Bionic Strategies for Pump Anti-Cavitation: A Comprehensive Review

Abstract

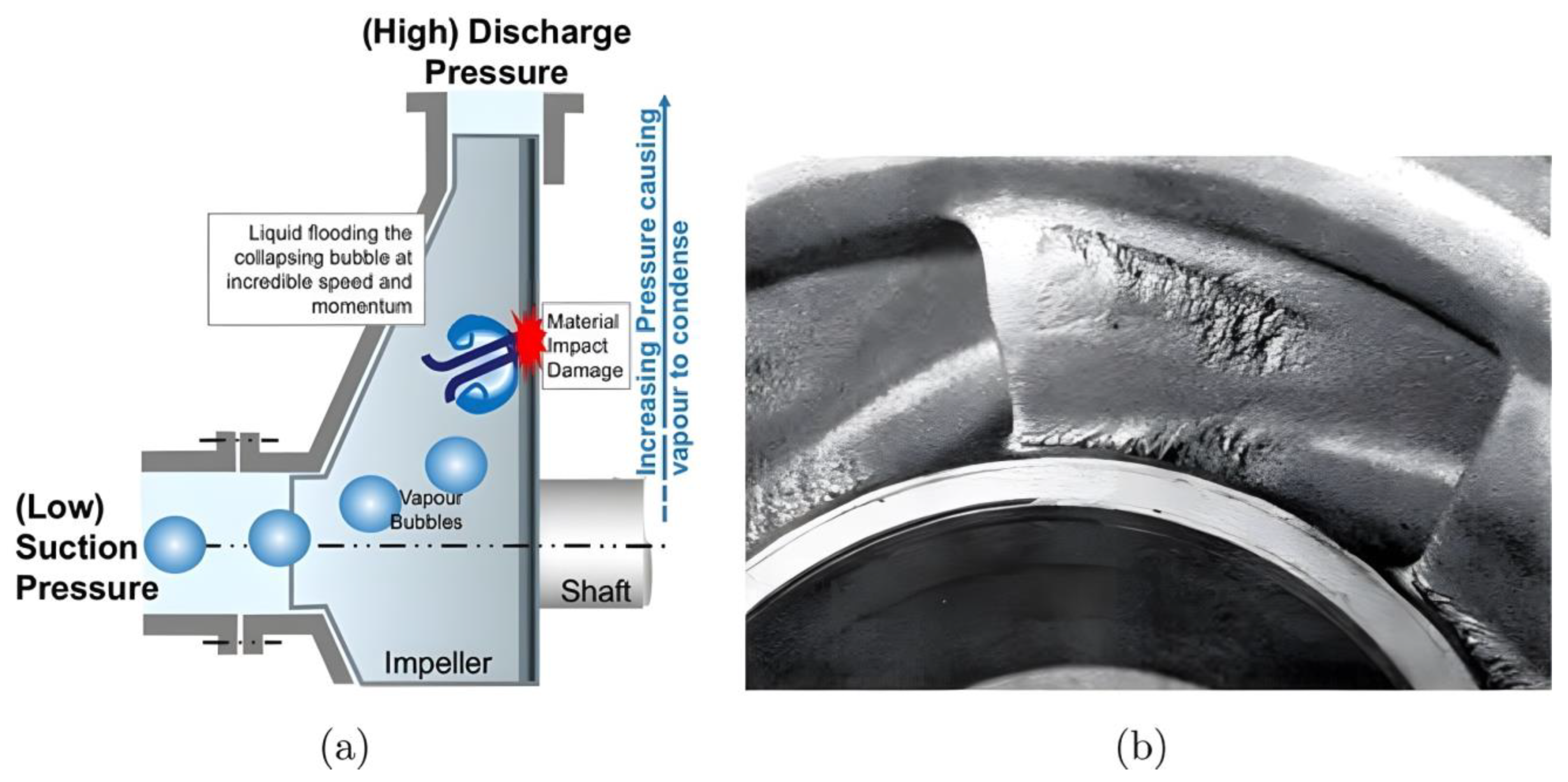

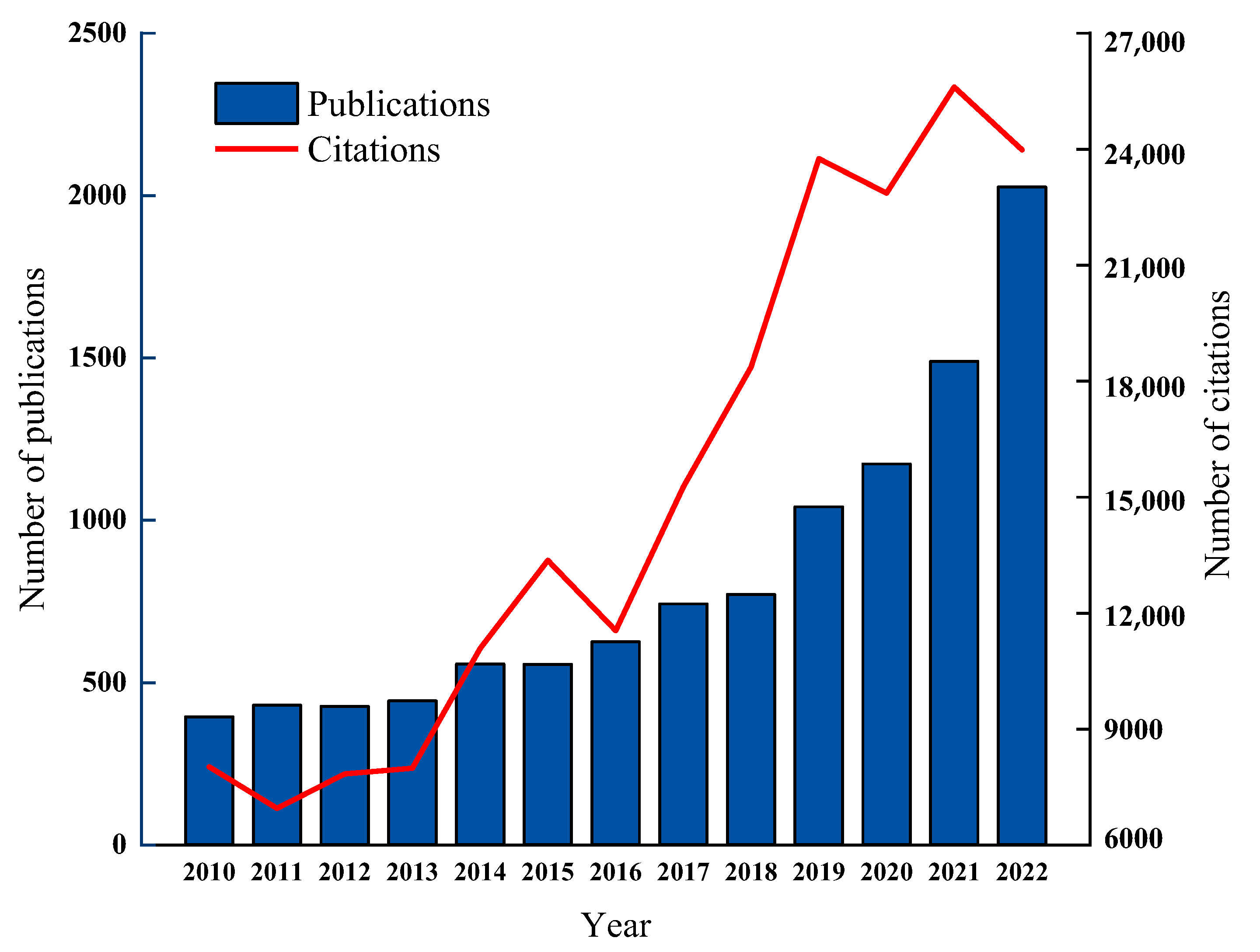

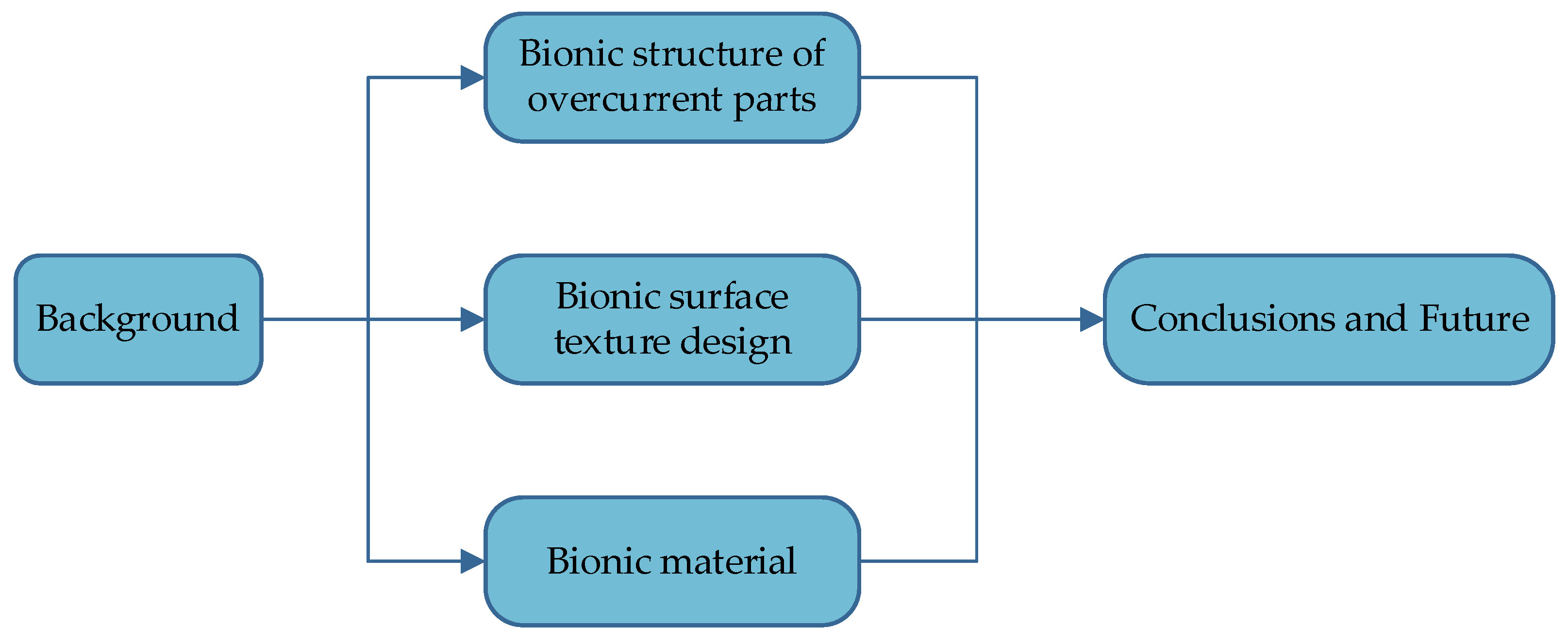

1. Introduction

2. Bionic Structure of Overcurrent Parts

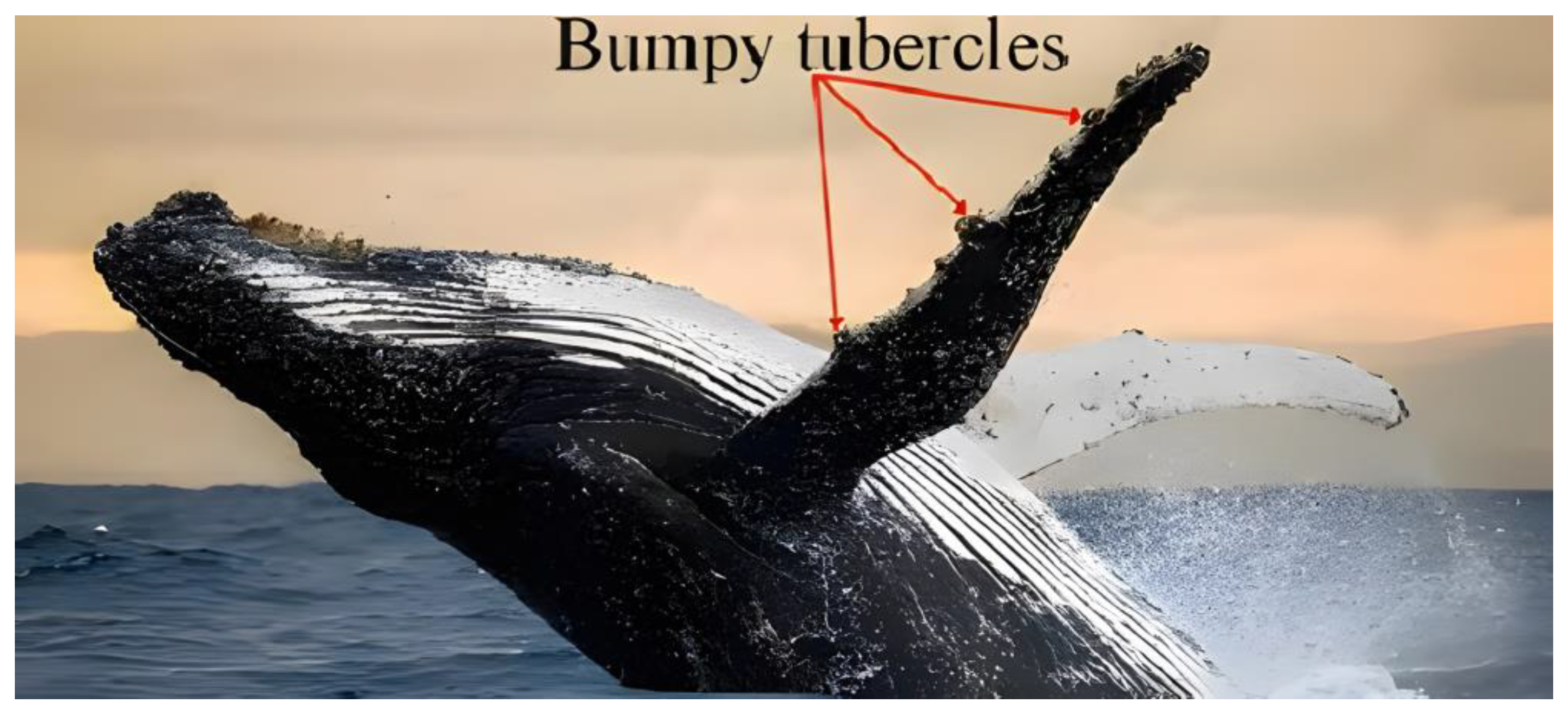

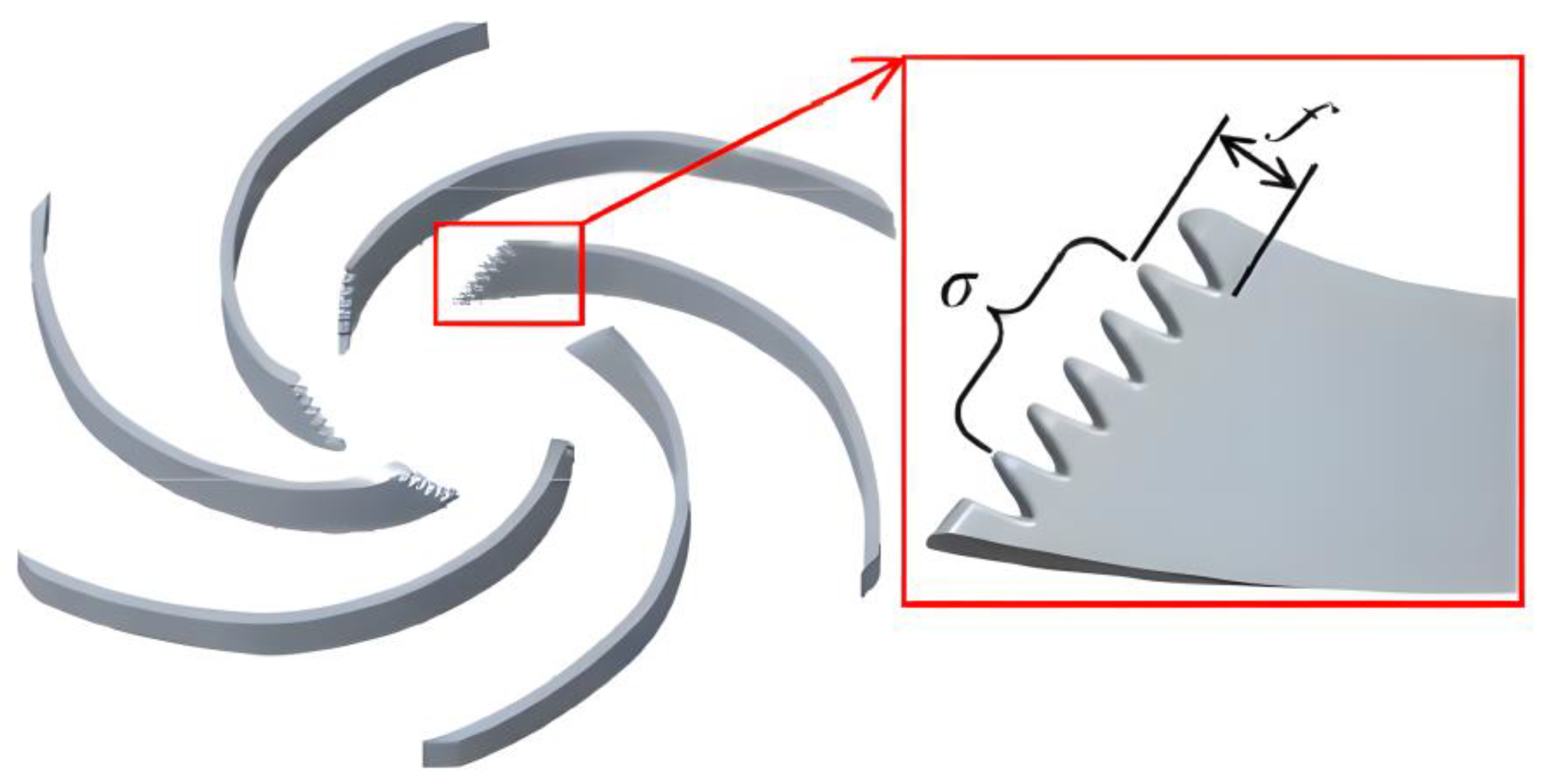

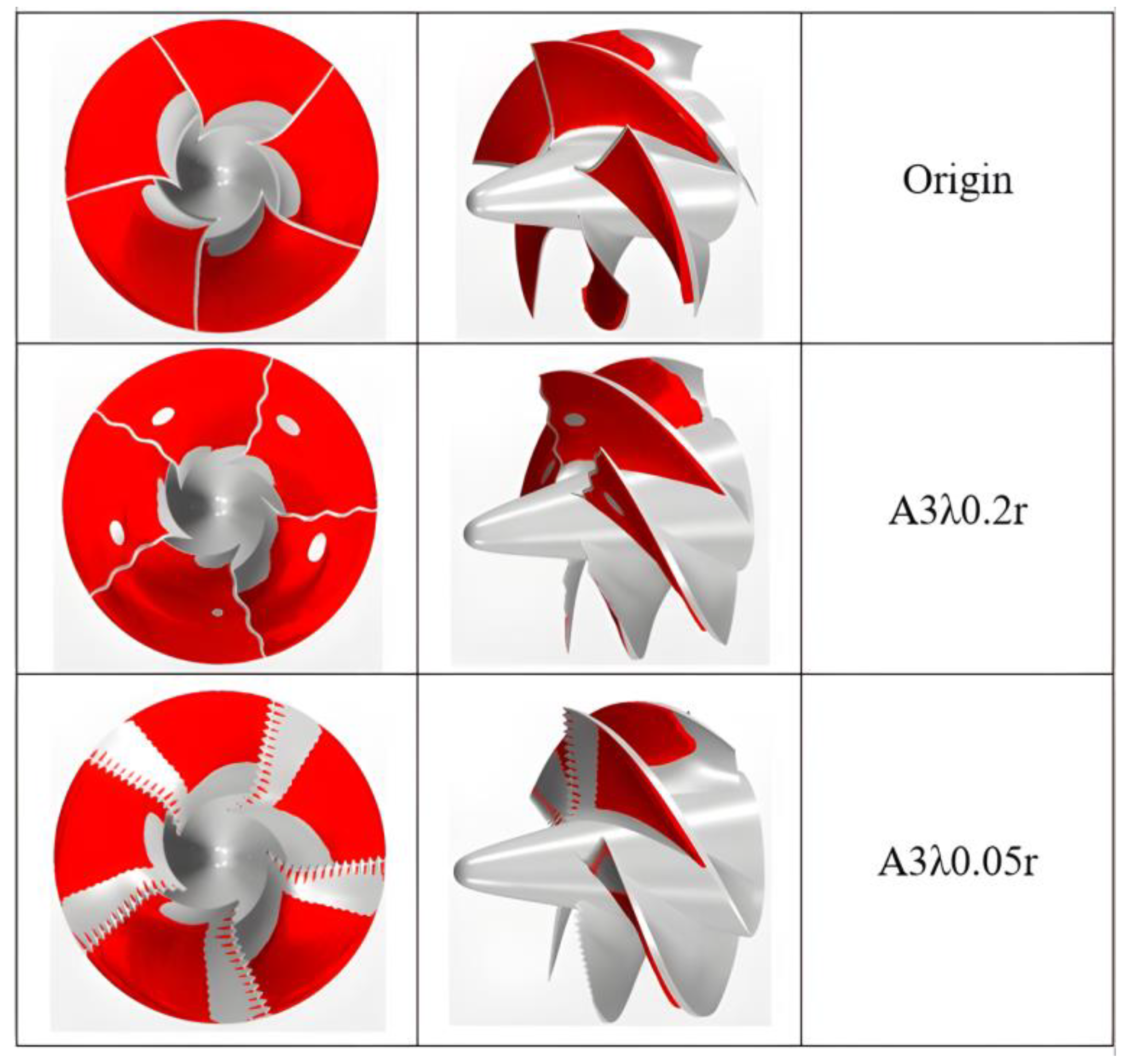

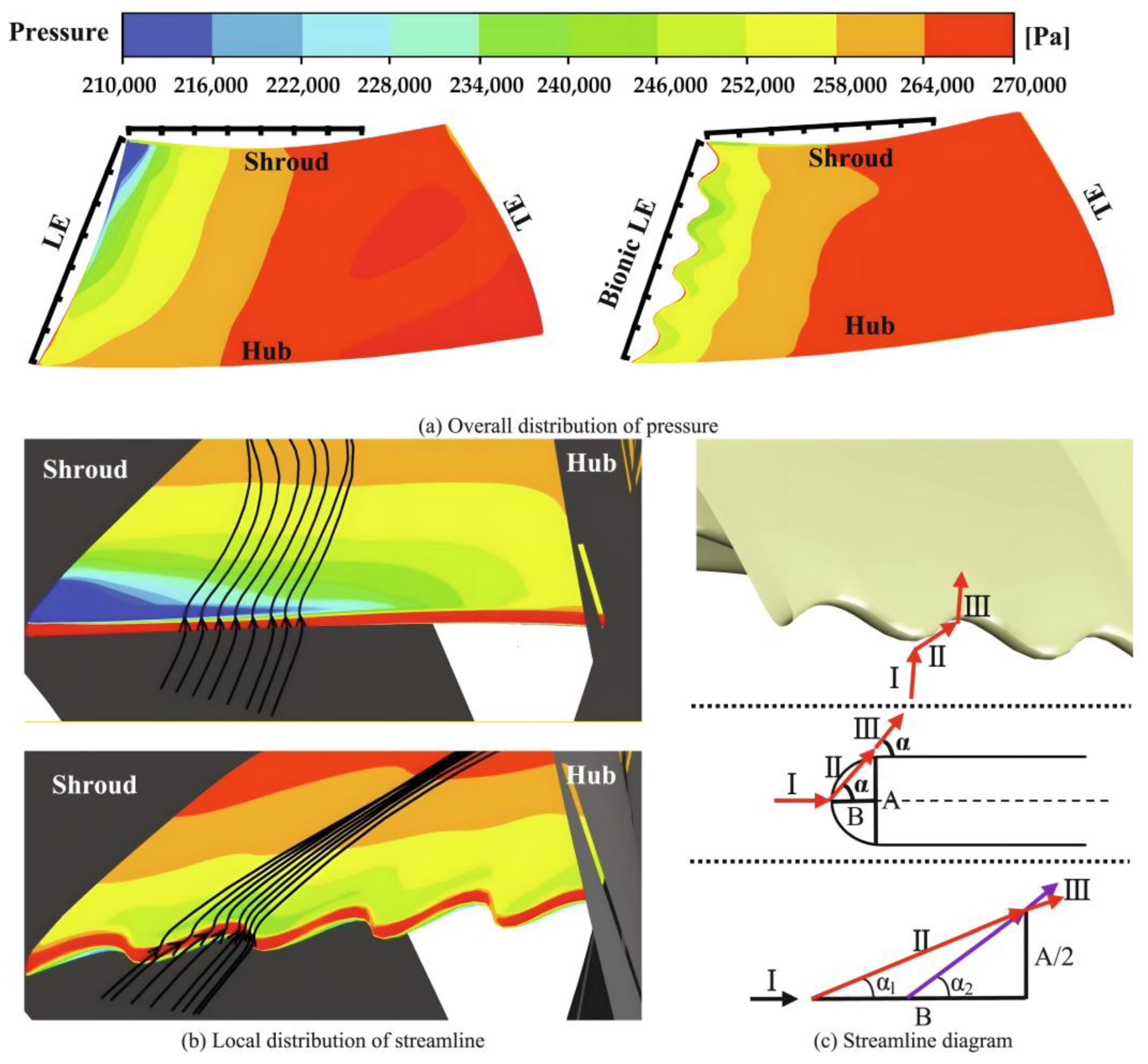

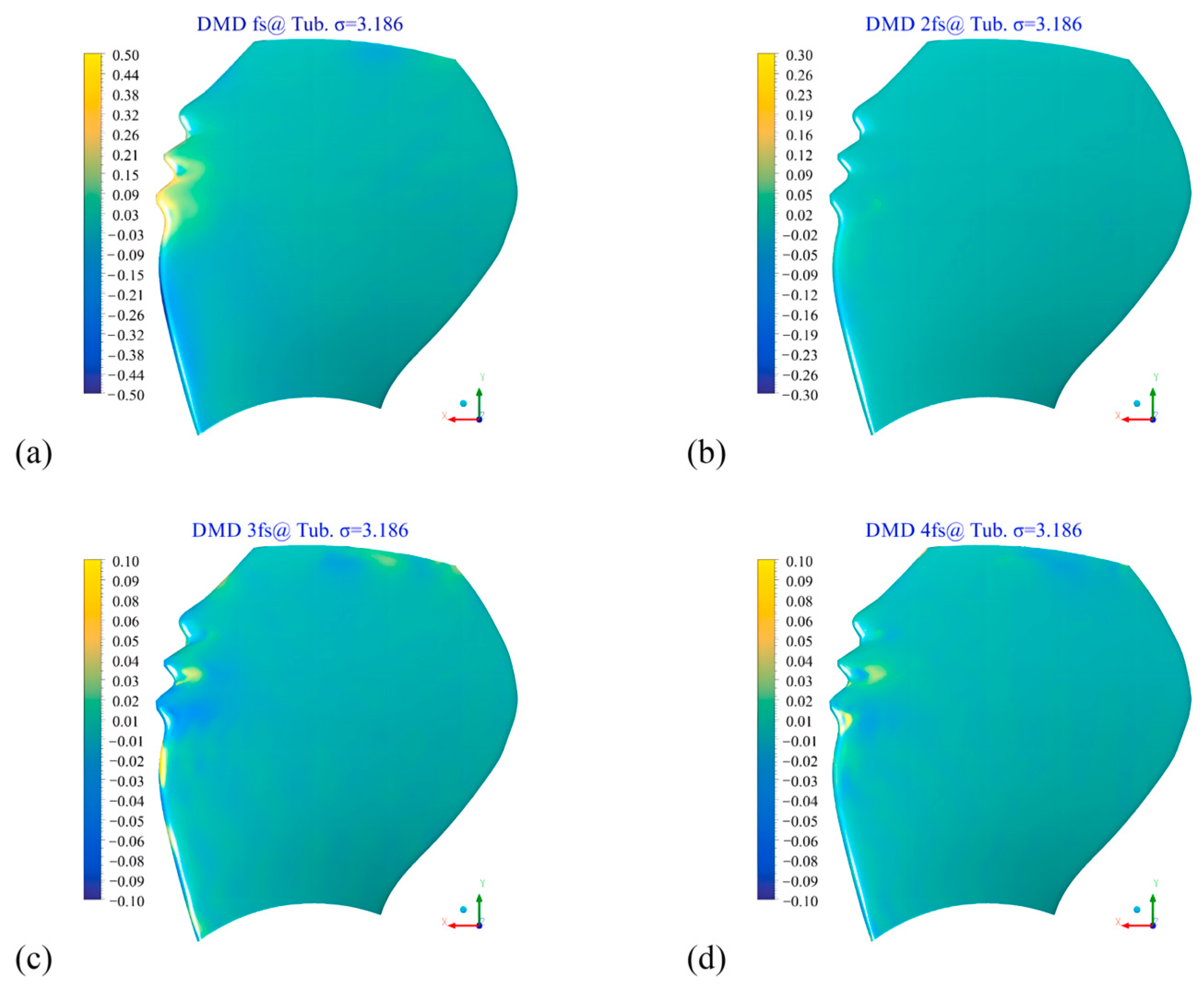

2.1. Bionic Structure of Leaf Blade Leading Edge

2.2. Bionic Shell Structure

3. Bionic Surface Texture Design

4. Bionic Material

5. Conclusions

- (1)

- The application of bionic structures in pump overflow components has proven effective in reducing cavitation. These structures include blade leading-edge bionic structures and bionic worm shell structures. The blade leading-edge bionic structure, inspired by humpback whale flippers and owl feathers, prevents cavitation by imitating elevated nodules and streamlined shapes. This is achieved by controlling the surface flow field of the blade, reducing the size of leading-edge separating vortices and U-shaped vortices. Additionally, the structure reduces pressure pulsations and bubble volume. The design of a bionic snail shell, inspired by the nautilus shell, optimizes the septum tongue and linear elements, promotes pressure distribution, and increases the stability of the internal flow field, contributing to the suppression of cavitation. Modifying the blade leading-edge structure has become a common approach to preventing pump cavitation due to the reduced cost of impeller design and the simplified optimization process. In the future, optimizing the parameters of bionic geometry will likely be the most effective approach to enhance the pump’s anti-cavitation performance.

- (2)

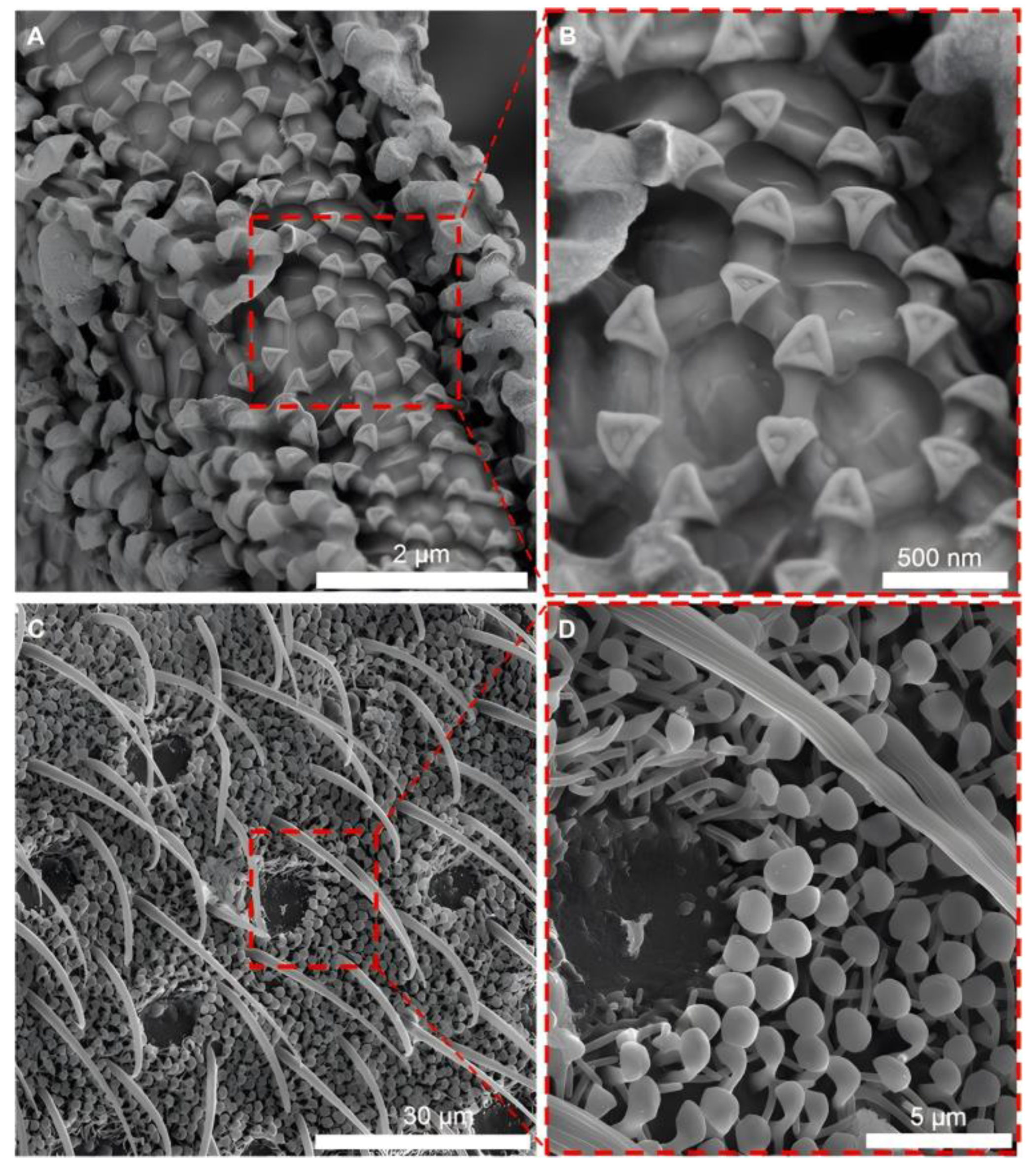

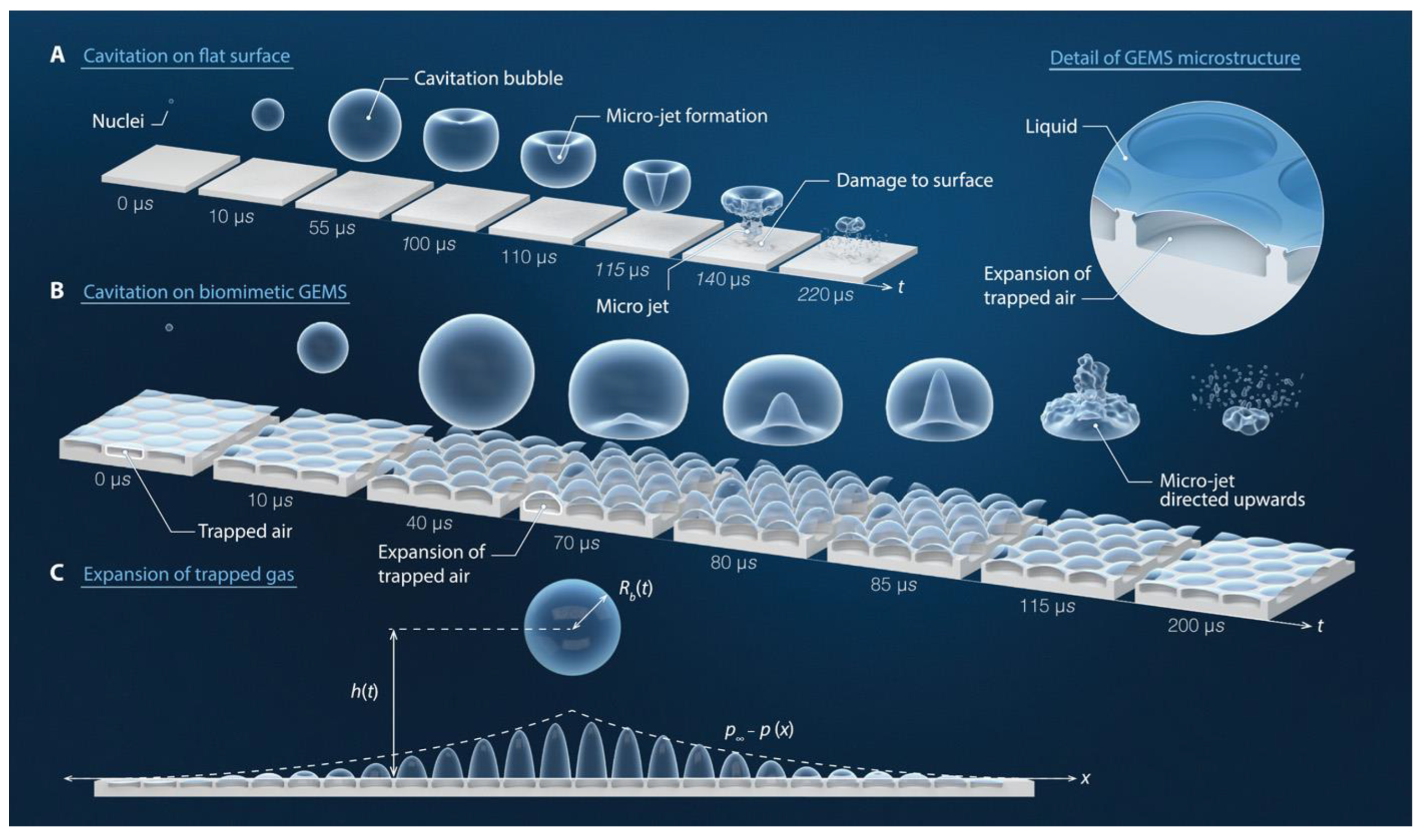

- Bionic surface textures, inspired by the distinct microstructures seen in shark skin, dung beetles, and lizards, have demonstrated several advantageous properties. These designs efficiently regulate the flow of the boundary layer near the wall, thereby decreasing shear stresses and flow resistance associated with the wall, thus preventing cavitation and noise. A novel advancement in this field is biomimetic gas-entrapping microtextured surfaces (GEMSs), which draw inspiration from the unique waterproof structures found in the poplar tail fish and the Chinese seaworm. GEMSs effectively mitigate cavitation erosion by capturing cavitation bubbles and redirecting them away from the material’s surface, preventing their rupture. This development introduces a fresh avenue for exploring biomimetic microtexturing further. Although designing biomimetic textures is challenging, their exceptional resistance to cavitation makes the micrometer and nanometer scale a promising field for future research.

- (3)

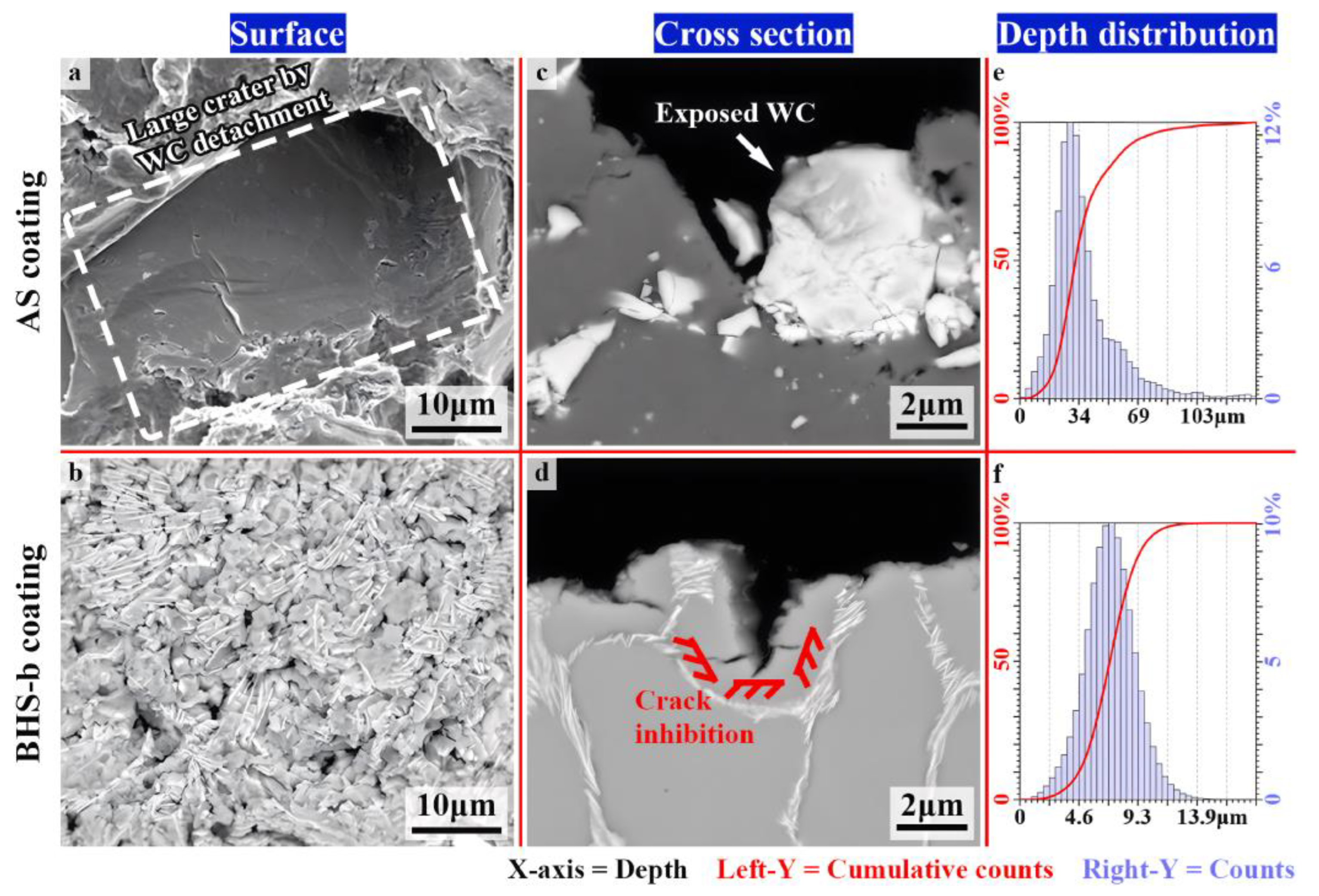

- Novel anti-cavitation biomimetic coatings have been developed based on the properties of biological materials. These coatings include high-strength gradient coatings mimicking shells and super-hydrophobic coatings inspired by lotus leaves. These coatings effectively prevent cavitation by reducing friction and enhancing wear and corrosion resistance. The application of composite biomimetic materials on blade surfaces has emerged as a novel area of investigation for achieving anti-cavitation effects. Nevertheless, the limited use of bionic materials might be attributed to the high costs associated with research and development. In the future, enhancements in the durability and performance of these coatings will be achieved through optimization of their formulation and processing techniques. Additionally, the emergence of novel bionic materials will drive the advancement of anti-cavitation technology, offering promising prospects.

Author Contributions

Funding

Conflicts of Interest

References

- Kadivar, E.; Timoshevskiy, M.V.; Nichik, M.Y.; Moctar, O.E.; Schellin, T.E.; Pervunin, K.S. Control of Unsteady Partial Cavitation and Cloud Cavitation in Marine Engineering and Hydraulic Systems. Phys. Fluids 2020, 32, 052108. [Google Scholar] [CrossRef]

- Vokhidov, O.F.; Nazarov, B.U.; Rayimova, I. Influence of Cavitation-hydro Abrasive Wear and Wear of Vane Hydraulic Machines on the Hydraulic Resistance of the Suction Line of Pumping Units. AIP Conf. Proc. 2023, 2612, 020024. [Google Scholar]

- Benigni, H. Cavitation in Hydraulic Machines: Measurement, Numerical Simulation and Damage Patterns. In Proceedings of the ASME 2020 Fluids Engineering Division Summer Meeting Collocated with the ASME 2020 Heat Transfer Summer Conference and the ASME 2020 18th International Conference on Nanochannels, Microchannels, and Minichannels, Virtual, 13–15 July 2020; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2020. [Google Scholar]

- Brennen, C.E. Cavitation in Medicine. Interface Focus 2015, 5, 20150022. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, Y.; Wu, Y. A review of rotating stall in reversible pump turbine. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 1181–1204. [Google Scholar] [CrossRef]

- Cravero, C.; Marsano, D.; Sishtla, V.; Halbe, C.; Cousins, W.T. Numerical investigations of near surge operating conditions in a two-stage radial compressor with refrigerant gas. J. Eng. Gas Turbines Power 2024, 146, 021010. [Google Scholar] [CrossRef]

- Čdina, M. Detection of Cavitation Phenomenon in a Centrifugal Pump Using Audible Sound. Mech. Syst. Signal Process. 2003, 17, 1335–1347. [Google Scholar] [CrossRef]

- Wu, D.; Ren, Y.; Mou, J.; Gu, Y.; Jiang, L. Unsteady Flow and Structural Behaviors of Centrifugal Pump under Cavitation Conditions. Chin. J. Mech. Eng. 2019, 32, 17. [Google Scholar] [CrossRef]

- Lu, J.; Yuan, S.; Luo, Y.; Yuan, J.; Zhou, B.; Sun, H. Numerical and Experimental Investigation on the Development of Cavitation in a Centrifugal pump. Proc. Inst. Mech. Eng. Part E-J. Process Mech. Eng. 2016, 230, 171–182. [Google Scholar] [CrossRef]

- Kan, K.; Binama, M.; Chen, H.; Zheng, Y.; Zhou, D.; Su, W.; Muhirwa, A. Pump as Turbine Cavitation Performance for Both Conventional and Reverse Operating Modes: A review. Renew. Sustain. Energy Rev. 2022, 168, 112786. [Google Scholar] [CrossRef]

- Li, Y.; Feng, G.; Li, X.; Si, Q.; Zhu, Z. An Experimental Study on the Cavitation Vibration Characteristics of a Centrifugal Pump at Normal Flow Rate. J. Mech. Sci. Technol. 2018, 32, 4711–4720. [Google Scholar] [CrossRef]

- Schiavello, B.; Visser, F.C. Pump Cavitation: Various NPSHR Criteria, NPSHA Margins, Impeller Life Expectancy. In Proceedings of the 25th International Pump Users Symposium, Houston, TX, USA, 23–26 February 2009; Texas A&M University, Turbomachinery Laboratories: College Station, TX, USA, 2009. [Google Scholar]

- Al-Obaidi, A.R. Investigation of Effect of Pump Rotational Speed on Performance and Detection of Cavitation within a Centrifugal Pump Using Vibration Analysis. Heliyon 2019, 5, e01910. [Google Scholar] [CrossRef] [PubMed]

- Friedrichs, J.; Kosyna, G. Rotating Cavitation in a Centrifugal Pump Impeller of Low Specific Speed. J. Fluids Eng. 2002, 124, 356–362. [Google Scholar] [CrossRef]

- Orlandi, F.; Montorsi, L.; Milani, M. Cavitation Analysis through CFD in Industrial Pumps: A review. Int. J. Thermofluids 2023, 20, 100506. [Google Scholar] [CrossRef]

- Homa, D.; Wróblewski, W. Modelling of Flow with Cavitation in Centrifugal Pump. J. Phys. Conf. Ser. 2014, 530, 012032. [Google Scholar] [CrossRef]

- Zhu, H.; Qiu, N.; Wang, C.; Si, Q.; Wu, J.; Deng, F.; Liu, X. Prediction of Cavitation Evolution and Cavitation Erosion on Centrifugal Pump Blades by the DCM-RNG Method. Scanning 2021, 2021, 6498451. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Li, J.; Gao, Z.; Zhang, B. Design and Performance Evaluation of Bionics-based Combined Blade for Horizontal Axis Tidal Current Hydro-turbine. J. Renew. Sustain. Energy 2022, 14, 054501. [Google Scholar] [CrossRef]

- Wang, K.; Ju, Y.; Zhang, C. A Quantitative Evaluation Method for Impeller-Volute Tongue Interaction and Application to Squirrel Cage Fan with Bionic Volute Tongue. J. Fluids Eng. 2019, 141, 081104. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, H.; Wang, J.; Song, T.; Qi, F. The Leading-Edge Structure Based on Geometric Bionics Affects the Transient Cavitating Flow and Vortex Evolution of Hydrofoils. Front. Energy Res. 2022, 9, 821925. [Google Scholar] [CrossRef]

- Dai, C.; Guo, C.; Chen, Y.; Dong, L.; Liu, H. Analysis of the Influence of Different Bionic Structures on the Noise Reduction Performance of the Centrifugal Pump. Sensors 2021, 21, 886. [Google Scholar] [CrossRef]

- Lin, Y.; Li, X.; Zhu, Z.; Wang, X.; Lin, T.; Cao, H. An Energy Consumption Improvement Method for Centrifugal Pump Based on Bionic Optimization of Blade Trailing Edge. Energy 2022, 246, 123323. [Google Scholar] [CrossRef]

- Iannetti, A. A Numerical and Experimental Study on Cavitation in Positive Displacement Pumps and Its Application in Valve Design Optimization. Ph.D. Thesis, University of Strathclyde, Glasgow, UK, 2015. [Google Scholar]

- Calimanescu, I.; Stan, L.-C. Optimization Study of a Centrifugal Pump in Cavitation. In Advanced Topics in Optoelectronics, Microelectronics and Nanotechnologies X; SPIE-Int Soc Optical Engineering: Bellingham, UK, 2020; Volume 11718, pp. 471–480. [Google Scholar]

- Škerlavaj, A.; Titzschkau, M.; Pavlin, R.; Vehar, F.; Mežnar, P.; Lipej, A. Cavitation Improvement of Double Suction Centrifugal Pump HPP Fuhren. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 022009. [Google Scholar] [CrossRef]

- Niazi, E.; Mahjoob, M.J.; Bangian, A. Experimental and Numerical Study of Cavitation in Centrifugal Pumps. In Proceedings of the ASME 2010 10th Biennial Conference on Engineering Systems Design and Analysis, Istanbul, Turkey, 12–14 July 2010; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2010; pp. 395–400. [Google Scholar]

- Mousmoulis, G.; Anagnostopoulos, J.; Papantonis, D. A Review of Experimental Detection Methods of Cavitation in Centrifugal Pumps and Inducers. Int. J. Fluid Mach. Syst. 2019, 12, 71–88. [Google Scholar] [CrossRef]

- Mousmoulis, G.; Karlsen-Davies, N.; Aggidis, G.; Anagnostopoulos, J.; Papantonis, D. Experimental Analysis of the Onset and Development of Cavitation in a Centrifugal Pump. J. Phys. Conf. Ser. 2017, 813, 012044. [Google Scholar] [CrossRef]

- McCaul, C. An Advanced Cavitation Resistant Austenitic Stainless Steel for Pumps. In Proceedings of the CORROSION 96, Denver, CO, USA, 24–29 March 1996; OnePetro: Richardson, TX, USA, 1996. [Google Scholar]

- Kesba, O.K.; Mihoubi, M.K.; Bourkia, M. Study of the Effect of Cavitation upon the Wheels of Different Types of Materials for Pump. Mech. Ind. 2013, 14, 299–304. [Google Scholar] [CrossRef][Green Version]

- Noon, A.A.; Jabbar, A.U.; Koten, H.; Kim, M.; Ahmed, H.W.; Mueed, U.; Shoukat, A.A.; Anwar, B. Strive to Reduce Slurry Erosion and Cavitation in Pumps through Flow Modifications, Design Optimization and Some Other Techniques: Long Term Impact on Process Industry. Materials 2021, 14, 521. [Google Scholar] [CrossRef] [PubMed]

- Pawel, S.J. Assessment of Cavitation-Erosion Resistance of Potential Pump Impeller Materials for Mercury Service at the Spallation Neutron Source: ORNL/TM-2007/033; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2007. [Google Scholar]

- Qiu, N.; Wang, L.; Wu, S.; Likhachev, D.S. Research on cavitation erosion and wear resistance performance of coatings. Eng. Fail. Anal. 2015, 55, 208–223. [Google Scholar] [CrossRef]

- Liu, H.; Cao, M.; Chen, J.; Wang, Y.; Wang, C. Experimental Study on Abrasion and Cavitation Resistance of Non-Metallic Coating Materials for Pump. In Proceedings of the ASME-JSME-KSME 2019 8th Joint Fluids Engineering Conference, San Francisco, CA, USA, 28 July–1 August 2019; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2019. [Google Scholar]

- Steller, J.; Krella, A.; Koronowicz, J.; Janicki, W. Towards Quantitative Assessment of Material Resistance to Cavitation Erosion. Wear 2005, 258, 604–613. [Google Scholar] [CrossRef]

- Li, X.; Yuan, S.; Pan, Z.; Yuan, J.; Fu, Y. Numerical Simulation of Leading-edge Cavitation within the Whole Flow Passage of a Centrifugal Pump. Sci. China Technol. Sci. 2013, 56, 2156–2162. [Google Scholar] [CrossRef]

- Hirschi, R.; Dupont Ph Avellan, F.; Favre, J.; Guelich, J.; Parkinson, E. Centrifugal Pump Performance Drop Due to Leading-edge Cavitation: Numerical Predictions Compared with Model Tests. J. Fluids Eng. 1998, 120, 705–711. [Google Scholar] [CrossRef]

- Tao, R.; Xiao, R.; Wang, Z. Influence of Blade Leading-Edge Shape on Cavitation in a Centrifugal Pump Impeller. Energies 2018, 11, 2588. [Google Scholar] [CrossRef]

- Balasubramanian, R.; Bradshaw, S.; Sabini, E. Influence of Impeller Leading-edge Profiles on Cavitation and Suction Performance. In Proceedings of the Middle East Turbomachinery Symposia. 2013 Proceedings, QA, DOH, QA, DOH, Paphos, Cyprus, 17 March–20 March 2013; Turbomachinery Laboratory, Texas A&M Engineering Experiment Station: College Station, TX, USA, 2013. [Google Scholar]

- Arabnejad, M.H.; Amini, A.; Farhat, M.; Bensow, R.E. Numerical and Experimental Investigation of Shedding Mechanisms from Leading-edge Cavitation. Int. J. Multiph. Flow 2019, 119, 123–143. [Google Scholar] [CrossRef]

- Zheng, H.W.; Liu, J.; Lai, G.H.; Zeng, Y.S.; Yao, Z.F. Application of Different Turbulence Models to Numerical simulation of Hydrofoil Cavitating Flow Field. J. Northeast Electr. Power Univ. 2021, 41, 43–52. (In Chinese) [Google Scholar]

- Fish, F.E.; Battle, J.M. Hydrodynamic Design of the Humpback Whale Flipper. J. Morphol. 1995, 225, 51–60. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.G.; Qin, J.W.; Tian, X.F.; Tian, X.F.; Wen, T.M. Cavitation Characteristics of Bionic Centrifugal Pump Based on “Nodule Effect” of Humpback Whale. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 23–31. (In Chinese) [Google Scholar]

- Wang, L.K.; Liang, C.; Luo, X.Q.; Xie, H.; Zhu, G.J.; Feng, J.J.; Li, C.H. Numerical Investigation of Cavitation Suppression of Centrifugal Pump Based on the Bionic Humpback Whale Blade. J. Phys. Conf. Ser. 2024, 2752, 012126. [Google Scholar] [CrossRef]

- Li, B.; Li, X.; Jia, X.; Chen, F.; Fang, H. The Role of Blade Sinusoidal Tubercle Trailing Edge in a Centrifugal Pump with Low Specific Speed. Processes 2019, 7, 625. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Yan, Q.; Khoo, B.C.; Liu, C.; Guo, M.; Wei, W. Numerical and Experimental Analysis of Biomimetic Tubercle for Cavitation Suppression in Viscous Oil Flow around Hydrofoil. Eng. Appl. Comput. Fluid Mech. 2024, 18, 2394176. [Google Scholar] [CrossRef]

- Xu, K.L.; Bai, T.C.; Wu, F.L.; Xia, L.S.; Zhao, G.T.; Cao, L.L.; Qin, S.J.; Wu, D.Z. Blade Cavitation Control by Leading-Edge Tubercles in Water Jet Pump. J. Propuls. Technol. 2022, 43, 210534. (In Chinese) [Google Scholar]

- Xu, K.L. Study on the Cavitation Control Mechanism of Leading-Edge Tubercles in Axial-Flow Pump Blade. Master’s Thesis, Zhejiang University, Hangzhou, China, 2023. (In Chinese). [Google Scholar]

- Wang, J.Q.; Wan, C.R.; Zhou, M.; Wang, Z.L.; Yang, M.Z. Investigations on Cavitation Suppression of Bionic Water-jet Impeller. J. Phys. Conf. Ser. 2024, 2707, 012147. [Google Scholar] [CrossRef]

- Liu, H.; Lu, Y.; Wang, X.; Li, Y.; Yan, Y.; Lai, X. Investigation of the Effects of the Vane Blades on the CAP1400 Nuclear Coolant Pump’s Performance Based on a Bionic Strategy. Nucl. Eng. Des. 2021, 384, 111465. [Google Scholar] [CrossRef]

- Zhao, G.; Liang, N.; Li, Q.; Cao, L.; Wu, D. Effect Mechanisms of Leading-edge Tubercle on Blade Cavitation Control in a Waterjet Pump. Ocean Eng. 2023, 290, 116240. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Dai, Y.; Gu, Y.Q.; Shi, Z.; Mou, J. Effect of Bionic Groove Surface Blade on Cavitation Characteristics of Centrifugal Pump. In Proceedings of the ASME-JSME-KSME 2019 8th Joint Fluids Engineering Conference, San Francisco, CA, USA, 28 July–1 August 2019; Fluid Mechanics. ASME: New York, NY, USA, 2019; Volume 1, pp. 1–8. [Google Scholar]

- Su, X.Z.; Li, W.J.; Xie, W.C.; Song, f.; Chang, H.; Wang, L. Cavitation Characteristics of Impeller of Water Jet Propulsion Pumps Based on Bionic Airfoil. J. Qingdao Agric. Univ. (Nat. Sci.) 2022, 39, 147–152. (In Chinese) [Google Scholar]

- Zhu, Y.; Zhou, L.; Lv, S.; Shi, W.D.; Ni, H.J.; Li, X.Y.; Tao, C.Z.; Hou, Z.J. Research Progress on Identification and Suppression Methods for Monitoring the Cavitation State of Centrifugal Pumps. Water 2024, 16, 52. [Google Scholar] [CrossRef]

- Rao, Z.; Tang, L.; Zhang, H. Double-Tongue Worm Shell Structure on Plastic Centrifugal Pump Performance Study. Appl. Sci. 2023, 13, 8507. [Google Scholar] [CrossRef]

- Wang, J.; Sun, L.; Zhou, Y.; Liu, Y.; Zhao, F. Numerical Simulation of Cavitation Characteristics of a Centrifugal Pump Based on an Improved ZGB Model. Processes 2023, 11, 438. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Li, Z. Numerical Simulation of Internal Flow Field of Self-Designed Centrifugal Pump. J. Phys. Conf. Ser. 2021, 2097, 012017. [Google Scholar] [CrossRef]

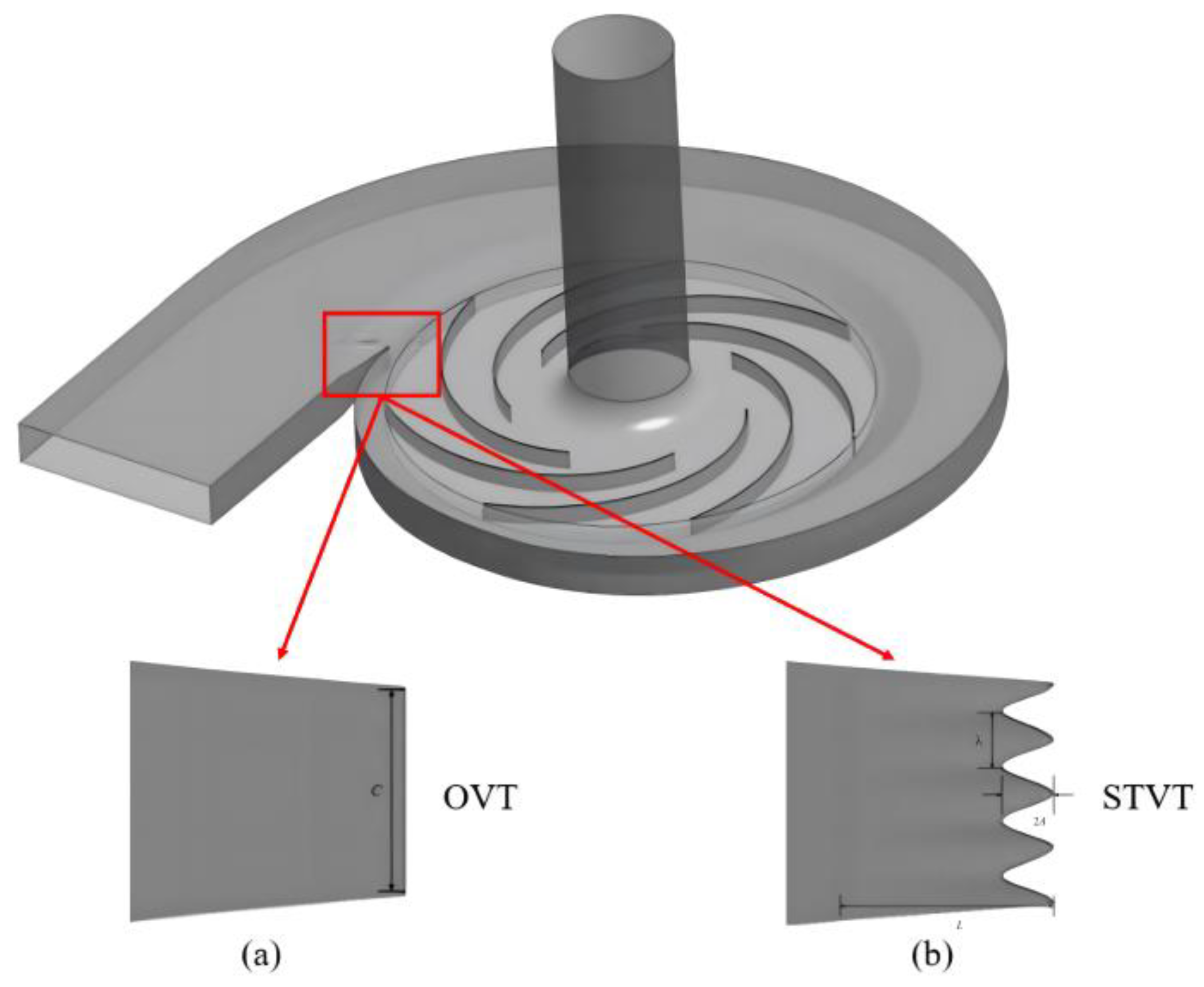

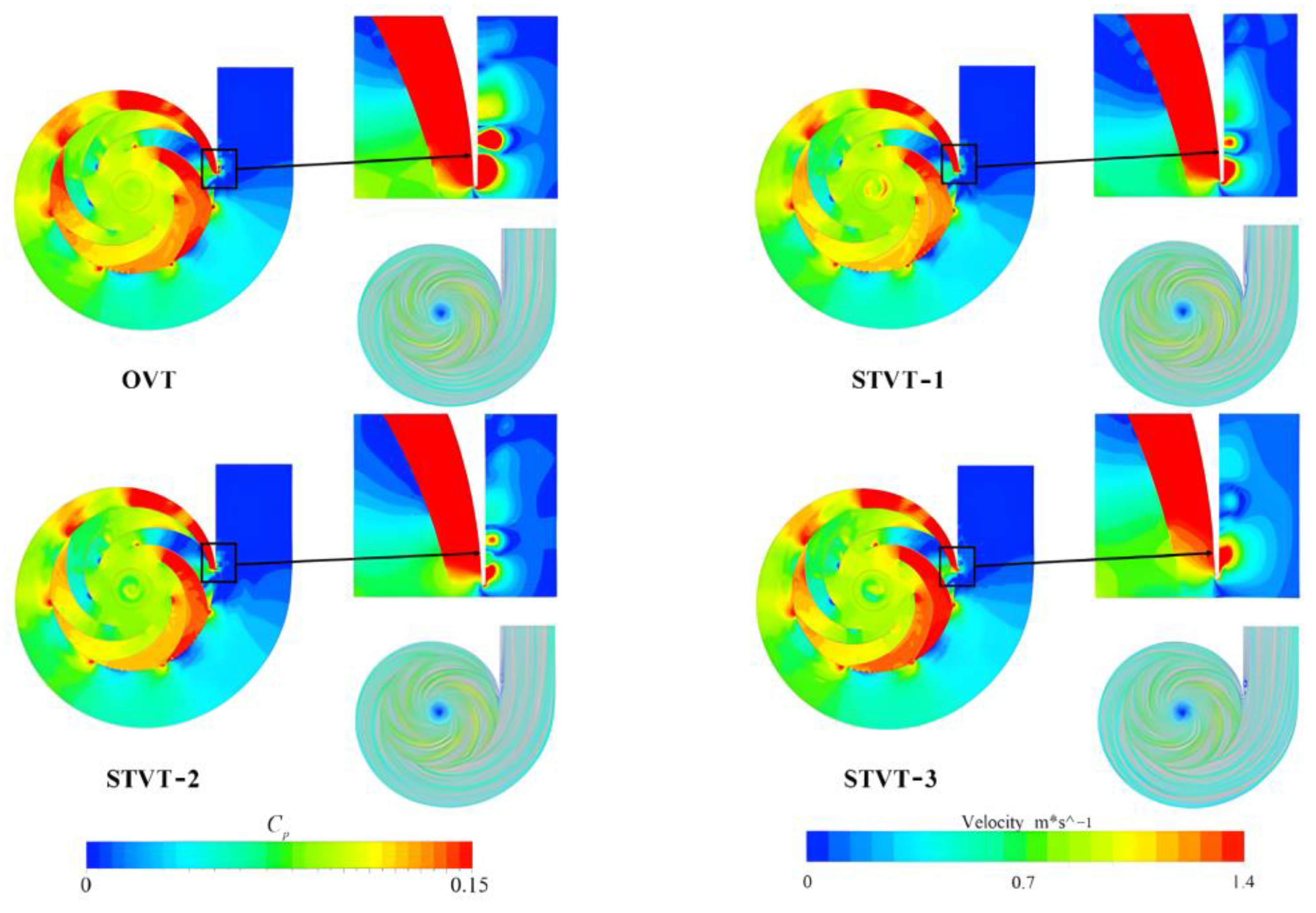

- Lin, P.; Wang, C.; Song, P.; Li, X. Analysis of the Energy Loss and Performance Characteristics in a Centrifugal Pump Based on Sinusoidal Tubercle Volute Tongue. Entropy 2023, 25, 545. [Google Scholar] [CrossRef]

- Wei, W.; Tao, T.; Si, L.; Wang, G.; Yan, Q. Design and Optimization of Bionic Nautilus Volute for a Hydrodynamic Retarder. Eng. Appl. Comput. Fluid Mech. 2023, 17, 2273391. [Google Scholar] [CrossRef]

- Dai, C.; Ge, Z.P.; Dong, L.; Liu, H. Research on Characteristics of Drag Reduction and Noise Reduction on V-groove Surface of Bionic Blade of Centrifugal Pump. Huazhong Univ. Sci. Tech. (Nat. Sci. Ed.) 2020, 48, 113–118. (In Chinese) [Google Scholar]

- Dai, C.; Guo, C.; Ge, Z.; Liu, H.; Dong, L. Study on Drag and Noise Reduction of Bionic Blade of Centrifugal Pump and Mechanism. J. Bionic Eng. 2021, 18, 428–440. [Google Scholar] [CrossRef]

- Ge, Z.P. Research on Drag Reduction and Noise Reduction Characteristics of Bionic Blades of Centrifugal Pump Based on Massive Parallel Grid. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2020. (In Chinese). [Google Scholar]

- Qian, Z.D.; Dong, J.; Guo, Z.W.; Wang, Z.Y.; Wang, F. Study of a Bionic Anti-Erosion Bladeina Double Suction Centrifugal Pump; American Society of Mechanical Engineers: Washington, DC, USA, 2016. [Google Scholar]

- Dong, J.; Qian, Z.; Thapa, B.S.; Thapa, B.; Guo, Z. Alternative Design of Double-Suction Centrifugal Pump to Reduce the Effects of Silt Erosion. Energies 2019, 12, 158. [Google Scholar] [CrossRef]

- Hensel, R.; Neinhuis, C.; Werner, C. The Springtail Cuticle as a Blueprint for Omniphobic Surfaces. Chem. Soc. Rev. 2016, 45, 323–341. [Google Scholar] [CrossRef] [PubMed]

- Nickerl, J.; Helbig, R.; Schulz, H.-J.; Werner, C.; Neinhuis, C. Diversity and Potential Correlations to the Function of Collembola Cuticle Structures. Zoomorphology 2013, 132, 183–195. [Google Scholar] [CrossRef]

- Cheng, L. Biology of Halobates (Heteroptera: Gerridae). Ann. Rev. Entomol. 1985, 30, 111–135. [Google Scholar] [CrossRef]

- Cheng, L. Marine and Freshwater Skaters: Differences in Surface Fine Structures. Nature 1973, 242, 132–133. [Google Scholar] [CrossRef]

- Gonzalez-Avila, S.R.; Nguyen, D.M.; Arunachalam, S.; Domingues, E.M.; Mishra, H.; Ohl, C. Mitigating Cavitation Erosion Using Biomimetic Gas-entrapping MiCrotextured Surfaces (GEMS). Sci. Adv. 2020, 6, eaax6192. [Google Scholar] [CrossRef]

- Zhao, W.G.; Zhao, F.R.; Lu, J.J. Study on the Control of Cavitation of Axial Flow Pump with Discontinuous Bulges on the Back of Blades. J. Eng. Thermophys. 2021, 42, 96–105. (In Chinese) [Google Scholar]

- Tian, L.M.; Ren, L.Q.; Peng, Z.Y. Numerical Simulation of Efficiency and Energy Saving Characteristics of Bionic Non-Smooth Centrifugal Water Pumps; China Agricultural Machinery Association: Jilin, China, 2008; p. 5. (In Chinese) [Google Scholar]

- Mou, J.G.; Zhang, Z.C.; Gu, Y.Q.; Shi, D.Z.; Zheng, S.H. Effect of Circular Non-Smooth Surface Blades on Cavitation Characteristics of Centrifugal Pump. J. Shanghai Jiao Tong Univ. 2020, 54, 577–583. (In Chinese) [Google Scholar]

- Ren, L.Q.; Peng, Z.Y.; Chen, Q.H.; Zhao, G.R.; Wang, T.J. Experi Mental Study on Efficiency Enhancement of Centrifugal Water Pump by Bionic Non-smooth Technique. J. Jilin Univ. (Eng. Technol. Ed.) 2007, 37, 575–581. (In Chinese) [Google Scholar]

- Peng, Z.Y. Research on Bionic Non-Smooth Increased Efficiency of Centrifugal Water Pump. Master’s Thesis, Jilin University, Changchun, China, 2006. (In Chinese). [Google Scholar]

- Zhao, W.G.; Zhao, G.S.; Xian, L.X.; Zhao, X.D. Effect of Surface-fitted Obstacle in Centrifugal Pump on Cavitation Suppression. J. Agric. Mach. 2017, 48, 111–120. (In Chinese) [Google Scholar]

- Zhang, X.; Xie, J.; Chen, J.; Okabe, Y.; Pan, L.; Xu, M. The Beetle Elytron Plate: A Lightweight, High-strength and Buffering Functional-structural Bionic Material. Sci. Rep. 2017, 7, 4440. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Zhou, F.; Chen, X.; Zhang, Y. Performance Analysis of Axial Air Cooling System with Shark-skin Bionic Structure Containing Phase Change Material. Energy Convers. Manag. 2021, 250, 114921. [Google Scholar] [CrossRef]

- Liu, E.; Li, L.; Wang, G.; Zeng, Z.; Zhao, W.; Xue, Q. Drag Reduction through Self-texturing Compliant Bionic Materials. Sci. Rep. 2017, 7, 40038. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Wang, C.; Wang, W.; Xing, H.; Zhang, Z.; Gao, D. Effect of Composite Bionic Micro-Texture on Bearing Lubrication and Cavitation Characteristics of Slipper Pair. J. Mar. Sci. Eng. 2023, 11, 582. [Google Scholar] [CrossRef]

- Yu, H.; Shao, L.; Zhang, S.; Zhang, J.; Han, Z. An Innovative Strategy of Anti-erosion: Combining Bionic Morphology and Bionic Arrangement. Powder Technol. 2022, 407, 117653. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, W.; Chen, W.; Feng, Z.; Wu, D.; Liu, L.; Wang, Y. Integration of Antifouling and Anti-Cavitation Coatings on Propellers: A Review. Coatings 2023, 13, 1619. [Google Scholar] [CrossRef]

- Yu, Z.; Xin, R.; Xu, Z.; Sha, L.; Chen, L.; Zhu, Y.; Liang, P.; Zhang, Z.; Liu, Z.; Cao, Q. Shock-Resistant Energy-Absorbing Properties of Bionic NiTi Lattice Structure Manufactured by, S.L.M. J. Bionic Eng. 2022, 19, 1684–1698. [Google Scholar] [CrossRef]

- Bozkurt, S.; Van De Vosse, F.N.; Rutten, M.C.M. Enhancement of Arterial Pressure Pulsatility by Controlling Continuous-Flow Left Ventricular Assist Device Flow Rate in Mock Circulatory System. J. Med. Biol. Eng. 2016, 36, 308–315. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, Z.; Ge, Z.; Dong, L.; Dai, C. Collaborative Improvement of Efficiency and Noise of Bionic Vane Centrifugal Pump Based on Multi-objective Optimization. Adv. Mech. Eng. 2021, 13, 1687814021994976. [Google Scholar] [CrossRef]

- Grossman, M.; Pivovarov, D.; Bouville, F.; Dransfeld, C.; Masania, K.; Studart, A. Hierarchical Toughening of Nacre-like Composites. Adv. Funct. Mater. 2019, 29, 1806800. [Google Scholar] [CrossRef]

- Limei, T.; Haoran, M.; Xinhong, L.; Tian, L.; Mei, H.; Li, X.; Wang, Y.; Yang, L.; Shao, P. Enhancement Mechanism Investigation of Centrifugal Pump Based on Bionic Coupling Functional Surface. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2015, 46, 1–6. [Google Scholar]

- Tian, L.; Gao, Z.; Ren, L.; Han, Z.; Liao, G. The Study of the Efficiency Enhancement of Bionic Coupling Centrifugal Pumps. J. Braz. Soc. Mech. Sci. Eng. 2013, 35, 517–524. [Google Scholar] [CrossRef]

- Huang, C.; He, X.; Zhang, J. Interaction between Cavitation Bubbles and Plastrons on Superhydrophobic Surfaces. Ultrason. Sonochem. 2024, 109, 107016. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Zhang, B.; Wang, Z.; Su, W.; Niu, S.; Han, Z.; Ren, L. Bioinspired Strategies for Excellent Mechanical Properties of Composites. J. Bionic Eng. 2022, 19, 1203–1228. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, R.; Gu, Z.; Zhao, H.; Wu, X.; Dehaghani, S.T.; Chen, H.; Liu, X.; Xiao, T.; McDonald, A.; et al. Ultrahigh Cavitation Erosion Resistant Metal-matrix Composites with Biomimetic Hierarchical Structure. Compos. Part B Eng. 2022, 234, 109730. [Google Scholar] [CrossRef]

- Zhang, J.X. Fabrication and Protection Mechanism of Anti-Corrosion Bionic and Elastic Functionally Gradient Surface. Master’s Thesis, Jilin University, Changchun, China, 2019. (In Chinese). [Google Scholar]

- Wen, S.-M.; Chen, S.-M.; Gao, W.; Zheng, Z.; Bao, J.Z.; Cui, C.; Liu, S.; Gao, H.L.; Yu, S.H. Biomimetic Gradient Bouligand Structure Enhances Impact Resistance of Ceramic-Polymer Composites. Adv. Mater. 2023, 35, 2211175. [Google Scholar] [CrossRef]

| Author | Inspired By | Design | Effectiveness |

|---|---|---|---|

| Zhao et al. [41] | Humpback whale nodule effect. | Biomimetic centrifugal pump blades. | Reduced cavitation volume in impeller by 99.72%, stable hydraulic performance. |

| Wang et al. [42] | Humpback whale flippers. | Biomimetic centrifugal pump blades. | Higher lift and slower cavitation development increased pump stability. |

| Li et al. [43] | Humpback whale flippers. | Biomimetic wavy trailing edge (STTE). | Reduced pressure pulsation, improved hydraulic performance. |

| Zhang et al. [44] | Humpback whale flippers. | Biomimetic tubercles on leading edge. | Reduced cavitation bubble volume by 9.67%, decreased drag coefficient by 9.36%. |

| Xu et al. [45] | Humpback whale flippers. | Biomimetic impeller. | Increased head by up to 10%, minimal efficiency loss (<2.5%). |

| Wang et al. [47] | Humpback whale nodule effect. | Non-smooth sinusoidal leading edge | Better anti-cavitation ability with shorter wavelengths. |

| The Time-Averaged Total Entropy (J/m2) | Reduction (%) | Efficiency (%) | |

|---|---|---|---|

| OVT | 3633 | 0 | 83.4 |

| STVT—1 | 3309 | 8.93 | 84.7 |

| STVT—2 | 3304 | 9.07 | 85.1 |

| STVT—3 | 3270 | 10.01 | 85.5 |

| Flow Rate | Average Shear Stress (Pa) | Shear Strain (%) | |

|---|---|---|---|

| Smooth Blade | Bionic Blade | ||

| 0.8 Qd | 22.02 | 17.13 | 22.16 |

| 1.0 Qd | 40.63 | 30.01 | 26.20 |

| 1.2 Qd | 85.13 | 60.75 | 29.00 |

| 1.4 Qd | 98.00 | 71.13 | 27.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhou, X.; Zhao, H.; Mou, C.; Meng, L.; Sun, L.; Zhou, P. Bionic Strategies for Pump Anti-Cavitation: A Comprehensive Review. Energies 2024, 17, 5149. https://doi.org/10.3390/en17205149

Li J, Zhou X, Zhao H, Mou C, Meng L, Sun L, Zhou P. Bionic Strategies for Pump Anti-Cavitation: A Comprehensive Review. Energies. 2024; 17(20):5149. https://doi.org/10.3390/en17205149

Chicago/Turabian StyleLi, Jian, Xing Zhou, Hongbo Zhao, Chengqi Mou, Long Meng, Liping Sun, and Peijian Zhou. 2024. "Bionic Strategies for Pump Anti-Cavitation: A Comprehensive Review" Energies 17, no. 20: 5149. https://doi.org/10.3390/en17205149

APA StyleLi, J., Zhou, X., Zhao, H., Mou, C., Meng, L., Sun, L., & Zhou, P. (2024). Bionic Strategies for Pump Anti-Cavitation: A Comprehensive Review. Energies, 17(20), 5149. https://doi.org/10.3390/en17205149