Methanol Equilibrium Curves of Power Transformer Oil–Paper Insulation

Abstract

1. Introduction

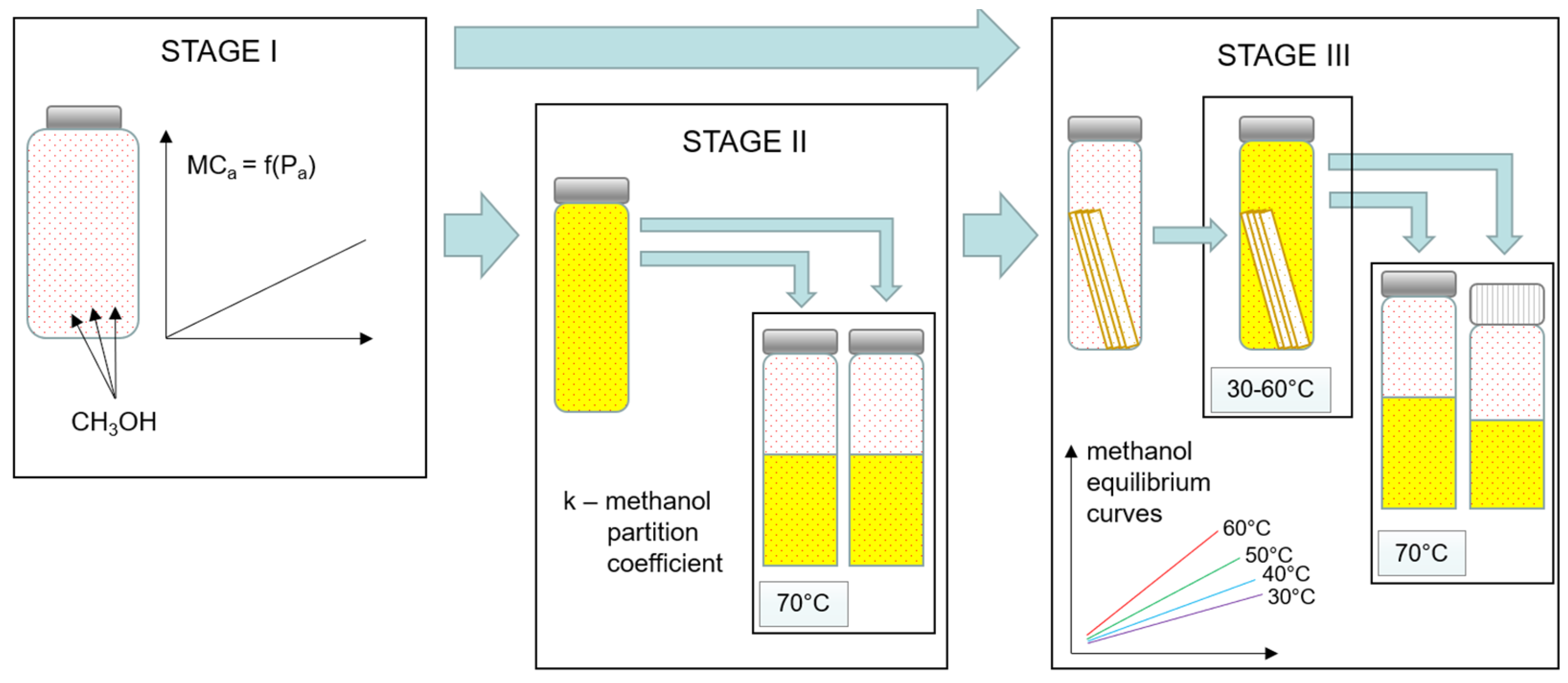

2. Materials and Methods

3. Results

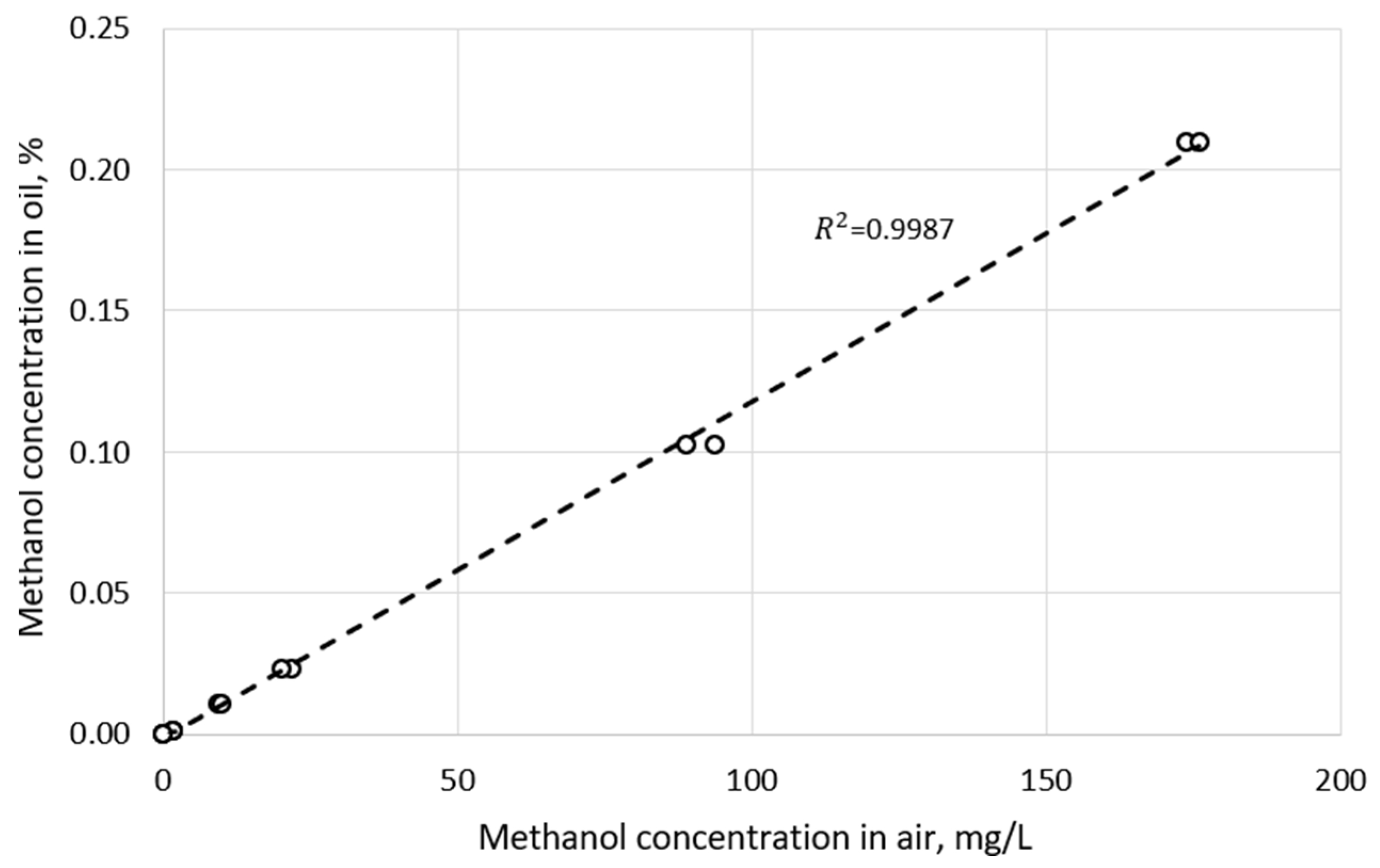

3.1. Measurement of Methanol Content in Air

3.2. Determination of Methanol Content in Oil–Methanol Partition Coefficient Between Oil and Air

3.3. Methanol Equilibrium Curves of Oil–Paper Insulation

4. Discussion

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Arsad, S.R.; Ker, P.J.; Jamaludin, M.Z.; Choong, P.Y.; Lee, H.J.; Thiviyanathan, V.A.; Yang Ghazali, Y.Z. Water Content in Transformer Insulation System: A Review on the Detection and Quantification Methods. Energies 2023, 16, 1920. [Google Scholar] [CrossRef]

- Emsley, A.M.; Heywood, R.J.; Ali, M.; Xiao, X. Degradation of cellulosic insulation in power transformers. Part 4: Effects of aging on the tensile strength of paper. IEE Proc.-Sci. Meas. Technol. 2000, 147, 285–290. [Google Scholar] [CrossRef]

- Fofana, I.; Borsi, H.; Gockenbach, G.; Farzaneh, M. Ageing of Cellulose in Mineral-Oil Insulated Transformers; Cigré Technical Brochure 323; International Council on Large Electric Systems (CIGRE): Paris, France, 2007. [Google Scholar]

- Jiang, J.P.; Du, B.X.; Cavallini, A. Effect of moisture migration on surface discharge on oil-pressboard of power transformers under cooling. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1743–1751. [Google Scholar] [CrossRef]

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture Migration in an Oil-Paper Insulation System in Relation to Online Partial Discharge Monitoring of Power Transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef]

- Gmati, G.; Rao, U.M.; Fofana, I.; Picher, P.; Arroyo-Fernàndez, O.; Rebaine, D. Bubbling Phenomena in Liquid-Filled Transformers: Background and Assessment. Energies 2023, 16, 3829. [Google Scholar] [CrossRef]

- Ariannik, M.; Rezaei-Zare, A.; Kuhnke, M.; Werle, P. A Comparison Between Bubble Formation on Kraft and Thermally Upgraded Papers in Synthetic Ester. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1566–1572. [Google Scholar] [CrossRef]

- Yang, C.; Zhao, T.; Liu, Y.; Zhu, W.; Gu, Z. Prediction Model of Bubble Formation in Oil-Paper Insulation Based on the ITBE Envelope. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 1735–1744. [Google Scholar] [CrossRef]

- Betie, A.; Meghnefi, F.; Fofana, I.; Yeo, Z. Modeling the Insulation Paper Drying Process from Thermogravimetric Analyses. Energies 2018, 11, 517. [Google Scholar] [CrossRef]

- Oommen, T.V.; Prevost, T.A. Cellulose insulation in oil-filled power transformers: Part II maintaining insulation integrity and life. IEEE Electr. Insul. Mag. 2006, 22, 5–14. [Google Scholar] [CrossRef]

- Cybulski, M.; Przybyłek, P. The application of a molecular sieve for drying the insulation system of a power transformer in terms of improving its perational reliability. Eksploat. i Niezawodn.–Maint. Reliab. 2022, 24, 502–509. [Google Scholar] [CrossRef]

- Rindlisbacher, G.; von Ah, M. Cut and Dry: Low Frequency Drying Process in Transformer Production Can Cut Energy Costs in Half. ABB Review 2005. Available online: https://library.e.abb.com/public/22f229958625da3ec125707b004c4466/66-69%203M557_ENG72dpi.pdf (accessed on 8 September 2024).

- Koestinger, P.; Aronsen, E.; Boss, P.; Rindlisbacher, G. Practical Experience with the Drying of Power Transformers in the Field, Applying the LFH Technology; Reference: A2-205_2004; International Council on Large Electric Systems (CIGRE): Paris, France, 2004. [Google Scholar]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Ageing of Oil-impregnated Paper in Power Transformers. IEEE Trans. Power Del. 2004, 19, 230–239. [Google Scholar] [CrossRef]

- Przybylek, P.; Gielniak, J. The Use of Methanol Vapour for Effective Drying of Cellulose Insulation. Energies 2023, 16, 4465. [Google Scholar] [CrossRef]

- Jalbert, J.; Gilbert, R.; Tétreault, P.; Morin, B.; Lessard-Déziel, D. Identification of a chemical indicator of the rupture of 1,4-β-glycosidic bonds of cellulose in an oil-impregnated insulating paper system. Cellulose 2007, 14, 295–309. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Lesaint, C.; Martins, M.A.; Bauchemin, C.; Martin, R.; Pagger, E.; Prevost, T.; Jalbert, J.; Lessard, M.C.; Meltzer, L.; et al. Ageing of Liquid Impregnated Cellulose for Power Transformers; Cigré Technical Brochure 738; International Council on Large Electric Systems (CIGRE): Paris, France, 2018; Available online: https://www.e-cigre.org/publications/detail/738-ageing-of-liquid-impregnated-cellulose-for-power-transformers.html (accessed on 22 September 2024).

- Yoshida, H.; Ishioka, Y.; Suzuki, T.; Yanari, T.; Teranishi, T. Degradation of Insulating Materials of Transformers. IEEE Trans. Dielectr. Electr. Insul. EI-22, 795–800. [CrossRef]

- Emsley, A.M. The kinetics and mechanism of degradation of cellulosic insulation in power transformers. Polym. Degrad. Stab. 1994, 44, 343–349. [Google Scholar] [CrossRef]

- Behjat, V.; Emadifar, R.; Pourhossein, M.; Rao, U.M.; Fofana, I.; Najjar, R. Improved Monitoring and Diagnosis of Transformer Solid Insulation Using Pertinent Chemical Indicators. Energies 2021, 14, 3977. [Google Scholar] [CrossRef]

- Ortiz, F.; Fernandez, F.O.; Santisteban, A.; Delgado, F.; Ortiz, A. Estimating the age of power transformers using the concentration of furans in dielectric oil. Renew. Energy Power Qual. J. 2016, 1, 1011–1015. [Google Scholar] [CrossRef]

- Rodriguez-Celis, E.M.; Duchesne, S.; Jalbert, J.; Ryadi, M. Understanding ethanol versus methanol formation from insulating paper in power transformers. Cellulose 2015, 22, 3225–3236. [Google Scholar] [CrossRef]

- Chen, Q.; Sun, W.; Cheng, S.; Huang, G. A review on a novel method for aging evaluation of transformer insulating paper based on methanol. IET Gener. Transm. Dis. 2023, 17, 1955–1971. [Google Scholar] [CrossRef]

- IEC TR 63025; Insulating Liquids—Quantitative Determination of Methanol and Ethanol in Insulating Liquids. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2021.

- Bare, C.E.; Merritt, S.Y. Methanol as an Ageing Marker for In Service Transformers. IEEE Trans. Ind. Appl. 2018, 54, 6598–6602. [Google Scholar] [CrossRef]

- Jalbert, J.; Lessard, M.C. Cellulose chemical markers relationship with insulating paper post-mortem investigations. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3550–3554. [Google Scholar] [CrossRef]

- Aciu, A.-M.; Nițu, M.-C.; Nicola, C.-I.; Nicola, M. Determining the Remaining Functional Life of Power Transformers Using Multiple Methods of Diagnosing the Operating Condition Based on SVM Classification Algorithms. Machines 2024, 12, 37. [Google Scholar] [CrossRef]

- Fu, Q.; Peng, L.; Li, L.; Lin, M.; Zhao, Y.; Li, S. Detection of Methanol in Power Transformer Oil Using Spectroscopy. J. Electr. Eng. Technol. 2019, 14, 861–867. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Y.; Liu, J.; Wang, Z.; Bai, S.; Lu, J. A New Method for the Aging Evaluation of Oil-Paper Insulation Using n-Butanol and Methanol. CSEE J. Power Energy Syst. 2024, 10, 717–726. [Google Scholar] [CrossRef]

- Mihajlovic, D.; Ivancevic, V.; Vasovic, V.; Lukic, J. Cellulose Degradation and Transformer Fault Detection by the Application of Integrated Analyses of Gases and Low Molecular Weight Alcohols Dissolved in Mineral Oil. Energies 2022, 15, 5669. [Google Scholar] [CrossRef]

- Jalbert, J.; Gilbert, R.; Denos, Y.; Gervais, P. Methanol: A Novel Approach to Power Transformer Asset Management. IEEE Trans. Power Deliv. 2012, 27, 514–520. [Google Scholar] [CrossRef]

- Zheng, H.; Shi, K.; Yang, T.; Li, Y.; Zhang, E.; Zhang, C.; Shao, G.; Shi, Z.; Zhang, C. Investigation on the equilibrium distribution of methanol in transformer oil-immersed cellulosic insulation. Cellulose 2021, 28, 1703–1714. [Google Scholar] [CrossRef]

- Matharage, S.Y.; Liu, Q.; Wang, Z.D.; Wilson, G.; Krause, C. Aging assessment of synthetic ester impregnated thermally non-upgraded kraft paper through chemical markers in oil. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 507–515. [Google Scholar] [CrossRef]

- Jalbert, J.; Lessard, M.; Ryadi, M. Cellulose chemical markers in transformer oil insulation Part 1: Temperature correction factors. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 2287–2291. [Google Scholar] [CrossRef]

- Liland, K.B.; Linhjell, D.; Lesaint, C.; Ese, M.G.; Lundgaard, L.E.; Mavrommatis, P.; Stjepanovic, N. Comparison between synthetic ester and mineral oil impregnated transformer paper aging markers. In Proceedings of the IEEE International Conference on Dielectric Liquids, Manchester, UK, 25–29 June 2017. [Google Scholar]

- Jalbert, J.; Hernandez, L.; Coulibaly, M.L.; Lessard, L.; Lesaint, C.; Lukic, J.; Melzer, L.; Maina, R.; Wang, Z.; Martins, M.A.; et al. Field Experience with Transformer Solid Insulation Ageing Markers; Cigré Technical Brochure 779; International Council on Large Electric Systems (CIGRE): Paris, France, 2019; Available online: https://www.e-cigre.org/publications/detail/779-field-experience-with-transformer-solid-insulation-ageing-markers.html (accessed on 22 September 2024).

- Przybylek, P. Water Saturation Limit of Insulating Liquids and Hygroscopicity of Cellulose in Aspect of Moisture Determination in Oil-paper Insulation. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1886–1893. [Google Scholar] [CrossRef]

- Liao, R.; Lin, Y.; Guo, P.; Liu, H.; Xia, H. Thermal aging effects on the moisture equilibrium curves of mineral and mixed oil-paper insulation systems. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 842–850. [Google Scholar] [CrossRef]

- Przybylek, P. The influence of temperature and aging of cellulose on water distribution in oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 552–556. [Google Scholar] [CrossRef]

- Jalbert, J.; Rodriguez-Celis, E.M.; Arroyo-Fernández, O.H.; Duchesne, S.; Morin, B. Methanol Marker for the Detection of Insulating Paper Degradation in Transformer Insulating Oil. Energies 2019, 12, 3969. [Google Scholar] [CrossRef]

| Vial No | Mass of Methanol —Mma, mg | State of Methanol in the Vial | Air Volume —Av, L | Methanol Concentration in Air —MCa, mg/L | Peak Area —Pa, mV×s |

|---|---|---|---|---|---|

| 1 | 0 | vial without methanol | 0.116 | 0 | 0 |

| 2 | 1.0 | dissolved | 0.116 | 8.621 | 755 |

| 3 | 4.9 | dissolved | 0.116 | 42.241 | 2997 |

| 4 | 8.3 | dissolved | 0.116 | 71.552 | 5532 |

| 5 | 41.1 | undissolved | - | - | - |

| 6 | 79.2 | undissolved | - | - | - |

| Vial No | Mass of Methanol—Mma, mg | State of Methanol in the Vial | Air Volume —Av, L | Methanol Concentration in Air—MCa, mg/L | Peak Area— Pa, mV×s |

|---|---|---|---|---|---|

| 1a | 0.792 | dissolved | 0.068 | 11.647 | 1431 |

| 2a | 7.92 | dissolved | 0.068 | 116.471 | 8392 |

| Vial No | Mass of Oil —Mo, g | Mass of Methanol—Mmo, g | Methanol Concentration in Oil —MCo, % |

|---|---|---|---|

| 1 | 48.5992 | 0.1020 | 0.210 |

| 2 | 48.0497 | 0.0493 | 0.103 |

| 3 | 48.2527 | 0.0112 | 0.023 |

| 4 | 48.7236 | 0.0052 | 0.011 |

| 5 | 48.4122 | 0.0008 | 0.002 |

| 6 | 48.4071 | 0 | 0 |

| Vial No | Mass of Oil —Mo, g | Volume of Oil —Vo, mL | Volume of Air —Va, mL | Peak Area —Pa, mV×s | Mass of Methanol in Air —Mma, mg | Methanol Content in Oil —Mco, mg | Methanol Content in Oil @70 °C —Mco70, mg | Methanol Partition Coefficient k ± u(k) |

|---|---|---|---|---|---|---|---|---|

| 1-1 | 18.6554 | 21.4430 | 35.9070 | 13171 | 6.2452 | 39.1540 | 32.9088 | 5.27 ± 0.15 |

| 1-2 | 18.7969 | 21.6056 | 35.7444 | 13326 | 6.2900 | 39.4509 | 33.1610 | 5.27 ± 0.15 |

| 2-1 | 20.0685 | 23.0672 | 34.2828 | 7085 | 3.2083 | 20.5907 | 17.3824 | 5.42 ± 0.16 |

| 2-2 | 19.0710 | 21.9207 | 35.4293 | 6738 | 3.1534 | 19.5672 | 16.4138 | 5.21 ± 0.15 |

| 3-1 | 19.7299 | 22.6780 | 34.6720 | 1641 | 0.7534 | 4.5795 | 3.8261 | 5.08 ± 0.17 |

| 3-2 | 18.5294 | 21.2982 | 36.0518 | 1529 | 0.7301 | 4.3009 | 3.5708 | 4.89 ± 0.16 |

| 4-1 | 18.5323 | 21.3015 | 36.0485 | 696 | 0.3334 | 1.9778 | 1.6445 | 4.93 ± 0.23 |

| 4-2 | 19.6492 | 22.5853 | 34.7647 | 745 | 0.3440 | 2.0971 | 1.7531 | 5.10 ± 0.23 |

| 5-1 | 20.1849 | 23.2010 | 34.1490 | 112 | 0.0527 | 0.3336 | 0.2808 | 5.33 ± 1.17 |

| 5-2 | 20.4970 | 23.5598 | 33.7902 | 115 | 0.0536 | 0.3387 | 0.2851 | 5.32 ± 1.15 |

| 6-1 | 20.0611 | 23.0587 | 34.2913 | 0 | 0 | 0 | 0 | - |

| 6-2 | 20.0760 | 21.4430 | 34.2741 | 0 | 0 | 0 | 0 | - |

| Vial No | Mass of Dry Pressboard —Mdp, g | Mass of Added Methanol—Mam, g | Peak Area —Pa, mV×s | Methanol Concentration in Air —MCa, mg/L | Volume of 16 Pressboard Samples —Vp, cm3 | Volume of Air in Vial—Va, mL | Mass of Methanol in Air —Mma, mg | Mass of Methanol in Pressboard —Mmp, g | Methanol Content in Pressboard —MCP, % |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 17.4884 | 0.0681 | 226.7 | 3.0588 | 17.0606 | 27.9394 | 0.0855 | 0.0680 | 0.39 |

| 2 | 17.6400 | 0.2725 | 866.9 | 11.5095 | 17.0606 | 27.9394 | 0.3216 | 0.2722 | 1.54 |

| 3 | 17.6844 | 0.4450 | 1201.9 | 15.9315 | 17.0606 | 27.9394 | 0.4451 | 0.4446 | 2.51 |

| 4 | 17.6587 | 0.6175 | 2134.4 | 28.2405 | 17.0606 | 27.9394 | 0.7890 | 0.6167 | 3.49 |

| Vial No | Mass of Pressboard—Mp, g | Mass of Oil —Mo, g | Methanol Content in Pressboard —MCP, % | Temperature of Sample Conditioning —T, °C |

|---|---|---|---|---|

| 1-1 | 4.4744 | 31.7928 | 0.39 | 30 |

| 1-2 | 4.4503 | 31.6355 | 1.54 | 30 |

| 1-3 | 4.6912 | 32.1936 | 2.51 | 30 |

| 1-4 | 4.6584 | 31.4254 | 3.49 | 30 |

| 2-1 | 4.3724 | 31.3755 | 0.39 | 40 |

| 2-2 | 4.5078 | 30.8854 | 1.54 | 40 |

| 2-3 | 4.3864 | 31.6534 | 2.51 | 40 |

| 2-4 | 4.4789 | 31.1162 | 3.49 | 40 |

| 3-1 | 4.3607 | 31.9044 | 0.39 | 50 |

| 3-2 | 4.5048 | 31.5168 | 1.54 | 50 |

| 3-3 | 4.5140 | 31.4910 | 2.51 | 50 |

| 3-4 | 4.4985 | 31.4082 | 3.49 | 50 |

| 4-1 | 4.3579 | 31.7437 | 0.39 | 60 |

| 4-2 | 4.4550 | 31.7654 | 1.54 | 60 |

| 4-3 | 4.5429 | 31.4071 | 2.51 | 60 |

| 4-4 | 4.6458 | 30.8232 | 3.49 | 60 |

| Vial No | Mass of Oil —Mo, g | Volume of Oil —Vo, mL | Volume of Air —Va, mL | Peak Area —Pa, mV×s | Methanol Concentration in Air —MCa, mg/L | Methanol Concentration in Oil —MCo, mg/L |

|---|---|---|---|---|---|---|

| 1-1a | 20.4872 | 23.5485 | 37.8015 | 124.2 | 1.7058 | 11.57 |

| 1-1b | 9.2327 | 10.6123 | 38.3877 | 83.4 | 1.1673 | 10.27 |

| 1-2a | 20.0847 | 23.0859 | 38.2641 | 802.4 | 10.6581 | 72.87 |

| 1-2b | 9.2844 | 10.6717 | 38.3283 | 655.7 | 8.7216 | 76.50 |

| 1-3a | 20.0532 | 23.0497 | 38.3003 | 1540.8 | 20.4050 | 139.60 |

| 1-3b | 9.7476 | 11.2041 | 37.7959 | 1211.2 | 16.0542 | 137.32 |

| 1-4a | 20.585 | 23.6609 | 37.6891 | - | - | - |

| 1-4b | 8.6451 | 9.9369 | 39.0631 | 1937.1 | 25.6361 | 233.57 |

| 2-1a | 20.7932 | 23.9002 | 37.4498 | 140 | 1.9144 | 12.92 |

| 2-1b | 8.7405 | 10.0466 | 38.9534 | 90.6 | 1.2623 | 11.43 |

| 2-2a | 20.6619 | 23.7493 | 37.6007 | 920.9 | 12.2223 | 82.66 |

| 2-2b | 8.2842 | 9.5221 | 39.4779 | 689.1 | 9.1625 | 85.45 |

| 2-3a | 20.212 | 23.2322 | 38.1178 | 2118.1 | 28.0253 | 191.15 |

| 2-3b | 9.3332 | 10.7278 | 38.2722 | 1587.5 | 21.0214 | 183.89 |

| 2-4a | 20.6621 | 23.7495 | 37.6005 | 3958.9 | 52.3239 | 353.88 |

| 2-4b | 8.2058 | 9.4320 | 39.5680 | 2867.5 | 37.9174 | 355.48 |

| 3-1a | 20.1167 | 23.1226 | 38.2274 | 138 | 1.8880 | 12.90 |

| 3-1b | 10.0524 | 11.5545 | 37.4455 | 107 | 1.4788 | 12.45 |

| 3-2a | 19.3569 | 22.2493 | 39.1007 | 1171.6 | 15.5315 | 107.75 |

| 3-2b | 10.1646 | 11.6834 | 37.3166 | 902.8 | 11.9834 | 100.35 |

| 3-3a | 20.4174 | 23.4683 | 37.8817 | 2717.3 | 35.9348 | 244.15 |

| 3-3b | 9.0448 | 10.3963 | 38.6037 | 1962.9 | 25.9767 | 231.02 |

| 3-4a | 19.6043 | 22.5337 | 38.8163 | - | - | - |

| 3-4b | 9.8381 | 11.3082 | 37.6918 | 4214.4 | 55.6965 | 474.15 |

| 4-1a | 20.2923 | 23.3245 | 38.0255 | 146.4 | 1.9989 | 13.61 |

| 4-1b | 9.1325 | 10.4971 | 38.5029 | 113.2 | 1.5606 | 13.81 |

| 4-2a | 20.647 | 23.7322 | 37.6178 | 1586.7 | 21.0108 | 142.14 |

| 4-2b | 8.9889 | 10.3321 | 38.6679 | 1211.9 | 16.0635 | 143.33 |

| 4-3a | 20.1555 | 23.1672 | 38.1828 | 4167.8 | 55.0814 | 376.10 |

| 4-3b | 8.7337 | 10.0387 | 38.9613 | 2924.6 | 38.6711 | 350.40 |

| 4-4a | 20.1146 | 23.1202 | 38.2298 | 7807.5 | 103.1254 | 704.71 |

| 4-4b | 8.1444 | 9.3614 | 39.6386 | 5450.7 | 72.0156 | 677.97 |

| Vial No. | Methanol Concentration in Oil —MCoav, mg/L | Volume of Oil —Vo, L | Mass of Methanol in Oil —Mmo, mg | Mass of Methanol in Pressboard —Mmp, g | Mass of Methanol in Pressboard —Mmpeq, g | Mass of Dry Pressboard—Mdp, g | Methanol Content in Pressboard —MCPeq, % |

|---|---|---|---|---|---|---|---|

| 1-1 | 10.92 | 0.036543 | 0.40 | 0.0174 | 0.0170 | 4.4570 | 0.38 |

| 1-2 | 74.69 | 0.036362 | 2.27 | 0.0675 | 0.0648 | 4.3828 | 1.48 |

| 1-3 | 138.46 | 0.037004 | 5.12 | 0.1149 | 0.1097 | 4.5763 | 2.40 |

| 1-4 | 233.57 | 0.036121 | 8.44 | 0.1571 | 0.1487 | 4.5013 | 3.30 |

| 2-1 | 12.17 | 0.036063 | 0.44 | 0.0170 | 0.0165 | 4.3554 | 0.38 |

| 2-2 | 84.06 | 0.03550 | 2.98 | 0.0684 | 0.0654 | 4.4394 | 1.47 |

| 2-3 | 187.52 | 0.036383 | 6.82 | 0.1074 | 0.1006 | 4.2790 | 2.35 |

| 2-4 | 354.68 | 0.035765 | 12.69 | 0.1510 | 0.1384 | 4.3279 | 3.20 |

| 3-1 | 12.68 | 0.036671 | 0.46 | 0.0169 | 0.0165 | 4.3438 | 0.38 |

| 3-2 | 104.05 | 0.036226 | 3.77 | 0.0683 | 0.0646 | 4.4365 | 1.46 |

| 3-3 | 237.58 | 0.036196 | 8.60 | 0.1105 | 0.1019 | 4.4035 | 2.31 |

| 3-4 | 474.15 | 0.036101 | 17.12 | 0.1517 | 0.1346 | 4.3468 | 3.10 |

| 4-1 | 13.71 | 0.036487 | 0.50 | 0.0169 | 0.0164 | 4.3410 | 0.38 |

| 4-2 | 142.73 | 0.036511 | 5.21 | 0.0676 | 0.0624 | 4.3874 | 1.42 |

| 4-3 | 363.25 | 0.036100 | 13.11 | 0.1112 | 0.0981 | 4.4317 | 2.21 |

| 4-4 | 691.34 | 0.035428 | 24.49 | 0.1567 | 0.1322 | 4.4891 | 2.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przybylek, P. Methanol Equilibrium Curves of Power Transformer Oil–Paper Insulation. Energies 2024, 17, 5333. https://doi.org/10.3390/en17215333

Przybylek P. Methanol Equilibrium Curves of Power Transformer Oil–Paper Insulation. Energies. 2024; 17(21):5333. https://doi.org/10.3390/en17215333

Chicago/Turabian StylePrzybylek, Piotr. 2024. "Methanol Equilibrium Curves of Power Transformer Oil–Paper Insulation" Energies 17, no. 21: 5333. https://doi.org/10.3390/en17215333

APA StylePrzybylek, P. (2024). Methanol Equilibrium Curves of Power Transformer Oil–Paper Insulation. Energies, 17(21), 5333. https://doi.org/10.3390/en17215333