Mean Droplet Size Prediction of Twin Swirl Airblast Nozzle at Elevated Operating Conditions

Abstract

1. Introduction

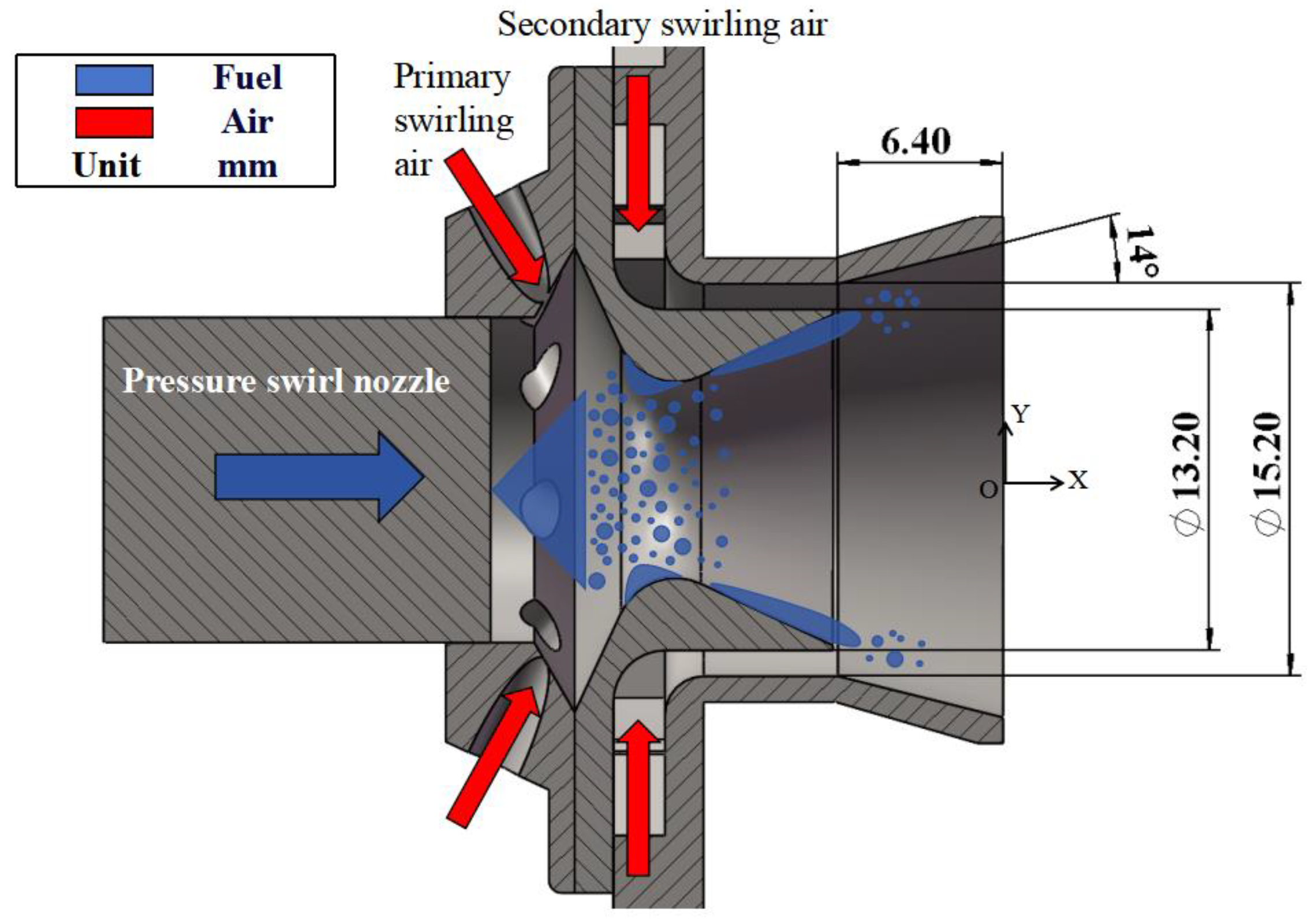

2. Experimental Setup

2.1. Test System

2.2. Experimental Conditions

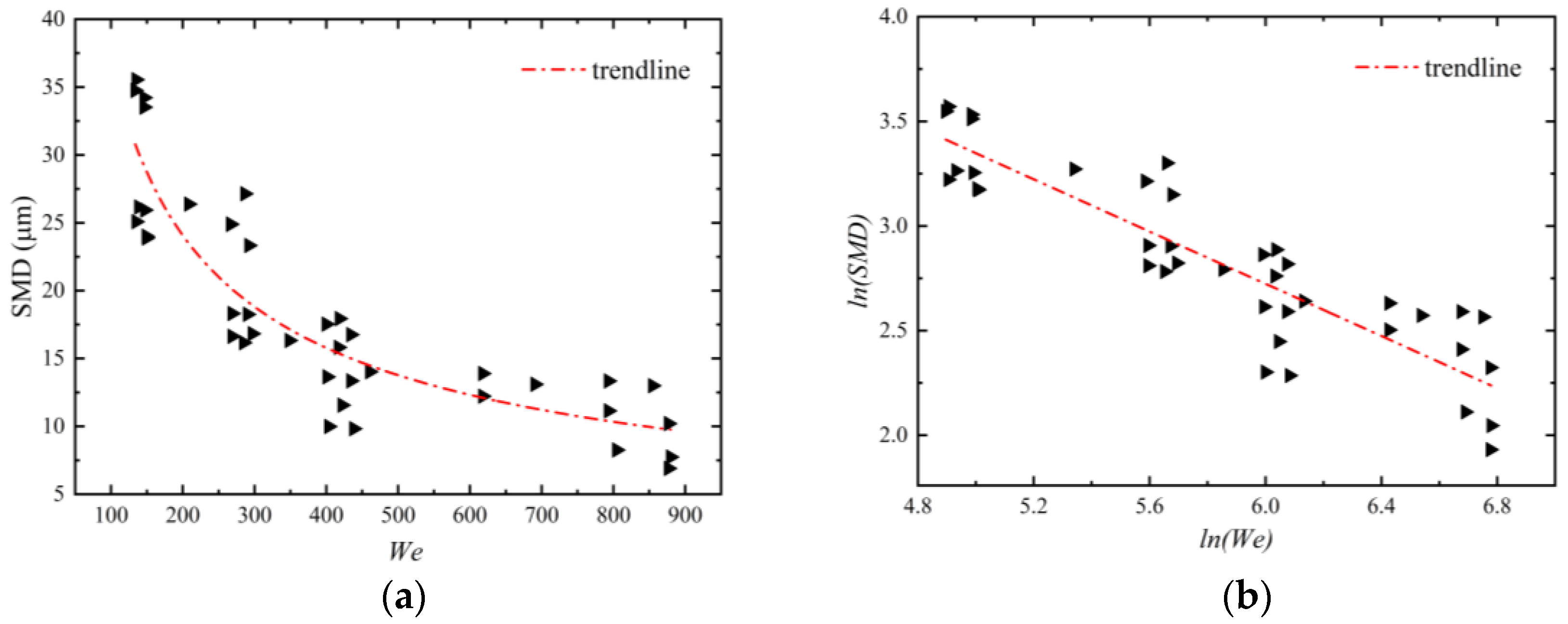

3. Semi-Empirical Prediction Model for SMD

3.1. Atomization Process of Twin Swirl Airblast Nozzle

3.2. Semi-Empirical Prediction Models

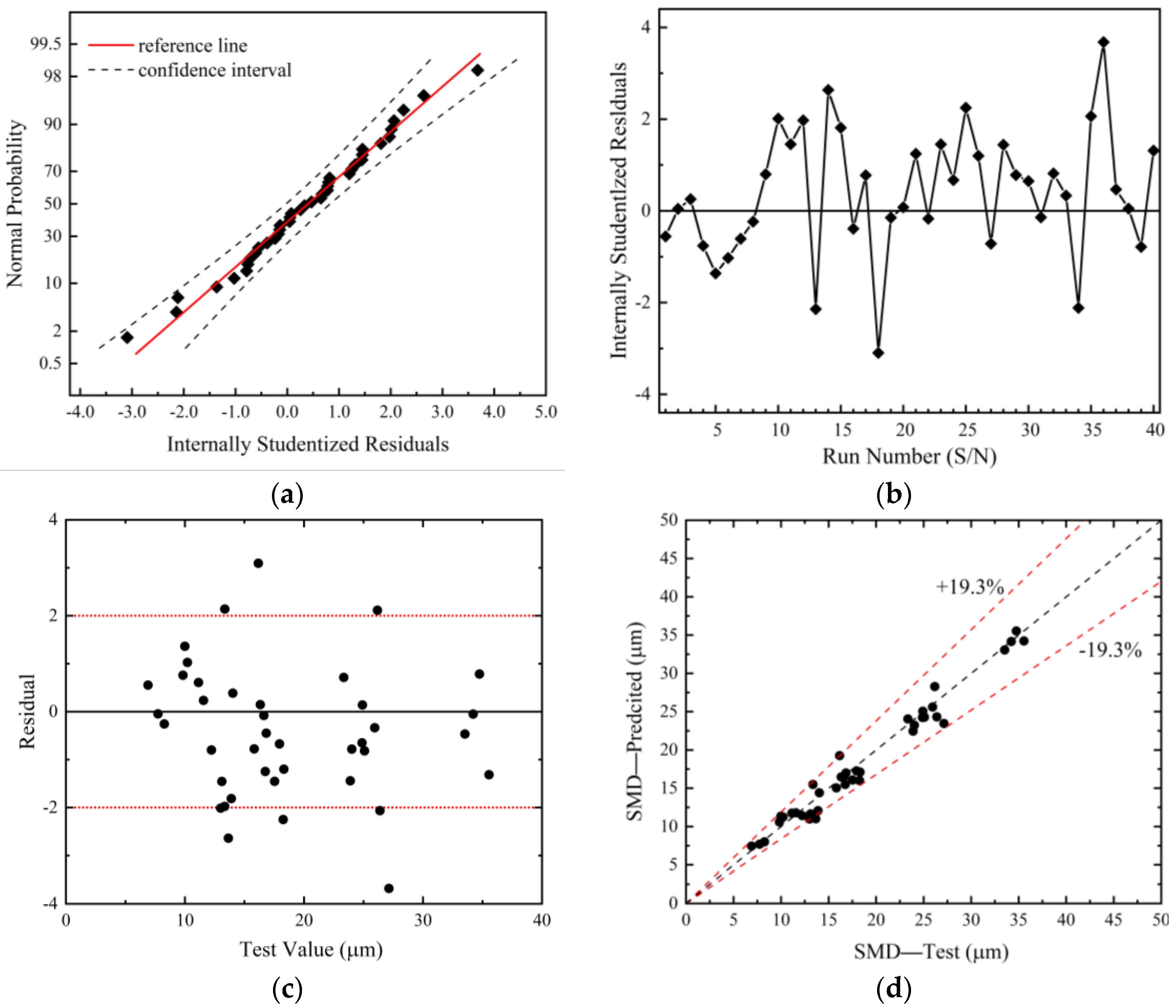

4. Evaluation of the Model

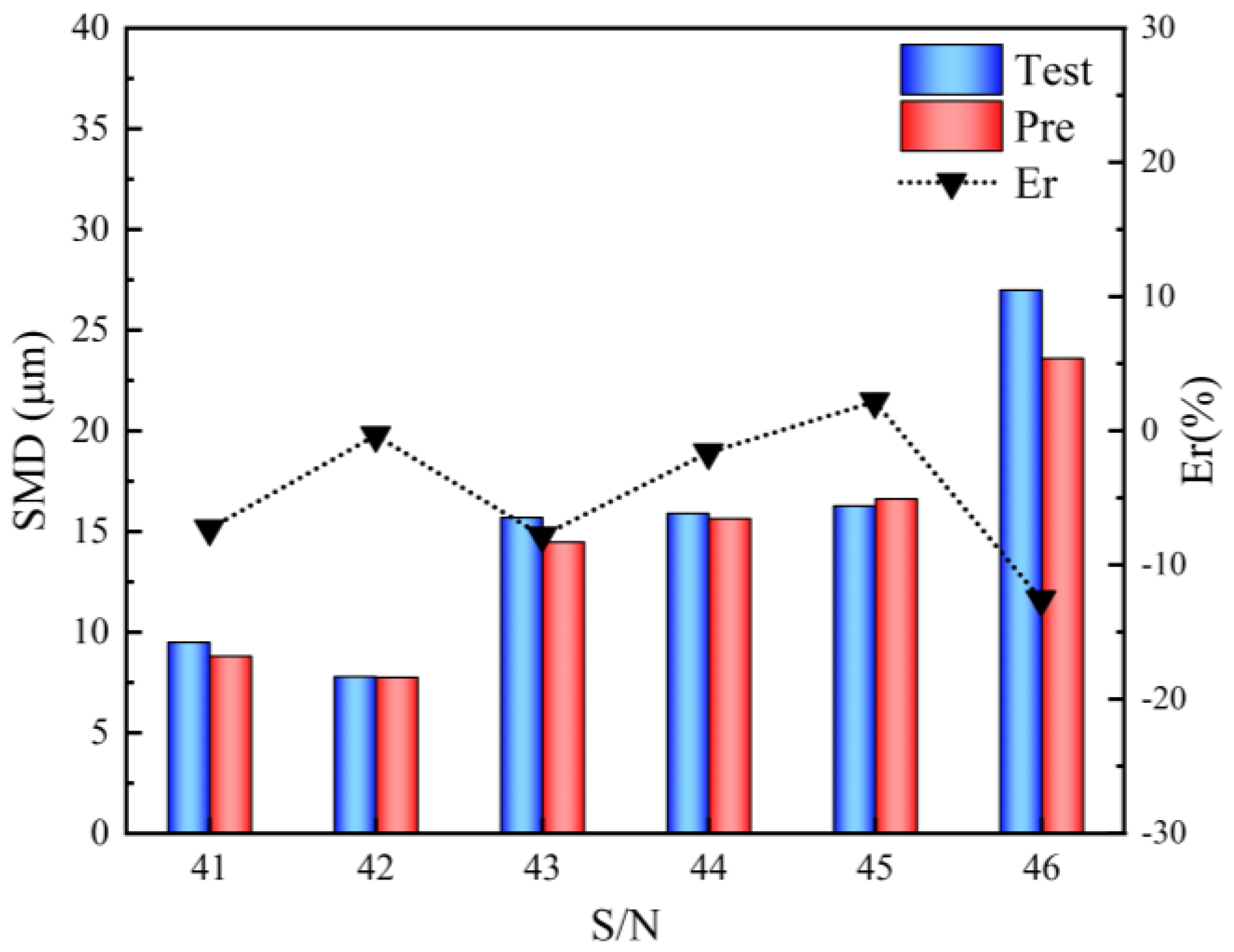

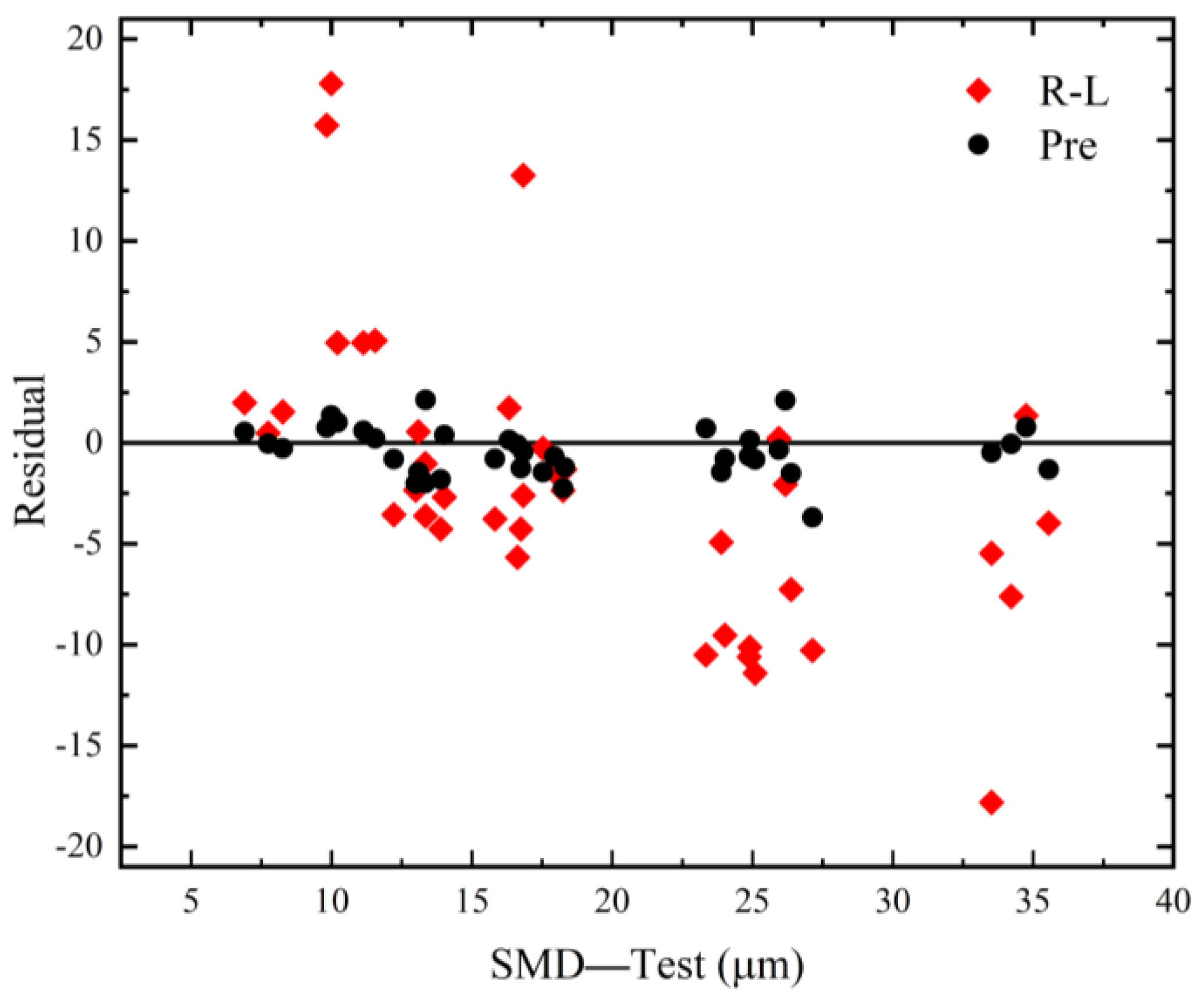

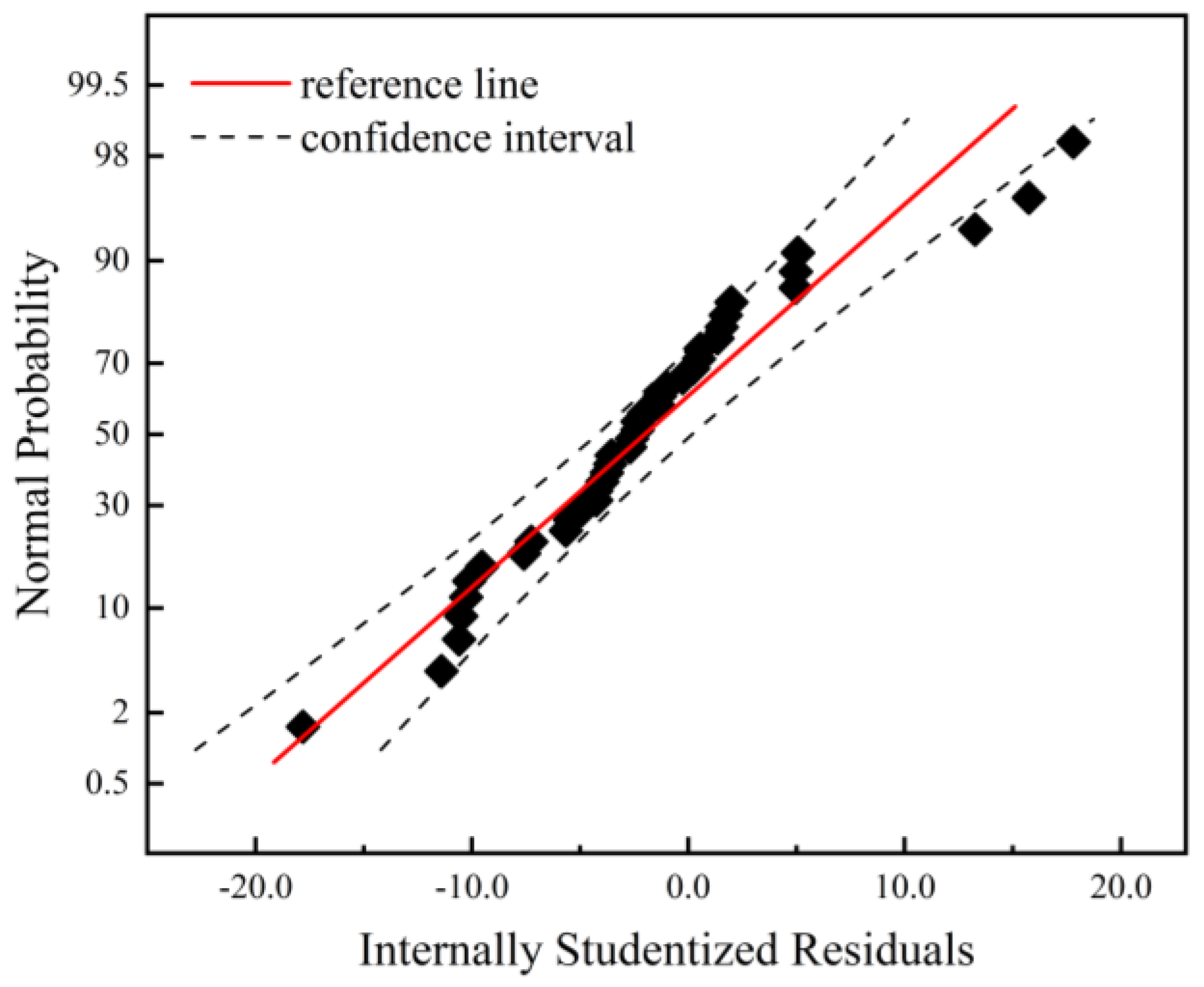

4.1. The Validation of the Predictive Model

4.2. Comparison with Other SMD Prediction Model

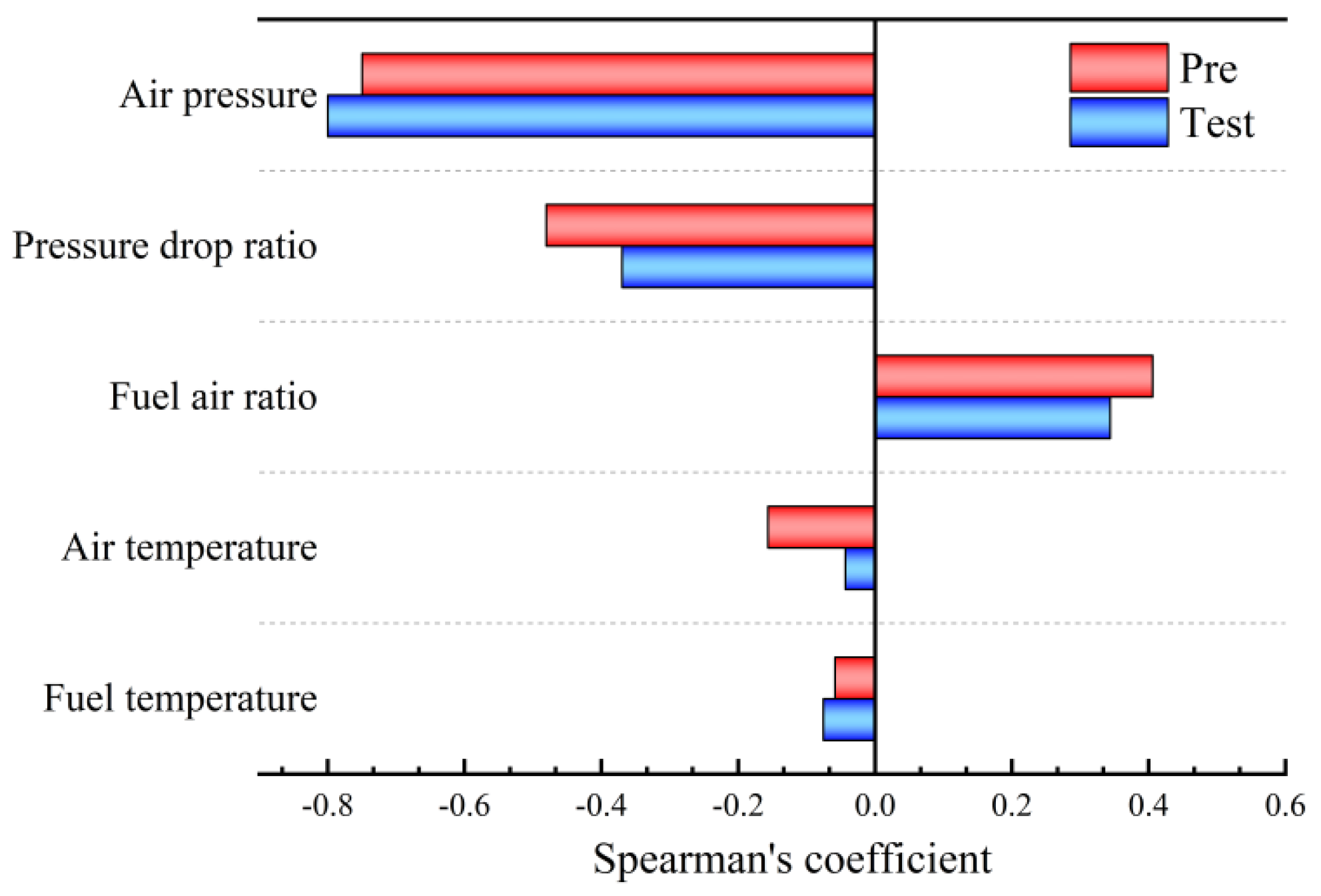

4.3. The Spearman Analysis of the Experimental Variables

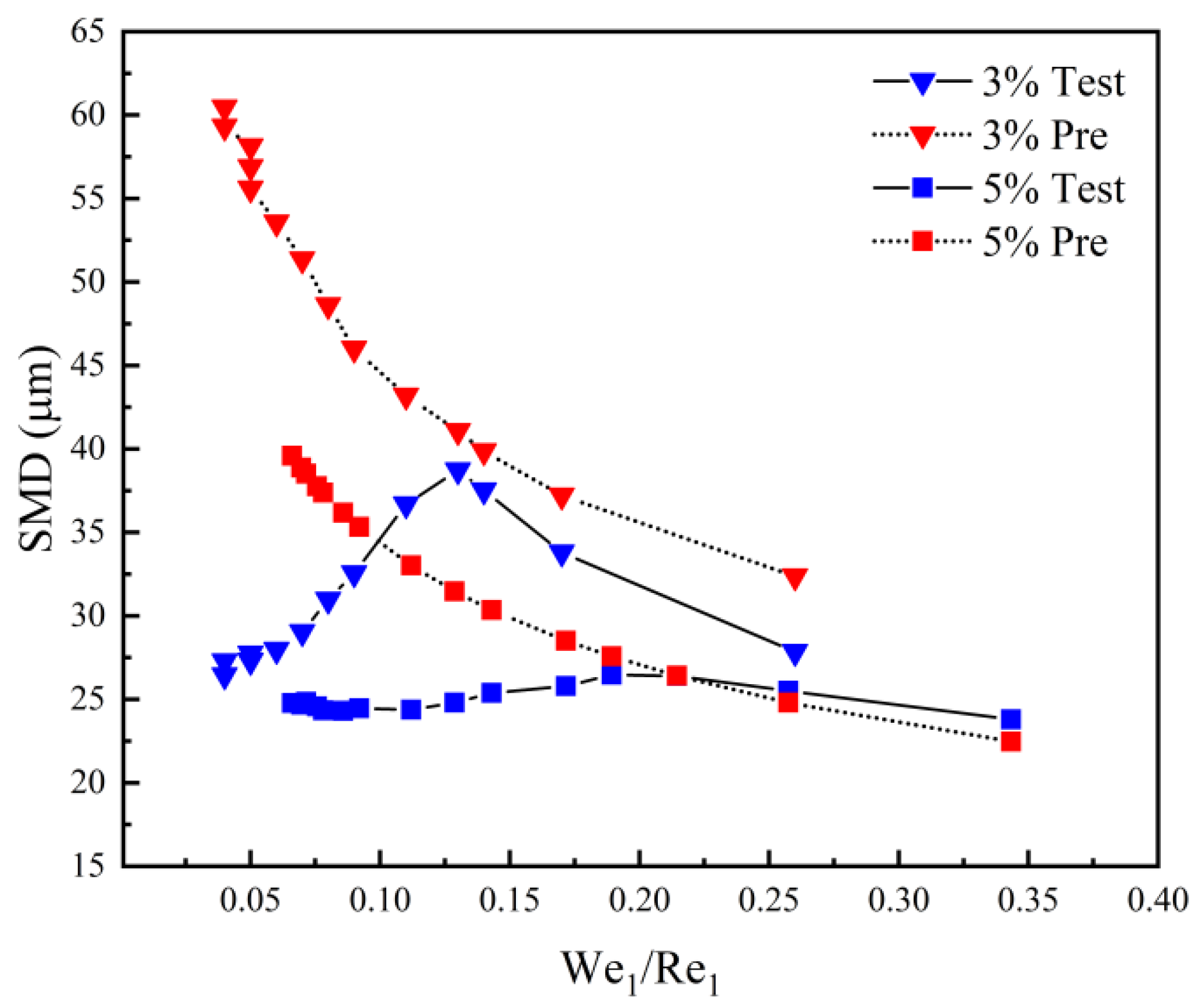

4.4. The Discussion at Ambient Temperature and Pressure Conditions

5. Conclusions

- The results of the ANOVA, etc., indicate that the model structure is both reliable and reasonable, demonstrating a high prediction accuracy and robust generalization capabilities. The maximum relative error in predictions is 19.3%, while the average relative error is 6.8%.

- In comparison to the classic atomization model proposed by Rizkalla and Lefebvre, the model presented here is founded upon theoretical analysis and incorporates the effects of various interacting variables that were considered during the experimental design. This results in superior applicability and precision.

- The results of the Spearman analysis indicate that the model accurately reflects the qualitative impacts and correlations of variables on atomization droplet size. Among the variables, the most significant negative impact on droplet size is observed for air pressure and the air pressure drop ratio, while the FAR shows a positive correlation with droplet size.

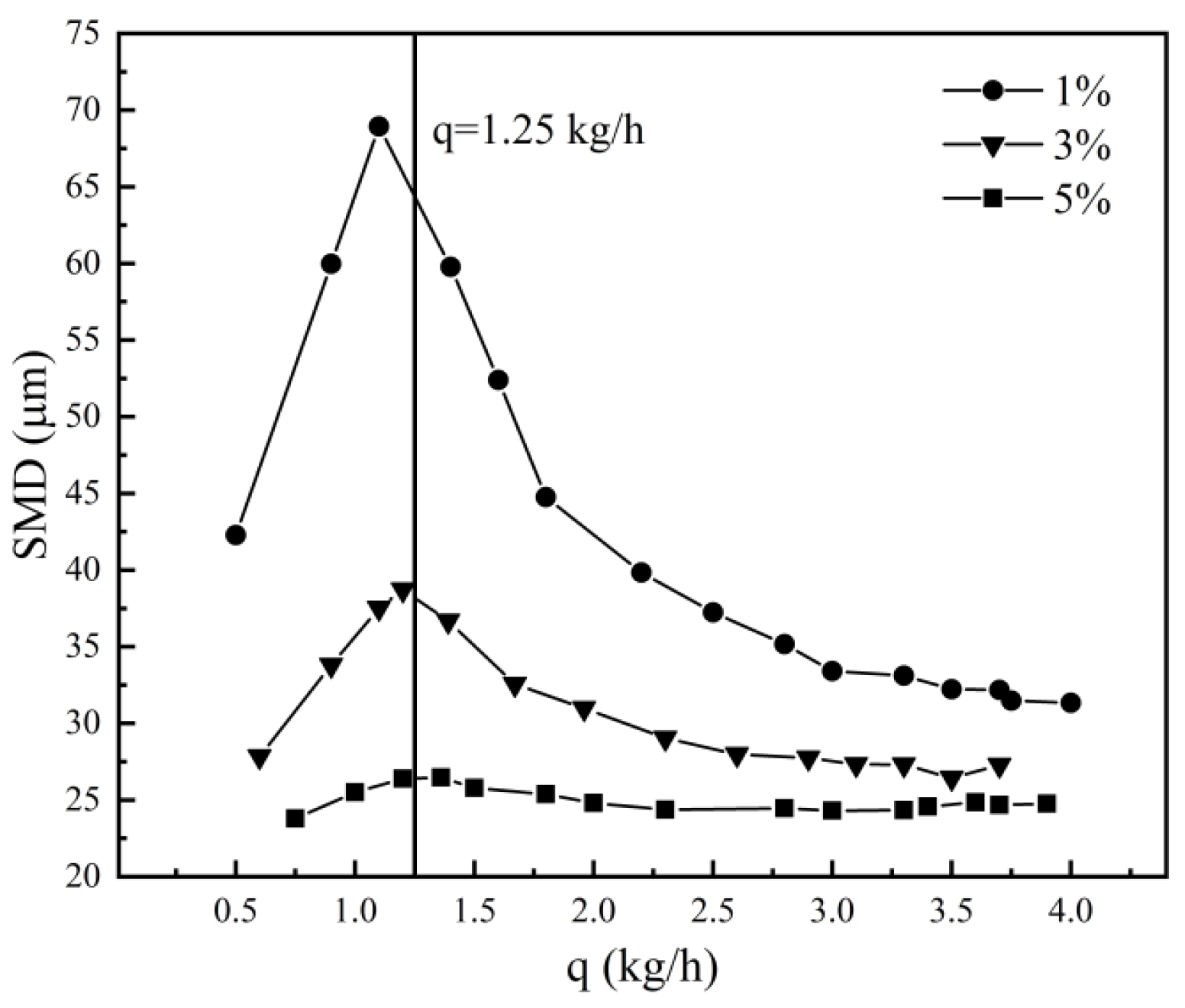

- Experiments conducted at ambient temperature and pressure indicate that the model’s applicability falls within the range defined by We1/Re1 ≥ 0.13. The twin swirl airblast nozzle exhibits competing mechanisms of aerodynamic and pressure swirl atomization. At ambient conditions and a fuel flow rate of q > 1.25 kg/h, the pressure swirl mechanism is observed to predominate over the aerodynamic mechanism.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Air density | |

| Fuel density | |

| ∑ | Liquid surface tension coefficient |

| Ua | Air velocity |

| Ul | Fuel velocity |

| Ta | Air temperature |

| Tl | Fuel temperature |

| Pa | Air pressure |

| q | Fuel flow rate |

| Maximum unstable wave number | |

| Size of liquid blocks | |

| Air pressure drop | |

| Fuel pressure drop | |

| Liquid viscosity coefficient | |

| h | Liquid film initial thickness |

| Liquid film breaking thickness | |

| t | Liquid film thickness at the outlet of the venturi |

| Pressure swirl nozzle diameter | |

| Liquid film breaking length | |

| θ | Semi-liquid fog cone angle |

| Initial size of droplets |

References

- Bayvel, L.P.; Orzechowski, Z. Liquid Atomization; Taylor & Francis: Washington, DC, USA, 1993. [Google Scholar]

- Birouk, M.; Gokalp, I. Current Status of Droplet Evaporation in Turbulent Flows. Prog. Energy Combust. Sci. 1993, 32, 408–423. [Google Scholar] [CrossRef]

- Chiu, H.H.; Liu, T.M. Group Combustion of Liquid Droplets. Combust. Sci. Technol. 1977, 17, 127–142. [Google Scholar] [CrossRef]

- Chiu, H.H.; Kim, H.Y.; Croke, E.J. Internal Group Combustion of Liquid Droplets. Spray Combust. 1982, 19, 971–980. [Google Scholar] [CrossRef]

- Glassman, I.; Yetter, R.A. Combustion, 4th ed.; Academic Press: San Diego, CA, USA, 2008. [Google Scholar]

- Lefebvre, A.H. Atomization and Sprays; Hemisphere: London, UK, 1989. [Google Scholar]

- Lorcher, M.; Schmidt, F.; Mewes, D. Effervescent Atomization of Liquids. At. Sprays 2005, 15, 145–168. [Google Scholar] [CrossRef]

- Bachalo, W.D. Spray Diagnostics for the Twenty-First Century. At. Sprays 2000, 10, 439–474. [Google Scholar] [CrossRef]

- Wang, H.Y.; Mcdonell, V.G.; Samuelsen, S. Influence of Hardware Design on the Flow Field Structures and the Patterns of Droplet Dispersion: Part I—Mean Quantities. J. Eng. Power 1995, 117, 282–289. [Google Scholar] [CrossRef]

- Chaussonnet, G.; Mueller, A.; Holz, S.; Koch, R.; Bauer, H.-J. Time-Response of Recent Prefilming Airblast Atomization Models in an Oscillating Air Flow Field. J. Eng. Gas Turbines Power 2017, 139, 121501. [Google Scholar] [CrossRef]

- Fang, C.; Liu, Y.; Wang, S.; Liu, C.; Liu, F.; Yang, J.; Wang, K.; Mu, Y.; Xu, G.; Zhu, J. Aerodynamic Effect on Atomization Characteristics in a Swirl Cup Airblast Fuel Injector. Phys. Fluids 2023, 35, 103319. [Google Scholar] [CrossRef]

- Gurubaran, R.K.; Sujith, R.I.; Chakravarthy, S.R. Characterization of a Prefilming Airblast Atomizer in a Strong Swirl Flowfield. J. Propuls. Power 2008, 24, 1124–1132. [Google Scholar] [CrossRef]

- Wang, S.; Yang, V.; Hsiao, G.; Hsieh, S.; Mongia, H.C. Large-eddy simulations of gas-turbine swirl injector flow dynamics. J. Fluid Mech. 2007, 583, 99–122. [Google Scholar] [CrossRef]

- Ateshkadi, A.; McDonell, V.; Samuelsen, G. Effect of Mixer Geometry on Fuel Spray Distribution, Emissions and Stability. In Proceedings of the 36th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 12–15 January 1998. [Google Scholar]

- Fan, X. Study on Interaction Mechanism of Aero-Engine Atomizers. Ph.D. Dissertation, Institute of Engineering Thermophysics, Chinese Academy of Sciences, Beijing, China, 2021. [Google Scholar]

- Li, P.; Yang, D.; Fang, Z.; Fu, Q.; Yang, L. Atomization Characteristics of Gelled Fuels Containing Different Concentrations of Metal Particles. Aerospace 2023, 10, 221. [Google Scholar] [CrossRef]

- Jeng, S.-M.; Flohre, N.; Mongia, H. Swirl Cup Modeling—Part IX: Liquid Atomization Modeling. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004. [Google Scholar]

- Ma, R.; Dong, B.; Yu, Z.; Zhang, T.; Wang, Y.; Li, W. An experimental study on the spray characteristics of the air-blast atomizer. Appl. Therm. Eng. 2015, 88, 149–156. [Google Scholar] [CrossRef]

- Liu, C. Investigations of Spray Characteristics and Optical Measuring Methods for Multi-Swirl Air-Blast Atomizer. Ph.D. Dissertation, Institute of Engineering Thermophysics, Chinese Academy of Sciences, Beijing, China, 2012. [Google Scholar]

- Vidovic, S.; Bizjak, A.; Sitar, A.; Horvat, M.; Jankovic, B.; Golobic, I. Development of a Semi-Empirical Model for Droplet Size Determination of a Three-Channel Spray Nozzle for Pellet Coating Based on the Optical Method Concept. Processes 2022, 10, 86. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Sun, P.; Huo, W. Formulation of a Fuel Spray SMD Model at Atmospheric Pressure Using Design of Experiments (DoE). Fuel 2015, 153, 355–360. [Google Scholar] [CrossRef]

- Liu, H.F.; Xin, G.; Wei, F.L.; Fu, C.W.; Zun, H.Y. Prediction of Droplet Size Distribution in Sprays of Prefilming Air-Blast Atomizers. Chem. Eng. Sci. 2006, 61, 1741–1747. [Google Scholar] [CrossRef]

- Gao, Z.; Liu, Y.; Zhang, Q.; Huang, Y.; Wang, D. Semi-Theoretical Prediction of SMD for Liquid Spray in Centrifugal Nozzles Based on Instability Theory. J. Aerosp. Power 2024, 252–262. [Google Scholar] [CrossRef]

- Roudini, M.; Wozniak, G. Experimental Investigation of Spray Characteristics of Pre-Filming Air-Blast Atomizers. J. Appl. Fluid Mech. 2018, 11, 1455–1469. [Google Scholar] [CrossRef]

- Wei, X.; Huang, Y. Improved Semiempirical Correlation to Predict Sauter Mean Diameter for Pressure-Swirl Atomizers. J. Propuls. Power 2014, 30, 1628–1635. [Google Scholar] [CrossRef]

- Rivas, J.R.R.; Pimenta, A.P.; Lessa, J.S.; Rivas, G.A.R. An Improved Theoretical Formulation for Sauter Mean Diameter of Pressure-Swirl Atomizers Using Geometrical Parameters of Atomization. Propuls. Power Res. 2022, 11, 240–252. [Google Scholar] [CrossRef]

- Rizkalla, A.A.; Lefebvre, A.H. Influence of Air and Liquid Properties on Airblast Atomization. J. Fluids Eng. 1975, 97, 316–320. [Google Scholar] [CrossRef]

- Urbán, A.; Malý, M.; Józsa, V.; Jedelský, J. Effect of Liquid Preheating on High-Velocity Airblast Atomization: From Water to Crude Rapeseed fuel. Exp. Therm. Fluid Sci. 2019, 102, 137–151. [Google Scholar] [CrossRef]

- Moon, S.; Bae, C.; Abo-Serie, E.F.; Choi, J. Internal and Near-Nozzle Flow of a Pressure-Swirl Atomizer Under Varied Fuel Temperature. At. Sprays 2007, 17, 529–550. [Google Scholar] [CrossRef]

- Davanlou, A.; Lee, J.D.; Basu, S.; Kumar, R. Effect of Viscosity and Surface Tension on Breakup and Coalescence of Bicomponent Sprays. Chem. Eng. Sci. 2015, 131, 243–255. [Google Scholar] [CrossRef]

- Tareq, M.M.; Dafsari, R.A.; Jung, S.; Lee, J. Effect of the Physical Properties of Liquid and ALR on the Spray Characteristics of a Pre-Filming Airblast Nozzle. Int. J. Multiph. Flow 2020, 126, 103150. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, X.; Kou, R.; Li, C.; Zhang, P.; Hai, H.; Li, C.; Yang, F.; Liu, Q.; Cao, T. Numerical Study on Pre-Film Atomization Mechanism and Characteristics by a Coaxial Swirl Injector. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 233, 1022–1038. [Google Scholar] [CrossRef]

- Holz, S.; Braun, S.; Chaussonnet, G.; Koch, R.; Bauer, H.-J. Close Nozzle Spray Characteristics of a Prefilming Airblast Atomizer. Energies 2019, 12, 2835. [Google Scholar] [CrossRef]

- Liu, J. Experimental and Numerical Simulation of the Breakup Process of Swirling Conical Liquid Sheet; National University of Defense Technology: Changsha, China, 2012. [Google Scholar]

- Fokaides, P.; Weiß, M.; Kern, M.; Zarzalis, N. Experimental and Numerical Investigation of Swirl Induced Self-Excited Instabilities at the Vicinity of an Airblast Nozzle. Flow Turbul. Combust. 2009, 83, 511–533. [Google Scholar] [CrossRef]

- Senecal, P.; Schmidt, D.; Nouar, I.; Rutland, C.; Reitz, R.; Corradini, M. Modeling High-Speed Viscous Liquid Sheet Atomization. Int. J. Multiph. Flow 1999, 25, 1073–1097. [Google Scholar] [CrossRef]

- Su, K.; Zhu, H. Research on Theoretical Models and Computational Methods for Fuel Spray Particle Size. Aviat. Engines 1994, 4, 34–39. [Google Scholar]

- Reitz, R.D.; Bracco, F.V. Mechanism of Atomization of a Liquid Jet. Phys. Fluids 1982, 25, 1730–1742. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Z.W.; Li, W.F.; Xu, J.L.; Liu, H.F. Nonmonotonic Effects of Aerodynamic Force on Droplet Size of Prefilming Air-Blast Atomization. Ind. Eng. Chem. Res. 2018, 57, 1726–1732. [Google Scholar] [CrossRef]

- Han, Z.; Parrish, S.E.; Farrell, P.V.; Reitz, R.D. Modeling Atomization Processes of Pressure-Swirl Hollow-Cone Fuel Sprays. At. Sprays 1997, 7, 663–684. [Google Scholar] [CrossRef]

- Cui, Y.; Cheng, C.; Wang, P.; Liu, Y.; Li, R.; Zhang, Y.; Li, M.; Li, S. A Mathematical Model for Predicting the Droplet Size of Micro-Fog Nozzle with Circular-Hole Rotating Core Based on Orthogonal Design. Appl. Sci. 2023, 13, 6670. [Google Scholar] [CrossRef]

- Chen, S.; Ashgriz, N. Droplet Size Distribution in Swirl Nozzles. Int. J. Multiph. Flow 2022, 156, 104219. [Google Scholar] [CrossRef]

- Zhang, J.; Di, D.; Zhang, P.; Zhang, T.; Yan, Y.; Li, J. Initial Atomization Experiments of a Flat-Plate Pre-Membrane Nozzle Under High Temperature and Pressure. J. Aerosp. Power 2022, 37, 55–66. [Google Scholar] [CrossRef]

- Varga, C.M.; Lasheras, J.C.; Hopfinger, E.J. Initial Breakup of a Small-Diameter Liquid Jet by a High-Speed Gas Stream. J. Fluid Mech. 2003, 497, 405–434. [Google Scholar] [CrossRef]

- Zheng, K.; Gan, Z.; Wang, X.; Han, X.; Zheng, T.; Wang, J. Experimental Study on Spray Characteristics of Aviation Kerosene from a Pressure-Swirl Nozzle in High-Speed Airflow with Elevated Temperatures. Phys. Fluids 2024, 36, 023332. [Google Scholar] [CrossRef]

- Sheen, H.J.; Chen, W.J.; Jeng, S.Y.; Huang, T.L. Correlation of swirl number for a radial-type swirl generator. Exp. Therm. Fluid Sci. 1996, 12, 444–451. [Google Scholar] [CrossRef]

- Carvalho, I.S.; Heitor, M.V. Liquid Film Break-Up in a Model of a Prefilming Airblast Nozzle. Exp. Fluids 1998, 24, 408–415. [Google Scholar] [CrossRef]

- Kim, S.; Khil, T.; Kim, D.; Yoon, Y. Effect of Geometric Parameters on the Liquid Film Thickness and Air Core Formation in a Swirl Injector. Meas. Sci. Technol. 2010, 21, 035403. [Google Scholar] [CrossRef]

- Dombrowski, N.; Johns, W.R. The Aerodynamic Instability and Disintegration of Viscous Liquid Sheets. Chem. Eng. Sci. 1963, 18, 203–214. [Google Scholar] [CrossRef]

- Rizkalla, A.A.; Lefebvre, A.H. Influence of Liquid Properties on Airblast Atomizer Spray Characteristics. J. Eng. Power 1975, 97, 173–177. [Google Scholar] [CrossRef]

| S/N | Pa (MPa) | ∆P/Pa (%) | Ta (K) | Tl (K) | FAR |

|---|---|---|---|---|---|

| 1 | 0.3 | 4 | 450 | 316 | 0.04 |

| 2 | 0.3 | 4 | 450 | 346 | 0.04 |

| 3 | 0.3 | 6 | 450 | 316 | 0.04 |

| 4 | 0.3 | 4 | 450 | 316 | 0.02 |

| 5 | 0.3 | 4 | 450 | 316 | 0.06 |

| 6 | 0.1 | 4 | 450 | 316 | 0.04 |

| 7 | 0.4 | 6 | 490 | 331 | 0.02 |

| 8 | 0.4 | 6 | 490 | 331 | 0.06 |

| 9 | 0.2 | 6 | 490 | 331 | 0.06 |

| 10 | 0.4 | 2 | 490 | 301 | 0.02 |

| 11 | 0.4 | 6 | 410 | 301 | 0.02 |

| 12 | 0.2 | 2 | 410 | 301 | 0.06 |

| 13 | 0.4 | 2 | 490 | 301 | 0.06 |

| 14 | 0.2 | 2 | 410 | 301 | 0.02 |

| 15 | 0.4 | 2 | 410 | 331 | 0.06 |

| 16 | 0.4 | 2 | 410 | 301 | 0.06 |

| 17 | 0.2 | 2 | 490 | 301 | 0.06 |

| 18 | 0.2 | 6 | 490 | 301 | 0.06 |

| 19 | 0.4 | 2 | 490 | 331 | 0.02 |

| 20 | 0.4 | 6 | 410 | 301 | 0.06 |

| 21 | 0.4 | 6 | 410 | 331 | 0.02 |

| 22 | 0.2 | 2 | 490 | 331 | 0.02 |

| 23 | 0.2 | 2 | 410 | 331 | 0.06 |

| 24 | 0.2 | 6 | 490 | 301 | 0.02 |

| 25 | 0.4 | 6 | 490 | 301 | 0.06 |

| 26 | 0.4 | 2 | 490 | 331 | 0.06 |

| 27 | 0.2 | 2 | 410 | 331 | 0.02 |

| 28 | 0.4 | 2 | 410 | 301 | 0.02 |

| 29 | 0.1 | 4 | 303 | 316 | 0.04 |

| 30 | 0.2 | 4 | 340 | 316 | 0.04 |

| 31 | 0.45 | 4 | 500 | 316 | 0.04 |

| 32 | 0.25 | 4 | 450 | 316 | 0.04 |

| 33 | 0.5 | 4 | 450 | 316 | 0.04 |

| 34 | 0.3 | 4 | 350 | 316 | 0.04 |

| 35 | 0.3 | 2 | 450 | 316 | 0.04 |

| 36 | 0.4 | 6 | 410 | 331 | 0.06 |

| 37 | 0.2 | 6 | 410 | 301 | 0.02 |

| 38 | 0.2 | 6 | 490 | 331 | 0.02 |

| 39 | 0.2 | 2 | 490 | 331 | 0.06 |

| 40 | 0.4 | 2 | 410 | 331 | 0.02 |

| A | B | C | D | E | R2 |

|---|---|---|---|---|---|

| 1249 | −0.8645 | 0.1551 | −0.0113 | 0.0148 | 0.967 |

| D-W | ||||

|---|---|---|---|---|

| 1.259 | 2.335 | 3.560 | 3.355 | 1.706 |

| S/N | Pa (MPa) | ∆P/Pa (%) | Ta (K) | Tl (K) | FAR |

|---|---|---|---|---|---|

| 41 | 0.8 | 4 | 550 | 316 | 0.02 |

| 42 | 0.4 | 6 | 490 | 301 | 0.02 |

| 43 | 0.3 | 4 | 550 | 316 | 0.04 |

| 44 | 0.3 | 4 | 450 | 286 | 0.04 |

| 45 | 0.2 | 6 | 410 | 301 | 0.06 |

| 46 | 0.2 | 2 | 490 | 301 | 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, J.; Wang, B.; Ren, G.; Gan, X. Mean Droplet Size Prediction of Twin Swirl Airblast Nozzle at Elevated Operating Conditions. Energies 2024, 17, 5027. https://doi.org/10.3390/en17205027

Miao J, Wang B, Ren G, Gan X. Mean Droplet Size Prediction of Twin Swirl Airblast Nozzle at Elevated Operating Conditions. Energies. 2024; 17(20):5027. https://doi.org/10.3390/en17205027

Chicago/Turabian StyleMiao, Jiaming, Bo Wang, Guangming Ren, and Xiaohua Gan. 2024. "Mean Droplet Size Prediction of Twin Swirl Airblast Nozzle at Elevated Operating Conditions" Energies 17, no. 20: 5027. https://doi.org/10.3390/en17205027

APA StyleMiao, J., Wang, B., Ren, G., & Gan, X. (2024). Mean Droplet Size Prediction of Twin Swirl Airblast Nozzle at Elevated Operating Conditions. Energies, 17(20), 5027. https://doi.org/10.3390/en17205027