Abstract

Among the technologies for the recovery of energy from waste, in particular residual municipal solid waste (rMSW), combustion is the most widely used thermo-chemical treatment process associated with thermal and electric power production by a steam cycle, named, shortly, Waste to Energy (WtE). Today, more than 500 WtE plants in the EU, about 400 in China and 76 in the USA are in operation, based on efficient technologies and advanced air pollution control systems. Energy recovery can be accomplished also by means of gasification; however, the presence of impurities together with the atmospheric pressure, at which syngas is normally produced, impose the feeding of syngas to a conventional steam cycle, leading to generally lower performances than WtE. The energy recovered by WtE offsets traditional energy sources such as fossil fuels and related emissions, providing savings in term of climate change. However, the savings obtainable by replacing electricity and/or heat will diminish as the energy systems will hopefully become increasingly renewable. Over this medium–long-term horizon, one possibility is to capture the CO2 from WtE flue gases and to store/use it. From the life cycle assessment perspective, it has been calculated that the introduction of CO2 capture and storage in WtE, despite energy penalties, is able to reduce the impact on climate change. The alternative approach, proposed to contain the emissions of greenhouse gases in the thermal treatment of waste, is using the carbon contained in it to produce commonly used chemical compounds (waste to chemicals). The benefits, in terms of reductions of greenhouse gases, are expected from the possibility of obtaining chemicals that can replace their analogue normally produced from fossil sources. To date, only one WtC demonstration plant is operating by being fed by rMSW-derived waste, and some similar initiatives are planned, but still adequate assurances in terms of robust knowledge of the involved complex processes, above all, if applied to highly inhomogeneous feed streams such as those obtained from rMSW, are not available. Once the several initiatives come to completion, it will enable waste management professionals to assess performance and to begin to consider such a facility in their planning.

1. Introduction

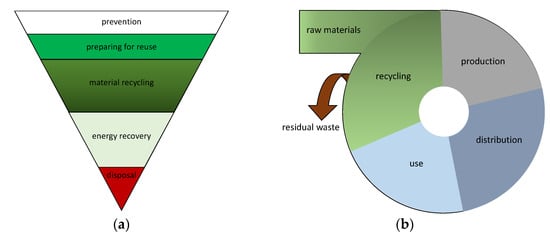

Waste management must take place in compliance with the well-known hierarchy (Figure 1a): (a) prevention; (b) preparation for reuse; (c) recycling; (d) recovery of other types, for example, energy recovery; and (e) disposal. This hierarchy represents the order of priority of what constitutes the best environmental option: it is in fact widely shared [] that, in most cases, the recycling of materials makes it possible to obtain lower environmental impacts, compared to the recovery energy or disposal. However, there is a technical limit to recycling, especially for paper and plastic [].

Figure 1.

(a) Waste hierarchy; (b) circular economy approach.

More recently, reuse and recycling have found further support and encouragement through the introduction, at the European Union (EU) level, of the concept of circular economy (EC) (Figure 1b). The main attribute of this concept is a model of production and consumption that expects the sharing, loan, reuse, repair, refurbishment and recycling of existing materials and products for as long as possible. The Directive 2018/851/EU is basically an Action Plan for a new circular economy, with the subsequent packages of specific measures and rules, through which the European Commission is guiding the transition towards this new model. The EU imports around half of the raw materials it consumes []; therefore, the Directive has the aim of reducing the dependency on raw materials while simultaneously protecting the environment. It is expected that significant support for these activities will come from the EU Recovery Fund.

In this context, energy recovery may be considered a technology of the past. Yet when viewed in a more holistic context, sustainable waste management initiatives must consider all solutions and combine a pragmatic approach. For example, an over emphasis on the reuse and recycling of waste will not address streams that have been recycled multiple times or those that cannot be recycled or reused. Within the scope of municipal solid waste (MSW), everything that cannot be recycled, i.e., what is residual after separate waste collection (SWC), is named residual MSW (rMSW). Therefore, if the recovery of energy and materials is not considered to be a solution, those streams will be disposed of in a landfill, which is the lowest option on the waste hierarchy.

The aim of this work is to shortly describe the state of the art of the energy recovery from rMSW and to discuss possible perspectives for the next decades.

2. MSW and Residual MSW

In 2020, the EU27 produced approximately 231 million (M) of tonnes (t) of MSW. The EU Directive 2018/851 (amending the previous 2008/98/EC) sets ambitious targets for preparing for reuse and recycling, which is to be achieved by 2025 (55%), 2030 (60%) and 2035 (65%). Furthermore, EU Directive 2018/850, also a part of the circular economy package, amended the previous Directive 1991/31/EC relating to landfills, setting the objective of reducing the percentage of landfilled waste to less than 10% by 2035 and expecting an increase in recycling.

The separate collection of relatively homogeneous flows of waste allows them to be sent to industrial recovery processes. However, separately collected waste may contain undesired materials (not recyclable and/or contaminated) that need to be removed to avoid performance losses of the separation/recovery facilities. The total scraps generated in the various pre-treatment and recycling phases of separately collected waste may reach approximately 20%, as has been found in Italy []. Similarly, a Danish study showed that for separate plastic waste, impurities are about 28% []. The scraps from separate collection increase the overall stream of non-recyclable waste of urban origin.

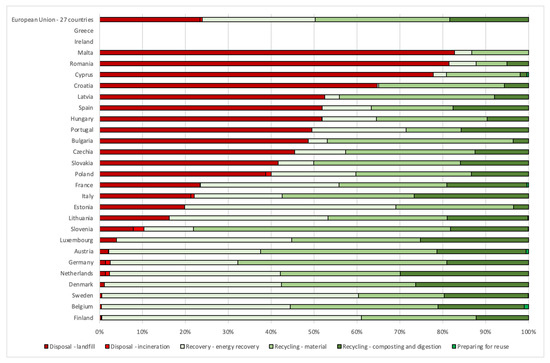

Summing up in the EU27, in 2021, in terms of final destinations, approximately 23% of MSW was disposed of in landfills. Approximately 31% of MSW was sent for material recovery, organic waste sent for biological treatment represents 18%, and incineration with energy recovery amounts to 26% []. Importantly, there are countries where landfill disposal is already well below the 10% target such as Finland, Belgium, Sweden, Denmark, The Netherlands, Germany Austria, Luxemburg and Slovenia (Figure 2).

Figure 2.

Share of MSW disposal and recovery for the 27 countries of EU and total EU for the year 2021. Data for Greece and Ireland are not available at the time of writing. Data are from Eurostat [], adapted by the authors.

However, in several other countries, to ensure the achievement of the recycling targets of 65% by 2035, the amount of waste to be sent for recycling will have to increase, just as the amount of waste sent to landfills will need to be reduced by more than half in order to meet the target of reduction to below 10% by 2035. It has been demonstrated that places that use energy recovery result in an increase in recycling. Therefore, non-recyclable waste such as multi-layer films and end-of-life materials can only be diverted from landfills through increasing energy recovery. Recently, Cewep [] estimated, for Europe, that even if the most ambitious targets for recycling and landfilling are reached, an additional 41 Mt of thermal treatment capacity will be needed by 2035.

rMSW can be fed directly to combustion for energy recovery without expensive separation, with its average lower heating value (LHV) being around 10 MJ/kg in the EU and USA. However, it may be desirable and possible to send the rMSW to Mechanical Biological Treatment (MBT) plants to generate a combustible fraction, also named Refuse-Derived Fuel (RDF), whose LHV can be increased up to 15–16 MJ/kg. MBT plants typically generate output streams other than combustible fraction [] such as recyclable metals and organics that can be stabilized and sent to landfills. RDF may comply with technical/legislative standards [,] and can be classified as a Solid Recovered Fuel (SRF). However, several studies have shown that the production of SRF or RDF appears justified only for the replacement of fossil fuels in cement kilns, power plants [,,] and blast furnaces [], rather than for feeding waste combustion plants. Especially in blast furnaces and cement kilns, high temperature combustion conditions (more than 1000 and 2000 °C, respectively) and long retention times assure the complete combustion and very low levels of several pollutants in the flue gas [].

The pre-treatment is essential whether the use of fluidized bed combustion technologies or gasification processes are pursued. The latter is better described below.

3. Waste Combustion with Energy Recovery: Waste to Energy

Among the technologies for the recovery of energy from waste, especially rMSW, combustion is the most widely used thermal treatment process and is commonly adopted. At present, there are more than 500 plants in the EU, 76 in USA and about 400 in China, where the overall treatment capacity has exceeded that of the EU’s []. It is characterized by using excess air, nearly 50% more than is required to completely combust the material, resulting in the transformation of rMSW into combustion gases (CO2, N2 and H2O) and the production of thermal energy.

The first incineration plants built in Europe and in the United States from the end of the 1800s to the mid-1900s aimed at realizing the fundamental characteristics of the incineration process on an industrial scale: sanitation, the elimination of putrescibility, relative odor problems and the reduction in volume (and mass). Indeed, combustion residue is represented by non-combustible elements, called slag/ashes, which have a volume that is 80–90% lower than that of the incoming waste [] and which are not subject to putrefaction.

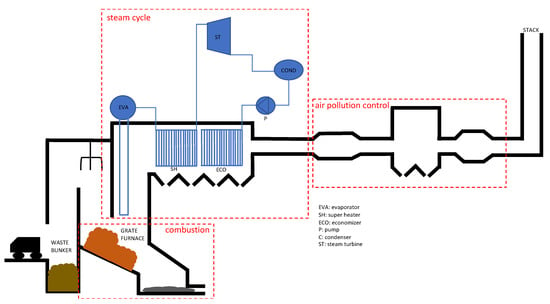

The growth of the energy content of rMSW sparked an interest to construct more efficient technologies and to extract energy to offset traditional energy sources such as fossil fuels. Furthermore, advanced air pollution control (APC) systems have been installed and are continually updated to result in one of the most environmentally friendly sources of energy and material recovery. The changes from incineration to a more controlled combustion with maximum energy extraction and robust APC systems are now best considered waste to Energy (WtE), as depicted in Figure 3. The role of WtE is not only the reliable treatment of waste but also the production of energy. In many countries, the latter is mandatory and is almost as relevant as the former.

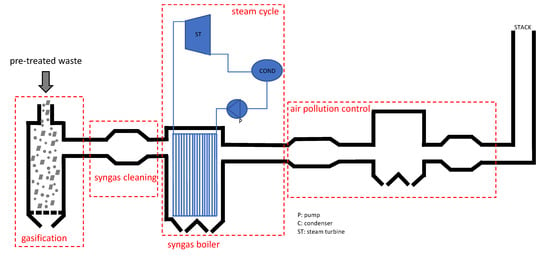

Figure 3.

Simplified schematic of WtE, mainly composed of the three sections: combustion, steam cycle and air pollution control.

The ability of combustion to guarantee the sterilization of waste attracted renewed interest during the initial stages of the COVID-19 pandemic, when, for unsorted waste collected from subjects positive to COVID-19 or in quarantine, incineration without any pre-treatment or further selection had to be prioritized, creating destination problems for those territories in which this type of plant is lacking, if not completely absent [,]. This aspect has become particularly visible recently. Yet since 1980, it has been demonstrated that WtE can render virus and disease vectors inert. A well-designed and well-operated WtE facility will result in the destruction and removal of viruses, enteric bacteria, fungi and human and animal parasites at an efficiency between 99.99% and 99.9999% []. Several other studies obtained similar results for several pathogens such as Bacillus anthracis [] and Ebola []. The recent attention given to halogenated flame retardants has recognized WtE as a viable method based on an exhaustive analysis of all possible methods []. Finally, WtE is able to destroy several toxic organic substances, such as bisphenol A (BPA), added in thermal paper as well as persistent organic pollutants (POPs)—including insecticides, polychlorinated biphenyls (PCBs), polybrominated diphenyl ethers (PBEs), polychlorinated dibenzo-p-dioxins (PCDDs) and polychlorinated dibenzo furans (PCDFs)—contributing to keep those substances away from material cycles and from the environment [].

WtE plants have a rather small thermal power input, from a few MW to over 500 MW, considering that conventional power plants’ thermal power input ranges from hundreds of MW to more than a thousand MW. In terms of mass flow, the thermal power input ranges between 10 and 20 kt/y and over 1 Mt/y. The heat released by the combustion of waste is recovered in a steam generator which engages a steam cycle, which, in turn, can be designed to produce electricity alone or for the combined production of heat and electricity (cogeneration). Like all technologies, the economics of the steam cycle are affected by the scale, with the specific investment cost, i.e., the investment cost per unit size, decreasing as size increases. Because of their medium–small size, and the negative consequences of the scale effect, the steam cycles of WtE plants are made in simple configurations, with relatively low values of the main parameters, resulting in contained performances that are generally lower than those in large steam power plants. For a more detailed description of the technologies, the reader is directed to the previous literature [,,].

Consequently, for small-scale plants (i.e., less than 100 kt/y), the significant investments for the improvement of the technological level of the steam cycle are generally not yet accessible, and the maximum net electrical efficiency is limited to around 20–24% in the case of power production only. On the contrary, with an economically sustainable technological level on large plants (i.e., above 250 kt/y), a net electrical efficiency of up to 30–31% is achieved (in power-only mode). In terms of specific electricity production, assuming the LHV is equal to 10 GJ/t, the output electricity ranges from 0.56–0.67 to 0.83–0.86 MWh/t. Table 1 shows the obtainable specific net electricity output from different types of waste, assuming the net conversion efficiency ranges from 20 to 30%.

Table 1.

Specific net electricity output from different types of waste, assuming the net conversion efficiency ranges from 20 to 30%.

Cogeneration is considered the best available technique for energy recovery from waste [] and has better performance in life cycle assessments (LCAs), compared to the production of electricity alone []. However, for cogenerated heat to be effectively exploited, the presence of an industrial thermal user or buildings to be district heated is required in the vicinity of the plant. In this configuration, energy recovery increases significantly up to values of 60–65%, with electrical efficiencies of the order of 15–20%, coupled with thermal efficiencies of 40–45%. In terms of specific electricity and heat production, again assuming the LHV is equal to 10 GJ/t, the output electricity is in the range of 0.42–0.56 MWh/t, and the output heat is in the range of 1.1–1.25 MWh/t, comparable to the average present values and expected ones in the future, as reported in [].

Recent figures show that about 68% of European WtE plants operate in cogeneration mode, 22% operate in only power production mode and 10% produce only heat [], with a clear shift towards cogeneration, with respect to previous data []. WtE cogeneration is considered a favorable investment with positive economic indicators [].

Today, district heating is increasingly used alongside district cooling, which consists, in the distribution, in the hottest periods, of chilled water produced by the plant by means of absorption refrigeration units (trigeneration), making it possible to extend the period of the year in which the plant operates in cogeneration mode, even in central and southern European regions [].

Furthermore, the most recent technological developments offer the possibility of increasing energy recovery through the condensation of flue gases to also recover the latent heat of the condensation of the humidity contained in them and/or by using absorption heat pumps. These are applied at the Amager Bakke plant, also known as Copenhill, in Copenhagen, managed by the Amager Resource Center (ARC) and owned by five municipalities in Greater Copenhagen: Copenhagen, Federiksberg, Hvidovre, Tårnby and Dragør. This plant can operate in two configurations. In the first one, heat is transferred from the warm liquid of the scrubber (where flue gases condensate) to district heating return flow, adding about 9% of the points to the plant’s efficiency (about 25.4% of electric efficiency, plus about 63% of heat efficiency), reaching an overall 98%. In the second one, the use of an absorption heat pump (fed by steam extracted from the turbine at about 7 bar) makes the total gross thermal efficiency equal to 107% [].

With reference to Europe, WtE plants produce about 43 TWh of electricity [], which represents about 5.8% of the electricity consumed in 2021 by the household sector (about 747 TWh []), corresponding to the consumption of more than 25 million European inhabitants (considering the average 1.7 MWh/inhabitant/year []). This electricity source is programmable and flexible, contrary to many other renewable electricity sources. Also, 99 TWh of heat is produced by CHP, corresponding to about 10 billion of natural gas (2% of the overall natural gas consumption in Europe []).

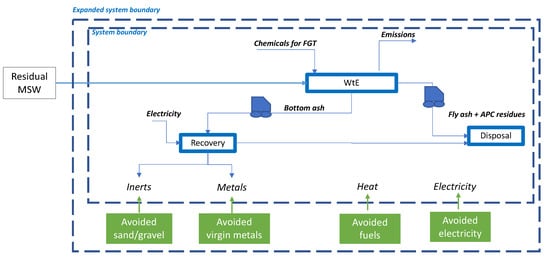

One of the most relevant implications of energy recovery consists of having a beneficial effect on the environmental performance of the process, because the electricity and/or thermal energy generated by waste replaces the consumption of fossil fuels and related emissions, as shown in several LCA studies (for instance []), as depicted in Figure 4.

Figure 4.

Simplified sketch of the expanded system boundary approach in LCA to account for the benefits deriving from the electricity and thermal energy generated from waste (and also inert metals recovered from bottom ash), which replace the consumption of fossil fuels and related emissions.

Different approaches have been used in the literature to account for substituted energy—i.e., mix or average in a region or marginal technologies according to the change induced in the energy system []—but it is rather obvious that, considering the impacts on climate change, the merit of energy recovery is greater when replacing energy of fossil origin (or energy mixes with high fossil energy). Similarly, climate change impact is strongly affected by the composition of rMSW: for instance, increasing the recycling of plastic reduces the fossil carbon in the rMSW sent for WtE, reducing the climate change impact []. The ratio of fossil to biogenic carbon in rMSW may change seasonally, in the long-term and in different countries; however, with reference to the EU and USA, around 50–60% of the carbon content is of biogenic origin [,], leading to a specific emission of about 400–500 kg of fossil CO2 at the stack per t of waste [].

Generally, the climate change impact of WtE LCA is reported in reference to the input waste. However, Sathre et al. [] calculated and compared the specific fossil CO2 emission at the stack per unit of produced electricity for coal power plants and MSW WtE, reporting values of 710 vs. 384 kgCO2/MWh, respectively. When CO2 specific emissions are calculated from the LCA perspective, the value results are lower than several renewable energy sources and are comparable to natural gas-based electricity [].

Many studies have shown that high electricity recovery combined with high heat recovery for district heating, otherwise based on fossil fuels, leads to significant savings with respect to climate change. The balance between the loads and the savings, from the LCA perspective, leads to a net climate change value ranging from positive values of around 150–180 kg CO2eq./t (strongly dependent on rMSW composition and displaced electricity), typical of plants with poor energy recovery, to near-zero values or negative ones for highly efficient plants operating in cogeneration mode [,]. State-of-the-art plants are almost zero-CO2 emitters.

However, the savings obtainable by replacing electricity and/or heat are reduced when future projections of increasingly renewable energy mixes are included: avoided CO2 emissions decrease, and the benefit becomes thinner [].

4. Gasification and Energy Recovery

Gasification slightly differs from combustion in a few ways, but most importantly, it uses a much lower amount of oxygen than that necessary for complete oxidation (25–50%). This results in the generation of a synthetic gas (or syngas) rich in carbon monoxide (CO) and hydrogen (H2), with a certain amount of methane (CH4) []. This syngas, which retains a significant fraction of the energy originally present in the waste, could theoretically be used in highly efficient internal combustion cycles such as gas turbines or gas engines. However, the presence of impurities and, in particular, the high tar content are some of the main challenges for operation, as tar—aromatic hydrocarbons prone to condense—can block the valve, pipes and injectors of engines, requiring high maintenance, unexpected shutdowns and, ultimately, an uneconomic operation [,]. Indeed, tar must be significantly reduced from the initial concentration, in the range of 2000–20,000 mg/m3 in the raw syngas, before this can be used in devices such as reciprocating engines (<50 mg/m3), gas turbines (<1 mg/m3), fuel cells (<0.1 mg/m3) or for methanol synthesis (<1 mg/m3) []. Thus, realizing an efficient and economic syngas cleaning system, able to achieve the required levels, is the main challenge for syngas use in added-value applications []. Tar reduction can be achieved by primary methods, realized inside the gasification reactor by a specific design and by controlling the operating conditions, and by secondary methods that are downstream the gasification reactor. Secondary methods are based on mechanical, dry, wet, thermal and catalytic methods for tar and particulate removal. At present, the secondary methods can reach high removal efficiency; however, they are economically and technically limited and are not yet commercialized [].

This is why, together with the atmospheric pressure at which syngas is normally produced, the use of a conventional steam cycle is still the employed way to recover the syngas energy content (Figure 5), with the same limitations described above in the case of steam cycles associated with combustion; thus, most of the potential advantages of gasification are not currently exploited [,].

Figure 5.

Simplified schematic of a gasification plant that is fed by pre-treated waste, where the syngas is cleaned and then burnt in a boiler to produce steam feeding a stem cycle. After the syngas combustion, the combustion gases proceed through the air pollution control section.

An example is the Metso gasification plant in Lahti (Finland) where 250 kt/y of combustible fraction from selected MSW and commercial and industrial waste are gasified. The syngas is purified and feeds a steam cycle to produce 50 MW of electrical power and 90 MW of thermal power for district heating. The electrical efficiency is about 31%, which is slightly higher than the average WtE facility.

A specific feature of some gasification processes, which has led to numerous commercial applications in Japan [], is the possibility of obtaining completely inert vitrified solid residues by the combustion of syngas and ash above the melting point of the ashes. This essentially eliminates the need for landfill space if the material is beneficially used, although it further reduces energy efficiency.

A similar approach was realized in a gasification plant in Italy, which started up in 2009 but stopped in 2011, in the Malagrotta area (Rome). This plant was based on a high temperature oxygen gasification technology with slag melting, using fuel derived from municipal waste, after a mechanical selection treatment, and feeding the syngas to a steam cycle []. The net electrical efficiency calculated through the simulation of a similar plant [] is about 13%, with about 20% of the gross power consumed by the air separation unit for the production of pure oxygen.

While for some types of industrial waste it is possible to feed them directly to a gasification reactor, in the case of rMSW, mechanical pre-treatments are necessary to obtain a more homogeneous flow in terms of chemical, physical and size characteristics. Primarily due to these factors, gasification use is presently only a small fraction compared to WtE. However, it should be mentioned that some authors report gasification as the preferable option for energy recovery from rMSW, whether delocalization and a relatively small size are the boundary conditions [,].

5. Emission Control

In modern WtE plants, the rigorous control of combustion (high temperature and correct air supply) and advanced APC technologies make it possible to achieve very low emission levels. Measurement campaigns [] and data reported in scientific articles [,] show that concentrations at the stack are far lower than the limits set for WtE by the very stringent EU legislation (the most restrictive compared to other types of air emission sources, both from combustion and from other industrial activities) and are generally below the lower end of the range defined by the Industrial Directive (Table 2), according to the application of the Best Available Techniques (BATs) [], or close to it. The current performance of WtE facilities in the USA, and globally, shows that their emissions are more than 70% below maximum achievable control technology (MACT) standards, and they are continually reduced due to better control, system efficiency and APC upgrades [].

Table 2.

BAT-associated emission levels (BAT-AELs) for channeled emissions to the air from the incineration of waste, according to the EU Best Available Techniques (BATs) Reference Document for Waste Incineration [].

Very stringent emission limits are also in force in South Korea and Japan, while in India and China, the limited values of some pollutants still have room to be further reduced [], even if Chinese-measured values show to be already 45−96% lower than the national standard [].

These high-level environmental performances were obtained during the last few decades through a deep evolution of the APC section and the overall layout of WtE plants [], leading the APC section to represent 25–35% of the total cost of the investment, since the operation of the plant is dominated by the need to always comply with the emission limits.

The same limits, the same BATs and the same APC technologies apply to emissions in the atmosphere deriving from the gasification associated with syngas combustion.

Among the several types of pollutants present in WtE flue gases, PCDDs and PCDFs are the most famous and discussed ones, since they were detected, for the first time, after the 1976 Seveso accident in the ashes filtered at a WtE plant in The Netherlands []. Later on, thanks to the introduction of combustion requirements (temperature higher than 850 °C for at least 2 s with oxygen availability) and efficient fly ash removal by fabric filters (indeed, organic compounds such as PCDDs and PCDFs are adsorbed on particles and soot), their emission was dramatically reduced []. PCDDs and PCDFs might also be re-formed by the so-called de novo synthesis, which basically consists of the oxi-chlorination of incomplete combustion products, catalyzed by copper compounds, at a temperature higher than 200 °C. Thus, secondary methods to remove de novo-formed PCDDs and PCDFs are available such as absorption by activated carbon, destruction by a catalyst that is operated in oxidative mode (i.e., the same catalyst used for NOx selective catalytic reduction (SCR) is effective for PCDDs and PCDFs), catalytic filtration and adsorption in the packing material of wet scrubbers (made by polypropylene molded with carbon) []. PCDDs’ and PCDFs’ limits and effective emissions at WtE stacks have significantly decreased over time (from values of around 4000 ng/Nm3 in the 1990s of last century to the present 0.01–0.08 ng/Nm3, as shown in Table 2). The overall PCDD and PCDF emissions in the EU reduced by 43% between 2005 and 2021 [], with a significant reduction contribution coming from the waste sector. At present, PCDD and PCDF emissions from WtE account for less than 0.2% of the total emissions from the industrial sector [].

6. Perspectives

As mentioned above, considering the impacts on climate change, the benefits obtainable through the recovery of electrical and thermal energy from waste will diminish as the energy systems will hopefully become increasingly renewable. Over this medium–long-term horizon, the possibility of containing CO2 emissions from the energy recovery/thermal treatment of waste can essentially follow two paths:

- Capture and storage/use of CO2 from flue gases;

- Use of carbon contained in waste to produce fuels or chemicals.

6.1. WtE with Carbon Capture

Carbon capture technologies (CCs) have been proposed and have been partially implemented in different industrial processes in the last few decades []. In carbon capture and storage (CCS), the captured CO2 can be stored underground or injected into the oceans, thus subtracting it from the carbon cycle, providing it is economically and environmentally feasible [,]. Alternatively, in carbon capture and use (CCU), the CO2 can be used in several processes and products, such as intensive horticulture (greenhouses), algae growth, the lightening of concrete, food preservation, drinks, refrigerants, extinguishing gas, oil extraction and mineralization. Many of these uses are consolidated and have been commercially available for a long time, using CO2 produced on purpose or as a by-product from other processes. The main issue is related to the match between additional CO2 supply and demand. CO2 can also be used, potentially, to produce chemicals and fuels where a carbon source is required. However, in most of the cases, the research is still at initial stages, and developments should lead to cost-effective processes in order to allow for real applications []. However, the large-scale implementation of CC to WtE, as a post-combustion technology, is still minimal, although it is receiving great attention in Europe [] with some initiatives already in place [], some of which are described in the following or are under evaluation [].

In 2014, Twence introduced the capture of part of the CO2 from combustion gases to convert it into sodium bicarbonate, which is in turn used to purify flue gas, at the Hengelo waste-to-energy plant in The Netherlands. In 2020, a small-scale CO2 capture plant was also built that liquefies CO2 for use in growing plants in greenhouse horticulture. There are currently plans to build a large-scale plant, capable of capturing 100 kt of CO2 per year, which is expected to come into operation in the last quarter of 2023. In Japan, in Saga City, a plant has been in operation since 2016 that captures CO2—about 10 t/day—from the combustion gases of a waste-to-energy plant that is used for the growth of algae for the production of biomass. Since August 2019, AVR in Duiven, also in The Netherlands, has been building a large-scale plant for the capture of CO₂ from the waste gases of the waste-to-energy plant, which is supplied to greenhouse horticulture, totaling about 60.000 t/y. The Amager Bakke plant in Copenhagen, designed to treat 600 kt of residual waste per year, is studying the installation of CC, with the aim of being fully operational by 2025 [].

The CO2 post-combustion solvent-based capture unit requires heat and electricity for operation, which are about, respectively, 3.2 GJ/t of captured CO2 in the form of low-pressure steam and 14.2 kWh/t of captured CO2 []. Additionally, the separated CO2 needs conditioning before transport, generally consisting of compression and liquefaction (requiring about 100 kWh/t of captured CO2) []. The simulation of a conventional WtE (i.e., 160–170 kt/y, 60 bar and 400 °C superheated steam) with and without CO2 post-combustion [] calculated that the electricity penalty for CO2 capture is around 30–35% in the case of only power production operations, while the electricity penalty in the cogeneration mode can range between 20 and 60%, depending on the initial CHP configuration, and the heat penalty is lower (depending on the CHP configuration) and heat recovery can either increase, as in the case of an advanced heat integration. The specific fossil CO2 emissions at the stack can be reduced from 348 to 68 kgCO2/MWh []. However, biogenic CO2 needs to be subtracted from the balance, shifting the values calculated in the case without CCS—equal to 482 kgCO2/MWh and 353 kgCO2/t of waste—to negative figures equal to −1011 kgCO2/MWh and −486 kgCO2/t of waste when CCS is applied, as reported by [], in the case of only power production (lower values are reported in the CHP and/or optimized cases).

Some LCA studies have calculated that the introduction of CCS/CCU, despite the energy penalties, still reduces the impact on climate change: the benefit becomes more evident as an energy system more based on renewables is considered [] or when the CO2 of fossil origin is replaced, as in the CCU case []. The use of CO2 for the purpose of producing raw chemical materials or fuels, such as methane, methanol, etc., offers much higher benefits, but only if the energy system is strongly renewable, due to the significantly high electricity consumption of these processes []. While CCS provides substantial reduction regarding climate change effects, other environmental effects are worsened, as calculated by [].

CCS technologies different from solvent-based ones were also proposed, as a calcium looping process, to study the techno-economic feasibility with the aim of calculating the levelized cost of electricity (LCOE) of the post-combustion calcium looping process applied to WtE, which, of course, increased with respect to the base WtE case [,]. Haaf et al. [] also reported results from the operation of a calcium looping pilot plant, using RDF to provide the additional required heat to process the WtE flue gases, that reach more than 90% of CO2 capture.

One of the main motivations pushing for CCS applications to WtE, in the EU, is that the European Parliament has preliminarily approved—in June 2022—the inclusion of MSW WtE within the scope of the EU Emission Trading System (ETS), starting from 2026. The ETS is a tool, set up in 2005, for reducing greenhouse gas (GHG) emissions cost-effectively, operating according to the “cap & trade” principle in all EU countries (plus Iceland, Liechtenstein and Norway), and it covers around 40% of the EU’s GHG emissions (Directive 2003/87/CE). Later, the European Council asked if, before proceeding definitively, a prior assessment of the impact of the EU ETS introduction on the integrated MSW management system could be carried out. This is fundamental due to the absence of a clear EU framework for monitoring and reporting emissions that adapts to the specific characteristics of the WtE sector. Thus, in April 2023, the European Parliament approved the ETS reform which was then also ratified by the Council. Directive 2023/959/EU entered into force in May 2023 and requires EU countries to measure, report and verify emissions from MSW WtE facilities starting from 2024. By 31 January 2026, the Commission will present a report with the aim of including such installations in the EU ETS from 2028, with a possible exclusion until 2030 at the latest. The report must contain a holistic impact analysis, looking at the MSW management system as a whole and also evaluating the possibility of including other processes with an impact on GHG gases, such as landfills.

6.2. Waste to Chemicals

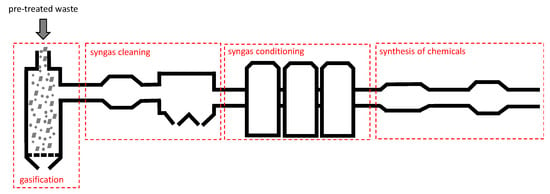

The alternative approach, proposed to contain the emissions of GHG gases in the thermal treatment of waste, is to use the carbon contained in it to produce commonly used chemical compounds (Waste to Chemicals) or fuels. There are a wide number of possible processes, but with reference to rMSW and scraps from SWC, the main proposed technology is gasification, as already introduced before, which is aimed at the production of syngas which, in this case, can feed, after suitable purification and conditioning treatments, a chemical synthesis process (Figure 6). Benefits, in terms of reductions in GHGs, are expected from the possibility of obtaining a chemical product/fuel that can replace its analogue that is normally produced from fossil sources. Today, the processes that attract the most interest at an international level are the production of methanol, hydrogen or synthetic natural gas. The discussion of the numerous experiences underway in the context of European projects on a pilot scale is omitted in order to focus the attention on the few demonstrative or commercial experiences.

Figure 6.

Simplified schematic of a waste-to-chemical process where, after gasification, the syngas is cleaned, then conditioned and then fed to the synthesis section where different kinds of chemicals might be produced.

In particular, the methanol/ethanol production process appears to be the most advanced one. Indeed, at the international level, there is one demonstration plant in Edmonton Canada that is designed, built and managed by Enerkem, who has developed the process and technology since its foundation in 2000, starting from the pilot project, through the demonstration up to the commercial state. About 100 kt/y of non-recyclable municipal waste, after appropriate and necessary pre-treatments, is fed to a bubbling fluidized bed gasification reactor (with a temperature of 700–900 °C and atmospheric pressure) using steam and oxygen as the gasification agents. The syngas is subsequently subjected to a complex cleaning and conditioning process—essential for the efficiency of the process—to then feed the catalytic synthesis (at a high pressure and high temperature 220 °C) and the purification of the product which can be methanol, ethanol or ethylene. This process requires a high level of waste separation and large amounts of energy []. One of the key parameters is the yield of the desired chemical, and some expected values are reported to be equal to about 0.378 m3 of biofuel per dry t of rMSW [], while values expected from theoretical simulations of similar processes are reported to be up to 677 kg of methanol per t of RDF [], corresponding to 0.855 m3 of methanol per t of RDF. Despite the long timeline of the operation of the plant in Edmonton, there is little public information on the effective yields of the process, the consumption of the plant and the quality of the feed flow. Therefore, the availability of a facility that would operate continuously is uncertain. Recently, Enerkem announced the construction of a second similar plant in Canada (Varennes) whose start-up, for the first phase, is planned for 2025. Furthermore, Enerkem and Repsol have plans to build a similar plant in El Morell (Tarragona), Spain for the production of about 220 kt/y of methanol which is mainly from about 400 kt/y of pre-treated non-recyclable waste (i.e., 550 kg of methanol per t of waste). This plant is currently in the development phase, awaiting the final decision of the investors. The Enerkem site presents two other plants under development in the USA and in Rotterdam, The Netherlands, where the new plants will be designed for the capacity of 360 kt/y of waste to produce 220 kt/y of methanol (i.e., 611 kg of methanol per t of waste). Once these come to completion, they will enable waste management professionals to assess performance and to begin to consider such a facility in their planning.

The other process, which is at a rather advanced stage of development, is that of the Advanced Biofuel Solution Ltd. (ABSL) in Swindon in the UK. The information provided by the ABSL website states that the plant should have been operational by as early as 2022. The process requires that non-recyclable municipal waste, sorted and prepared elsewhere, is fed to a fluidized bed gasifier, together with steam and oxygen, to produce raw syngas. The syngas is treated in a plasma reactor for tar removal; then cooled (in a boiler, producing steam); filtered to remove particulate matter; and scrubbed to remove acid and alkaline contaminants. The clean syngas is compressed and subjected to the shift reaction through the injection of steam, which converts it into a mixture of hydrogen and carbon dioxide. The hydrogen can be removed as a final product in this step or converted, by means of catalysts, into a mixture of methane and carbon dioxide. After the removal of carbon dioxide, the methane can be fed into the national grid.

At the moment, other international experiences that declare the potential use of a fraction obtainable from rMSW are at a less advanced stage than the previous ones, such as the commercial-scale demonstration plant built by KEW Technology Ltd. in Wednesbury (UK), which, starting from different types of waste, currently generates syngas for the production of electricity: KEW Technology Ltd. declares that from 2023 onwards, it will generate advanced fuels, for example, hydrogen.

There are other experiences with different degrees of development, which aim to produce advanced fuels from rMSW or from specific feedstocks, such as biomass, wood residues or non-recyclable plastic. Specifically, in relation to plastics, a recent report by the JRC [] concluded, on the basis of the LCA, that considering the effects of climate change, chemical and physical recycling, in some cases aimed at obtaining fuels, seems to be preferable to the recovery of energy, especially for mixed polyolefin waste bales currently produced by sorting plants in the EU and not mechanically recycled. Considering impact categories other than climate change, chemical or physical recycling can sometimes be less efficient than energy recovery. JRC underlines that the main limitations associated with the study conducted are due to the lack of maturity of some of the technologies studied, and, therefore, the representativeness of the related inventory data, especially in terms of energy consumption. There is a need for more detailed information on the composition of the plastic waste treated by the investigated technologies, highlighting that the level of information obtained is not always sufficient to describe the specific quality of the input flow to chemical recycling (quality requirement, acceptable level of impurities, pre-treatments required, etc.).

The scarcity of detailed information on the part of the few owners of advanced fuel production technologies in demonstration/commercial plants is, therefore, one of the main obstacles to the robust assessment of the potential benefits that can be obtained in environmental—but also economic—terms of these processes compared to the conventional, current operations. The reluctance to provide very detailed information may be due to competitive advantages that some have with respect to others.

Beyond the availability of data from the few existing plants, the discussion about the benefits obtainable from WtC is partly faced by the scientific literature, with few comparisons, specifically for the case of rMSW, between WtE and WtC, based on the LCA and generally using data generated by WtC simulations.

Voss et al. [] studied the climate change associated with the chemical recycling of rMSW in Germany, simulating the process to produce olefins to be further used for plastic production and, additionally, fuel gas, LPG, butadiene, butene, heat as process steam and sulfur. According to their study, incineration-based conventional pathways (assumed to have 17% of gross electricity efficiency and 32% of heat efficiency, with average values representative of the overall European WtE fleet at present []) present better performances (−100 kgCO2eq./t of rMSW) than chemical recycling (−87 kgCO2eq./t of rMSW) when located in the present energy system, while the opposite happens when predominantly renewable energy systems are assumed (WtE: 61 kgCO2eq./t of rMSW; chemical recycling: −60 kgCO2eq./t of rMSW).

Sun et al. [] simulated and compared, among others, MSW to methanol integrated with CCS and conventional WtE (only power production), in the Chinese context, not including, within the system boundary, the fate of fractions separated upstream the gasification. Rather obviously, the MSW to methanol with CCS obtained better performances in terms of climate change than the traditional WtE, likely because of the CCS contribution.

The few available examples highlight that there is a gap in the literature regarding a fair comparison of WtC and WtE. Indeed, comparisons should consider that, as long as the WtC technologies will be fully commercially available, some changes are expected in the WtE as well, namely, WtE efficiencies are expected to improve, as previously discussed; thus, a fair comparison should be applied to future scenarios not only considering the increased renewable energy mix but also the improvement of the average WtE performances. Additionally, it can be argued that future WtE plants might be equipped with CCS too. The feasibility of this innovation is comparable to the introduction of WtC; thus, future comparisons should be carried out which also include CCS: in this case, climate change indicators calculated for the WtE would be around −500 kgCO2eq./t of rMSW, depending on the assumed future energy scenario [] but would be definitely lower than the chemical recycling values previously reported, even if a direct comparison of the LCA numerical results calculated by different authors is always risky. Thus, a comprehensive comparison of WtE and WtC, in different future energy mixes and with the introduction of CCS, and for the WtC, should be carried out in the near future to clarify the benefits obtainable from the two technologies.

7. Conclusions

WtE plants, to date, are a consolidated, safe and reliable technology available for the recovery of energy from non-recyclable waste and to close the waste cycle. Through the recovery of electricity and heat, WtE plants allow for the saving of fossil resources and operate today, substantially, in a neutral way with respect to climate change. However, the savings obtainable by replacing electricity and/or heat will be reduced in the future perspective of increasingly renewable energy mixes. In this sense, the introduction of CCS/CCU, despite inevitable energy penalties, will be able to reduce the impact on climate change, leading to WtE operating as a carbon sink.

The possibility of recovering the carbon contained in non-recyclable waste (WtC) certainly appears as a fascinating alternative, but to date, it does not offer adequate assurances in terms of the robust knowledge of the complex processes involved, and, above all, if applied to highly inhomogeneous feed streams such as those obtained from rMSW. Given the high added value of the products obtainable from WtC processes, a high consumption of other chemical products and energy is required, with a direct influence on operating and environmental costs.

To the aim of clarifying in which conditions one technology might be preferable to the other, a comprehensive comparison is required, taking into consideration the expected changes in energy mixes, increases in efficiency and the introduction of CCS.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Haupt, M.; Waser, E.; Würmli, J.C.; Hellweg, S. Is there an environmentally optimal separate collection rate? Waste Manag. 2018, 77, 220–224. [Google Scholar] [CrossRef] [PubMed]

- Sharma, D.K.; Bapat, S.; Brandes, W.F.; Rice, E.; Castaldi, M.J. Technical feasibility of zero waste for paper and plastic wastes. Waste Biomass Valorization 2019, 10, 1355–1363. [Google Scholar] [CrossRef]

- Eurostat. Material Flow Accounts Statistics-Material Footprints. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Material_flow_accounts_statistics_-_material_footprints#EU.27s_material_footprint_by_material_category_over_time (accessed on 30 November 2023).

- Bellan, M.; Grosso, M. Valutazione dei flussi di scarto nella gestione dei rifiuti urbani in Italia. Ing. Ambiente 2020, 7, 161–175. [Google Scholar] [CrossRef]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- Eurostat. Municipal Solid Waste Statistics. 2021. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics#Municipal_waste_treatment (accessed on 30 November 2023).

- CEWEP. Achieved Circular Economy Targets Will Leave 40 Million Tonnes Residual Waste Gap in 2035; CEWEP: Bruxelles, Belgium, 2019. [Google Scholar]

- Bourtsalas, A.C.; Themelis, N.J. Materials and energy recovery at six European MBT plants. Waste Manag. 2022, 141, 79–91. [Google Scholar] [CrossRef] [PubMed]

- Sarquah, K.; Narra, S.; Beck, G.; Bassey, U.; Antwi, E.; Hartmann, M.; Derkyi, N.S.A.; Awafo, E.A.; Nelles, M. Characterization of Municipal Solid Waste and Assessment of Its Potential for Refuse-Derived Fuel (RDF) Valorization. Energies 2023, 16, 200. [Google Scholar] [CrossRef]

- Bessi, C.; Lombardi, L.; Meoni, R.; Canovai, A.; Corti, A. Solid recovered fuel: An experiment on classification and potential applications. Waste Manag. 2016, 47, 184–194. [Google Scholar] [CrossRef]

- Consonni, S.; Giugliano, M.; Grosso, M. Alternative strategies for energy recovery from municipal solid waste. Part A: Mass and energy balances. Waste Manag. 2005, 25, 123–135. [Google Scholar] [CrossRef]

- Papageorgiou, A.; Barton, J.R.; Karagiannidis, A. Assessment of the greenhouse effect impact of technologies used for energy recovery from municipal waste: A case for England. J. Environ. Manag. 2009, 90, 2999–3012. [Google Scholar] [CrossRef]

- Cimpan, C.; Wenzel, H. Energy implications of mechanical and mechanical–biological treatment compared to direct waste-to-energy. Waste Manag. 2013, 33, 1648–1658. [Google Scholar] [CrossRef]

- Gałko, G.; Mazur, I.; Rejdak, M.; Jagustyn, B.; Hrabak, J.; Ouadi, M.; Jahangiri, H.; Sajdak, M. Evaluation of alternative refuse-derived fuel use as a valuable resource in various valorised applications. Energy 2023, 263, 125920. [Google Scholar] [CrossRef]

- ISWA. White Book on Energy-from-Waste (EfW) Technologies; ISWA: Rotterdam, The Netherlands, 2023. [Google Scholar]

- Brunner, P.H.; Rechberger, H. Waste to energy—Key element for sustainable waste management. Waste Manag. 2015, 37, 3–12. [Google Scholar] [CrossRef]

- Di Maria, F.; Beccaloni, E.; Bonadonna, L.; Cini, C.; Confalonieri, E.; La Rosa, G.; Milana, M.R.; Testai, E.; Scaini, F. Minimization of spreading of SARS-CoV-2 via household waste produced by subjects affected by COVID-19 or in quarantine. Sci. Total Environ. 2020, 743, 140803. [Google Scholar] [CrossRef] [PubMed]

- Puertas, R.; Carracedo, P.; Marti, L. Environmental policies for the treatment of waste generated by COVID-19: Text mining review. Waste Manag. Res. 2022, 2022, 1480–1493. [Google Scholar] [CrossRef]

- Ware, S.A. A Survey of Pathogen Survival during Municipal Solid Waste and Manure Treatment Processes; Municipal Environmental Research Laboratory, Office of Research and Development, U.S. Environmental Protection Agency: Washington, DC, USA, 1980.

- Wood, J.P.; Lemieux, P.; Betancourt, D.; Kariher, P.; Griffin, N. Pilot-Scale Experimental and Theoretical Investigations into the Thermal Destruction of a Bacillus anthracis Surrogate Embedded in Building Decontamination Residue Bundles. Environ. Sci. Technol. 2008, 42, 5712–5717. [Google Scholar] [CrossRef] [PubMed]

- Barbeito, M.S.; Taylor, L.A.; Seiders, R.W. Microbiologic evaluation of a large volume air incinerator. Appl. Microbiol. 1968, 16, 490–495. [Google Scholar] [CrossRef]

- Lucas, D.; Petty, S.M.; Keen, O.; Luedeka, B.; Schlummer, M.; Weber, R.; Barlaz, M.; Yazdani, R.; Riise, B.; Rhodes, J.; et al. Methods of Responsibly Managing End-of-Life Foams and Plastics Containing Flame Retardants: Part I. Environ. Eng. Sci. 2018, 35, 573–587. [Google Scholar] [CrossRef] [PubMed]

- Van Caneghem, J.; Van Acker, K.; De Greef, J.; Wauters, G.; Vandecasteele, C. Waste-to-energy is compatible and complementary with recycling in the circular economy. Clean Technol. Environ. Policy 2019, 21, 925–939. [Google Scholar] [CrossRef]

- Castaldi, M.J.; LeBlanc, J.; Licata, A. The Case for Waste to Energy. Mech. Eng. 2022, 144, 34–39. [Google Scholar] [CrossRef]

- Consonni, S.; Lombardi, L.; Viganò, F. Municipal Solid Waste to Energy Technology. In Encyclopedia of Sustainable Technologies; Elsevier: Amsterdam, The Netherlands, 2017; pp. 389–401. [Google Scholar]

- Lombardi, L.; Carnevale, E.; Corti, A. A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef]

- Lombardi, L.; Nocita, C.; Bettazzi, E.; Fibbi, D.; Carnevale, E. Environmental comparison of alternative treatments for sewage sludge: An Italian case study. Waste Manag. 2017, 69, 365–376. [Google Scholar] [CrossRef] [PubMed]

- EN ISO 21640:2021; Solid Recovered Fuels—Specifications and Classes. European Commission: Brussels, Belgium, 2021.

- Broz, P.; Złoczowska, E.; Staude, M.; Baszak, K.; Sosnowski, M.; Bryll, K. Study of the Combustion Process for Two Refuse-Derived Fuel (RDF) Streams Using Statistical Methods and Heat Recovery Simulation. Energies 2022, 15, 9560. [Google Scholar] [CrossRef]

- Kumara, A.; Samadder, S.R. Development of lower heating value prediction models and estimation of energy recovery potential of municipal solid waste and RDF incineration. Energy 2023, 274, 127273. [Google Scholar] [CrossRef]

- Lombardi, F.; Bartolucci, L.; Cordiner, S.; Costa, G.; Falsetti, A.; Mele, P.; Mercurio, M.; Mulone, V.; Sorino, D. Chemical–Physical Characterization of Bio-Based Biodegradable Plastics in View of Identifying Suitable Recycling/Recovery Strategies and Numerical Modeling of PLA Pyrolysis. Waste Biomass Valorization 2023, 1–18. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- EUR 29971 EN; Best Available Techniques (BAT) Reference Document for Waste Incineration. Joint Research Centre of European Community: Brussels, Belgium, 2019. [CrossRef]

- Lombardi, L.; Carnevale, E. Evaluation of the environmental sustainability of different waste-to-energy plant configurations. Waste Manag. 2018, 73, 232–246. [Google Scholar] [CrossRef]

- CEWEP. Waste-to-Energy Climate Roadmap—The Path to Carbon Negative; CEWEP: Bruxelles, Belgium, 2022. [Google Scholar]

- Scarlat, N.; Fahl, F.; Dallemand, J.F. Status and Opportunities for Energy Recovery from Municipal Solid Waste in Europe. Waste Biomass Valorization 2019, 10, 2425–2444. [Google Scholar] [CrossRef]

- Eboh, F.C.; Andersson, B.A.; Richards, T. Economic evaluation of improvements in a waste-to-energy combined heat and power plant. Waste Manag. 2019, 100, 75–83. [Google Scholar] [CrossRef]

- Matak, N.; Tomic, T.; Schneider, D.R.; Krajacic, G. Integration of WtE and district cooling in existing Gas-CHP based district heating system e Central European city perspective. Smart Energy 2021, 4, 100043. [Google Scholar] [CrossRef]

- Bisinella, V.; Nedenskov, J.; Riber, C.; Hulgaard, T.; Christensen, T.H. Environmental assessment of amending the Amager Bakke incineration plant in Copenhagen with carbon capture and storage. Waste Manag. Res. 2022, 40, 79–95. [Google Scholar] [CrossRef]

- Poretti, F.; Stengler, E. The Climate Roadmap of the European Waste-to-Energy Sector The path to Carbon Negative. In Proceedings of the 16th International Conference on Greenhouse Gas Control Technologies (GHGT-16), Lyon, France, 23–27 October 2022. [Google Scholar]

- Eurostat. Energy Consumption in Households. 2021. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_consumption_in_households#Energy_consumption_in_households_by_type_of_end-use (accessed on 30 November 2023).

- Ardolino, F.; Boccia, C.; Arena, U. Environmental performances of a modern waste-to-energy unit in the light of the 2019 BREF document. Waste Manag. 2020, 104, 94–103. [Google Scholar] [CrossRef]

- Astrup, T.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [PubMed]

- Hupponen, M.; Havukainen, J.; Horttanainen, M. Long-term evolution of the climate change impacts of solid household waste management in Lappeenranta, Finland. Waste Manag. 2023, 157, 69–81. [Google Scholar] [CrossRef]

- Schwarzböck, T.; Rechberger, H.; Cencic, O.; Fellner, J. Determining national greenhouse gas emissions from waste-to-energy using the Balance Method. Waste Manag. 2016, 49, 263–271. [Google Scholar] [CrossRef] [PubMed]

- Sathre, R.; Gustavsson, L.; Le Truong, N. Climate effects of electricity production fuelled by coal, forest slash and municipal solid waste with and without carbon capture. Energy 2017, 122, 711–723. [Google Scholar] [CrossRef]

- Pfadt-Trilling, A.R.; Volk, T.A.; Fortier, M.O.P. Climate Change Impacts of Electricity Generated at a Waste-to- Energy Facility. Environ. Sci. Technol. 2021, 55, 1436–1445. [Google Scholar] [CrossRef]

- Astrup, T.; Møller, J.; Fruergaard, T. Incineration and co-combustion of waste: Accounting of greenhouse gases and climate change contributions. Waste Manag. Res. 2009, 27, 789–799. [Google Scholar] [CrossRef]

- Bisinella, V.; Hulgaard, T.; Riber, C.; Damgaard, A.; Christensen, T.H. Environmental assessment of carbon capture and storage (CCS) as a post-treatment technology in waste incineration. Waste Manag. 2021, 128, 99–113. [Google Scholar] [CrossRef] [PubMed]

- Arena, U. Process and technological aspects of municipal solid waste gasification. A review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef]

- Hai, I.U.; Sher, F.; Zarren, G.; Liu, H. Experimental investigation of tar arresting techniques and their evaluation for product syngas cleaning from bubbling fluidized bed gasifier. J. Clean. Prod. 2019, 240, 118239. [Google Scholar] [CrossRef]

- Chan, W.P.; Yusoff, S.A.M.B.; Veksha, A.; Giannis, A.; Lim, T.T.; Lisak, G. Analytical assessment of tar generated during gasification of municipal solid T waste: Distribution of GC–MS detectable tar compounds, undetectable tar residues and inorganic impurities. Fuel 2020, 268, 117348. [Google Scholar] [CrossRef]

- Vehlow, J. Air pollution control systems in WtE units: An overview. Waste Manag. 2015, 37, 58–74. [Google Scholar] [CrossRef] [PubMed]

- Boccia, C.; Parrillo, F.; Ruoppolo, G.; Commodo, M.; Berruti, F.; Arena, U. The effect of steam concentration on hot syngas cleaning by activated carbons. Fuel Process. Technol. 2021, 224, 107033. [Google Scholar] [CrossRef]

- Consonni, S.; Viganò, F. Waste gasification vs. conventional Waste-To-Energy: A comparative evaluation of two commercial technologies. Waste Manag. 2012, 32, 653–666. [Google Scholar] [CrossRef] [PubMed]

- Lombardi, L.; Carnevale, E.; Corti, A. Analysis of energy recovery potential using innovative technologies of waste gasification. Waste Manag. 2012, 32, 640–652. [Google Scholar] [CrossRef]

- Tanigaki, N.; Manako, K.; Osada, M. Co-gasification of municipal solid waste and material recovery in a large-scale gasification and melting system. Waste Manag. 2012, 32, 667–675. [Google Scholar] [CrossRef] [PubMed]

- Zagaroli, M. La Centrale di Termogassificazione di Malagrotta. In Recupero di Energia e Materia da Rifiuti Solidi i Processi, le Tecnologie, le Esperienze, le Norme; Arena, U., Leone, U., Mastellone, M.L., Eds.; AMRA S.c.a r.l.: Napoli, Italy, 2007. [Google Scholar]

- Aracil, C.; Haro, P.; Fuentes-Cano, D.; Gómez-Barea, A. Implementation of waste-to-energy options in landfill-dominated countries: Economic evaluation and GHG impact. Waste Manag. 2018, 76, 443–456. [Google Scholar] [CrossRef]

- Ragazzi, M.; Torretta, V.; Torres, E.A.; Schiavon, M.; Rada, E.C. Perspectives of decentralised gasification of residual municipal solid waste. Energy Rep. 2022, 8, 1115–1124. [Google Scholar] [CrossRef]

- Utilitalia. Libro Bianco sull’Incenerimento dei Rifiuti Urbani; Utilitalia: Roma, Italy, 2020. [Google Scholar]

- Onondaga County Resource Recovery Agency. Annual Report 2020. Available online: https://ocrra.org (accessed on 30 November 2023).

- Hodgkinson, I.; Maletz, R.; Simon, F.G.; Dornack, C. Mini-review of waste-to-energy related air pollution and their limit value regulations in an international comparison. Waste Manag. Res. 2022, 40, 849–858. [Google Scholar] [CrossRef]

- Ma, W.; Cui, J.; Abdoulaye, B.; Wang, Y.; Du, H.; Bourtsalas, A.C.; Chen, G. Air Pollutant Emission Inventory of Waste-to-Energy Plants in China and Prediction by the Artificial Neural Network Approach. Environ. Sci. Technol. 2023, 57, 874–883. [Google Scholar] [CrossRef]

- European Environment Agency. Persistent Organic Pollutant Emissions in Europe; European Environment Agency: Copenhagen, Denmark, 2023.

- CEWEP. Dioxins and WtE Plants: State of the Art European-Wide Overview of Long-Term Analysis of Dioxins in WtE Plant Surroundings March 2022; CEWEP: Bruxelles, Belgium, 2022. [Google Scholar]

- IPCC. Climate Change 2022-Mitigation of Climate Change; Working Group III Contribution to the WGIII Sixth Assessment Report of the Intergovernamental Panel on Climate Change; IPCC: Geneva, Switzerland, 2022. [Google Scholar]

- Bhavsar, A.; Hingar, D.; Ostwal, S.; Thakkar, S.; Jadeja, S.; Shah, M. The current scope and stand of carbon capture storage and utilization—A comprehensive review. Case Stud. Chem. Environ. Eng. 2023, 8, 100368. [Google Scholar] [CrossRef]

- Krishnan, A.; Nighojkar, A.; Kandasubramanian, B. Emerging towards zero carbon footprint via carbon dioxide capturing and sequestration. Carbon Capture Sci. Technol. 2023, 9, 100137. [Google Scholar] [CrossRef]

- Jakobsen, J.; Roussanaly, S.; Anantharaman, R. A techno-economic case study of CO2 capture, transport and storage chain from a cement plant in Norway. J. Clean. Prod. 2017, 144, 523–539. [Google Scholar] [CrossRef]

- Su, D.; Herraiz, L.; Lucquiaud, M.; Thomson, C.; Chalmers, H. Thermal integration of waste to energy plants with Post-combustion CO2 capture. Fuel 2023, 332, 126004. [Google Scholar] [CrossRef]

- Christensen, T.H.; Bisinella, V. Climate change impacts of introducing carbon capture and utilisation (CCU) in waste incineration. Waste Manag. 2021, 126, 754–770. [Google Scholar] [CrossRef]

- Lausselet, C.; Cherubini, F.; Oreggioni, G.D.; del Alamo Serrano, G.; Becidan, M.; Hu, X.; Rørstad, P.K.; Strømman, A.H. Norwegian Waste-to-Energy: Climate change, circular economy and carbon capture and storage. Resour. Conserv. Recycl. 2017, 126, 50–61. [Google Scholar] [CrossRef]

- Lim, L.H.; Tan, P.; Chan, W.P.; Veksha, A.; Lim, T.T.; Lisak, G.; Liu, W. A techno-economic assessment of the reutilisation of municipal solid waste incineration ash for CO2 capture from incineration flue gases by calcium looping. Chem. Eng. J. 2023, 464, 142567. [Google Scholar] [CrossRef]

- Haaf, M.; Anantharaman, R.; Roussanaly, S.; Ströhle, J.; Epple, B. CO2 capture from waste-to-energy plants: Techno-economic assessment of novel integration concepts of calcium looping technology. Resour. Conserv. Recycl. 2020, 162, 104973. [Google Scholar] [CrossRef]

- Haaf, M.; Peters, J.; Hilz, J.; Unger, A.; Ströhle, J.; Epple, B. Combustion of solid recovered fuels within the calcium looping process–T Experimental demonstration at 1 MWth scale. Exp. Therm. Fluid Sci. 2020, 113, 110023. [Google Scholar] [CrossRef]

- Solis, M.; Silveira, S. Technologies for chemical recycling of household plastics—A technical review and TRL assessment. Waste Manag. 2020, 105, 128–138. [Google Scholar] [CrossRef]

- Ciuta, S.; Tsiamis, D.; Castaldi, M.J. Gasification of Waste Materials: Technologies for Generating Energy, Gas, and Chemicals from Municipal Solid Waste, Biomass, Nonrecycled Plastics, Sludges, and Wet Solid Wastes; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Keller, F.; Mamani Soliza, P.; Seidla, L.G.; Lee, R.P.; Meyer, B. Life cycle inventory data generation by process simulation for conventional, feedstock recycling and power-to-X technologies for base chemical production. Data Brief 2022, 41, 107848. [Google Scholar] [CrossRef] [PubMed]

- EUR 31423 EN; Environmental and Economic Assessment of Plastic Waste Recycling—A Comparison of Mechanical, Physical, Chemical Recycling and Energy Recovery of Plastic Waste. Joint Research Centre of European Community: Brussels, Belgium, 2023. [CrossRef]

- Voss, R.; Lee, R.P.; Seidl, L.; Keller, F.; Frohling, M. Global warming potential and economic performance of gasification-based chemical recycling and incineration pathways for residual municipal solid waste treatment in Germany. Waste Manag. 2021, 134, 206–219. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Qin, Z.; Tang, Y.; Liao, C.; Liu, Y.; Ma, X. Techno-environmental-economic assessment on municipal solid waste to methanol coupling with/without solid oxygen electrolysis cell unit. Process Saf. Environ. Prot. 2022, 161, 611–628. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).