Abstract

It is now widely confirmed by scientific evidence that greenhouse gas emissions must be reduced to counteract the effects of global warming. The production of heat for industrial purposes is responsible for 36.8% of world energy-related emissions due to the widespread use of fossil fuels. Heat pumps are a key technology in the transition towards more sustainable industrial processes. In this paper, a systematic review of the literature produced in the last 5 years in international journals regarding the integration of heat pumps in industrial processes is presented. Firstly, papers presenting innovative configurations for high temperature heat pumps (HTHP), i.e., heat pumps delivering temperatures in the range between 100 °C and 200 °C, suitable for many industrial processes but still under development, are reviewed. Then, papers reporting innovative solutions for the integration of heat pumps in specific industrial processes and sectors (e.g., distillation, drying, desalination, etc.) are analyzed. Finally, the literature about alternative low-GWP refrigerants for industrial heat pumps, both pure compounds and mixtures, is described. It is concluded that many progresses have been realized in the last 5 years (2020–2024) regarding the identification of innovative heat pumps for industrial applications, but further research is certainly required.

1. Introduction

Historically, the impact of greenhouse gas emissions on global climate change has been recognized since the early 1990s, leading to international agreements such as the United Nations Framework Convention on Climate Change (UNFCCC) [1], the Kyoto Protocol [2], and the Paris Agreement [3], which aim to reduce atmospheric greenhouse gasses and mitigate climate change. In recent years, many countries have committed to achieving carbon neutrality, with targets set as early as 2025 for Denmark and 2060 for China. These commitments highlight the global urgency of reducing greenhouse gas (GHG) emissions, particularly from industrial sources such as heating processes, which are responsible for significant emissions. The continued growth of industrial processes corresponds also to an increase in energy consumption and GHG emissions. In 2019, global primary energy consumption reached 178,899 terawatt hours (TWh), with fossil fuels accounting for 82.9% of this total [4]. Although the heat required by industrial processes constitutes only 19% of total energy demand, they are responsible for 36.8% of energy-related emissions, due to the predominance of fossil fuel boilers [5]. To meet the International Energy Agency (IEA) benchmarks for net-zero greenhouse gas emissions by 2050, industries must transition to sustainable and renewable energy sources, increasing the energy efficiency of industrial processes and reducing direct greenhouse gas emissions from fossil fuel combustion. Heat pumps, providing heat at temperatures up to 200 °C, emerge as a key technology in this transition. In particular, high temperature heat pumps (HTHP), delivering heat over 80 °C, are attractive and suitable for various industrial applications. Heat pumps can recover low-quality waste heat by requalifying it at higher temperatures, significantly improving energy efficiency compared to traditional heat production methods (primarily fossil fuel boilers). Recent papers highlight the importance of heat pump technology in industrial applications to reduce energy consumption and CO2 emissions, but also the technological challenges and barriers to their diffusion. Kosmadakis [6] maps the potential of industrial heat pumps across EU industries, focusing on waste heat recovery for decarbonization. Key findings include a total potential of 28.37 TWh/year, covering 1.5% of total heat consumption. Non-metallic minerals, food, paper, and non-ferrous metals show the highest potential. Results highlight the capability to cover 15% of heat consumption within the 100–200 °C range, mainly in nonferrous metals. The study underscores opportunities for heat pump applications in industry, emphasizing the need for site-specific assessments to fully realize this potential and address existing barriers effectively. Ononogbo et al. [7] highlight the use of heat pumps, including compression (CHP) and absorption (AHP) types, for upgrading waste heat (WH) for industrial processes and simultaneous heating and cooling applications. Hamid et al. [8] underscore the significant potential of HTHPs when integrated with various systems like thermal energy storage, waste heat recovery, and organic Rankine cycles. Challenges to widespread adoption include high costs, technological limitations, regulatory issues, and public acceptance. Golmohamadi [9] shows how industrial heat pumps play a significant role in enhancing the flexibility of industrial energy systems, aiding the integration of renewable energy by balancing power fluctuations. These systems are particularly effective in heavy industries like cement manufacturing, metal smelting, and oil refining, where energy-intensive processes can provide substantial power flexibility. Despite high potential, challenges include high costs and regulatory issues. Maruf et al. [10] address the complexity of modeling power-to-heat (P2H) and thermal energy storage (TES) technologies for large-scale energy systems in Europe. Electric heat pumps are identified among key P2H technologies and HTHPs are highlighted for their growing role in industrial sectors like food, paper, and chemicals. Studies show significant market potential for industrial heat pumps, though economic constraints limit their current use. The paper also discusses the importance of combined heat and power (CHP) systems and various TES technologies. Nandhini et al. [11] explore low-temperature waste heat (LTWH) recovery technologies, emphasizing the efficiency and environmental benefits of heat pumps. Hybrid absorption-compression heat pumps can recover up to 95% of waste heat, while air-source and CO2 transcritical heat pumps reduce energy consumption by 60–75%. Nanofluids like silver/pentane enhance system efficiency and reduce carbon footprints. Experimental and theoretical analyses of various heat pump configurations demonstrate significant energy recovery and efficiency improvements. Integrating heat pumps with power cycles, such as the organic Rankine cycle, boosts performance and energy output. Economic analyses indicate heat pumps are cost-effective with a maximum payback period of 16 years. Leonzio et al. [12] highlight air-source heat pumps (ASHPs) for water heating as a key technology for decarbonization. ASHPs can achieve high temperatures, with trans-critical cycles reaching up to 90 °C, and heat recuperative solutions potentially achieving up to 99 °C. Absorption cycles, though less studied, can reach up to 115 °C. Despite industrial ASHPs typically achieving lower temperatures, they offer significant energy, cost, and CO2 savings compared to traditional boilers, especially with renewable electricity. Integrating ASHPs with direct air capture (DAC) technologies can enhance efficiency and reduce environmental impact. Wang et al. [13] propose heat pumps as a key solution for reducing carbon emissions by efficiently using low-carbon electricity. Their study highlights the potential of heat pumps to support both heat and power decarbonization by offering flexibility on a gigawatt scale, which can aid in integrating variable renewable energy sources. Major challenges include high costs, complex system designs, and space constraints. Carmona-Martínez et al. [14] outline renewable energy (RE) technologies as crucial for decarbonizing Energy Intensive Industries (EIIs) by 2050. It classifies these technologies into those utilizing renewable electricity and those providing renewable heat, essential for industrial processes that cannot be electrified. Heat pumps, which cover various temperature needs, are identified as key technologies for these purposes. Rajablooa et al. [15] address the significant fossil CO2 emissions from the energy and industrial sectors, focusing on energy-intensive industries like metallurgy and chemicals. The role of heat pumps is highlighted in reducing fossil CO2 emissions from the energy sector, especially within energy-intensive industries like metallurgy and chemicals. They conclude that heat pumps are crucial for decarbonizing industrial processes by enhancing efficiency, integrating renewable energy, and reducing energy consumption.

The aim of this review is to update and summarize the scientific knowledge on industrial heat pumps through an exhaustive analysis of the literature from the last 5 years (2020–2024). A first goal is analyzing the most recent developments in HTHPs, with special attention to innovative configurations of the cycle, aimed at optimizing the performance in relation to boundary conditions and applications. Vapor compression cycles have mostly been considered, but also hybrid solutions with absorption cycles are included. Unlike common HPs, which are a mature technology, HTHPs are particularly interesting from a research point of view because they are under development and lots of enhancements have been proposed in recent years. A systematic bibliographic analysis has been performed through Google Scholar by using the specific keywords “industrial high temperature heat pumps”. The search has been performed limiting the period year per year (e.g., 2020), because in this way the search was more effective. The second goal is to describe the most recent proposals for the application of heat pumps in the most significant industrial sectors and processes. A specific search, again with Google Scholar, has been conducted using the keywords “industrial heat pump + specific sector/process” (e.g., “petrochemical”). Objectives and results of each relevant paper have been synthesized in such a way to give the reader enough information to be able to evaluate his interest for further in-depth analysis of the papers.

2. High Temperature Heat Pumps (HTHP) for Industrial Applications

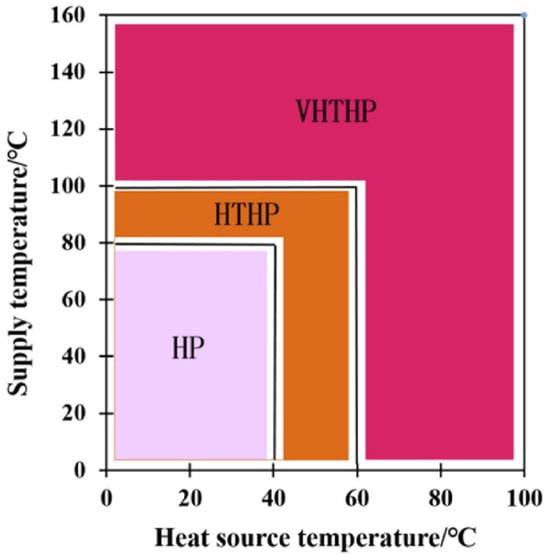

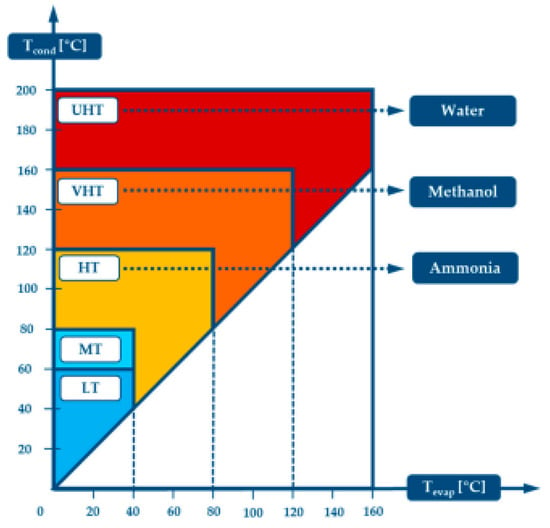

In the current literature, heat pumps are generally classified in three different groups, as shown in Figure 1: heat pumps (HP) for supply temperatures up to 80 °C; high temperature heat pumps (HTHP) from 80 °C to 100 °C; and very high temperature heat pumps (VHTHP) from 100 °C up to 160 °C (or even 200 °C) [16]. For convenience, in this paper, we will use the acronym HTHP for both HTHPs and VHTHPs.

Figure 1.

The classification of vapor compression heat pumps [16].

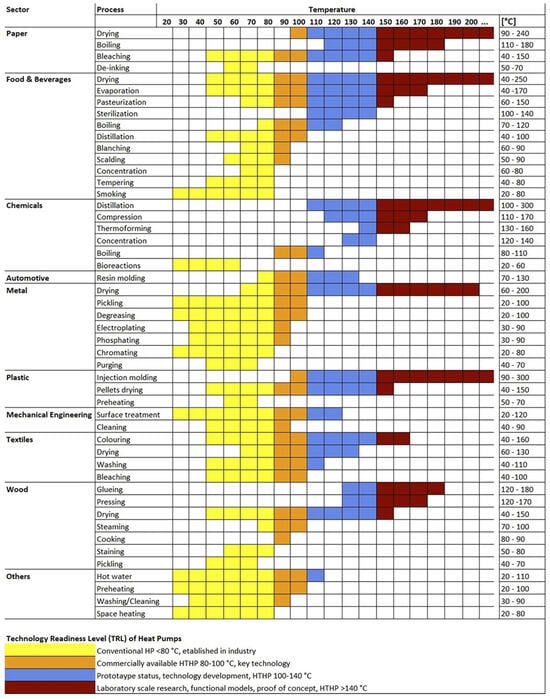

While common HPs, mostly used to deliver domestic hot water (DHW) and heating for residential and commercial buildings, are well consolidated and widely commercially available, HTHPs show a vast potential in industrial applications, but the technology remains under-explored, with limited commercial availability at temperatures over 90 °C. Currently, most commercial heat pumps provide heat up to a maximum of 90 °C, while there are still a few cases where the temperature can reach the temperature range between 120 °C and 160 °C. HTHP technology is suitable for many industrial processes that require high temperatures, such as drying, thermal separation, and steam generation, in sectors such as food, paper, chemicals, metals, and plastics. Figure 2 summarizes the situation, highlighting the supply temperature range required by the most important industrial processes and the corresponding Technology Readiness Level (TRL) of the available HTHPs.

Figure 2.

Overview of processes in different industrial sectors structured by typical supply temperature ranges and Technology Readiness Level (TRL) of heat pumps [10,17].

Current research on vapor compression HTHPs focuses on both subcritical and transcritical cycles, but absorption cycles also offer interesting opportunities that are being studied. In any case, to optimize the efficiency of the heat pump, a careful choice of its most appropriate configuration is needed (e.g., standard cycle, use of internal exchanger, economizer, intercooling, parallel compression, multistage compression, cascade cycle, etc.) in relation to the type of application and boundary conditions, with particular reference to the heat sink temperature and the temperature lift between source and sink. The integration of HTHPs with renewable energy sources and waste heat recovery systems can further improve their efficiency and sustainability. Furthermore, HTHPs can increase the flexibility of energy networks by acting as electricity demand response tools to support the integration of intermittent renewable energy sources.

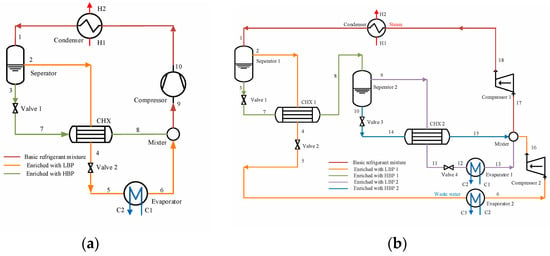

In this paragraph, we concentrate on the recent literature on HTHPs, with particular attention to the proposal of new effective configurations to meet the requirements of the specific industrial processes where they must be integrated. Some recent papers report a general analysis of the possible configurations and applications of HTHPs. The review of Adamson et al. [18] compiles 49 high-temperature or transcritical heat pump cycle structures and identifies 10 performance-enhancing components. It addresses six technical challenges, proposing solutions including a new transcritical-transcritical cascade cycle. The review suggests that new transcritical cycles, with further research, can enhance COP, making them competitive with alternative fuels up to 200 °C and achieving mean temperature lifts around 100 °C. Tveit et al. [19] explore the growing adoption of high temperature heat pumps (HTHPs) in industries driven by environmental concerns and energy system electrification. These devices, including VHTHPs, address heat demands above 100 °C not met by conventional systems. Evaluating their environmental impact involves complexities like system efficiency, coefficient of performance (COP), and electricity source emissions. The paper employs thermodynamic tools like exergy and Pinch analysis with European energy data, alongside a life cycle impact assessment (LCA). Comparing a Stirling engine-type VHTHP with conventional heaters illustrates environmental benefits, though LCA demands extensive data and interpretation effort, while simpler analyses like Pinch or exergy offer clearer results at the cost of detail. Jiang et al. [20] review laboratory-scale HTHPs with heat sink temperatures over 80 °C, exploring single-stage, multi-stage, cascade, and hybrid systems. About 71% of prototypes use low-GWP refrigerants, some achieving temperature lifts above 100 °C. Industrial HTHPs range from 60 kW to 18 MW, mostly using high-GWP refrigerants like R245fa and R134a. The paper identify some key perspectives for HTHPs, the most important of which are: low-GWP refrigerants, higher output temperatures (>100 °C), heating capacities over 1 MW, and COPs above 4 under a 40 °C lift; HTHPs need further development to handle higher temperature lifts, with research gaps above 100 °C output and COP > 4; the focus should shift from conventional cycles to new transcritical cycles for better performance at high temperatures; large-capacity HTHPs, proven effective in some applications, require further customization and cooling technology improvements for safe, high-temperature operations; future advancements should aim to achieve all four key prospects for HTHPs, creating an “Ultra Heat Pump.” The review of Hamida et al. [8] examines future HTHP improvements, addressing technical obstacles and integrating HTHPs into processes like thermal energy storage, waste heat recovery, and more. Challenges include technological limitations, high costs, regulatory uncertainties, policy issues, and public acceptance. The review consolidates data on HTHPs in industrial applications, emphasizing single-stage and multi-stage systems, vapor compression, absorption, hybrid systems, and novel combinations. It highlights issues such as compressor discharge temperature, lubrication, oil-free operation, and new developments, suggesting future research directions like refrigerant charge management and flash tank cycle control. Improving understanding among stakeholders and addressing integration costs and alternative heating technologies are essential for broader HTHP adoption. Mateu-Royo et al. [21] investigated high temperature heat pumps (HTHPs) for industrial waste heat recovery, evaluating eight advanced cycle configurations and nine low GWP refrigerants. Configurations like TS Cascade excel at high temperature lifts (>60 K), while single-stage setups with economizers suit lower lifts (<50 K). Refrigerants HCFO-1233zd(E) and HCFO-1224yd(Z) balance COP and volumetric capacity, crucial for energy-efficient applications. Significant CO2 reductions (up to 68%) compared to natural gas boilers highlight environmental benefits. Economically, advanced configurations show slight cost variations (~9%) from a reference TS Economizer cycle, proving viable for industrial adoption. Less recently, Arpagaus et al. [17] reviewed HTHPs with heat sink temperatures of 90–160 °C. Heat pump cycles and refrigerants were analyzed, identifying over 20 HTHPs from 13 manufacturers, suitable for industries like food, paper, metal, and chemicals, with capacities from 20 kW to 20 MW. Most HTHPs are single stage, using refrigerants like R245fa, R717, R744, R134a, and R1234ze(E). COPs range from 2.4 to 5.8 at a 95–40 K temperature lift. Research aims to improve COPs and temperatures, achieving up to 160 °C with refrigerant R1336mzz(Z). Key findings include potential for 113 PJ of process heat in Europe and barriers like insufficient integration knowledge, refrigerant availability, and electricity costs.

The next paragraphs are dedicated to the analysis of the literature reporting more specific cases of solutions for HTHPs, defined on the base of the numerosity of paper published in the last 5 years, i.e., cascade, transcritical, and hybrid absorption-compression heat pump systems. Single cases are grouped in the paragraph “other solutions”.

2.1. Cascade Heat Pump System

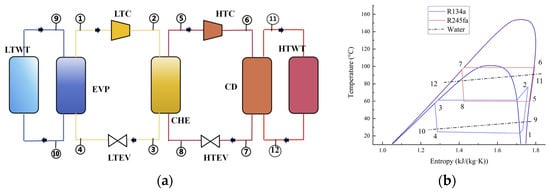

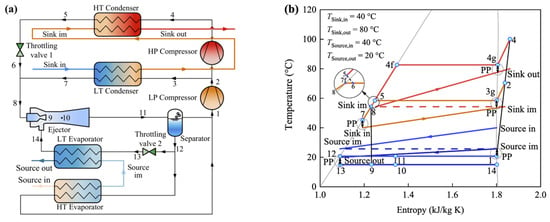

The most studied configurations for HTHPs cycles in the last 5 years are those based on cascade high-temperature heat pumps (CHTHPs), applying different refrigerants as working fluids. Figure 3 reports the scheme for a typical CHTHP system, with the corresponding T-s diagram of the cycle. Hu et al. [22] evaluated CHTHPs for recovering low-temperature industrial waste heat using conventional and advanced exergy and exergoeconomic analyses. Results highlight that 62.26% of the exergy destruction in CHTHP systems is avoidable, mainly attributed to component inefficiencies: thus, CHTHP systems still have significant potential for improvement. The exergoeconomic factor is notably low at 0.75%, emphasizing high exergy destruction costs. The high- and low-temperature compressors are identified as critical areas for improvement due to their significant exergy destruction.

Figure 3.

(a) Schematic diagram of a CHTHP system with (b) the corresponding T-s diagram [22].

Dong and Wang [23] analyze cascade high-temperature heat pump (CHTHP) configurations and fluid pairs across multiple criteria, emphasizing their suitability for utilizing ultra-low-grade waste heat efficiently. Key findings include the optimal Δtlift ≥ 70 °C for cascade configurations, shifting to two-stage, single-stage with injection, and single-stage setups as Δtlift decreases. Preferred fluid pairs such as R1234ze(E), R1234ze(Z), R1224yd(Z), R1233zd(E), and R1336mzz(Z) demonstrate trade-offs in COP, cost, exergy efficiency, and TEWI. Schlemminger et al. [24] investigate a newly developed industrial propane-butane CHTHP designed for simultaneous cooling and heating in applications like dairy production. Featuring a semi-hermetic compressor for high-temperature operation, it achieves a temperature lift of 88 K to 108 K, with peaks at 125 K between evaporation and condensation. The system, installed in a Norwegian dairy, supplies hot water at 112 °C from ice water at 0.5 °C, yielding a COP of 3.0 to 4.0. The HTHP reduces energy consumption by up to 64% and CO2 emissions by up to 94%, suitable for both retrofit and new installations. Dai et al. [25] introduce CHTHP systems in comparison to conventional HTHPs and boilers. Five optimized layouts are proposed and evaluated using models for energy consumption, emissions, life cycle cost (LCC), and payback period (PBP). The cascade-heating water-cooled saturated system (CWSAS) (Figure 4) demonstrates significant advantages: 1.8–22.8% lower primary energy consumption (PEC) compared to HTHPs and boilers, 1.7–6.1% lower life cycle carbon emissions than HTHPs, and superior pollutant emission reductions. CWSAS emerges as the optimal choice for its comprehensive performance in energy efficiency, environmental impact, and economic feasibility in recovering waste heat from oil fields for hot water and steam production.

Figure 4.

Cascade heating water cooled saturated suction system (CWSAS) [25].

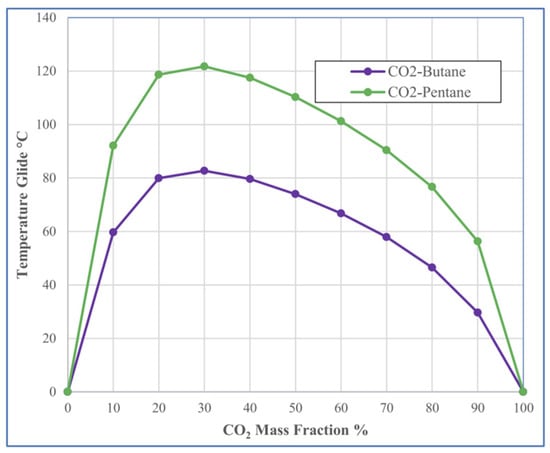

Dong et al. [26] focus on optimizing CHTHP design parameters considering both thermodynamic and economic performance. Using a multi-objective optimization model with improved genetic algorithms, key parameters like evaporation and condensation temperatures were determined. Optimal values were found for certain conditions, showing slight variations with different operational scenarios. Results indicate that condensation temperature increases with output water temperature, while heat source temperature minimally affects optimal temperatures for constant output water conditions. Wu et al. [27] introduce a HTCHP system designed to recover waste heat from a chemical plant and replace steam, emphasizing economic and thermodynamic performance via a developed mathematical model. Simulation results with a multi-objective optimization method confirm system stability and feasibility under varying conditions. Optimal conditions at 71 °C heat source inlet and 145 °C condensing temperature yield a heating capacity of 498.9 kW and a 3.9-year payback period. Key conclusions highlight improved COP and exergy efficiency with higher inlet temperatures, ANP sensitivity to heating capacity variations, and favorable payback periods under specific economic conditions, validating HTCHP as a viable industrial solution. Ganesan et al. [28] explore a two-stage CHTHP using natural zeotropic refrigerants to produce hot water exceeding 100 °C, reaching up to 118 °C. MATLAB simulations were employed to design and analyze the HTHP model, highlighting its robust performance metrics including high heating capacity (up to 205 kW) and a total COP of 4.5. The system’s use of CO2 + butane and CO2 + pentane mixtures (see Figure 5 for the temperature glide) in the Low-stage (LS) and High-stage (HS) cycles, respectively, demonstrated efficient heat transfer capabilities. Comparison with published results indicates a notable 36% COP improvement potential, emphasizing the system’s advancement in achieving high-temperature heating efficiently.

Figure 5.

Temperature glide of the zeotropic mixtures employed by [28,29].

Ganesan et al. [29] present a modeling and optimization approach for a CHTHP using CO2/butane and CO2/pentane mixtures in the LS and HS cycles, respectively, for industrial high-temperature heating. The MATLAB-based model explored heating capacities up to 201.5 kW and COP improvements of 20% compared to pure fluids, showcasing the efficacy of the refrigerant mixtures. Analysis highlighted the influence of CO2 composition on heat sink temperatures and system performance, with notable impacts on COP and efficiency metrics. Navarro-Esbrí et al. [30] evaluate a two-stage CHTHP system (Figure 6), aiming to produce hot water up to 150 °C from inlet temperatures of 35 °C and 25 °C. Using experimental data from single-stage prototypes (R-1234ze(E) and R-1336mzz(Z)), a semi-empirical model assesses energy performance with novel refrigerant mixtures like R-152a/600 and R-1233zd(E)/161 for the two stages, achieving up to 14% higher COP compared to baselines. Despite a 30% increase in volumetric heat capacity (VHC), negligible direct CO2 emissions are observed due to low GWP refrigerants.

Figure 6.

Schematic representation and P-h diagram of the two-stage cascade HTHP [30].

Chen et al. [31] introduce a novel vapor injection autocascade heat pump (VAHP) for high-temperature water heating. Through simulation-based investigations, it outperforms conventional autocascade systems with a 51.8% increase in COP and 104.3% in capacity at evaporating temperatures from 0 °C to 20 °C. Exergy analysis highlights reduced irreversible losses in throttling valves and cascade condensers, enhancing overall performance. The VAHP shows competitive energy costs and minimal pollutant emissions compared to conventional boilers. Kezier et al. [32] propose a novel semi-cascade heat pump system (Figure 7a) designed to enhance energy efficiency across varied temperature lifts. Operating in single-stage, conventional cascade, and semi-cascade modes, it adapts to ΔTsource-sink from 20 to 110 °C and ΔTsink from 10 to 100 °C. A validated thermodynamic model evaluates each mode’s performance, revealing that the single-stage mode suits small ΔTsource-sink and ΔTsink, while the conventional cascade is optimal for larger ΔTsource-sink and smaller ΔTsink (see Figure 7b). Semi-cascade mode maintains high efficiency over a wide range. Compared to conventional cascade, the novel system achieves up to 22.3% energy efficiency improvement, making it promising for diverse temperature lift applications.

Figure 7.

(a) Schematic of semi-cascade heat pump system and (b) operating range for each mode of the semi-cascade system [32].

Chen et al. [33] introduce a novel solar-assisted vapor injection autocascade high-temperature heat pump (SVAHP) designed to overcome insufficient heating performance limitations. It operates in two modes to efficiently utilize solar and air energy. Theoretical investigations highlight the SV mode’s superiority over the simple vapor injection autocascade heat pump (VAHP) under solar radiation exceeding 200 W/m2. SVAHP shows average improvements of 16.5% in maximum heating COP and 18.1% in heating capacity compared to VAHP. It exhibits the lowest life cycle cost and air pollutant emissions, with payback periods of 2.06 years and 2.95 years relative to VAHP and the basic autocascade heat pump (ACHP), respectively.

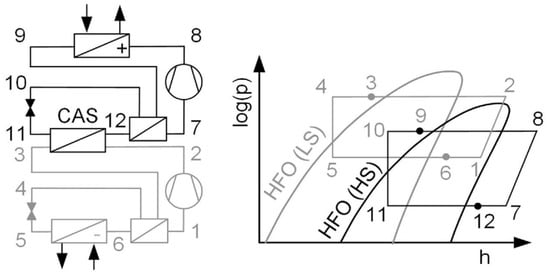

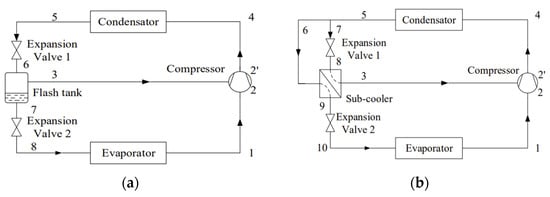

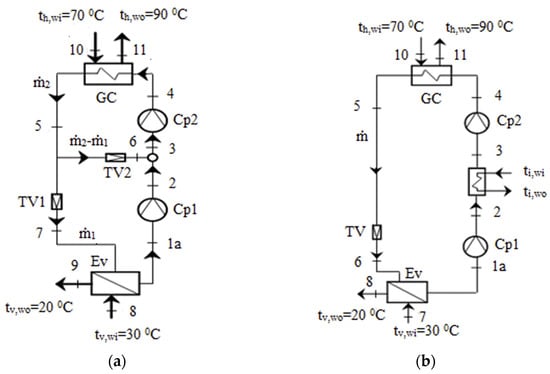

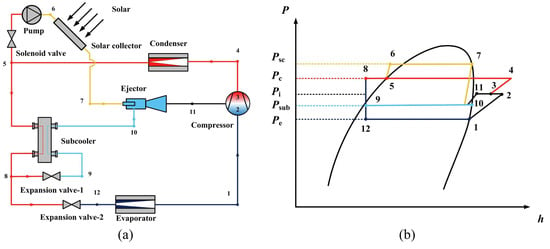

2.2. Transcritcal Heat Pump Systems

A significant interest has been found in the literature about heat pumps working with transcritical cycles. Zhao et al. [34] introduce high-temperature transcritical heat pump cycles using R1233zd(E), R1336mzz(Z), n-Butane, and ammonia for heating applications up to 200 °C in spray-drying processes. Emphasizing optimal COP through compressor pressure ratio optimization, R1233zd(E) emerges with a leading COP, balancing first- and second-law efficiencies with gas cooler sizing considerations. Despite ammonia’s favorable pressure ratio, its complexity and size requirements highlight R1233zd(E) as the most promising option due to its safety, efficiency (COP of 3.6), and operational practicality at lower pressures. Yang et al. [35] compare high-temperature heat pumps with flash tank vapor injection (FTVC, Figure 8a) and sub-cooler vapor injection (SVIC, Figure 8b) configurations across various operational parameters. FTVC demonstrates superior COP, injection mass flow ratio, and volumetric heating capacity (VHC) compared to SVIC at 4 different injections and superheats (0 °C, 5 °C, 10 °C, 20 °C) under similar conditions. FTVC maintains discharge temperatures comparable to SVIC-0 but lower than SVIC-5, SVIC-10, and SVIC-20. However, caution is advised regarding potential wet compression at low compressor suction superheat, impacting system performance and safety. Key factors influencing COP include compressor isentropic efficiency, evaporation, and condensation temperatures, while suction superheat and subcooling have lesser effects. At 55 °C evaporation, 125 °C condensation, and 921.4 kPa injection pressure, FTVC achieves the highest COP of 4.49, outperforming SVIC configurations.

Figure 8.

Principle diagram of the vapor injection heat pump with (a) flash tank and (b) sub-cooler [35].

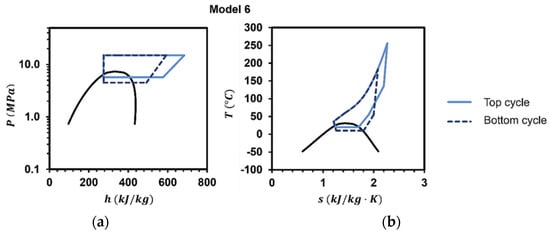

Kong et al. [36] investigate HTHPs using transcritical-transcritical cascade CO2 cycles with internal heat exchangers (IHX) to achieve 200 °C sink temperatures (in Figure 9a,b, an example of the P-h and the T-s diagrams, respectively). The evaluated cycles show that incorporating IHX in both top and bottom cycles lowers maximum discharge pressure by up to 1.27 MPa compared to single-stage configurations, enhancing COP to 2.22 for 200 °C air outlet temperatures. Despite increased exergy destruction with IHX, their strategic placement mitigates losses during expansion, optimizing performance.

Figure 9.

(a) P-h and (b) T-s diagram for one of the HTHP models analyzed by [36] for a sink temperature of 200 °C.

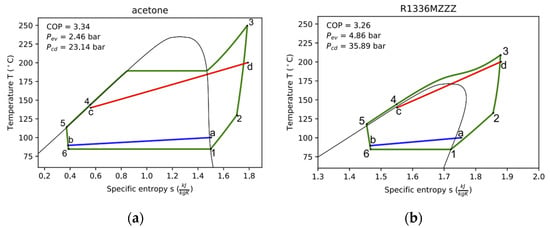

Udroiu et al. [37] propose a transcritical high-temperature heat pump (THTHP) utilizing R1336mzz(Z) to achieve temperatures up to 250 °C, feasible due to the refrigerant’s thermal stability at this range. Computational models of the cycle, with and without internal heat exchangers, explore optimal parameters like evaporation, gas cooler temperatures, and superheating degrees. Results show COP enhancements from 2.5 to 5.9 by varying evaporation temperature (80 °C to 140 °C) and from 3.2 to 7 with superheating degree adjustments (20 °C to 100 °C). System efficiency peaks at COP 3.3 under a 150 °C temperature lift. Vieren et al. [38] proposes a thermodynamic model for optimizing transcritical cycles in industrial heat pumps up to 200 °C, focusing on three case studies: thermal oil heating, superheated steam drying, and spray drying with heat sink temperature glides of 60 K, 81 K, and 105 K, respectively. The T,s diagrams for the best performing subcritical and subcritical cycle are reported in Figure 10a and 10b, respectively. The model identifies that transcritical cycles outperform subcritical ones with temperature glides above 60 K, achieving up to 7.3% higher COP. The preferred working fluids, such as HFOs and HCFOs, offer superior performance in transcritical cycles, providing higher volumetric heating capacities and lower pressure ratios, despite requiring compressors capable of handling pressures up to 60 bar.

Figure 10.

T,s-diagram, with scaled entropy for secondary fluid, for the best performing subcritical cycle (a) and transcritical cycle (b) [37,39].

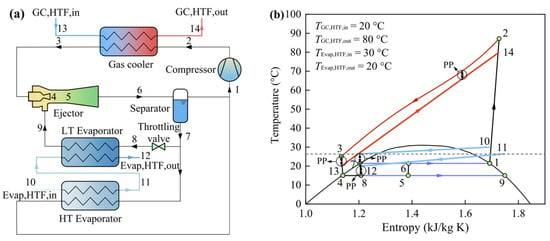

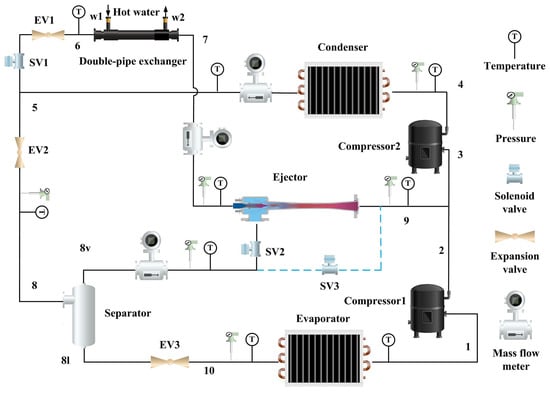

Dai et al. [39] propose three novel transcritical CO2 HTHP systems (Ej-Evap2-A, Ej-Evap2-B, and Ej-Evap2-C) featuring dual-temperature evaporation using an ejector for industrial waste heat recovery. Compared to traditional boilers, these systems are evaluated using comprehensive life cycle models focusing on energy, exergy, emissions, and economic aspects. Ej-Evap2-C achieves a maximum COP of 4.85, 14.40% higher than baseline systems, with exergy efficiency improvements of 7.86–15.19%. The scheme and the T-s diagram for the Ej-Evap2-C cycle are reported in Figure 11. It exhibits the lowest emissions and life cycle costs, with a payback period under 7 years, making it a promising alternative for high-temperature heating applications.

Figure 11.

(a) Dual-temperature evaporation transcritical CO2 heat pump system C with ejector (Ej-Evap2-C). (a) Schematic. (b) T,s diagram [39].

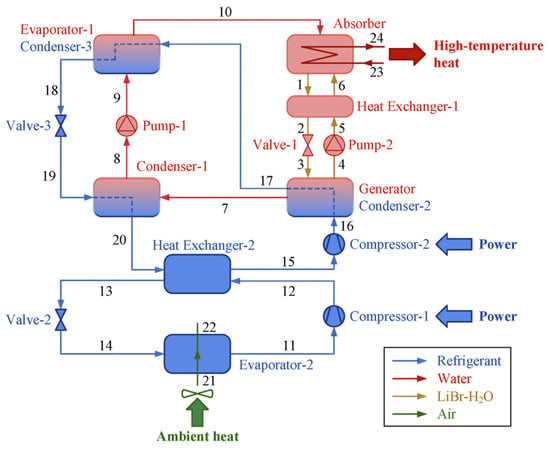

2.3. Hybrid Absorption-Compression Heat Pump System

Thermally coupled hybrid absorption-compression heat pump cycles raise some interest because they could achieve large temperature lift and high output temperature. You et al. [40] explore thermally coupled hybrid absorption-compression heat pump cycles for high-temperature industrial applications, highlighting their potential but also the challenges from multiple heat exchange processes causing performance degradation. Entransy dissipation analysis is introduced to evaluate irreversibilities and optimize heat exchange components, showing up to 3.92% COP improvement by reducing internal heat recovery irreversibilities. The optimal coupling temperature of 73.9 °C, aligns with enhanced COP and minimized exergy destruction, demonstrating the efficacy of entransy analysis in optimizing thermal system performance and guiding heat pump design improvements. Kosmadakis [6] explores three-stage hybrid absorption-compression heat pump (HACHP) cycles for enhancing temperature lift in air-source systems, crucial for industrial heat applications. Internal heat recovery configurations are investigated to boost output temperatures (100–190 °C) and COP (1.26–2.23) under 30 °C ambient. The proposed enhanced HACHP (EHACHP) overcomes HACHP limitations, achieving up to 190 °C output and 170 °C temperature lift, with 13% higher COP under 100 °C lift. Figure 12 reports the schematic diagram of the EHACP cycle. Despite higher refrigerant pressures, EHACHP offers a broader operational range and superior performance, laying the groundwork for advanced high-temperature heat pump applications in diverse industrial settings.

Figure 12.

Schematic diagram of the EHACHP cycle, where the exhaust heat is recovered to medium-temperature stage. The blue blocks represent VCHP sub-cycle, the red blocks represent AHT sub-cycle, and the blocks with gradient color from blue to red are the coupling component [6].

2.4. Other Solutions

Several other configurations of HTHPs have been proposed in the literature in the search for innovative and efficient solutions to enhance their performance. Dai et al. [41] propose dual-temperature condensation and dual-temperature evaporation (Ej-DCDE) heat pump systems for high-temperature industrial heating, integrating ejector and two-stage compression technologies. Comparative analyses with five existing heat pumps and four boilers highlight Ej-DCDE-2 (see Figure 13) as optimal, achieving a COP of 4.25, which is 11.55% and 1.43% higher than dual-temperature condensation and single-temperature evaporation HP and Ej-DCDE-1, respectively. It reduces exergy destruction by 27.88% and primary energy consumption by 22.19% compared to baseline systems. Ej-DCDE-2 also exhibits the lowest CO2 emissions and life cycle cost (LCC), surpassing traditional boilers by significant margins, making it highly recommended for industrial heating applications.

Figure 13.

Dual-temperature condensation and dual-temperature evaporation HP 2 with an ejector (Ej-DCDE-2). (a) System diagram. (b) T-s diagram [41].

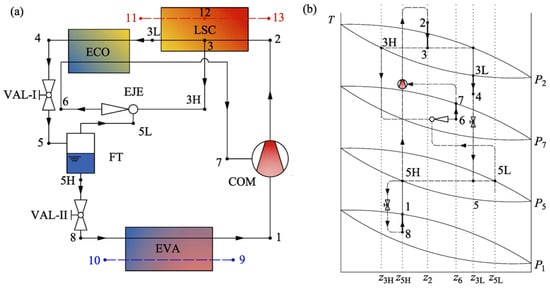

Huang et al. [42] introduce a novel vapor-injected high-temperature heat pump (LEHP) integrating a liquid-separation condenser (LSC) and an ejector for zeotropic mixture composition adjustment. The scheme and the T-z diagram for the LEHP cycle are reported in Figure 14. Compared to conventional heat pumps, LEHP achieves a 21.86% higher coefficient of performance (COP). Parametric studies show benefits from adjusting vapor quality and flash tank pressure to enhance system performance and temperature matching. Genetic Algorithm mappings reveal optimal zeotropic mixtures: Propane/Cyclobutene below 30 °C, Cyclopropane/Pentane or Cyclopropane/Hexane from 40 °C to 50 °C, and Butene/Cyclohexane above 50 °C. Butene/Cyclohexane exhibits the highest COP and exergy efficiency.

Figure 14.

(a) Schematic view of LEHP and (b) its T-z diagram [42].

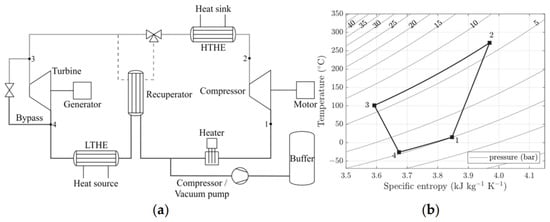

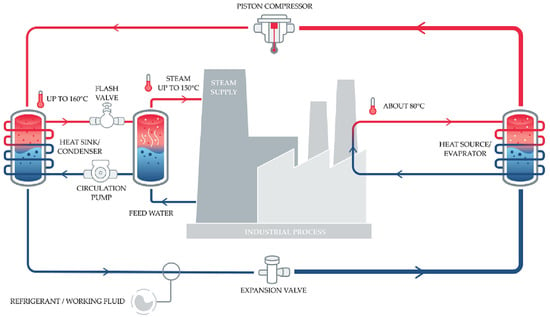

Wang et al. [43] explore the feasibility of using Advanced Nuclear Reactors to supply high-quality heat to Industrial Processes. While Advanced Reactors offer higher operating temperatures than Light Water Reactors, their steam characteristics generally do not align with industrial needs without additional modifications. Proposals include enhancing steam quality through heat pumps, analogous to refrigeration technology, to raise steam temperatures to 900 °C. The scheme of the Brayton heat pump and the T-s diagram for the cycle are reported in Figure 15. Numerical examples from a Pressurized Water Reactor demonstrate improved thermal efficiencies when integrating a compressor to boost steam heating values, compared to direct electric heating methods. Pettinari et al. [44] investigate Brayton heat pumps as a pivotal technology for integrating renewables into grids, focusing on their adaptability and performance in industrial and energy storage settings. Emphasizing high-temperature heat supply via renewable electricity, these systems undergo evaluation through demonstration plants. The research assesses transient capabilities using a prototype model, exploring thermal and volumetric dynamics.

Figure 15.

Brayton heat pump developed by DLR: (a) plant layout; (b) T-s diagram [44].

Briola et al. [45] introduce a novel high-temperature heat pump (HTHP) utilizing low-temperature waste heat via two-phase compressors and expanders, operating without external electric power. The scheme of novel HTHP is reported in Figure 16. A sensitivity analysis of five variables identifies optimal conditions for a rubber manufacturer and a canning industry, achieving maximum COP values of 0.258 and 0.452, respectively. The system’s economic viability hinges on achieving isentropic efficiencies above 0.59 for compressors, above 0.55 for expanders in the rubber industry, and above 0.45 in the canning industry. Key contributions include overcoming current HTHP limitations with efficient performance across high temperature differentials and no electric consumption, benefiting diverse industrial heating needs with significant energy and cost savings potential.

Figure 16.

Novel HTHP system: circuital scheme [45].

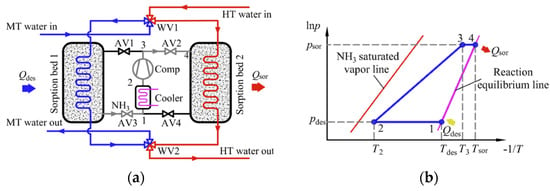

Xie et al. [46] introduce a novel ammonia-based hybrid chemisorption-compression high-temperature heat pump using SrCl2-NH3 to efficiently convert 50–80 °C waste heat into 90–120 °C high-temperature heat without requiring a costly high-pressure ammonia compressor. Figure 17 reports the scheme and the lnp-(1/T) diagram of the cycle. Key parameters like sorption pressure and reaction time are optimized, achieving a COP of 4.58 at 70 °C waste heat and 110 °C output, 14.5% higher than R245fa compression pumps.

Figure 17.

Hybrid chemisorption-compression high-temperature heat pump cycle: (a) schematic and (b) lnp-T diagram (HT: high temperature, MT: medium temperature) [46].

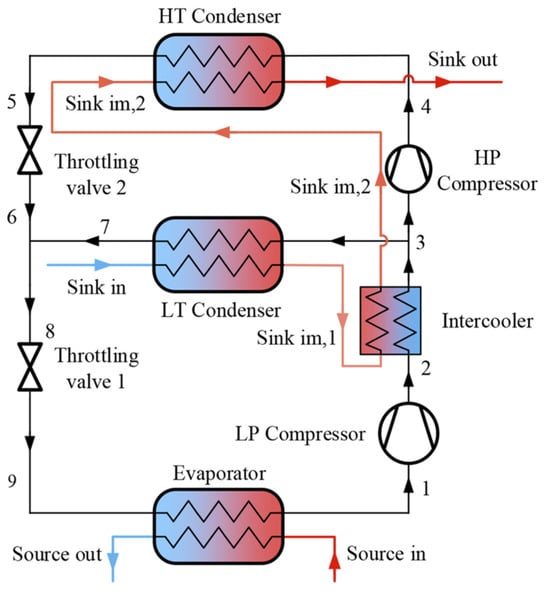

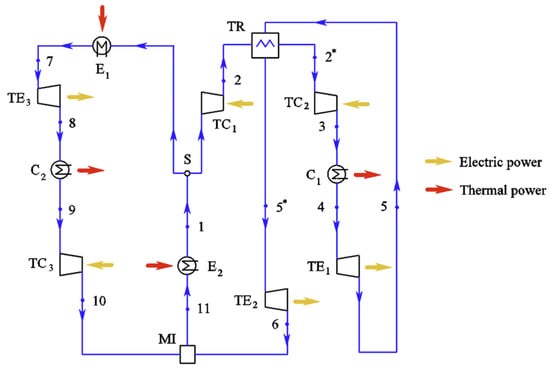

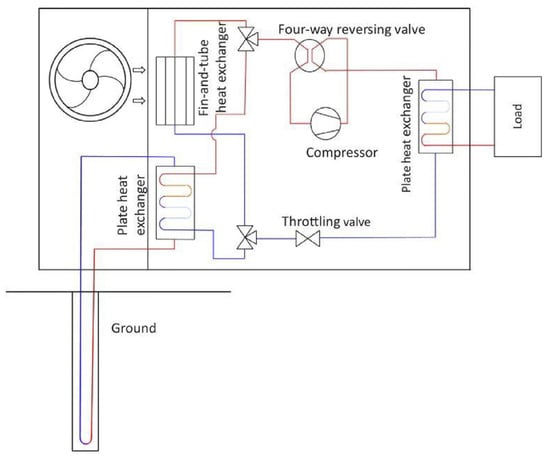

Kim et al. [47] explore HTHPs using water vapor (R-718) in three reversed Rankine cycles with varied intercooling strategies to deliver thermal energy above 200 °C. Thermodynamic analyses revealed optimal performance with equal pressure ratios (PR) across compressors, enhancing efficiency metrics such as φ and ηexergy. Among cycles tested, the cycle with intercooler (IC) between the first and second compression stages and with an inward flow direction of heat sink to the IC (IC-in cycle) showed superior COP and Tsink out values compared to spray-injection and IC-out cycles, achieving a COP of 5.86 and Tsink out over 200 °C at practical PR limits (PR < 2.5). Marinelli et al. [48] conduct a comprehensive life cycle assessment (LCA) of a dual-source heat pump (DSHP), utilizing air or ground as heat sources, with data provided by the manufacturer. Figure 18 reports the layout of the DSHP prototype. The study covers production, use, maintenance, and end-of-life phases, using dynamic simulations for energy performance evaluation. Results highlight the DSHP’s environmental benefits in respect to conventional air and ground source heat pumps, especially in varied energy scenarios and climates.

Figure 18.

Layout of the DSHP prototype [48].

Zhang et al. [49] introduce a high temperature heat pump double effect evaporation concentration system to enhance energy efficiency in low vacuum, low temperature evaporation processes. An industrial experimental platform validates its performance, achieving a heat pump COP of 4.92 and 11.86 kg/(kW·h) unit power consumption evaporation. Key conclusions highlight system feasibility and stability, with insights into heat transfer performance under variable conditions and economic analysis supporting energy-efficient operations and future system advancements. Talaba et al. [50] focus on high-temperature water heating using CO2 heat pumps, highlighting their efficiency compared to electric heating. One-stage and two-stage configurations are parametrically tested to optimize structure and operation, aiming to minimize exergy destruction. Th flow chart of the cycles is reported in Figure 19. While two-stage systems show potential with external precooling, exergy coefficients in gas-coolers play a crucial role.

Figure 19.

Flow chart of (a) two-stage system with the injection of a cold stream between the two compression stages and (b) two-stage cycle with intermediary external cooling by preheating a stream of water [50].

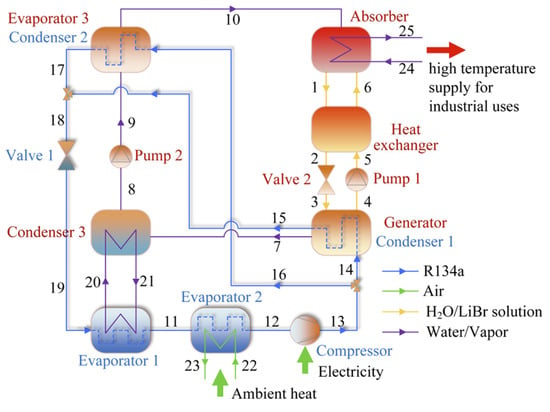

Stefanou [51] focuses on high-temperature heat pumps (HTHPs) as crucial for industrial heat decarbonization above 90 °C. Two prototypes were developed and tested: the first, integrated into a district heating loop, achieved temperatures limited by external factors, while the second, using environmentally friendly R1233zdE, operated under controlled conditions. The first prototype employed R245fa, achieving COP of 5.3–6 with heating capacity up to 43.7 kW and saving 1.44 tnCO2/yr. The second prototype achieved outlet temperatures up to 123.4 °C, with COP values ranging from 2.5 to 4.5 and efficiencies up to 85%. Economic analysis showed payback periods from 2.3 to 3.4 years, highlighting significant CO2 emissions savings, up to 85%, compared to gas boilers. Gao et al. [52] proposed a novel air-source hybrid absorption-compression heat pump for stepped temperature lifts. The scheme is reported in Figure 20. It achieves a large temperature lift (over 90 °C) and thermodynamic perfectibility (0.34). The coefficient of performance (COP) changes from 1.7 to 1.2 as temperature lifts from 70 °C to 110 °C. Internal heat recovery reduces heat exchanger area and cost. This system offers a feasible and efficient method for upgrading ambient heat for industrial uses.

Figure 20.

Schematic diagram of the air-source hybrid absorption-compression system [52].

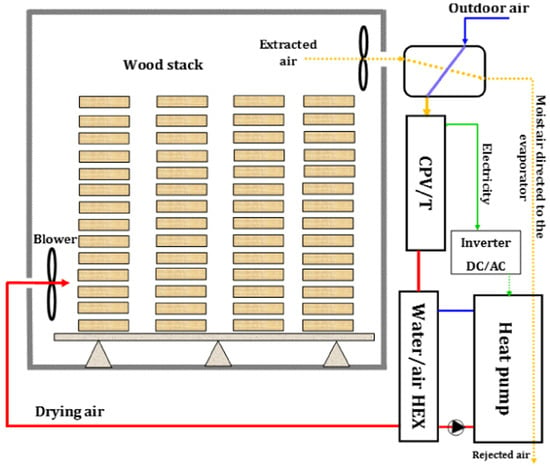

3. Industrial Heat Pumps Applications by Sector

As already said, heat pumps, and particularly HTHPs, are a very promising solution to improve the energy efficiency of industrial processes and to reduce CO2 emissions. However, every industrial process has its own necessities, and heat must be recovered at different source temperatures and released at different sink temperatures, thus requiring specific heat pump configurations to optimize the performance. In this paragraph, the objectives and the results of the most relevant papers published in the last 5 years dealing with innovative and specific solutions for the application of heat pumps in the main industrial sectors will be synthesized.

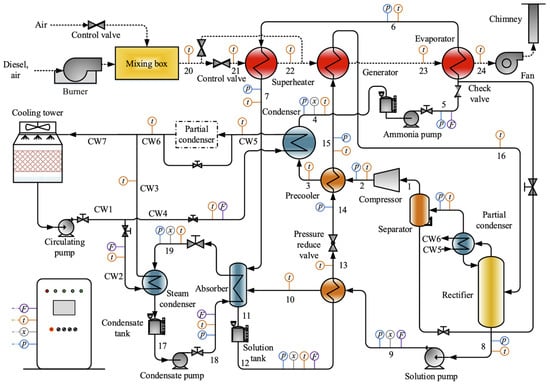

3.1. Chemical and Petrochemical Industries

The chemical and petrochemical sector is of vital economic importance. Global production amounted to 5.7 trillion United States dollars (USD) in 2017, including pharmaceuticals. Production is projected to quadruple by 2060 [53]. The supply of process heat in the chemical industry is dominated by fossil fuel combustion. The chemical and petrochemical sector is a major contributor to global industrial CO2 emissions, ranking third behind iron- and steelmaking and cement production. These sectors produce1.6 gigatonnes (Gt) of CO2 per year total direct emissions and0.6 Gt of CO2 per year of indirect emissions [54]). However, it could be supplied by vapor compression heat pumps (VCHPs), allowing for efficient electrification. VCHPs could supply heat with temperatures up to 200 °C and, as shown by Marina et al. [55], they are able to cover 614 PJ/a (171 TWh/a) in the EU-28, with the chemical sector having the largest opportunity (283 PJ/a).

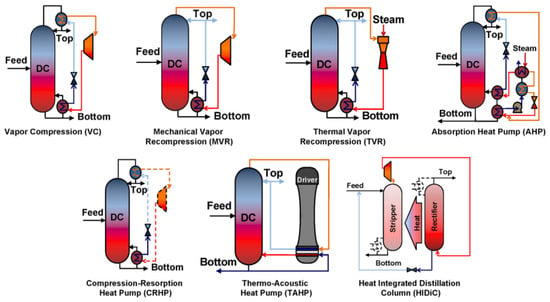

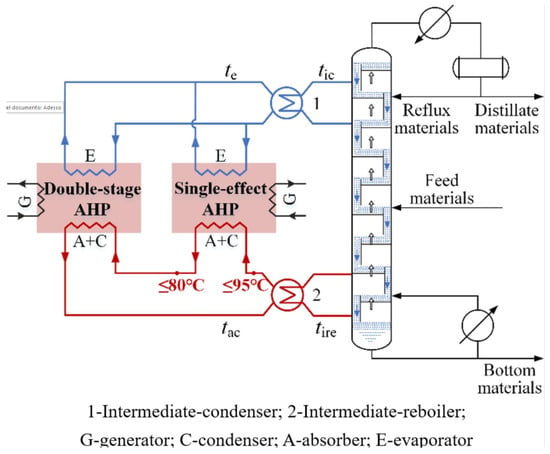

The most important process in the chemical industry is distillation. Many papers propose new solutions to introduce heat pumps in distillation plants to optimize energy performance. Kiss and Smith [56] observe that heat pumping in distillation processes is crucial for energy conservation, utilizing various heat pump concepts to upgrade and reuse energy. Besides traditional heat pumps, new hybrid and novel designs are emerging for higher temperature lifts and performance (see Figure 21). Heat pumps can significantly reduce utility consumption, especially when waste heat is available. Compression heat pumps, using either closed cycles or process fluids, are being optimized with new eco-efficient working fluids. Heat pump-assisted distillation technologies can cut energy use by up to 70%. A notable innovation is the heat-integrated distillation column (HIDiC), which internally integrates heat by operating the rectifying section at a higher pressure. The SuperHIDiC, developed by Toyo Engineering, exemplifies advanced commercial applications of this technology.

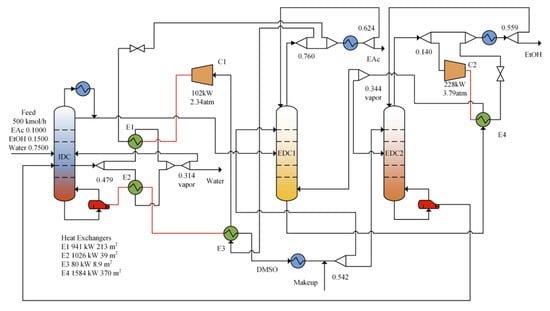

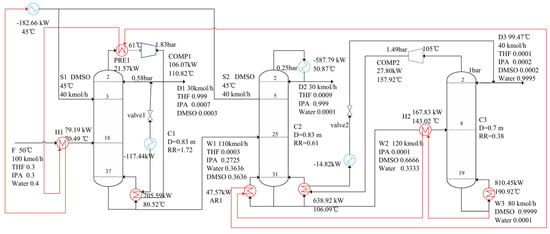

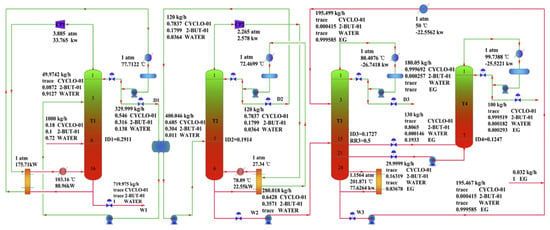

Separating ternary azeotropes with a high content of one component using extractive distillation is energy-intensive, but preconcentration can enhance process economy. Wu et al. [57] optimize three processes for recovering ethyl acetate (EAc) and ethanol (EtOH) from wastewater: the conventional three-column extractive distillation (TCED), four-column extractive distillation (FCED) with preconcentration, and three-column extractive distillation with integrated distillation column (TCED-IDC), focusing on minimizing total annual cost (TAC). The IDC integrates preconcentration and solvent recovery. A vapor recompression heat pump (VRHP) is introduced to the TCED-IDC process to reduce energy consumption, leading to two VRHP-TCED-IDC process designs. These processes are evaluated on economy, energy consumption, environment, and exergy destruction (4E analysis). The VRHP-TCED-IDC processes excel in 4E analysis. The most efficient VRHP-TCED-IDC process (the scheme is shown in Figure 22) reduces TAC by over 32.0%, energy consumption by 53.4%, GWP by 62.0%, and exergy destruction by 49.7% compared to TCED, with significant improvements over FCED and TCED-IDC as well.

Figure 22.

VRHP-TCED-IDC scheme (B) process [57].

Figure 21.

Main heat pump assisted distillation technologies [54,58].

Wang et al. [58] analyze the thermo-economic benefits of vapor recompression in an ethane-ethylene distillation process. Initial simulations of the current process align closely with real plant data, showing high refrigerant consumption. The proposed vapor recompression method reduces the investment cost by 5.72% and cuts refrigerant use by 34.29%. Exergy analysis shows significant improvements, with reduced losses in the reboiler and condenser. Li et al. [59] explore separating cyclohexane/tert-butanol from industrial effluent using heterogeneous pressure-swing azeotropic distillation. Optimal parameters for the conventional process are determined using the simulated annealing algorithm. Heat pump and heat integration strategies are incorporated to enhance energy efficiency. The heat pump-assisted process with auxiliary reboilers and heat integration (HADPSD-ARHI) achieves significant reductions: 41.98% in total annual cost (TAC), 55.32% in total energy consumption (TEC), 52.30% in gas emissions, and 55.26% in exergy destruction, compared to the conventional process. The flowsheet of HADPSD-ARHI is shown in Figure 23.

Figure 23.

The flowsheet of HADPSD-ARHI [59].

Vieren et al. [60] discussed the potential application of heat pumps to deliver heat up to 200 °C in distillation, drying and steam production. Possible integration points and heat pump configurations are presented. Both the VCHP and a combination of a heat transformer with auxiliary natural gas boiler appeared as the most optimal solutions, depending on the energy prices. Steam production, however, may be of particular interest, since direct integration of heat pumps may be less favorable due to the potential reliability concerns. Li et al. [61] explore enhancing distillation energy efficiency through absorption heat pumps (AHP) and waste heat recovery in a petrochemical context. A novel AHP distillation system is proposed using intermediate heat exchange, optimizing parameters such as pressure and temperature to reduce steam consumption by 25%. The scheme of AHP distillation system is reported in Figure 24. The design includes a three-column process yielding significant savings: 38.8% in steam, 42.5% in softened water, and an annual economic profit which ensures a quick payback period of 3 years.

Figure 24.

The form of AHPs for a new system [61].

Xu et al. [62] investigate the separation of isopropanol/tetrahydrofuran/water using extractive distillation methods, comparing indirect (IED) and direct (DED) approaches. Vapor recompressed heat pump technology and heat integration strategies are integrated to enhance energy efficiency. Evaluations encompass energetic, economic, environmental, and exergy considerations. DED proves superior to IED, with double-heat pump assisted direct approach (DED-DP) and heat integration achieving the highest energy savings (64.97%) and cost reduction (34.26%) compared to direct extractive distillation alone. Figure 25 shows the flowsheet of DED-DP process. The DED-DP process excels across all evaluated criteria, demonstrating substantial improvements in energy efficiency (64.97%), total annual cost (34.26%), and environmental impact (48.82%), with the highest exergy efficiency (11.34%) and lowest exergy destruction.

Figure 25.

Double heat pump assisted DED process [62].

The same research group in [63] introduces two energy-efficient extractive distillation processes for separating acetonitrile/1,4-dioxane/water mixtures. Heat pumps and heat integration enhance energy conservation in both processes. The heat pump-assisted direct extractive distillation achieves a 53.58% energy reduction, and 53.56% CO2 emission reduction compared to the indirect scheme, while direct distillation with heat integration reduces total annual cost by 40.38%. The direct extractive distillation with heat integration (DED-HI) process excels in economic and exergetic aspects, while the heat pump-assisted DED process (DED-VR) demonstrates superior energetic and environmental benefits among the proposed designs. Zhu et al. [64] focus on the extractive distillation of the cyclohexane/sec-butyl alcohol/water azeotropic mixture, critical in environmental risk mitigation and solvent recycling. Using the COSMO-SAC model, solvents were screened based on relative volatility and solvent power, with ethylene glycol (EG) chosen for its lower boiling point. Optimizing the extractive distillation process with a sequential iterative algorithm and incorporating energy-saving methods like thermal coupling and heat pumps led to significant improvements. The best configuration (HPCWTCED, heat pump combined with thermal coupling extractive distillation), the scheme for which is shown in Figure 26, increased thermodynamic efficiency by 73.89%, reduced total annual cost by 25.62%, and decreased CO2 emissions by 81.08%, supporting sustainable development in the chemical industry.

Figure 26.

HPCWTCED process flow diagram [64].

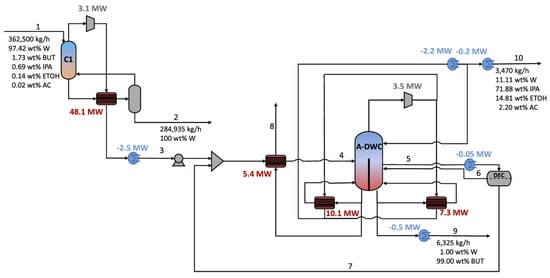

Wang et al. [65] explore pressure-swing distillation (PSD) for separating water/acetonitrile/isopropanol, emphasizing two PSD processes with different separation sequences. The W-A-I sequence outperforms in economy, energy consumption, and environmental impact. Energy-saving techniques like heat integration, heat pumps, and heat exchanger networks utilize both sensible and latent heat effectively. T-S diagrams of overheads from heat-pump processes evaluate dry compression feasibility. PSD-THP-HEN (triple-heat-pump and heat exchanger network) exhibits the lowest cost, energy consumption, and emissions (CO2, SO2, NOx), saving 71.4% TEC and 57.59% TAC compared to PSD-HEN. This study underscores PSD’s efficiency without entrainers and validates energy-saving benefits via heat-pump technology in ternary mixture separation. Isopropanol-butanol-ethanol (IBE) fermentation is superior to acetone-butanol-ethanol (ABE) fermentation due to better fuel properties, but its downstream processing is complex. Jankvic et al. [66] propose a novel, thermally self-sufficient, and eco-efficient industrial-scale (74 ktonne/y) recovery process for IBE fermentation from a highly dilute broth (>97 wt% water). Figure 27 shows the scheme of the system. The process uses gas stripping and heat pump-assisted vacuum evaporation to separate valuable products. An advanced heat pump-assisted azeotropic dividing wall column recovers high-purity butanol (99%) and isopropanol-ethanol fuel supplement (89%). The purification process is cost-effective, energy-efficient, and allows full biomass and water recycling. This enhances fermentation yield by continuously removing inhibitory products and reducing water needs.

Figure 27.

Flowsheet of the recovery process after IBE fermentation [66].

Zhai et al. [67] present a new extractive-azeotropic dividing wall column (EADWC) configuration for recovering acetonitrile from wastewater, replacing the conventional two-column process. The proposed design significantly improves energy efficiency by incorporating vapor recompression heat pumps and heat exchanger networks (HPEADWC-FP-HI, Figure 28). Evaluation of the HPEADWC-FP-HI shows substantial reductions in total annual cost (up to 51.95%), CO2 emissions (89.96%), and total energy consumption (63.58%) compared to the conventional process. The enhanced design is also inherently safer. Despite a 65% increase in total capital cost, the payback period is 3 years with a 30.46% reduction in total annual cost. A similar approach is applied by Zhai et al. [68] for the separation of the acetone/n-heptane mixture, which forms a minimum-boiling azeotrope. Four energy-efficient extractive dividing wall column (EDWC) designs incorporating feed preheating, heat pump (HP), and heat exchanger network (HEN) are analyzed to improve sustainability. The best configuration (HPEADWC-FP-HI) achieves a 38% reduction in energy consumption, 20% in total annual cost (TAC), and 41% in CO2 emissions compared to conventional methods.

Figure 28.

(a) Process flow diagram and (b) T-H diagram of HPEADWC-FP-HI scheme [68].

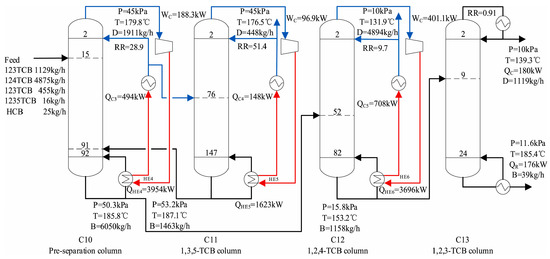

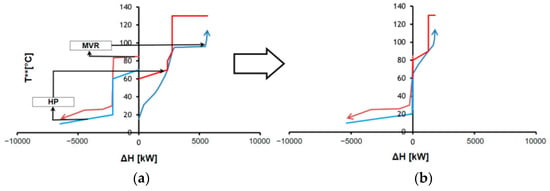

Trichlorobenzene, consisting of three isomers, requires significant energy for separation due to their close boiling points. Yang et al. [69] applied heat integration and mechanical vapor recompression (MVR) heat pump technologies to reduce energy consumption. Additionally, the Organic Rankine Cycle (ORC) is coupled with the MVR heat pump to convert waste heat into electricity for the compressor (the scheme of the process is shown in Figure 29). Compared to a four-column conventional distillation process, heat integration and MVR reduce energy consumption by 32.7% and 83.5%, respectively, and save total annual cost (TAC) by 12.4% and 22.9%, respectively. Coupling ORC with MVR further reduces energy consumption by 18.8% and TAC by 1.42%.

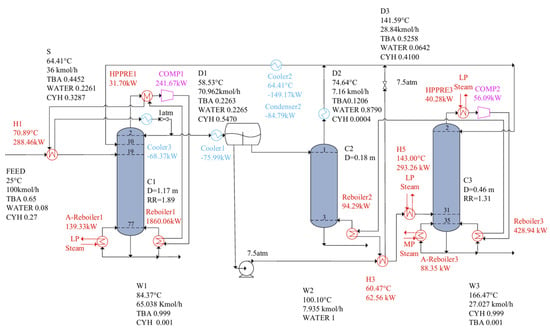

Wang et al. [70] explored improving the economic efficiency and environmental sustainability of the classic extractive distillation (CED) process using vapor recompression heat pump (VRHP) and an intermediate-boiling entrainer, benzene. The direct (DCED) and indirect (ICED) CED sequences for separating the acetone/n-heptane azeotrope were optimized to minimize total annual costs (TAC). Six VRHP-DCED and six VRHP-ICED sequences were designed to reduce steam and electricity consumption. Results show ICED outperforms DCED in economic and environmental aspects. VRHP-DCED (V) sequences reduced steam use by 83.38%, while VRHP-ICED (IV’) sequences decreased TAC and gas emissions by 8.24% and 26.87%. Despite their benefits, VRHP-CED sequences face challenges in operability and controllability, warranting further optimization. Zhai et al. [71] addressed energy consumption in isopropanol recovery from wastewater using pressure-swing distillation (PSD) with heat pump (HP) techniques. Three energy-efficient PSD processes were proposed and optimized: HIPSD, PSD-HP, and HIPSD-HP. Compared to conventional PSD (CPSD), these alternatives achieved significant cost and energy savings. PSD-HP showed the highest efficiency, reducing total annual cost (TAC) by 51.30% and CO2 emissions by 84.73%. The heat pump application proved most effective, despite a 54.51% higher capital cost. The combined heat integration and HP approach (HIPSD-HP) also improved economic, environmental, and thermodynamic efficiency. These methods promise significant improvements in sustainable industrial alcohol dehydration. Ulyev et al. [72] focus on the thermal integration of an existing ethylbenzene (EB) production facility. Four variants for modifying the heat exchange network (HEN) were investigated by applying a Hysys simulation model. The first variant, using classical Pinch analysis, reduced hot utility consumption by 10.7%. Two variants proposed integrating a recompression heat pump, each reducing hot utilities by 34% but differing in compressor power requirements. The first option was more economical despite both reducing utility consumption by 1691 kW. Combining Pinch analysis with the preferred heat pump integration reduced steam consumption by 37% and CO2 emissions by 1.0 t/h, making it the most effective modernization project for the HEN of the EB production unit. This approach achieved greater reductions in steam consumption compared to previous methods and had a favorable payback period.

Figure 29.

MVR heat pump distillation process with main parameters [67,71].

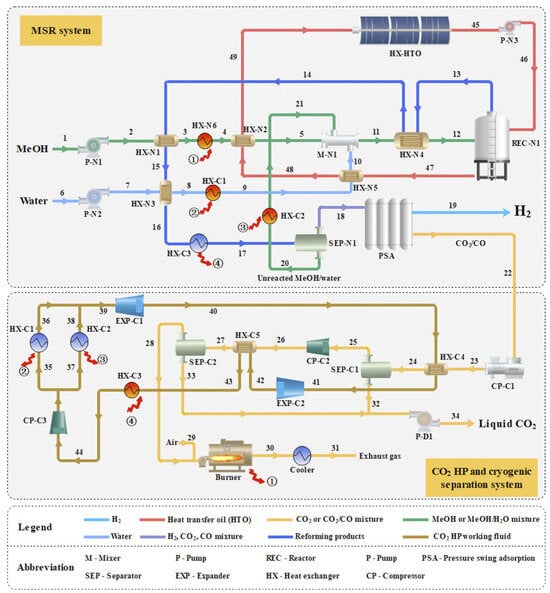

However, heat pumps can be applied also in other chemical processes. Boldyryev et al. [73] explore heat pump integration in natural gas–liquid processing within a petrochemical plant. They studied the simulation of 3 different types of heat pump equipment and evaluated the economic trade-offs for different pressures in evaporators and condensers. The total annual costs for the two best heat pumps were reduced by 6% and 50%, respectively, compared to configurations targeted by grand composite curves, despite increased electricity consumption and cooling requirements. This reduction translates to savings of 21.5 million EUR annually, highlighting significant investment potential. The study emphasizes optimizing heat exchanger networks (HEN) and addressing cost assessments for effective industrial application. Wu et al. [74] present a novel methanol steam reforming (MSR) system integrated with a CO2 heat pump (HP) and cryogenic separation system to optimize performance. The diagram of the integrated system is shown in Figure 30. The cryogenic system separates CO2 in liquid phase, while the CO2 HP system connects the MSR and cryogenic systems, utilizing waste energy and providing necessary heat. This integration fully utilizes waste heat and CO energy, producing liquid CO2 as a byproduct. Energy and exergy efficiencies improved by 5.57% and 5.15%, respectively.

Figure 30.

Schematic diagram of the integrated system [74].

De Raad et al. [75] used Process Change Analysis (PCA) with exergy to identify improvements, demonstrated in biodiesel and vinyl chloride monomer plants. In biodiesel production, a heat pump with a COP of 4.2 faced a 40 kW penalty for transferring heat above the Pinch temperature, which was mitigated by replacing the wet water washer with a membrane separation unit, reducing energy needs from 0.9 MW to 0.3 MW. In the vinyl chloride monomer process, strategic heat extraction increased the heat pump’s performance by 6.5%.

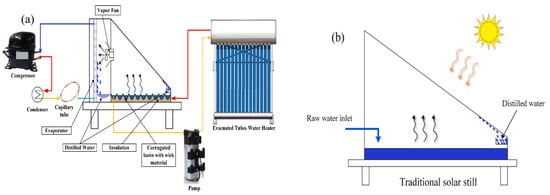

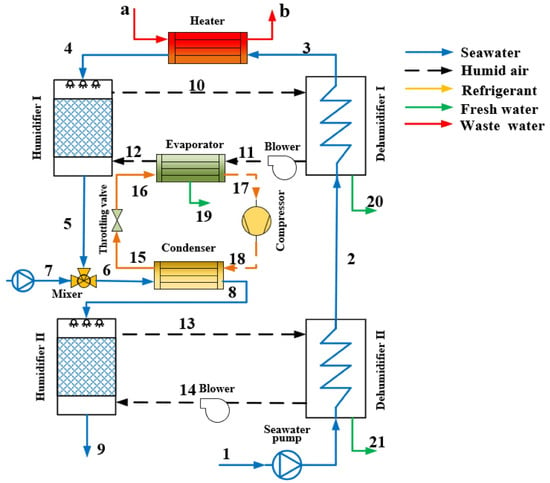

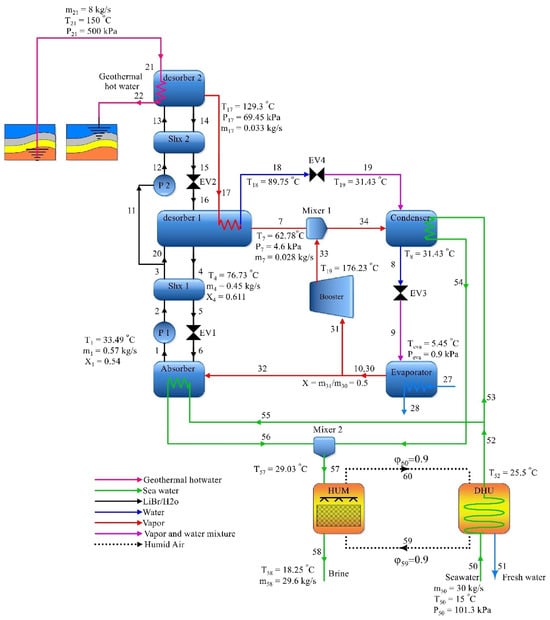

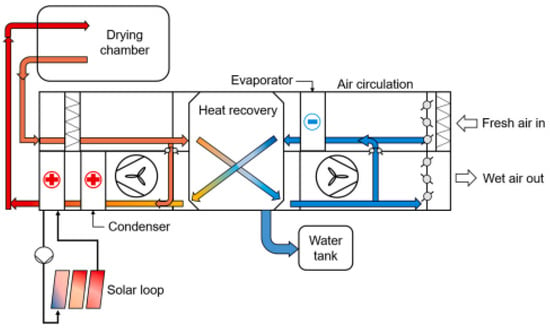

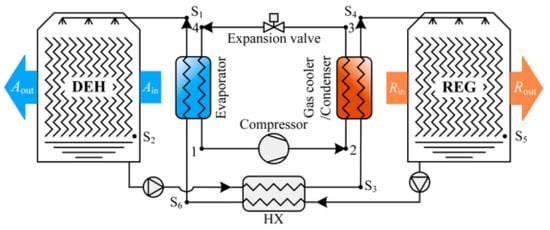

3.2. Desalination

Desalination, the process of converting saltwater into freshwater, offers a viable approach to address challenges presented by water scarcity related to depletion of freshwater sources and population growth [76,77]. Amongst the various techniques developed to make the desalination process consume minimum energy [78], humidification-dehumidification-based desalination (HDH) can benefit from the use of heat pumps, which could be employed as a heat source, or by the use of absorption heat pumps to exploit the exhaust heat of the desalination process. Heat pumps can also be integrated with the membrane method to improve thermal efficiency [79]. Several papers have been published in the last 5 years regarding new solutions to apply heat pumps to desalination. Tareemi et al. [80] address water shortage and energy utilization by enhancing production capacity and thermo-economic performance in solar still desalination. Passive modifications included a V-corrugated basin and black cotton wick material. Active enhancements used a 250 W heat pump, a 200 L evacuated tube water heater and glass cover cooling to improve evaporation and condensation. A scheme of the two systems is shown in Figure 31. The combined system achieved a daily yield of 19.75 L/m2, thermal efficiency of 64.49%, and exergy efficiency of 6.31%, surpassing the basic design by 439.6%, 59.7%, and 81.84%, respectively. Economic analysis showed a distilled water cost of 0.0164 $/L, a 9.4% reduction, and CO2 mitigation increased from 1.35 to 9.31 tons/year, demonstrating environmental benefits and applicability in remote and arid regions.

Figure 31.

Test-rig real illustration of (a) proposed design with heat pump and (b) traditional design [80].

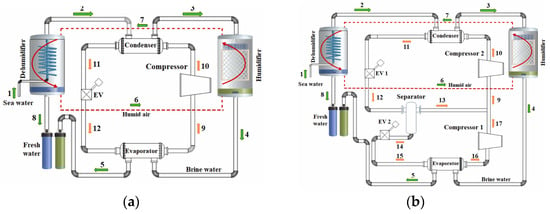

Hai et al. [81] explore eco-friendly organic mixtures in heat pump-driven humidification-dehumidification desalination systems, comparing organic blends with structural modifications. Two scenarios are analyzed: a basic heat pump and a vapor injection heat pump. Exergoeconomic analysis and optimization reveal significant efficiency improvements with organic blends. R142b, R22/R142b, and R142b/R22/R236fa have the lowest electricity consumption and highest GOR. Organic blends, especially ternary ones, significantly enhance cycle performance without high costs. R134a in humidification-dehumidification vapor injection head pump (HDH-VIHP) improves GOR by 14.25%, while R22/R142b in HDH simple heat pumps (HDH-SHP) boosts GOR by 41.26%. R142b/R22/R236fa increases GOR by 45.85% in HDH-SHP and 33.19% in HDH-VIHP. Figure 32 shows the scheme of HDH-SHP and HDH-VIHP. Optimizing scenarios improves exergetic efficiency by up to 12.55% and unit cost of distilled water by up to 16.21%.

Figure 32.

Layout of distilled water production systems coupled with different types of heat pumps: (a) first scenario (HDH-SHP); (b) second scenario (HDH-VIHP) [81].

Petersen et al. [82] explore integrating a transcritical CO2 heat pump into thermal desalination, operating up to 180 °C with an eco-friendly fluid. Six configurations show energy demands comparable to reverse osmosis (RO), with the integrated system outperforming RO when considering cooling energy. A 19 MWel CO2 heat pump can produce 64,000 m3/d of potable water and 75 MW of cooling energy, highlighting its potential for water scarcity and cooling solutions. This integration could significantly reduce carbon emissions, potentially saving up to 19 kg CO2eq/m3. Shahzad et al. [83] present a novel system combining an open cycle absorption heat pump (OAHP) and FlashME desalination to utilize waste heat from industrial flue gasses. The system, modeled in Aspen Plus, recovers 89.42% of waste heat at a thermal COP of 2.21, using it to heat seawater to 70 °C for the FlashME process, achieving a performance ratio of 3.05. The system’s performance varies with inlet flue gas parameters and regeneration pressure, recovering 9.19% to 37.17% of water. The study concludes that the integrated OAHP-FlashME system is effective for waste heat recovery and seawater desalination, suitable for industries like coal-fired power plants and textiles. The same research group in [84] proposed a novel system combining the open absorption multifunctional heat pump, FlashME desalination, coupled to a compressed air dryer to recover latent heat from flue gas for seawater desalination and compressed air drying. The system, modeled in Aspen Plus, achieves 83.02% heat recovery efficiency, a thermal COP of 1.95, and 23.14% freshwater recovery. The system’s performance is influenced by spray solution parameters and flue gas humidity, with water recovery dependent on heat capacity and regeneration pressure. The coupled system can reduce regeneration load by up to 37.78% and enhance distillate productivity by 54.24%. Chen et al. [85] propose a novel system combining a heat pump, multi-effect desalination (MED), and ice storage, providing both thermal and cold energy for desalination and ice generation. Compared to conventional mechanical vapor compression (MVC) and air conditioning systems, the proposed system shows significant improvements in thermodynamic, economic, and environmental performance. The specific energy consumption (SEC) is reduced from 8.94 kWh/t to 4.71 kWh/t, and the payback period decreases from 5.90 to 3.85 years. The environmental impact is also lower, with CO2 emissions reduced by 7.68%. Zhou et al. [86] propose a heat pump coupled two-stage (HPTS) humidification and dehumidification (HDH) desalination system utilizing waste heat for heating feed seawater and brine (see Figure 33). Performance evaluations with different working fluids were conducted, focusing on freshwater production (mpw), gained output ratio (GOR), recovery ratio (RR), specific entropy generation (stot), and unit cost of fresh water (Zpw). Results indicate that R22 yields the highest mpw, while R600 achieves the lowest Zpw and stot and the highest GOR. Higher spraying temperatures improve mpw and Zpw and increase stot. Optimal performance occurs at specific mass flow rate ratios and compression ratios. The system shows promising thermodynamic and economic performance compared to existing systems.

Figure 33.

Schematic diagram of the HPTS-HDH system [86].

Ghiasirad et al. [87] address the high electricity consumption of integrated desalination and heat pump cycles by modifying a double-effect absorption heat pump cycle combined with a humidification-dehumidification desalination system. Innovations include preheating seawater with waste heat from the absorption chiller and designing a hybrid thermal-mechanical heat pump. A scheme of the system is shown in Figure 34. The proposed system increased freshwater and cooling production by 23.23% and 47.7%, respectively, and achieved a 17.89% higher energy utilization factor (EUF) of 6.96. Optimal steam extraction improved exergy efficiency by 27.23%, and freshwater cost was reduced to $2.051/m3. The humidifier was the main source of exergy destruction, constituting 16.5% of the total rate.

Figure 34.

Sketch of the proposed new low thermal driven cooling/desalination system assisted with a booster (also called an integrated DEARC-HDH system) [87].

Khalifa et al. [88] present a theoretical analysis of integrated direct contact membrane distillation (DCMD) and heat pump (HP) systems for water desalination, focusing on performance, energy efficiency, and production cost. Various integration scenarios with open and closed water cycles and refrigerants R134a and R22 were examined. Results indicated that heat pump specifications set the performance limits of condenser and evaporator heat exchangers. The DCMD-HP system showed lower energy consumption and production costs compared to electrically driven systems. Customizing a heat pump for DCMD in closed cycles achieved GOR values between 1.8 and 2.1, SEC values between 330 and 400 kWh/m3, and production costs from 0.5 to 4 $/m3. Integrating a multistage parallel DCMD further reduced production costs to 0.5–2 $/m3 while maintaining high efficiency.

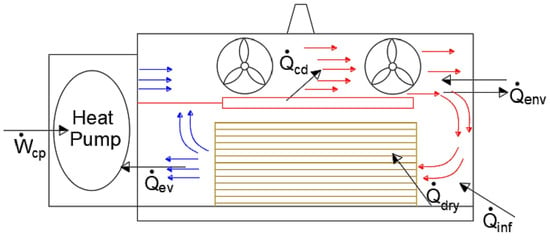

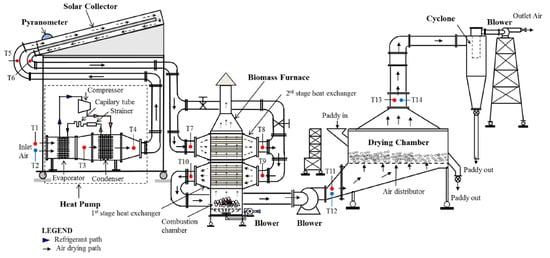

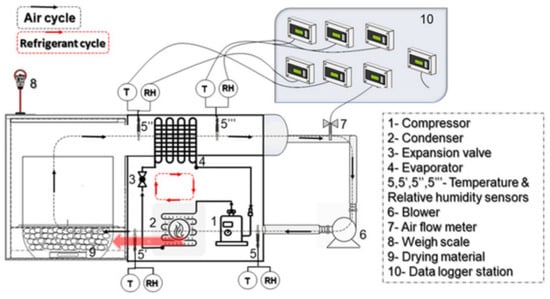

3.3. Food and Beverage Industry

The food and beverage industry, focusing on energy use, water consumption, climate change, and other subsystems, has profound environmental impacts [89]. Increasing energy efficiency and reducing the use of fossil fuels are key strategies for achieving climate neutrality in the food supply chain. To this purpose, high-temperature heat pumps are a promising technology for both heat recovery and energy efficiency in this sector [90]. As an example, Zuberi et al. [91] explore the potential of electrifying industrial process heat in major U.S. food manufacturing sectors using high-temperature and steam-generating heat pumps. By 2050, it identifies substantial annual energy savings of 325 PJ and CO2 reductions of 31 MtCO2, equivalent to emissions from 6 million cars annually. Several papers in the last 5 years have analyzed the application of heat pumps in food and beverage sector. Loemba et al. [92] investigate a novel solar-assisted heat pump dryer with soapstone thermal energy storage, examining three operational modes: daytime storage (mode 1), nighttime without storage (mode 2), and daytime without storage (mode 3). Using 500 g of Cavendish banana, experiments showed moisture reduction from 74.4% to 9.6% in 270, 390, and 360 min for modes 1, 2, and 3, respectively. Mode 1 exhibited the highest efficiency at 23.23% and COP values of 3.69, 2.57, and 2.54 for modes 1, 2, and 3, respectively. Economic analysis indicated a 1.5-year payback period and 65% return on investment for mode 1.

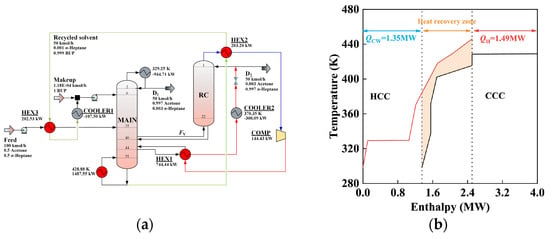

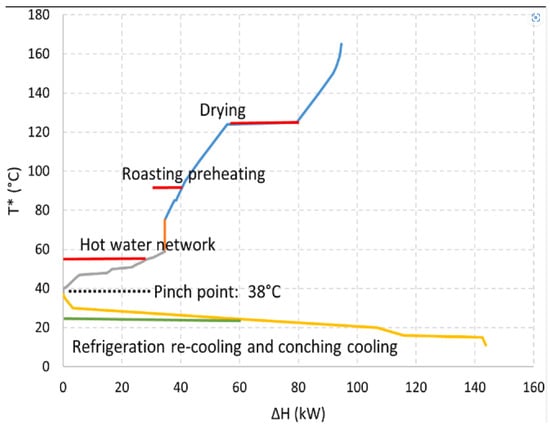

Bhadbhade et al. [93] focus on decarbonizing industrial processes like Swiss chocolate production through heat pump (HP) electrification. It introduces a methodology to create exemplar, representative, and sector-wide energy demand profiles, using Pinch Analyses (Figure 35) for accurate data. Results identify five HP integration opportunities based on company size and operational parameters, showing HPs with COPs above 2.6 are generally cost-effective. Potential reductions include up to 56% in CO2 emissions and 28% in energy efficiency.

Figure 35.

Representative grand composite curves (profile) for chocolate production in Switzerland [93].

Moritani et al. [94] propose a subirrigation system using heat pumps to control substrate temperature, enhancing greenhouse farming sustainability. Heat pumps sourced from air or geothermal systems maintained optimal growth conditions (18.4 °C) for strawberries, with geothermal heat pumps showing 1.8 times higher COP during heating and reducing electricity by 14.9%. Yields increased by 21% (geothermal) and 36% (air-source) compared to controls due to improved growth conditions. Knorr et al. [95] explore integrating renewable energy and enhancing energy efficiency in industrial heat generation, emphasizing electrification to reduce energy consumption and emissions. When comparing electric boilers and heat pumps using Pinch analysis and optimization, electrification can increase costs by 26% to 176% while reducing emissions by up to 39%. For sterilizing pet food pouches at 120 °C, electrification proves economically viable at average European prices in 2021, with electric boilers being the most cost-effective among electrified solutions. A hybrid approach combining a heat pump’s efficiency with a boiler’s flexibility offers the lowest costs and competitive performance with natural gas systems at specific electricity-to-gas price ratios. Klinac et al. [96] apply a novel Pinch-based Total Site Heat Integration (TSHI) method, tailored for industrial heat pump applications, at a meat processing site in New Zealand, leveraging renewable electricity to cut carbon emissions significantly. Figure 36 shows the total site integration plots of the heat exchange flows. The method enhances traditional approaches by pinpointing overlooked heat pump opportunities, like Mechanical Vapour Recompression (MVR) in the Rendering plant and a centralized air-source heat pump for the hot water ring main, potentially reducing site emissions by over 50%.

Figure 36.

Total site integration plots showing potential heat pump installations (a), leading to final expected total site plot (b). The red lines on the Gross cold utility use side of the plot represent process streams that require cooling, and the blue lines represent the cold utility streams that would be required to carry out this cooling. The blue lines on the Gross hot utility use side of the plot represent process streams that require heating, and the red lines represent the hot utility streams that would be required to carry out this heating. Total site integration plots showing potential heat pump installations (a), leading to final expected total site plot (b). The red lines on the Gross cold utility use side of the plot represent process streams that require cooling, and the blue lines represent the cold utility streams that would be required to carry out this cooling. The blue lines on the Gross hot utility use side of the plot represent process streams that require heating, and the red lines represent the hot utility streams that would be required to carry out this heating [96].

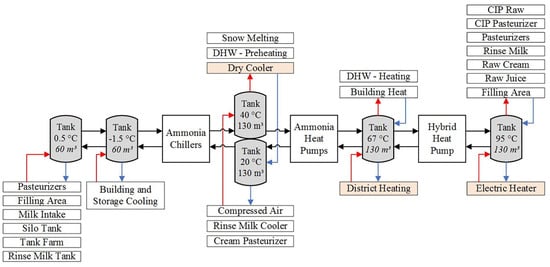

Foslie et al. [97] emphasize the significance of electrifying low temperature heat in industries by applying heat pumps to cut emissions, using a model to optimize energy system investments at a dairy. Integrating thermal and electrical systems reduces costs by 24% and emissions by 96% compared to traditional methods, with thermal energy storage proving crucial for cost-effective flexibility. Martyanov et al. [98] highlight key principles for designing furnaces and thermal chambers for the heat treatment of meat products: efficient energy use, enhanced productivity via compact product arrangement, precise airflow direction, temperature and humidity control, reliability, and compliance with emission regulations. Heat pumps offer advantages in high-power enterprises where water as a coolant is impractical, promoting uniform product quality and bacterial control in meat processing. Integrating heat pumps in industrial food equipment circuits, such as rotary kilns, optimizes energy use by harnessing waste heat, reducing fuel and electricity costs. Hermanucz et al. [99] investigate an experimental dual-source heat pump (DSHP) system designed to meet simultaneous cooling and heating needs in brewing processes, achieving a 60% reduction in CO2 emissions and a 10% decrease in energy costs compared to traditional methods. The DSHP system operates with two evaporators at different temperatures and times, replacing natural gas for heating with energy from the heat pump’s condenser. With an average COP of 2.5, the DSHP significantly lowers energy consumption, notably by reducing CO2 emissions formerly attributed to natural gas combustion. Energy cost comparisons between the DSHP and boiler + chiller system (BCS) show a 10% cost reduction favoring the DSHP. Ahrens et al. [100] examined the energy consumption and performance of a green-field dairy’s integrated heat pump system in Bergen, Norway. The dairy employs high-temperature heat pumps with natural refrigerants for all heating and cooling demands. A scheme of the integrated energy supply system is shown in Figure 37. An energy analysis based on a high-demand week in February showed the system meets demands with a specific energy consumption of 0.22 kWh/L, outperforming the replaced dairy. Energy consumption was reduced by 37.9% and GHG emissions by up to 91.7% through extensive waste heat recovery, which accounts for 32.7% of energy used and achieves a recovery rate over 95%. The system’s COP is 4.1, with potential for further improvements.

Figure 37.

Integrated energy supply system including heat pump systems and thermal storage tanks [100].

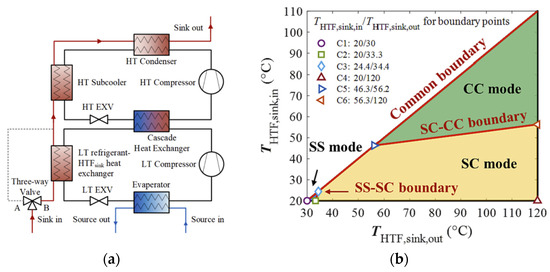

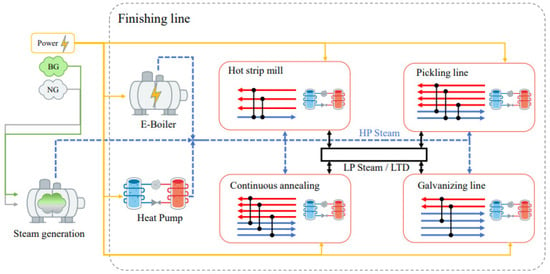

3.4. Industrial Steam Generation

Several sectors, such as pulp, paper, or chemical industries, consume wide amounts of industrial steam to feed their processes that often require steam at temperatures from 100 °C to 200 °C. This temperature range involves 26% of total process heat demand, and the heat is generally produced with fossil fuel burners.

Payà et al. [101] evaluate replacing industrial gas boilers for steam production with Solar Heat for Industrial Processes (SHIP), Electric Boilers (EBs), High-Temperature Heat Pumps (HTHPs), and Absorption Heat Transformers (AHTs) across Europe. EBs are not cost-effective except in Sweden due to high electricity prices, while HTHPs achieve PBs < 4 years at 120 °C and are optimal with electricity-to-gas ratios < 3.5. Ma et al. [102] evaluate a High-Temperature Heat Pump Steam System (HTHPSS) generating steam at 170 °C from industrial waste heat, aiming to replace coal-fired boilers. Key findings include a maximum COP of 2.73, peak exergy efficiency at 43.26%, and a payback period (PBP) ranging from 0.03 to 4.40 years, depending on waste heat and condenser temperatures. Feng et al. [103] focus on enhancing High-Temperature Heat Pumps (HTHPs) for steam generation using industrial waste heat. By employing two-stage separation and dual-pressure evaporation technology with low-GWP refrigerant mixtures, significant improvements were achieved. The schemes of the two systems are reported in Figure 38. The optimal R1234ze(E)/R1233zd(E) mixture outperformed others, showing 0.85%–1.86% higher thermodynamic effectiveness than benchmark mixtures. The improved cycle exhibited a 45.17% increase in heat source utilization efficiency and a 24.48% higher coefficient of performance (COP) compared to the basic cycle.

Figure 38.

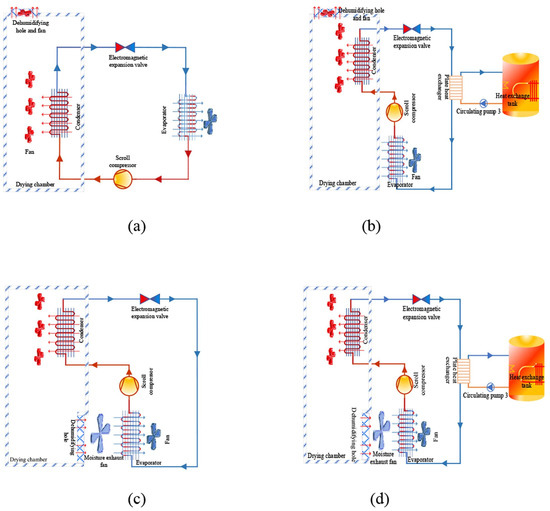

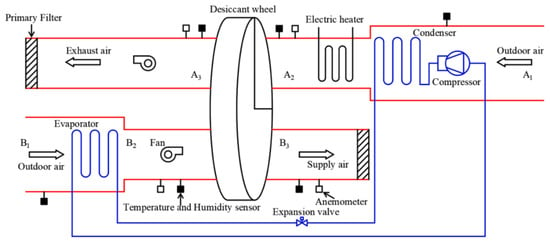

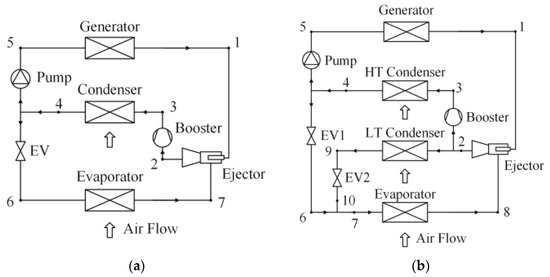

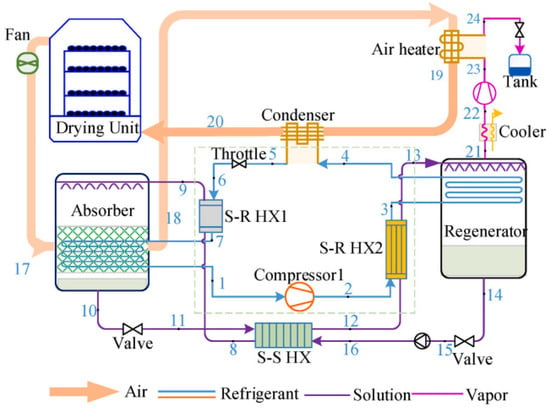

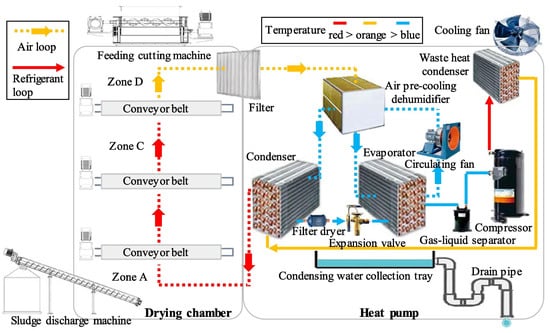

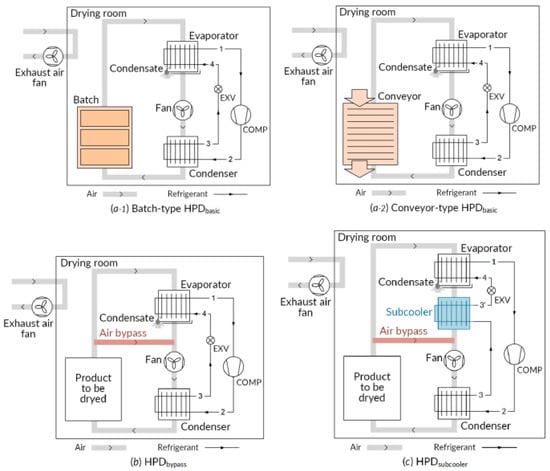

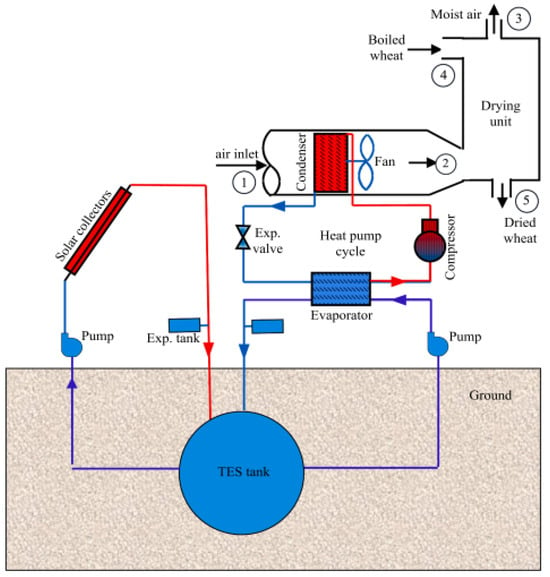

System schematic diagram of heat pump: (a) the basic auto-cascade cycle (basic cycle); (b) the dual-pressure evaporation auto-cascade cycle (improved cycle) [103].