Energy and Conventional Exergy Analysis of an Integrated Transcritical CO2 (R-744) Refrigeration System

Abstract

1. Introduction

2. Materials and Methods

2.1. Installation

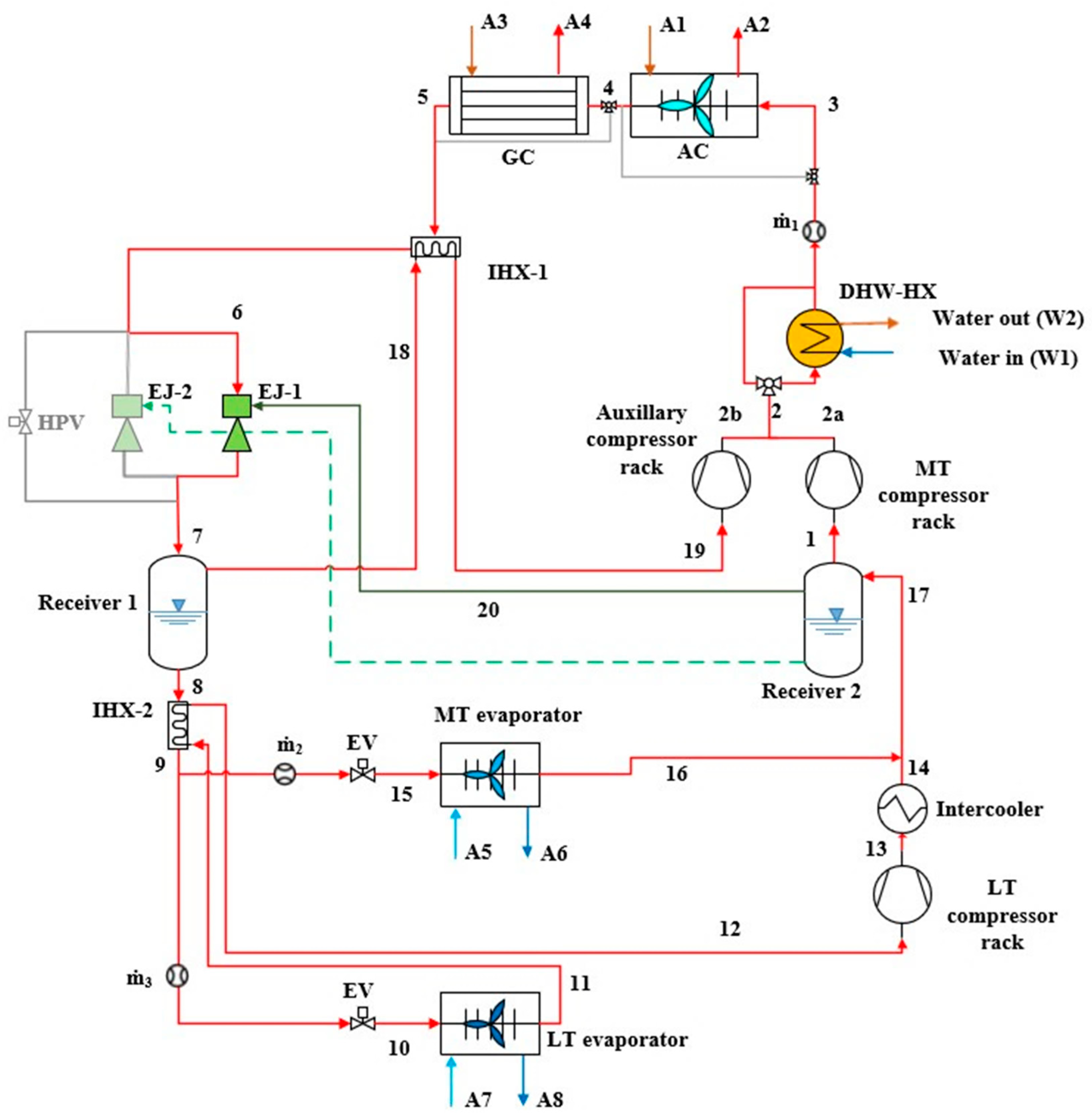

2.2. System Layout

2.3. Field Measurement

2.4. Energy Analysis

2.5. Conventional Exergy Analysis

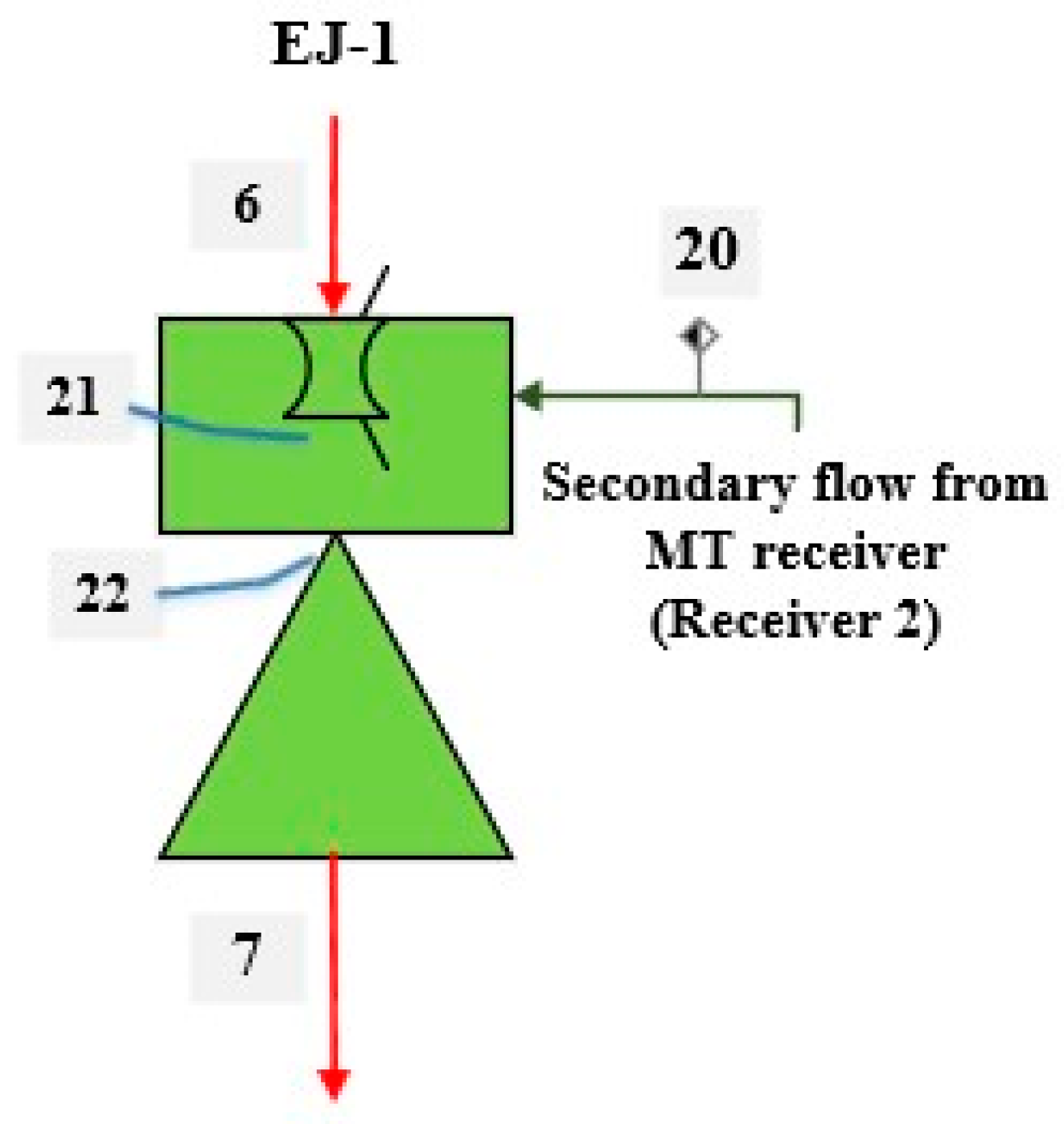

2.6. Calculations for the Vapor Ejector

3. Results and Discussion

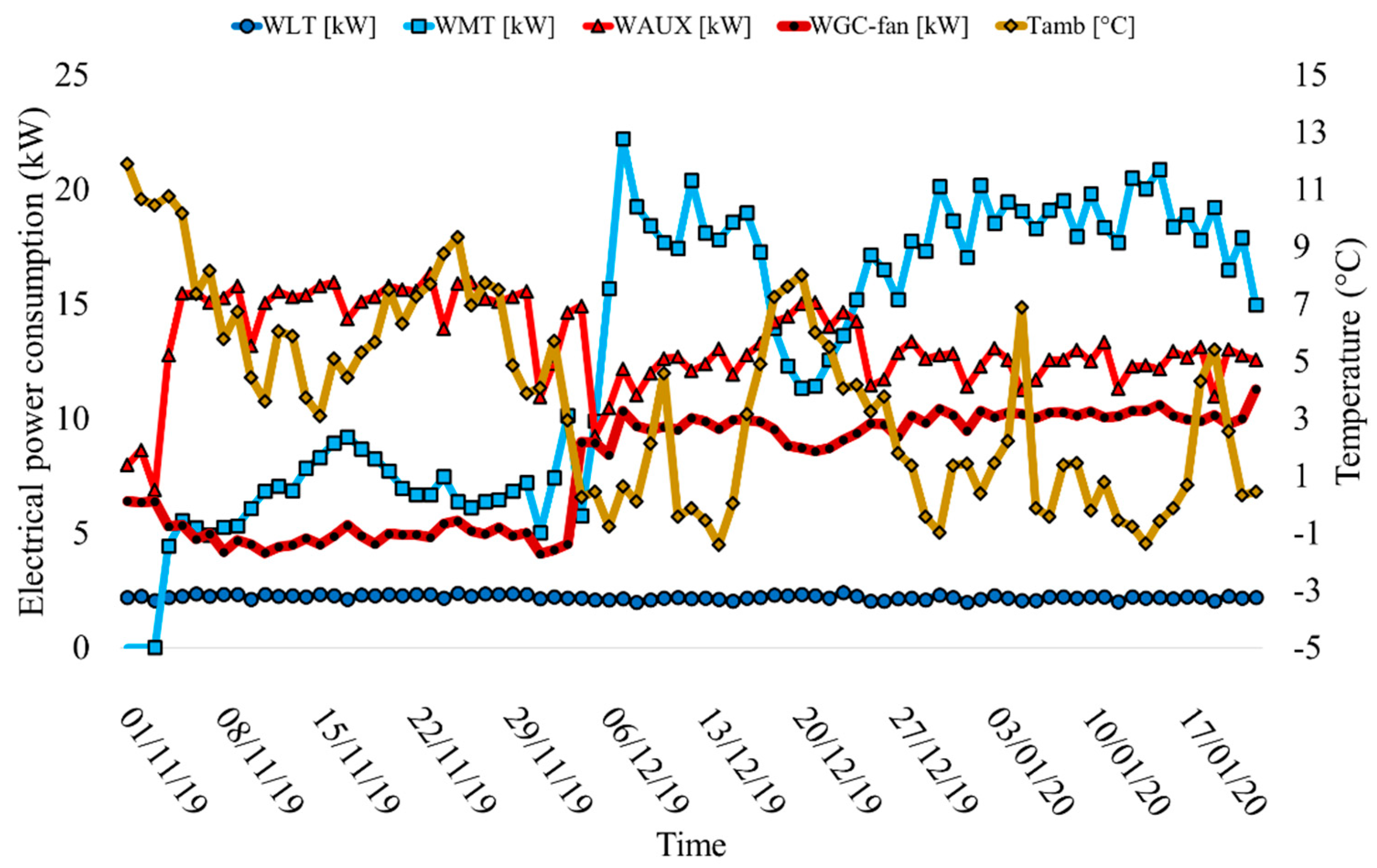

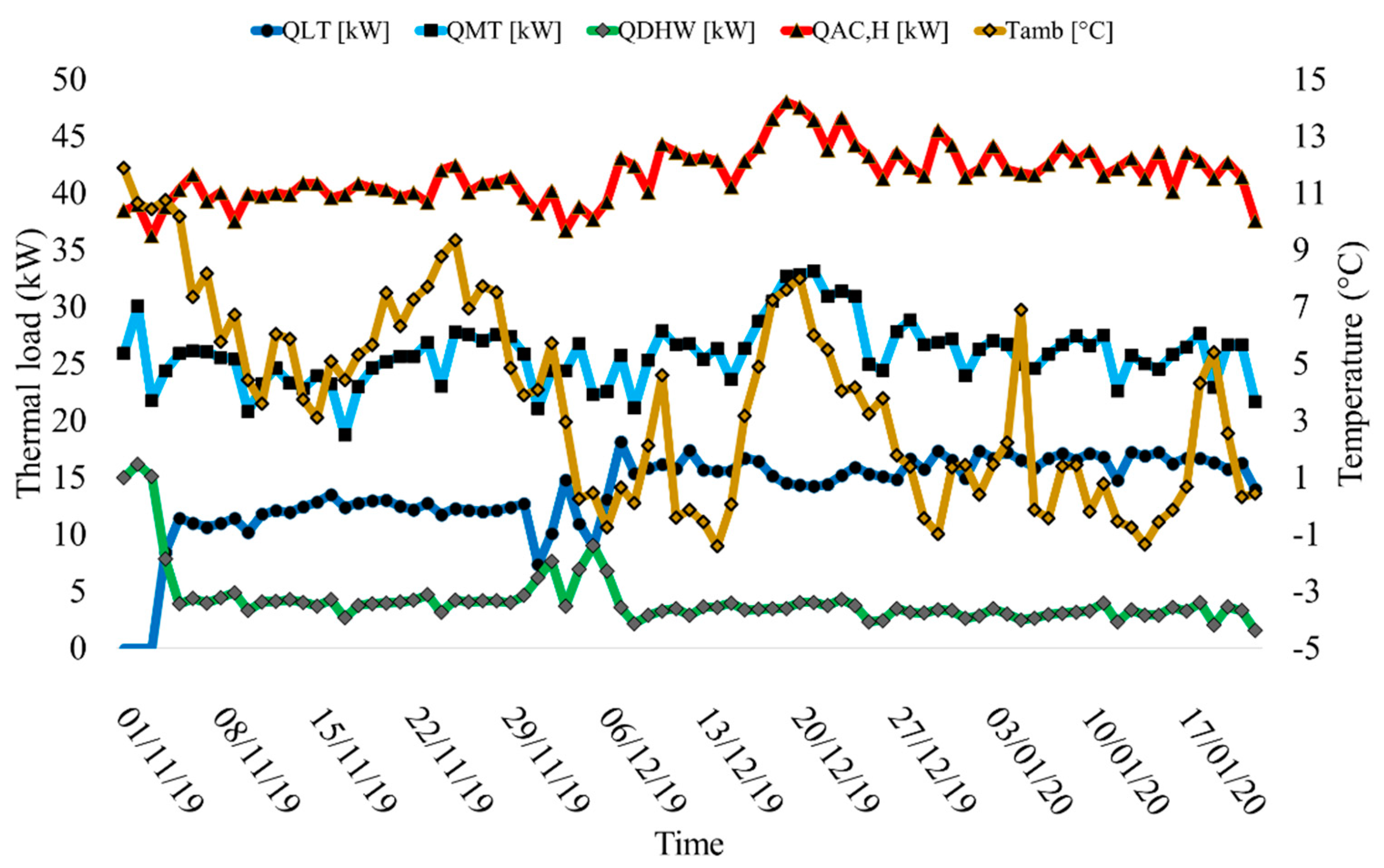

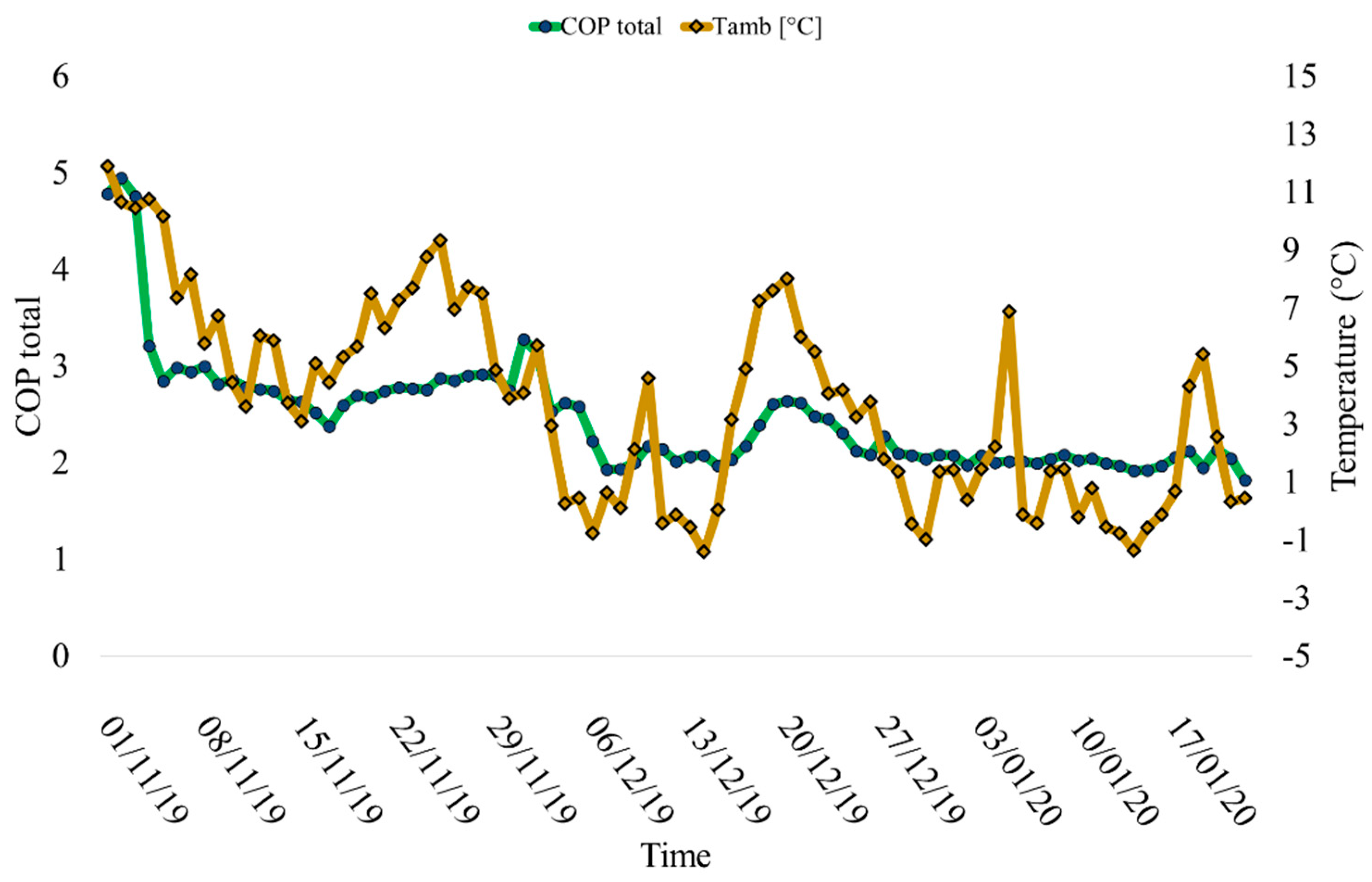

3.1. Energy Analysis

3.2. Exergy Analysis

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| AC | air conditioning |

| AUX | auxiliary |

| COP | coefficient of performance |

| DHW | domestic hot water |

| EJ | ejector |

| EV | expansion valve |

| exergy (kW) | |

| e | specific exergy (kJ/kg) |

| GC | gas cooler |

| h | specific enthalpy (kJ/kg) |

| HVAC | heating, ventilation, and air conditioning |

| HX | heat exchanger |

| ṁ | mass flow rate (kg/s) |

| IHX | internal heat exchanger |

| LT | low-temperature |

| MT | medium-temperature |

| P | pressure (bar) |

| heat load (kW) | |

| s | specific entropy (kJ/kgK) |

| T | temperature (°C) |

| VCT | vapor compression technology |

| work (kW) | |

| ɸ | Exergy destruction ratio |

| Greek symbols | |

| µ | entrainment ratio |

| ε | exergy efficiency |

| ƞ | efficiency |

| Superscripts | |

| PH | physical |

| PHA | physical air |

| PHW | physical water |

| M | mechanical |

| T | thermal |

| Subscripts | |

| A | air |

| amb | ambient |

| d | diffuser |

| D | destruction |

| evap | evaporator |

| F | fuel |

| i | inlet |

| is | isentropic |

| j | exergy carrier positions |

| k | the k-th component |

| m | mixing |

| mix | mixture |

| n | nozzle |

| o | outlet |

| P | product |

| p | primary |

| s | secondary |

| tot | total (overall) |

| 0 | reference condition |

| 1–22 | locations in the system and ejector |

References

- Koegelenberg, I.; Laumen, Z.; Garry, M.; Christiansen, T.S.; Yoshimoto, D.; Dusek, J.; Aleu, P. World Guide to Transcritical CO2 Refrigeration; Shecco: Brussels, Belgium, 2020. [Google Scholar]

- ASHRAE. 2018 ASHRAE Handbook-Refrigeration; ASHRAE: Atlanta, GA, USA, 2018. [Google Scholar]

- Skacanová, K.Z.; Battesti, M. Global market and policy trends for CO2 in refrigeration. Int. J. Refrig. 2019, 107, 98–104. [Google Scholar] [CrossRef]

- Purohit, N.; Sharma, V.; Sawalha, S.; Fricke, B.; Llopis, R.; Dasgupta, M.S. Integrated supermarket refrigeration for very high ambient temperature. Energy 2018, 165, 572–590. [Google Scholar] [CrossRef]

- Mitsopoulosa, G.; Syngounasa, E.; Tsimpoukisa, D.; Bellosa, E.; Tzivanidisa, C.; Anagnostatos, S. Annual performance of a supermarket refrigeration system using different configurations with CO2 refrigerant. Energy Convers. Manag. X 2019, 1, 100006. [Google Scholar] [CrossRef]

- Cui, Q.; Gao, E.; Zhang, Z.; Zhang, X. Preliminary study on the feasibility assessment of CO2 booster refrigeration systems for supermarket application in China: An energetic, economic, and environmental analysis. Energy Convers. Manag. 2020, 225, 113422. [Google Scholar] [CrossRef]

- Tsimpoukis, D.; Syngounas, E.; Petsanas, D.; Mitsopoulos, G.; Anagnostatos, S.; Bellos, E.; Tzivanidis, C.; Vrachopoulos, M.G. Energy and environmental investigation of R744 all-in-one configurations for refrigeration and heating/air conditioning needs of a supermarket. J. Clean. Prod. 2021, 279, 123234. [Google Scholar] [CrossRef]

- Morosuka, T.; Tsatsaronis, G. A new approach to the exergy analysis of absorption refrigeration machines. Energy 2008, 33, 890–907. [Google Scholar] [CrossRef]

- Morosuk, T.; Tsatsaronis, G. Advanced exergetic evaluation of refrigeration machines using different working fluids. Energy 2009, 34, 2248–2258. [Google Scholar] [CrossRef]

- Fangtian, S.; Yitai, M. Thermodynamic analysis of transcritical CO2 refrigeration cycle with an ejector. Appl. Therm. Eng. 2011, 31, 1184–1189. [Google Scholar] [CrossRef]

- Bai, T.; Yan, G.; Yu, J. Thermodynamics analysis of a modified dual-evaporator CO2 transcritical refrigeration cycle with two-stage ejector. Energy 2015, 84, 325–335. [Google Scholar] [CrossRef]

- Bai, T.; Yu, J.; Yan, G. Advanced exergy analyses of an ejector expansion transcritical CO2 refrigeration system. Energy Convers. Manag. 2016, 126, 850–861. [Google Scholar] [CrossRef]

- Gholamian, E.; Hanafizadeh, P.; Ahmadi, P. Advanced exergy analysis of a carbon dioxide ammonia cascade refrigeration system. Appl. Therm. Eng. 2018, 137, 689–699. [Google Scholar] [CrossRef]

- Purohit, N.; Gupta, D.K.; Dasgupta, M.S. Experimental investigation of a CO2 trans-critical cycle with IHX for chiller application and its energetic and exergetic evaluation in warm climate. Appl. Therm. Eng. 2018, 136, 617–632. [Google Scholar] [CrossRef]

- Dai, B.; Qi, H.; Liu, S.; Ma, M.; Zhong, Z.; Li, H.; Song, M.; Sun, Z. Evaluation of transcritical CO2 heat pump system integrated with mechanical subcooling by utilising energy, exergy and economic methodologies for residential heating. Energy Convers. Manag. 2019, 192, 202–220. [Google Scholar] [CrossRef]

- Wang, Y.; Ye, Z.; Song, Y.; Yin, X.; Cao, F. Energy, exergy, economic and environmental analysis of refrigerant charge in air source transcritical carbon dioxide heat pump water heater. Energy Convers. Manag. 2020, 223, 113209. [Google Scholar] [CrossRef]

- Cao, F.; Ye, Z.; Wang, Y. Experimental investigation on the influence of internal heat exchanger in a transcritical CO2 heat pump water heater. Appl. Therm. Eng. 2020, 168, 114855. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Yu, J. Performance analysis of a modified dual-ejector and dual-evaporator transcritical CO2 refrigeration cycle for supermarket application. Int. J. Refrig. 2021, 131, 109–118. [Google Scholar] [CrossRef]

- Li, Y.; Deng, J.; Ma, L.; Zhang, Y. Visualisation of two-phase flow in primary nozzle of a transcritical CO2 ejector. Energy Convers. Manag. 2018, 171, 729–741. [Google Scholar] [CrossRef]

- Elbarghthi, A.F.; Hafner, A.; Banasiak, K.; Dvorak, V. An experimental study of an ejector-boosted transcritical R744 refrigeration system including an exergy analysis. Energy Convers. Manag. 2021, 238, 114102. [Google Scholar] [CrossRef]

- Zheng, L.; Hu, Y.; Mi, C.; Deng, J. Advanced exergy analysis of a CO2 two-phase ejector. Appl. Therm. Eng. 2022, 209, 118247. [Google Scholar] [CrossRef]

- Liu, X.; Yu, K.; Wan, X.; Zheng, M.; Li, X. Conventional and advanced exergy analyses of transcritical CO2 ejector refrigeration system equipped with thermoelectric subcooler. Energy Rep. 2021, 7, 1765–1779. [Google Scholar] [CrossRef]

- Project, T.M. The MultiPACK Project Website. Available online: https://spfarm.ntnu.no/sites/project/192/SitePages/Home.aspx (accessed on 15 October 2023).

- Artuso, P.; Minetto, S.; Rossetti, A.; Tosato, G.; Marinetti, S. Two years of data monitoring of all-CO2 retail stores within the MultiPACK project. In Proceedings of the 9th IIR Conference: Ammonia and CO2 Refrigeration Technologies, Ohrid, North Macedonia, 16–17 September 2021. [Google Scholar]

- Tosato, G.; Minetto, S.; Hafner, A.; Rossetti, A.; Marinetti, A.; Girotto, S. Field assessment of the performance of a state-of-the-art CO2 integrated system for supermarket with distributed HVAC terminals in the shopping area. In Proceedings of the 9th IIR Conference: Ammonia and CO2 Refrigeration Technologies, Nantes, France, 16–17 September 2021. [Google Scholar]

- Bejan, A.; Tsatsaronis, G.; Moran, J. Thermal Design and Optimisation; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Tsatsaronis, G.; Cziesla, F. Thermoeconomics. In Encyclopedia of Physical Science and Technology; Academic Press: New York, NY, USA, 2001; pp. 659–680. [Google Scholar]

- Chen, J.; Havtun, H.; Palm, B. Conventional and advanced exergy analysis of an ejector refrigeration system. Appl. Energy 2015, 144, 139–151. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, X.; Yu, J. Theoretical study on a novel dual-nozzle ejector. Energy Convers. Manag. 2013, 73, 278–284. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, J.; Gao, L. Exergy analysis, parametric analysis and optimization for a novel combined power and ejector refrigeration cycle. Appl. Therm. Eng. 2009, 29, 1983–1990. [Google Scholar] [CrossRef]

- Liu, F.; Groll, E.A.; Li, D. Investigation on performance of variable geometry ejectors for CO2 refrigerarion cycles. Energy 2012, 45, 829–839. [Google Scholar] [CrossRef]

| Demand | Design Temperature | Capacities |

|---|---|---|

| Medium-temperature stage (cooling) | −4 °C (evaporating) | 90 kW |

| Low-temperature stage (freezing) | −30 °C (evaporating) | 22 kW |

| Space heating | 10 °C (outdoor) | 200 kW |

| Space cooling | 30 °C (outdoor) | 280 kW |

| Component | State | Fuel | Product |

|---|---|---|---|

| MT compressors | 1–2a | m1 (ePH2a − ePH1) | |

| AUX compressors | 19–2b | m19 (ePH2b − ePH19) | |

| DHW-HX | 2–3 | m3 (ePH2 − ePH3) | mW1 (ePHW2 − ePHW1) |

| AC coils (heating) | 3–4 | m3 (ePH3 − ePH4) | mA1 (ePHA2 − ePHA1) × 24 |

| GC | 4–5 | m4 (ePH4 − ePH5) + WGC-fan | mA3 (ePHA4 − ePHA3) |

| Ejector 1 | 6–7 | m6 (ePH6 − ePH21) | m20 (ePH7 −ePH20) |

| EVLT | 9–10 | m10 (e9m − e10m +e9T) | m10e10T |

| LT evaporator | 10–11 | m10 (ePH10 − ePH11) | mA7 (ePHA8 − ePHA7) |

| EVMT | 9–15 | m15 (e9m − e15m+ e9T) | m15e15T |

| MT evaporator | 15–16 | m15 (ePH15 − ePH16) | mA5 (ePHA6 − ePHA5) |

| LT compressors | 12–13 | m12 (ePH13 − ePH12) |

| State | Exergy Carrier | ṁ | Pj | Tj | hj | sj | hpj,T0 | spj,T0 | ejT | ejM | ePH |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/s | bar | °C | kJ/kg | kJ/kgK | kJ/kg | kJ/kgK | kJ/kg | kJ/kg | kJ/kg | ||

| 1 | R-744 | 0.19 | 29.63 | 2.05 | 445.92 | 1.923 | 442.99 | 1.91 | 0.01 | 142.42 | 142.43 |

| 2a | R-744 | 0.19 | 84.22 | 100.07 | 516.76 | 1.989 | 196.26 | 0.97 | 41.38 | 153.72 | 195.10 |

| 2b | R-744 | 0.17 | 84.22 | 137.55 | 564.83 | 2.112 | 196.26 | 0.97 | 55.89 | 153.72 | 209.61 |

| 2 | R-744 | 0.36 | 84.22 | 99.48 | 515.94 | 1.987 | 196.26 | 0.97 | 41.16 | 153.72 | 194.88 |

| 3 | R-744 | 0.36 | 84.22 | 79.65 | 486.95 | 1.907 | 196.26 | 0.97 | 34.02 | 153.72 | 187.74 |

| 4 | R-744 | 0.36 | 84.22 | 33.38 | 298.07 | 1.316 | 196.26 | 0.97 | 6.58 | 153.72 | 160.30 |

| 5 | R-744 | 0.36 | 84.22 | 26.03 | 264.80 | 1.206 | 196.26 | 0.97 | 3.28 | 153.72 | 157.00 |

| 6 | R-744 | 0.36 | 84.22 | 24.33 | 259.06 | 1.187 | 196.26 | 0.97 | 2.79 | 153.72 | 156.51 |

| 21 | R-744 | 0.36 | 29.43 | −6.25 | 251.78 | 1.197 | 444.46 | 1.92 | 4.87 | 141.45 | 146.32 |

| 7 | R-744 | 0.40 | 36.21 | 2.45 | 277.49 | 1.282 | 199.85 | 1.00 | 0.40 | 148.65 | 149.05 |

| 8 | R-744 | 0.23 | 36.21 | 2.45 | 203.57 | 1.012 | 199.85 | 1.00 | 0.01 | 148.65 | 148.66 |

| 9 | R-744 | 0.23 | 36.21 | 1.25 | 203.14 | 1.011 | 199.85 | 1.00 | 0.01 | 148.65 | 148.66 |

| 10 | R-744 | 0.08 | 14.39 | −29.69 | 203.14 | 1.037 | 468.19 | 2.12 | 30.46 | 111.20 | 141.66 |

| 11 | R-744 | 0.08 | 14.39 | −8.21 | 459.92 | 2.088 | 468.19 | 2.12 | 0.13 | 111.20 | 111.33 |

| 12 | R-744 | 0.08 | 14.39 | −7.01 | 461.14 | 2.092 | 468.19 | 2.12 | 0.09 | 111.20 | 111.29 |

| 13 | R-744 | 0.08 | 29.63 | 63.56 | 517.17 | 2.157 | 442.99 | 1.91 | 7.15 | 142.42 | 149.57 |

| 15 | R-744 | 0.15 | 29.63 | −6.03 | 203.14 | 1.014 | 442.99 | 1.91 | 5.29 | 142.42 | 147.71 |

| 16 | R-744 | 0.15 | 29.63 | −1.48 | 440.82 | 1.904 | 442.99 | 1.91 | 0.01 | 142.42 | 142.43 |

| 18 | R-744 | 0.17 | 36.21 | 2.45 | 431.90 | 1.844 | 199.85 | 1.00 | 1.22 | 148.65 | 149.87 |

| 19 | R-744 | 0.17 | 36.21 | 2.55 | 432.09 | 1.845 | 199.85 | 1.00 | 1.22 | 148.65 | 149.88 |

| 20 | R-744 | 0.04 | 29.63 | 2.05 | 445.92 | 1.923 | 442.99 | 1.91 | 0.01 | 142.42 | 142.43 |

| A1 | Air | 0.50 | 1.01 | 20.00 | 293.41 | 6.843 | 273.29 | 6.77 | 0.70 | 0.01 | 0.71 |

| A2 | Air | 0.50 | 1.01 | 25.69 | 299.14 | 6.863 | 273.29 | 6.77 | 1.14 | 0.01 | 1.15 |

| A3 | Air | 1.51 | 1.01 | 0.00 | 273.29 | 6.772 | 273.29 | 6.77 | 0.00 | 0.01 | 0.01 |

| A4 | Air | 1.51 | 1.01 | 15.00 | 288.38 | 6.826 | 273.29 | 6.77 | 0.40 | 0.01 | 0.41 |

| A5 | Air | 4.50 | 1.01 | 3.00 | 276.31 | 6.783 | 273.29 | 6.77 | 0.02 | 0.01 | 0.03 |

| A6 | Air | 4.50 | 1.01 | −4.99 | 268.27 | 6.754 | 273.29 | 6.77 | 0.05 | 0.01 | 0.06 |

| A7 | Air | 3.00 | 1.01 | −20.00 | 253.17 | 6.696 | 273.29 | 6.77 | 0.77 | 0.01 | 0.78 |

| A8 | Air | 3.00 | 1.01 | −26.58 | 246.55 | 6.669 | 273.29 | 6.77 | 1.39 | 0.01 | 1.40 |

| W1 | R-718 | 0.07 | 1.01 | 30.00 | 125.82 | 0.44 | 0.10 | 0.00007 | 6.43 | 0.00 | 6.43 |

| W2 | R-718 | 0.07 | 1.01 | 66.01 | 276.40 | 0.91 | 0.10 | 0.00007 | 28.80 | 0.00 | 28.80 |

| Component | State | ɸ | ɸ* | ||||

|---|---|---|---|---|---|---|---|

| - | - | kW | kW | kW | (%) | (%) | (%) |

| MT compressor rack | 1–2a | 13.57 | 10.08 | 3.48 | 74.3 | 8.8 | 9.0 |

| AUX compressor rack | 19–2b | 22.85 | 10.28 | 12.56 | 45.0 | 31.8 | 32.5 |

| DHW-HX | 2–3 | 2.60 | 1.57 | 1.03 | 60.3% | 2.6% | 2.7 |

| AC coils (heating) | 3–4 | 9.98 | 5.30 | 4.68 | 53.1 | 11.8 | 12.1 |

| GC | 4–5 | 12.12 | 0.60 | 11.52 | 5.0 | 29.1 | 29.8 |

| Ejector 1 (EJ-1) | 6–7 | 3.63 | 0.25 | 3.37 | 7.0 | 8.5 | 8.7% |

| EVLT | 9–10 | 2.90 | 2.36 | 0.54 | 81.3 | 1.4 | 1.4% |

| LT evaporator | 10–11 | 2.35 | 1.85 | 0.49 | 79.0 | 1.2 | 1.3% |

| EVMT | 9–15 | 0.95 | 0.81 | 0.14 | 84.8 | 0.4 | 0.4% |

| MT evaporator | 15–16 | 0.80 | 0.14 | 0.67 | 16.8 | 1.7 | 1.7% |

| LT compressor rack | 12–13 | 3.12 | 2.96 | 0.16 | 95.0 | 0.4 | 0.4% |

| Overall | - | 39.53 | 8.85 | 38.65 | 22.4 | 97.8 | 100.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Söylemez, E. Energy and Conventional Exergy Analysis of an Integrated Transcritical CO2 (R-744) Refrigeration System. Energies 2024, 17, 479. https://doi.org/10.3390/en17020479

Söylemez E. Energy and Conventional Exergy Analysis of an Integrated Transcritical CO2 (R-744) Refrigeration System. Energies. 2024; 17(2):479. https://doi.org/10.3390/en17020479

Chicago/Turabian StyleSöylemez, Engin. 2024. "Energy and Conventional Exergy Analysis of an Integrated Transcritical CO2 (R-744) Refrigeration System" Energies 17, no. 2: 479. https://doi.org/10.3390/en17020479

APA StyleSöylemez, E. (2024). Energy and Conventional Exergy Analysis of an Integrated Transcritical CO2 (R-744) Refrigeration System. Energies, 17(2), 479. https://doi.org/10.3390/en17020479