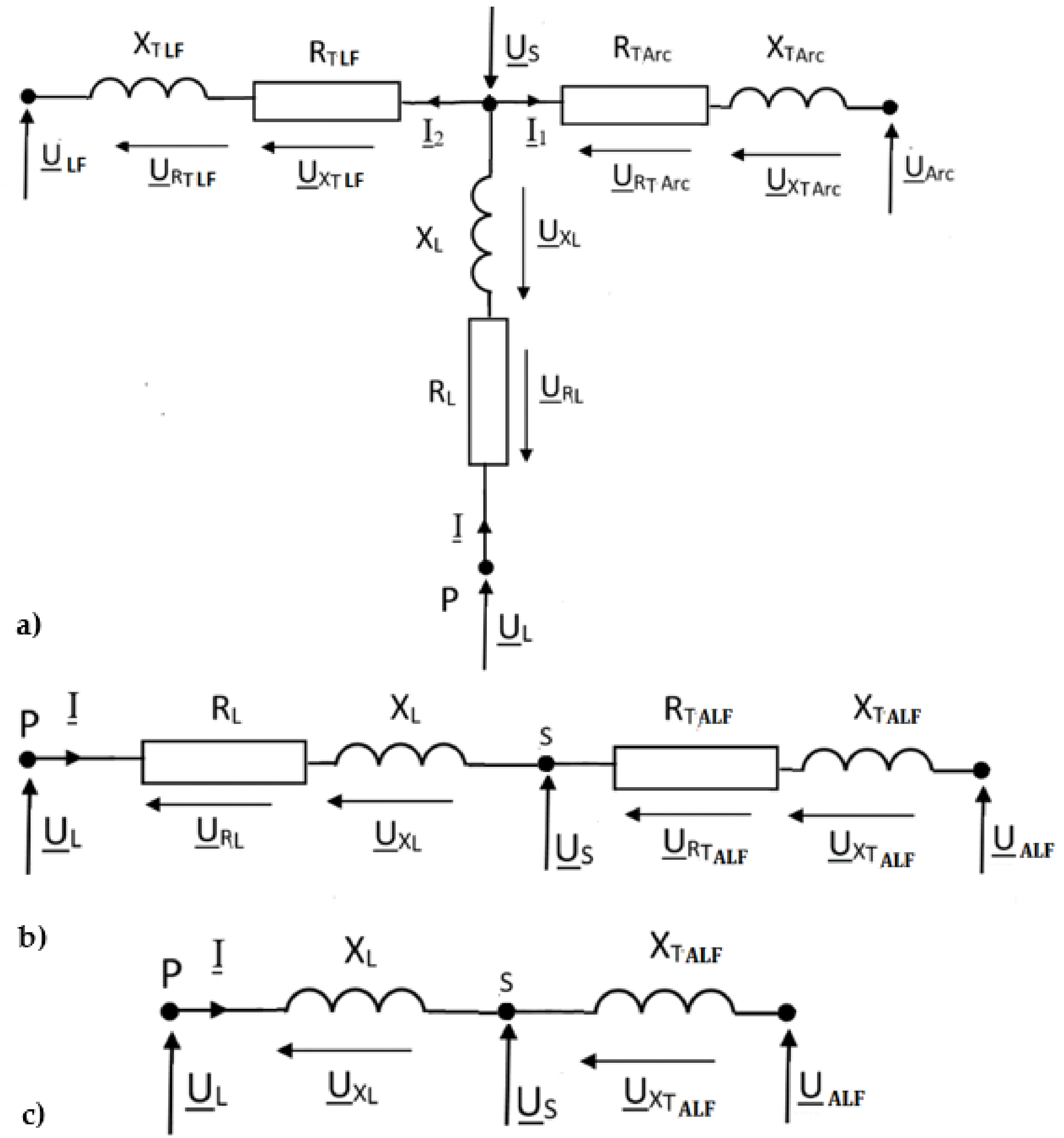

4. Model of the Power Supply System for Devices with Stable Power Consumption

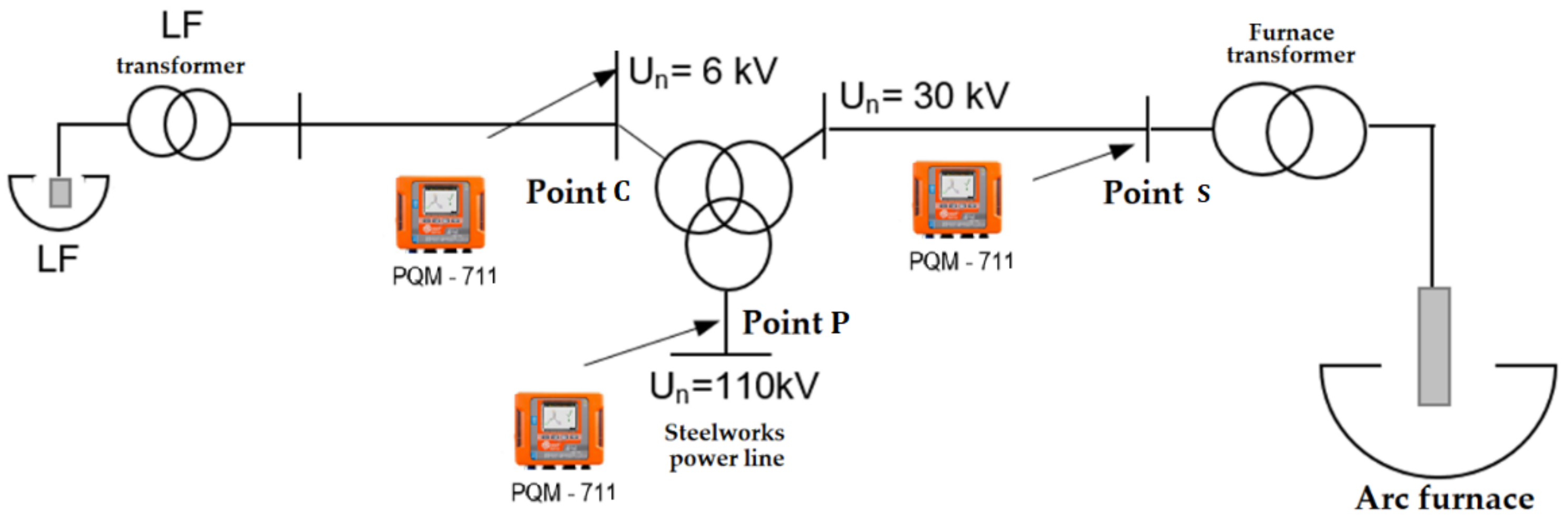

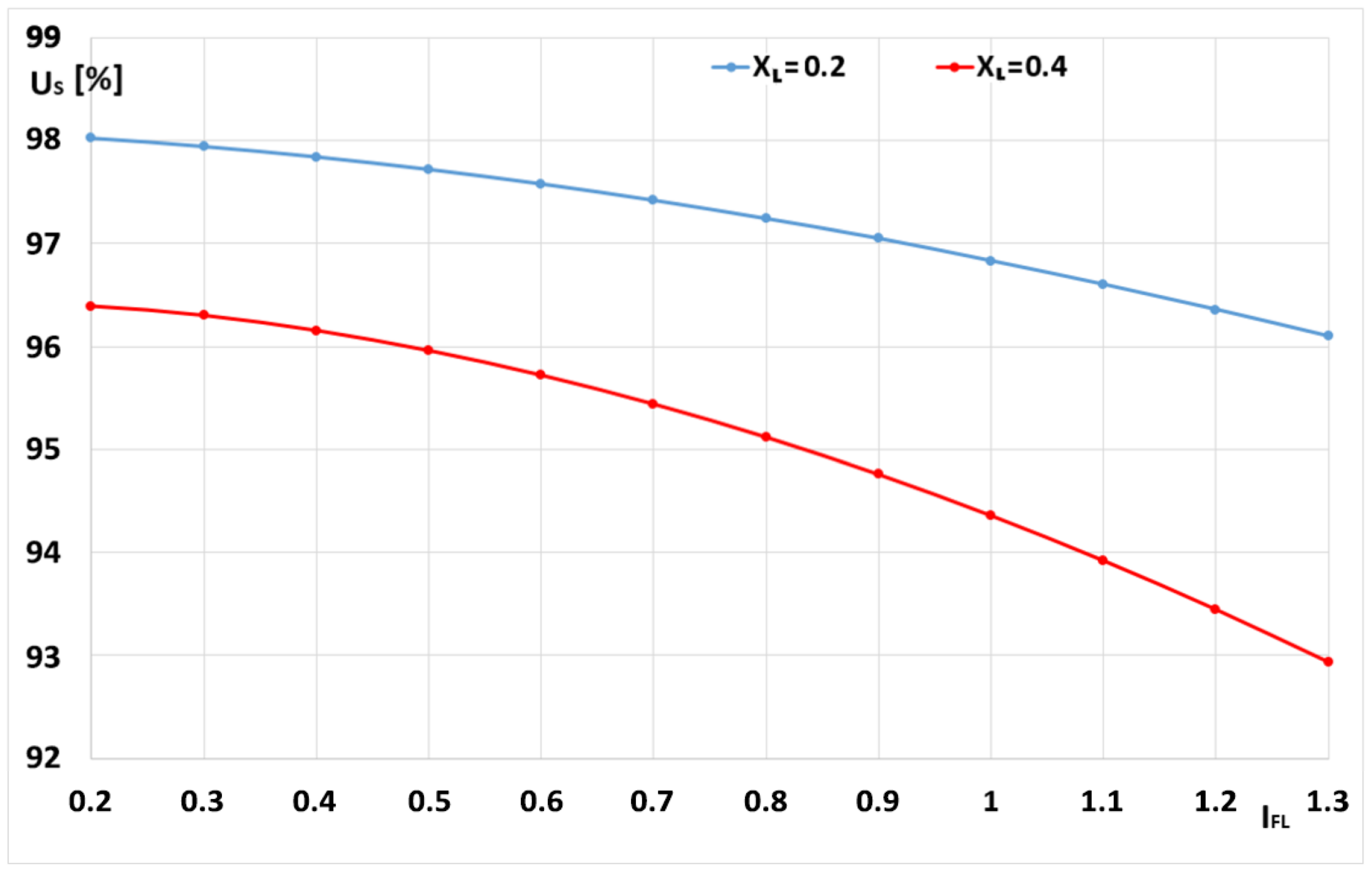

5. Modeling of Voltage Fluctuations in Parallel Operation of Arc Furnace and LF

6. Discussion

7. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| I | arc furnace melting current |

| IFL | ladle furnace current LF |

| IN | nominal current |

| RL | power line resistance |

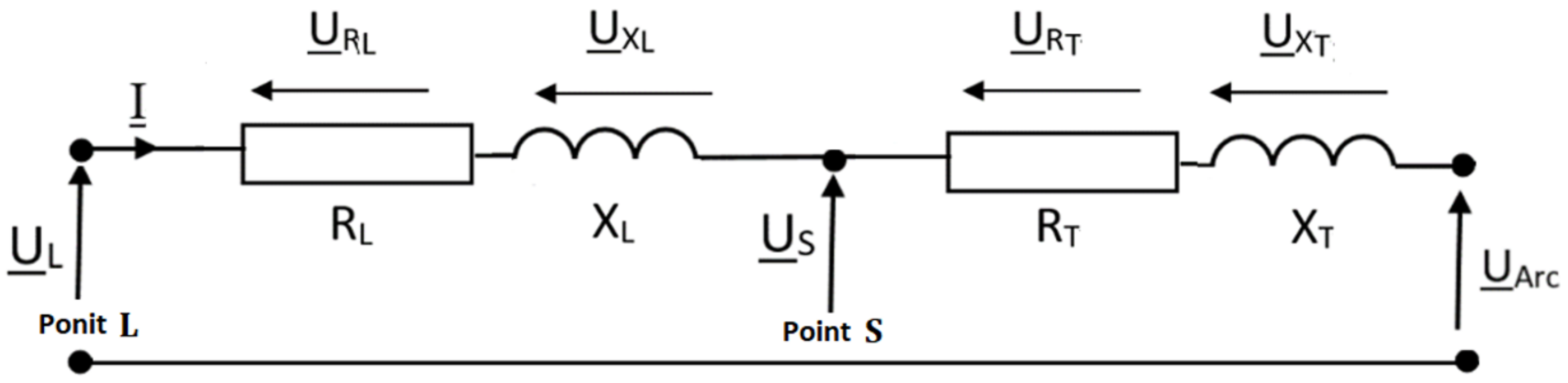

| RT | resistance high-current path with the furnace transformer |

| Scc | short-circuit power line |

| XL | power line reactance |

| XT | reactance high-current path with the furnace transformer |

| SCT | power of the furnace transformer |

| SD(U) | standard deviation of voltage |

| UL | supply voltage |

| UN | rated voltage |

| US | steelworks supply voltage |

| UArc | furnace arc voltage |

| ULF | arc voltage of the ladle furnace LF |

| ΔIAB | arc furnace current fluctuations |

| ΔU | voltage fluctuations |

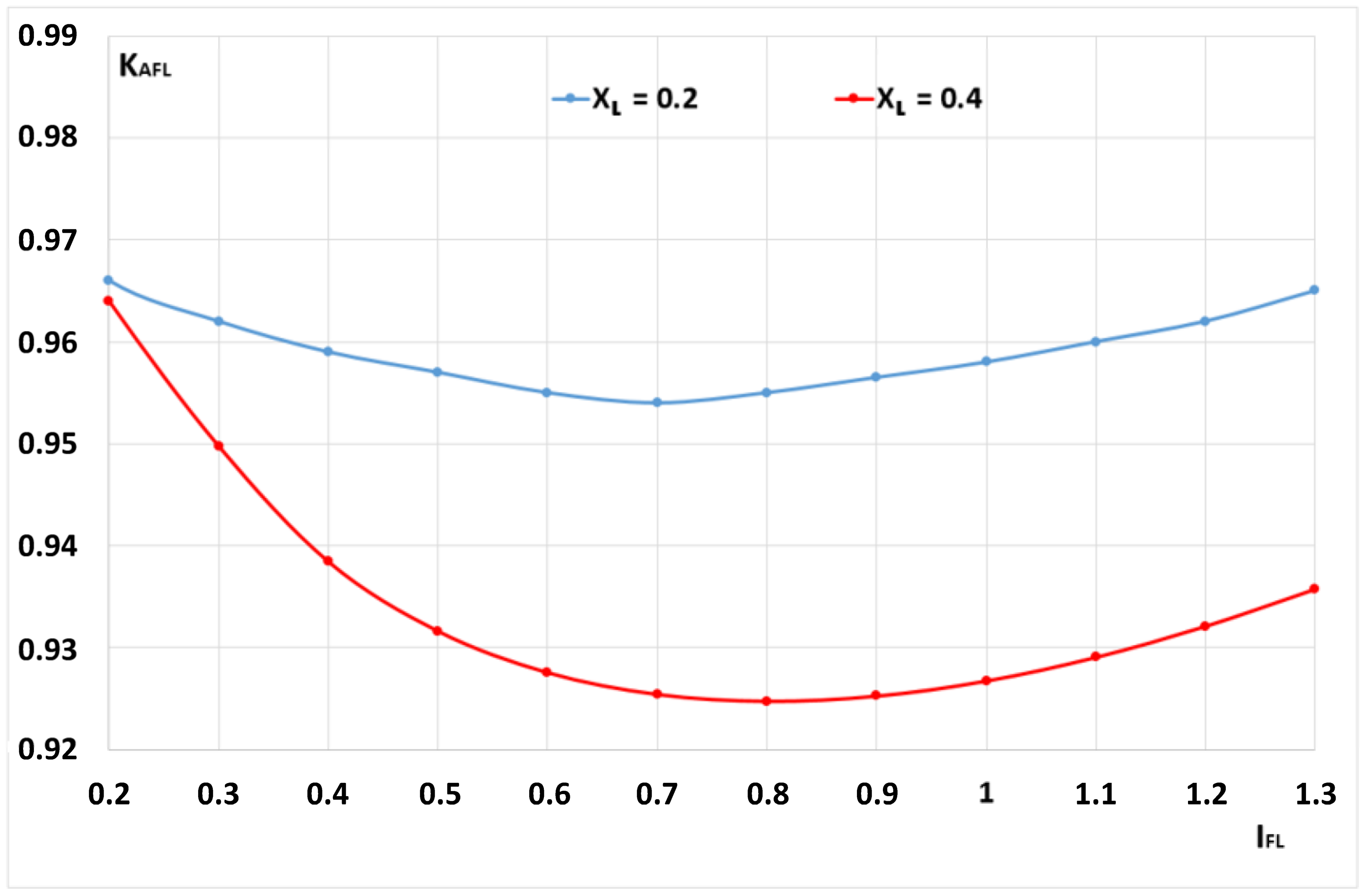

| KAFL | voltage fluctuation reduction factor |

| EAF | electric arc furnace |

| LF | ladle furnace |

| VOD | vacuum oxygen decarburization |

| VAD | vacuum arc degassing |

References

- World Steel in Figures 2023, World Steel Association 2023. Available online: https://worldsteel.org/wp-content/uploads/World-Steel-in-Figures-2023-4.pdf (accessed on 16 September 2024).

- Al Nasser, M.; Karimi-Sibaki, E.; Wu, M.; Redl, C.; Ishmurzind, A.; Voller, N.; Hackl, G.; Kharicha, A. A Numerical Study on the Influence of External Magnetic field on Hydrogen Electric Arc Flow. IOP Conf. Ser. Mater. Sci. Eng. 2024, 1309, 012003. Available online: https://iopscience.iop.org/article/10.1088/1757-899X/1309/1/012003/pdf (accessed on 5 September 2024). [CrossRef]

- Gajdzik, B.; Skoka, W.; Vveinhardt, J. Energy Intensity of Steel Manufactured Utilising EAF Technology as a Function of Investments Made: The Case of the Steel Industry in Poland. Energies 2021, 14, 5152. [Google Scholar] [CrossRef]

- Karbowniczek, M. Electric Arc Furnace Steelmaking; CRC Press: Boca Raton, FL, USA, 2021; ISBN 9780367673482. [Google Scholar] [CrossRef]

- Tenova. Electric Arc Furnaces, A complete range of Leading-edge Products for the Steelmaking Industry. Available online: https://tenova.com/sites/default/files/files/solutions/2021/brochure_Electric%20Arc%20Furnaces.pdf (accessed on 16 September 2024).

- Ioana, A.; NConstantin, N.; PMoldovan, P. Constructive and functional modernization of EAF. IOP Conf. Ser. Mater. Sci. Eng. 2015, 85, 012014. [Google Scholar] [CrossRef]

- Dicker, J. Monitoring of Slag Foaming and other Performance Indicators in an Electric Arc Furnace. Ph.D. Thesis, The University of New South Wales, Faculty of Science, School of Materials Science and Engineering, Sydney, NSW, Australia, 2014. Available online: https://unsworks.unsw.edu.au/entities/publication/46783e11-6025-406a-8976-74983acb5ef8/full (accessed on 5 September 2024). [CrossRef]

- Samet, H.; Farjah, E.; Zahra Sharifi, Z. A dynamic, nonlinear and time-varying model for electric arc furnace. Int. Trans. Electr. Energy Syst. 2015, 25, 2165–2180. [Google Scholar] [CrossRef]

- Skrzyniecki, K.; Kolasa, A.; Cegielski, P. Study of static and dynamic characteristics of welding power source-arc systems. Weld. Int. 2015, 29, 865–867. [Google Scholar] [CrossRef]

- Bhonsle, D.C.; Kelkar, R.B. Simulation of Electric Arc Furnace Characteristics for Voltage Flicker study using MATLAB. In Proceedings of the International Conference on Recent Advancements in Electrical, Electronics and Control Engineering, Sivakasi, India, 15–17 December 2011. [Google Scholar]

- Yan, Q.; Aoki, M. Suppression of voltage fluctuation by utilizing consumer-side energy storage devices in PV connected distribution system. IFAC-PaperOnLine 2018, 51, 432–437. [Google Scholar] [CrossRef]

- Albert, H.; Golovanov, N.; Elefterescu, L. Propagation of disturbances as voltage fluctuations in transmission networks. Probl. Energeticii Reg. 2016, 2016, 48–54. [Google Scholar]

- Hanzelka, Z. Electricity Supply Quality. RMS Voltage Disturbance, (Jakość Dostawy Energii Elektrycznej. Zaburzenia Wartości Skutecznej Napięcia); Wydawnictwa AGH: Kraków, Poland, 2013. (In Polish) [Google Scholar]

- Kiyoumarsi, A.; Ataei, M.; Hooshmand, R.; Kolagar, A.D. Electric arc furnace voltage flicker mitigation by applying a predictive method with closed loop control of the TCR/FC compensator. J. Electr. Eng. Technol. 2010, 5, 116–128. [Google Scholar] [CrossRef]

- Singh, A.; Singh, R.K.; Singh, A.K. Power Quality Issues of Electric Arc Furnace and their Mitigations—A Review. Int. J. Adv. Eng. Res. Sci. 2017, 4, 22–41. [Google Scholar] [CrossRef]

- Yu, Y.; Ju, P.; Peng, Y.; Lou, B.; Huang, H. Analysis of dynamic voltage fluctuation mechanism in interconnected power grid with stochastic power disturbances. J. Mod. Power Syst. Clean Energy 2020, 8, 38–45. [Google Scholar] [CrossRef]

- Sarma, P.M.; Jayaram Kumar, S.V. Electric Arc furnace flicker mitigation in a steel plant using a Statcom. Int. J. Eng. Sci. Innov. Technol. 2013, 2, 227–231. [Google Scholar]

- Kowalski, Z. Unbalance in Electrical Power Systems; PWN (Polish Scientific Publishers): Warszawa, Poland, 1987. (In Polish) [Google Scholar]

- Popa, G.N.; Iagăr, A.; Diniș, C.M. Considerations on Current and Voltage Unbalance of Nonlinear Loads in Residential and Educational Sectors. Energies 2021, 14, 102. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, J.; Liu, Y.; Sai, X.; Ji, Y. Analysis of unbalanced clustered voltage and control strategy of clustered voltage balancing for cascaded H-bridge STATCOM. J. Mod. Power Syst. Clean Energy 2019, 7, 1697–1708. [Google Scholar] [CrossRef]

- Samet, H.; Golshan, M.E.H. A wide nonlinear analysis of reactive power time series related to electric arc furnaces. Electr. Power Energy Syst. 2012, 36, 127–134. [Google Scholar] [CrossRef]

- Jebaraj, B.S.; Bennet, J.; Kannadasan, R.; Alsharif, M.H.; Kim, M.K.; Aly, A.A.; Ahmed, A.H. Power Quality Enhancement in Electric Arc Furnace Using Matrix Converter and Static VAR Compensator. Electronics 2021, 10, 1125. [Google Scholar] [CrossRef]

- Srivastava, A.; Singh, A. Harmonics generated by Electric Arc Furnace in Electric Power System. J. Phys. Sci. Eng. Technol. 2019, 11, 57–62. Available online: https://smsjournals.com/index.php/SAMRIDDHI/article/view/993 (accessed on 10 September 2024). [CrossRef][Green Version]

- Beites, L.F.; Mayordomo, J.G. Harmonics, Interharmonics and Unbalances of Arc Furnaces: A New Frequency Domain Approach. IEEE Trans. Power Deliv. 2001, 16, 661–668. Available online: https://ieeexplore.ieee.org/abstract/document/956754 (accessed on 10 September 2024). [CrossRef]

- Emre Durna, E.; Gerçek, C.Ö.; Salor, O.; Ermis, M. Suppression of the Second Harmonic Subgroup Injected by an AC EAF: Design Considerations and Performance Estimation of a Shunt AP. Electronics 2018, 7, 53. [Google Scholar] [CrossRef]

- Varan, M.; Uyaroglu, Y. Elimination of harmonic induced viable bifurcations with TCSC for AC-fed electric arc furnaces. J. Electr. Eng. 2019, 63, 303–309. [Google Scholar] [CrossRef]

- Gol, M.; Salor, O.; Alboyaci, B.; Mutluer, B.; Cadirci, I.; Ermi, M. A New Field-Data-Based EAF Model for Power Quality Studies. IEEE Trans. Ind. Appl. 2010, 46, 1230–1242. Available online: https://ieeexplore.ieee.org/document/5438736 (accessed on 10 September 2024). [CrossRef]

- Kaiser, F.; Reichel, T.; Echterhof, T.; Mier, D.; Unamuno, I.; Pfeifer, H. Decreasing the environmental impact of the electric steel making process through implementation of furnace retrofitting solutions. IOP Conf. Ser. Mater. Sci. Eng. 2024, 1309, 012009. Available online: https://iopscience.iop.org/article/10.1088/1757-899X/1309/1/012009/pdf (accessed on 5 September 2024). [CrossRef]

- Komolova, O.A.; Grigorovich, K.V. Development of LF-software for modeling of refining processes in a ladle–furnace. J. Phys. Conf. Ser. 2019, 1347, 012066. Available online: https://iopscience.iop.org/article/10.1088/1742-6596/1347/1/012066/pdf (accessed on 5 September 2024). [CrossRef]

- Olczykowski, Z. Modeling of Voltage Fluctuations Generated by Arc Furnaces. Appl. Sci. 2021, 11, 3056. [Google Scholar] [CrossRef]

- UIE. Part 5. Flicker and Voltage Fluctuations. In Guide to Quality of Electical Supply for Industrial Installations; Power Quality, Working Group WG 2; UIE: North Andover, MA, USA, 1999. [Google Scholar]

- PN-EN 50160: 23-10; Parameters of the Supply Voltage in the Public Power Networks. Polish Committee of Standardization: Warsaw, Poland, 2023. Available online: https://sklep.pkn.pl/pn-en-50160-2023-10e.html (accessed on 16 September 2024).

- Regulation of the Minister of Climate and Environment of 22 March 2023 on Detailed Conditions for the Operation of the Power System 2023. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20230000819/O/D20230819.pdf (accessed on 16 September 2024). (In Polish)

- Olczykowski, Z. Superposition of Voltage Fluctuations during the Operation of Arc Receivers. Doctoral Dissertation, Warsaw University of Technology, Warsaw, Poland, 2001. [Google Scholar]

- Ramsaur, O.; Treweek, J.E. System capacity required for 3-phase arc furnaces. Trans. Am. Inst. Electr. Engineers. Part III Power Appar. Syst. 1954, 73, 1373–1374. [Google Scholar]

- Ryżniew, J.L.; Minejew, R.W.; Michajew, A.P.; Smelanski, M.J. The Impact of Arc Furnaces on Power Systems; Energia: Moscow, Russia, 1975. [Google Scholar]

- Wciślik, M. The Method of Estimating the Parameters of the Electric arc Path for the Purposes of Controlling the Electrothermal Process; Kielce University of Technology. Electricity: Kielce, Poland, 1992; p. 28. [Google Scholar]

- Design Guidelines for Limiting Voltage Distortions and Fluctuations in 110 kV, Medium and Low Voltage Networks of Professional Power Engineering, Wytyczne Kontroli oraz Ograniczania Odkształcenia i Wahań Napięcia w Sieciach 110 kV, SN i nn Energetyki Zawodowej; zaakceptowane i zalecone do stosowania przez Departament Ministerstwa Górnictwa i Energetyki (znak DE/Grz/87-1828); Instytut Energetyki Warszawa, Zakład Sieci Rozdzielczych Katowice: Warszawa, Poland, 1987. (In Polish)

- Wąsowski, A. Interaction of Arc Furnaces Operated in Parallel and the Power System; WSI: Radom, Poland, 1979. [Google Scholar]

| Arc | Arc + Arc | Arc + LF |

|---|---|---|

| Parameters of the power supply network and the arc furnace | ||

| UL = 100 | UL = 100 | UL = 100 |

| RL = 0.04 | RL = 0.04 | RL = 0.04 |

| XL = 0.2 | XL = 0.2 | XL = 0.2 |

| RT = 1.5 | RT = 1.5 | RT = 1.5 |

| XT = 5 | XT = 5 | XT = 5 |

| IA = 0.9IN | IA = 0.9IN | IA = IN |

| IB = 1.5IN | IB = 1.5IN | IB = IN |

| Calculation results | ||

| USArc(mean) = 98.10 | US2Arc(mean) = 96.29 | USAFL(mean) = 96.35 |

| DS(USArc) = 0.775 | DS(US2Arc) = 1.06 | DS(USAFL) = 0.748 |

| - | K2ARC = 1.367 | KAFL = 0.965 |

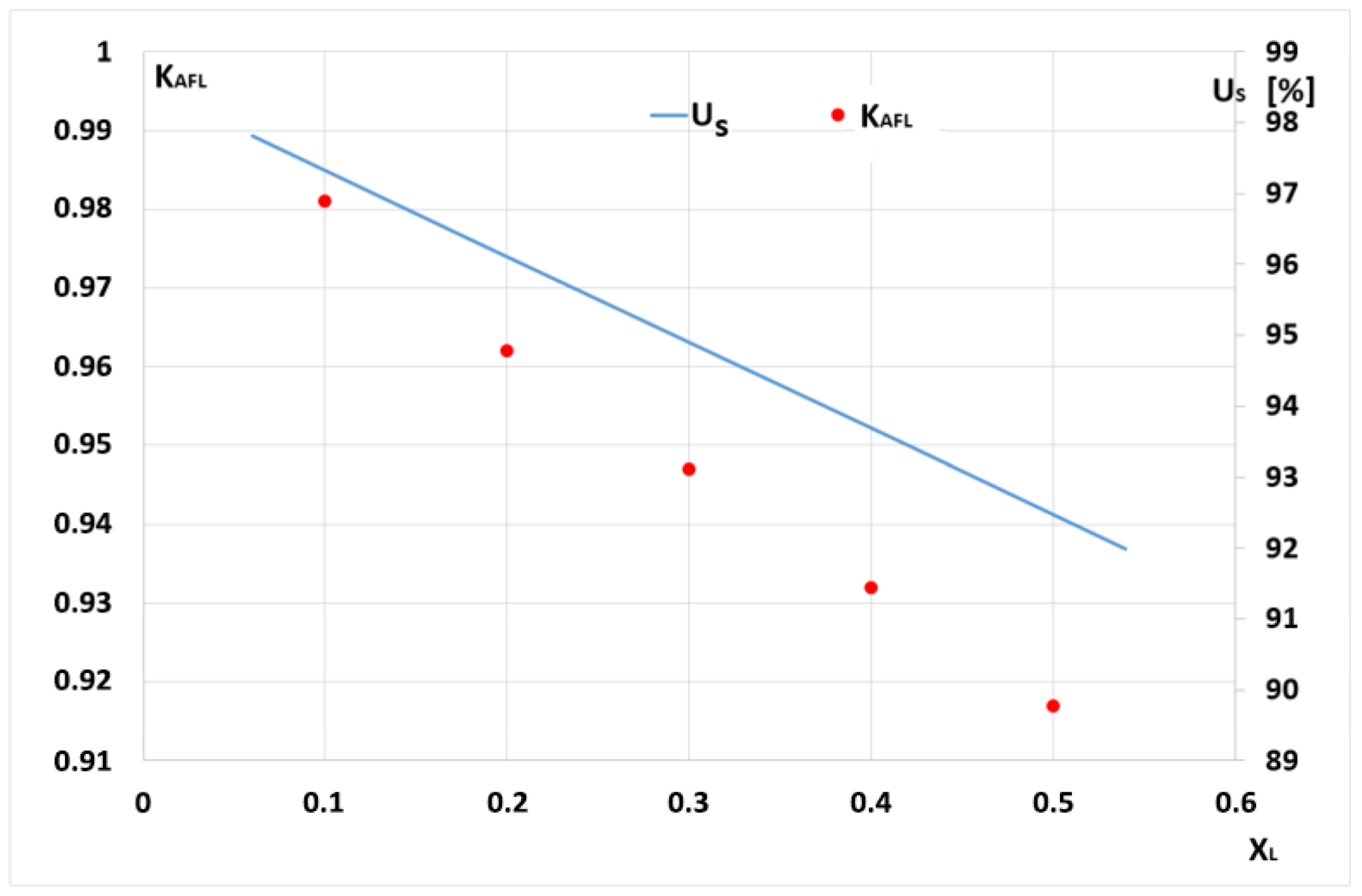

| XL | Us | DS(UArc) | DS(UAFL) | KAFL |

|---|---|---|---|---|

| 0.1 | 97.80 | 0.4 | 0.39 | 0.98 |

| 0.2 | 96.35 | 0.77 | 0.74 | 0.96 |

| 0.3 | 94.90 | 1.16 | 1.10 | 0.94 |

| 0.4 | 93.44 | 1.57 | 1.46 | 0.93 |

| 0.5 | 91.98 | 1.99 | 1.82 | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olczykowski, Z. The Impact of Post-Furnace Steel Processing Equipment on Reducing Voltage Fluctuations Caused by Arc Furnaces. Energies 2024, 17, 5360. https://doi.org/10.3390/en17215360

Olczykowski Z. The Impact of Post-Furnace Steel Processing Equipment on Reducing Voltage Fluctuations Caused by Arc Furnaces. Energies. 2024; 17(21):5360. https://doi.org/10.3390/en17215360

Chicago/Turabian StyleOlczykowski, Zbigniew. 2024. "The Impact of Post-Furnace Steel Processing Equipment on Reducing Voltage Fluctuations Caused by Arc Furnaces" Energies 17, no. 21: 5360. https://doi.org/10.3390/en17215360

APA StyleOlczykowski, Z. (2024). The Impact of Post-Furnace Steel Processing Equipment on Reducing Voltage Fluctuations Caused by Arc Furnaces. Energies, 17(21), 5360. https://doi.org/10.3390/en17215360