Piezoelectric Energy Harvesting for Civil Engineering Applications

Abstract

1. Introduction

2. Fundamentals of Piezoelectric Energy Harvesting

2.1. Direct Piezoelectric Effect

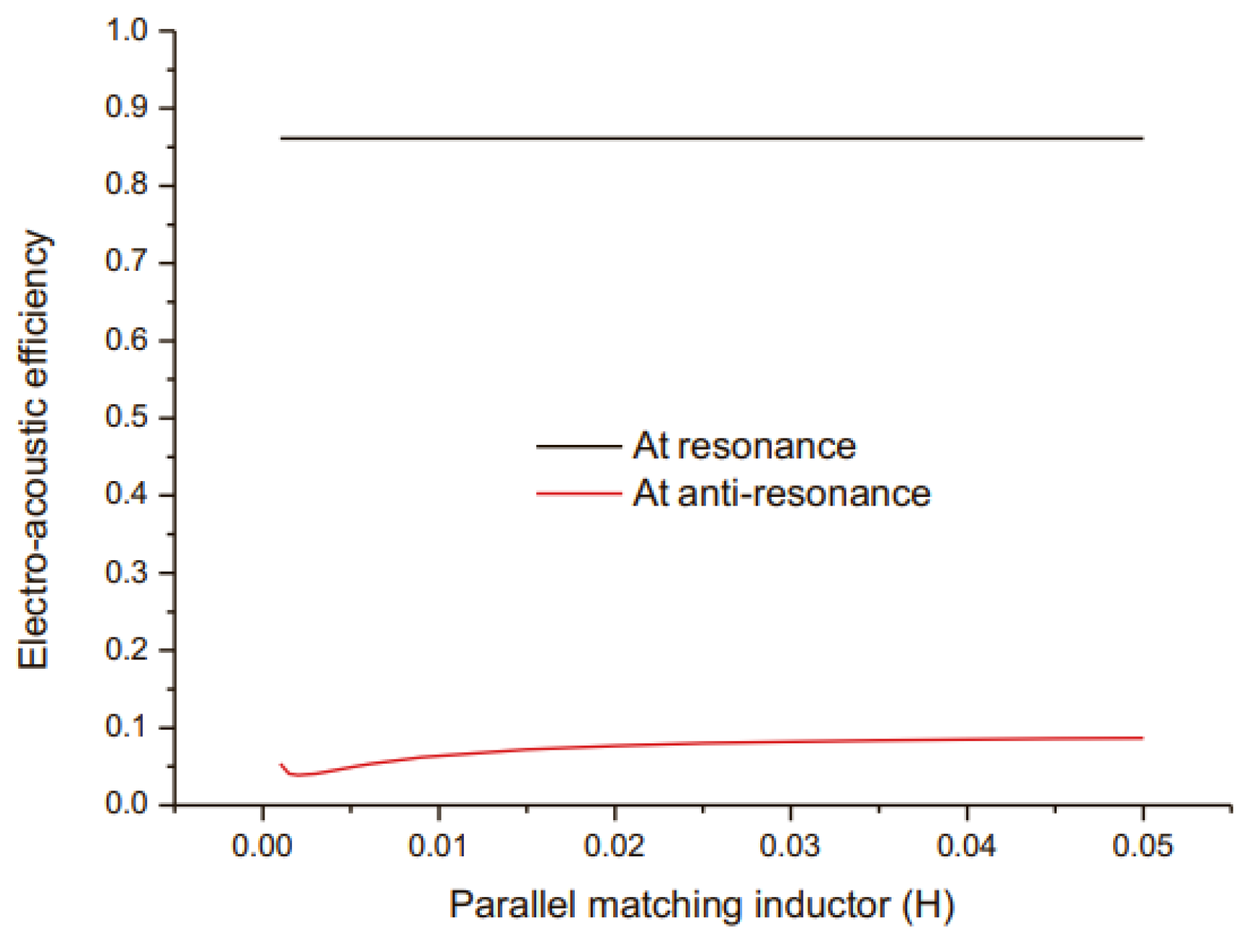

2.2. Resonance and Frequency Matching

2.3. Piezoelectric Materials

- Characteristics of piezoelectric materials

- Common piezoelectric materials

- Crystals: Crystalline piezoelectric materials, including quartz, tourmaline, and Rochelle’s salt, have specific attributes. Quartz, valued for its stiffness, durability, and resistance to high temperatures, is less ideal for high-frequency excitation and structural control [27]. Nonetheless, it has found application in the concrete industry [28]. Tourmaline and crystalline tourmaline are prized for their high piezoelectric voltage coefficient [29]. Rochelle’s salt, a synthetically produced material, is notable for its chemical sensitivity and resistance to adverse environmental conditions, boasting a very high piezoelectric constant [30].

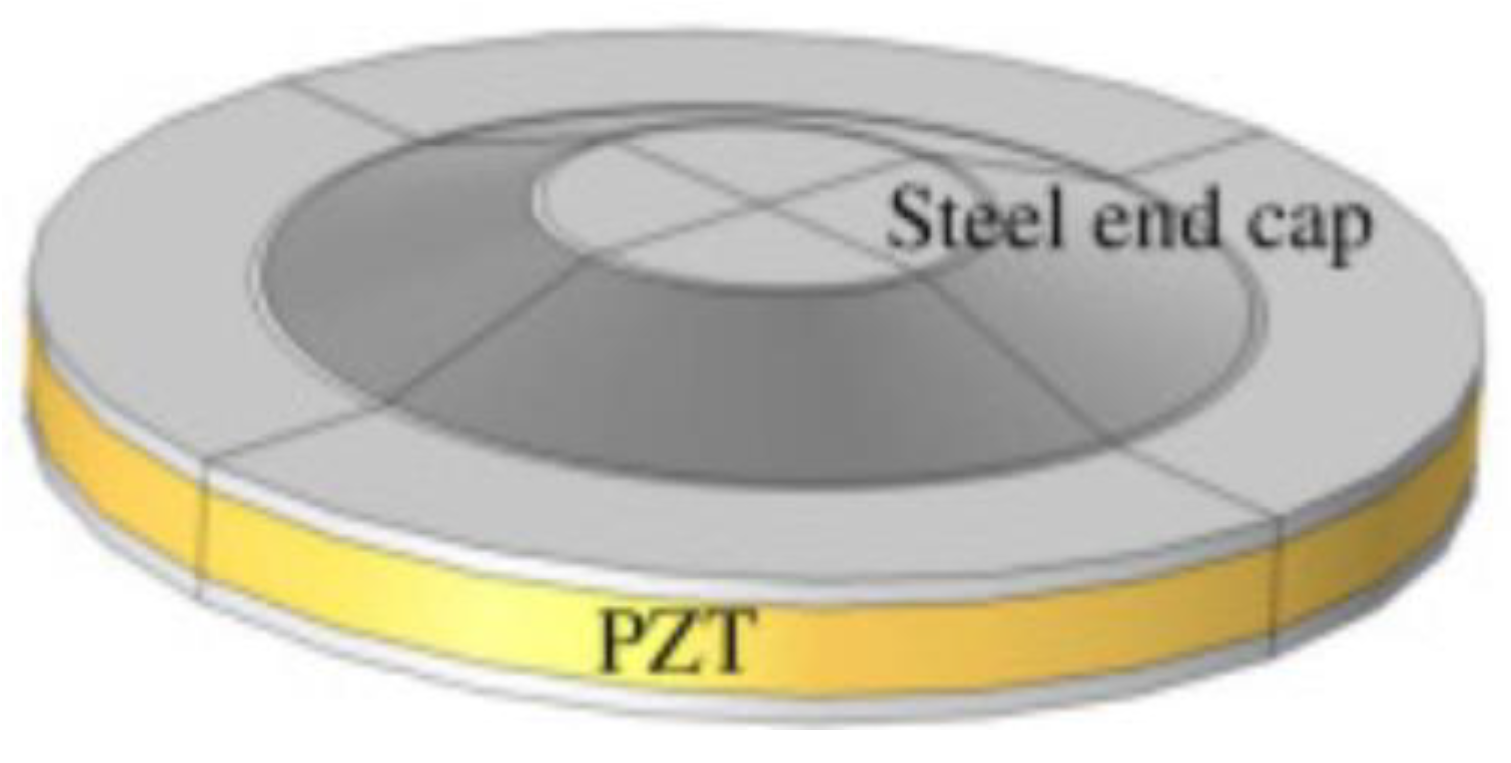

- Ceramics: PZT and barium titanate are prominent piezoceramic materials commonly employed in civil engineering [31]. PZT is renowned for its strength, sensitivity, and high electromechanical coupling coefficients, making it well-suited for structural health monitoring and energy harvesting [32]. Barium titanate serves various electronic elements and can be environmentally friendly when lead-free variants are used [33,34].

- Polymers: Polyvinylidene difluoride (PVDF) is a flexible and robust polymer featuring piezoelectric properties [35]. It is favored for applications involving intricate and sizable shapes and finds utility across diverse industries, including aerospace [36]. PVDF offers advantages over ceramic piezoelectric materials, such as cost-effectiveness, resilience, and resistance to harsh environmental conditions [37,38].

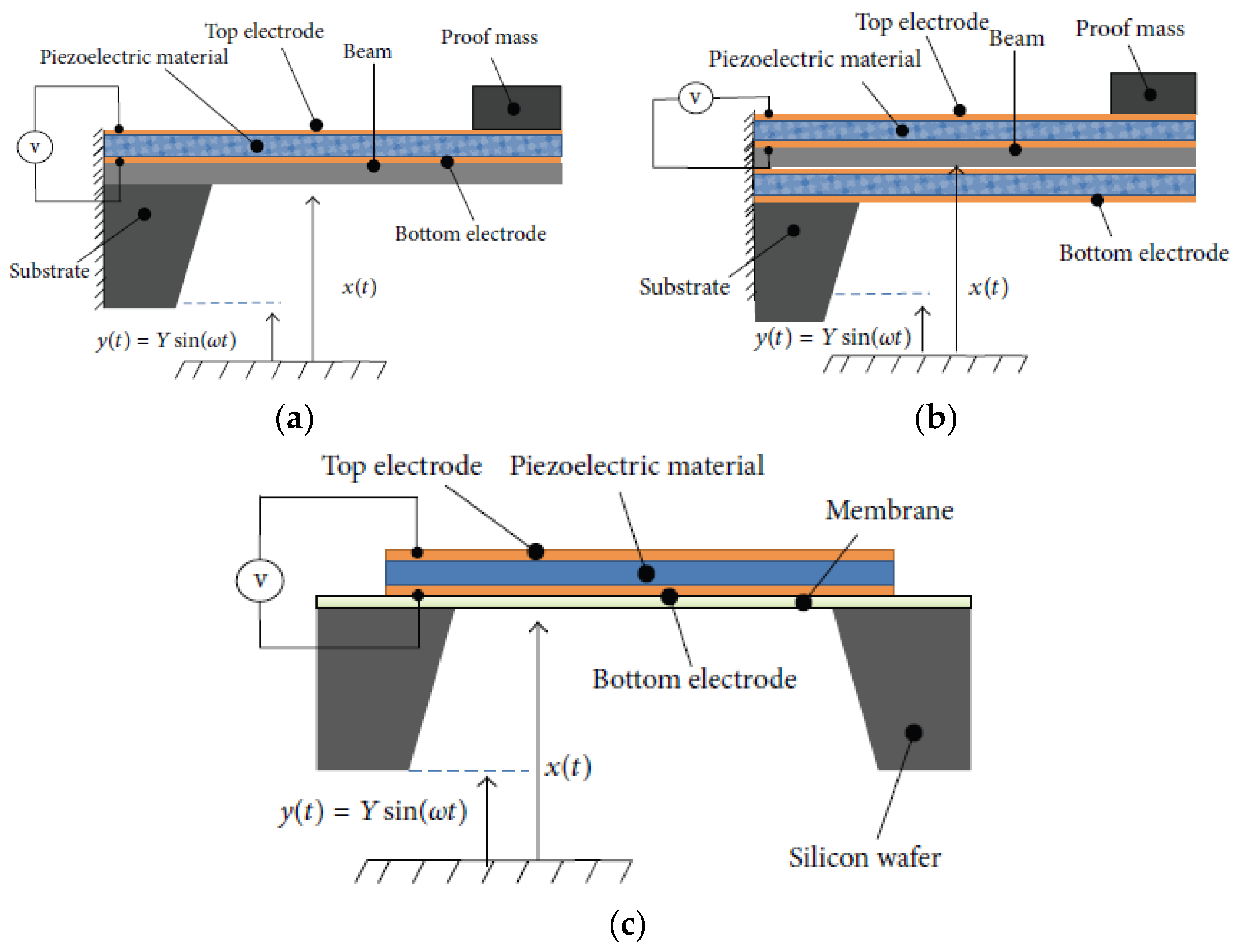

2.4. Fabrication of PEH Used in Civil Engineering

2.5. Methodologies, Design and Modeling

- Analytical Modeling: Erturk and Inman [55] developed distributed parameter electromechanical models for PEH integrated with slender structural elements, like beams and plates, optimizing power output for different excitation frequencies and electrical loads. Roundy and Wright [56] presented a coupled modeling approach combining mechanical elements modeled by distributed parameter equations and electrical elements by simple circuit equivalents, predicting steady-state responses for piezoelectric vibration-based energy harvesters. Triplett and Quinn [57] derived an analytical piezoelectric harvester model specifically for base-excited cantilever beams, enabling predictions of maximum power output versus resistance for given vibration amplitudes and frequencies.

- Finite-element Modeling: Badel et al. [58] used ATILA finite-element software to model a reinforced concrete beam with piezoelectric patches, predicting stored electrical energy under dynamic loading. Shen et al. [59] presented a finite-element framework for modeling piezoelectric composites for structural health monitoring and energy harvesting in concrete structures, accounting for anisotropic piezoelectric properties. De Marqui Jr et al. [60] compared analytical and finite-element numerical predictions versus experiments for a uni-morph PEH, finding that FEM accurately captured coupled strain and electrical response.

- Other Approaches: Qiu et al. [61] used wavelet analysis to predict dynamic responses and electricity generation in PEH from fluid–structure interactions. Dwivedi et al. [62] applied neural network models to predict power generation from piezoelectric cantilevers based on training datasets, enabling rapid optimization for different designs and loading conditions. Shu and Lien [63] developed lumped parameter models using electrical equivalents of inductors, resistors, and transformers to model a PEH.

2.6. Mechanisms and Fatigue

3. PEH Applications

3.1. Key Publications on PEH for Civil Engineering in the Last Decade

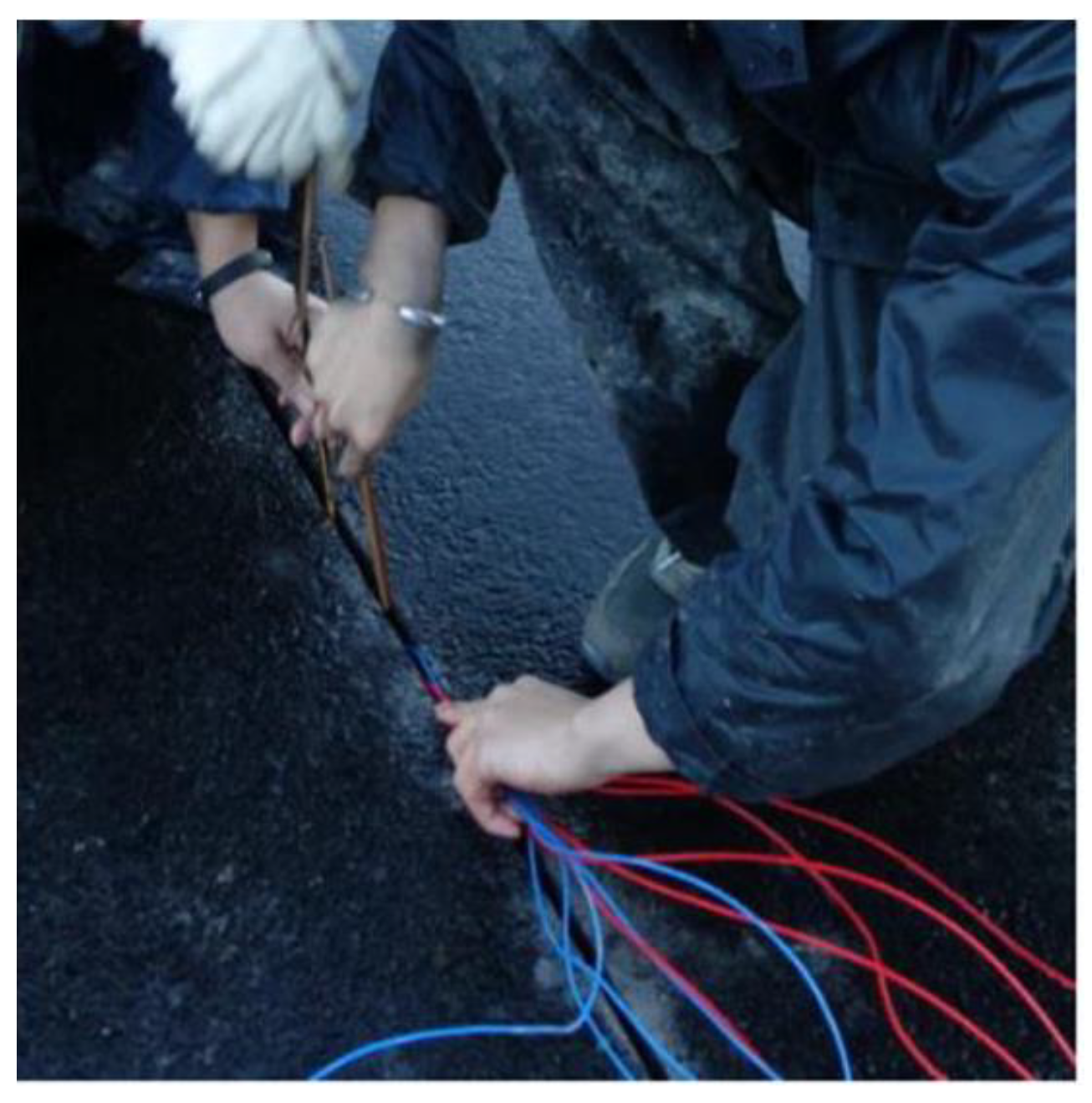

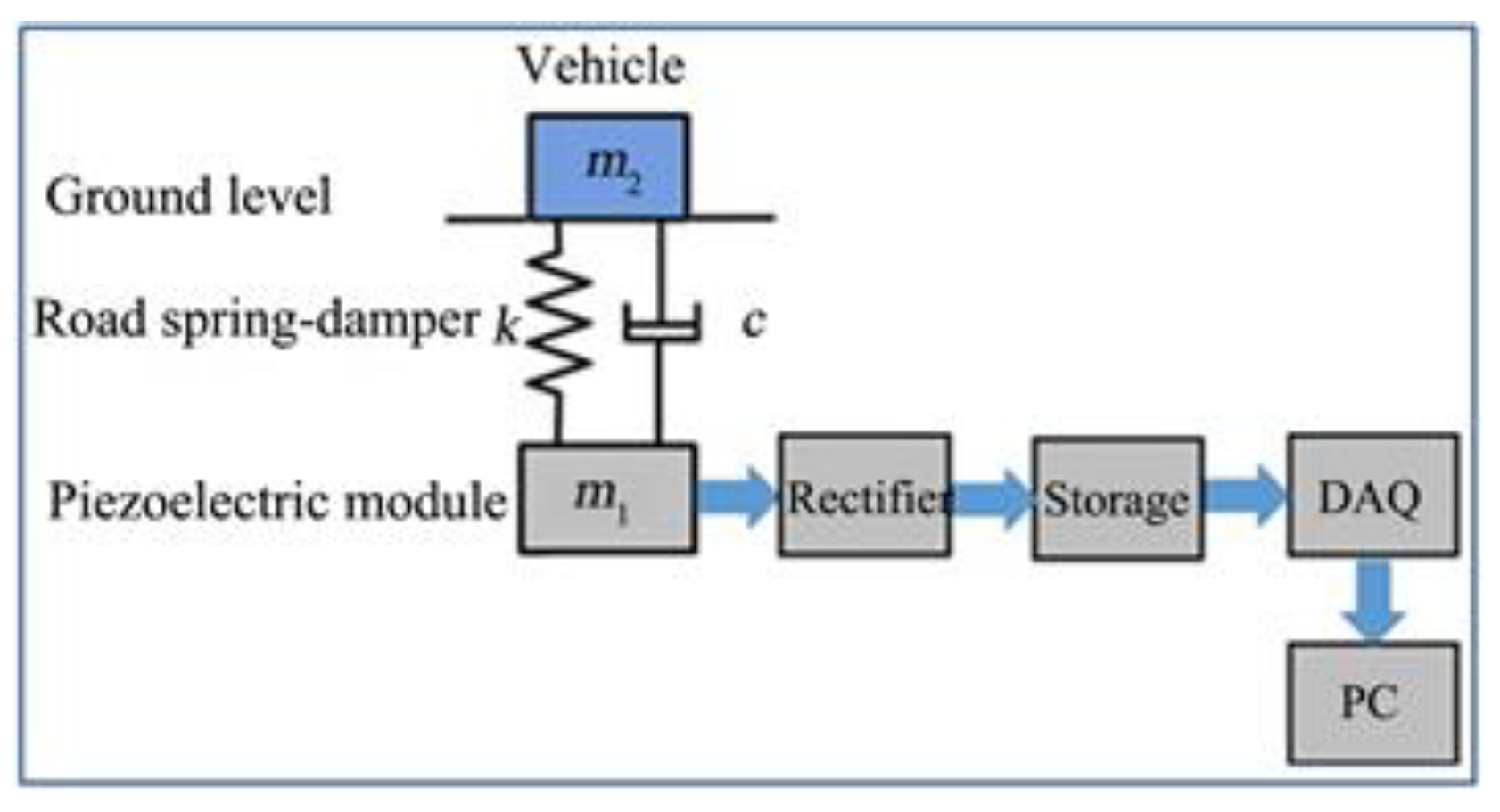

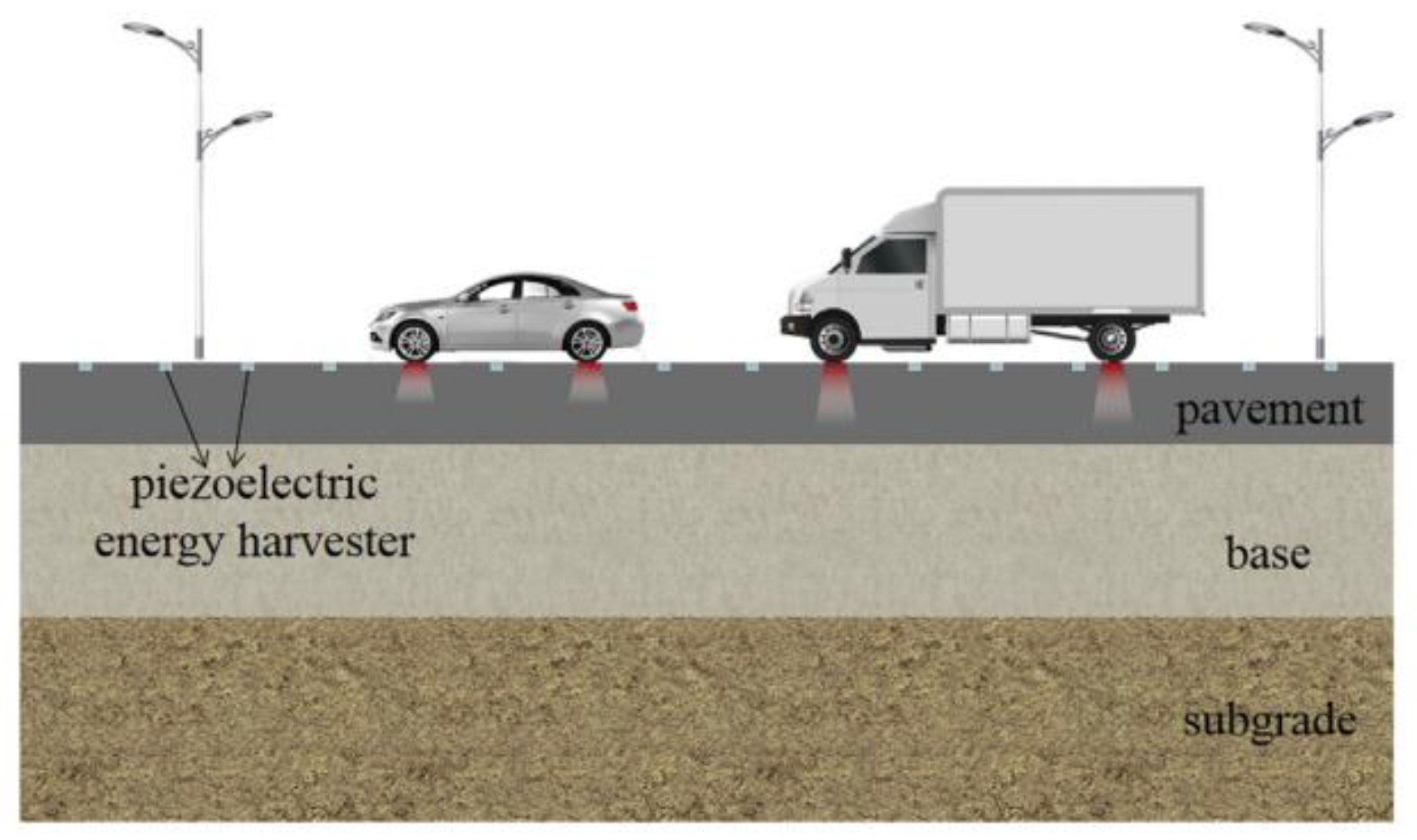

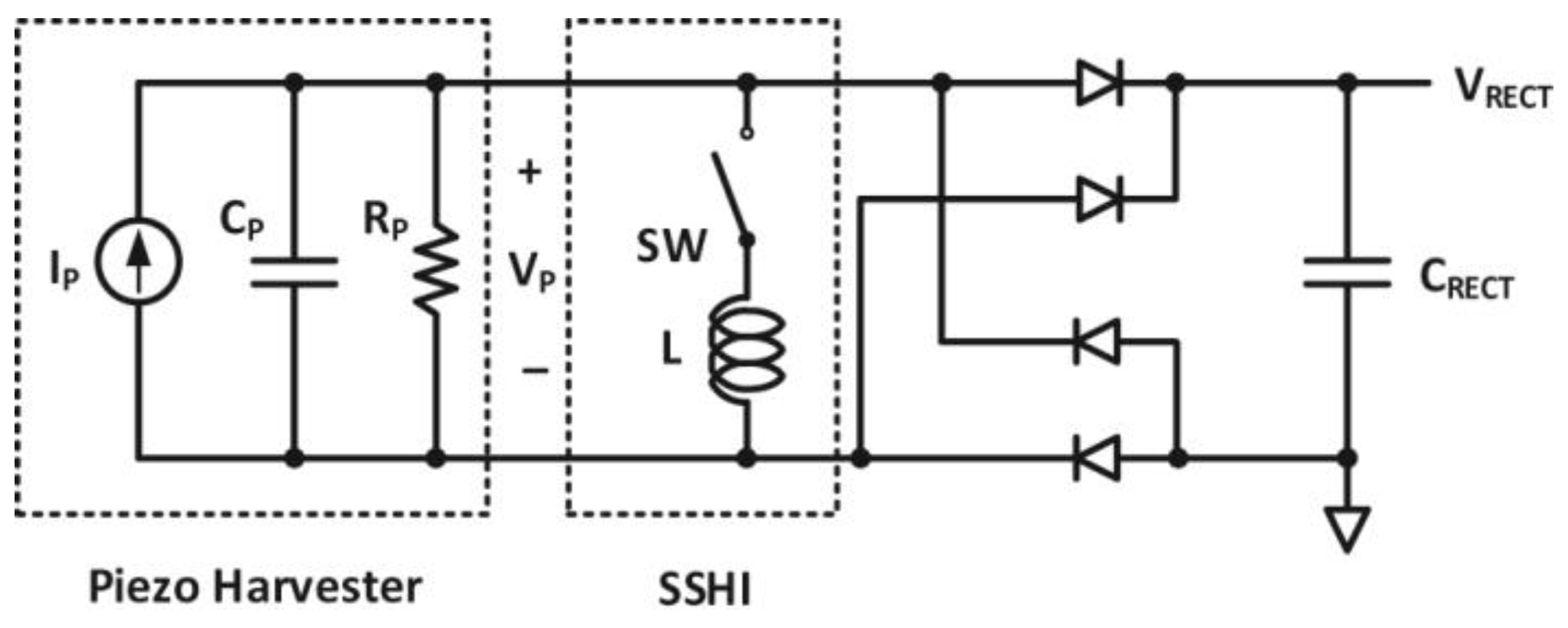

3.2. PEH Applications in Roadways

3.3. PEH Applications in Railways

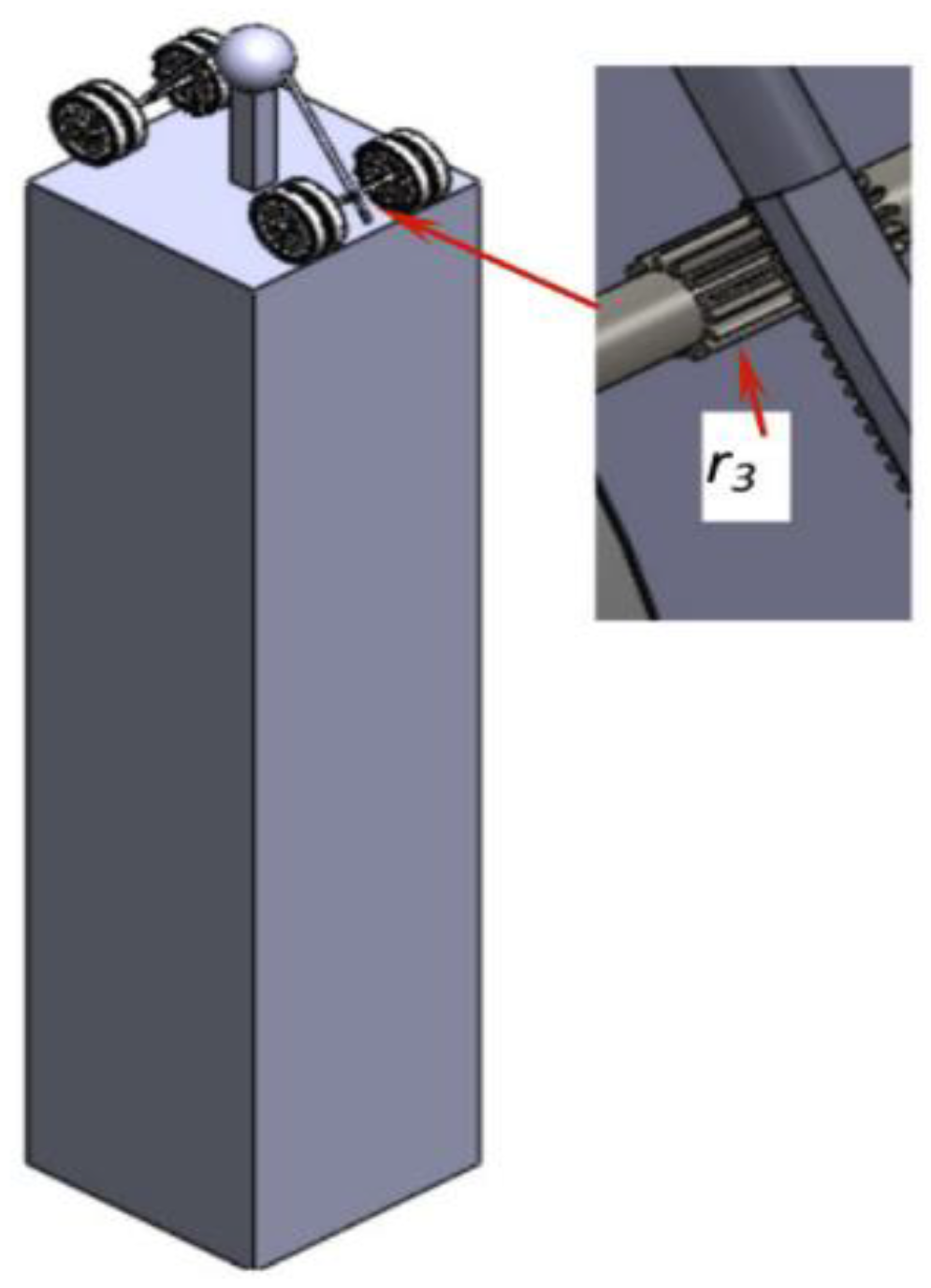

3.4. PEH Applications in Bridges

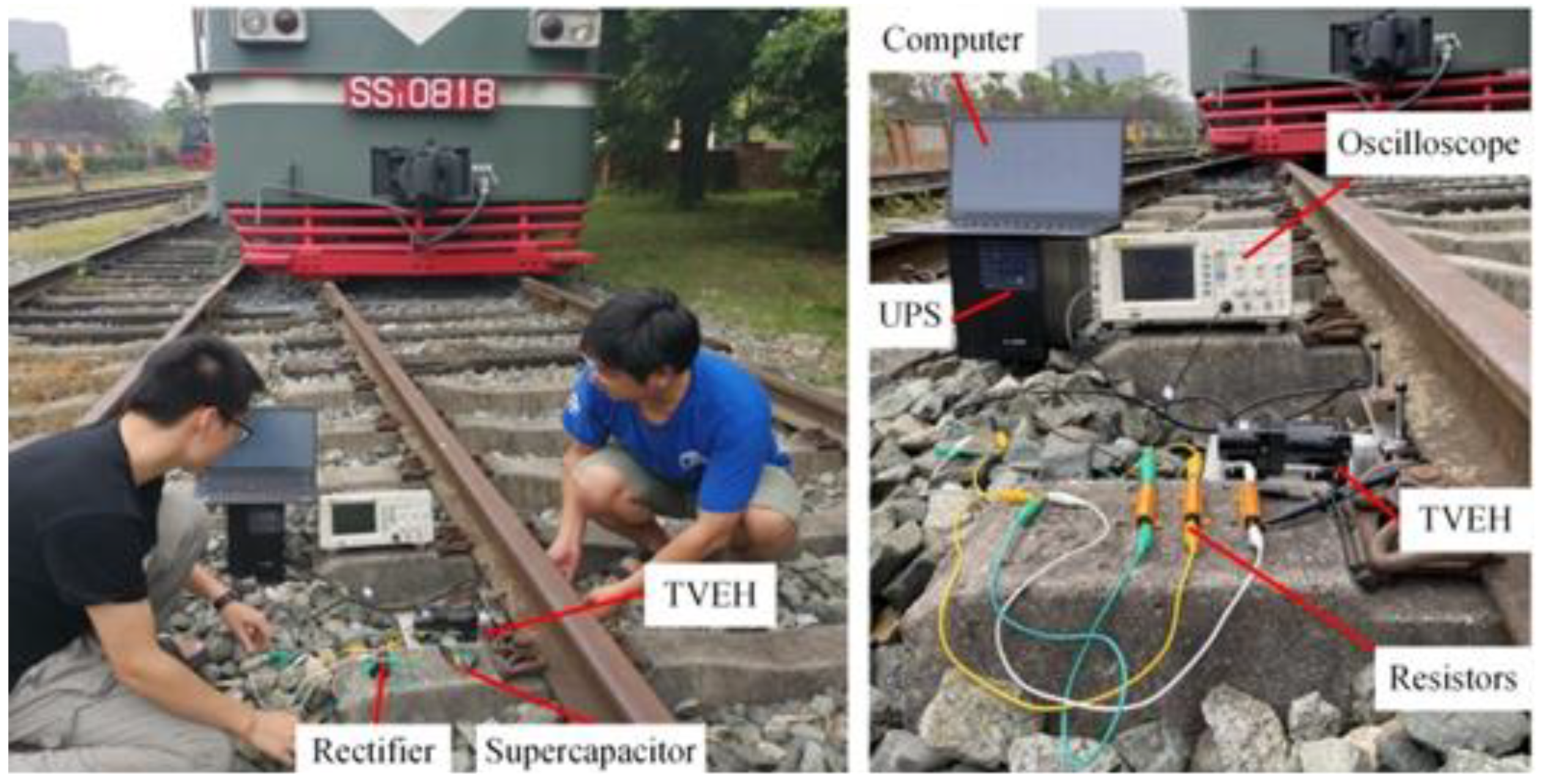

3.5. PEH Applications in Buildings

3.6. PEH Applications in Ocean Waves

3.7. PEH Applications in Structural Health Monitoring

- The EMI technique involves monitoring the electrical impedance of piezoelectric sensors bonded to the structure. Several research papers have explored the use of the EMI technique for damage detection in various structures, including composite materials, concrete structures, and metallic structures. For example, Annamdas et al. [185] demonstrated the use of the EMI technique for detecting and locating damage in reinforced concrete structures using surface-bonded piezoelectric sensors. They developed a damage index based on the impedance signatures and showed its effectiveness in identifying and locating simulated damage scenarios.

- Wave propagation-based methods involve exciting, guided waves in the structure using piezoelectric actuators and receiving the waves using piezoelectric sensors. The presence and location of damage can be inferred from the changes in the wave characteristics, such as wave velocity, amplitude, and mode conversion. Giurgiutiu et al. [186] investigated the use of piezoelectric wafer active sensors (PWAS) for detecting and locating damage in thin-walled structures using guided wave propagation methods. They developed algorithms for damage detection and localization based on the time-of-flight and amplitude analysis of the received signals. Raghavan and Cesnik [187] explored the use of piezoelectric sensors for damage detection in composite plates using guided wave propagation. They developed a damage metric based on the changes in the wave signals and demonstrated its effectiveness in detecting and locating various types of damage, including delamination and impact damage.

- In addition to the sensing techniques, researchers have also focused on developing advanced Signal Processing and Damage Identification Algorithms to enhance the accuracy and reliability of piezoelectric sensor-based SHM systems. Janeliukstis et al. [188] proposed a damage identification algorithm based on wavelet transform and Bayesian inference for piezoelectric sensor-based SHM of plate-like structures as shown in Figure 17. Gharibnezhad et al. [189] developed a damage detection algorithm based on the principal component analysis (PCA) of the piezoelectric sensor signals.

- Acoustic emission (AE) is defined as a term for the brief elastic stress waves that result from the energy released when a material undergoes microstructural changes [190]. Vibration is transmitted to the PZT inside the transducer through the wear plate when the transducers are pressed up against the material’s surface. The PZT element produces an electric signal when it vibrates.

- Piezo-floating-gates (PFG); a self-powered mechanical strain monitoring sensor was introduced by Salehi et al. [191]. It was based on the impact-ionized hot electron injection principle driven by piezoelectricity, and the floating gate serves as a non-volatile memory. The physics of hot electron injection and piezoelectric power harvesting are combined in this sensing technology to sense, compute, and store mechanical usage statistics.

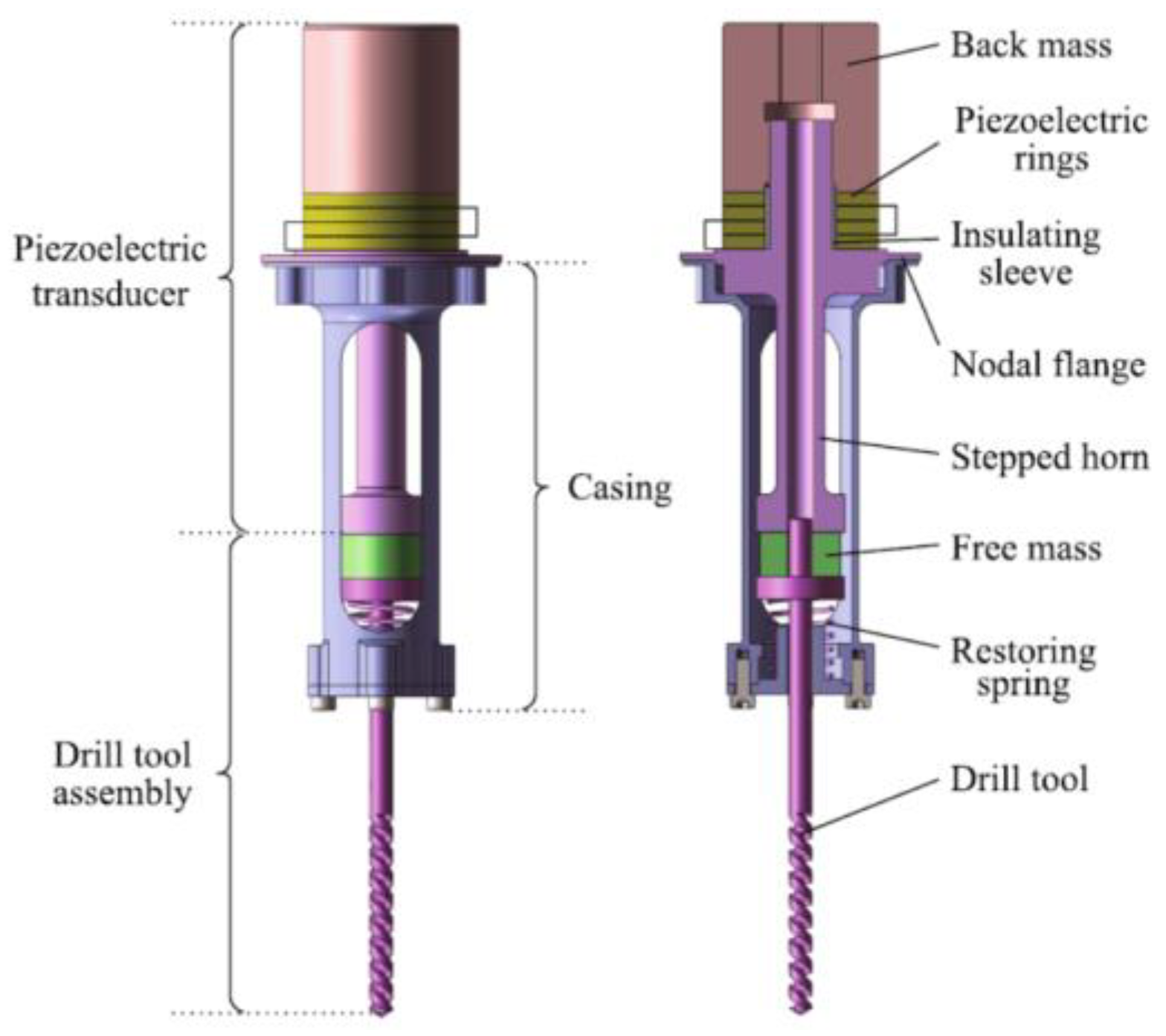

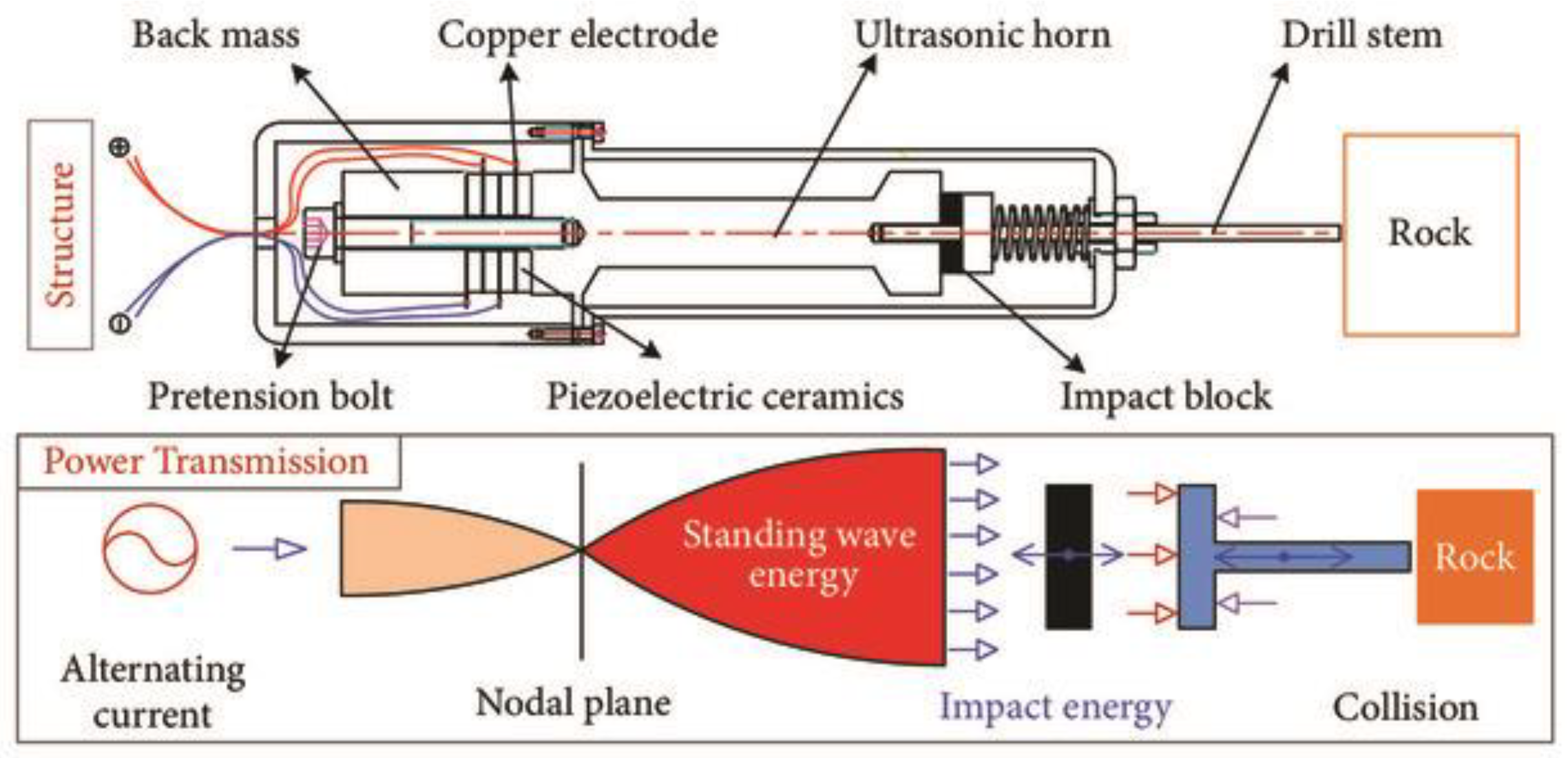

3.8. PEH in Extraterrestrial Applications

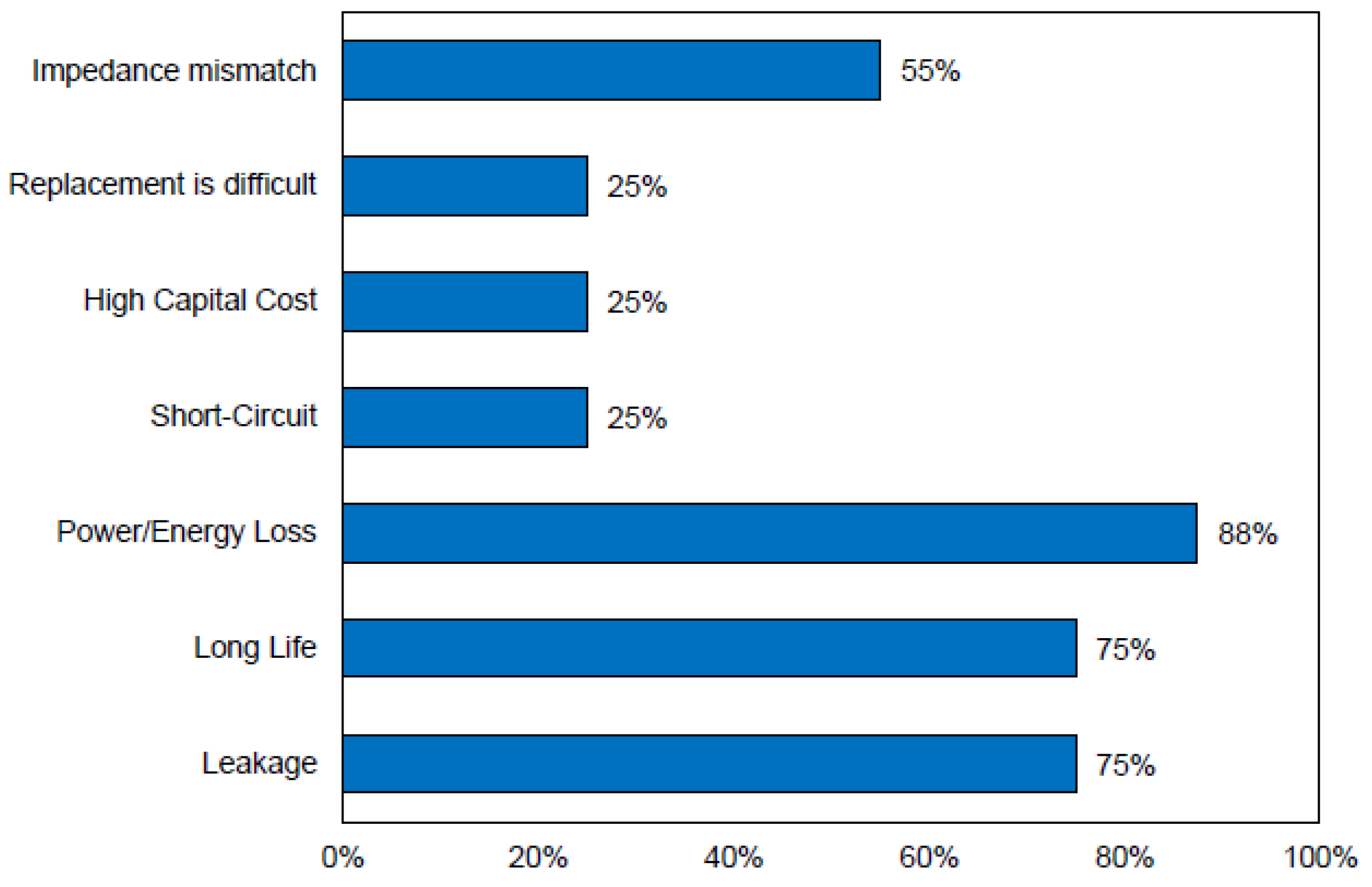

4. Challenges and Future Perspective

5. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y. Piezoelectric Based Energy Harvesting on Low Frequency Vibrations of Civil Infrastructures of Civil Infrastructures. Ph.D. Thesis, Louisiana State University, Baton Rouge, LA, USA, 2014. [Google Scholar]

- Aydin, A.C.; Çelebi, O. Piezoelectric Materials in Civil Engineering Applications: A Review. ACS Omega 2023, 8, 19168–19193. [Google Scholar] [CrossRef] [PubMed]

- Nechibvute, A.; Chawanda, A.; Luhanga, P. Piezoelectric Energy Harvesting Devices: An Alternative Energy Source for Wireless Sensors. Smart Mater. Res. 2012, 2012, 1–13. [Google Scholar] [CrossRef]

- Briscoe, J.; Dunn, S. Piezoelectric Nanogenerators—A Review of Nanostructured Piezoelectric Energy Harvesters. Nano Energy 2014, 14, 15–29. [Google Scholar] [CrossRef]

- Caliò, R.; Rongala, U.B.; Camboni, D.; Milazzo, M.; Stefanini, C.; de Petris, G.; Oddo, C.M. Piezoelectric Energy Harvesting Solutions. Sensors 2014, 14, 4755–4790. [Google Scholar] [CrossRef]

- Bowen, C.R.; Kim, H.A.; Weaver, P.M.; Dunn, S. Piezoelectric and Ferroelectric Materials and Structures for Energy Harvesting Applications. Energy Environ. Sci. 2014, 7, 25–44. [Google Scholar] [CrossRef]

- Elahi, H.; Eugeni, M.; Gaudenzi, P. A Review on Mechanisms for Piezoelectric-Based Energy Harvesters. Energies 2018, 11, 1850. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, S.; Zu, J.; Inman, D. High-Performance Piezoelectric Energy Harvesters and Their Applications. Joule 2018, 2, 642–697. [Google Scholar] [CrossRef]

- Sharma, P.K.; Baredar, P.V. Analysis on Piezoelectric Energy Harvesting Small Scale Device—A Review. J. King Saud. Univ. Sci. 2019, 31, 869–877. [Google Scholar] [CrossRef]

- Feng, Y.; Pan, G.; Wu, C. Experiment Study of Deformable Honeycomb Triboelectric Nanogenerator for Energy Collection and Vibration Measurement in Downhole. Appl. Sci. 2024, 14, 2539. [Google Scholar] [CrossRef]

- Safaei, M.; Sodano, H.A.; Anton, S.R. A Review of Energy Harvesting Using Piezoelectric Materials: State-of-the-Art a Decade Later (2008–2018). Smart Mater. Struct. 2019, 28, 113001. [Google Scholar] [CrossRef]

- Sarker, M.R.; Julai, S.; Sabri, M.F.M.; Said, S.M.; Islam, M.M.; Tahir, M. Review of Piezoelectric Energy Harvesting System and Application of Optimization Techniques to Enhance the Performance of the Harvesting System. Sens. Actuators A Phys. 2019, 300, 111634. [Google Scholar] [CrossRef]

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, 3512. [Google Scholar] [CrossRef] [PubMed]

- Ghazanfarian, J.; Mohammadi, M.M.; Uchino, K. Piezoelectric Energy Harvesting: A Systematic Review of Reviews. Actuators 2021, 10, 312. [Google Scholar] [CrossRef]

- Shi, Q.; Liu, H. Energy Harvesters and Self-Powered Sensors for Smart Electronics. Micromachines 2024, 15, 1455. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Lee, P.S. Piezoelectric Energy Harvesting Technology: From Materials, Structures, to Applications. Small Struct. 2022, 3, 2100128. [Google Scholar] [CrossRef]

- Priya, S.; Song, H.C.; Zhou, Y.; Varghese, R.; Chopra, A.; Kim, S.G.; Kanno, I.; Wu, L.; Ha, D.S.; Ryu, J.; et al. A Review on Piezoelectric Energy Harvesting: Materials, Methods, and Circuits. Energy Harvest. Syst. 2019, 4, 3–39. [Google Scholar] [CrossRef]

- Bera, B.; Das Sarkar, M. Piezoelectric Effect, Piezotronics and Piezophototronics: A Review. Imp. J. Interdiscip. Res. (IJIR) 2016, 2, 1407–1410. [Google Scholar]

- Damjanovic, D. Stress and Frequency Dependence of the Direct Piezoelectric Effect in Ferroelectric Ceramics. J. Appl. Phys. 1997, 82, 1788–1797. [Google Scholar] [CrossRef]

- Hamdi, O.; Mighri, F.; Rodrigue, D. Piezoelectric Polymer Films: Synthesis, Applications, and Modeling. In Polymer Nanocomposite-Based Smart Materials: From Synthesis to Application; Elsevier: Amsterdam, The Netherlands, 2020; pp. 79–101. ISBN 9780081030134. [Google Scholar]

- Krishna, G.M.; Rajanna, K. Tactile Sensor Based on Piezoelectric Resonance. IEEE Sens. J. 2004, 4, 691–697. [Google Scholar] [CrossRef]

- Getman, I.; Lopatin, S. Matching of Series and Parallel Resonance Frequencies for Ultrasonic Piezoelectric Transducers. In Proceedings of the 2000 12th IEEE International Symposium on Applications of Ferroelectrics (IEEE Cat. No. 00CH37076); IEEE: New York, NY, USA, 2001. [Google Scholar]

- Lin, S. Study on the Parallel Electric Matching of High Power Piezoelectric Transducers. Acta Acust. United Acust. 2017, 103, 385–391. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Addoweesh, K.E. A Novel Self-Power SSHI Circuit for Piezoelectric Energy Harvester. IEEE Trans. Power Electron. 2017, 32, 7663–7673. [Google Scholar] [CrossRef]

- Sekhar, M.C.; Veena, E.; Kumar, N.S.; Naidu, K.C.B.; Mallikarjuna, A.; Basha, D.B. A Review on Piezoelectric Materials and Their Applications. Cryst. Res. Technol. 2023, 58, 2200130. [Google Scholar] [CrossRef]

- Martínez-Ayuso, G.; Friswell, M.I.; Haddad Khodaparast, H.; Roscow, J.I.; Bowen, C.R. Electric Field Distribution in Porous Piezoelectric Materials during Polarization. Acta Mater. 2019, 173, 332–341. [Google Scholar] [CrossRef]

- Guerin, S.; Tofail, S.A.M.; Thompson, D. Organic Piezoelectric Materials: Milestones and Potential. NPG Asia Mater. 2019, 11, 10. [Google Scholar] [CrossRef]

- de Carvalho, F.A.; Nobre, J.N.P.; Cambraia, R.P.; Silva, A.C.; Fabris, J.D.; Dos Reis, A.B.; Prat, B.V. Quartz Mining Waste for Concrete Production: Environment and Public Health. Sustainability 2022, 14, 389. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Yu, F.; Jiang, X.; Lee, H.Y.; Luo, J.; Shrout, T.R. Recent Developments in Piezoelectric Crystals. J. Korean Ceram. Soc. 2018, 55, 419–439. [Google Scholar] [CrossRef]

- Brown, C.; Kell, R.; Taylor, R.; Thomas, L. Piezoelectric materials, a review of progress. IRE Trans. Compon. Parts 1962, 9, 193–211. [Google Scholar] [CrossRef]

- Habib, M.; Lantgios, I.; Hornbostel, K. A Review of Ceramic, Polymer and Composite Piezoelectric Materials. J. Phys. D Appl. Phys. 2022, 55, 423002. [Google Scholar] [CrossRef]

- Patel, I.; Siores, E.; Shah, T. Utilisation of Smart Polymers and Ceramic Based Piezoelectric Materials for Scavenging Wasted Energy. Sens. Actuators A Phys. 2010, 159, 213–218. [Google Scholar] [CrossRef]

- Galassi, C. Processing of Porous Ceramics: Piezoelectric Materials. J. Eur. Ceram. Soc. 2006, 26, 2951–2958. [Google Scholar] [CrossRef]

- Jordan, T.L. Piezoelectric Ceramics Characterization; Universities Space Research Association: Washington, DC, USA, 2001. [Google Scholar]

- Das Mahapatra, S.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric Materials for Energy Harvesting and Sensing Applications: Roadmap for Future Smart Materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef] [PubMed]

- Ramadan, K.S.; Sameoto, D.; Evoy, S. A Review of Piezoelectric Polymers as Functional Materials for Electromechanical Transducers. Smart Mater. Struct. 2014, 23, 033001. [Google Scholar] [CrossRef]

- Smith, M.; Kar-Narayan, S. Piezoelectric Polymers: Theory, Challenges and Opportunities. Int. Mater. Rev. 2022, 67, 65–88. [Google Scholar] [CrossRef]

- Usher, T.D.; Cousins, K.R.; Zhang, R.; Ducharme, S. The Promise of Piezoelectric Polymers. Polym. Int. 2018, 67, 790–798. [Google Scholar] [CrossRef]

- Veved, A.; Ejuh, G.W.; Djongyang, N. Review of Emerging Materials for PVDF-Based Energy Harvesting. Energy Rep. 2022, 8, 12853–12870. [Google Scholar] [CrossRef]

- Kovalovs, A.; Barkanov, E.; Gluhihs, S. Active Control of Structures Using Macro-Fiber Composite (MFC). J. Phys. Conf. Ser. 2007, 93, 012034. [Google Scholar] [CrossRef]

- Wang, T.; Roychowdhury, J. Rigorous Q Factor Formulation and Characterization for Nonlinear Oscillators. arXiv 2017, arXiv:1710.02015. [Google Scholar]

- Tu, R.; Sprague, E.; Sodano, H.A. Precipitation-Printed High-β Phase Poly(Vinylidene Fluoride) for Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 58072–58081. [Google Scholar] [CrossRef]

- Pei, H.; Shi, S.; Chen, Y.; Xiong, Y.; Lv, Q. Combining Solid-State Shear Milling and FFF 3D-Printing Strategy to Fabricate High-Performance Biomimetic Wearable Fish-Scale PVDF-Based Piezoelectric Energy Harvesters. ACS Appl. Mater. Interfaces 2022, 14, 15346–15359. [Google Scholar] [CrossRef]

- Jeong, C.K.; Han, J.H.; Palneedi, H.; Park, H.; Hwang, G.T.; Joung, B.; Kim, S.G.; Shin, H.J.; Kang, I.S.; Ryu, J.; et al. Comprehensive Biocompatibility of Nontoxic and High-Output Flexible Energy Harvester Using Lead-Free Piezoceramic Thin Film. APL Mater. 2017, 5, 074102. [Google Scholar] [CrossRef]

- Park, J., II; Lee, G.Y.; Yang, J.; Kim, C.S.; Ahn, S.H. Flexible Ceramic-Elastomer Composite Piezoelectric Energy Harvester Fabricated by Additive Manufacturing. J. Compos. Mater. 2016, 50, 1573–1579. [Google Scholar] [CrossRef]

- Lozano Montero, K.; Laurila, M.-M.; Mäntysalo, M. Effect of Electrode Structure on the Performance of Fully Printed Piezoelectric Energy Harvesters. IEEE J. Flex. Electron. 2022, 1, 24–31. [Google Scholar] [CrossRef]

- Wu, N.; He, Y.; Fu, J.; Liao, P. Study of the Properties of a Hybrid Piezoelectric and Electromagnetic Energy Harvester for a Civil Engineering Low-Frequency Sloshing Environment. Energies 2021, 14, 391. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, S.C.S.; Deng, L. Piezoelectric-Based Energy Harvesting in Bridge Systems. J. Intell. Mater. Syst. Struct. 2014, 25, 1414–1428. [Google Scholar] [CrossRef]

- Kim, J.W.; Lee, C.; Park, S. Damage Localization for CFRP-Debonding Defects Using Piezoelectric Shm Techniques. Res. Nondestruct. Eval. 2012, 23, 183–196. [Google Scholar] [CrossRef]

- Tzou, H.S.; Tseng, C.I. Distributed piezoelectric sensor/actuator design for dynamic measurement/control of distributed parameter systems: A piezoelectric finite element approach. J. Sound Vib. 1990, 138, 17–34. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D.J. An Experimentally Validated Bimorph Cantilever Model for Piezoelectric Energy Harvesting from Base Excitations. Smart Mater. Struct. 2009, 18, 025009. [Google Scholar] [CrossRef]

- Ibrahim, D.S.; Muthalif, A.G.A.; Nordin, N.H.D.; Saleh, T. Comparative Study of Conventional and Magnetically Coupled Piezoelectric Energy Harvester to Optimize Output Voltage and Bandwidth. Microsyst. Technol. 2017, 23, 2663–2674. [Google Scholar] [CrossRef]

- Cahill, P.; Hazra, B.; Karoumi, R.; Mathewson, A.; Pakrashi, V. Data of Piezoelectric Vibration Energy Harvesting of a Bridge Undergoing Vibration Testing and Train Passage. Data Brief. 2018, 17, 261–266. [Google Scholar] [CrossRef]

- Bian, Y.; Zhang, Y.; Sun, K.; Jin, H.; Dai, L.; Shen, H. A Biomimetic Vibration Sensor Using a Symmetric Electrodes Metal Core Piezoelectric Fiber. J. Intell. Mater. Syst. Struct. 2018, 29, 1015–1024. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D.J. A Distributed Parameter Electromechanical Model for Cantilevered Piezoelectric Energy Harvesters. J. Vib. Acoust. 2008, 130, 041002. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.K. A Piezoelectric Vibration Based Generator for Wireless Electronics. Smart Mater. Struct. 2004, 13, 1131–1142. [Google Scholar] [CrossRef]

- Triplett, A.; Quinn, D.D. The Effect of Non-Linear Piezoelectric Coupling on Vibration-Based Energy Harvesting. J. Intell. Mater. Syst. Struct. 2009, 20, 1959–1967. [Google Scholar] [CrossRef]

- Badel, A.; Guyomar, D.; Lefeuvre, E.; Richard, C. Piezoelectric Energy Harvesting Using a Synchronized Switch Technique. J. Intell. Mater. Syst. Struct. 2006, 17, 831–839. [Google Scholar] [CrossRef]

- Shen, H.; Qiu, J.; Ji, H.; Zhu, K.; Balsi, M.; Giorgio, I.; Dell’Isola, F. A Low-Power Circuit for Piezoelectric Vibration Control by Synchronized Switching on Voltage Sources. Sens. Actuators A Phys. 2010, 161, 245–255. [Google Scholar] [CrossRef]

- De Marqui Junior, C.; Erturk, A.; Inman, D.J. An Electromechanical Finite Element Model for Piezoelectric Energy Harvester Plates. J. Sound. Vib. 2009, 327, 9–25. [Google Scholar] [CrossRef]

- Qiu, J.; Jiang, H.; Ji, H.; Zhu, K. Comparison between Four Piezoelectric Energy Harvesting Circuits. Front. Mech. Eng. China 2009, 4, 153–159. [Google Scholar] [CrossRef]

- Dwivedi, A.; Banerjee, A.; Adhikari, S.; Bhattacharya, B. Optimal Electromechanical Bandgaps in Piezo-Embedded Mechanical Metamaterials. Int. J. Mech. Mater. Des. 2021, 17, 419–439. [Google Scholar] [CrossRef]

- Shu, Y.C.; Lien, I.C. Analysis of Power Output for Piezoelectric Energy Harvesting Systems. Smart Mater. Struct. 2006, 15, 1499–1512. [Google Scholar] [CrossRef]

- Peigney, M.; Siegert, D. Piezoelectric Energy Harvesting from Traffic-Induced Bridge Vibrations. Smart Mater. Struct. 2013, 22, 095019. [Google Scholar] [CrossRef]

- Tzou, H.S.; Zhou, Y.H. Dynamics and control of non-linear circular plates with piezoelectric actuators. J. Sound Vib. 1995, 188, 189–207. [Google Scholar] [CrossRef]

- Dai, H.L.; Abdelkefi, A.; Wang, L. Piezoelectric Energy Harvesting from Concurrent Vortex-Induced Vibrations and Base Excitations. Nonlinear Dyn. 2014, 77, 967–981. [Google Scholar] [CrossRef]

- Quinn, D.D.; Triplett, A.L.; Vakakis, A.F.; Bergman, L.A. Energy Harvesting from Impulsive Loads Using Intentional Essential Nonlinearities. J. Vib. Acoust. 2011, 133, 011004. [Google Scholar] [CrossRef]

- Li, H.; Tian, C.; Deng, Z.D. Energy Harvesting from Low Frequency Applications Using Piezoelectric Materials. Appl. Phys. Rev. 2014, 1, 041301. [Google Scholar] [CrossRef]

- Daniels, A.; Giuliano, A.; Zhu, M.; Tiwari, A. Modeling, Validation and Design Analyses of a Piezoelectric Cymbal Transducer for Non-Resonant Energy Harvesting. In Proceedings of the 2013 IEEE International Conference on Green Computing and Communications and IEEE Internet of Things and IEEE Cyber, Physical and Social Computing, Beijing, China, 20–23 August 2013; pp. 1665–1667. [Google Scholar]

- Wang, H.; Jasim, A. Piezoelectric Energy Harvesting from Pavement. In Eco-Efficient Pavement Construction Materials; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 367–382. ISBN 9780128189818. [Google Scholar]

- Divsholi, B.S.; Yang, Y.; Bing, L. Monitoring Beam-Column Joint in Concrete Structures Using Piezolmpedance Sensors. Adv. Mater. Res. 2009, 79–82, 59–62. [Google Scholar] [CrossRef]

- Kim, H.; Gweon, D.G. Development of a Compact and Long Range XYθ z Nano-Positioning Stage. Rev. Sci. Instrum. 2012, 83, 085102. [Google Scholar] [CrossRef]

- Jiang, M.; Liu, X.; Chen, G.; Zhou, C. Dielectric and Piezoelectric Properties of LiSbO3 Doped 0.995 K0.5Na0.5NbO3-0.005BiFeO3 Piezoelectric Ceramics. Mater. Lett. 2009, 63, 1262–1265. [Google Scholar] [CrossRef]

- Uprety, B.; Kim, S.; Mathews, V.J.; Adams, D.O. A Comparative Evaluation of Piezoelectric Sensors for Acoustic Emission-Based Impact Location Estimation and Damage Classification in Composite Structures. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2015; Volume 1650, pp. 1146–1154. [Google Scholar]

- Kitagawa, Y.; Takeshita, M.; Tamai, H.; Miura, K. Characteristics of Piezoelectric Damper in Smart Structural System. In Smart Structures and Materials 2003: Smart Systems and Nondestructive Evaluation for Civil Infrastructures; SPIE: Cergy, France, 2003. [Google Scholar]

- Nijesh Kunnamkuzhakkal, J.; Van Den Ende, D.; Lafont, U.; Van Der Zwaag, S.; Groen, W.A. Piezoelectric and Mechanical Properties of Structured PZT-Epoxy Composites. J. Mater. Res. 2013, 28, 635–641. [Google Scholar] [CrossRef]

- Lin, B.; Gresil, M.; Giurgiutiu, V.; Mendez-Torres, A.E. Structural health monitoring with piezoelectric wafer active sensors exposed to irradiation effects. In Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, Toronto, ON, Canada, 15–19 July 2012. [Google Scholar]

- Downey, A.; D’Alessandro, A.; Laflamme, S.; Ubertini, F. Smart Bricks for Strain Sensing and Crack Detection in Masonry Structures. Smart Mater. Struct. 2018, 27, 015009. [Google Scholar] [CrossRef]

- Zanuy, C.; Albajar, L.; De La Fuente, P. Serviceability of Reinforced Concrete Beams under High-Cycle Fatigue Loading. In Large Structures and Infrastructures for Environmentally Constrained and Urbanised Areas; International Association for Bridge and Structural Engineering (IABSE): Zurich, Switzerland, 2010; pp. 100–101. [Google Scholar]

- Avvari, P.V.; Yang, Y.; Soh, C.K. Long-Term Fatigue Behavior of a Cantilever Piezoelectric Energy Harvester. J. Intell. Mater. Syst. Struct. 2017, 28, 1188–1210. [Google Scholar] [CrossRef]

- Yang, H.; Wang, L.; Zhou, B.; Wei, Y.; Zhao, Q. A Preliminary Study on the Highway Piezoelectric Power Supply System. Int. J. Pavement Res. Technol. 2018, 11, 168–175. [Google Scholar] [CrossRef]

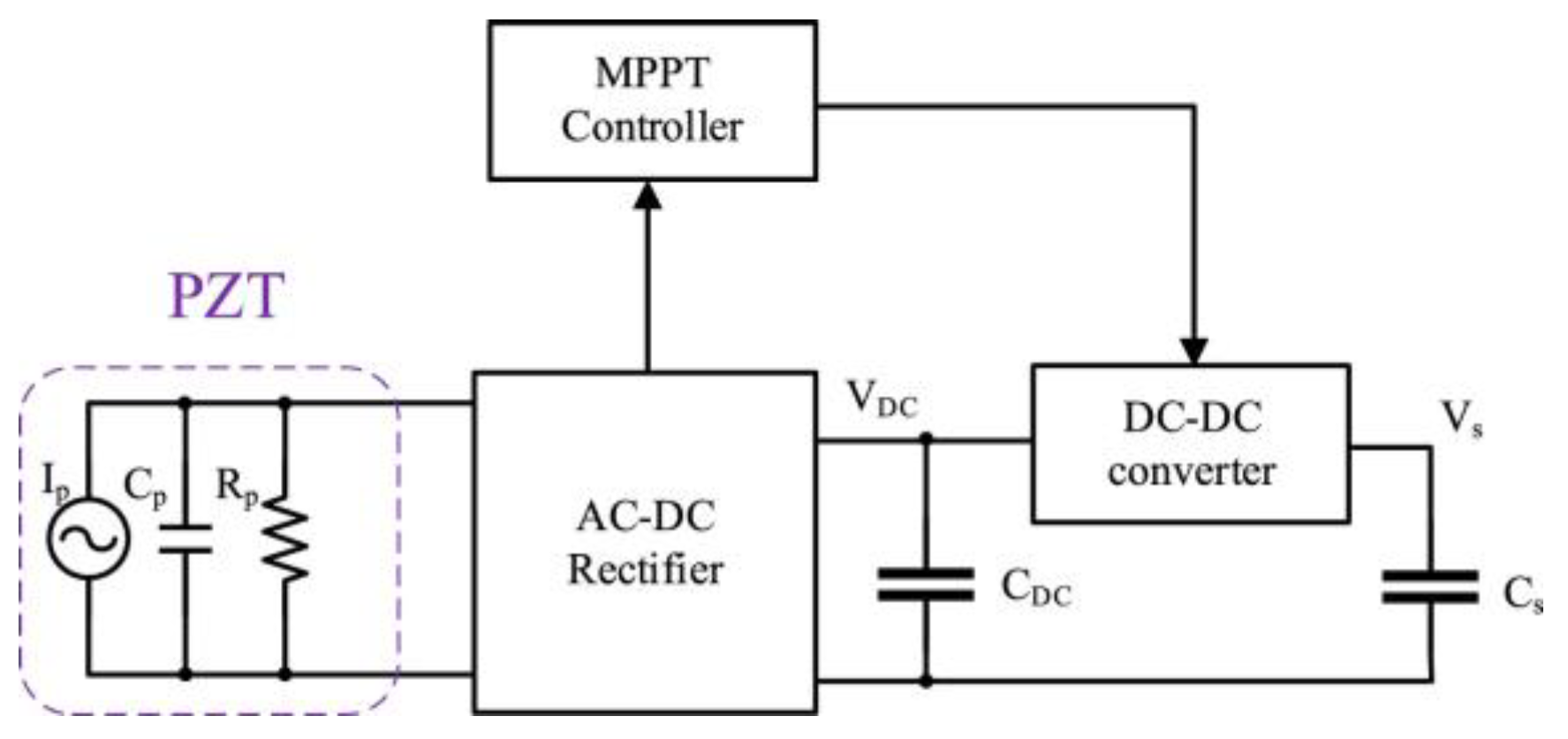

- Wang, X.; Xia, Y.; Shi, G.; Xia, H.; Chen, M.; Chen, Z.; Ye, Y.; Qian, L. A Novel MPPT Technique Based on the Envelope Extraction Implemented with Passive Components for Piezoelectric Energy Harvesting. IEEE Trans. Power Electron. 2021, 36, 12685–12693. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, S.; Wang, C.; Song, Z.; Li, Y. Design of Piezoelectric Device Compatible with Pavement Considering Traffic: Simulation, Laboratory and on-Site. Appl. Energy 2022, 306, 118153. [Google Scholar] [CrossRef]

- Song, Y. Finite-Element Implementation of Piezoelectric Energy Harvesting System from Vibrations of Railway Bridge. J. Energy Eng. 2019, 145, 04018076. [Google Scholar] [CrossRef]

- Hong, S.D.; Kim, K.B.; Hwang, W.; Song, Y.S.; Cho, J.Y.; Yeong Jeong, S.; Ahn, J.H.; Kim, G.H.; Cheong, H.; Sung, T.H. Enhanced Energy-Generation Performance of a Landfilled Road-Capable Piezoelectric Harvester to Scavenge Energy from Passing Vehicles. Energy Convers. Manag. 2020, 215, 112900. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiang, H.; Shi, Z. Modeling on Piezoelectric Energy Harvesting from Pavements under Traffic Loads. J. Intell. Mater. Syst. Struct. 2016, 27, 567–578. [Google Scholar] [CrossRef]

- Song, Y.; Yang, C.H.; Hong, S.K.; Hwang, S.J.; Kim, J.H.; Choi, J.Y.; Ryu, S.K.; Sung, T.H. Road Energy Harvester Designed as a Macro-Power Source Using the Piezoelectric Effect. Int. J. Hydrogen Energy 2016, 41, 12563–12568. [Google Scholar] [CrossRef]

- Jasim, A.; Wang, H.; Yesner, G.; Safari, A.; Maher, A. Optimized Design of Layered Bridge Transducer for Piezoelectric Energy Harvesting from Roadway. Energy 2017, 141, 1133–1145. [Google Scholar] [CrossRef]

- Khalili, M.; Biten, A.B.; Vishwakarma, G.; Ahmed, S.; Papagiannakis, A.T. Electro-Mechanical Characterization of a Piezoelectric Energy Harvester. Appl. Energy 2019, 253, 113585. [Google Scholar] [CrossRef]

- Cho, J.Y.; Kim, K.B.; Hwang, W.S.; Yang, C.H.; Ahn, J.H.; Hong, S.D.; Jeon, D.H.; Song, G.J.; Ryu, C.H.; Woo, S.B.; et al. A Multifunctional Road-Compatible Piezoelectric Energy Harvester for Autonomous Driver-Assist LED Indicators with a Self-Monitoring System. Appl. Energy 2019, 242, 294–301. [Google Scholar] [CrossRef]

- Jung, I.; Shin, Y.H.; Kim, S.; Choi, J.Y.; Kang, C.Y. Flexible Piezoelectric Polymer-Based Energy Harvesting System for Roadway Applications. Appl. Energy 2017, 197, 222–229. [Google Scholar] [CrossRef]

- Cao, Y.; Li, J.; Sha, A.; Liu, Z.; Zhang, F.; Li, X. A Power-Intensive Piezoelectric Energy Harvester with Efficient Load Utilization for Road Energy Collection: Design, Testing, and Application. J. Clean. Prod. 2022, 369, 133287. [Google Scholar] [CrossRef]

- Bogatsis, I.; Rigogiannis, N.; Tsakiridis, C.; Kyritsis, A.; Papanikolaou, N. Overview and Experimental Study of Piezolectric Energy Harvesters for Roadway Applications. In Proceedings of the 2023 4th International Conference on Communications, Information, Electronic and Energy Systems (CIEES), Plovdiv, Bulgaria, 23–25 November 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NY, USA, 2023. [Google Scholar]

- Bartasyte, A.; Clementi, G.; Micard, Q.; Labbaveettil Basheer, I.; De Sousa, A.; Moreira, L.; Boujnah, S.; Ouhabaz, M.; Verma, A.; Ichangi, A.; et al. Material Strategies to Enhance the Performance of Piezoelectric Energy Harvesters Based on Lead-Free Materials. J. Micromech. Microeng. 2023, 2023, 053001. [Google Scholar] [CrossRef]

- Ahn, J.H.; Hwang, W.S.; Jeong, S.; Cho, J.Y.; Hong, S.D.; Hwang, S.J.; Song, G.J.; Yoo, H.H.; Sung, T.H. Nonlinear Piezoelectric Energy Harvester with Ball Tip Mass. Sens. Actuators A Phys. 2018, 277, 124–133. [Google Scholar] [CrossRef]

- Wang, H.; Meng, Q. Analytical Modeling and Experimental Verification of Vibration-Based Piezoelectric Bimorph Beam with a Tip-Mass for Power Harvesting. Mech. Syst. Signal Process 2013, 36, 193–209. [Google Scholar] [CrossRef]

- Muhamad, A.; Arifin, A.; Asri, A.; Nooraiin Mohd Razali, S.; Musa Mohamed, H. A Study of Piezoelectric as Electric Transducer on Asphalt Pavement. Multidiscip. Appl. Res. Innov. 2021, 2, 46–60. [Google Scholar]

- Tittmann, B.R.; Parks, D.A.; Zhang, S.O. High Temperature Piezoelectrics—A Comparison. In Proceedings of the 13th International Symposium on Nondestructive Characterization of Materials (NDCM-XIII), Le Mans, France, 20–24 May 2013. [Google Scholar]

- Noh, H.M. Acoustic Energy Harvesting Using Piezoelectric Generator for Railway Environmental Noise. Adv. Mech. Eng. 2018, 10, 1687814018785058. [Google Scholar] [CrossRef]

- Isacsson, U.; Lu, X. Testing and Appraisal of Polymer Modified Road Bitumens-State of the Art. Mater. Struct. 1995, 28, 139–159. [Google Scholar] [CrossRef]

- Sherren, A.; Fink, K.; Eshelman, J.; Taha, L.Y.; Anwar, S.; Brennecke, C. Design and Modelling of Piezoelectric Road Energy Harvesting. Open J. Energy Effic. 2022, 11, 24–36. [Google Scholar] [CrossRef]

- Cao, Y.; Sha, A.; Liu, Z.; Li, J.; Jiang, W. Energy Output of Piezoelectric Transducers and Pavements under Simulated Traffic Load. J. Clean. Prod. 2021, 279, 123508. [Google Scholar] [CrossRef]

- Qabur, A.; Alshammari, K. A Systematic Review of Energy Harvesting from Roadways by Using Piezoelectric Materials Technology. Innov. Energy Res. 2018, 7, 1–6. [Google Scholar] [CrossRef]

- Zhao, H.; Qin, L.; Ling, J. Synergistic Performance of Piezoelectric Transducers and Asphalt Pavement. Int. J. Pavement Res. Technol. 2018, 11, 381–387. [Google Scholar] [CrossRef]

- Wu, N.; Bao, B.; Wang, Q. Review on Engineering Structural Designs for Efficient Piezoelectric Energy Harvesting to Obtain High Power Output. Eng. Struct. 2021, 235, 112068. [Google Scholar] [CrossRef]

- Wale, P.; Patil, C.; Thakare, A.; Vinchurkar, A.; Pagare, P. Generation of electricity from roads by using piezoelectric sensors. Int. J. Creat. Thoughts 2021, 9, b799–b804. [Google Scholar]

- Wang, S.; Wang, C.; Yuan, H.; Ji, X.; Yu, G.; Jia, X. Size Effect of Piezoelectric Energy Harvester for Road with High Efficiency Electrical Properties. Appl. Energy 2023, 330, 120379. [Google Scholar] [CrossRef]

- Jiang, X.; Li, Y.; Li, J.; Wang, J.; Yao, J. Piezoelectric Energy Harvesting from Traffic-Induced Pavement Vibrations. J. Renew. Sustain. Energy 2014, 6, 043110. [Google Scholar] [CrossRef]

- Mehmood, A.; Abdelkefi, A.; Hajj, M.R.; Nayfeh, A.H.; Akhtar, I.; Nuhait, A.O. Piezoelectric Energy Harvesting from Vortex-Induced Vibrations of Circular Cylinder. J. Sound. Vib. 2013, 332, 4656–4667. [Google Scholar] [CrossRef]

- Zhu, M.; Worthington, E.; Tiwari, A. Design Study of Piezoelectric Energy-Harvesting Devices for Generation of Higher Electrical Power Using a Coupled Piezoelectric-Circuit Finite Element Method. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 427–437. [Google Scholar] [CrossRef]

- De Fazio, R.; De Giorgi, M.; Cafagna, D.; Del-Valle-Soto, C.; Visconti, P. Energy Harvesting Technologies and Devices from Vehicular Transit and Natural Sources on Roads for a Sustainable Transport: State-of-the-Art Analysis and Commercial Solutions. Energies 2023, 16, 3016. [Google Scholar] [CrossRef]

- Lefeuvre, E.; Lallart, M.; Richard, C.; Guyomar, D. Piezoelectric Material-Based Energy Harvesting Devices: Advance of SSH Optimization Techniques (1999–2009). In Piezoelectric Ceramics; Sciyo: Nanjing, China, 2010; pp. 165–184. [Google Scholar]

- Silveira, R.D.; das Neves, G.P.; da Silva, S.A.O.; Angélico, B.A. An Enhanced MPPT Algorithm Based on Adaptive Extremum-Seeking Control Applied to Photovoltaic Systems Operating under Partial Shading. IET Renew. Power Gener. 2021, 15, 1227–1239. [Google Scholar] [CrossRef]

- Shen, J.; Xia, Y.; Xia, H. ReL-SSHI Rectifier Based Piezoelectric Energy Harvesting Circuit with MPPT Control Technique. Microelectron. J. 2022, 121, 105379. [Google Scholar] [CrossRef]

- Wang, J.; Qin, X.; Liu, Z.; Shi, K.; Ding, G.; Li, X.; Cai, G. Experimental Field Study on a Full-Scale Road Piezoelectric Energy Harvester. Smart Mater. Struct. 2022, 31, 055003. [Google Scholar] [CrossRef]

- Heller, L.F.; Brito, L.A.T.; Coelho, M.A.J.; Brusamarello, V.; Nuñez, W.P. Development of a Pavement-Embedded Piezoelectric Harvester in a Real Traffic Environment. Sensors 2023, 23, 4238. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Ling, J.; Yu, J. A Comparative Analysis of Piezoelectric Transducers for Harvesting Energy from Asphalt Pavement. J. Ceram. Soc. Jpn. 2012, 120, 317–323. [Google Scholar] [CrossRef]

- Cafiso, S.; Cuomo, M.; Di Graziano, A.; Vecchio, C. Experimental Analysis for Piezoelectric Transducers Applications into Roads Pavements. Adv. Mater. Res. 2013, 684, 253–257. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, J.; Assistant, G.R. Piezoelectric Energy Harvesting in Airport Pavement; Rutgers University: New Brunswick, NJ, USA, 2019. [Google Scholar]

- Wang, J.; Liu, Z.; Shi, K.; Ding, G. Development and Application Performance of Road Spring-Type Piezoelectric Transducer for Energy Harvesting. Smart Mater. Struct. 2021, 30, 085020. [Google Scholar] [CrossRef]

- Tianchen, Y.; Jian, Y.; Ruigang, S.; Xiaowei, L. Vibration Energy Harvesting System for Railroad Safety Based on Running Vehicles. Smart Mater. Struct. 2014, 23, 125046. [Google Scholar] [CrossRef]

- Ao, S.I. International Association of Engineers. In Proceedings of the World Congress on Engineering (WCE 2012), London, UK, 4–6 July 2012; Newswood Ltd.: Hong Kong, China, 2012. ISBN 9789881925213. [Google Scholar]

- Wei, B.; Iyer, R. Sensordevices_2020. In Proceedings of the Eleventh International Conference on Sensor Device Technologies and Applications, Design and Modelling of a Piezoelectric Road Energy Harvester, Valencia, Spain, 21–25 November 2020; IARIA: Lisbon, Portugal, 2020. ISBN 978-1-61208-820-4. [Google Scholar]

- Guo, L. Development of a New Piezoelectric-Based Energy Harvesting Development of a New Piezoelectric-Based Energy Harvesting Pavement System Pavement System. Ph.D. Thesis, University of South Florida, Tampa, FL, USA, 2018. [Google Scholar]

- Erturk, A.; Inman, D.J. A Brief Review of the Literature of Piezoelectric Energy Harvesting Circuits. In Piezoelectric Energy Harvest; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011; ISBN 978-0-470-68254-8. [Google Scholar]

- Nuffer, J.; Bein, T. Application of piezoelectric materials in transportation industry. In Proceedings of the Global Symposium on Innovative Solutions for the Advancement of the Transport Industry, San Sebastian, Spain, 4–6 October 2006. [Google Scholar]

- Nelson, C.A.; Platt, S.R.; Albrecht, D.; Kamarajugadda, V.; Fateh, M. Power Harvesting for Railroad Track Health Monitoring Using Piezoelectric and Inductive Devices. In Proceedings of the Active and Passive Smart Structures and Integrated Systems, San Diego, CA, USA, 27 March 2008; SPIE: San Francisco, CA, USA, 2008; Volume 6928, p. 69280R. [Google Scholar]

- Cleante, V.G.; Brennan, M.J.; Gatti, G.; Thompson, D.J. On the Target Frequency for Harvesting Energy from Track Vibrations Due to Passing Trains. Mech. Syst. Signal Process 2019, 114, 212–223. [Google Scholar] [CrossRef]

- Gao, M.Y.; Wang, P.; Cao, Y.; Chen, R.; Liu, C. A Rail-Borne Piezoelectric Transducer for Energy Harvesting of Railway Vibration. J. Vibroeng. 2016, 18, 4647–4663. [Google Scholar] [CrossRef]

- Wang, J.; Lin, T.; Zuo, L. High Efficiency Electromagnetic Energy Harvester for Railroad Application. In Proceedings of the ASME 2013 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Portland, OR, USA, 4–7 August 2013. [Google Scholar]

- Mishra, M.; Mahajan, P.; Garg, R. Piezoelectric Energy Harvesting System Using Railway Tracks. In Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2021; Volume 661, pp. 247–259. [Google Scholar]

- Lin, T.; Wang, J. Education and Workforce Development Title: Energy Harvesting from Rail Track for Transportation Safety and Monitoring Project’s Website. 2014. Available online: http://Www.Utrc2.Org/Research/Projects/Energy-Harvesting-Railway-Track-Vibrations (accessed on 20 February 2014).

- Qu, S.; Ren, Y.; Hu, G.; Ding, W.; Dong, L.; Zhu, S.; Yang, J.; Yang, Y.; Zhai, W. Event-Driven Piezoelectric Energy Harvesting for Railway Field Applications. Appl. Energy 2024, 364, 123160. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, X.; Pan, Y.; Luo, D.; Xu, Y.; Zhang, Z.; Yuan, Y.; Yan, J. Vibration Energy Harvesting System Based on Track Energy-Recycling Technology for Heavy-Duty Freight Railroads. Appl. Energy 2022, 323, 119673. [Google Scholar] [CrossRef]

- Qi, L.; Pan, H.; Pan, Y.; Luo, D.; Yan, J.; Zhang, Z. A Review of Vibration Energy Harvesting in Rail Transportation Field. iScience 2022, 25, 103849. [Google Scholar] [CrossRef] [PubMed]

- Nelson, C.A.; Platt, S.R.; Hansen, S.E.; Fateh, M. Power Harvesting for Railroad Track Safety Enhancement Using Vertical Track Displacement. In Proceedings of the Active and Passive Smart Structures and Integrated Systems, San Diego, CA, USA, 26 March 2009; SPIE: San Francisco, CA, USA, 2009; Volume 7288, p. 728811. [Google Scholar]

- Mi, J.; Liu, M.; Li, Q.; Li, X.; Zuo, L. Electromagnetic Energy Harvesting from Train Induced Railway Bridge Vibrations. In IFAC-Papers OnLine; Elsevier B.V.: Amsterdam, The Netherlands, 2021; Volume 54, pp. 185–190. [Google Scholar]

- Wang, J.; Shi, Z.; Xiang, H.; Song, G. Modeling on Energy Harvesting from a Railway System Using Piezoelectric Transducers. Smart Mater. Struct. 2015, 24, 105017. [Google Scholar] [CrossRef]

- Costanzo, L.; Lin, T.; Lin, W.; Schiavo, A.L.; Vitelli, M.; Zuo, L. Power Electronic Interface with an Adaptive MPPT Technique for Train Suspension Energy Harvesters. IEEE Trans. Ind. Electron. 2021, 68, 8219–8230. [Google Scholar] [CrossRef]

- Ung, C.; Moss, S.D.; Chiu, W.K. Vibration Energy Harvesting from Heavy Haul Railcar Vibrations Using a Two-Degree-of-Freedom Coupled Oscillating System. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit. 2016, 230, 924–934. [Google Scholar] [CrossRef]

- Moss, S.D.; Hart, G.A.; Burke, S.K.; Carman, G.P. Hybrid Rotary-Translational Vibration Energy Harvester Using Cycloidal Motion as a Mechanical Amplifier. Appl. Phys. Lett. 2014, 104, 033506. [Google Scholar] [CrossRef]

- Min, Z.; Hou, C.; Sui, G.; Shan, X.; Xie, T. Simulation and Experimental Study of a Piezoelectric Stack Energy Harvester for Railway Track Vibrations. Micromachines 2023, 14, 892. [Google Scholar] [CrossRef]

- Walter, P.L. The History of the Accelerometer. Sound Vib. 1920, 31, 16–23. [Google Scholar]

- Lu, L.; Sun, H.; Han, L.; Zhang, Z.; Cao, H.; Wang, W.; Wu, X.; Lyu, X. Omnidirectional Hybrid Wave Energy Harvester for Self-Powered Sensors in Sea-Crossing Bridges. Ocea. Eng. 2023, 287, 115829. [Google Scholar] [CrossRef]

- Cámara-Molina, J.C.; Romero, A.; Moliner, E.; Connolly, D.P.; Martínez-Rodrigo, M.D.; Yurchenko, D.; Galvín, P. Design, Tuning and in-Field Validation of Energy Harvesters for Railway Bridges. Mech. Syst. Signal Process 2024, 208, 111012. [Google Scholar] [CrossRef]

- Khan, F.U.; Ahmad, I. Review of Energy Harvesters Utilizing Bridge Vibrations. Shock. Vib. 2016, 2016, 1340402. [Google Scholar] [CrossRef]

- Galchev, T.V.; McCullagh, J.; Peterson, R.L.; Najafi, K. Harvesting Traffic-Induced Vibrations for Structural Health Monitoring of Bridges. J. Micromech. Microeng. 2011, 21, 104005. [Google Scholar] [CrossRef]

- Sheng, W.; Xiang, H.; Zhang, Z.; Yuan, X. High-Efficiency Piezoelectric Energy Harvester for Vehicle-Induced Bridge Vibrations: Theory and Experiment. Compos. Struct. 2022, 299, 116040. [Google Scholar] [CrossRef]

- Harish Valluru, S. Energy Harvesting from Vibration of a Bridge. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2007. [Google Scholar]

- Balguvhar, S.; Dalal, P.; Bhalla, S. Feasibility of Piezoelectric Energy Harvesting from Real-Life City Flyover: A Case Study. In Smart Structures and NDE for Energy Systems and Industry; SPIE: San Francisco, CA, USA, 2019; p. 28. [Google Scholar]

- Edla, M.; Lim, Y.Y.; Deguchi, M.; Padilla, R.V.; Izadgoshasb, I. An Improved Self-Powered H-Bridge Circuit for Voltage Rectification of Piezoelectric Energy Harvesting System. IEEE J. Electron. Devices Soc. 2020, 8, 1050–1062. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, H.; Qin, W.; Zhu, P.; Wang, P.; Du, W. Harvesting Energy from Bridge Vibration by Piezoelectric Structure with Magnets Tailoring Potential Energy. Materials 2022, 15, 33. [Google Scholar] [CrossRef]

- Kouritem, S.A.; Bani-Hani, M.A.; Beshir, M.; Elshabasy, M.M.Y.B.; Altabey, W.A. Automatic Resonance Tuning Technique for an Ultra-Broadband Piezoelectric Energy Harvester. Energies 2022, 15, 7271. [Google Scholar] [CrossRef]

- Peralta-Braz, P.; Alamdari, M.M.; Ruiz, R.O.; Atroshchenko, E.; Hassan, M. Design Optimisation of Piezoelectric Energy Harvesters for Bridge Infrastructure. Mech. Syst. Signal Process. 2022, 205, 110823. [Google Scholar] [CrossRef]

- Yildiz, F.; Dakeev, U.; Baltaci, K.; Coogler, K.L. Energy Harvesting from Air Conditioning Condensers with the Use of Piezo-Electric Devices. In Proceedings of the 122nd ASEEAnnualConference & Exposition, Seattle, WA, USA, 14–17 June 2015. [Google Scholar]

- Hobbs, W.B.; Hu, D.L. Tree-Inspired Piezoelectric Energy Harvesting. J. Fluids Struct. 2012, 28, 103–114. [Google Scholar] [CrossRef]

- McGarry, S.; Knight, C. The Potential for Harvesting Energy from the Movement of Trees. Sensors 2011, 11, 9275–9299. [Google Scholar] [CrossRef]

- Li, X.; Strezov, V. Modelling Piezoelectric Energy Harvesting Potential in an Educational Building. Energy Convers. Manag. 2014, 85, 435–442. [Google Scholar] [CrossRef]

- Xie, X.D.; Wang, Q.; Wang, S.J. Energy Harvesting from High-Rise Buildings by a Piezoelectric Harvester Device. Energy 2015, 93, 1345–1352. [Google Scholar] [CrossRef]

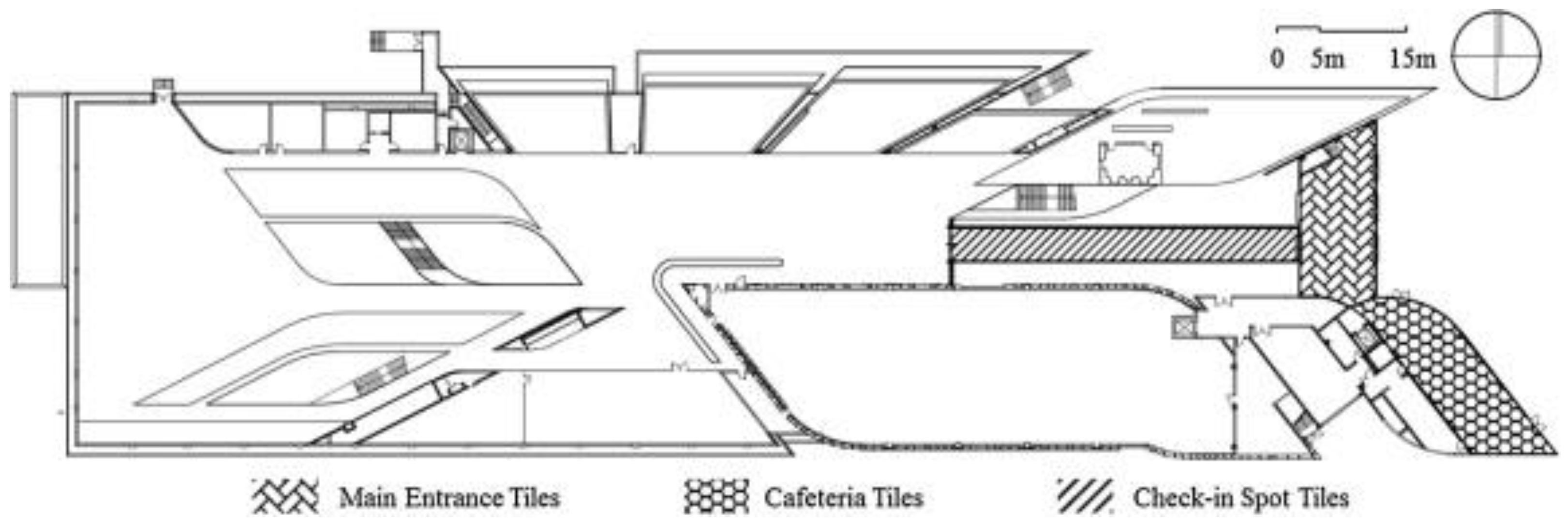

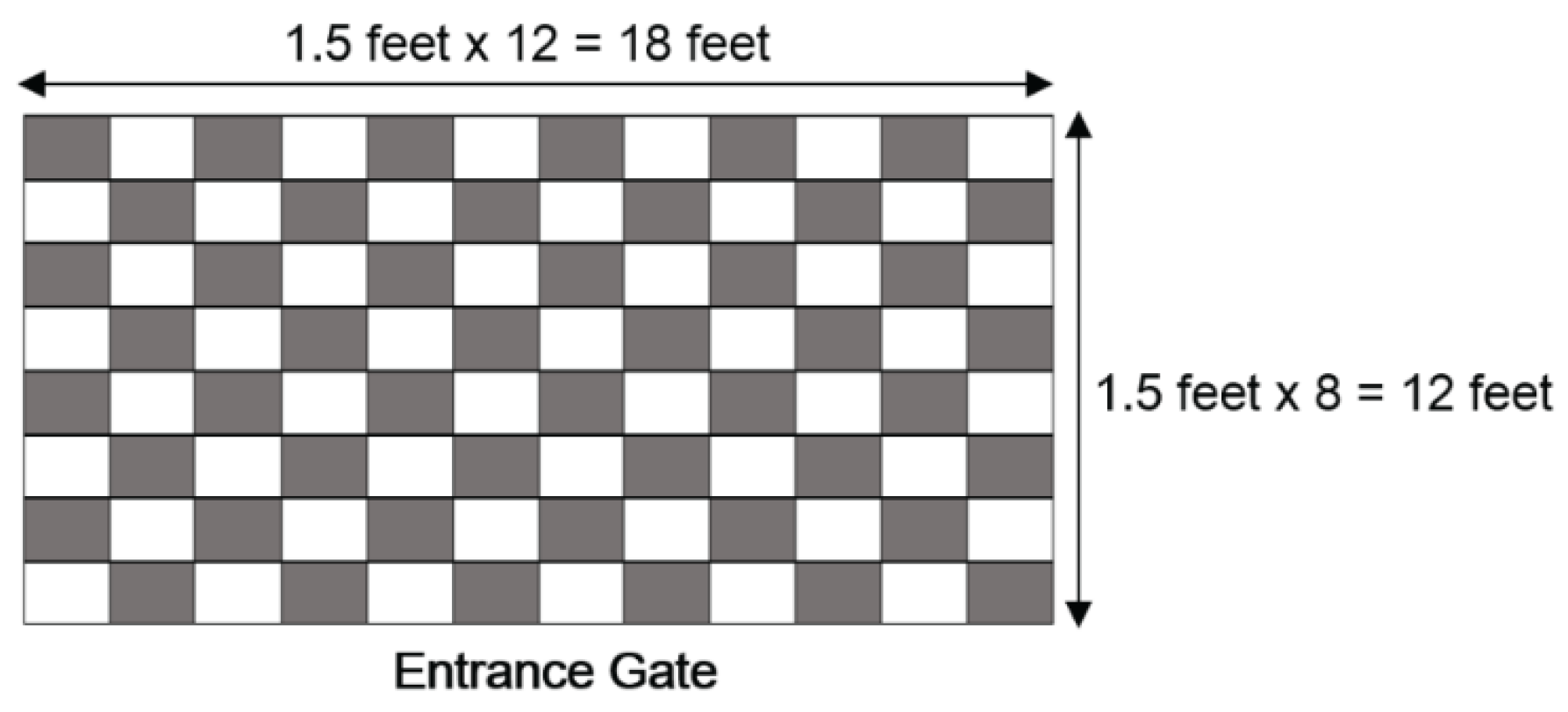

- Chew, B.C.; Loo, H.S.; Bohari, I.A.; Hamid, S.R.; Sukri, F.H.; Kusumarwadani, R. Feasibility of Piezoelectric Tiles Adoption: A Case Study at Kuala Lumpur International Airport (KLIA) Malaysia. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2017; Volume 1818. [Google Scholar]

- Elhalwagy, A.M.; Ghoneem, M.Y.M.; Elhadidi, M. Feasibility Study for Using Piezoelectric Energy Harvesting Floor in Buildings’ Interior Spaces. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 115, pp. 114–126. [Google Scholar]

- Kale, S.; Nawkhare, N.; Jamodkar, U.; Banayat, A.; Bhole, N.; Ade, N. Implementation of Piezoelectric Tiles to Generate Electricity. Int. J. Eng. Res. Electr. Electron. Eng. 2018, 4. [Google Scholar]

- Solban, M.M.; Moussa, R.R. Piezoelectric Tiles Is a Sustainable Approach for Designing Interior Spaces and Creating Self-Sustain Projects. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2019; Volume 397. [Google Scholar]

- Xie, X.D.; Wang, Q.; Wu, N. Potential of a Piezoelectric Energy Harvester from Sea Waves. J. Sound. Vib. 2014, 333, 1421–1429. [Google Scholar] [CrossRef]

- He, M.; Wang, S.; Zhong, X.; Guan, M. Study of a Piezoelectric Energy Harvesting Floor Structure with Force Amplification Mechanism. Energies 2019, 12, 3516. [Google Scholar] [CrossRef]

- Gkoumas, K.; Petrini, F.; Bontempi, F. Piezoelectric Vibration Energy Harvesting from Airflow in HVAC (Heating Ventilation and Air Conditioning) Systems. In Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 199, pp. 3444–3449. [Google Scholar]

- Abidin, N.A.K.Z.; Nayan, M.N.; Azizan, M.M.; Ali, A. Implementation of Rain Power Generation Using Circular Piezoelectric. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2018; Volume 2030. [Google Scholar]

- Sitharthan, R.; Yuvaraj, S.; Padmanabhan, S.; Holm-Nielsen, J.B.; Sujith, M.; Rajesh, M.; Prabaharan, N.; Vengatesan, K. Piezoelectric Energy Harvester Converting Wind Aerodynamic Energy into Electrical Energy for Microelectronic Application. IET Renew. Power Gener. 2021, 15, 1968–1975. [Google Scholar] [CrossRef]

- Burns, J.R. Ocean Wave Energy Conversion Using Piezoelectric Material Members. U.S. Patent 4,685,296, 11 August 1987. [Google Scholar]

- Taylor, G.W.; Burns, J.R.; Kammann, S.M.; Powers, W.B.; Welsh, T.R. The Energy Harvesting Eel: A Small Subsurface Ocean/River Power Generator. IEEE J. Ocean. Eng. 2001, 26, 539–547. [Google Scholar] [CrossRef]

- Zurkinden, A.S.; Campanile, F.; Martinelli, L. Wave Energy Converter through Piezoelectric Polymers. In User Presentations and Proceedings cd; Comsol: Phoenix, AZ, USA, 2007. [Google Scholar]

- Mutsuda, H.; Watanabe, R.; Azuma, S.; Tanaka, Y.; Doi, Y. Ocean power generator using flexible piezoelectric device. In International Conference on Offshore Mechanics and Arctic Engineering; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar]

- Viet, N.V.; Carpinteri, A.; Wang, Q. A Novel Heaving Ocean Wave Energy Harvester with a Frequency Tuning Capability. Arab. J. Sci. Eng. 2019, 44, 5711–5722. [Google Scholar] [CrossRef]

- Viet, N.V.; Xie, X.D.; Liew, K.M.; Banthia, N.; Wang, Q. Energy Harvesting from Ocean Waves by a Floating Energy Harvester. Energy 2016, 112, 1219–1226. [Google Scholar] [CrossRef]

- Arshadul Karim, M.; Ibn Awal, Z. An Ocean Wave Energy Harnessing Model Using Piezo-Electric Device. In Proceedings of the International Conference on Mechanical, Industrial and Energy Engineering 2020, Khulna, Bangladesh, 19–21 December 2020. [Google Scholar]

- Kargar, S.M.; Hao, G. A Drifter-Based Self-Powered Piezoelectric Sensor for Ocean Wave Measurements. Sensors 2022, 22, 5050. [Google Scholar] [CrossRef]

- Karga, S.M.; Hao, G. An Atlas of Piezoelectric Energy Harvesters in Oceanic Applications. Sensors 2022, 22, 1949. [Google Scholar] [CrossRef]

- Wu, N.; Wang, Q.; Xie, X.D. Ocean Wave Energy Harvesting with a Piezoelectric Coupled Buoy Structure. Appl. Ocean Res. 2015, 50, 110–118. [Google Scholar] [CrossRef]

- Murray, R.; Rastegar, J. Novel Two-Stage Piezoelectric-Based Ocean Wave Energy Harvesters for Moored or Unmoored Buoys. In Active and Passive Smart Structures and Integrated Systems 2009; SPIE: San Francisco, CA, USA, 2009; Volume 7288, p. 72880E. [Google Scholar]

- Tanaka, Y.; Oko, T.; Mutsuda, H.; Patel, R.; Mcwilliam, S.; Popov, A.A. An Experimental Study of Wave Power Generation Using a Flexible Piezoelectric Device. In Proceedings of the Twenty-Fourth International Ocean and Polar Engineering Conference, Busan, Republic of Korea, 15–20 June 2014; Volume 2. [Google Scholar]

- Yamaç, H.İ.; Koca, A. Numerical Analysis of Wave Energy Converting Systems in Case of Using Piezoelectric Materials for Energy Harvesting. J. Mar. Eng. Technol. 2021, 20, 138–149. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, X.; Song, G.; Du, G.; Liu, D. A Study on a Near-Shore Cantilevered Sea Wave Energy Harvester with a Variable Cross Section. Energy Sci. Eng. 2019, 7, 3174–3185. [Google Scholar] [CrossRef]

- Mirab, H.; Jahangiri, V.; Ettefagh, M.; Fathi, R. Reliability Study of Power Harvesting System from Sea Waves with Piezoelectric Patches. arXiv 2018, arXiv:1810.06426. [Google Scholar]

- Sivasuriyan, A.; Vijayan, D.S.; Górski, W.; Wodzyń, Ł.; Vaverková, M.D.; Koda, E. Practical Implementation of Structural Health Monitoring in Multi-Story Buildings. Buildings 2021, 11, 263. [Google Scholar] [CrossRef]

- Gopal Madhav Annamdas, V.; Yang, Y.; Kiong Soh, C. Impedance Based Concrete Monitoring Using Embedded PZT Sensors. Int. J. Civ. Struct. Eng. 2010, 1, 414–424. [Google Scholar]

- Giurgiutiu, V.; Zagrai, A.; Bao, J.J. Piezoelectric Wafer Embedded Active Sensors for Aging Aircraft Structural Health Monitoring. Struct. Health Monit. 2002, 1, 41–61. [Google Scholar] [CrossRef]

- Raghavan, A.; Cesnik, C.E.S. Review of Guided-Wave Structural Health Monitoring. Shock. Vib. Dig. 2007, 39, 91–114. [Google Scholar] [CrossRef]

- Janeliukstis, R.; Rucevskis, S.; Akishin, P.; Chate, A. Wavelet Transform Based Damage Detection in a Plate Structure. In Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; Volume 161, pp. 127–132. [Google Scholar]

- Gharibnezhad, F.; Mujica, L.E.; Rodellar, J.; Fritzen, C.P. Damage Detection Using Principal Component Analysis Based on Wavelet Ridges. In Key Engineering Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2013; Volume 569–570, pp. 916–923. [Google Scholar]

- Unnorsson, R. Hit Detection and Determination in AE Bursts. In Acoustic Emission-Research and Applications; InTech: Houston TX, USA, 2013. [Google Scholar]

- Salehi, H.; Burgueño, R.; Chakrabartty, S.; Lajnef, N.; Alavi, A.H. A Comprehensive Review of Self-Powered Sensors in Civil Infrastructure: State-of-the-Art and Future Research Trends. Eng. Struct. 2021, 234, 111963. [Google Scholar] [CrossRef]

- Feng, Q.; Liang, Y. Development of Piezoelectric-Based Technology for Application in Civil Structural Health Monitoring. Earthq. Res. Adv. 2023, 3, 100154. [Google Scholar] [CrossRef]

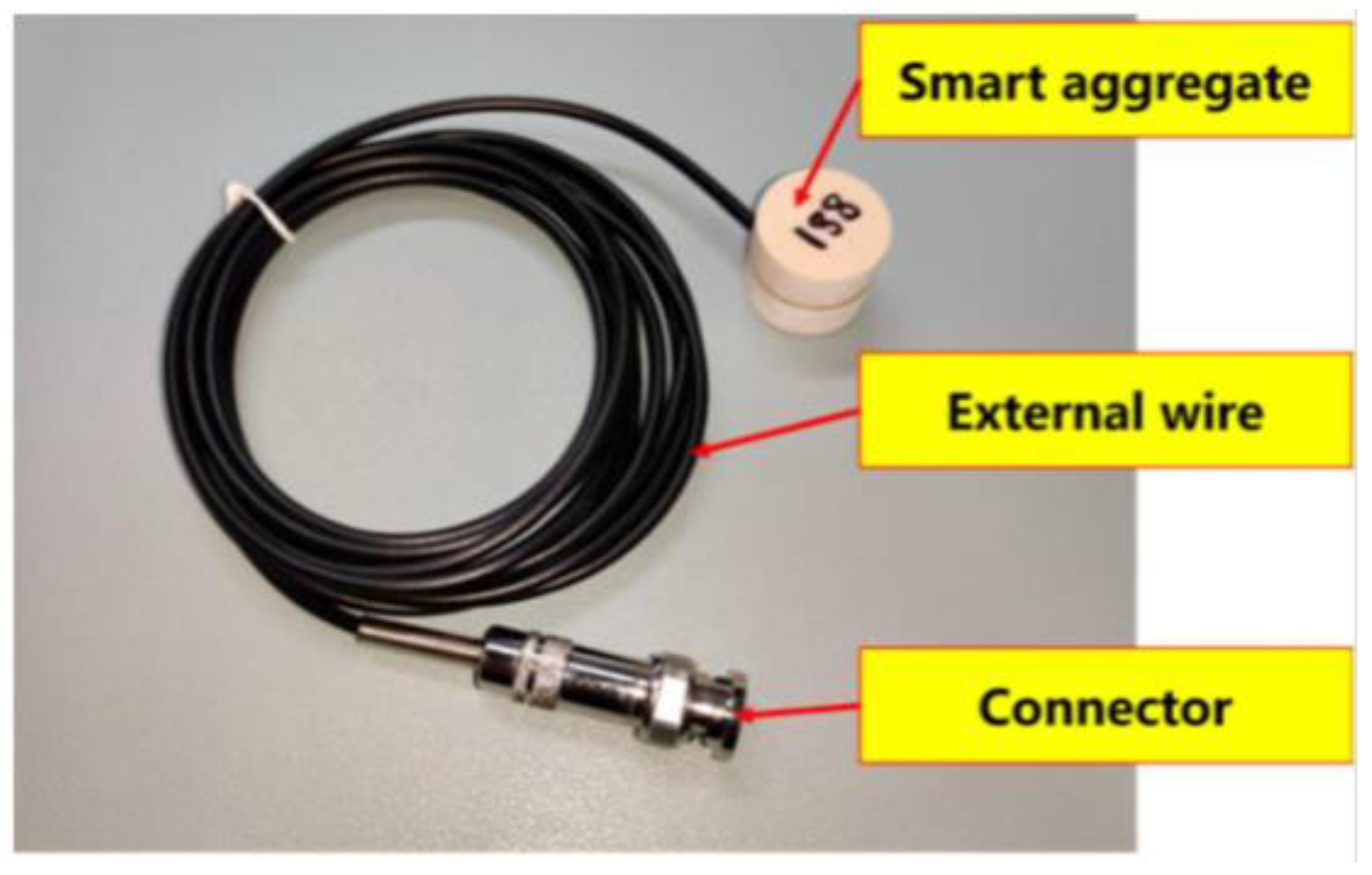

- Zhang, H.; Li, J.; Kang, F. Real-Time Monitoring of Humidity inside Concrete Structures Utilizing Embedded Smart Aggregates. Constr. Build. Mater. 2022, 331, 127317. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, K.B.; Woo, S.B.; Song, Y.; Sung, T.H. A Magneto-Mechanical Piezoelectric Energy Harvester Designed to Scavenge Ac Magnetic Field from Thermal Power Plant with Power-Line Cables. Energies 2021, 14, 2387. [Google Scholar] [CrossRef]

- Zuo, J.; Dong, L.; Yang, F.; Guo, Z.; Wang, T.; Zuo, L. Energy Harvesting Solutions for Railway Transportation: A Comprehensive Review. Renew. Energy 2022, 202, 56–87. [Google Scholar] [CrossRef]

- Rogallo, V.L.; Neuman, F. A Wide-Range Piezoelectric Momentum Transducer for Measuring Micrometeoroid Impacts; National Aeronautics and Space Administratio: Washington, DC, USA, 1965. [Google Scholar]

- Bowen, C.R.; Taylor, J.; Leboulbar, E.; Zabek, D.; Chauhan, A.; Vaish, R. Pyroelectric Materials and Devices for Energy Harvesting Applications. Energy Environ. Sci. 2014, 7, 3836–3856. [Google Scholar] [CrossRef]

- Liu, J.; McInnes, C.R. Resonant Space Tethered System for Lunar Orbital Energy Harvesting. Acta Astronaut. 2019, 156, 23–32. [Google Scholar] [CrossRef]

- Jin, D.W.; Ko, Y.J.; Ahn, C.W.; Hur, S.; Lee, T.K.; Jeong, D.G.; Lee, M.; Kang, C.Y.; Jung, J.H. Polarization- and Electrode-Optimized Polyvinylidene Fluoride Films for Harsh Environmental Piezoelectric Nanogenerator Applications. Small 2021, 17, 2007289. [Google Scholar] [CrossRef]

- Wang, T.; Quan, Q.; Tang, D.; Yang, Z.; Huang, J.; Guo, F.; Meng, L.; Zhao, Z.; Deng, Z. Effect of Hyperthermal Cryogenic Environments on the Performance of Piezoelectric Transducer. Appl. Therm. Eng. 2021, 193, 116725. [Google Scholar] [CrossRef]

- Li, H.; Shen, Y.; Wang, Q.; Wang, Y.; Bai, D.; Deng, Z. A Piezoelectric-Driven Rock-Drilling Device for Extraterrestrial Subsurface Exploration. Shock. Vib. 2018, 2018, 8368012. [Google Scholar] [CrossRef]

- Izadgoshasb, I. Piezoelectric Energy Harvesting towards Self-powered Internet of Things (IoT) Sensors in Smart Cities. Sensors 2021, 21, 8332. [Google Scholar] [CrossRef]

- Aldin, H.N.S.; Ghods, M.R.; Nayebipour, F.; Torshiz, M.N. A Comprehensive Review of Energy Harvesting and Routing Strategies for IoT Sensors Sustainability and Communication Technology. Sens. Int. 2024, 5, 100258. [Google Scholar] [CrossRef]

- Kim, S.; Shen, J.; Ahad, M. Piezoelectric-Based Energy Harvesting Technology for Roadway Sustainability. Int. J. Appl. Sci. Technol. 2015, 5, 20–25. [Google Scholar]

- Wang, Z.; Liu, S.; Yang, Z.; Dong, S. Perspective on Development of Piezoelectric Micro-Power Generators. Nanoenergy Adv. 2023, 3, 73–100. [Google Scholar] [CrossRef]

- Calautit, K.; Nasir, D.S.N.M.; Hughes, B.R. Low Power Energy Harvesting Systems: State of the Art and Future Challenges. Renew. Sustain. Energy Rev. 2021, 147, 111230. [Google Scholar] [CrossRef]

- Niu, S.; Wang, X.; Yi, F.; Zhou, Y.S.; Wang, Z.L. A Universal Self-Charging System Driven by Random Biomechanical Energy for Sustainable Operation of Mobile Electronics. Nat. Commun. 2015, 6, 8975. [Google Scholar] [CrossRef]

- Vijayakanth, T.; Shankar, S.; Finkelstein-Zuta, G.; Rencus-Lazar, S.; Gilead, S.; Gazit, E. Perspectives on Recent Advancements in Energy Harvesting, Sensing and Bio-Medical Applications of Piezoelectric Gels. Chem. Soc. Rev. 2023, 52, 6191–6220. [Google Scholar] [CrossRef]

- Minea, M.; Dumitrescu, C.M. On the Feasibility and Efficiency of Self-Powered Green Intelligent Highways. Energies 2022, 15, 4693. [Google Scholar] [CrossRef]

- Andrade, J.R. Piezoelectric Energy Harvesting: A Comprehensive Review and Applications; (Research Paper); University of Groningen: Groningen, The Netherlands, 2022; Available online: https://fse.studenttheses.ub.rug.nl/id/eprint/27092 (accessed on 20 September 2024).

| Material | Advantages | Disadvantages | References |

|---|---|---|---|

| Quartz crystal |

|

| [3,30] |

| Rochelle’s salt |

|

| [3,30] |

| Tourmaline |

|

| [3,39] |

| PVDF |

|

| [3,40] |

| MFC |

|

| [2] |

| Barium titanate |

|

| [3,40] |

| PZT |

|

| [3,30] |

| Reference | Piezoelectric Energy Harvester | Method Based On | |||

|---|---|---|---|---|---|

| Materials | Shape | Dimensions | |||

| [86] | PZT-5H | Square (Plate) | Theoretical approach based on Kirchhoff plate theory, dynamic load using sine series expansion, Fourier transform, and Cauchy’s residue theorem. | ||

| [115] | PZT-5H | Disc | Experimental and numerical approaches based on field tests and finite-element analysis. | ||

| [101] | PZT-5H | Disc | diameter | Numerical approach for optimization. | |

| [116] | PZT-5H | Disc | Experimental approach based on field tests. | ||

| [117] | PZT-5H | Rectangle (Plate) | Multilayer | Numerical approach using finite-element analysis. | |

| [118] | PZT | Square (Plate) | Experimental and numerical approaches based on laboratory tests and finite-element analysis. | ||

| [119] | Various Model | Cuboid | Numerical approach using finite-element analysis. | ||

| [104] | PZT | Rectangle | Experimental and numerical approaches based on laboratory tests and finite-element analysis. | ||

| [83] | Polypropylene (PP) | Square (Plate) | Experimental and numerical approaches based on laboratory tests and finite-element analysis. | ||

| [90] | PZT-PZNN | Rectangle (Plate) | Experimental approach based on field tests. | ||

| [120] | PZT-5H | Rectangle (Plate) | Experimental and numerical approaches based on laboratory tests and finite-element analysis. | ||

| [121] | PZT-5H | Disc | diameter | Experimental and numerical approaches based on laboratory tests and finite-element analysis. | |

| [122] | Microfiber Composite | Rectangle (Plate) | Experimental approach based on laboratory tests. | ||

| [107] | PZT-5H | Square (Plate) | diameter | Theoretical approach based on electrical theory. | |

| [87] | PZT-PZNM | Rectangle (Plate) | Experimental approach based on frequency matching and impedance matching. | ||

| [123] | PZ-EHPS | Cylinder | diameter | Numerical approach using MatLab and SolidWorks. | |

| [124] | PZT-5H | Square (Plate) | Theoretical, experimental, and numerical approaches using a three-degree-of-freedom electromechanical model, material testing system, and finite-element analysis. | ||

| Reference | Piezoelectric Energy Harvester | Method Based On | Power Output | ||

|---|---|---|---|---|---|

| Materials | Shape | Dimensions | |||

| [137] | Not mentioned | Shaft | Not mentioned | Experimental and numerical approaches based on bench tests and finite-element analysis. | |

| [138] | PZT-5A | Rectangle | Theoretical and experimental approaches based on infinite Euler–Beornulli beam and patch-type and stack-type harvesters. | ||

| [132] | Not mentioned | Shaft | Not mentioned | Theoretical and experimental approaches based on mechanical motion rectifier and laboratory tests. | |

| [139] | Not mentioned | Shaft | Not mentioned | Experimental approach based on Speed Driven Adaptive (SDA) technique. | |

| [129] | PZT | Cantilever | Experimental and numerical approaches based on laboratory tests, modeling, and simulations. | ||

| [131] | PZT | Rectangle | Experimental approach based on laboratory tests. | ||

| [134] | Not mentioned | Cantilever | Not mentioned | Experimental approach based on field tests. | |

| [140] | Not mentioned | Ring | 4 pcs diameter | Numerical approach based on finite-element analysis. | |

| [141] | Not mentioned | Sphere | diameter | Experimental approach based on laboratory tests. | |

| [142] | PZT | Rectangle | Experimental approach based on laboratory tests. | ||

| Reference | Piezoelectric Energy Harvester | Method Based On | Power Output (mW/cm3) | ||

|---|---|---|---|---|---|

| Materials | Shape | Dimensions | |||

| [149] | PVDF | Beam | Numerical approach using the method of integral transformations and method of Laplace–Carson. | ||

| [147] | PZT | Cantilever | Experimental approach based on field tests. | ||

| [146] | PVDF | Cubic | Experimental and numerical approaches based on laboratory tests, modeling, and simulations. | ||

| [64] | PZT | 2 × bimorph patches | Experimental and numerical approaches based on laboratory tests and simulations. | ||

| [150] | Microfiber Composite (MFC) | Rectangle (plate) | Experimental approach based on field tests. | ||

| [151] | Microfiber Composite (MFC) | Rectangle (plate) | Experimental and numerical approaches using MOSFET device and finite-element analyses. | ||

| [152] | PVDF | Rectangle (plate) | Experimental approach based on potential energy, restoring force, and stiffness analyses. | ||

| [153] | PZT | Rectangle (plate) | Numerical approach based on finite-element analyses and the Automatic Resonance Tuning (ART) technique. | ||

| [148] | PVDF | Cube | Theoretical and experimental approaches based on harvesting efficiency and laboratory tests. | ||

| [154] | PZT5A | Rectangle (plate) | Theoretical approach based on Kirchhoff–Love plate theory and isogeometric analysis. | ||

| Reference | Piezoelectric Energy Harvester | Method Based On | Power Output (mW/cm3) | ||

|---|---|---|---|---|---|

| Materials | Shape | Dimensions | |||

| [163] | 1. PZT 2. SEF | 1. Square Tiles 2. Square Tiles | 1. 2. | Experimental and numerical approaches based on laboratory tests and simulations. | |

| [160] | PZT | Square Tiles | Numerical approaches based on simulations. | ||

| [158] | Pavegen | Triangular Tiles | Experimental approach based on field tests. | ||

| [161] | Waynergy | Square Tiles | Experimental and numerical approaches based on field tests and simulations. | ||

| [164] | PZT-4 | Cantilever | Theoretical and numerical approaches based on sinusoidal wave seismic motion and simulations. | ||

| [165] | PZT-5H | Beam | Theoretical and experimental approaches based on Fourier transform and laboratory tests. | ||

| [155] | 1. Piezoelectric fiber composite bimorph 2. Mide Volture harvester | 1. Cantilever 2. Cantilever | 1. 2. | Numerical approach based on simulations, vibration, and airflow-driven energy harvesting method | |

| [166] | Ceramic P-876K015 | T-shape | Experimental and numerical approaches based on laboratory tests and modeling energy simulation. | ||

| [162] | PZT | Square Tiles | Numerical approach based on linear relation review. | ||

| [167] | Piezo crystals | Square Tiles | Experimental approach using harvester prototype implementation. | ||

| [168] | 1. Thiol + PVDF 2. PVDF 3. PZT | 1. Spheric 2. Spheric 3. Spheric | 1. 2. 3. | Experimental and numerical approaches using harvester prototype implementation and simulations. | |

| Reference | Piezoelectric Energy Harvester | Method Based On | Power Output (mW/cm3) | ||

|---|---|---|---|---|---|

| Materials | Shape | Dimensions | |||

| [170] | PVDF | Eel | Experimental and numerical approaches using a utility acoustic modem and simulations. | ||

| [164] | PZT4 | Cantilever | Numerical simulation using a mathematical model. | ||

| [178] | Not mentioned | Double beam | Numerical approach based on finite-element analyses. | ||

| [179] | Not mentioned | Buoy | diameter | Theoretical and experimental approaches based on the transfer of energy between two systems and prototypical design. | |

| [174] | PVDF | Cuboid | Theoretical and numerical approaches based on the Lagrangian–Euler method and a mathematical model. | ||

| [180] | PVDF | Sheet | Experimental approach using flexible piezoelectric devices. | ||

| [173] | Not mentioned | Cylinder | diameter | Numerical approach using a mathematical model. | |

| [181] | Not mentioned | Patches | Numerical approach using computational fluid dynamics software Ansys Fluent 14.0. | ||

| [182] | Not mentioned | Patches | Theoretical and numerical approach based on Airy linear wave theory and a mathematical model. | ||

| [183] | Not mentioned | Cantilever | diameter | Theoretical and numerical approach based on JONSWAP wave theory and MatLab software. | |

| Theoretical Approach | Experimental Approach | Numerical Approach | Field Test | |

|---|---|---|---|---|

| Roadways | 12% | 40% | 36% | 12% |

| Railways | 13% | 60% | 20% | 7% |

| Bridges | 13% | 40% | 33% | 13% |

| Buildings | 11% | 37% | 42% | 11% |

| Ocean Waves | 27% | 20% | 53% | 0% |

| Total | 15% | 39% | 37% | 9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shehu, L.; Yeon, J.H.; Song, Y. Piezoelectric Energy Harvesting for Civil Engineering Applications. Energies 2024, 17, 4935. https://doi.org/10.3390/en17194935

Shehu L, Yeon JH, Song Y. Piezoelectric Energy Harvesting for Civil Engineering Applications. Energies. 2024; 17(19):4935. https://doi.org/10.3390/en17194935

Chicago/Turabian StyleShehu, Ledia, Jung Heum Yeon, and Yooseob Song. 2024. "Piezoelectric Energy Harvesting for Civil Engineering Applications" Energies 17, no. 19: 4935. https://doi.org/10.3390/en17194935

APA StyleShehu, L., Yeon, J. H., & Song, Y. (2024). Piezoelectric Energy Harvesting for Civil Engineering Applications. Energies, 17(19), 4935. https://doi.org/10.3390/en17194935