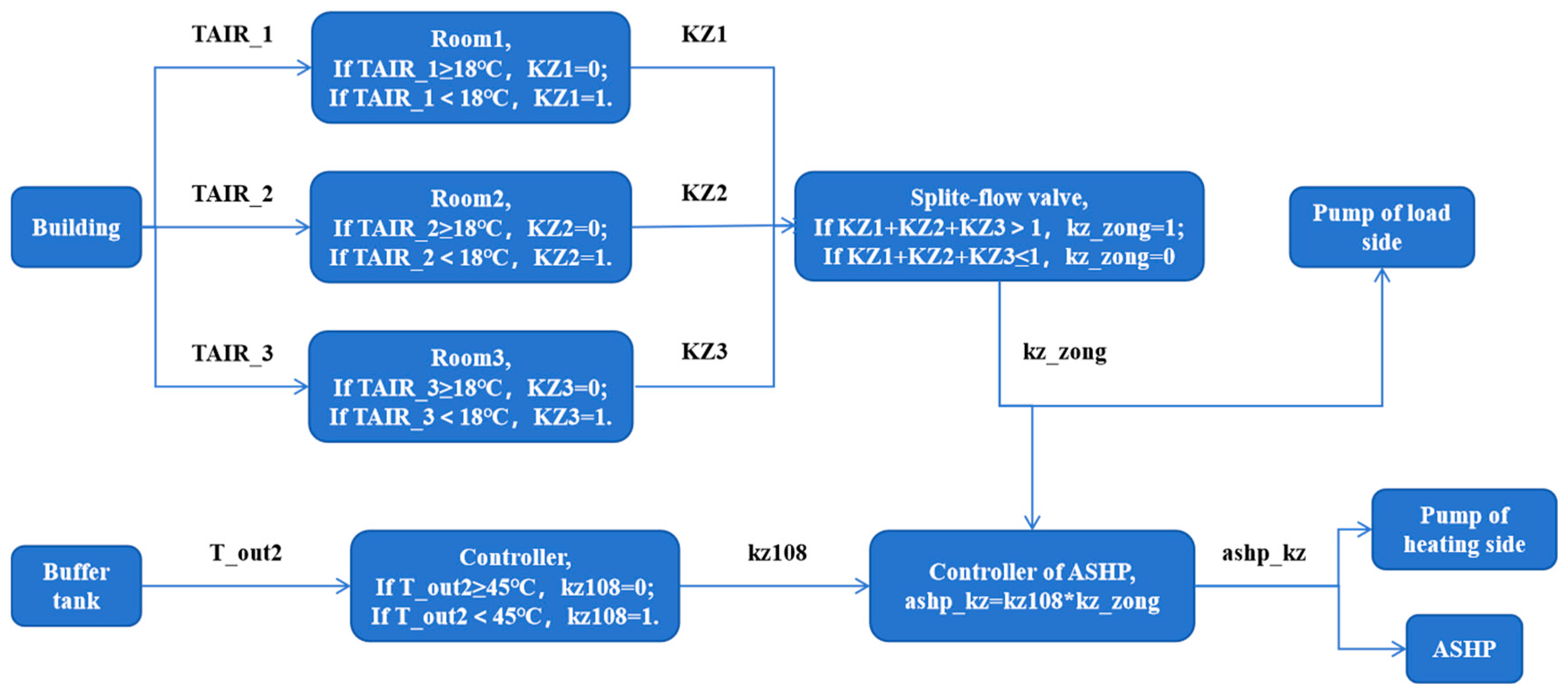

Figure 1.

The logic diagram of the research content.

Figure 1.

The logic diagram of the research content.

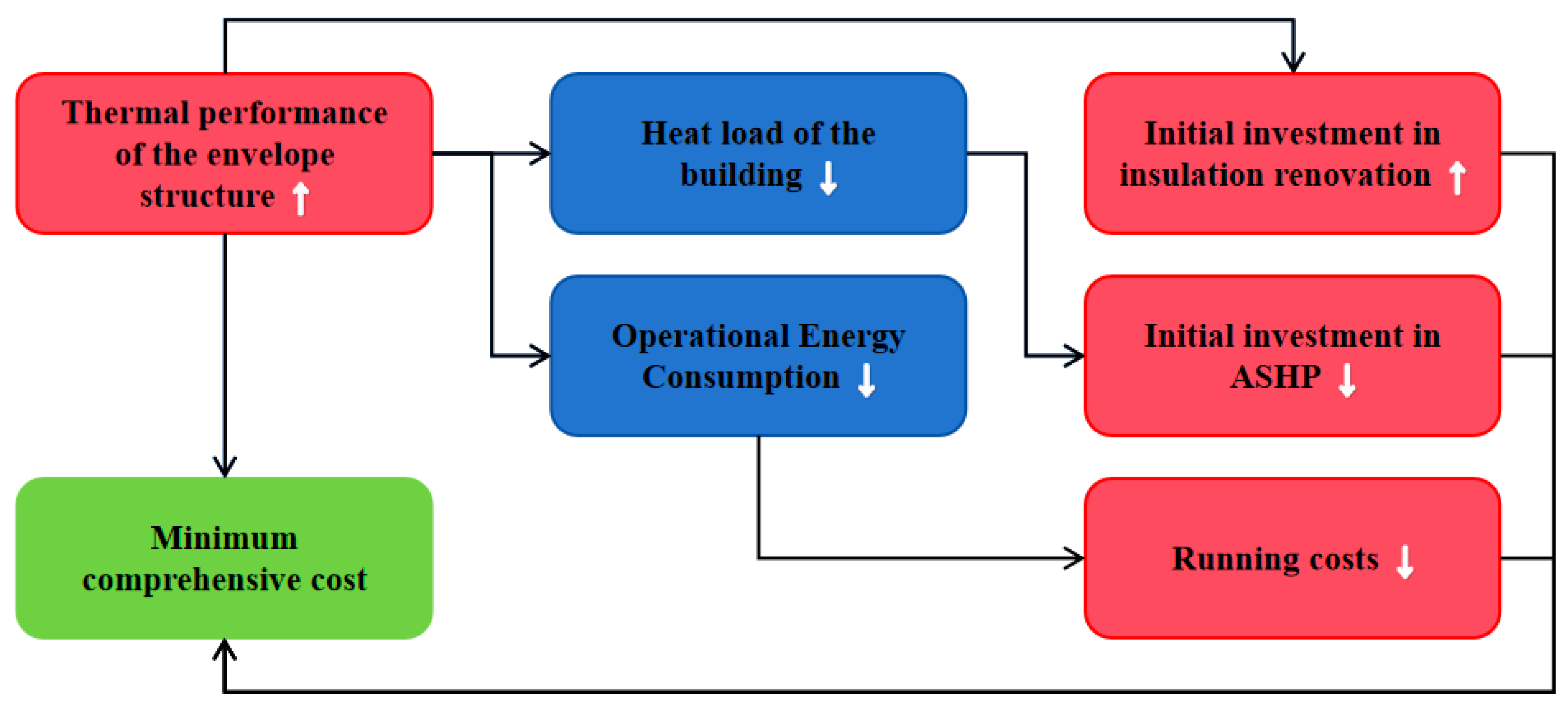

Figure 2.

Diagram of the research route.

Figure 2.

Diagram of the research route.

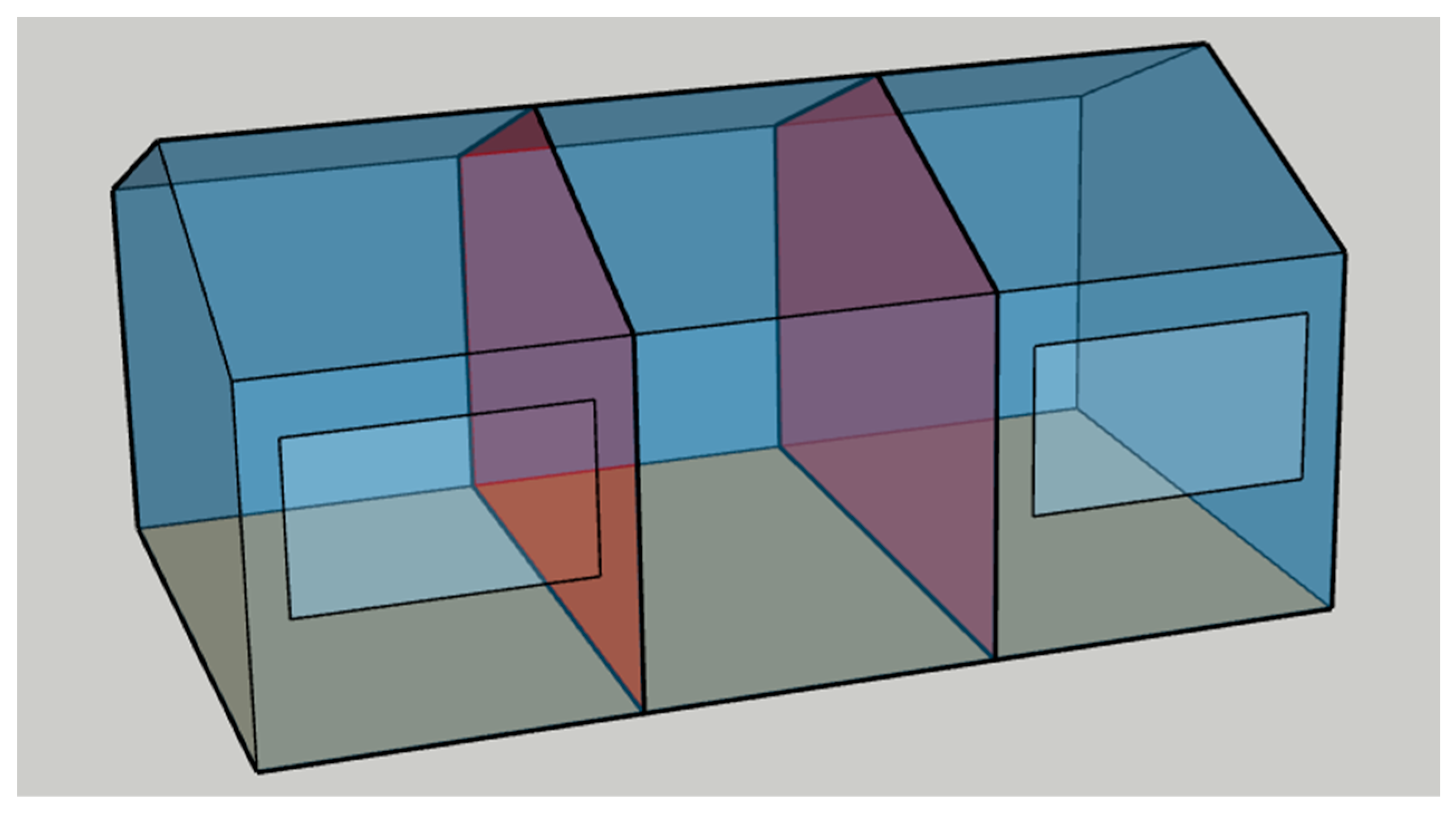

Figure 3.

Sketch Up architectural model of typical rural residential building.

Figure 3.

Sketch Up architectural model of typical rural residential building.

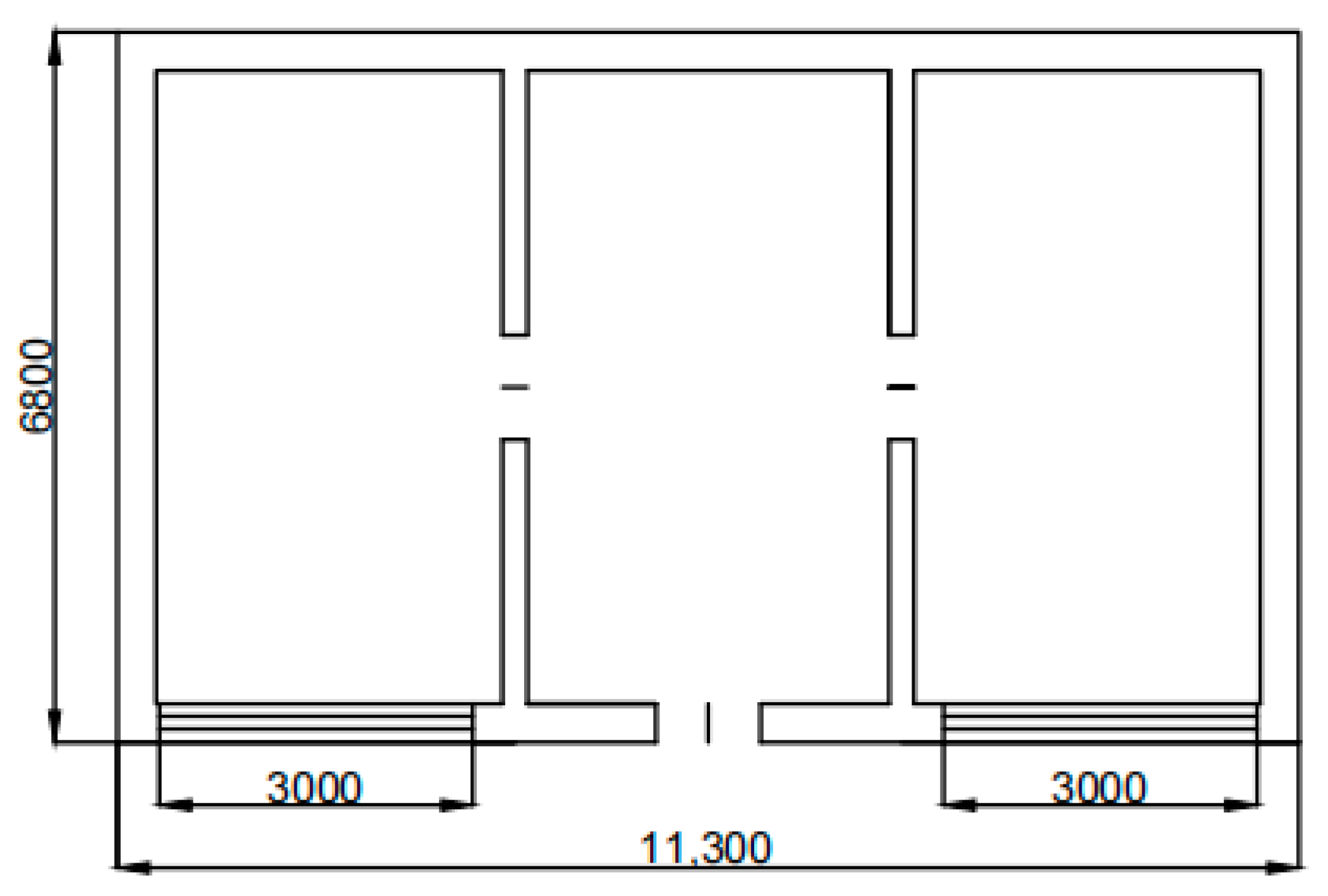

Figure 4.

Floor plan of typical rural residential building.

Figure 4.

Floor plan of typical rural residential building.

Figure 5.

The surface plot of the COP correction factor of ASHP.

Figure 5.

The surface plot of the COP correction factor of ASHP.

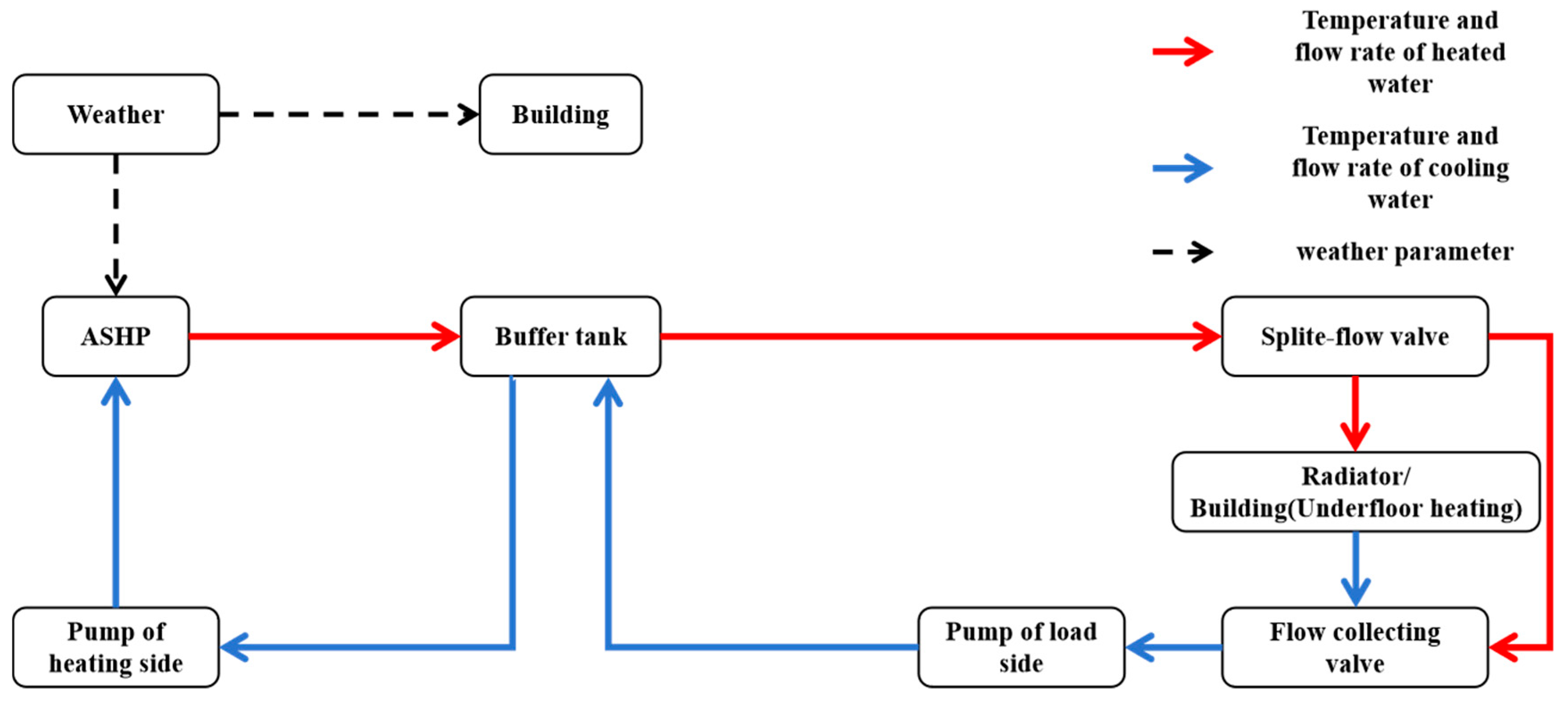

Figure 6.

The diagram of under-floor heating system.

Figure 6.

The diagram of under-floor heating system.

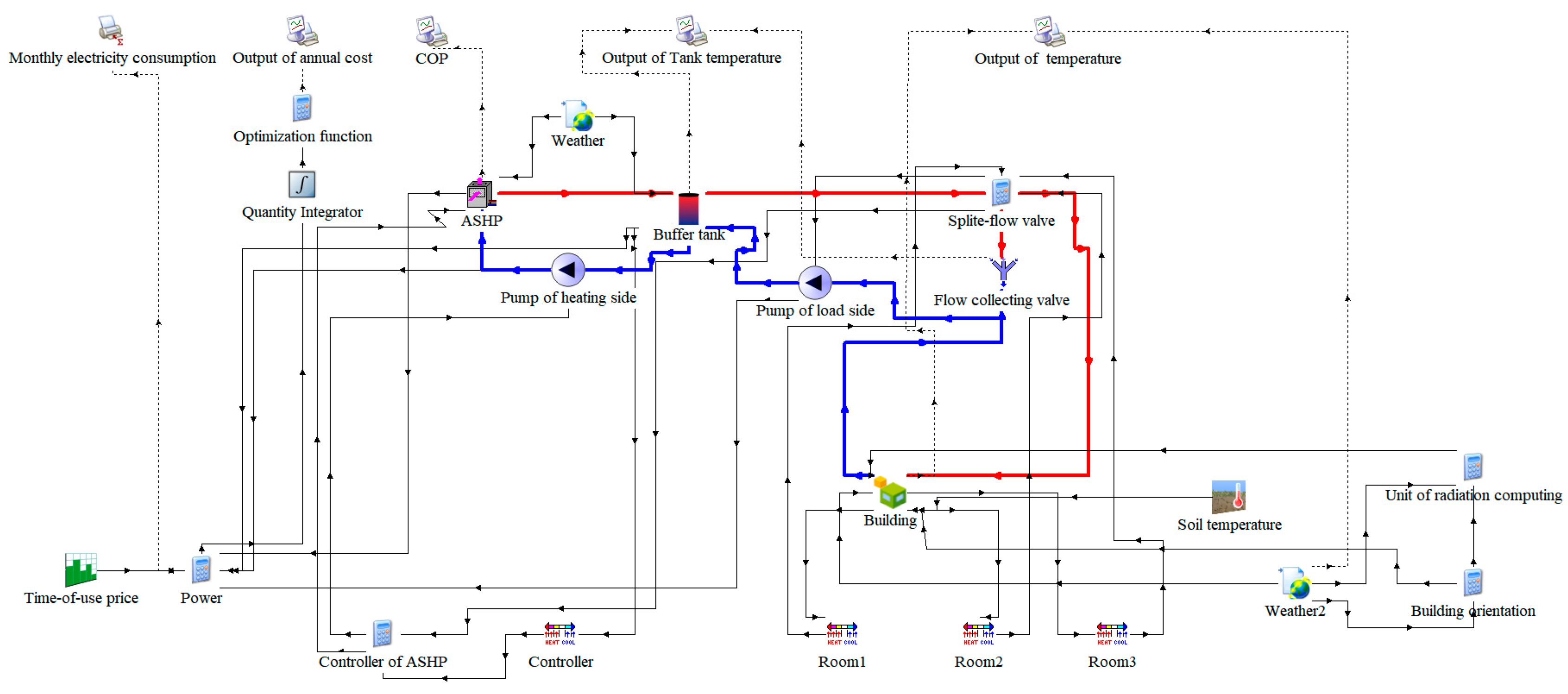

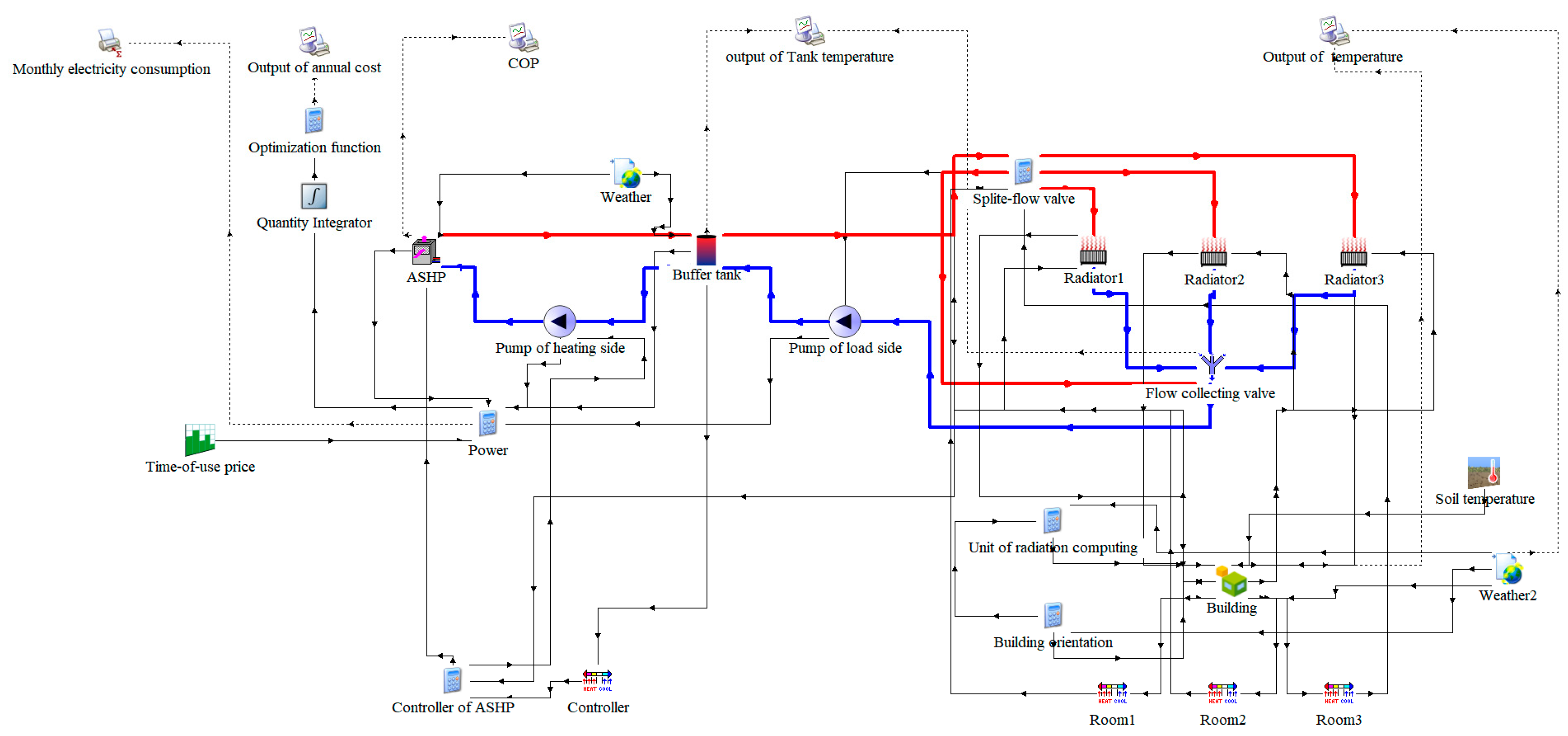

Figure 7.

The diagram of radiator heating system.

Figure 7.

The diagram of radiator heating system.

Figure 8.

Schematic layout of the TRNSYS simulation model of ASHP.

Figure 8.

Schematic layout of the TRNSYS simulation model of ASHP.

Table 1.

The goal, gaps and novelties of the research in this paper.

Table 1.

The goal, gaps and novelties of the research in this paper.

| Name | Content |

|---|

| Research goals | Reduce the heat load of the building. Reduce building heating energy consumption. Reduce the rated power of the ASHP (air source heat pump) [ 10]. Improve thermal performance of building envelope. Find the best transformation program that minimizes the annual cost. Research the economy of energy-saving transformation.

|

| Research gaps | Unlike previous research, which usually focuses on a single aspect (envelope structure or heating mode), this paper considers both the thermal performance of the envelope structure and the modification of the heating system, reflecting a more comprehensive research perspective. This paper provides an in-depth analysis of the impact of envelope structure thermal performance enhancement on the rated power of the heating system and explores the resulting equilibrium relationship between the positive and negative effects on initial investment and running costs, which has been less addressed in previous research.

|

| Research novelties | This paper presents a program for replacing traditional coal-fired boilers with ASHP, emphasizing energy-saving transformation of the heating system on the basis of enhancing the thermal performance of the envelope structure, demonstrating a novel application of the technology. Focusing not only on the economic perspective but also on the usage satisfaction of rural residents, this paper highlights innovative ideas for balancing economic benefits and user experience in energy-saving transformation. This paper provides a systematic analytical framework for future research on energy-saving transformation by comprehensively considering the interactions between envelope structure and heating system, which provides a new direction for future research on energy-saving transformation.

|

Table 2.

Thermal parameters of building envelopes.

Table 2.

Thermal parameters of building envelopes.

| Project | Building Envelope (From the Inside Out) | Heat Transfer Coefficient

[W/(m2‧K)] | Limits of Thermal Performance

[W/(m2‧K)] | Comment |

|---|

| Exterior wall | 15 mm Cement mortar + 37 mm Common brick + 15 mm Cement mortar + (Layer for heat preservation) | 1.078 | 0.3 | The brackets in the column of the building envelope are the thermal insulation structure of the transformation; reference to the Energy Conservation Design Standard for Residential Buildings in Severe Cold and Cold Regions (JGJ26-2018) [12] in the column of limits of thermal performance. |

| Roof | (Layer for heat preservation) + 20 mm Cement mortar + 40 mm Cement-based expanded perlite + 40 mm Concrete with crushed stone + 4 mm Asphalt felt + 20 mm Reinforced concrete | 1.969 | 0.2 |

Ground

(Radiator) | (20 mm Cement mortar + 40 mm Concrete with crushed stone + Layer for heat preservation) + 20 mm Cement mortar + 100 mm Concrete with crushed stone | 3.88 | 1.8 |

Ground

(Under-floor heating) | 20 mm Cement mortar + 55 mm Concrete with crushed stone + 50 mm EPS + 20 mm Cement mortar + 100 mm Concrete with crushed stone | 0.649 |

| Exterior window | Window with wooden single frame and single glass pane | 4.7 | 2.2 |

Table 3.

Table of main parameters of other main modules of the heating system.

Table 3.

Table of main parameters of other main modules of the heating system.

| Name | Value |

|---|

| Heat loss coefficient of the buffer tank envelope structure [W/(m2‧K)] | 0.4 |

| Spacing of the under-floor heating pipes (m) | 0.15 |

| Outer diameter of the under-floor heating pipes (m) | 0.02 |

| Wall thickness of the under-floor heating pipes (m) | 0.002 |

| Thermal conductivity of the under-floor heating pipe walls [W/(m‧K)] | 1.26 |

| Number of pipes in the radiator | 10 |

| Designed surface temperature of the radiator (°C) | 42.5 |

| Type of the radiator | radiator of foundry iron |

Table 4.

Initial investment in heating equipment and the cost of improving the thermal performance of the walls.

Table 4.

Initial investment in heating equipment and the cost of improving the thermal performance of the walls.

| Project | Unit Price |

|---|

| Expanded polystyrene (EPS) | CNY 210/m3 (USD 29.71/m3) |

| Extruded polystyrene (XPS) | CNY 240/m3 (USD 33.96/m3) |

| Concrete with crushed stone | CNY 300/m3 (USD 42.45/m3) |

| Cement mortar | CNY 38/m2 (USD 9.81/m2) |

| Labor costs for exterior wall transformation | CNY 50/m2 (USD 7.07/m2) |

| Labor costs for roof transformation | CNY 40/m2 (USD 5.66/m2) |

| Labor costs for ground transformation | CNY 42/m2 (USD 5.94/m2) |

| Buffer tank | CNY 600/m3 (USD 84.90/m3) |

| ASHP | CNY 1000/kW (USD 141.50/kW) |

Table 5.

Cost of transformation to improve thermal performance of exterior windows.

Table 5.

Cost of transformation to improve thermal performance of exterior windows.

| Code Name | Classes | Heat Transfer Coefficient [W/(m2·K)] | Integrated Unit Price | Comment |

|---|

| A | Plastic insulating glass windows | 2.423 | CNY 280/m2 (USD 39.61/m2) | The Integrated unit price includes labor and materials |

| B | Low-e film-coated plastic steel insulating glass window | 1.761 | CNY 360/m2 (USD 50.93/m2) |

| C | Three-glass, two-chamber insulation aluminum alloy hollow glass window | 1.52 | CNY 900/m2 (USD 127.34/m2) |

| D | Three-glass, two-chamber, double-Low-e film aluminum-wood composite window | 1.1 | CNY 2600/m2 (USD 367.89/m2) |

Table 6.

The time-of-use price of the heating season in Changchun City.

Table 6.

The time-of-use price of the heating season in Changchun City.

| Classes | Time Frame | Price (CNY/kWh) |

|---|

| Peak power | 8:00–21:00 | 0.562 |

| Valley power | 21:00–8:00 | 0.329 |

Table 7.

The orthogonal test factor level setting table of EPS as an energy-saving transformation program for thermal insulation materials.

Table 7.

The orthogonal test factor level setting table of EPS as an energy-saving transformation program for thermal insulation materials.

| Number | Exterior Window | Exterior Wall (mm) | Roof (mm) | Ground (mm) |

|---|

| 1 | A | 120 | 200 | 20 |

| 2 | B | 160 | 240 | 30 |

| 3 | C | 200 | 280 | 40 |

| 4 | D | 240 | 320 | 50 |

Table 8.

The orthogonal test factor level setting table of XPS as an energy-saving transformation program for thermal insulation materials.

Table 8.

The orthogonal test factor level setting table of XPS as an energy-saving transformation program for thermal insulation materials.

| Number | Exterior Window | Exterior Wall (mm) | Roof (mm) | Ground (mm) |

|---|

| 1 | A | 80 | 200 | 20 |

| 2 | B | 110 | 230 | 30 |

| 3 | C | 140 | 260 | 40 |

| 4 | D | 170 | 290 | 50 |

Table 9.

The orthogonal test table for energy-saving transformation (EPS, Radiator).

Table 9.

The orthogonal test table for energy-saving transformation (EPS, Radiator).

| Number | Exterior Window | Exterior Wall (mm) | Roof (mm) | Ground (mm) | Annual Cost (CNY/year) |

|---|

| 1 | A | 120 | 200 | 20 | 7098.93 (USD 1003.22/year) |

| 2 | A | 160 | 240 | 30 | 6451.00 (USD 912.81/year) |

| 3 | A | 200 | 280 | 40 | 6105.09 (USD 863.86/year) |

| 4 | A | 240 | 320 | 50 | 5923.50 (USD 838.17/year) |

| 5 | B | 120 | 240 | 40 | 6261.79 (USD 886.04/year) |

| 6 | B | 160 | 200 | 50 | 5959.57 (USD 843.27/year) |

| 7 | B | 200 | 320 | 20 | 7028.93 (USD 994.58/year) |

| 8 | B | 240 | 280 | 30 | 6463.93 (USD 917.64/year) |

| 9 | C | 120 | 280 | 50 | 6383.02 (USD 903.19/year) |

| 10 | C | 160 | 320 | 40 | 6516.37 (USD 922.06/year) |

| 11 | C | 200 | 200 | 30 | 6788.90 (USD 960.02/year) |

| 12 | C | 240 | 240 | 20 | 7328.26 (USD 1036.94/year) |

| 13 | D | 120 | 320 | 30 | 8475.83 (USD 1199.32/year) |

| 14 | D | 160 | 280 | 20 | 8897.07 (USD 1258.92/year) |

| 15 | D | 200 | 240 | 50 | 7774.97 (USD 1100.15/year) |

| 16 | D | 240 | 200 | 40 | 7999.16 (USD 1131.87/year) |

Table 10.

The orthogonal test table for energy-saving transformation (XPS, Radiator).

Table 10.

The orthogonal test table for energy-saving transformation (XPS, Radiator).

| Number | Exterior Window | Exterior Wall (mm) | Roof (mm) | Ground (mm) | Annual Cost (CNY/year) |

|---|

| 1 | A | 80 | 200 | 20 | 6526.59 (USD 923.56/year) |

| 2 | A | 110 | 230 | 30 | 5844.76 (USD 827.07/year) |

| 3 | A | 140 | 260 | 40 | 5617.25 (USD 794.88/year) |

| 4 | A | 170 | 290 | 50 | 5458.16 (USD 772.37/year) |

| 5 | B | 80 | 230 | 40 | 5837.18 (USD 826.00/year) |

| 6 | B | 110 | 200 | 50 | 5514.28 (USD 780.31/year) |

| 7 | B | 140 | 290 | 20 | 6404.66 (USD 906.30/year) |

| 8 | B | 170 | 260 | 30 | 5886.23 (USD 832.94/year) |

| 9 | C | 80 | 260 | 50 | 6011.22 (USD 850.63/year) |

| 10 | C | 110 | 290 | 40 | 6058.77 (USD 857.36/year) |

| 11 | C | 140 | 200 | 30 | 6205.62 (USD 878.14/year) |

| 12 | C | 170 | 230 | 20 | 6668.25 (USD 943.60/year) |

| 13 | D | 80 | 290 | 30 | 8005.87 (USD 1132.88/year) |

| 14 | D | 110 | 260 | 20 | 8301.32 (USD 1174.69/year) |

| 15 | D | 140 | 230 | 50 | 7320.29 (USD 1035.87/year) |

| 16 | D | 170 | 200 | 40 | 7459.20 (USD 1055.53/year) |

Table 11.

The orthogonal test table for energy-saving transformation (EPS, Under-floor heating).

Table 11.

The orthogonal test table for energy-saving transformation (EPS, Under-floor heating).

| Number | Exterior Window | Exterior Wall (mm) | Roof (mm) | Annual Cost (CNY/year) |

|---|

| 1 | A | 120 | 200 | 5445.26 (USD 770.54/year) |

| 2 | A | 160 | 240 | 5317.10 (USD 752.41/year) |

| 3 | A | 200 | 280 | 5286.37 (USD 748.06/year) |

| 4 | A | 240 | 320 | 5333.39 (USD 754.71/year) |

| 5 | B | 120 | 240 | 5488.25 (USD 776.62/year) |

| 6 | B | 160 | 200 | 5399.68 (USD 764.09/year) |

| 7 | B | 200 | 320 | 5386.21 (USD 762.19/year) |

| 8 | B | 240 | 280 | 5377.01 (USD 760.88/year) |

| 9 | C | 120 | 280 | 5813.06 (USD 822.59/year) |

| 10 | C | 160 | 320 | 5745.36 (USD 813.01/year) |

| 11 | C | 200 | 200 | 5683.66 (USD 804.28/year) |

| 12 | C | 240 | 240 | 5688.88 (USD 805.01/year) |

| 13 | D | 120 | 320 | 7359.52 (USD 1041.42/year) |

| 14 | D | 160 | 280 | 7239.49 (USD 1024.44/year) |

| 15 | D | 200 | 240 | 7211.36 (USD 1020.46/year) |

| 16 | D | 240 | 200 | 7207.58 (USD 1019.92/year) |

Table 12.

The orthogonal test table for energy-saving transformation (XPS, Under-floor heating).

Table 12.

The orthogonal test table for energy-saving transformation (XPS, Under-floor heating).

| Number | Exterior Window | Exterior Wall (mm) | Roof (mm) | Annual Cost (CNY/year) |

|---|

| 1 | A | 80 | 200 | 5394.76 (USD 763.40/year) |

| 2 | A | 110 | 230 | 5237.98 (USD 741.21/year) |

| 3 | A | 140 | 260 | 5198.38 (USD 735.61/year) |

| 4 | A | 170 | 290 | 5192.65 (USD 734.80/year) |

| 5 | B | 80 | 230 | 5451.21 (USD 771.38/year) |

| 6 | B | 110 | 200 | 5289.19 (USD 748.46/year) |

| 7 | B | 140 | 290 | 5274.20 (USD 746.33/year) |

| 8 | B | 170 | 260 | 5238.77 (USD 741.32/year) |

| 9 | C | 80 | 260 | 5792.40 (USD 819.66/year) |

| 10 | C | 110 | 290 | 5671.00 (USD 802.48/year) |

| 11 | C | 140 | 200 | 5548.93 (USD 785.21/year) |

| 12 | C | 170 | 230 | 5554.37 (USD 785.98/year) |

| 13 | D | 80 | 290 | 7409.01 (USD 1048.43/year) |

| 14 | D | 110 | 260 | 7163.11 (USD 1013.63/year) |

| 15 | D | 140 | 230 | 7089.55 (USD 1003.22/year) |

| 16 | D | 170 | 200 | 7063.12 (USD 999.48/year) |

Table 13.

Table of the results of the range analysis method of

Table 9.

Table 13.

Table of the results of the range analysis method of

Table 9.

| Name | Level | Factor1 (Exterior Window) | Factor2 (Exterior Wall) | Factor3 (Roof) | Factor4 (Ground) |

|---|

| K | 1 | 25,578.51 | 28,219.57 | 27,846.55 | 30,353.19 |

| 2 | 25,714.21 | 27,824.01 | 27,816.01 | 28,179.65 |

| 3 | 27,016.55 | 27,697.89 | 27,849.11 | 26,882.42 |

| 4 | 33,147.03 | 27,714.84 | 27,944.63 | 26,041.05 |

| k | 1 | 6394.63 | 7054.89 | 6961.64 | 7588.30 |

| 2 | 6428.55 | 6956.00 | 6954.00 | 7044.91 |

| 3 | 6754.14 | 6924.47 | 6962.28 | 6720.60 |

| 4 | 8286.76 | 6928.71 | 6986.16 | 6510.26 |

| optimum level | 1 | 3 | 2 | 4 |

| R | −1892.13 | −130.42 | −32.15 | −1078.03 |

Table 14.

Table of the results of the range analysis method of

Table 10.

Table 14.

Table of the results of the range analysis method of

Table 10.

| Name | Level | Factor1 (Exterior Window) | Factor2 (Exterior Wall) | Factor3 (Roof) | Factor4 (Ground) |

|---|

| K | 1 | 23,786.76 | 26,720.86 | 26,045.69 | 28,240.81 |

| 2 | 23,982.35 | 26,059.14 | 26,010.48 | 26,282.48 |

| 3 | 25,283.86 | 25,887.82 | 26,156.03 | 25,312.39 |

| 4 | 31,426.68 | 25,811.84 | 26,267.46 | 24,643.96 |

| k | 1 | 5946.69 | 6680.22 | 6511.42 | 7060.20 |

| 2 | 5995.59 | 6514.78 | 6502.62 | 6570.62 |

| 3 | 6320.97 | 6471.96 | 6539.01 | 6328.10 |

| 4 | 7856.67 | 6452.96 | 6566.87 | 6160.99 |

| optimum level | 1 | 4 | 2 | 4 |

| R | −1909.98 | −227.26 | −64.25 | −899.21 |

Table 15.

Table of the results of the range analysis method of

Table 11.

Table 15.

Table of the results of the range analysis method of

Table 11.

| Name | Level | Factor1 (Exterior Window) | Factor2 (Exterior Wall) | Factor3 (Roof) |

|---|

| K | 1 | 23,446.76 | 26,380.86 | 25,705.69 |

| 2 | 23,642.35 | 25,719.14 | 25,670.48 |

| 3 | 24,943.86 | 25,547.82 | 25,816.03 |

| 4 | 31,086.68 | 25,471.84 | 25,927.46 |

| k | 1 | 5861.69 | 6595.22 | 6426.42 |

| 2 | 5910.59 | 6429.78 | 6417.62 |

| 3 | 6235.97 | 6386.96 | 6454.01 |

| 4 | 7771.67 | 6367.96 | 6481.87 |

| optimum level | 1 | 4 | 2 |

| R | −1909.98 | −227.26 | −64.25 |

Table 16.

Table of the results of the range analysis method of

Table 12.

Table 16.

Table of the results of the range analysis method of

Table 12.

| Name | Level | Factor1 (Exterior Window) | Factor2 (Exterior Wall) | Factor3 (Roof) |

|---|

| K | 1 | 21,023.77 | 24,047.38 | 23,296.01 |

| 2 | 21,253.36 | 23,361.28 | 23,333.10 |

| 3 | 22,566.71 | 23,111.06 | 23,392.66 |

| 4 | 28,724.79 | 23,048.90 | 23,546.87 |

| k | 1 | 5255.94 | 6011.85 | 5824.00 |

| 2 | 5313.34 | 5840.32 | 5833.28 |

| 3 | 5641.68 | 5777.77 | 5848.16 |

| 4 | 7181.20 | 5762.23 | 5886.72 |

| optimum level | 1 | 4 | 1 |

| R | −1925.26 | −249.62 | −62.71 |

Table 17.

The optimal program of energy-saving transformation.

Table 17.

The optimal program of energy-saving transformation.

| Heating Terminal | Optimal Program | Optimal Annual Cost (CNY/year) |

|---|

| Under-floor heating | XPS is used as insulation material, and the thickness of each insulation layer is set as follows: Exterior wall 170 mm + Roof 200 mm + Exterior window A | 5146.17 (USD 728.22/year) |

| Radiator | XPS is used as insulation material, and the thickness of each insulation layer is set as follows: Exterior wall 170 mm + Roof 230 mm + Ground 50 mm + Exterior window A | 5499.15 (USD 778.17/year) |

Table 18.

Ranking table of the magnitude of the effect of each factor on the response variable.

Table 18.

Ranking table of the magnitude of the effect of each factor on the response variable.

| Heating Terminal | Ranking of Factors in Order of Influence |

|---|

| Under-floor heating | roof > exterior wall > ground > exterior window |

| Radiator | roof > exterior wall > exterior window |

Table 19.

The life-cycle costs of the two energy-saving transformation methods.

Table 19.

The life-cycle costs of the two energy-saving transformation methods.

| Heating Terminal | Envelope Structure | Envelope Structure + Heating System |

|---|

| Under-floor heating | CNY 23,131.90 | CNY 35,920.34 |

| Radiator | CNY 27,802.74 | CNY 39,874.07 |

Table 20.

Annual running cost of heating under two working conditions before and after transformation.

Table 20.

Annual running cost of heating under two working conditions before and after transformation.

| Heating Terminal | Annual Running Cost |

|---|

| Before Transformation | After Transformation |

|---|

| Envelope Structure | Envelope Structure + Heating System |

|---|

| Under-floor heating | CNY 9736.52/year | CNY 2638.3/year | CNY 2012.56/year |

| Radiator | CNY 13,770.35/year | CNY 2092.4/year | CNY 1951.99/year |

Table 21.

The table of the incremental benefits of energy conservation of the two energy-saving transformation methods.

Table 21.

The table of the incremental benefits of energy conservation of the two energy-saving transformation methods.

| Heating Terminal | Envelope Structure | Envelope Structure + Heating System |

|---|

| Under-floor heating | CNY 141,964.4 | CNY 154,479.2 |

| Radiator | CNY 233,559 | CNY 236,367.2 |

Table 22.

Table labor cost for coal ash cleaning in the whole heating season.

Table 22.

Table labor cost for coal ash cleaning in the whole heating season.

| Minimum Wage for Part-Time Workers in Changchun | Single Cleaning Time of Coal Ash | Times of Coal Ash Removal per Day | Heating Season Cycle | The Cost of Labor in Whole Heating Season |

|---|

| CNY 17/h (USD 2.41/h) | 10 min | 3 times | 169 days | CNY 1436.5 (USD 203.20) |

Table 23.

Table of comprehensive benefits of two energy-saving transformation methods.

Table 23.

Table of comprehensive benefits of two energy-saving transformation methods.

| Heating Terminal | Envelope Structure | Envelope Structure + Heating System |

|---|

| Under-floor heating | CNY 23,131.90 | CNY 35,920.34 |

| Radiator | CNY 27,802.74 | CNY 39,874.07 |

Table 24.

Table of payback period of investment of two energy-saving transformation methods.

Table 24.

Table of payback period of investment of two energy-saving transformation methods.

| Heating Terminal | Envelope Structure | Envelope Structure + Heating System |

|---|

| Under-floor heating | 3.26 years | 3.92 years |

| Radiator | 2.38 years | 3.01 years |