Control of Liquid Hydrocarbon Combustion Parameters in Burners with Superheated Steam Supply

Abstract

1. Introduction

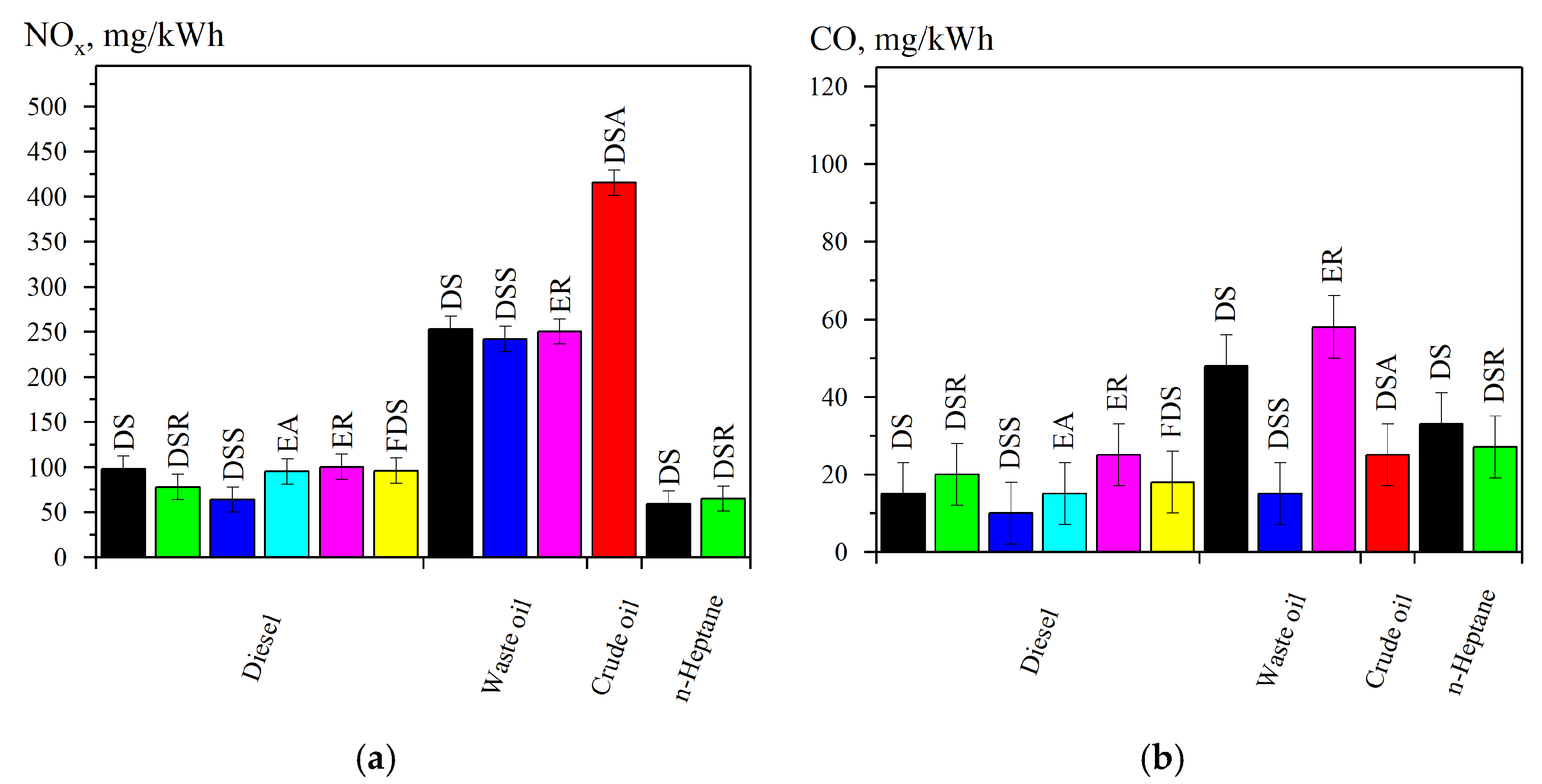

2. Methods and Materials

3. Results

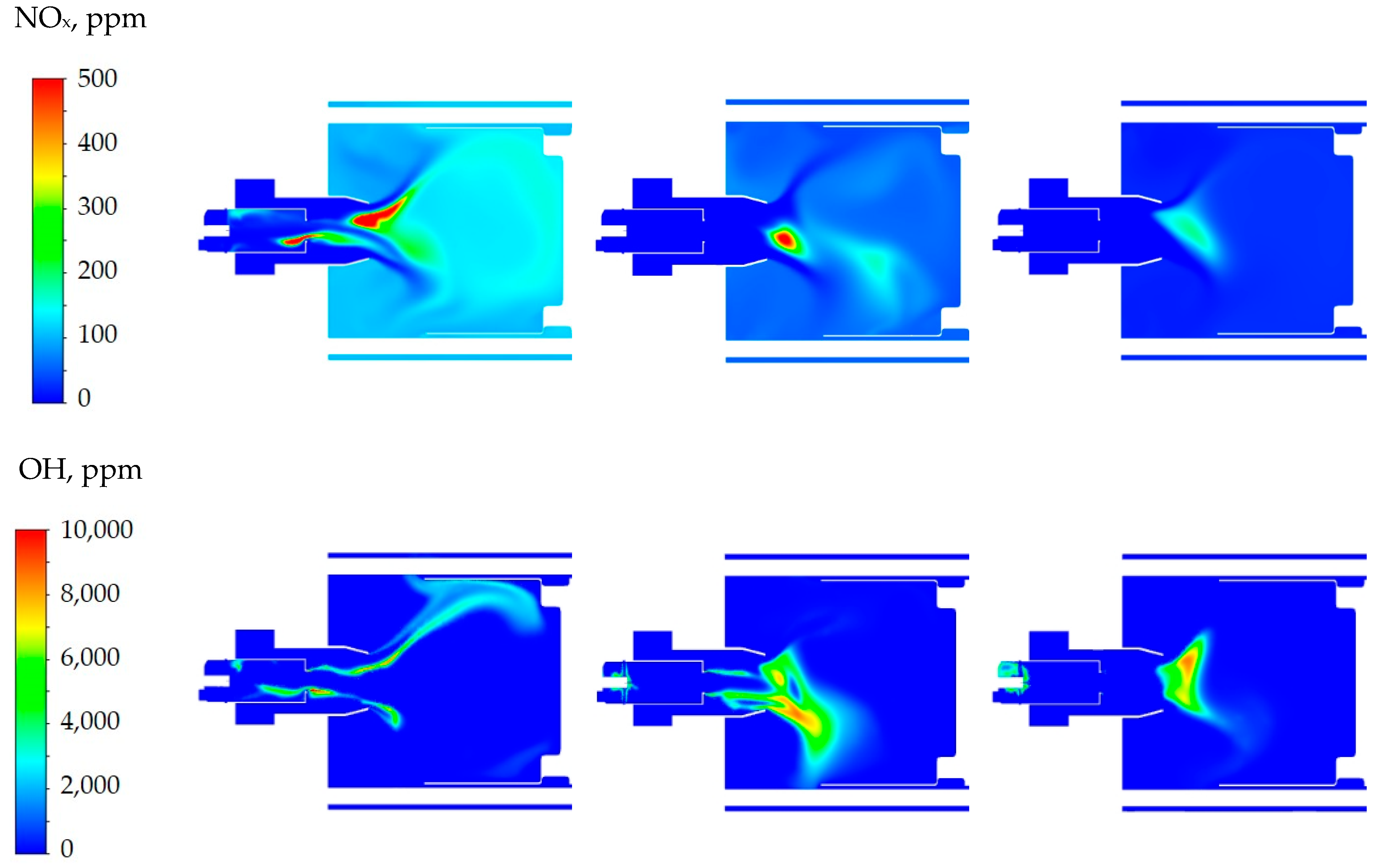

3.1. Numerical Simulation

3.2. Comparison with Experimental Data on Atmospheric Burners with Partial Gasification

3.2.1. Evaporative Burners

Evaporative Burner with Autonomous Steam Generation (EA)

Evaporative Burner with Regulated Steam Supply (ER)

3.2.2. Spray Steam Burners

Direct-Flow Spray Burner (DS)

Direct-Flow Spray Burner with Afterburner (DSA)

Direct-Flow Swirl Spray Burner (DSS)

Direct-Flow Spray Burner with Regulated Air Supply to the Gas Generation Chamber (DSR)

3.3. Discussion

4. Conclusions

- (1)

- To comply with the emissions of toxic combustion products from class 3 EN-267 burners up to 20 kW, relative steam consumption must exceed 0.6. At the same time, high combustion completeness is ensured, whereby this ratio does not exceed a certain value depending on the type of burner device—1.0 for an evaporation burner; 1.0 for a direct flow spray burner; and 1.2 for a swirl spray burner.

- (2)

- A temperature of superheated steam of 250 °C ensures stable operation over a wide range of conditions.

- (3)

- An additional reduction in the production of toxic products depends on the excess air ratio. A supply of air to the gas generation chamber ranging from 0.3 to 0.15 times stoichiometric leads to a decrease in NOx by up to 20% (too low an air intake does not ensure stable combustion).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- De Giorgi, M.G.; Pescini, E.; Campilongo, S.; Ciccarella, G.; Fontanarosa, D.; Ficarella, A. Effects of emulsified fuel on the performance and emission characteristics of aeroengine combustors. J. Eng. Gas Turbines Power 2019, 141, 101021. [Google Scholar] [CrossRef]

- Xiaogang, W.; Bolan, L.; Xiyang, Y.; Chao, Y.; Fei, Y.; Zhenfeng, Z. Study on fuel and injection influence on a spark ignition aeropiston engine. J. Eng. Gas Turbines Power 2020, 142, 71006. [Google Scholar] [CrossRef]

- Aradhey, Y.; Stroud, Z.; Meadows, J. The Effect of Swirl Number On Lean Blow Out Limits of Lean Direct Injection Combustors. J. Eng. Gas Turbines Power 2024, 146, 101005-1. [Google Scholar] [CrossRef]

- Glassman, I.; Yetter, R.A. Combustion; Glassman, I., Yetter, R.A., Glumac, N.G., Eds.; Academic Press: Cambridge, MA, USA, 2008; ISBN 978-0-12-088573-2. [Google Scholar]

- Anufriev, I.S.S. Review of water/steam addition in liquid-fuel combustion systems for NOx reduction: Waste-to-energy trends. Renew. Sustain. Energy Rev. 2021, 138, 110665. [Google Scholar] [CrossRef]

- Makwana, J.; Dhass, A.D.; Ramana, P.V.; Sapariya, D.; Patel, D. An analysis of waste/biomass gasification producing hydrogen-rich syngas: A review. Int. J. Thermofluids 2023, 20, 100492. [Google Scholar] [CrossRef]

- Anitescu, G.; Bruno, T.J.; Tavlarides, L.L. Dieseline for Supercritical Injection and Combustion in Compression-Ignition Engines: Volatility, Phase Transitions, Spray/Jet Structure, and Thermal Stability. Energy Fuels 2012, 26, 6247–6258. [Google Scholar] [CrossRef]

- Su, C.-G.; Lin, S.-J. Burner of Liquid Fuel. Patent TW201116779A, 16 May 2011. [Google Scholar]

- Kuk, O.B. Liquid Fuel Burner. Patent KR20170052186A, 12 May 2017. [Google Scholar]

- Ritter, K.; Klausmann, W. Burner for Liquid Fuel. Patent DE102009043681A1, 7 April 2011. [Google Scholar]

- Pannwitz, T.; Schwanecke, M.; Smigiel, B. Burner for Burning Liquid Fuel. Patent DE102011006370A1, 4 October 2012. [Google Scholar]

- Li, Y. Liquid Fuel Burner. Patent CN101968218A, 9 February 2011. [Google Scholar]

- Lin, R.; Tavlarides, L.L. Thermal stability and decomposition of diesel fuel under subcritical and supercritical conditions. J. Supercrit. Fluids 2013, 75, 101–111. [Google Scholar] [CrossRef][Green Version]

- Higman, C.; Van der Burgt, M. Gasification; Elsevier: Amsterdam, The Netherlands, 2008; ISBN 9780750685283. [Google Scholar] [CrossRef]

- Jin, X.; Teng, D.; Fang, J.; Liu, Y.; Jiang, Z.; Song, Y.; Zhang, T.; Siyal, A.A.; Dai, J.; Fu, J.; et al. Petroleum oil and products recovery from oily sludge: Characterization and analysis of pyrolysis products. Environ. Res. 2021, 202, 111675. [Google Scholar] [CrossRef]

- Castillo Santiago, Y.; Pérez, J.F.; Sphaier, L.A. Reaction-front and char characterization from a palm kernel shell—Oil sludge mixture under oxygen lean regimes in a fixed-bed gasifier. Fuel 2023, 333, 126402. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Masoumi, M.; Askarinezhad, R. Evolving Connectionist Model to Monitor the Efficiency of an In Situ Combustion Process: Application to Heavy Oil Recovery. Energy Technol. 2014, 2, 811–818. [Google Scholar] [CrossRef]

- Cheng, S.; Wang, Y.; Fumitake, T.; Kouji, T.; Li, A.; Kunio, Y. Effect of steam and oil sludge ash additive on the products of oil sludge pyrolysis. Appl. Energy 2017, 185, 146–157. [Google Scholar] [CrossRef]

- Chu, Z.; Li, Y.; Zhang, C.; Fang, Y.; Zhao, J. A review on resource utilization of oil sludge based on pyrolysis and gasification. J. Environ. Chem. Eng. 2023, 11, 109692. [Google Scholar] [CrossRef]

- Yan, B.; Jia, X.; Li, J.; Li, Z.; Che, Y.; Zhou, Z.; Zhao, J.; Zhou, S.; Chen, G. In-situ elimination of biomass gasification tar based on the understanding of tar formation process: A review. J. Energy Inst. 2024, 112, 101477. [Google Scholar] [CrossRef]

- Mendiara, T.; Adánez-Rubio, I.; Gayán, P.; Abad, A.; de Diego, L.F.; García-Labiano, F.; Adánez, J. Process Comparison for Biomass Combustion: In Situ Gasification-Chemical Looping Combustion (iG-CLC) versus Chemical Looping with Oxygen Uncoupling (CLOU). Energy Technol. 2016, 4, 1130–1136. [Google Scholar] [CrossRef]

- Shen, Y. Biomass pretreatment for steam gasification toward H2-rich syngas production—An overview. Int. J. Hydrogen Energy 2024, 66, 90–102. [Google Scholar] [CrossRef]

- Xu, M.; Wu, Y.; Nan, D.; Lu, Q.; Yang, Y. Effects of gaseous agents on the evolution of char physical and chemical structures during biomass gasification. Bioresour. Technol. 2019, 292, 121994. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Yu, I.K.M.; Xiong, X.; Tsang, D.C.W.; Zhang, S.; Clark, J.H.; Hu, C.; Ng, Y.H.; Shang, J.; Ok, Y.S. Biorenewable hydrogen production through biomass gasification: A review and future prospects. Environ. Res. 2020, 186, 109547. [Google Scholar] [CrossRef]

- Piazzi, S.; Menin, L.; Antolini, D.; Patuzzi, F.; Baratieri, M. Potential to retrofit existing small-scale gasifiers through steam gasification of biomass residues for hydrogen and biofuels production. Int. J. Hydrogen Energy 2021, 46, 8972–8985. [Google Scholar] [CrossRef]

- Alekseenko, S.V.; Pashchenko, S.É.; Salomatov, V.V. Nanocluster initiation of combustion of off-grade hydrocarbon fuels. J. Eng. Phys. Thermophys. 2010, 83, 729–741. [Google Scholar] [CrossRef]

- Jang, H.H.; Hwa, S.S. Combustion Burner Apparatus Using Superheated Steam. Patent KR102018297B1, 5 September 2019. [Google Scholar]

- Jian, L.; Deyong, W.; Dong, W. Heavy Component Reinforced Torch Burner. Patent CN214370256U, 8 October 2021. [Google Scholar]

- Fuxiang, G.; Jun, C.; Jian, H. Burner for Incineration. Patent CN105605573A, 25 May 2016. [Google Scholar]

- Jian, L.; Deyong, W.; Dong, W. Low-Calorific-Value Heavy Component Combined Torch Burner. Patent CN214275702U, 24 September 2021. [Google Scholar]

- Ott, J.; Gronemann, V.; Lehmann, M.; Krimlowski, P.M. Burner and Process for Producing Synthesis Gas. Patent US20200180954A1, 11 June 2020. [Google Scholar]

- Alekseenko, S.V.; Anufriev, I.S.; Vigriyanov, M.S.; Kopyev, E.P.; Sharypov, O.V. Characteristics of diesel fuel combustion in a burner with injection of a superheated steam jet. Combust. Explos. Shock Waves 2016, 52, 286–293. [Google Scholar] [CrossRef]

- Anufriev, I.S.; Alekseenko, S.V.; Sharypov, O.V.; Kopyev, E.P. Diesel fuel combustion in a direct-flow evaporative burner with superheated steam supply. Fuel 2019, 254, 115723. [Google Scholar] [CrossRef]

- Anufriev, I.S.; Kopyev, E.P.; Mukhina, M.A.; Sadkin, I.S. Investigation into Characteristics of Combustion of n-Heptane Sprayed by Jet of Steam or Air. J. Eng. Thermophys. 2022, 31, 420–428. [Google Scholar] [CrossRef]

- Anufriev, I.S.; Kopyev, E.P.; Sadkin, I.S.; Mukhina, M.A. Diesel and waste oil combustion in a new steam burner with low NOX emission. Fuel 2021, 290, 120100. [Google Scholar] [CrossRef]

- Anufriev, I.S.; Alekseenko, S.V.; Kopyev, E.P.; Sharypov, O.V. Combustion of Substandard Liquid Hydrocarbons in Atmosphere Burners with Steam Gasification. J. Eng. Thermophys. 2019, 28, 324–331. [Google Scholar] [CrossRef]

- Anufriev, I.S.; Kopyev, E.P.; Sadkin, I.S.; Mukhina, M.A.; Minakov, A.V.; Kuznetsov, V.A. Combustion of n-heptane with steam injection in a laboratory spray burner. Thermophys. Aeromech. 2023, 30, 249–262. [Google Scholar] [CrossRef]

- Sadkin, I.S.; Mukhina, M.A.; Shadrin, E.Y.; Kopyev, E.P. Design, Adjustment, and Mode Research of Low-Emission Burner for Fuel Combustion in a Superheated Steam Jet. J. Appl. Mech. Tech. Phys. 2024, 65, 1–6. [Google Scholar] [CrossRef]

- DIN EN 267:2011-11; Automatic Forced Draught Burners for Liquid Fuels. Beuth Verlag GmbH: Berlin, Germany, 2011.

- Minakov, A.V.; Anufriev, I.S.; Kuznetsov, V.A.; Dekterev, A.A.; Kopyev, E.P.; Sharypov, O.V. Combustion of liquid hydrocarbon fuel in an evaporative burner with forced supply of superheated steam and air to the reaction zone. Fuel 2022, 309, 122181. [Google Scholar] [CrossRef]

- Anufriev, I.S.; Shadrin, E.Y.; Kopyev, E.P.; Sharypov, O.V. Experimental investigation of size of fuel droplets formed by steam jet impact. Fuel 2021, 303, 121183. [Google Scholar] [CrossRef]

- Alekseenko, S.V.; Anufriev, I.S.; Arsentyev, S.S.; Vigriyanov, M.S.; Kopyev, E.P.; Sharypov, O.V. Influence of parameters of superheated steam on combustion of liquid hydrocarbons. Thermophys. Aeromech. 2019, 26, 103–107. [Google Scholar] [CrossRef]

- Mulhem, B.; Fritsching, U.; Schulte, G.; Bauckhage, K. Effect of solid particle characteristics on suspension atomization. At. Sprays 2003, 13, 321–343. [Google Scholar] [CrossRef]

- Ashgriz, N. Handbook of Atomization and Sprays; Springer: New York, NY, USA, 2011. [Google Scholar] [CrossRef]

- Azzopardi, B.J. Drop sizes in annular two-phase flow. Exp. Fluids 1985, 3, 53–59. [Google Scholar] [CrossRef]

- Hede, P.D.; Bach, P.; Jensen, A.D. Two-fluid spray atomisation and pneumatic nozzles for fluid bed coating/agglomeration purposes: A review. Chem. Eng. Sci. 2008, 63, 3821–3842. [Google Scholar] [CrossRef]

- Danis, A.M.; Namer, I.; Cernansky, N.P. Droplet size and equivalence ratio effects on spark ignition of monodisperse N-heptane and methanol sprays. Combust. Flame 1988, 74, 285–294. [Google Scholar] [CrossRef]

- Odgers, J.; Kretschmer, D.; Pearce, G.F. The Combustion of Droplets Within Gas Turbine Combustors: Some Recent Observations on Combustion Efficiency. J. Eng. Gas Turbines Power 1993, 115, 522–532. [Google Scholar] [CrossRef]

- Kramm, K.; Orth, M.; Teiwes, A.; Kammerhofer, J.C.; Meunier, V.; Pietsch-Braune, S.; Heinrich, S. Influence of Nozzle Parameters on Spray Pattern and Droplet Characteristics for a Two-Fluid Nozzle. Chem. Ing. Tech. 2023, 95, 151–159. [Google Scholar] [CrossRef]

- Razak, A.M.Y. Industrial Gas Turbines: Performance and Operability; Woodhead Publishing Limited: Sawston, UK, 2007; ISBN 9781845692056. [Google Scholar] [CrossRef]

- Anufriev, I.; Kovyev, E.; Alekseenko, S.S.; Sharypov, O.; Butakov, E.; Vigriyanov, M.; Sadkin, I. Cleaner crude oil combustion during superheated steam atomization. Therm. Sci. 2021, 25, 331–345. [Google Scholar] [CrossRef]

| Numerical Simulation | Experiment [38] | ||||

|---|---|---|---|---|---|

| Relative steam consumption | 0.02 | 0.3 | 0.5 | 1.0 | 1.4 |

| Temperature, °C | 493 | 446 | 436 | - | - |

| CO, ppm (mg/kWh) | 20,000 (28,900) | 23 (33) | 16 (22) | 35 (53) | 24 (35) |

| NOx, ppm (mg/kWh) | 145 (344) | 61 (147) | 58 (135) | 57 (138) | 52 (127) |

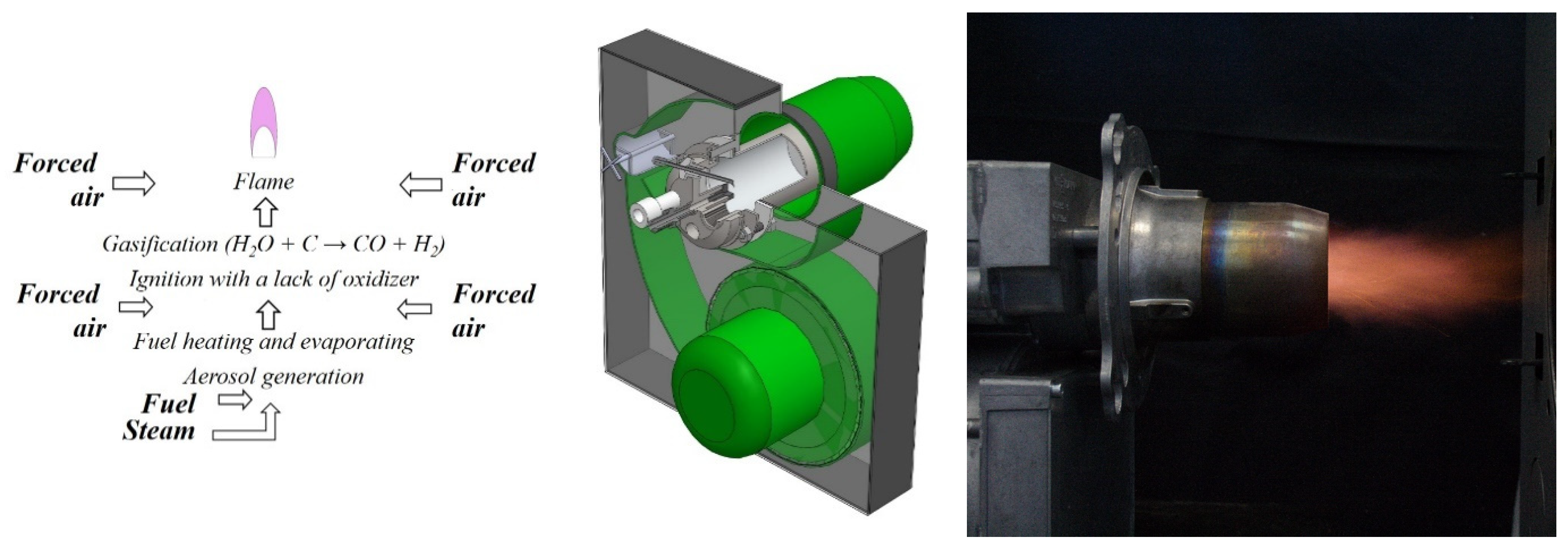

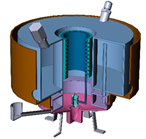

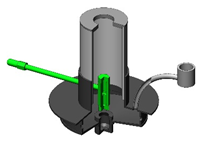

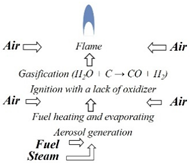

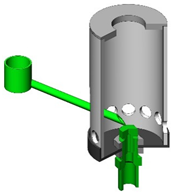

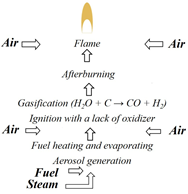

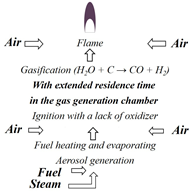

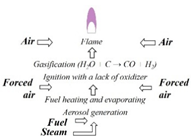

| Name | Scheme | Graphic Model | Flame Photo |

|---|---|---|---|

| Evaporative burner with Autonomous steam generation (EA) |  |  |  |

| Evaporative burner with Regulated steam supply (ER) |  |  | |

| Direct-flow Spray burner (DS) |  |  |  |

| Direct-flow spray burner with Afterburner (DSA) |  |  |  |

| Direct-flow Swirl Spray burner (DSS) |  |  |  |

| Direct-flow Spray burner with Regulated air supply to the gas generation chamber (DSR) |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopyev, E.; Kuznetsov, V.; Minakov, A.; Alekseenko, S.; Sharypov, O. Control of Liquid Hydrocarbon Combustion Parameters in Burners with Superheated Steam Supply. Energies 2024, 17, 5047. https://doi.org/10.3390/en17205047

Kopyev E, Kuznetsov V, Minakov A, Alekseenko S, Sharypov O. Control of Liquid Hydrocarbon Combustion Parameters in Burners with Superheated Steam Supply. Energies. 2024; 17(20):5047. https://doi.org/10.3390/en17205047

Chicago/Turabian StyleKopyev, Evgeny, Viktor Kuznetsov, Andrey Minakov, Sergey Alekseenko, and Oleg Sharypov. 2024. "Control of Liquid Hydrocarbon Combustion Parameters in Burners with Superheated Steam Supply" Energies 17, no. 20: 5047. https://doi.org/10.3390/en17205047

APA StyleKopyev, E., Kuznetsov, V., Minakov, A., Alekseenko, S., & Sharypov, O. (2024). Control of Liquid Hydrocarbon Combustion Parameters in Burners with Superheated Steam Supply. Energies, 17(20), 5047. https://doi.org/10.3390/en17205047