Electric Vehicles—An Overview of Current Issues—Part 2—Infrastructure and Road Safety

Abstract

1. Introduction

2. Infrastructure and its Availability across Countries

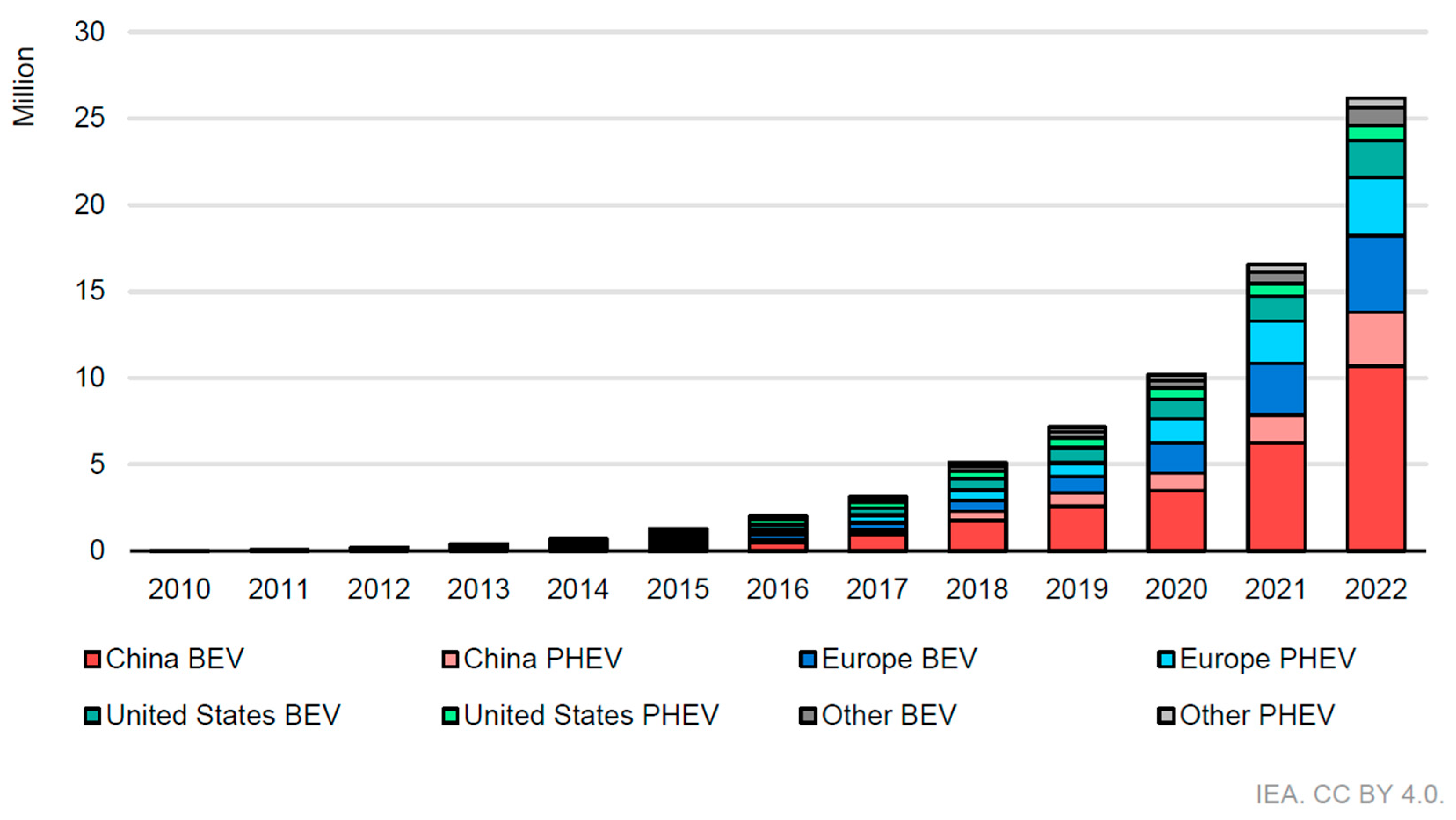

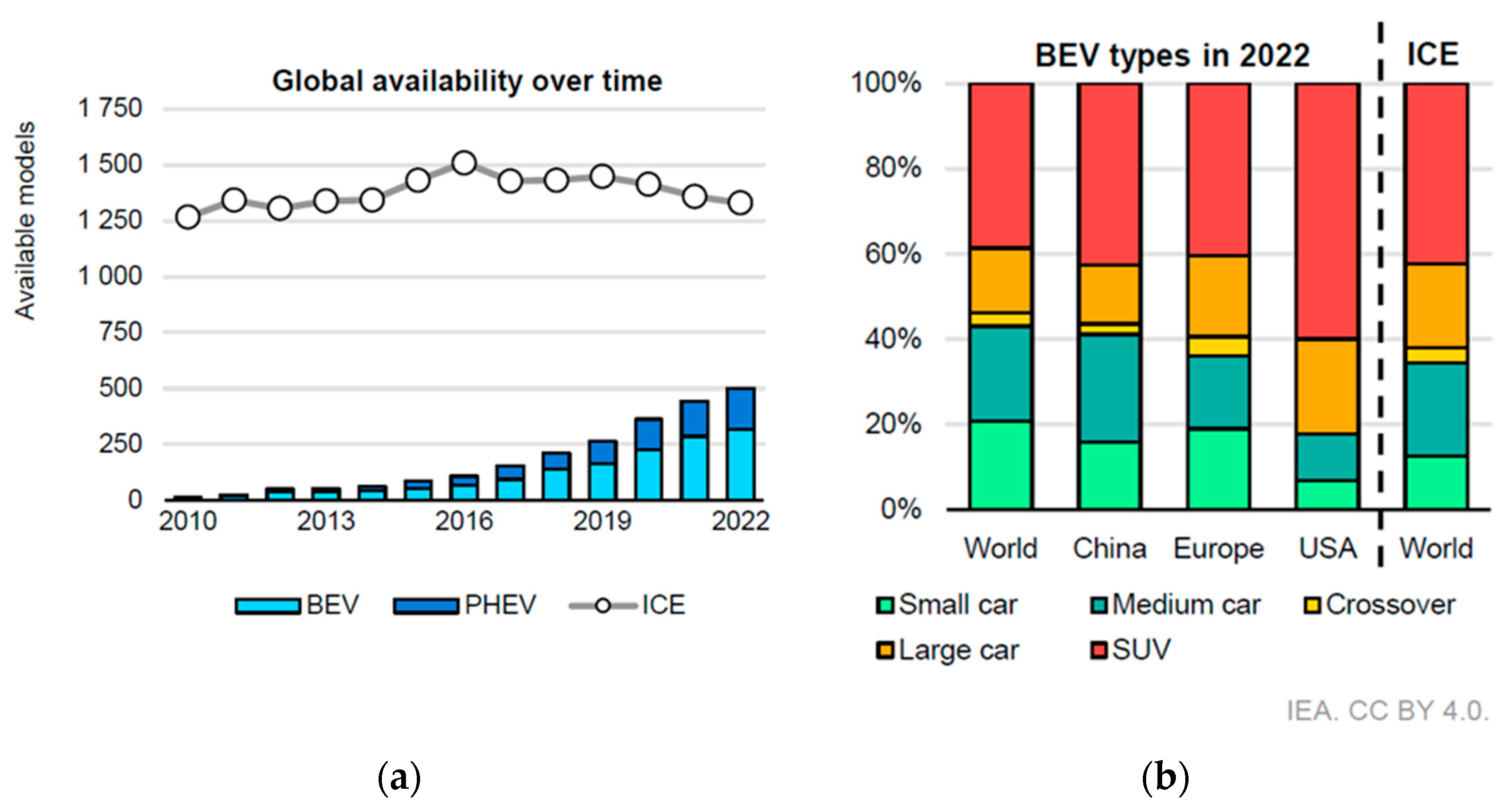

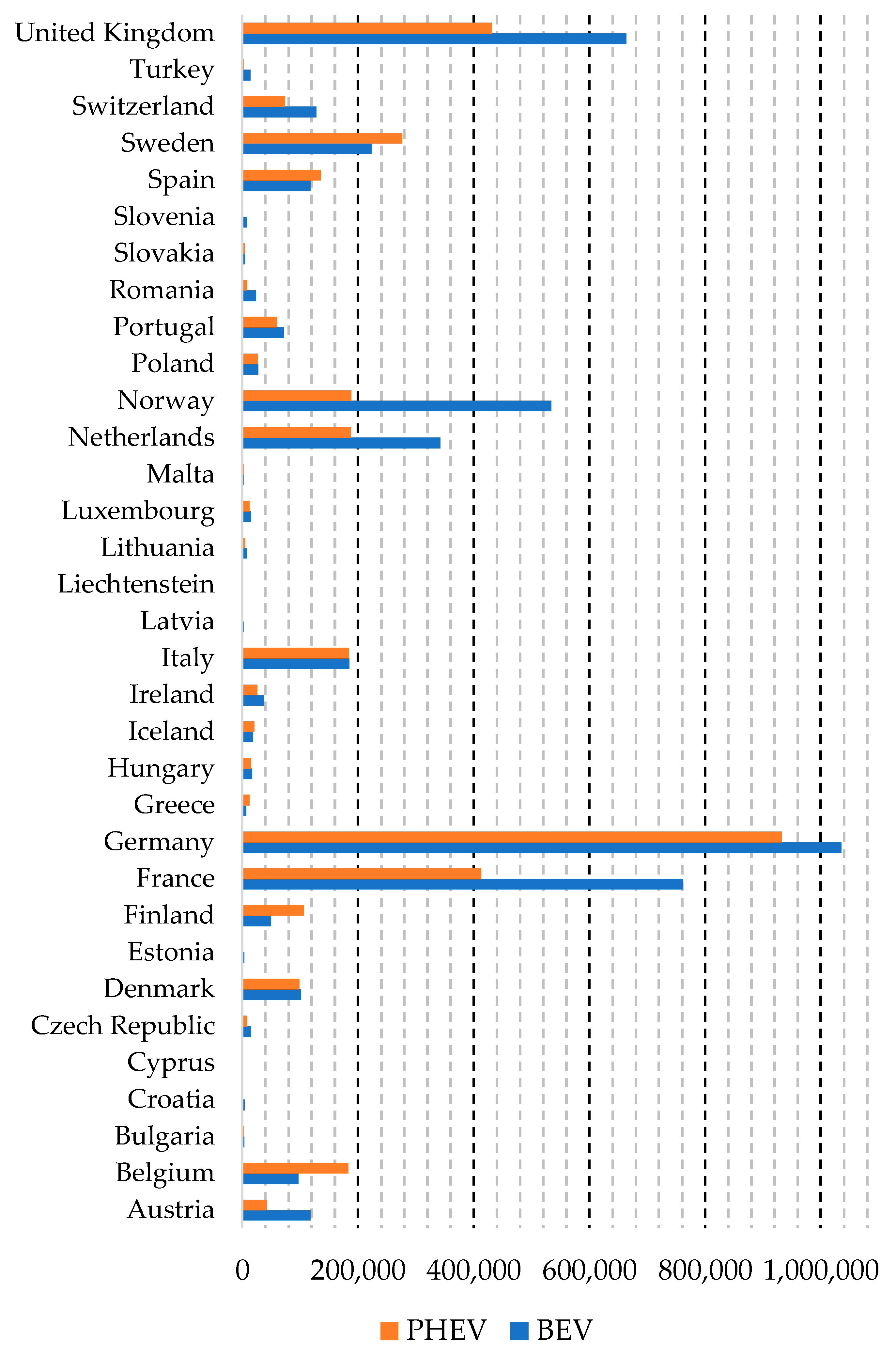

2.1. Statistical Data on the Number of Electric Vehicles Worldwide and in the EU

2.2. General Characteristics of Home EV Chargers and Public EV Recharging Stations

- Type 1—single-phase AC charging (250 V, 32 A) connector popular mainly in the USA and Japan;

- Type 1 Combo (combined charging system—CCS 1)—DC charging, Type 1 (AC) connector extended with two additional direct current (DC) contacts; this charging connector is popular mainly in the USA;

- Type 2—single-phase AC charging (250 V, 13 A or 20 A or 32 A or 63 A or 70 A) or three-phase (480 V, 13 A or 20 A or 32 A or 63 A) connector popular mainly in Europe;

- Type 2 Combo (CCS 2)—DC charging, Type 2 (AC) connector extended with two additional direct current (DC) contacts, short-term charging power up to 500 kW; this connector is popular mainly in Europe;

- Type 3—single-phase (250 V, 16 A or 32 A) or three-phase (480 V, 32 A or 63 A) AC charging, currently not used and replaced in Europe by Type 2/Combo,

- CHadeMO—DC charging, bi-directional energy flow (implementation of the V2G—vehicle to grid standard), charging standard used in various means of transport, output power for wheeled vehicles: 10 kW ÷ 400 kW (150 V ÷ 1000 V), the latest CHAdeMO (3.0) “ChaoJi” protocol provides for charging at up to 900 kW (600 A × 1.5 kV), developed jointly by CHAdeMO and the China Electricity Council (CEC); this connection is prevalent in Japan;

- GB/T—connector popular mainly in China;

- Tesla—a proprietary standard of EV connectors used by Tesla; the same connector is used for AC and DC charging; since the end of 2018, vehicles introduced to the EU market are equipped with the European CCS 2 socket.

- Case A—a cable is permanently connected to the vehicle;

- Case B—a cable that is detachable at both ends;

- Case C—a cable that is permanently connected to the EV recharging station.

- Mode 1—charging from a standard single-phase AC socket (not more than 250 V, 16 A) or three-phase AC socket (not more than 480 V, 16 A) without an additional protection device;

- Mode 2—charging from a standard single-phase AC socket (not more than 250 V, 32 A) or three-phase AC socket (not more than 480 V, 32 A) with an additional protection device (e.g., in-cable control box, ICCB) placed between the power socket and the EV (e.g., control and protection devices);

- Mode 3—charging using a power supply device with an AC output dedicated to EV charging with appropriate protective devices; the device must be equipped with a grounding wire;

- Mode 4—charging using a power supply device with a DC output dedicated to EV charging with appropriate protective devices; the device must be equipped with a grounding wire.

- Mode 1 charging is currently not supported by vehicle manufacturers. In this mode, vehicles are charged without additional protection and the leads connected to the electrical outlet are always live. Charging is slow and limited to domestic electric installations. Mode 1 charging is banned in the United States, Israel and the United Kingdom [23].

- Mode 2 uses the electric vehicle supply equipment (EVSE), which supplies AC to the EV onboard charger (OBC). The OBC converts the AC main current into DC and sends it to the battery. Mode 2 in the United States of America and Canada is limited to 250 V. In Switzerland, mode 2 charging is limited to 16 A and 250 V (in single-phase systems). Some European countries apply charging current limitations during charging (using charging devices equipped with a household plug) for more than 2 h. Modes 1 and 2 are prohibited to use in public places in Italy. No voltage and current limits are set in international standard for modes 3 and 4.

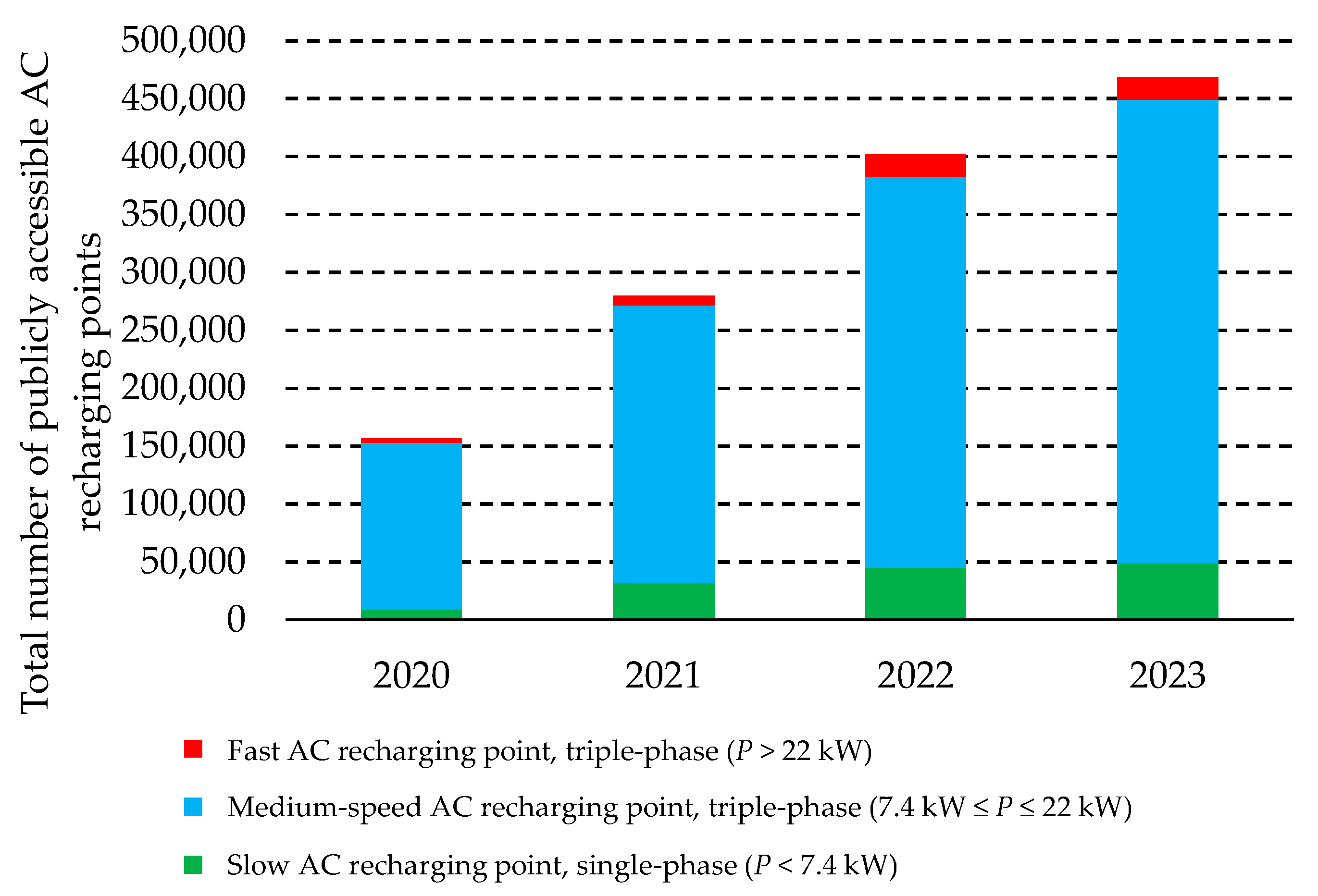

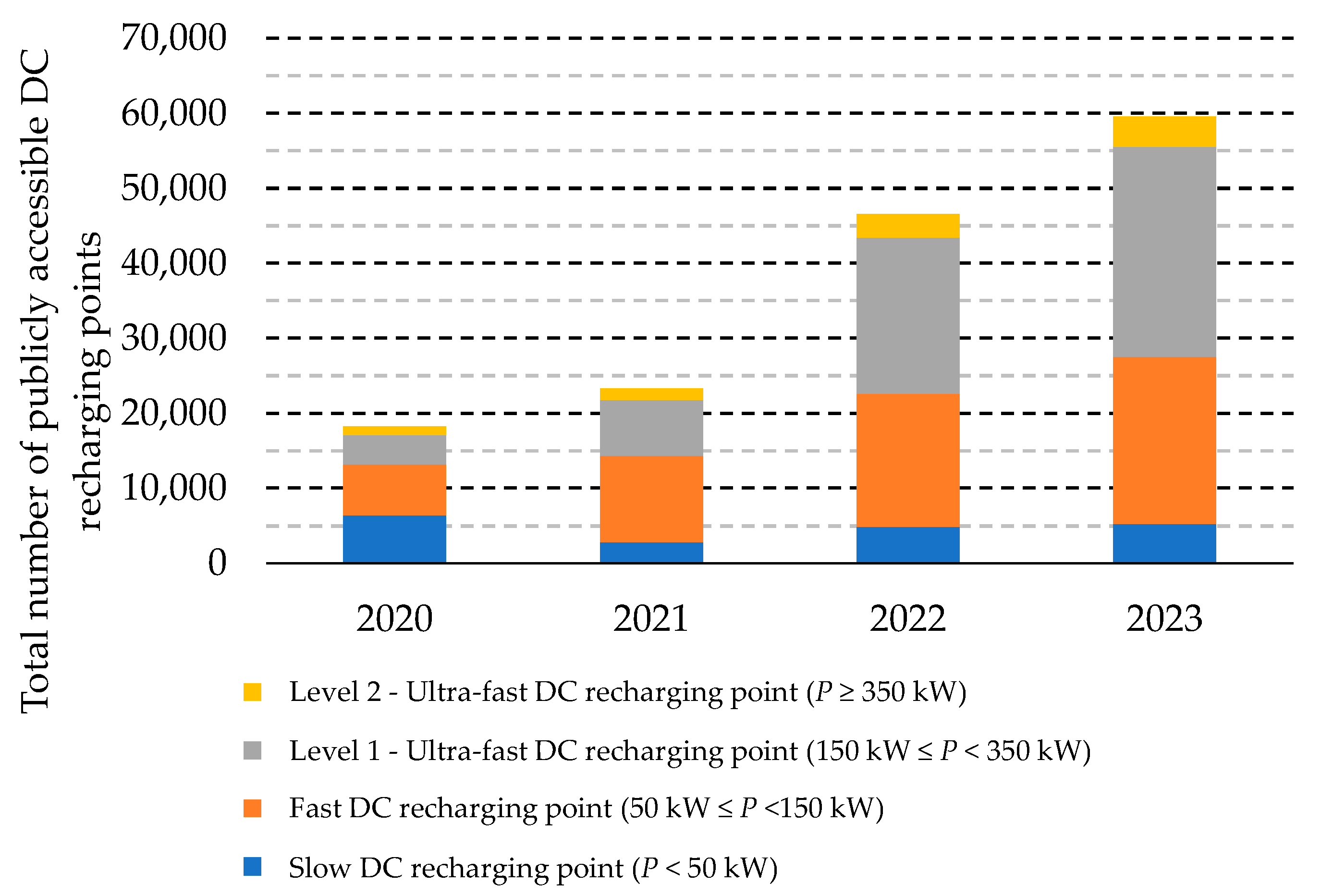

2.3. Distribution of EV Recharging Points/Recharging Stations in the European Union

2.4. EV Charging Time

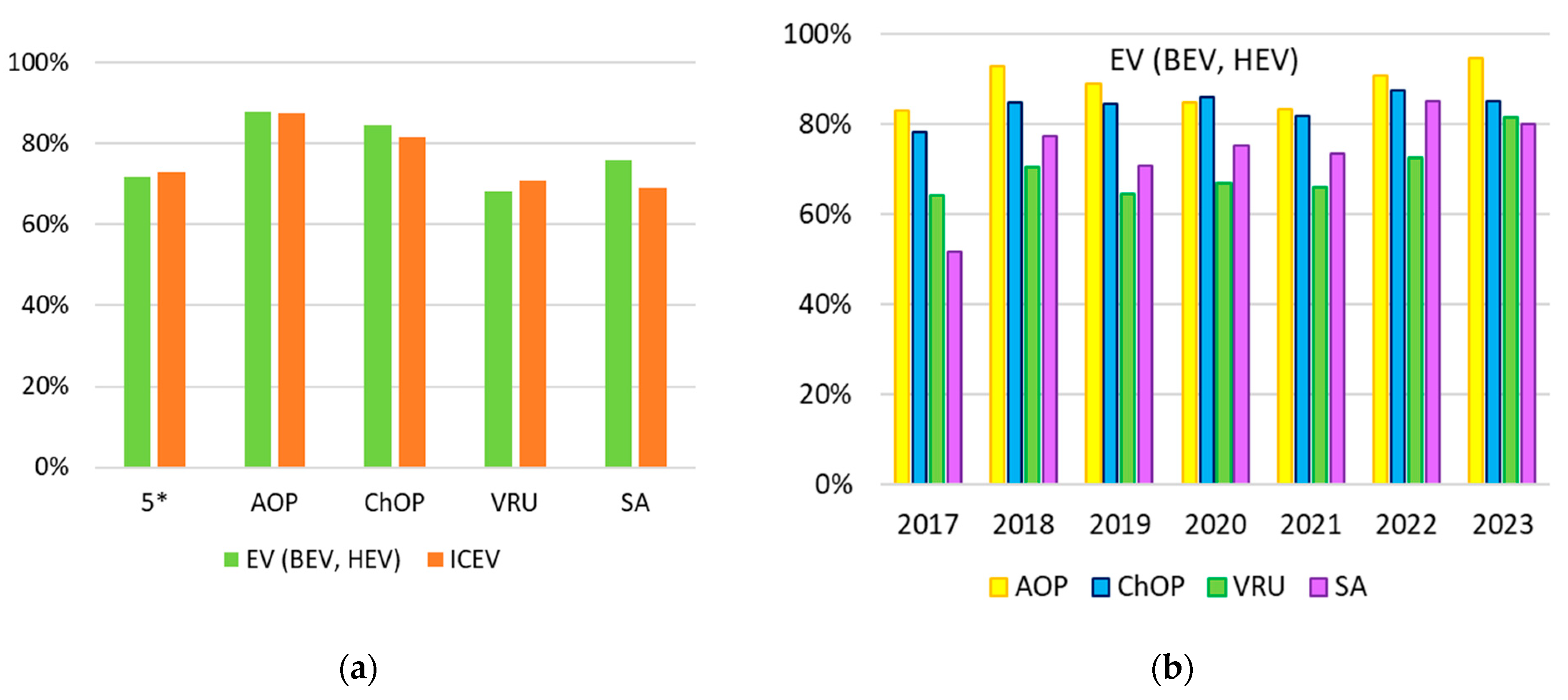

3. Safety of EVs

3.1. Review of EV Safety Issues

3.2. Problems in Cases of Accidents, including Fire

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zieliński, A. Samochody Osobowe. Dzieje Rozwoju; WKŁ: Warsaw, Poland, 2009. (In Polish) [Google Scholar]

- Szumska, E.; Jurecki, R.; Pawełczyk, M. Evaluation of the use of hybrid electric powertrain system in urban traffic conditions. Eksploat. I Niezawodn.—Maint. Reliab. 2020, 22, 154–160. [Google Scholar] [CrossRef]

- Szumska, E.; Jurecki, R. The Analysis of Energy Recovered during the Braking of an Electric Vehicle in Different Driving Conditions. Energies 2022, 15, 9369. [Google Scholar] [CrossRef]

- Jackowski, J.; Łęgiewicz, J.; Wieczorek, M. Samochody Osobowe i Pochodne; WKŁ: Warsaw, Poland, 2011. (In Polish) [Google Scholar]

- Electric Vehicles Initiative. Available online: https://www.iea.org/programmes/electric-vehicles-initiative (accessed on 11 July 2023).

- International Energy Agency. Global EV Outlook. 2023. Available online: https://iea.blob.core.windows.net/assets/dacf14d2-eabc-498a-8263-9f97fd5dc327/GEVO2023.pdf (accessed on 4 July 2023).

- Global EV Data Explorer. Available online: https://www.iea.org/data-and-statistics/data-tools/global-ev-data-explorer (accessed on 12 June 2023).

- European Alternative Fuels Observatory. Road. Available online: https://alternative-fuels-observatory.ec.europa.eu/transport-mode/road (accessed on 4 June 2023).

- Hellgren, M.; Honeth, N. Efficiency of an AC Conductive In-Road Charging System for Electric Vehicles-Analysis of Pilot Project Data. SAE Int. J. Electrified Veh. 2020, 9, 27–40. [Google Scholar] [CrossRef]

- Bazarnik, W. Domowa Stacja Ładowania Samochodów Elektrycznych—Wszystko. co Powinieneś o Niej Wiedzieć. Available online: https://blog.swiatbaterii.pl/domowa-stacja-ladowania-samochodow-elektrycznych-wszystko-co-powinienes-o-niej-wiedziec/ (accessed on 12 July 2023). (In Polish).

- European Alternative Fuels Observatory. Recharging Systems. Available online: https://alternative-fuels-observatory.ec.europa.eu/general-information/recharging-systems (accessed on 13 July 2023).

- Netherlands Enterprise Agency. Electric Vehicle Charging. Definitions and Explanation. Version: January 2019. Available online: https://nklnederland.nl/wp-content/uploads/2021/12/Electric_Vehicle_Charging_-_Definitions_and_Explanation_-_january_2019.pdf (accessed on 13 July 2023).

- Urząd Dozoru Technicznego. Typy Ładowania. Available online: https://www.udt.gov.pl/typy-ladowania (accessed on 13 July 2023). (In Polish)

- CHAdeMO. High Power (ChaoJi). Available online: https://www.chademo.com/technology/high-power (accessed on 13 July 2023).

- CHAdeMO. Protocol Development. Available online: https://www.chademo.com/technology/protocol-development (accessed on 13 July 2023).

- TU Delf. Electric Cars: Technology. Lecture Notes: Lecture 3.3. Available online: https://ocw.tudelft.nl/wp-content/uploads/eCARS2x_Lecture_Notes_L3-3.pdf (accessed on 13 July 2023).

- IEC 62196-2; Plugs. Socket-Outlets. Vehicle Connectors and Vehicle Inlets—Conductive Charging of Electric Vehicles—Part 2: Dimensional Compatibility Requirements for AC Pin and Contact-Tube Accessories. Edition 2.0. 2016-02. IEC: Geneva, Switzerland, 2016.

- Phoenix Contact. Charging Sockets for Electric Cars and Utility Vehicles. Available online: https://www.phoenixcontact.com/en-us/products/charging-technology-for-e-mobility/vehicle-charging-inlets?#se-result (accessed on 17 July 2023).

- Phoenix Contact. DC Charging Cables for Fast Charging Stations. Available online: https://www.phoenixcontact.com/en-us/products/charging-technology-for-e-mobility/dc-charging-cables?#se-result (accessed on 17 July 2023).

- Phoenix Contact. AC Charging Cables for Electric Cars. Charging Stations and Home Charging Points. Available online: https://www.phoenixcontact.com/en-in/products/charging-technology-for-e-mobility/ac-charging-cables (accessed on 17 July 2023).

- Electway Electric. Battery Charger. Available online: https://www.electway.net/product/Battery_charger_1.html (accessed on 18 July 2023).

- Congress: Tesla Superchargers and Plugs Should be the U.S. Standard for Evs. Available online: https://www.change.org/p/congress-tesla-superchargers-and-plugs-should-be-the-u-s-standard-for-evs (accessed on 2 August 2023).

- IEC 61851-1; Electric Vehicle Conductive Charging System—Part 1: General Requirements. Edition 3.0. 2017-02. IEC: Geneva, Switzerland, 2017.

- EVEXPERT. Product Selection by Electric Car. Available online: https://www.evexpert.eu/c/product-selection-by-electric-car (accessed on 19 July 2023).

- Electric Vehicle Database. Available online: https://ev-database.org/ (accessed on 19 July 2023).

- MINIVOLT. Samochody Elektryczne—Dane Techniczne i Ładowanie. Available online: https://www.milivolt.pl/category/samochody/ (accessed on 19 July 2023). (In Polish).

- Bezszelestni.pl. Ładowanie AC Auta Elektrycznego—Na Czym Polega? Available online: https://bezszelestni.pl/ladowanie-ac-auta-elektrycznego-na-czym-polega-wychowanieelektromobilne/ (accessed on 19 July 2023). (In Polish).

- Wang, H.; Tang, J.; Guo, D.; Tan, G. Optimal Planning of Charging Stations Based on Charging Behavior of Electric Vehicles and Charging Selection. SAE Int. J. Sustain. Transp. Energy Environ. Policy 2021, 2, 3–24. [Google Scholar] [CrossRef]

- Hamadi, A.; Alam, M.; Arefifar, S. Analyzing the Impact of Electric Vehicles Charging Stations on Power Quality in Power Distribution Systems; SAE Technical Paper 2021, 2021-01-0199; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries. Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020PC0798&qid=1608192505371 (accessed on 16 June 2023).

- EU Guidelines for the Development of the Trans-European Transport Network. Available online: https://eur-lex.europa.eu/en/legal-content/summary/eu-guidelines-for-the-development-of-the-trans-european-transport-network.html (accessed on 28 July 2023).

- Mobility And Transport TENtec Interactive Map Viewer. Available online: https://ec.europa.eu/transport/infrastructure/tentec/tentec-portal/map/maps.html (accessed on 25 July 2023).

- Zhang, J.; Wozniak, C. EV Charge Station System Reliability Modeling and Analysis; SAE Technical Paper, 2017-01-0198; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- UNECE Transport Vehicle Regulations. Available online: https://unece.org/transport/vehicle-regulations (accessed on 18 July 2023).

- Xu, K.; Wang, X.; Meng, X.; Liu, G.; Wen, B.; Zhou, R. Comparative research on standards and regulations of electric vehicle post crash safety requirement. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Kilian, P.; Köhler, A.; Van Bergen, P.; Gebauer, C.; Pfeufer, B.; Koller, O.; Bertsche, B. Principle Guidelines for Safe Power Supply Systems Development. IEEE Access 2021, 9, 107751–107766. [Google Scholar] [CrossRef]

- Gong, C.; Liu, J.; Han, Y.; Hu, Y.; Yu, H.; Zeng, R. Safety of Electric Vehicles in Crash Conditions: A Review of Hazards to Occupants. Regulatory Activities. and Technical Support. IEEE Trans. Transp. Electrif. 2022, 8, 3870–3883. [Google Scholar] [CrossRef]

- Zhang, Z.; He, S.; Wang, K. Research on the Crash Test’s Safety in NCAP of Electrical Vehicle. In Proceedings of the 2017 9th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Changsha, China, 14–15 January 2017; pp. 310–315. [Google Scholar] [CrossRef]

- The European New Car Assessment Programme. Available online: https://www.euroncap.com/en (accessed on 17 July 2023).

- Karner, D.B. Current events in vehicle battery safety. In Proceedings of the Tenth Annual Battery Conference on Applications and Advances, Long Beach, CA, USA, 10–13 January 1995; pp. 167–169. [Google Scholar] [CrossRef]

- Freschi, F.; Mitolo, M.; Tommasini, R. Electrical safety of electric vehicles. In Proceedings of the 2017 IEEE/IAS 53rd Industrial and Commercial Power Systems Technical Conference (I&CPS), Niagara Falls, ON, Canada, 7–11 May 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Hu, P.; Jiang, Z.; Qi, C.; Guo, R.; Han, X.; An, W. Front crash simulation and design improvement of a pure electric vehicle. In Proceedings of the 2011 International Conference on Electrical and Control Engineering, Yichang, China, 16–18 September 2011; pp. 1085–1088. [Google Scholar] [CrossRef]

- Romo, J.; Cañibano, E.; Merino, J.C. Lightweighting and passive safety for urban electric vehicle. In Proceedings of the 2017 Electric Vehicles International Conference (EV), Bucharest, Romania, 5–6 October 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Vora, K.C.; Agrewale, M.R.B.; Desai, M.M.; Mishra, H.; Narkar, O. Development analysis and testing of an electric all-terrain vehicle. In Proceedings of the 2017 IEEE Transportation Electrification Conference (ITEC-India), Pune, India, 13–15 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Molinero Fresnillo, R.; Core Almarza, E.; Zink, L.; Edwards, M.J.; Holtz, J.; Steen Pedersen, M.; Torres Heras, R. Passive safety strategy for electric lightweight vehicles with multimaterial body and centered driver position—Opportunities and limitations. In Proceedings of the 25th International Technical Conference on the Enhanced Safety of Vehicles, Detroit, MI, USA, 5–8 June 2017; pp. 1346–1360. [Google Scholar]

- Van Poppel, J.; Stern, A.R.; Fortenbaugh, D. A parametric study of an adaptive load-limiting restraint system with weight sensing considerations. In Proceedings of the 26th International Technical Conference on the Enhanced Safety of Vehicles, Eindhoven, The Netherlands, 10–13 June 2019; pp. 258–279. [Google Scholar]

- Chen, G.; Shi, M.F.; Tyan, T. Optimization of front end structures for IIHS small overlap frontal crash test. In Proceedings of the 26th International Technical Conference on the Enhanced Safety of Vehicles, Eindhoven, The Netherlands, 10–13 June 2019; pp. 955–964. [Google Scholar]

- Wei, X.; Ma, Z.; Zhu, X.; Zheng, Y. An Analysis of the Safety of Low-Speed Electric Vehicles in the Event of a Frontal Collision; SAE Technical Paper 2021-01-5011; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, K.; Zhao, Y. Electrical vehicle crash test technique research. In Proceedings of the 2011 International Conference on Electronic & Mechanical Engineering and Information Technology, Harbin, China, 12–14 August 2011; pp. 4393–4396. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, S.; Liu, P. Research Progress on Collision Safety of Electric Vehicles. In Proceedings of the 2011 Third International Conference on Measuring Technology and Mechatronics Automation, Shanghai, China, 6–7 January 2011; pp. 153–156. [Google Scholar] [CrossRef]

- Ruina, D.; He, C.; Qiang, Z.; Keqiang, L.; Yusheng, L. ACC of electric vehicles with coordination control of fuel economy and tracking safety. In Proceedings of the 2012 IEEE Intelligent Vehicles Symposium, Madrid, Spain, 3–7 June 2012; 2012; pp. 240–245. [Google Scholar] [CrossRef]

- Guirong, Z.; Henghai, Z. Research of the electric vehicle safety. In Proceedings of the World Automation Congress 2012, Puerto Vallarta, Mexico, 24–28 June 2012; pp. 1–4. [Google Scholar]

- Fornells, A.; Parera, N. Safety Protocol for Crash Tests Involving Electric and Hybrid Vehicles; SAE Technical Paper 2017-26-0010; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Haque, T.S.; Rahman, M.H.; Islam, M.R.; Razzak, M.A.; Badal, F.R.; Ahamed, M.H.; Moyeen, S.I.; Das, S.K.; Ali, M.F.; Tasneem, Z.; et al. A Review on Driving Control Issues for Smart Electric Vehicles. IEEE Access 2021, 9, 135440–135472. [Google Scholar] [CrossRef]

- Feng, J.; Tian, Z.; Cui, J.; Zhou, F.; Tan, G. Downhill Safety Assistant Driving System for Battery Electric Vehicles on Mountain Roads; SAE Technical Paper 2019-01-2129; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Vavilapalli, K.R.; Abhijith, V.P.; Chandrashekhar, A.L.A. Implementation of ABS/ESC systems for light weight electric vehicle. In Proceedings of the 2017 IEEE Transportation Electrification Conference (ITEC-India), Pune, India, 13–15 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Savitski, D.; Ivanov, V.; Shyrokau, B.; De Smet, J.; Theunissen, J.; Shyrokau, B. Experimental Study on Continuous ABS Operation in Pure Regenerative Mode for Full Electric Vehicle. SAE Int. J. Passeng. Cars Mech. Syst. 2015, 8, 364–369. [Google Scholar] [CrossRef]

- Mohamed, E.; Abouel-Seoud, S.; Elsayed, M. Performance Analysis of the ABS Control on Parallel Hybrid Electric Vehicle Equipped with Regenerative Braking System. SAE Int. J. Passeng. Cars Electron. Electr. Syst. 2015, 8, 477–491. [Google Scholar] [CrossRef]

- Wang, C.; Yu, H.; Zhang, L.; Wang, Z.; Wang, Q.; Cao, D. Post-Impact Stability Control for Four-Wheel- Independently-Actuated Electric Vehicles. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 7197–7202. [Google Scholar] [CrossRef]

- Guodong, Y.; Qi, C.; Ahmed, Q.; Xianjian, J.; Chentong, B. Yaw stability of four-wheel-drive electric vehicle based on multi-model predictive control. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015; pp. 8159–8164. [Google Scholar] [CrossRef]

- Zhao, H.; Chen, W.; Zhao, J.; Zhang, Y.; Chen, H. Modular Integrated Longitudinal. Lateral. and Vertical Vehicle Stability Control for Distributed Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 1327–1338. [Google Scholar] [CrossRef]

- Dehkordi, S.G.; Cholette, M.E.; Larue, G.S.; Rakotonirainy, A.; Glaser, S. Energy Efficient and Safe Control Strategy for Electric Vehicles Including Driver Preference. IEEE Access 2021, 9, 11109–11122. [Google Scholar] [CrossRef]

- Van Schalkwyk, D.J.; Kamper, M.J. Effect of Hub Motor Mass on Stability and Comfort of Electric Vehicles. In Proceedings of the 2006 IEEE Vehicle Power and Propulsion Conference, Windsor, UK, 6–8 September 2006; pp. 1–6. [Google Scholar] [CrossRef]

- Neurauter, M.L.; Roan, M.; Song, M.; Harwood, L.; Moore, D.; Glaser, D. Electric vehicle detectability by the vision impaired: Quantifying impact of vehicle generated acoustic signatures on minimum detection distances. In Proceedings of the 25th International Technical Conference on the Enhanced Safety of Vehicles, Detroit, MI, USA, 5–8 June 2017. [Google Scholar]

- Garrott, W.R.; Hoover, R.L. Selection of NHTSA’s sound analysis code. In Proceedings of the 25th International Technical Conference on the Enhanced Safety of Vehicles, Detroit, MI, USA, 5–8 June 2017. [Google Scholar]

- Aboelsaoud, M.; Taha, A.A.; Elazm, M.A.; Elgamal, H. Comparative analysis of Hydroplaning in Electric and ICE Vehicles. In Proceedings of the 2022 IEEE 2nd International Maghreb Meeting of the Conference on Sciences and Techniques of Automatic Control and Computer Engineering (MI-STA), Sabratha, Libya, 23–25 May 2022; pp. 59–63. [Google Scholar] [CrossRef]

- Zhang, K.; Yin, Z.; Yang, X.; Yan, Z.; Huang, Y. Quantitative assessment of electric safety protection for electric vehicle charging equipment. In Proceedings of the 2017 International Conference on Circuits. Devices and Systems (ICCDS), Chengdu, China, 5–8 September 2017; pp. 89–94. [Google Scholar] [CrossRef]

- Linru, J.; Yuanxing, Z.; Taoyong, L.; Xiaohong, D.; Jing, Z. Analysis on Charging Safety and Optimization of Electric Vehicles. In Proceedings of the 2020 IEEE 6th International Conference on Computer and Communications (ICCC), Chengdu, China, 11–14 December 2020; pp. 2382–2385. [Google Scholar] [CrossRef]

- Wang, B.; Dehghanian, P.; Wang, S.; Mitolo, M. Electrical Safety Considerations in Large-Scale Electric Vehicle Charging Stations. IEEE Trans. Ind. Appl. 2019, 55, 6603–6612. [Google Scholar] [CrossRef]

- Ganesh, V.; Ajay Krishna, V.M.; Ajit Ram, R.R. Safety Feature in Electric Vehicle at Public Charging Station. In Proceedings of the 2021 7th International Conference on Electrical Energy Systems (ICEES), Chennai, India, 11–13 February 2021; pp. 156–161. [Google Scholar] [CrossRef]

- Sabbella, R.R.; Arunachalam, M. Functional Safety Development of Motor Control Unit for Electric Vehicles. In Proceedings of the 2019 IEEE Transportation Electrification Conference (ITEC-India), Bengaluru, India, 17–19 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Alexandersson, S. Functional safety and EMC for the automotive industry. In Proceedings of the 2008 IEEE International Symposium on Electromagnetic Compatibility, Detroit, MI, USA, 18–22 August 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, S. Improve vehicle’s function safety with an approach investigating vehicle’s electromagnetic interference with its function safety. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–7. [Google Scholar] [CrossRef]

- Tao, C. Functional safety concept design of hybrid electric vehicle following ISO 26262. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Mader, R.; Martin, H.; Obendrauf, R.; Prinz, P.; Winkler, B.; Grießnig, G. A framework for model-based safety requirements round-trip engineering. In Proceedings of the 10th IET System Safety and Cyber-Security Conference 2015, Bristol, UK, 21–22 October 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Yanwen, L.; Xiyang, W. Functional Safety Analysis for the Design of VCU Used in Pure Electric Vehicles. In Proceedings of the 2017 4th International Conference on Information Science and Control Engineering (ICISCE), Changsha, China, 21–23 July 2017; pp. 1004–1008. [Google Scholar] [CrossRef]

- Wu, Z.; Lu, K.; Zhu, Y.; Lei, X.; Duan, L.; Zhao, J. Functional Safety and Secure CAN in Motor Control System Design for Electric Vehicles; SAE Technical Paper 2017-01-1255; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Shankar Kumar, M.N.; Balakrishnan, K. Functional Safety Development of Battery Management System for Electric Vehicles. In Proceedings of the 2019 IEEE Transportation Electrification Conference (ITEC-India), Bengaluru, India, 17–19 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Christiaens, S.; Ogrzewalla, J.; Pischinger, S. Functional Safety for Hybrid and Electric Vehicles; SAE Technical Paper 2012-01-0032; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Batchu, S. Functional Safety in Inverter Hardware; SAE Technical Paper 2016-28-0166; SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Moure, C.; Kersting, K. Development of Functional Safety in a Multi-Motor Control System for Electric Vehicles; SAE Technical Paper 2012-01-0028; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Zakrzewicz, W.; Sys, E.; Mrowicki, A.; Siczek, K.; Kubiak, P. Safety issues for electric and hybrid vehicles. In Proceedings of the 2020 XII International Science-Technical Conference Automotive Safety, Kielce, Poland, 21–23 October 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Electric Cars Involved in More Accidents than Regular Vehicles. Study Shows. The Brussels Times. Sunday. 11 September 2022. Available online: https://www.brusselstimes.com/287315/electric-cars-involved-in-more-accidents-than-regular-vehicles-study-shows (accessed on 17 July 2023).

- Bodine, R.; Brennan, R. Gas vs. Electric Car Fires. 2023 Findings. Available online: https://www.autoinsuranceez.com/gas-vs-electric-car-fires/ (accessed on 18 July 2023).

- Zakazy WJAZDU dla Samochodów Elektrycznych „Bo Pożar” to Idiotyczne Sianie Paniki. Available online: https://spidersweb.pl/autoblog/pozary-samochodow-elektrycznych-w-polsce-bzdura/ (accessed on 17 July 2023). (In Polish).

- Dong, H.; Fan, J.; Wang, J.; Ren, Y.; Sun, W.; Yuan, R. Fault analysis of power battery based on voltage data record of realworld fired electric vehicles. In Proceedings of the 3rd International Conference on Computer Information and Big Data Applications (CIBDA 2022), Wuhan, China, 25–27 March 2022; pp. 1–10. [Google Scholar]

- Schei Blikeng, L.; Hegén Agerup, S. Fire in Electric Cars; SAE Technical Paper 2015-01-1382; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Meghana, N.; Pushparaju, M.; Kavitha, M.; Kalyan Chakravarthy, N.S.; Reddy, D.M. A Critical Review on Electric Vehicle Battery Failures and Causes. In Proceedings of the 2022 IEEE 2nd International Conference on Sustainable Energy and Future Electric Transportation (SeFeT), Hyderabad, India, 4–6 August 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Chet Sandberg, P.E. Integrating battery energy storage with a BMS for reliability. efficiency. and safety in vehicles. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012; pp. 1–3. [Google Scholar] [CrossRef]

- Sasirekha, P.; Sneka, E.; Velmurugan, B.; Sahul Hameed, M.; Sivasankar, P. A Battery Monitoring System based on IoT for Electric Vehicles. In Proceedings of the 2023 5th International Conference on Smart Systems and Inventive Technology (ICSSIT), Tirunelveli, India, 23–25 January 2023. [Google Scholar] [CrossRef]

- Wang, J.; Wang, C.; Deng, H.; Huang, H.; Li, L. Electric Vehicle Charging Detection and Early Warning System Based on Internet of Thing. In Proceedings of the 2020 7th International Conference on Information, Cybernetics, and Computational Social Systems (ICCSS), Guangzhou, China, 13–15 November 2020; pp. 650–654. [Google Scholar] [CrossRef]

- Li, Z.; Chenglong, L. Research on Fire Performance Test Technology of Electric Vehicle Power Battery System. In Proceedings of the 2022 2nd International Signal Processing. Communications and Engineering Management Conference (ISPCEM), Montreal, ON, Canada, 25–27 November 2022; pp. 340–344. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, X.; Wang, Z.; Shan, T.; Zhang, J.; Sun, Z. Safety assessment of thermal runaway behavior of lithium-ion cells with actual installed state. Appl. Therm. Eng. 2023, 229, 120617. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Sun, F.; Wang, Z. An Overview on Thermal Safety Issues of Lithium-ion Batteries for Electric Vehicle Application. IEEE Access 2018, 6, 23848–23863. [Google Scholar] [CrossRef]

- Song, L.; Zheng, Y.; Xiao, Z.; Wang, C.; Long, T. Review on Thermal Runaway of Lithium-Ion Batteries for Electric Vehicles. J. Electron. Mater. 2022, 51, 30–46. [Google Scholar] [CrossRef]

- Citarella, M.; Schiffbänker, P.; Suzzi, D.; Maier, G.; Brunnsteiner, B.; Schneider, J. Computational Modelling of Thermal Runaway Propagation in Lithium-Ion Battery Systems. In Proceedings of the 2019 IEEE Transportation Electrification Conference (ITEC-India), Bengaluru, India, 17–19 December 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Qu, C.; Ma, F.; Xu, X.; Yang, J.; Zhang, J.; Zhou, Y.; Shan, T.; Hou, Y. Fault Prognosis and Isolation of Lithium-Ion Batteries in Electric Vehicles Considering Real-Scenario Thermal Runaway Risks. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 88–99. [Google Scholar] [CrossRef]

- Gao, W.; Li, X.; Ma, M.; Fu, Y.; Jiang, J.; Mi, C. Case Study of an Electric Vehicle Battery Thermal Runaway and Online Internal Short-Circuit Detection. IEEE Trans. Power Electron. 2021, 36, 2452–2455. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Z.; Liu, P.; Zhang, Z.; Wang, S.; Dorrell, D.G. Relative Entropy based Lithium-ion Battery Pack Short Circuit Detection for Electric Vehicle. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020. [Google Scholar] [CrossRef]

- Xu, G.; Han, Q.; Chen, H.; Xia, Y.; Liu, Z.; Tian, S. Safety warning analysis for power battery packs in electric vehicles with running data. J. Energy Storage 2022, 56, 105878. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Abdollahi, A.; Jones, T. Data-driven Thermal Anomaly Detection for Batteries using Unsupervised Shape Clustering. In Proceedings of the 2021 IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021. [Google Scholar] [CrossRef]

- Li, D.; Zhang, Z.; Wang, Z.; Liu, P.; Liu, Z.; Lin, N. Timely Thermal Runaway Prognosis for Battery Systems in Real-World Electric Vehicles Based on Temperature Abnormality. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 120–130. [Google Scholar] [CrossRef]

- Liu, P.; Wang, J.; Wang, Z.; Zhang, Z.; Wang, S.; Dorrell, D.G. High-dimensional data abnormity detection based on improved Variance-of-Angle (VOA) algorithm for electric vehicles battery. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019. [Google Scholar] [CrossRef]

- Chen, M.; Dongxu, O.; Cao, S.; Liu, J.; Wang, Z.; Wang, J. Effects of heat treatment and SOC on fire behaviors of lithium-ion batteries pack. J. Therm. Anal. Calorim. 2019, 136, 2429–2437. [Google Scholar] [CrossRef]

- Wang, Z.; Ouyang, D.; Chen, M.; Wang, X.; Zhang, Z.; Wang, J. Fire behavior of lithium-ion battery with different states of charge induced by high incident heat fluxes. J. Therm. Anal. Calorim. 2019, 136, 2239–2247. [Google Scholar] [CrossRef]

- Li, H.; Peng, W.; Yang, X.; Chen, H.; Sun, J.; Wang, Q. Full-Scale Experimental Study on the Combustion Behavior of Lithium Ion Battery Pack Used for Electric Vehicle. Fire Technol. 2020, 56, 2545–2564. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, X.; Yu, Y.; Du, Z.; Hwang, H.Y.; Liu, L.; Deng, L. Experimental Investigation of Fire Extinguishing of a Full-Size Battery Box with FK-5-1-12. Fire Technol. 2023, 59, 1269–1282. [Google Scholar] [CrossRef]

- Höhne, C.C.; Gettwert, V.; Frank, F.; Kilian, S.; Menrath, A. Bench-scale fuel fire test for materials of rechargeable energy storage system housings. J. Therm. Anal. Calorim. 2023, 148, 305–313. [Google Scholar] [CrossRef]

- Anderson, J.; Larsson, F.; Andersson, P.; Mellander, B.E. Thermal modeling of fire propagation in lithium-ion batteries. In Proceedings of the 24th International Technical Conference on the Enhanced Safety of Vehicles, Gothenburg, Sweden, 8–11 June 2015; pp. 204–279. [Google Scholar]

- Singh, A.; Jana, M.; Basu, S. Role of OEM’s and Cell Manufacturer’s for Safety in Electric Vehicles. In Proceedings of the 2021 IEEE Transportation Electrification Conference (ITEC-India), New Delhi, India, 16–19 December 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Aalund, R.; Diao, W.; Kong, L.; Pecht, M. Understanding the Non-Collision Related Battery Safety Risks in Electric Vehicles a Case Study in Electric Vehicle Recalls and the LG Chem Battery. IEEE Access 2021, 9, 89527–89532. [Google Scholar] [CrossRef]

- Linja-aho, V. Assessing the Electrical Risks in Electric Vehicle Repair. In Proceedings of the 2022 IEEE IAS Electrical Safety Workshop (ESW), Jackonwille, FL, USA, 7–11 March 2022. [Google Scholar] [CrossRef]

- La Scala, A.; Sabbà, M.F.; Foti, D. Fire Hazard of Electric Vehicles in Enclosed Structures. In Proceedings of the 2022 AEIT International Annual Conference (AEIT), Rome, Italy, 3–5 October 2022. [Google Scholar] [CrossRef]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues. strategies. and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Huang, W.; Feng, X.; Han, X.; Zhang, W.; Jiang, F. Questions and Answers Relating to Lithium-Ion Battery Safety Issues. Cell Rep. Phys. Sci. 2021, 2, 100285. [Google Scholar] [CrossRef]

- Murray, K.; Lele, S. Electric Vehicle Battery Safety and Compliance; SAE Technical Paper 2023-01-0597; SAE International: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Safety Risks to Emergency Responders from Lithium-Ion Battery Fires in Electric Vehicles; Safety Report NTSB/SR-20/01 PB2020-101011; National Transportation Safety Board: Washington, DC, USA, 2020.

- Barbat, S.; Mehall, M.; Nayak, R.; Nusholtz, G.; Olds, N.; Shi, Y.; Stanko, W.; Tai Wang, J.; Weerappuli, P.; Xu, L.; et al. Crash Test Pulses for Advanced Batteries; SAE Technical Paper 2012-01-0548; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Nusholtz, G.S.; Shi, Y.; Xu, L.; Olds, N.M.; Barbat, S.; Mehall, M.; Stanko, W.; Weerappuli, P.; Nayak, R.; Tai Wang, J.; et al. Idealized Vehicle Crash Test Pulses for Advanced Batteries; SAE Technical Paper 2013-01-0764; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Chen, P.; Xia, Y.; Zhou, Q. Safety Comparison of Geometric Configurations of Electric Vehicle Battery under Side Pole Impact; SAE Technical Paper 2022-01-0265; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Electric Vehicles and the Untold Secret: Are They Actually Worse for the Environment and Dangerous than Gas? Available online: https://www.miamiherald.com/contributor-content/article272574443.html (accessed on 27 July 2023).

- Takahashi, M.; Takeuchi, M.; Maeda, K.; Nakagawa, S. Comparison of Fires in Lithium-Ion Battery Vehicles and Gasoline Vehicles. SAE Int. J. Passeng. Cars Electron. Electr. Syst. 2014, 7, 213–220. [Google Scholar] [CrossRef]

- Lubczański, M. Nie Tylko Kontenery Gaśnicze, tak Można Ugasić Elektryka. Available online: https://e.autokult.pl/nie-tylko-kontenery-gasnicze-tak-mozna-ugasic-elektryka.6883395986590624a (accessed on 27 July 2023). (In Polish).

- Jej Elektryk Splonal w Garazu Teraz ma Problem. Available online: https://www.o2.pl/informacje/jej-elektryk-splonal-w-garazu-teraz-ma-problemy-6915686180911840a (accessed on 27 July 2023). (In Polish).

- Cui, Y.; Liu, J.; Han, X.; Sun, S.; Cong, B. Full-scale experimental study on suppressing lithium-ion battery pack fires from electric vehicles. Fire Saf. J. 2022, 129, 103562. [Google Scholar] [CrossRef]

- Yu, D.; Li, Y.; Zhang, S.; Dong, H.; Han, G.; Xian, X. Fire Extinguishing Test of Lithium-Ion Battery Case in Electric Bus. In Proceedings of the 2019 9th International Conference on Fire Science and Fire Protection Engineering (ICFSFPE), Chengdu, China, 18–19 October 2019. [Google Scholar] [CrossRef]

- Do Electric Vehicles Pose Additional Hazards in a Crash. Available online: https://ankinlaw.com/do-electric-vehicles-pose-additional-hazards-in-a-crash (accessed on 27 July 2023).

- Geisbauer, C.; Wöhrl, K.; Lott, S.; Nebl, C.; Schweiger, H.-G.; Goertzb, R.; Kubjatko, T. Scenarios Involving Accident-Damaged Electric Vehicles. Transp. Res. Procedia 2021, 55, 1484–1489. [Google Scholar] [CrossRef]

- Kang, S.; Kwon, M.; Choi, J.Y.; Choi, S. Full-scale fire testing of battery electric vehicles. Appl. Energy 2023, 332, 120497. [Google Scholar] [CrossRef]

- Sturm, P.; Fößleitner, P.; Fruhwirt, D.; Galler, R.; Wenighofer, R.; Heindl, S.F.; Krausbar, S.; Heger, O. Fire tests with lithium-ion battery electric vehicles in road tunnels. Fire Saf. J. 2022, 134, 103695. [Google Scholar] [CrossRef]

- Held, M.; Tuchschmid, M.; Zennegg, M.; Figi, R.; Schreiner, C.; Mellert, L.D.; Welte, U.; Kompatscher, M.; Hermann, M.; Nachef, L. Thermal runaway and fire of electric vehicle lithium-ion battery and contamination of infrastructure facility. Renew. Sustain. Energy Rev. 2022, 165, 112474. [Google Scholar] [CrossRef]

| Kraj | BEVs | PHEVs | EVs | TPCs | BEVs/TPCs [%] | PHEVs/TPCs [%] | EVs/TPCs [%] |

|---|---|---|---|---|---|---|---|

| Austria | 117,919 | 42,289 | 160,208 | 5,677,614 | 2.08 | 0.74 | 2.82 |

| Belgium | 96,983 | 183,122 | 280,105 | 6,868,895 | 1.41 | 2.67 | 4.08 |

| Bulgaria | 3142 | 1897 | 5039 | 3,162,164 | 0.10 | 0.06 | 0.16 |

| Croatia | 4150 | 1634 | 5784 | 2,009,447 | 0.21 | 0.08 | 0.29 |

| Cyprus | 566 | 662 | 1228 | 711,874 | 0.08 | 0.09 | 0.17 |

| CzechRepublic | 14,798 | 8720 | 23,518 | 6,904,104 | 0.21 | 0.13 | 0.34 |

| Denmark | 10,1457 | 98,187 | 199,644 | 3,163,631 | 3.21 | 3.10 | 6.31 |

| Estonia | 3024 | 644 | 3668 | 962,463 | 0.31 | 0.07 | 0.38 |

| Finland | 49,287 | 106,276 | 155,563 | 4,084,584 | 1.21 | 2.60 | 3.81 |

| France | 761,494 | 412,693 | 1,174,187 | 45,527,439 | 1.67 | 0.91 | 2.58 |

| Germany | 1,034,947 | 932,152 | 1,967,099 | 52,000,325 | 1.99 | 1.79 | 3.78 |

| Greece | 6434 | 12,283 | 18,717 | 6,600,530 | 0.10 | 0.19 | 0.29 |

| Hungary | 16,856 | 14,669 | 31,525 | 4,622,570 | 0.36 | 0.32 | 0.68 |

| Iceland | 18,292 | 20,700 | 38,992 | 307,460 | 5.95 | 6.73 | 12.68 |

| Ireland | 37,940 | 25,523 | 63,463 | 2,766,430 | 1.37 | 0.92 | 2.29 |

| Italy | 185,086 | 184,142 | 369,228 | 44,256,433 | 0.42 | 0.42 | 0.84 |

| Latvia | 2130 | 569 | 2699 | 837,435 | 0.25 | 0.07 | 0.32 |

| Liechtenstein | 374 | 64 | 438 | 33,881 | 1.10 | 0.19 | 1.29 |

| Lithuania | 7561 | 4949 | 12,510 | 1,729,529 | 0.44 | 0.29 | 0.73 |

| Luxembourg | 15,328 | 12,834 | 28,162 | 490,142 | 3.13 | 2.62 | 5.75 |

| Malta | 2762 | 2719 | 5481 | 355,789 | 0.78 | 0.76 | 1.54 |

| Netherlands | 341,988 | 187,074 | 529,062 | 9,950,843 | 3.44 | 1.88 | 5.32 |

| Norway | 533,911 | 188,029 | 721,940 | 3,596,234 | 14.85 | 5.23 | 20.08 |

| Poland | 27,564 | 26,416 | 53,980 | 29,584,756 | 0.09 | 0.09 | 0.18 |

| Portugal | 71,607 | 59,738 | 131,345 | 7,064,476 | 1.01 | 0.85 | 1.86 |

| Romania | 23,644 | 8329 | 31,973 | 8,702,434 | 0.27 | 0.10 | 0.37 |

| Slovakia | 4705 | 4215 | 8920 | 2,831,779 | 0.17 | 0.15 | 0.32 |

| Slovenia | 7914 | 1546 | 9460 | 1,299,361 | 0.61 | 0.12 | 0.73 |

| Spain | 118,100 | 135,008 | 253,108 | 29,006,565 | 0.41 | 0.47 | 0.88 |

| Sweden | 223,677 | 276,580 | 500,257 | 5,635,658 | 3.97 | 4.91 | 8.88 |

| Switzerland | 128,158 | 72,982 | 201,140 | 5,236,879 | 2.45 | 1.39 | 3.84 |

| Turkey | 14,217 | 2346 | 16,563 | 18,819,314 | 0.08 | 0.01 | 0.09 |

| United Kingdom | 663,761 | 431,060 | 1,094,821 | 37,251,580 | 1.78 | 1.16 | 2.94 |

| EU 27 | 3,281,063 | 2,744,870 | 6,025,933 | 286,807,270 | 1.14 | 0.96 | 2.10 |

| Legend: | |||||||

| .....—countries where EV to TPC ratio exceeds 1%, .....—union of countries where EV to TPC ratio exceeds 1%. | |||||||

| Onboard Charger | |||||

| 3.7 kW one-phase, 16 A | 7.4 kW one-phase, 32 A | 11 kW three-phase, 16 A | 22 kW three-phase, 32 A | ||

| Charging Point | 2.3 kW one-phase, 10 A | 2.3 kW (a) | 2.3 kW (a) | 2.3 kW (a) | 2.3 kW (a) |

| 3.7 kW one-phase, 16 A | 3.7 kW (b) | 3.7 kW (a) | 3.7 kW (a) (1) | 3.7 kW (a) | |

| 7.4 kW one-phase, 32 A | 3.7 kW (d) | 7.4 kW (b) | 3.7 kW (c) (2) | 7.4 kW (a) | |

| 11 kW three-phase, 16 A | 3.7 kW (d) | 3.7 kW (c) (3) | 11 kW (b) | 11 kW (a) | |

| 22 kW three-phase, 32 A | 3.7 kW (d) | 7.4 kW (d) (4) | 11 kW (d) | 22 kW (b) | |

| Legend: | |||||

| (a) | - limitations related to the recharging point, | ||||

| (b) | - no restrictions, | ||||

| (c) | - limitations related to the recharging point and the OBC, | ||||

| (d) | - OBC-related limitations (the vehicle cannot charge faster), | ||||

| (1) | - on-board charger that only accepts single-phase charging, which is a limitation attributed to the AC recharging point: , | ||||

| (2) | - on-board charger that only accepts single-phase charging and a 16 A current due to the its OBC limitations: , | ||||

| (3) | - on-board charger that only accepts a single phase offered by a three-phase recharging point, which has the ability to supply AC at 16 A: , | ||||

| (4) | - on-board charger that only accepts a single phase offered by a three-phase recharging station, which has the ability to supply AC at 32 A: . | ||||

| Transportation Network | Distance (1) along the TEN-T Network | Minimum Power Output (2) | |

| Recharging Pools (3) | Recharging Stations (4) (Number × Power) | ||

| Light-duty vehicles | |||

| Core network | 60 km | 300 kW 2025 600 kW 2030 | 1 × 150 kW 2025 2 × 150 kW 2030 |

| Comprehensive network | 60 km | 300 kW 2030 600 kW 2035 | 1 × 150 kW 2030 2 × 150 kW 2035 |

| Heavy-duty vehicles | |||

| Core network | 60 km | 1400 kW 2025 3500 kW 2030 | 1 × 350 kW 2025 2 × 350 kW 2030 |

| Comprehensive network | 100 km | 1400 kW 2030 3500 kW 2035 | 1 × 350 kW 2030 2 × 350 kW 2035 |

| Legend: | |||

| (1) | - maximum distance between recharging pools in each direction of travel, | ||

| (2) | - theoretical maximum output power distributed among individual recharging pools, | ||

| (3) | - at least one recharging station per location, | ||

| (4) | - recharging station(s) with individual output power, | ||

| 2025 | - reaching the target by 31 December 2025, | ||

| 2030 | - reaching the target by 31 December 2030, | ||

| 2035 | - reaching the target by 31 December 2035, | ||

| Comprehensive transport network—is a transport network for ensuring accessibility and connectivity of all EU regions [31], | |||

| Core network—the transport network consists of those parts of the comprehensive network that are of the highest strategic importance for achieving the objectives for the development of the TEN-T. | |||

| Buffer zones around TEN-T roads of public and semi-public e-charging points | ||||||||||

| 1 km | 8 km | |||||||||

| Kraj | Type 2 | CCS | 50 kW ≤ p < 150 kW | 150 kW ≤ p < 350 kW | p ≥ 350 kW | Type 2 | CCS | 50 kW ≤ p < 150 kW | 150 kW ≤ p < 350 kW | p ≥ 350 kW |

| Austria | 2251 | 961 | 270 | 526 | 132 | 9873 | 1888 | 652 | 956 | 146 |

| Belgium | 7475 | 890 | 158 | 614 | 68 | 28,695 | 1646 | 447 | 976 | 101 |

| Bulgaria | 187 | 161 | 69 | 52 | 31 | 618 | 311 | 142 | 82 | 49 |

| Croatia | 153 | 143 | 78 | 46 | 10 | 506 | 240 | 132 | 64 | 20 |

| Cyprys | 92 | 10 | 4 | 6 | 0 | 173 | 13 | 5 | 6 | 0 |

| Czechia | 540 | 340 | 233 | 77 | 20 | 2079 | 832 | 647 | 147 | 20 |

| Denmark | 2573 | 750 | 106 | 596 | 48 | 11,201 | 1240 | 231 | 945 | 48 |

| Estonia | 145 | 46 | 28 | 14 | 4 | 206 | 57 | 34 | 19 | 4 |

| Finland | 2262 | 1015 | 265 | 704 | 22 | 6211 | 1519 | 565 | 899 | 26 |

| France | 12,913 | 6376 | 1400 | 3733 | 715 | 40,446 | 10,429 | 2865 | 5591 | 769 |

| Germany | 6620 | 6045 | 827 | 4545 | 589 | 46,860 | 11,947 | 2584 | 8032 | 862 |

| Greece | 484 | 54 | 18 | 31 | 0 | 1053 | 65 | 20 | 37 | 0 |

| Hungary | 409 | 181 | 83 | 69 | 20 | 1993 | 415 | 166 | 121 | 20 |

| Ireland | 500 | 174 | 58 | 85 | 30 | 1818 | 287 | 151 | 104 | 30 |

| Italy | 4808 | 2068 | 707 | 1192 | 124 | 23,159 | 4250 | 2110 | 1749 | 239 |

| Latvia | 150 | 83 | 62 | 8 | 2 | 282 | 142 | 106 | 21 | 2 |

| Lithuania | 362 | 122 | 85 | 28 | 8 | 774 | 190 | 142 | 32 | 8 |

| Luxembourg | 178 | 32 | 0 | 12 | 20 | 923 | 57 | 6 | 19 | 32 |

| Malta | 72 | 0 | 0 | 0 | 0 | 96 | 0 | 0 | 0 | 0 |

| The Netherlands | 25,594 | 2028 | 323 | 1616 | 66 | 108,362 | 2846 | 572 | 2051 | 83 |

| Poland | 538 | 390 | 266 | 49 | 32 | 2442 | 947 | 632 | 135 | 35 |

| Portugal | 818 | 359 | 276 | 89 | 26 | 4211 | 1231 | 1024 | 242 | 26 |

| Romania | 662 | 383 | 214 | 54 | 16 | 1362 | 704 | 392 | 97 | 28 |

| Slovakia | 426 | 217 | 121 | 66 | 7 | 1231 | 505 | 327 | 113 | 9 |

| Slovenia | 314 | 149 | 68 | 34 | 31 | 1121 | 202 | 100 | 36 | 32 |

| Spain | 6048 | 1792 | 996 | 583 | 127 | 17,594 | 3357 | 2064 | 882 | 144 |

| Sweden | 7325 | 2350 | 477 | 1700 | 182 | 20,065 | 3015 | 741 | 2069 | 220 |

| Legend: - five countries with the highest number of recharging points in the analyzed subcategories in 1 km and 8 km buffer zone: .....—type 2, .....—CCS, .....—50 kW ≤ p < 150 kW, .....—150 kW ≤ p < 350 kW, .....—p ≥ 350 kW, - one country with the highest number of recharging points in the analyzed subcategories: .....—in 1 km buffer zone, .....—in 8 km buffer zone. | ||||||||||

| Country | Ratio 1 | Ratio 2 | Ratio 3 | Country | Ratio 1 | Ratio 2 | Ratio 3 |

|---|---|---|---|---|---|---|---|

| Austria | 10.0 | 3.6 | 62.5 | Italy | 6.8 | 6.7 | 43.5 |

| Belgium | 3.2 | 6.0 | 58.9 | Latvia | 5.0 | 1.3 | 15.0 |

| Bulgaria | 3.4 | 2.0 | 10.1 | Lithuania | 7.8 | 5.1 | 39.8 |

| Croatia | 5.6 | 2.2 | 17.3 | Luxembourg | 15.6 | 13.1 | 268.9 |

| Cyprus | 3.0 | 3.6 | 43.5 | Malta | 28.8 | 28.3 | NaN |

| Czech Republic | 5.1 | 3.0 | 17.8 | Netherlands | 3.1 | 1.7 | 120.2 |

| Denmark | 8.2 | 7.9 | 81.8 | Poland | 8.1 | 7.8 | 29.1 |

| Estonia | 11.5 | 2.4 | 53.1 | Portugal | 13.2 | 11.0 | 58.2 |

| Finland | 6.4 | 13.7 | 32.4 | Romania | 11.4 | 4.0 | 33.6 |

| France | 15.0 | 8.1 | 73.0 | Slovakia | 2.7 | 2.4 | 9.3 |

| Germany | 17.6 | 15.9 | 86.6 | Slovenia | 6.0 | 1.2 | 39.2 |

| Greece | 5.8 | 11 | 99.0 | Spain | 5.6 | 6.4 | 35.2 |

| Hungary | 7.0 | 6.1 | 40.6 | Sweden | 9.7 | 12.0 | 74.2 |

| Ireland | 18.0 | 12.1 | 132.2 | EU 27 | 9.0 | 7.4 | 60.6 |

Legend:

.....—top five EU countries with the highest number of passenger EVs. | |||||||

| EV | Battery Capacity [kWh] | OBC (AC Charging) [kW] | Energy Consumption [Wh/km] | Time for AC Charging * [h:min] by Charging Point of Power | DC Charging Power [kW] | Time for DC Charging * [h:min] | Driving Distance *** [km] | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.3 kW | 3.7 kW | 7.4 kW | 11.0 kW | 22.0 kW | Max. ** | Ave. | ||||||

| Dacia Spring | 26.8 | 7.4 | 152 | 6:59 | 4:21 | 2:10 | 2:10 | 2:10 | 34 | 29 | 0:33 | 105 |

| VW ID.5 | 76.6 | 11.0 | 179 | 19:58 | 12:25 | 6:12 | 4:10 | 4:10 | 143 | 125 | 0:22 | 256 |

| Kia Niro EV | 64.8 | 11.0 | 168 | 16:54 | 10:30 | 5:15 | 3:31 | 3:31 | 80 | 70 | 0:33 | 231 |

| Audi Q4 e-tron | 76.6 | 11.0 | 189 | 19:58 | 12:25 | 6:12 | 4:10 | 4:10 | 143 | 125 | 0:22 | 243 |

| Cupra Born | 58.0 | 11.0 | 166 | 15:07 | 9:24 | 4:42 | 3:09 | 3:09 | 124 | 82 | 0:25 | 209 |

| Hyundai Kona Electric | 39.2 | 11.0 | 157 | 10:13 | 6:21 | 3:10 | 2:08 | 2:08 | 44 | 37 | 0:38 | 149 |

| Tesla 3 | 57.5 | 11.0 | 142 | 15:00 | 9:19 | 4:39 | 3:08 | 3:08 | 170 | 100 | 0:21 | 242 |

| Renault Zoe | 54.7 | 22.0 | 165 | 14:16 | 8:52 | 4:26 | 2:58 | 1:29 | 46 | 41 | 0:48 | 198 |

| Legend: | ||||||||||||

| * estimated charging time from 20% to 80% of battery capacity, ** EV limitations, *** estimated driving distance for 60% battery consumption, | .....— AC charging above 10 h, .....— limitation due to the OBC. | |||||||||||

| Car Type | Fire Number (Total) | Fire Number per 100k Sales |

|---|---|---|

| HEV | 16,051 | 3474.5 |

| ICEV | 199,533 | 1529.9 |

| EV | 52 | 25.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzek, M.; Jackowski, J.; Jurecki, R.S.; Szumska, E.M.; Zdanowicz, P.; Żmuda, M. Electric Vehicles—An Overview of Current Issues—Part 2—Infrastructure and Road Safety. Energies 2024, 17, 495. https://doi.org/10.3390/en17020495

Guzek M, Jackowski J, Jurecki RS, Szumska EM, Zdanowicz P, Żmuda M. Electric Vehicles—An Overview of Current Issues—Part 2—Infrastructure and Road Safety. Energies. 2024; 17(2):495. https://doi.org/10.3390/en17020495

Chicago/Turabian StyleGuzek, Marek, Jerzy Jackowski, Rafał S. Jurecki, Emilia M. Szumska, Piotr Zdanowicz, and Marcin Żmuda. 2024. "Electric Vehicles—An Overview of Current Issues—Part 2—Infrastructure and Road Safety" Energies 17, no. 2: 495. https://doi.org/10.3390/en17020495

APA StyleGuzek, M., Jackowski, J., Jurecki, R. S., Szumska, E. M., Zdanowicz, P., & Żmuda, M. (2024). Electric Vehicles—An Overview of Current Issues—Part 2—Infrastructure and Road Safety. Energies, 17(2), 495. https://doi.org/10.3390/en17020495