1. Introduction

One of the more important performance aspects in recent years is the operational security and safety of high-voltage apparatus. Reference [

1] still holds the most recent data for transformer failures, at least until the brochure, which is being prepared by Cigre working group A3.42, is finalized and published. According to [

1], fire and explosion failures account for roughly 3% of all failures recorded in instrument transformers, with the vast majority (almost 70%) of those failures connected to high-voltage current transformers.

In order to prevent and reduce the number of fire and explosion failures, internal arc testing has been introduced to all relevant international standards from early 2000s onwards [

1,

2,

3,

4,

5]. The more recent versions of the standards have updated the test requirements and procedures so that the test result can better simulate the situations in actual operation and avoid unnecessary re-tests and overlapping requirements [

1,

5]. Even with that, internal arc testing is still a controversial topic in the instrument transformer world. Papers [

6,

7,

8,

9] analyze different aspects of why that is and which measures should be taken in order to achieve more realistic and repeatable results. Conclusions from those references will be summarized and then expanded upon within this paper.

In addition to improving the testing techniques, requirements and test acceptance criteria, there is very little guidance on how to adequately determine internal arc parameters (arc voltage

Varc and total energy

Etot). This paper will detail the approach given in [

10] and cited in [

9], and comment on the drawbacks of that approach and the assumptions considered therein. These need to be taken into account to avoid underestimating the total energy of an arcing event.

Today, we are witnessing a very prominent movement to decarbonize the power system. One of the major influences on transmission and distribution equipment is a worldwide push to remove SF6 gas from the grid [

11]. For that reason, a multitude of alternative gasses are being considered for high-voltage application, such as fluorite gas mixtures, C0

2 mixtures and synthetic air [

12]. This movement is also reflected in paper-oil insulated units, with more alternative dielectric liquids being considered and used for different high-voltage equipment [

13,

14]. While the use of such liquids is already common in power and distribution transformers, it is also seen as the next evolutionary step in instrument transformers as well. However, there is only limited data on how these liquids perform under conditions inherent to instrument transformers, internal arc being one of them. This is a topic that the research on which this paper is based aims to answer specifically.

This paper will consider the influence of synthetic esters and bio-hydrocarbon based biodegradable oil on internal arc effects, and consequently on the fire and explosion safety of the instrument transformers [

15,

16]. Analyses presented and resulting conclusions are based on actual internal arc tests performed on identical 170 kV current transformers filled with different dielectric liquids. With that in mind, this paper will focus on inverted type current transformers. However, the conclusions presented herein are also applicable to dead tank current and voltage transformers. For voltage and station service transformers with arc energy-limiting features, references [

7,

8,

17] detail the methodology that should be used. In the end, the purpose of this paper is to provide guidance on how to correctly interpret the standard requirements, how to perform the basic assessment of the impact those requirements have on the instrument transformer design, what to look out for when carrying out actual testing and result analysis and, finally, what is the influence of using different dielectric liquids in instrument transformers.

2. Internal Arc Test Requirements

The first aim of this paper is to analyze requirements from different international standards from several aspects. The considered standards are IEC 61869-1:2007, IEEE C57.13.5:2019, IEEE/IEC 63253-5713-8 and the recently published IEC 61869-1:2023 [

2,

3,

4,

5]. The aspects considered will be internal arc current, arc inception location, relief of energy accumulated during an arcing event and, finally, the test setup and acceptance criteria. The aim is to clearly specify the level of expected performance, which is not given in sufficient detail in the aforementioned standards. This is highly important as it reduces unnecessary discussion and avoids possible re-tests due to different interpretations of the standards or possible differences between them.

Before going into different aspects of internal arc testing, several statements should be noted. The first is that internal arc test is not a guarantee against containment under all internal fault conditions, but a test to demonstrate the conformance to an agreed level of safety [

2,

3,

4,

5].

The second is that the agreed level of safety typically does not cover faults within the bushing (insulator) portion of instrument transformers in any way. Only arc inception within a metal enclosure (i.e., head assembly for top core CTs or tank enclosure for hairpin, eyebolt CTs or dead tank VTs) can adequately be tested according to existing clauses of IEC and IEEE standards [

18].

The third is that internal arc testing does not reduce the probability of a fault occurring, just the ability of the unit to release a certain amount of energy in a controlled way [

8].

The fourth is that internal arc is a highly violent, destructive test, that is both expensive and only possible to perform in a limited number of adequately equipped laboratories. Furthermore, to perform an internal arc test, specific measures must be taken to ensure that the fusing location is adequately supplied and does not result in an invalid test. For that matter, it is not possible to perform the test on a serial unit, rather on a prototype unit which inherits all the major design characteristics from the serial unit, most notably the metal enclosure design, pressure relief concept and active part design [

9]. For those reasons it is highly impractical to repeat the internal arc test due to various input parameters (e.g., international standard, arc current

Iarc, different accuracy requirements, thermal current, etc.), and the test should be performed on a unit representative of the product range, ideally with the maximum arc current for which the unit was designed.

2.1. Internal Arc Performance Classes

In an attempt to standardize the expected level of safety for a certain instrument transformer design, all international standards group internal arc performance into two classes. The detailed definitions from each standard are given in

Table 1. Basically, all standards specify the classes almost identically. In layman’s terms, Class I allows for a fracture of the structural components (housing, insulator) as long as all projected parts are confined within a prescribed containment area, while Class II requires that the structural parts remain intact, with only the pressure relief device operating. It is worth noting that IEEE C57.13.5 and IEC/IEEE 63253-5713-8 both allow the operation of any pressure relief device provided with the transformer [

2,

4].

There are several inconsistencies that should be pointed out in this chapter. The first is the existence of multiple protection stages in [

3]. Apart from having different safety definitions, they are also connected to different current values and durations, which can cause an unnecessary repetition of the test. This is the reason why the protection stages were abolished in other standards. The connection to current values and duration shall be discussed in the next chapter in more detail. Secondly, the requirement for a protection stage is also vaguely defined, as it is not clear what fragmentation is specifically, or how there can be a fire without the operation of a pressure relief device. The current version of the standard tries to explain this better but it still lacks an explicit definition. Specifically, emission of burning liquids is the vague point. The question is whether this applies to burning gases that are released during an arcing event or is it just to burning liquids that will come to the ground level immediately after the event.

Based on several tests, including those described in this paper and the available literature, the authors recommendation for the correct specification of internal arc performance is given in

Table 1. This definition makes all the standards mutually compatible and explicitly defines what to expect from each safety class. It also allows operation only of the pressure relief device in a way that directs the pressure relief away from parts of the transformer a human being can get near to during live operation (i.e., secondary terminal box and low-voltage connections).

2.2. Arc Current Magnitude, Waveform and Duration

The information on standard specified currents, associated duration and asymmetry factors are given in

Table 2.

At first glance, there are multiple differences between the various standards. The duration of the test is specified differently, where the duration in IEC ([

3,

5]) depends on the current magnitude and protection stage, while in IEEE C57.13.5 it is set firmly at 0.2 s. IEEE 63253-5713-8 is in-between the two previous groups with the duration depending on the current. In all cases, the applied current should be asymmetrical. However, IEEE ([

2,

4]) specifies an asymmetry factor of 2.7, while IEC ([

3,

5]) specifies the asymmetry factor of 1.7.

When the values of the current, duration and asymmetry peak are compared directly, they result in similar fault levels and, consequently, in similar energy for the same test object. The comparison of current levels is shown in

Figure 1. The values in the figure are based on the

I2t equivalent values according to clause 7.2.201 of the IEC 61869-2 standard, assuming the full asymmetry for the duration of one cycle, which approximates the decaying DC component of the fault current [

19]. There are two aspects that can immediately be identified from

Figure 1. The first is that specification of different protection stages and durations is not beneficial, which is another reason why it was removed from the current standard. The second is that currently active standards provide basically identical fault levels from 25 kA onwards, which means that, again, the test performed according to one standard is valid for another, which is highly beneficial. The values shown in

Figure 1 deal with the equivalency of the requirements for the arc current, which does not explain the appropriate selection of the current.

The distinction has to be made between the arc current and the short-time withstand current. Equating the two means that the impedance of the transformer insulation is reduced to zero, which is not realistic. This fact is corroborated by references [

6,

10,

20] which detail that the recorded arc currents are drastically lower than the rated system short-time withstand current, reaching as low as 40%. Equating the two currents results in an unnecessary over dimensioning of the instrument transformer, which is recognized by the standards [

2,

3,

4,

5]. Standards [

2,

4] introduce the term arc proof current, as the maximal current for which the internal arc classification applies. That current is explicitly disassociated from the system short-time withstand current and should correspond to its phase value. In the authors’ opinion, standard [

5] specifies the current levels in the best way, as it explicitly specifies 60% of rated short-time withstand current. This is realistic for the majority of actual applications and, in turn, allows the extension of applicability of existing test reports (e.g., a test performed at 40 kA is valid for units which have a short-time withstand current of 66.67 kA).

Similarly to current magnitude, current asymmetry peak and duration are also points of discussion. Multiple references report that the actual peak during an arcing event is lower than the peak under rated voltage conditions, in principle close to the 60% asymmetry, resulting in a factor of 1.7, which is specified in the IEC standards [

21,

22]. The most probable range of arc duration is 3 to 4 cycles at power frequency, whereas the standards specify 10–18 cycles, depending on the frequency and duration given in

Table 2. It is understandable that a certain margin needs to be established due to the probabilistic nature of arc faults, which is why an increase in values of either peak or duration are justified. In line with that, the authors recommendations are given in

Table 2.

As a final thought in this chapter, the best practice is to test an enclosure with the maximal current it is designed to endure and then evaluate the applicability of that test to the rated system short-time withstand current. This approach will reduce the number of unnecessary re-tests.

2.3. Arc Inception Location and Pressure Relief

The location of the arc inception is even more controversial than the actual arc current selection. Both IEEE and IEC initially specified the location to be at the location where the dielectric stress is the highest. As discussed in [

18], the highest dielectric stress in paper-oil insulated instrument transformers is typically located at the edge of capacitive screens in the bushing part of the insulation (i.e., within the insulator, not within the metal enclosures). Incepting an arc with the current levels and duration specified in the standards will lead to violent failure of the insulator. To bypass this, some manufacturers are intentionally increasing local dielectric stress to be able to perform the test in the most favorable scenario for pressure relief, which is not representative of actual in-service conditions [

6].

Later, these requirements were defined solely for gas insulated units, with the requirements for oil-insulated units given in

Table 3.

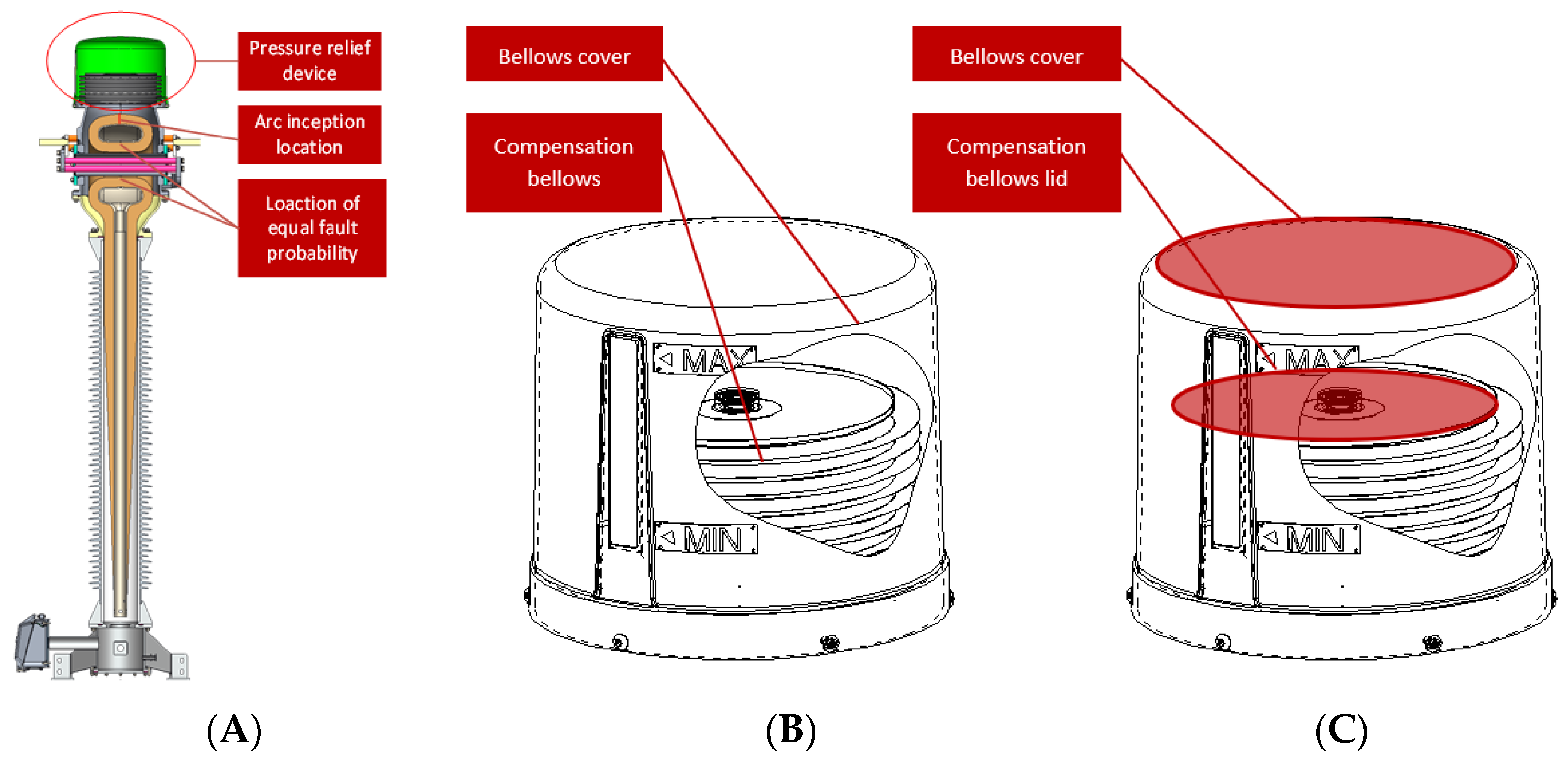

In a nutshell, both standard groups steer the requirement for the arc location towards the highest probability of failure, which is assumed to be at the top of the current transformer insulation for inverted type (top-core) current transformers, as indicated in

Figure 2A. This location is also convenient as it is located close to the pressure relief device (i.e., transformer bellows). A similar approach is used in [

6,

9]. This is a typical approach many manufacturers use because it makes the test more convenient and passable. The main reason is the fact that the metal enclosures for instrument transformers are small by volume and inflexible, unlike power and distribution transformer tanks.

This fact makes it almost impossible to contain the arc energy within the enclosure, with the only viable option to release it as quickly as possible in a controlled manner [

10].

In reality, the entire area between the high-voltage and ground electrodes of instrument transformers has an equal probability of arc inception, as it is manufactured in the same manner and at the same time. However, this fact has to be considered into the agreed level of safety proposed in the standards. This area is denoted in

Figure 2A.

This paper, much like references [

6,

9], used the arc inception location as indicated in

Figure 2A. An analysis of the different arc inception locations and their effect on overall performance is planned for future research.

The final point of contention is the operation of a pressure relief device. Standard [

5] does define that a pressure relief device must exist on an instrument transformer but gives no detail on what it is and how it should operate during internal arc event. It is similar in standards [

2,

4], which exclude the pressure relief device from the effects of the internal arc, but really do not define what it is. An absence of a clear definition or expected performance leaves too much open to interpretation when performing the test, and can result in failing the test or an unnecessary discussion on test results.

For top-core, hermetically sealed, paper-oil insulated instrument transformers, the transformer’s bellows (and its cover), shown in

Figure 2B, serve as oil volume compensation, keeping the pressure constant during normal operation. The same component frequently also serves the purpose of pressure relief, as its withstand pressures are significantly lower than the rest of the enclosure. Bellows assembly is always accompanied by a bellows cover, which protects it from mechanical damage while simultaneously serving as an oil level indicator [

7,

18]. A more detailed representation of the bellows and bellows cover is shown in

Figure 2B. If the standards [

2,

4,

5], are interpreted directly, it could be concluded that the entire pressure relief device can detach from the unit. However, depending on the unit design and oil volume contained within, the bellows assembly can be sizeable and weigh a dozen kilograms or more. If that dislodges from the unit, it can jeopardize equipment or personnel in the vicinity of the unit.

For this reason, the expected performance for oil-immersed units is that only the top lid of both the bellows cover and the bellows themselves can detach from the unit, while the bellows body must remain connected to the unit. This way, the weight of the projected part is limited to a reasonable degree, and the direction of the pressure relief is maintained upwards, thus minimizing the danger to neighboring equipment or an operator working in accessible places during normal operation. This is in line with recommendations given in [

5]. The parts that are allowed to detach from the unit are shown in

Figure 2C. Furthermore, it is worth noting that all units tested within the scope of this paper were tested according to the mentioned requirements and expected performance.

2.4. Test Setup and Considerations

Even though the test setup may seem straightforward, there are nuances between the standards that can be a source of unnecessary debate. The main test parameters are summarized in

Table 4.

The most important question that has repeatedly caused debate in the working groups is whether an enclosure wall is placed around the containment area in contrast to the area denoted by a line on the ground. The argument against a wall was that it can keep a certain component inside the containment area, therefore allowing a completion of the test that would otherwise be unsuccessful. In turn, if there is no physical barrier, a component can slide out of the containment area, making the test invalid. Perhaps the best compromise is given in standard [

4], where the containment area is dependent on the containment wall height, as shown in the formula in

Table 4. For more clarity, a schematic of the test setup is shown in

Figure 3, accompanied by an image of actual test setup used while testing 170 kV current transformers.

Other than that, the difference in pedestal height is irrelevant and should be neglected. The same goes for tolerances for current waveform and duration. It is recommended to use some leniency in order not to make the test invalid on a technicality. It should be noted that there are no tolerances on the peak value of current, which may have to be considered. The last difference is the requirement for the fusing element. Standards [

3,

5] place a geometric requirement on the fusing element, while standards [

2,

4] place a requirement on the angle of arc initiation, which is directly connected to the fusing element used.

While this approach does allow a broader range of options for the fusing element, it is tedious to measure and should not be considered a parameter which can nullify the test result.

3. Basic Approach for Arc Energy Assessment

Internal arc energy

Etot is a function of arc current

Iarc, arc voltage

Varc and duration

tarc, as shown in Equation (1). This equation can be simplified as suggested in [

9,

23,

24] and represented in Equation (2). As explained in previous chapters, the arc current and duration are specified by the internal arc requirement, while the arc voltage has to be evaluated from measurement or calculation.

As reported in [

23], the arc voltage is not related to the arc current, rather to the electrode shape, pressure and most importantly arc length

larc. The relationship between

Varc and

larc is presumed to be linear [

23]. An analytical correlation between arc length and voltage, considering the effects of gas bubble pressure influence, is widely used [

10,

25]. This correlation is shown in Equation (3).

P in the equation is the absolute pressure of gas bubble surrounding the arc. It is assumed it considers the atmospheric pressure and the hydrostatic pressure of the unit.

This approach is very straightforward, but there are several drawbacks associated with it, mainly because it simplifies or neglects several important influencing parameters. These parameters are the dynamic nature of the arc, force on the arc and change in electrode shape during an arcing event. As the arcing event progresses, the temperature of the arc destroys the material of electrodes the arc was initiated between, which makes the arc length longer, increasing the arc voltage. Furthermore, an arc is essentially a high current conductor, meaning that it is influenced by the Lorentz force, which again increases the effective length of the arc, also influencing the arc voltage. For those reasons, dynamic arc models are more suitable for accurate determination of arc voltage [

26,

27]. However, since these models are substantially more complex, they would supersede the scope of this paper. It is worth noting that the material of electrodes has little effect on the arc voltage [

27].

After determining

Varc, the total energy is easily calculated from Equation (2). Now it is time to relate the arc energy to developed pressure

Pd. The amount of gas generated has been observed to vary linearly with arc energy [

10,

24]. This means that arc energy is the main parameter for the evaluation of enclosure withstand and adequate operation of a pressure relief device. Equation (4) provides a relationship between the arc energy

Etot and developed pressure

Pd. It is a modified version of the original equation presented in [

23] and includes a more elaborate dynamic amplification factor

F and a conservative assumption of an isothermal expansion of the gas bubble [

9,

24].

In the equation,

F is the dynamic amplification factor given in [

10],

k is the arc energy conversion factor equal to 5.8 × 10

−4 [m

3/kJ],

C is the enclosure expansion coefficient [m

3/kPA], and

Ph is the hydrostatic pressure. It is important to note that the suggested value of factor

k is an empirical value, which suggests a gas generation rate of 85 cc/kJ and an average arc temperature of 2000 K. While the arc voltage may not be dependent on the electrode material, the gas generation rate is, which should be noted [

28]. In addition, since the gas generation during an arcing event is predominantly caused by the melting of the electrodes, the differences in dielectric liquids were disregarded.

As mentioned in earlier chapters, most instrument transformers, and specifically top core current transformers, do not exhibit any enclosure flexibility, as their enclosure is typically manufactured out of cast aluminum. This paper assumes a value of the

F factor of 2.5, which is the most conservative approach [

29]. It should be noted that Equation (4) was developed for power transformers primarily. The calculated values of

Varc, Etot and

Pd are shown in

Table 5 for an arc current of 50 kA, with an asymmetry factor of 1.7 and duration of 300 ms.

Once

Pd is known, it is possible to calculate the expected withstand of the enclosure using FEM methods. There is a little difference in approach compared to calculations inherent for power and distribution transformers. With instrument transformers it is critical to ensure that the pressure relief operates long before the rupture of the tank and leads away the fault energy, whereas in power and distribution transformers it is important to ensure that the deformation of the tank will contain the arc energy without breaching the containment [

9,

24,

25].

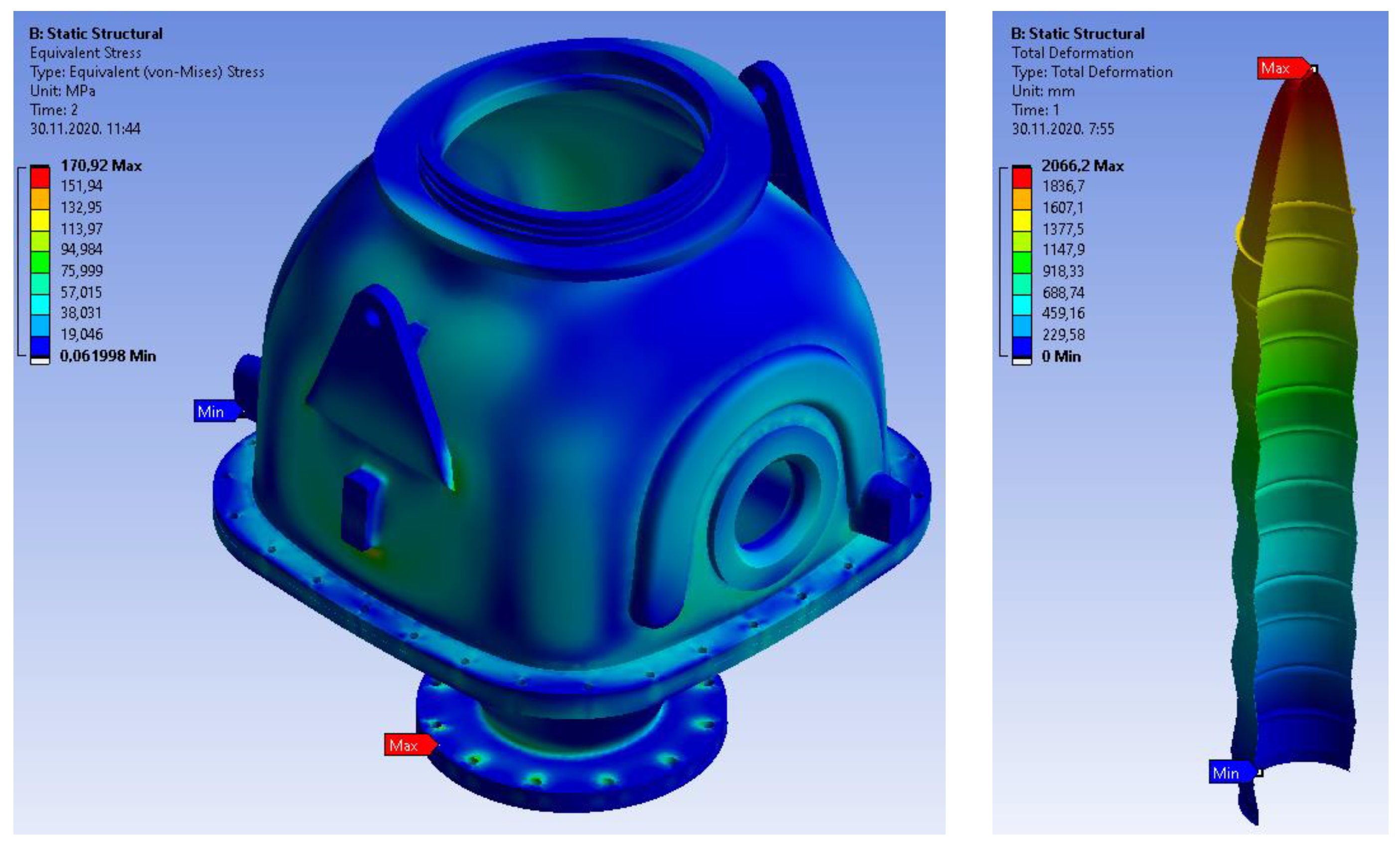

The FEM calculation results using the ANSYS 2022 R2 software package are shown in

Figure 4. For the calculation, pressure

Pd was evenly distributed along the head enclosure, as well as the transformer bellows. The purpose of this calculation is more to verify the expected performance during internal arc events, detailed in

Section 2, than it is to discuss enclosure dimensioning and intricacies connected to FEM modelling. This will be the subject of other work. However, it should be stated that, without having an accurate level of arc energy, FEM modelling is best used as an indicative calculation. If the correct arc energy is known, FEM modelling can be used as an accurate tool to obtain actual stress in mechanical components of the transformer.

With that in mind, the obtained results showcase two important aspects. The first is that the deformation of the bellows will happen much before the maximal stress in the enclosure is reached. The second is that the safety factor of the enclosure is sufficient for the expected performance and to cover for deficiencies of the used arc model. In both cases, the necessary indicator of expected performance, detailed in

Section 2, is achieved.

4. Internal Arc Test with Different Dielectric Liquids

As mentioned in the introductory chapters, the aim of this paper was to verify the influence of different biodegradable insulating liquids on internal arc performance. Three liquids were used, conventional mineral oil (Nynas Nytro Lyra X), synthetic ester (MIDEL 7131) and bio-hydrocarbon based biodegradable oil (Nynas Nytro Bio 300X). The main properties of these liquids, relevant for internal arc performance, are given in

Table 6 [

15,

16]. Synthetic esters (natural esters as well) are given a higher fire safety classification due to their increased flash and fire points. The advantages of those parameters are well documented for different spray tests, open and closed vessel tests and the probability of pool fire ignition [

30,

31]. However, there is very little information on the influence of fire safety during an internal arc. It should be noted that typical arc temperatures exceed 2000 K, so it is very debatable whether the increased fire point provides any practical advantage in this instance [

9].

To verify the internal arc performance of the dielectric liquids shown in

Table 6, three consecutive tests were performed on 170 kV current transformers. All three units had the exact same design, same insulation system, pressure relief design, electrode materials, etc. The only difference was the insulation liquid used. Moreover, all structural components used for the test units are used for serial production units. This also includes the insulators which, contrary to the recommendations of [

4] were made from porcelain, as this is considered a slightly worse case scenario. The expected performance of the units is detailed in

Section 2. The test setup used is shown in

Figure 3, and arc inception location as shown in

Figure 2. The expected energy levels are detailed in

Table 5.

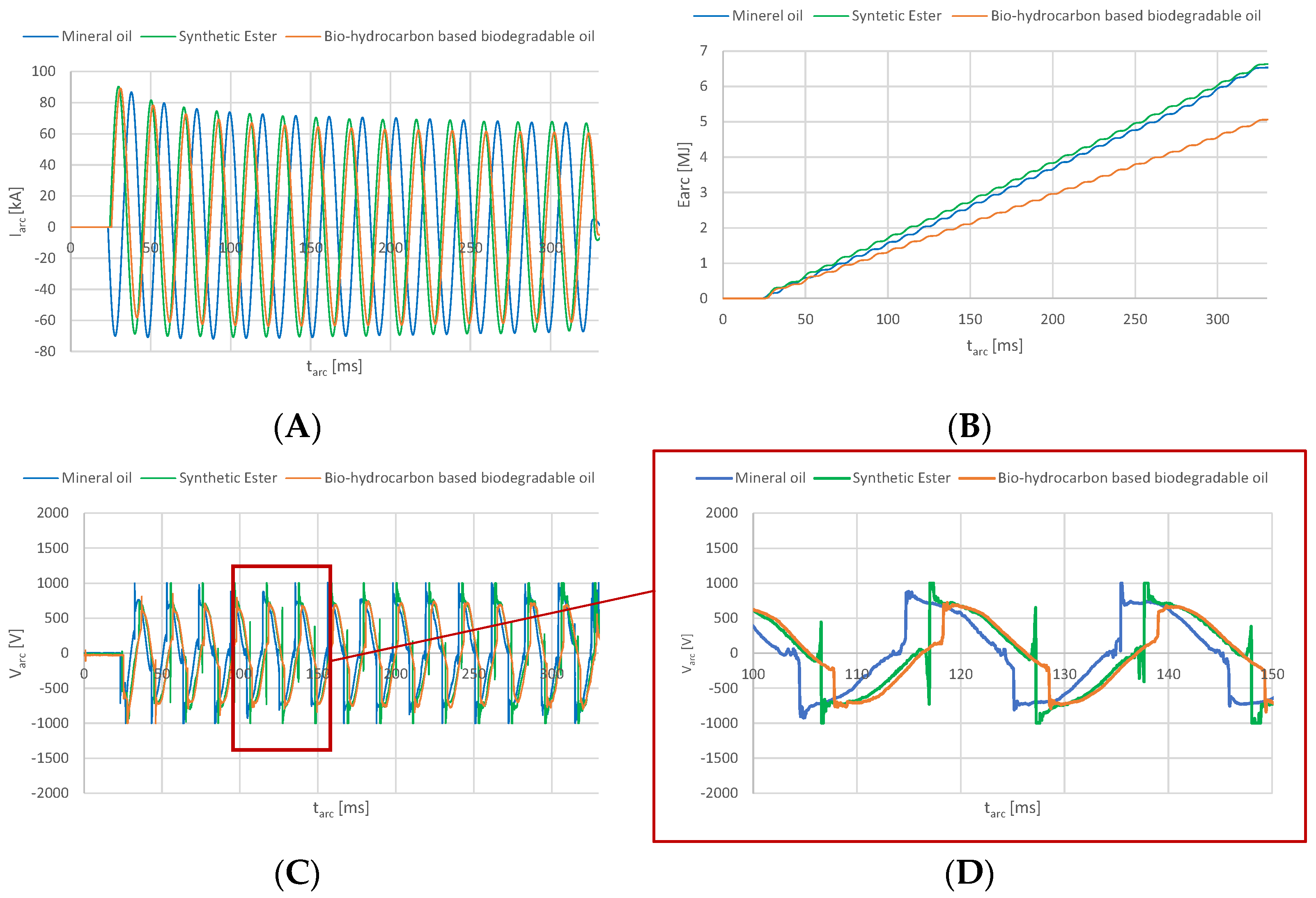

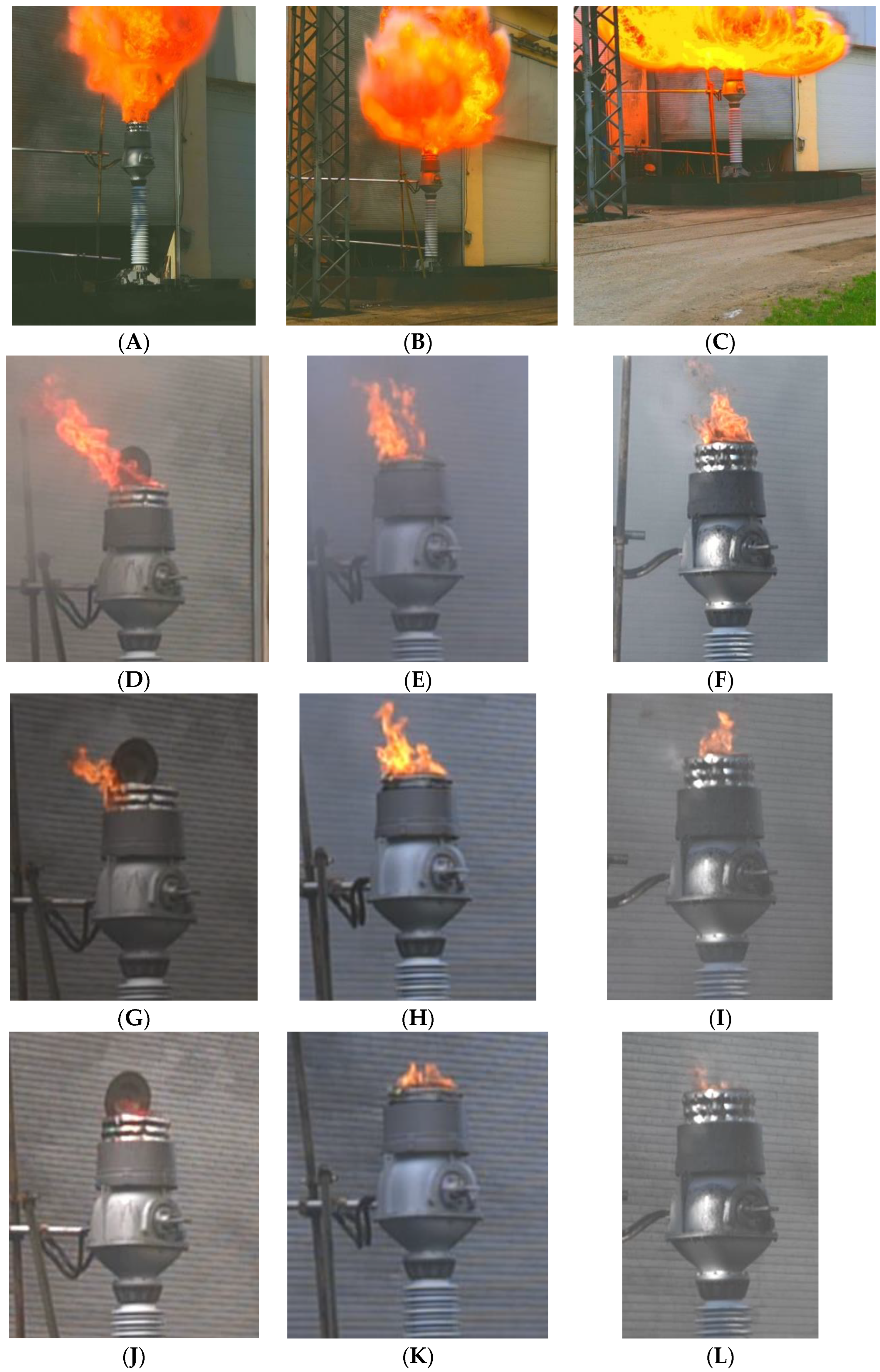

The oscillograms recorded during the tests are shown in

Figure 5, whereas the effects of the internal arc are shown in

Figure 6 for all three units.

Looking at the test results, there are several conclusions that can be drawn. The first is that all three units successfully completed internal arc testing for Class II at 50 kA, according to the expected performance disclosed in this paper and in accordance with standards [

2,

3,

4,

5]. If the test results for all three dielectric liquids are compared in more detail, as shown in

Table 7, it can be seen that the energy levels for mineral oil and synthetic ester are almost identical, which is expected. The recorded energy for bio-hydrocarbon based biodegradable oil is roughly 20% lower. This can be in part attributed to the slightly lower input current, which was at the lower border of tolerance according to

Table 4, but also to a somewhat lower

Uarc in comparison to the other two units. While the geometry of all three models was identical, it should be taken into account that the arc itself is still a statistical occurrence. Therefore, the authors do not attribute this reduction of energy to the property of the liquid. However, this aspect will be investigated further on smaller scale models which can rule out statistical variance better.

If the observed

Uarc values are compared to the calculated values given in

Table 5, it can be seen that the difference is drastic. This is expected due to the reasons explained in

Section 3, and only further solidifies the necessity for a more detailed arc model to obtain the correct values of

Uarc. Lastly,

Table 5 holds very valuable information on energy generation rates for the internal arc fault of current transformers, which are very difficult to come by in the literature [

7]. These values can be used for further research, design optimizations and fault evaluation.

As indicated above, all three dielectric liquids ignited during the internal arc test, which is absolutely expected given that the typical values of fire ignition energy are several orders lower than the energy exhibited during the test [

32]. Furthermore, if the behavior of units after the pressure relief is examined, as shown in

Figure 6D–K, there is no difference in the time it took for the flames to extinguish. This was concluded based on the test recordings, from which frames were extracted at identical time stamps. The referent time from which the time stamps were timed was considered at the point where the pressure relief stopped and the free flame was the only effect visible on the transformer, as shown in

Figure 6D–F.

This proves that fire point classification is irrelevant for internal arc performance in instrument transformers. For that reason, the test need not be repeated for different dielectric liquids, provided other details of the test object are the same (requested arc current, object geometry, pressure relief, etc.).

5. Conclusions

In order to be able to adequately analyze the performance of different liquids during an arcing event, the bulk of the paper was dedicated to ensuring a clear interpretation of existing standard requirements, thus explicitly defining the level of expected performance during an internal arc test. This part of the paper is intended to be used to augment the existing standards and help the manufacturers, testing personnel and customers to correctly interpret their requirements, making them mutually interchangeable. This reduces the necessity of re-tests due to bureaucratic aspects and can serve as a blueprint for discussion between manufacturers, end users and testing entities.

In addition, the main idea of this paper was to present the influence of using different dielectric liquids on internal arc performance of instrument transformers. Two biodegradable liquids were analyzed and compared to conventional mineral oil: synthetic esters and bio-hydrocarbon based biodegradable oil. The work presented here is a part of a broader research on the use of different biodegradable liquids in instrument transformers [

14].

Furthermore, this paper demonstrates that, in order to be able to model the arc voltage

Uarc and, consequently, the total energy released

Etot, advanced dynamic models should be used [

26,

27]. Using the commonly available analytical models is suitable for indicative purposes but is shown to substantially underestimate the arc energy. Therefore, caution should be used when implementing these simpler models.

Lastly, it can be concluded that the dielectric liquid type used has little effect on the internal arc performance of instrument transformers. This is logical as energy generation during an arcing event exceeds the energy rate any dielectric fluid can absorb before igniting, which makes the fire classification irrelevant for this aspect. For that reason, the use of a different dielectric liquid should not warrant a re-test, provided all other parameters are the same, or at least comparable. The noticed reduction of arc energy during the test with bio-hydrocarbon based biodegradable oil shall be investigated further, even though it is improbable that the reduced energy level observed was a consequence of the liquid used.

As a final thought, even though internal arc testing does contribute to the overall operational safety of instrument transformers, the test is designed to only verify the pressure relief during an arcing event. That being said, a successful completion of an internal arc test does not reduce the probability of the arc to happen. That prevention aspect is what international standards should focus on more. Hopefully, that will be one of the objectives moving forward.