Energy and Economic Analysis of a New Combination Cascade Waste Heat Recovery System of a Waste-to-Energy Plant

Abstract

1. Introduction

2. Literature Review

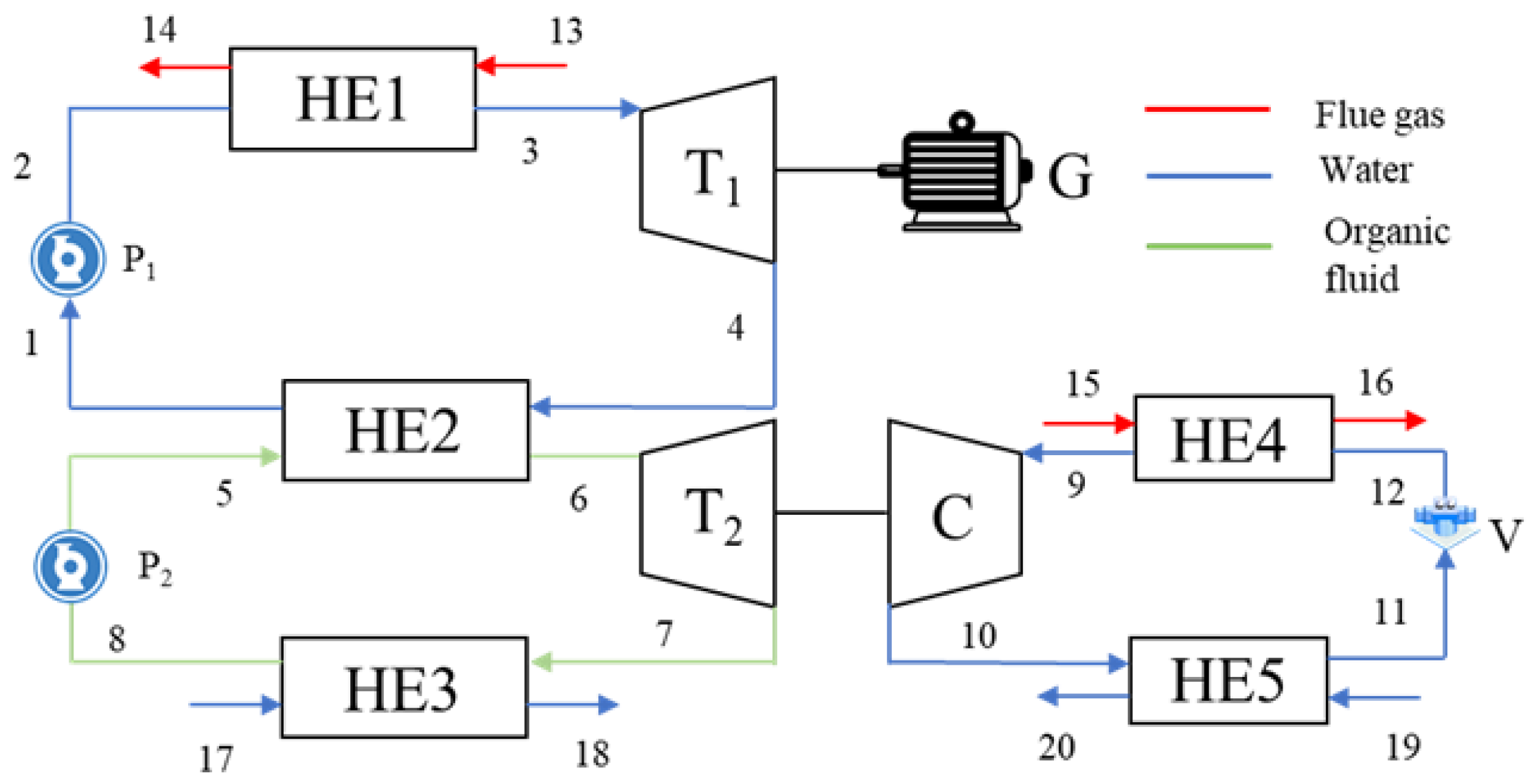

3. Description of New Combination Cascade Waste Heat Recovery System

4. Mathematical Model of New Combination Cascade Waste Heat Recovery System

4.1. Energy Explanation

4.2. Exergy Anatomy

4.3. Economic Analysis

4.4. Model Validation

5. Results and Discussion

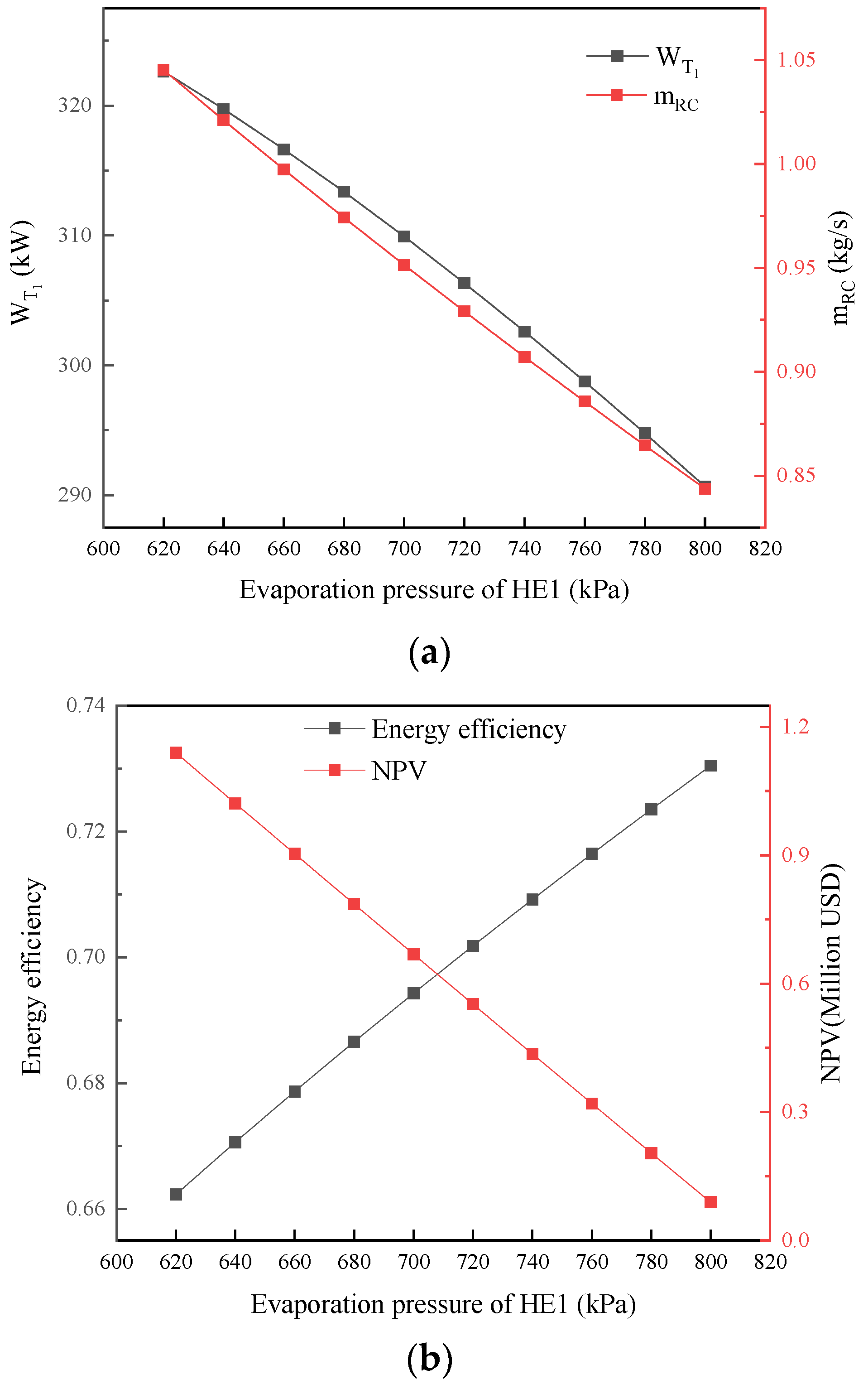

5.1. HE1 Evaporation Pressure Effect

5.2. HE4 Evaporation Temperature Impact

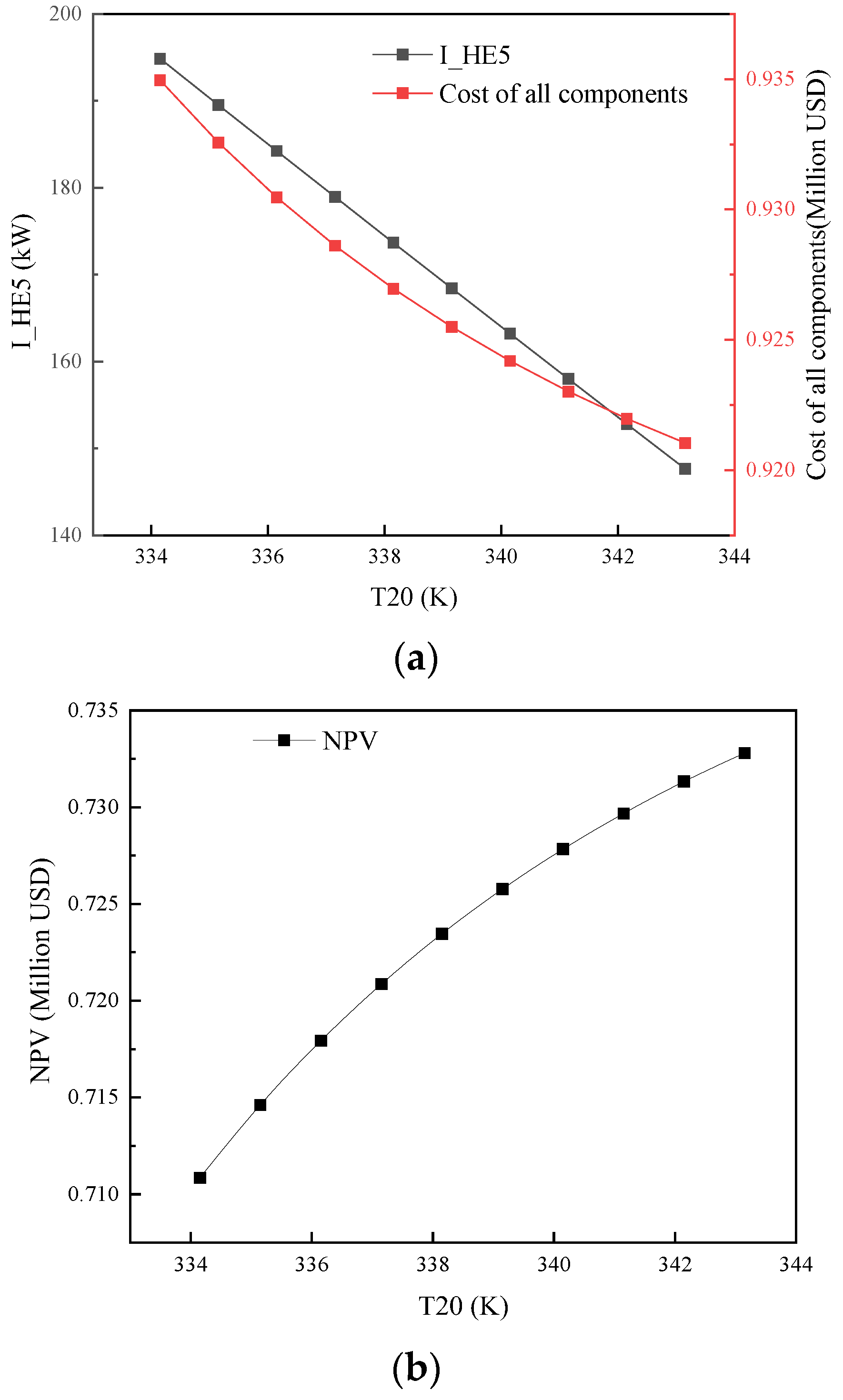

5.3. T20 Ascendancy

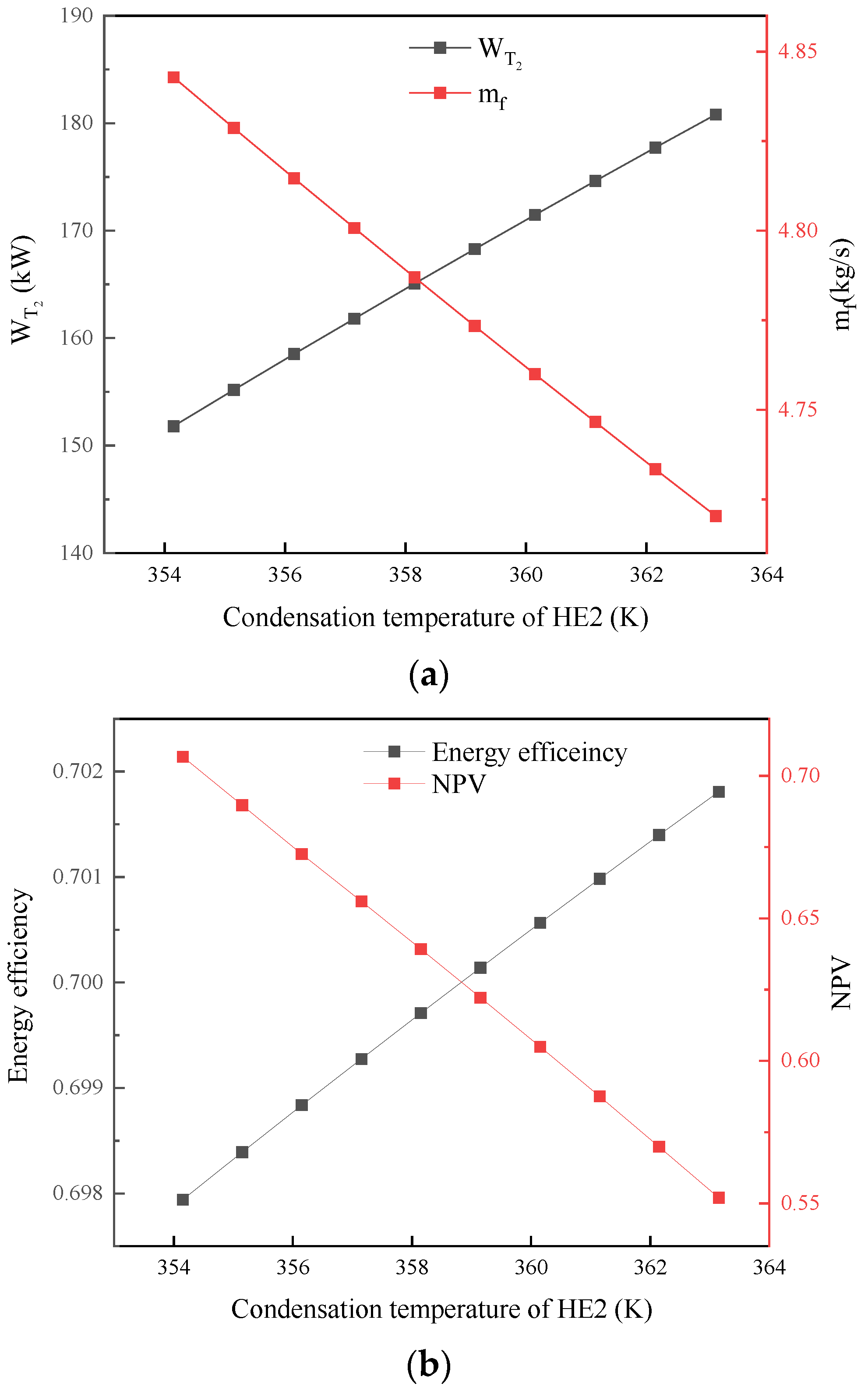

5.4. HE2 Condensation Temperature Influence

5.5. Effect of Pump Isentropic Efficiency

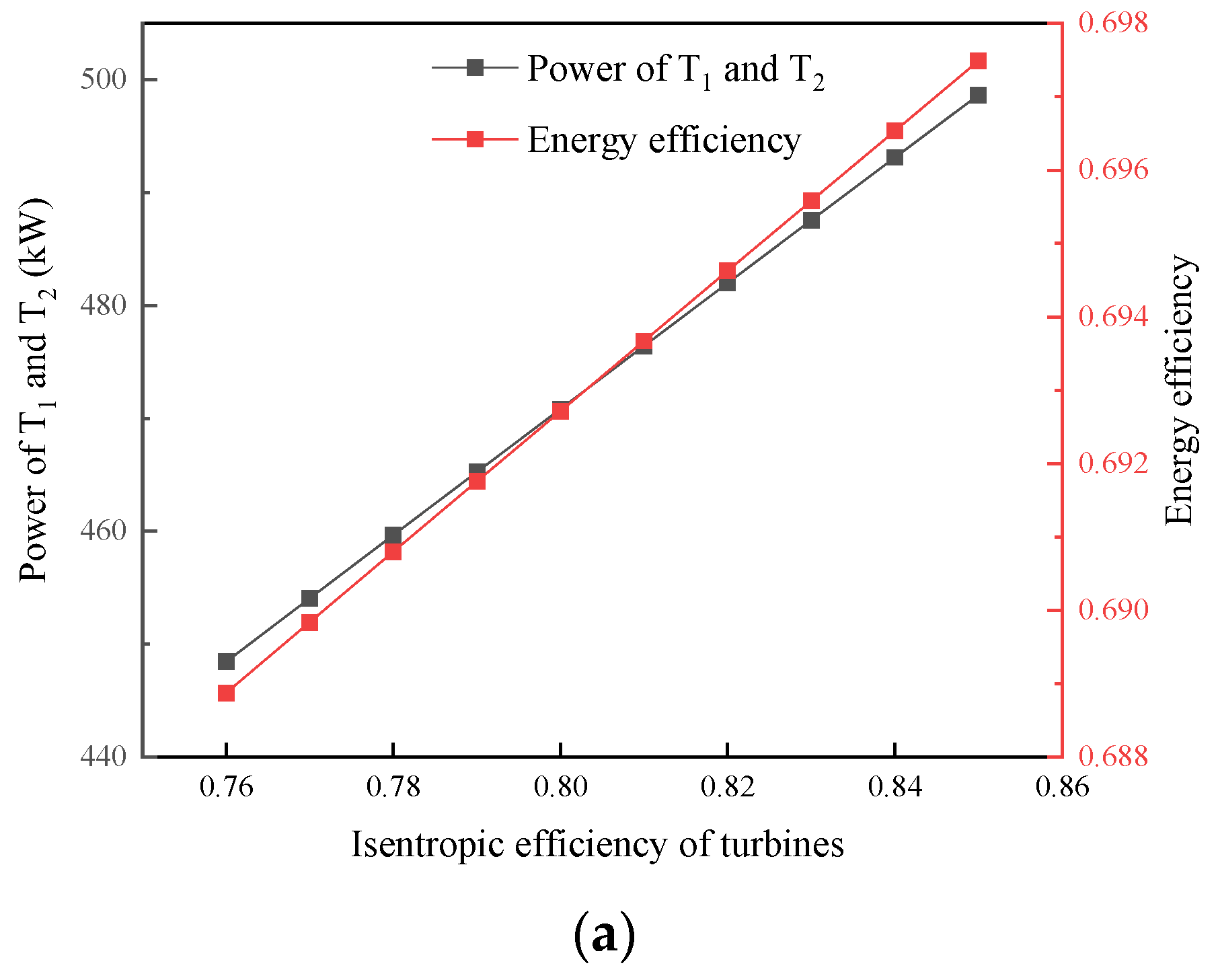

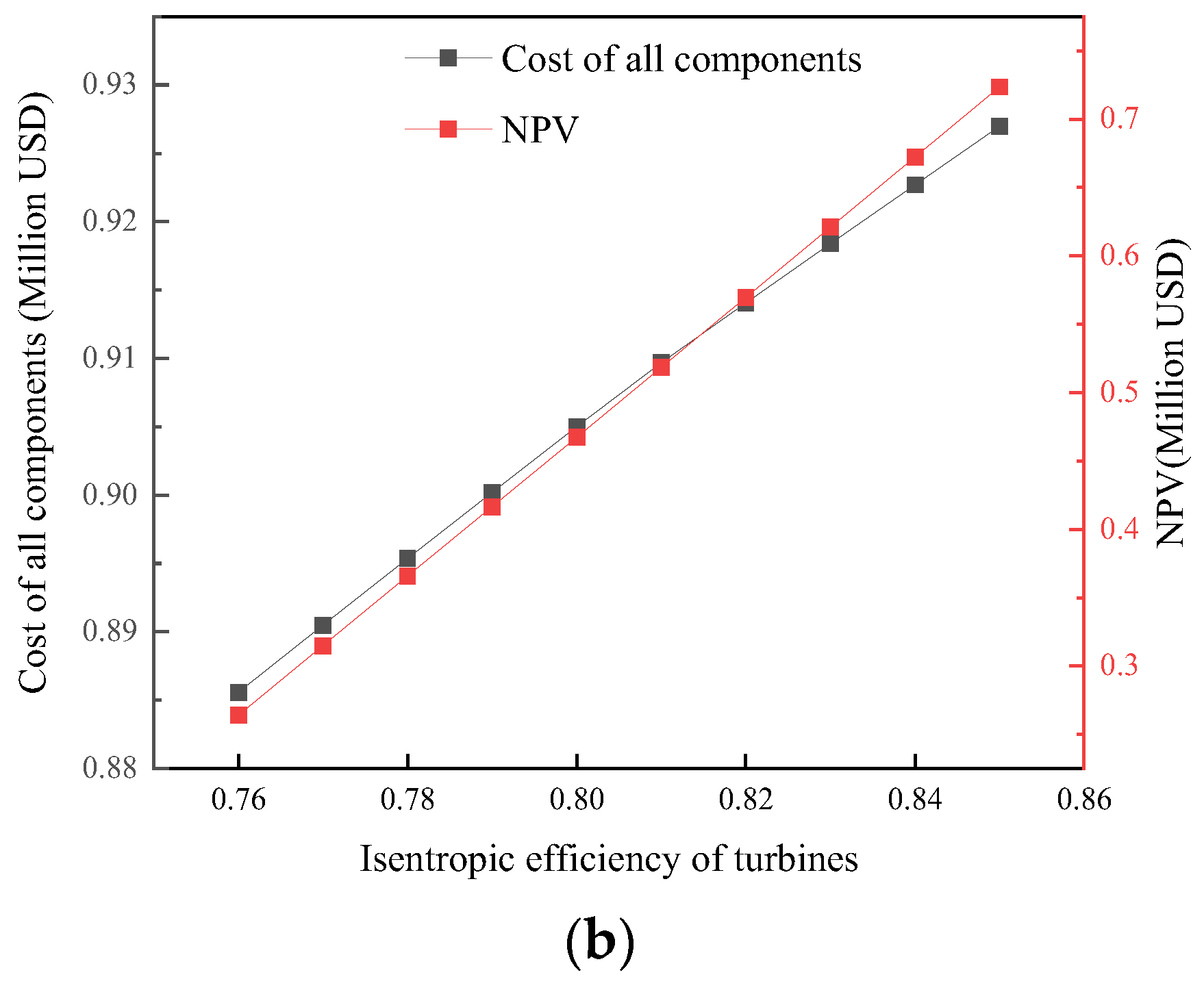

5.6. Turbine Isentropic Efficiency Effect

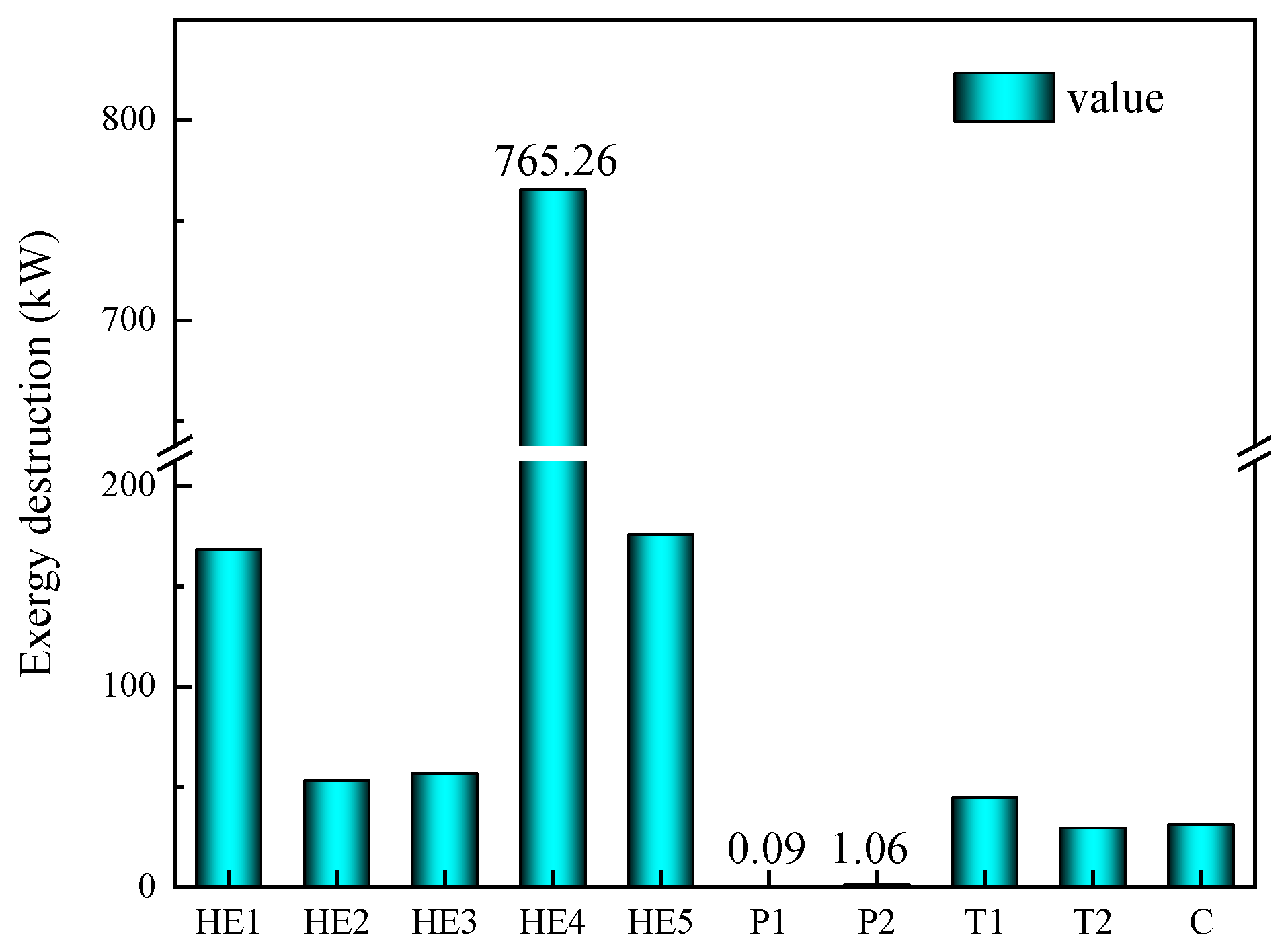

5.7. Exergy Analysis

6. Conclusions

- The maximum energy efficiency of the combined system can reach 73%. The evaporation pressure of the evaporator and the condensation temperature of the condenser in the RC system are proportional to the system efficiency.

- The energy efficiency of the system is generally inversely proportional to its economy. It is not advisable to blindly pursue energy efficiency, as it is necessary to comprehensively consider the cost of system components.

- The higher the isentropic efficiency of the pumps and turbines in the combined system, the better the system performance. The irreversible losses of the pumps and turbines are minimized based on the exergy analysis results.

- The highest NPV of the system reaches million USD 1.59, and the system’s DDP is approximately 6.5 years.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviation | |

| C | Compressor |

| DPP | Dynamic investment payback period |

| G | Generator |

| HE | Heat exchanger |

| NPV | Net present value |

| ORC | Organic Rankine cycle |

| RC | Rankine cycle |

| T | Turbine |

| V | Valve |

| Symbol | |

| A | Area () |

| cp | Specific heat capacity (kJ/(kg·K)) |

| E | Exergy (kW) |

| ID | Exergy destruction (kW) |

| e | Specific exergy (kJ/kg) |

| h | Specific enthalpy (kJ/kg) |

| id | Discount rate |

| m | Flow rate (kg/s) |

| Q | Heat transfer (kW) |

| W | Power (kW) |

| Subscripts and superscripts | |

| a | The environmental state |

| i | Input |

| o | Output |

References

- Zhang, R.; Cao, J.; Lei, L.; Cao, Y.; Liu, D. Pilot-tests of the coal-fired power plant indirect coupling with multi-source organic solid waste incineration technology. Fuel 2024, 369, 131740. [Google Scholar] [CrossRef]

- Bae, J.; Lee, S.; Kim, K.; Kang, J.; Jeon, T. Reassessment of lower heating value calculations for municipal solid waste incineration facilities in South Korea. Energy 2024, 293, 130669. [Google Scholar] [CrossRef]

- Deng, J.; Wu, G.; Xia, Y.; Liu, L. Preparation and Hydration Properties of Sodium Silicate-Activated Municipal Solid Waste Incineration Bottom Ash Composite Ground-Granulated Blast Furnace Slag Cementitious Materials. Materials 2024, 17, 2406. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Luo, H.; Feng, B.; Zheng, W.; Zeng, C.; Zhang, W.; Liu, J.; Xing, F. Research on using municipal solid waste incineration bottom ash for cement-stabilized macadam. Constr. Build. Mater. 2024, 425, 135850. [Google Scholar] [CrossRef]

- Bae Kim, Y.; Park, H.; Kim, Y. An empirical study on thermal efficiency and dusty moisture removal efficiency using enthalpy wheel in industrial waste incineration plant. Appl. Therm. Eng. 2024, 248, 123203. [Google Scholar] [CrossRef]

- Chen, H.; Guo, S.; Song, X.; He, T. Design and evaluation of a municipal solid waste incineration power plant integrating with absorption heat pump. Energy 2024, 294, 131007. [Google Scholar] [CrossRef]

- Wang, J.; Tian, H.; Wang, X.; Li, L.; Sun, R.; Bian, X.; Shu, G.; Liang, X. Process design methodology for rankine cycle based on heat matching. Renew. Sustain. Energy Rev. 2024, 193, 114295. [Google Scholar] [CrossRef]

- Guerron, G.; Nicolalde, J.F.; Martinez-Gomez, J.; Davila, P. Implementation of a waste heat recovery prototype facility based on the Rankine cycle with a twin-screw expander. Appl. Therm. Eng. 2024, 257, 124233. [Google Scholar] [CrossRef]

- Biancini, G.; Cioccolanti, L.; Moradi, R.; Moglie, M. Comparative study of steam, organic Rankine cycle and supercritical CO2 power plants integrated with residual municipal solid waste gasification for district heating and cooling. Appl. Therm. Eng. 2024, 241, 122437. [Google Scholar] [CrossRef]

- Kindra, V.; Maksimov, I.; Patorkin, D.; Rogalev, A.; Rogalev, N. Thermodynamic Analysis and Optimization of Binary CO2-Organic Rankine Power Cycles for Small Modular Reactors. Energies 2024, 17, 2377. [Google Scholar] [CrossRef]

- Lebedevas, S.; Cepaitis, T. Complex Use of the Main Marine Diesel Engine High- and Low-Temperature Waste Heat in the Organic Rankine Cycle. J. Mar. Sci. Eng. 2024, 12, 521. [Google Scholar] [CrossRef]

- Mirzaei, M.R.; Kasaeian, A.; Motlagh, M.S.; Fereidoni, S. Thermo-economic analysis of an integrated combined heating, cooling, and power unit with dish collector and organic Rankine cycle. Energy 2024, 296, 131089. [Google Scholar] [CrossRef]

- Besevli, B.; Kayabasi, E.; Akroot, A.; Talal, W.; Alfaris, A.; Assaf, Y.H.; Nawaf, M.Y.; Bdaiwi, M.; Khudhur, J. Technoeconomic Analysis of Oxygen-Supported Combined Systems for Recovering Waste Heat in an Iron-Steel Facility. Appl. Sci. 2024, 14, 2563. [Google Scholar] [CrossRef]

- Lyu, L.; Kan, A.; Chen, W.; Zhang, Y.; Fu, B. Energy, Exergy and Environmental Analysis of ORC Waste Heat Recovery from Container Ship Exhaust Gases Based on Voyage Cycle. J. Mar. Sci. Eng. 2023, 11, 2029. [Google Scholar] [CrossRef]

- Liu, H.; Lu, B.; Xu, Y.; Ju, X.; Wang, W.; Zhang, Z.; Shi, L.; Tian, H.; Shu, G. Experimental investigation of a splitting organic Rankine cycle for dual waste heat recovery. Energ. Convers. Manag. 2024, 320, 119005. [Google Scholar] [CrossRef]

- Wang, C.; Liu, S.; Zhan, S.; Ou, M.; Wei, J.; Cheng, X.; Zhuge, W.; Zhang, Y. Transcritical dual-loop Rankine cycle waste heat recovery system for China VI emission standards natural gas engine. Energy 2024, 292, 130577. [Google Scholar] [CrossRef]

- Ravindran, R.V.; Cotter, D.; Wilson, C.; Huang, M.J.; Hewitt, N.J. Experimental investigation of a small-scale reversible high-temperature heat pump-organic Rankine cycle system for industrial waste heat recovery. Appl. Therm. Eng. 2024, 257, 124237. [Google Scholar] [CrossRef]

- Feng, J.; Yan, Y.; Cheng, X.; Zhao, L.; Dong, H. Thermal-economic performance evaluation and bi-objective optimization of organic Rankine cycles using pure and mixed working fluids for waste heat recovery. Case Stud. Therm. Eng. 2024, 60, 104750. [Google Scholar] [CrossRef]

- Zhang, C.; Li, L.; Guo, X.; Hu, B.; Li, Z. Potential analysis of a waste heat recovery combined system based on recuperator and organic Rankine cycle on rotorcraft powerplant. Case Stud. Therm. Eng. 2024, 55, 104136. [Google Scholar] [CrossRef]

- Zhou, X.; Xin, Z.; Tanga, W.; Sheng, K.; Wu, Z. Comparative study for waste heat recovery in immersion cooling data centers with district heating and organic Rankine cycle (ORC). Appl. Therm. Eng. 2024, 242, 122479. [Google Scholar] [CrossRef]

- Ali, M.I.H.; Abdelsamie, M.M. Thermoeconomic evaluation of waste heat recovery system in aluminium smelters using a parallel two-stage organic Rankine cycle. Energ. Convers. Manag.-X 2024, 23, 100648. [Google Scholar]

- Zhang, Q.; Huang, H.; Zhai, H.; Zhao, W.; Lu, X. Experimental research on direct expansion heat pump flue gas waste heat recovery and humidification nitrogen reduction system. J. Clean. Prod. 2023, 406, 137000. [Google Scholar] [CrossRef]

- Jang, Y.; Lee, D.; Kim, J.; Ham, S.H.; Kim, Y. Performance characteristics of a waste-heat recovery water-source heat pump system designed for data centers and residential area in the heating dominated region. J. Build. Eng. 2022, 62, 105416. [Google Scholar] [CrossRef]

- Ghaderi, M.; Reddick, C.; Sorin, M. A Systematic Heat Recovery Approach for Designing Integrated Heating, Cooling, and Ventilation Systems for Greenhouses. Energies 2023, 16, 5493. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, B.; Zhu, B. Assessment of Optimal Operating Range and Case Verification of a Waste Heat Air-Source Heat Pump Water Heater Based on a Semiempirical Parametric Model. Energies 2023, 16, 2289. [Google Scholar] [CrossRef]

- Ma, D.; Sun, Y.; Ma, S.; Li, G.; Zhou, Z.; Ma, H. Study on the working medium of high temperature heat pump suitable for industrial waste heat recovery. Appl. Therm. Eng. 2024, 236, 121642. [Google Scholar] [CrossRef]

- Vannoni, A.; Sorce, A.; Traverso, A.; Massardo, A.F. Techno-economic optimization of high-temperature heat pumps for waste heat recovery. Energ. Convers. Manag. 2023, 290, 117194. [Google Scholar] [CrossRef]

- Meftahpour, H.; Saray, R.K.; Aghaei, A.T.; Bahlouli, K. Comprehensive analysis of energy, exergy, economic, and environmental aspects in implementing the Kalina cycle for waste heat recovery from a gas turbine cycle coupled with a steam generator. Energy 2024, 290, 130094. [Google Scholar] [CrossRef]

- Lu, B.; Shi, L.; Tian, H.; Wang, X.; Shu, G. CO2-mixture-based ship waste heat recovery system (SWHRS) with multiple energy outputs and composition-adjustable mixture. Energ. Convers. Manag. 2022, 251, 114994. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, W.; Zhao, X.; Wang, Y.; Luo, D.; Li, Y.; Ge, M. Energy and exergy analysis of a thermoelectric generator system for automotive exhaust waste heat recovery. Appl. Therm. Eng. 2024, 239, 122180. [Google Scholar] [CrossRef]

- Brahimi, F.; Madani, B.; Ghemmadi, M. Comparative Thermodynamic Environmental and Economic Analyses of Combined Cycles Using Air and Supercritical CO2 in the Bottoming Cycles for Power Generation by Gas Turbine Waste Heat Recovery. Energies 2022, 15, 9066. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, H.; Li, S.; Li, W.; Pan, P.; Liu, T.; Wu, L.; Xu, G. Thermodynamic and economic analysis of a novel design combining waste tire pyrolysis with silicon production waste heat recovery and organic Rankine cycle. Energy 2023, 283, 128500. [Google Scholar] [CrossRef]

- Nami, H.; Anvari-Moghaddam, A. Small-scale CCHP systems for waste heat recovery from cement plants: Thermodynamic, sustainability and economic implications. Energy 2020, 192, 116634. [Google Scholar] [CrossRef]

- Carneiro, M.L.N.M.; Gomes, M.S.P. Energy, exergy, environmental and economic analysis of hybrid waste-to-energy plants. Energ. Convers. Manag. 2019, 179, 397–417. [Google Scholar] [CrossRef]

- Galloni, E.; Fontana, G.; Staccone, S. Design and experimental analysis of a mini ORC (organic Rankine cycle) power plant based on R245fa working fluid. Energy 2015, 90, 768–775. [Google Scholar] [CrossRef]

- Ommen, T.; Jensen, J.K.; Markussen, W.B.; Reinholdt, L.; Elmegaard, B. Technical and economic working domains of industrial heat pumps: Part 1-Single stage vapour compression heat pumps. Int. J. Refrig.-Rev. Int. Du. Froid 2015, 55, 168–182. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Flue gas temperature | 463.15–513.15 K |

| Isentropic efficiency of turbine | 0.85 |

| Isentropic efficiency of pumps and compressors | 0.85 |

| Evaporator pinch-point temperature difference | 30 K |

| Pinch-point temperature difference of condenser | 5 K |

| Control Volume | Equations |

|---|---|

| HE1 | |

| HE2 | |

| HE3 | |

| HE4 | |

| HE5 | |

| T1 | |

| T2 | |

| P1 | |

| P2 | |

| C |

| Control Volume | |||

|---|---|---|---|

| HE1 | |||

| HE2 | |||

| HE3 | |||

| HE4 | |||

| HE5 | |||

| T1 | |||

| T2 | |||

| P1 | |||

| P2 | |||

| C |

| Control Volume | Equations |

|---|---|

| HE1 | |

| HE2 | |

| HE3 | |

| HE4 | |

| HE5 | |

| T1 | |

| T2 | |

| P1 | |

| P2 | |

| C |

| Parameter | This Study | References [35,36] | Difference |

|---|---|---|---|

| Heat transfer of ORC evaporator | 10.87 kW | 10.88 kW | 0.09% |

| Heat transfer of ORC condenser | 9.79 kW | 9.87 kW | 0.81% |

| Energy efficiency of ORC | 9.86% | 9.28% | 6.25% |

| Heat transfer of HP evaporator | 896.7 kW | 855 kW | 4.88% |

| Heat transfer of HP condenser | 1049.7 kW | 1000 kW | 4.97% |

| Energy efficiency of HP | 6.86% | 6.5% | 5.54% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ling, J.; Chen, X. Energy and Economic Analysis of a New Combination Cascade Waste Heat Recovery System of a Waste-to-Energy Plant. Energies 2024, 17, 5196. https://doi.org/10.3390/en17205196

Ling J, Chen X. Energy and Economic Analysis of a New Combination Cascade Waste Heat Recovery System of a Waste-to-Energy Plant. Energies. 2024; 17(20):5196. https://doi.org/10.3390/en17205196

Chicago/Turabian StyleLing, Jialu, and Xinjian Chen. 2024. "Energy and Economic Analysis of a New Combination Cascade Waste Heat Recovery System of a Waste-to-Energy Plant" Energies 17, no. 20: 5196. https://doi.org/10.3390/en17205196

APA StyleLing, J., & Chen, X. (2024). Energy and Economic Analysis of a New Combination Cascade Waste Heat Recovery System of a Waste-to-Energy Plant. Energies, 17(20), 5196. https://doi.org/10.3390/en17205196