Review of Reservoir Damage Mechanisms Induced by Working Fluids and the Design Principles of Reservoir Protection Fluids: From Oil–Gas Reservoirs to Geothermal Reservoirs

Abstract

1. Introduction

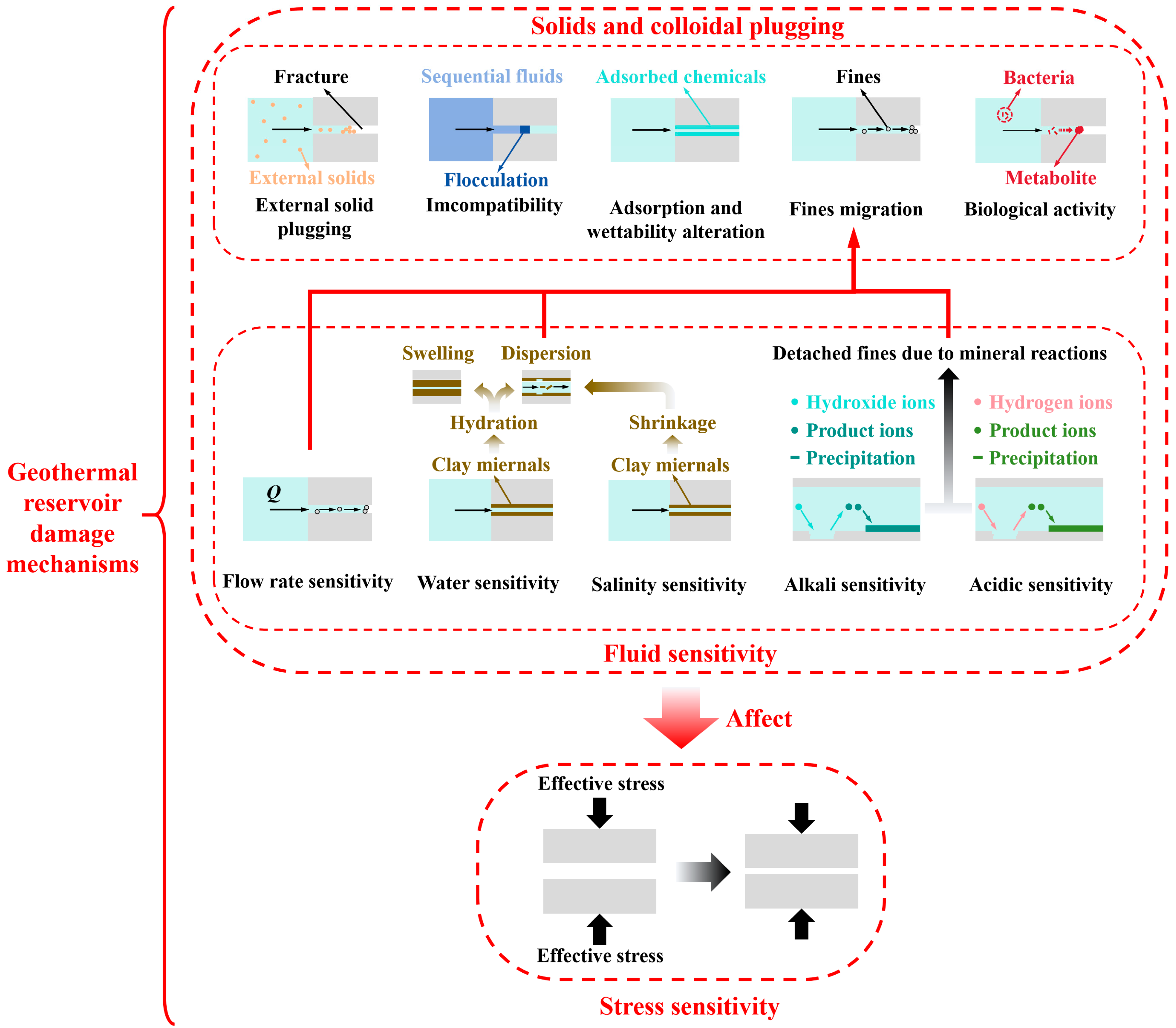

2. Reservoir Damage Mechanisms Induced by Working Fluids

2.1. Solids and Colloidal Plugging

2.1.1. External Solids Invasion

2.1.2. Incompatibility in and between Working Fluids

2.1.3. Chemical Adsorption and Wettability Alteration

2.1.4. Fines Migration

2.1.5. Biological Activity

2.2. Fluid Sensitivity

2.2.1. Flow Rate Sensitivity

2.2.2. Water Sensitivity and Salinity Sensitivity

2.2.3. Alkali Sensitivity and Acidic Sensitivity

2.3. Stress Sensitivity

2.4. Water Locking

2.5. Geothermal Reservoir Damage Mechanisms

3. Design Principles of Geothermal Reservoir Protection Working Fluids

3.1. Solid-Free

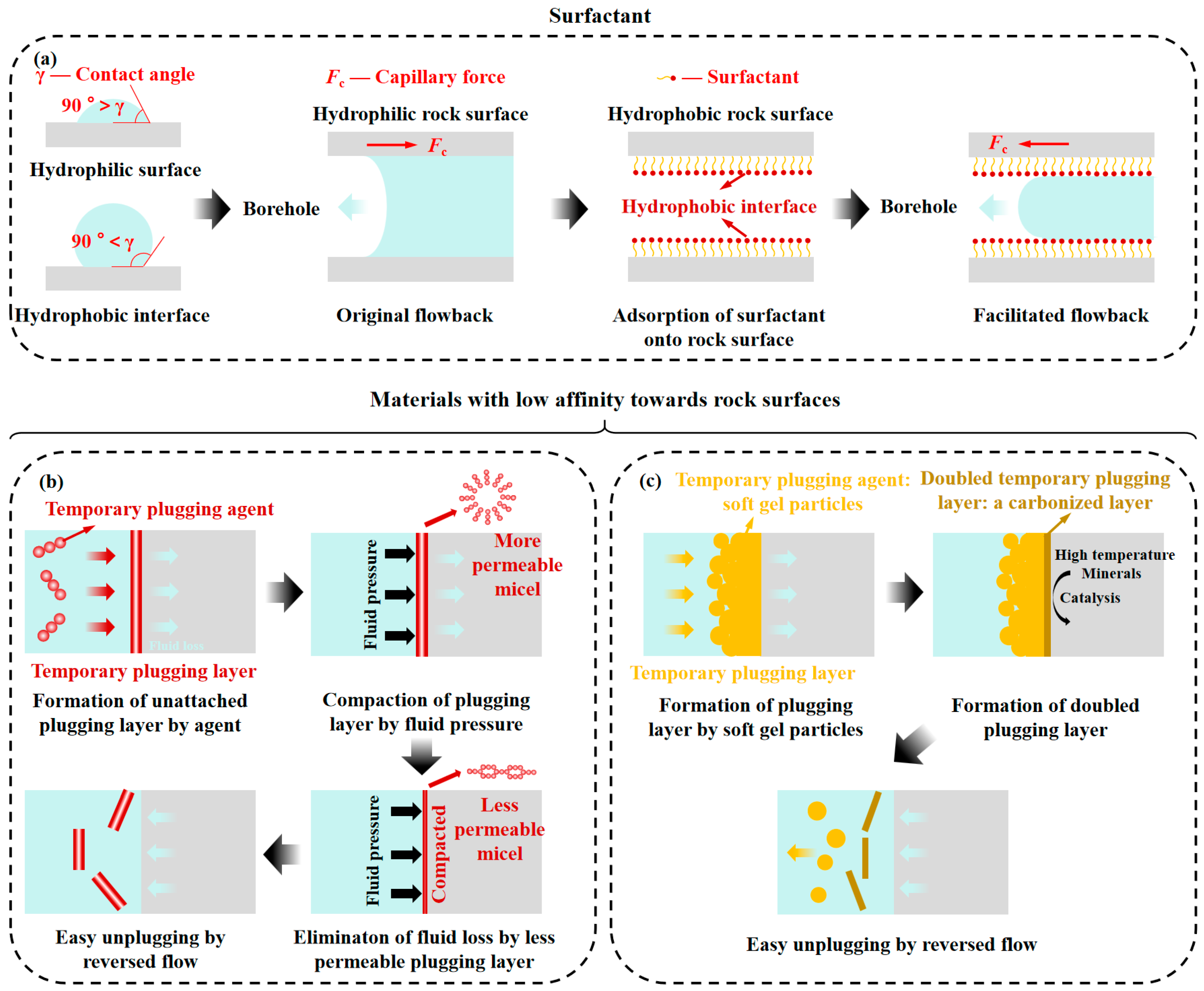

3.2. Facilitated Flowback

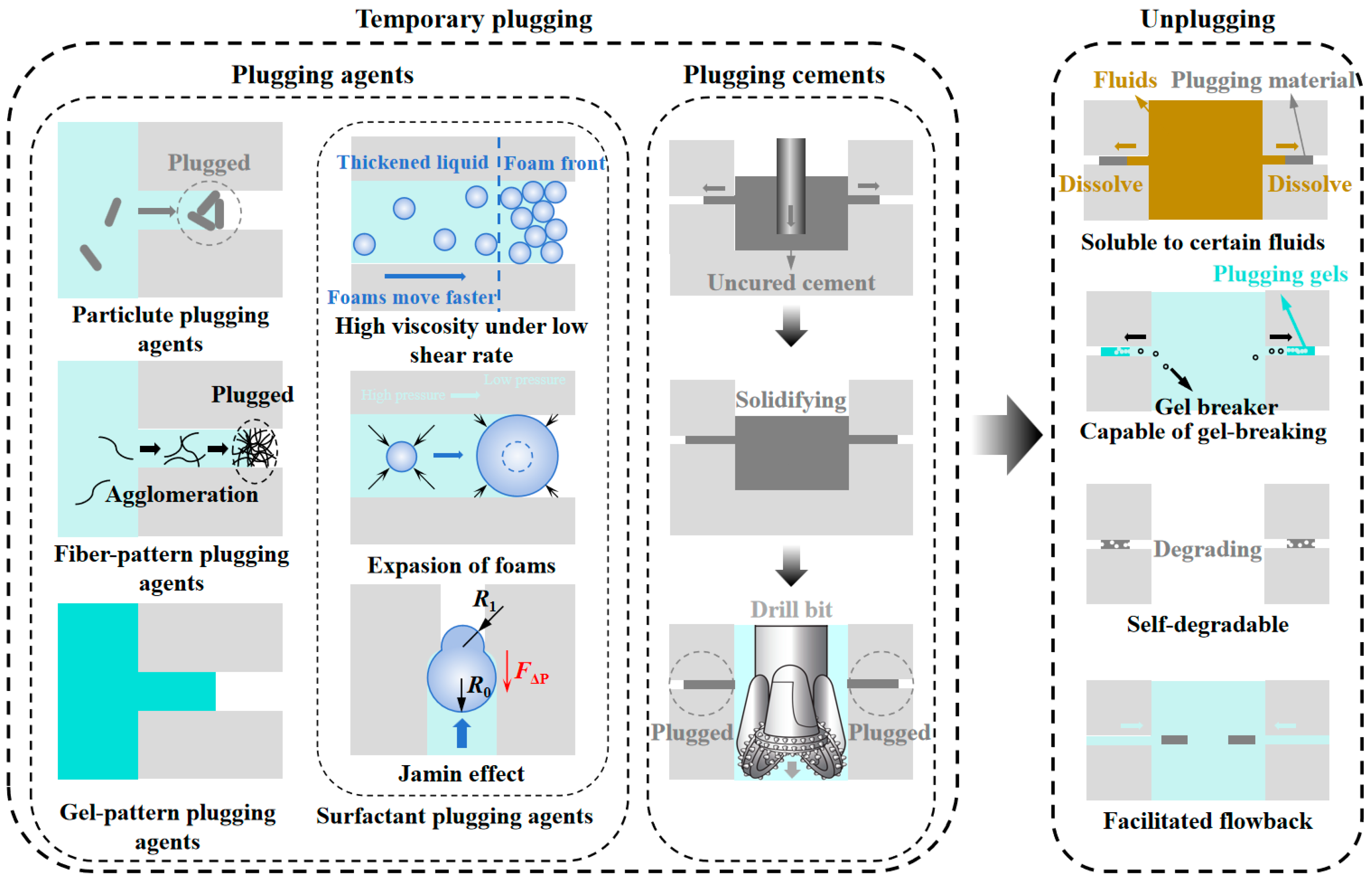

3.3. Temporary Plugging

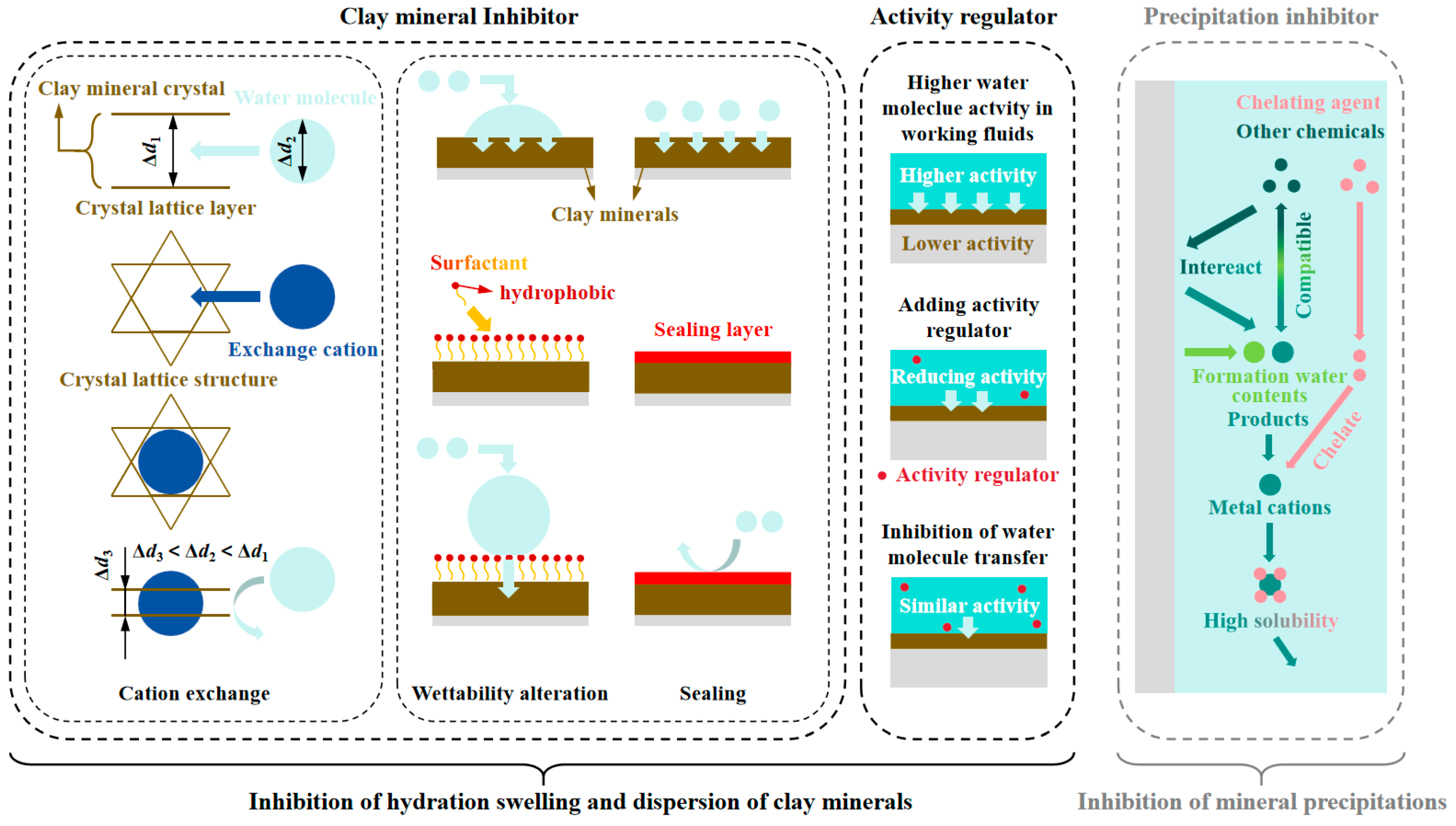

3.4. Inhibition

4. Conclusions

- The potential geothermal reservoir damage induced by working fluids include solids and colloidal plugging, fluid sensitivity, and stress sensitivity. Stress sensitivity can be exacerbated by solids and colloidal plugging as well as fluid sensitivity.

- The design principles of geothermal reservoir protection working fluids include solid-free, facilitated flowback, temporary plugging, and inhibition, which aims to reduce geothermal reservoir damage.

- The facilitated flowback, temporary plugging, and inhibition of working fluids can be accomplished by adding surfactant, emphasizing the application of surfactant in geothermal reservoir protection working fluids.

- The proposed design principles have been practically applied during geothermal reservoir development, for example, solid-free drilling fluid during carbonate geothermal reservoir drilling in Xiong’an New Area [60], as well as facilitated flowback and inhibition during carbonate geothermal reservoir stimulation in North China Plain [61,62]. However, the application cases are limited, and the geothermal reservoir protection working fluid technology is still under development. Future works can be focused on the application, validation, and remediation of the proposed design principles of geothermal reservoir working fluids, thus improving their reservoir protection capacity.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kaur, S.; Yadav, S.J.; Bhambri, R.; Sain, K.; Tiwari, S.K. Assessment of geothermal potential of Kumaun Himalaya: A perspective for harnessing green energy. Renew. Energy 2023, 212, 940–952. [Google Scholar] [CrossRef]

- Song, X.Z.; Li, G.S.; Huang, Z.W.; Shi, Y.; Wang, G.S.; Song, G.F.; Xu, F.Q. Review of high-temperature geothermal drilling and exploitation technologies. Gondwana Res. 2023, 12, 315–330. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, B.; Zhang, G.; Shangguan, S.; Qi, X.; Li, X.; Qiao, Y.; Xu, J. Study of the interaction between the granitic hot-dry rock (HDR) and different injection waters. Acta Geol. Sin. 2020, 94, 2115–2123. [Google Scholar]

- Yuan, B.; Wood, D.A. A holistic review of geosystem damage during unconventional oil, gas and geothermal energy recovery. Fuel 2018, 227, 99–110. [Google Scholar] [CrossRef]

- Xu, C.Y.; Xie, Z.C.; Kang, Y.L.; Yu, G.Y.; You, Z.J.; You, L.J.; Zhang, J.Y.; Yan, X.P. A novel material evaluation method for lost circulation control and formation damage prevention in deep fractured tight reservoir. Energy 2020, 210, 118574. [Google Scholar] [CrossRef]

- Chen, Z.J.; Li, J.M.; Yang, B.; Yang, C.D.; Jin, X.Z. Drilling and completion fluid technology for long horizontal openhole completion Changbei Gas Field. Nat. Gas Ind. 2007, 27, 49–51. [Google Scholar]

- Jia, H.; Yang, X.M.; Pu, W.F.; Zhao, J.Z.; Fu, H.; Guo, S.S.; Liu, P.C.; Wang, Q. Technology of optimized completion fluid in low-porosity and low-permeability gas fields at the East China Sea. Nat. Gas Ind. 2010, 30, 60–64. [Google Scholar]

- Huo, B.Y.; Cheng, T.; Zhang, X.W.; Wang, G.P.; Liu, D.H. High temperature resisting well completion fluid of organic acid salt. Oilfield Chem. 2013, 30, 500–504. [Google Scholar]

- Jiang, G.C.; Ni, X.X.; Li, W.Q.; Quan, X.H.; Luo, X.W. Super-amphiphobic, strong self-cleaning and high-efficiency water-based drilling fluids. Pet. Explor. Dev. 2020, 47, 421–429. [Google Scholar] [CrossRef]

- Xia, Z.Y.; Jiang, G.C.; Fan, Z.K.; Jia, J.; Xie, J.C.; Sha, N.Y. Strong inhibition and low damage water-based drilling fluid suitable for Linxing Well Area. Drill. Prod. Technol. 2022, 45, 160–164. [Google Scholar]

- Zhu, W.X.; Zheng, X.H.; Shi, J.J.; Wang, Y.F. A high-temperature resistant colloid gas aphron drilling fluid system prepared by using a novel graft copolymer xanthan gum-AA/AM/AMPS. J. Pet. Sci. Eng. 2021, 205, 108821. [Google Scholar] [CrossRef]

- Mao, H.B.; Liu, Y.; Li, L.; Yue, L.; Gao, J.; Qiu, F.; Jia, Z.L. Study on new nitrogen foam fracturing fluid system and its application in coalbed methane reservoir. Drill. Prod. Technol. 2022, 45, 139–143. [Google Scholar]

- Lin, S.Y.; Lu, Y.H.; Liu, Z.Q.; Lu, W.; Hu, P. Novel water-based mud for low-permeable reservoir in South China Sea. Energies 2023, 16, 1738. [Google Scholar] [CrossRef]

- Zhang, X.L.; Dang, B.H.; Wang, X.C.; Luo, S.; Chen, B.G.; Zheng, L.H. Acid-soluble drilling fluid in the northern carbonate reservoir of the Yishan Slope in the Ordos Basin. Energies 2023, 16, 6020. [Google Scholar] [CrossRef]

- You, F.C.; Zeng, J.; Gong, C.W.; Shen, Y.L. Experimental study of a degradable solid-free drill-in fluid system and its reservoir protection mechanism. SPE J. 2024, 29, 1337–1349. [Google Scholar] [CrossRef]

- Ezzat, A.M. Completion fluids design criteria and current technology weakness. In Proceedings of the SPE Formation Damage Control Symposium of the Conference, Lafayette, LA, USA, 22–23 February 1990. [Google Scholar]

- Zhao, X.; Qiu, Z.S.; Sun, B.J.; Liu, S.J.; Xing, X.J.; Wang, M.L. Formation damage mechanisms associated with drilling and completion fluids for deepwater reservoirs. J. Pet. Sci. Eng. 2019, 173, 112–121. [Google Scholar] [CrossRef]

- Gu, J.; Xiang, Y.; He, X.Q.; Jia, B. Research of the drilling and completion fluid system for fracture-pore type reservoir protection. J. Chengdu Univ. Technol. (Sci. Technol. Ed.) 2003, 30, 184–186. [Google Scholar]

- Wang, C.W.; Wang, Y.J.; Kuru, E.; Chen, E.; Xiao, F.F.; Chen, Z.H.; Yang, D.Y. A new low-damage drilling fluid for sandstone reservoirs with low-permeability: Formulation, evaluation, and applications. J. Energy Resour. Technol. 2021, 143, 053004. [Google Scholar] [CrossRef]

- Klungtvedt, K.R.; Saasen, A. A method for assessing drilling fluid induced formation damage in permeable formations using ceramic discs. J. Pet. Sci. Eng. 2022, 213, 110324. [Google Scholar] [CrossRef]

- Tan, Q.G.; You, L.j.; Kang, Y.L.; Xu, C.Y. Formation damage mechanisms in tight carbonate reservoirs: The typical illustrations in Qaidam Basin and Sichuan Basin. China. J. Nat. Gas Sci. Eng. 2021, 95, 104193. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Liu, Y.G.; Li, T.X.; Wei, M.H. Seepage and heat transfer of dominant flow in fractured geothermal reservoirs: A review and outlook. Water 2023, 15, 2953. [Google Scholar] [CrossRef]

- Bennion, D.B.; Thomas, F.B. Underbalanced drilling of horizontal wells: Does it really eliminate formation damage. In Proceedings of the SPE Formation Damage Control Symposium of the Conference, Lafayette, LA, USA, 7–10 February 1994. [Google Scholar]

- Shi, X.Y.; Prodanović, M.; Holder, J.; Gray, K.E.; DiCarlo, D. Coupled solid and fluid mechanics modelling of formation damage near wellbore. J. Pet. Sci. Eng. 2013, 112, 88–96. [Google Scholar] [CrossRef]

- He, W.W.; Liu, Z.Q. Numerical simulation of formation damage by drilling fluid in low permeability sandstone reservoirs. J. Pet. Explor. Prod. Technol. 2021, 11, 1865–1871. [Google Scholar] [CrossRef]

- Kang, Y.L.; Zhang, L.Y.; Li, X.C.; Zhou, L.C. Experimental evaluation of coalbed reservoir damage induced by sequential contacts with working fluids. Coal Geol. Explor. 2015, 43, 128–132. [Google Scholar]

- Xu, Z.Z.; Zhao, M.W.; Liu, J.W.; Zhang, Y.M.; Gao, M.W.; Song, X.G.; Sun, N.; Li, L.; Wu, Y.N.; Dai, C.L. Study on formation process and reservoir damage mechanism of blockages caused by polyacrylamide fracturing fluid in production wells. Fuel 2024, 358, 130154. [Google Scholar] [CrossRef]

- Xin, X.Z.; Zhao, J.M.; Xu, Y.W.; Jin, C.H.; Luo, Z.F.; Wang, Y.M.; Fu, H.R. Study on the spatial damage characteristics of working fluid in a sandstone reservoir and an unplugged fluid system. ACS Omega 2024, 9, 18400–18411. [Google Scholar] [CrossRef] [PubMed]

- Li, X.J.; Zhang, Q.J.; Liu, P.; Li, T.; Liu, G.F.; Liu, Z.K.; Zhao, H.F. Investigation on the microscopic damage mechanism of fracturing fluids to low-permeability sandstone oil reservoir by nuclear magnetic resonance. J. Pet. Sci. Eng. 2022, 209, 109821. [Google Scholar] [CrossRef]

- Yang, S.G.; Yu, Q.C. The role of fluid-rock interactions in permeability behavior of shale with different pore fluids. Int. J. Rock Mech. Min. Sci. 2022, 150, 105023. [Google Scholar] [CrossRef]

- Ma, K.; Jiang, H.Q.; Li, J.J.; Zhao, L. Experimental study on the micro alkali sensitivity damage mechanism in low-permeability reservoirs using QEMSCAN. J. Nat. Gas Sci. Eng. 2016, 36, 1004–1017. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Konstantinou, C.; Tang, S.K.; Chen, H.Y. Applications of microbial-induced carbonate precipitation: A state-of-the-art review. Biogeotechnics 2023, 1, 100008. [Google Scholar] [CrossRef]

- Badalyan, A.; Carageorgos, T.; Bedrikovetsky, P.; You, Z.J.; Zeinijahromi, A.; Aji, K. Critical analysis of uncertainties during particle filtration. Rev. Sci. Instrum. 2012, 83, 095106. [Google Scholar] [CrossRef] [PubMed]

- Le, T.T.B.; Finney, A.R.; Zen, A.; Bui, T.; Tay, W.J.; Chellappah, K.; Salvalaglio, M.; Micharlides, A.; Striolo, A. Mesoscale simulations reveal how salt influences clay particles agglomeration in aqueous dispersions. J. Chem. Theory Comput. 2024, 20, 1612–1624. [Google Scholar] [CrossRef] [PubMed]

- He, J.G.; Kang, Y.L.; You, L.J.; Cheng, Q.J. Influence of fluid damage on shale reservoir stress sensitivity. Nat. Gas Geosci. 2011, 22, 915–919. [Google Scholar]

- Huang, C.; Kang, Y.L.; You, L.J.; Li, X.L.; Tan, W.X.; Bai, R.T. Research on stress sensitivity of fracture-hole carbonate reservoirs under drilling fluid immersion. Geoenergy Sci. Eng. 2024, 223, 212537. [Google Scholar] [CrossRef]

- You, L.J.; Kang, Y.L.; Chen, Y.J.; Hao, S.M.; Cheng, Q.J. Experiments and applications of water phase trapping in tight gas sand reservoirs. Drill. Fluid Complet. Fluid 2006, 23, 4–7. [Google Scholar]

- Siddiqui, M.A.; Nasr-EI-Din, H.A. Evaluation of special enzymes as a means to remove formation damage induced by drill -in fluids in horizontal gas wells in tight reservoirs. SPE Prod. Fac. 2005, 20, 177–184. [Google Scholar] [CrossRef]

- Tuttle, J.D.; Listi, R. ‘Drill-in’ fluids and drilling practices drilling more productive, less costly geothermal wells. Geotherm. Resour. Counc. Trans. 2016, 40. Available online: https://www.geothermal-library.org/index.php?mode=pubs&action=view&record=1032335 (accessed on 17 August 2024).

- Yang, B.; Huang, L.J. No bentonite and low solids drilling fluids based on the formate brines. Drill. Prod. Technol. 2001, 24, 58–60. [Google Scholar]

- Liang, X.Y.; Zhou, F.J.; Liang, T.B.; Wang, C.Z.; Wang, J.; Yuan, S. Impacts of low harm fracturing fluid on fossil hydrogen energy production in tight reservoirs. Int. J. Hydrogen Energy 2020, 45, 21195–22120. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Dai, H.; Zhang, N.K.; Long, S.M. Study on formulation and properties of a new thickened acid. Nat. Gas Ind. 2007, 27, 85–87. [Google Scholar]

- Kang, Y.L.; Zhang, D.J.; You, L.J.; Xu, C.Y.; Yu, H.F. Mechanism and control methods of the working fluid damages in fractured tight reservoirs. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2015, 37, 77–84. [Google Scholar]

- Growcock, F.B.; Belkin, A.; Fosdick, M.; Irving, M.; O’Connor, B.; Brookey, T. Recent advances in aphron drilling fluids. In Proceedings of the IADC/SPE Drilling Conference of the Conference, Miami, FL, USA, 21–23 February 2006. [Google Scholar]

- Lv, K.H.; Qiu, Z.S.; Wang, Z.M. Techniques of auto-adapting shielding and temporary plugging drilling fluid. J. China Univ. Pet. (Sci. Technol. Ed.) 2008, 32, 68–71+75. [Google Scholar]

- Jiang, W.; Zhang, J.; Wang, J.J.; Peng, S.P.; Huang, W.Y.; Wang, G.P. Shielding and temporary plugging technology and application in the Biancheng Area of North Jiangsu Province. Nat. Gas Ind. 2006, 26, 81–83. [Google Scholar]

- Mu, M.; Tang, X.T.; Wang, L.S.; Zhang, X.; Liu, H.; Jiang, M.Z.; Jiang, D.; Zhang, Y.M. Progress of fabrications, properties and applications of chemical temporary plugging systems. Oilfield Chem. 2022, 39, 735–744+760. [Google Scholar]

- Lv, Q.C.; Li, Z.M.; Li, B.F.; Li, S.Y.; Sun, Q. Study of nanoparticle-surfactant-stabilized foam as a fracturing fluid. Ind. Eng. Chem. Res. 2015, 54, 9468–9477. [Google Scholar] [CrossRef]

- Liu, H.Z.; Li, L.C. Study and application of micro bubble temporary plugging technology. Pet. Drill. Tech. 2012, 40, 71–73. [Google Scholar]

- Tan, H.J.; Zheng, X.H.; Ma, L.M.L.; Huang, H.X.; Xia, B.R. A study on the effects of starches on the properties of alkali-activated cement and the potential of starch as a self-degradable additive. Energies 2017, 10, 1048. [Google Scholar] [CrossRef]

- Li, Z.Y.; Qi, L.; Gu, T.; Sun, J.F.; Guo, X.Y. Effect of micron-CaCO3 and nano-CaCO3 on the acid-soluble performance of oil-well cement stone. Bull. Chin. Ceram. Soc. 2018, 37, 2576–2582. [Google Scholar]

- Yang, H.B.; Lv, Z.Q.; Li, Z.; Guo, B.M.; Zhao, J.; Xu, Y.T.; Xu, W.J.; Kang, W.L. Laboratory evaluation of a controllable self-degradable temporary plugging agent in fractured reservoir. Phys. Fluids 2023, 35, 083314. [Google Scholar] [CrossRef]

- Zhao, X.; Ceng, Q.; Qi, Z.S.; Ceng, T.; Zhou, G.W.; Xing, X.J. Gel-breaking free drill-in fluid technology for deepwater high-porosity and high-permeability reservoirs. Nat. Gas Ind. 2021, 41, 107–114. [Google Scholar]

- Luo, C.D.; Wang, Q.Y.; Wang, F.B.; Feng, Q.Y.; Zeng, C.; Bai, X.D. Study and application of low branched polyamine inhibitor. Drill. Prod. Technol. 2023, 46, 151–156. [Google Scholar]

- Cao, L.; Yu, P.Z. Research and application of activity regulator in low activity water-based drilling fluid system. Appl. Chem. Ind. 2022, 51, 2344–2347+2361. [Google Scholar]

- Qin, G.C.; He, M.; Xu, M.B.; Chen, K.; Zhao, C.Y. Research progress of shale water-based drilling fluid inhibitors at home and abroad. Appl. Chem. Ind. 2020, 49, 1802–1806. [Google Scholar]

- Spinthaki, A.; Kamaratou, M.; Disci, D.; Hater, W.; Demadis, K.D. Inhibition of aluminum silicate scaling by phosphonate additives under geothermal stresses. Geothermics 2023, 111, 102690. [Google Scholar] [CrossRef]

- Chen, J.Y.; Xu, T.F.; Jiang, Z.J.; Feng, B.; Liang, X. Reducing formation damage by artificially controlling the fluid-rock chemical interaction in a double-well geothermal heat production system. Renew. Energy 2020, 149, 455–467. [Google Scholar] [CrossRef]

- Holmslykke, H.D.; Weibel, R.; Olsen, D.; Anthonsen, K.L. Geochemical reactions upon injection of heated formation water in a Danish geothermal reservoir. ACS Earth Space Chem. 2023, 7, 1635–1647. [Google Scholar] [CrossRef]

- Zhao, C.L.; Wang, Y.J.; Nie, D.J.; Wang, L. Gas lift reverse circulation drilling technology for D19 well in broken thermal reservoir in Xiong’an New Area. Drill. Eng. 2022, 49, 137–143. [Google Scholar]

- Zhao, Z.H.; Xu, H.R.; Chen, S.C.; Ma, F.; Wang, G.L. Numerical modeling on acid stimulation in carbonate geothermal reservoir in Xiong’an New Area. J. China Coal Soc. 2023, 48, 2691–2699. [Google Scholar]

- Wang, G.L.; Yue, G.F.; Lin, W.J.; Ma, F.; Liu, Y.G. Deep carbonate geothermal reservoir production enhancement technology in North China Plain. Earth Sci. 2024, 49, 1470–1486. [Google Scholar]

| Ref. | Application Scenario | Working Fluid Type | Formula and Function | Protection Mechanism |

|---|---|---|---|---|

| [6] | Changbei gas reservoir, Yulin, Shanxi, China | Drill-in fluid | Water + 1~3% filtration reducer + 0.1~0.3% tackifier and shear strength improving agent + 2~4% temporary plugging agent + 1~3% QS-2 + 0.2~0.5% MgO + 0.5~1% lubricant: non-fluorescent DRH + NaCOOH + preservative | (a) Eliminated solid plugging due to no clay solids (b) Temporary plugging by soluble and degradable plugging materials |

| [7] | Gas reservoir, East China Sea District | Drill-in fluid | Water + 0.5% Chelating agent + 1~2% temporary plugging agent: gelatinizer SW-1 + 0.5% rheological modifier: WDJ-1 | (a) Eliminated solid plugging due to no clay solids (b) Inhibition of precipitation (c) Temporary plugging by gel that is easy to flow back and capable of gel-breaking |

| [8] | Yuanba gas reservoir, Sichuan, China | Drill-in fluid | Water + density regulator: formate + 0.5% rheological regulator: modified XC DHV + 2% filtration reducer: PAC-142 + 1% corrosion inhibitor: SD-2 + 0.8% cleanup additive: zwitterionic surfactant SAT + 0.2% pH adjuster: NaOH + 0.5% deoxidizer: Na2SO3 | (a) No solid plugging due to no solids (b) Eliminated fluid loss of working fluids by plugging agents (c) Facilitated flowback of working fluids from reservoir formation by surfactant |

| [9] | Unconventional oil–gas reservoir | Drilling fluid | Water + 3% bentonite + 0.5% filtration reducer + 1% plugging agent + 1% filtration reducer: starch + density regulator: BaSO4 + 3% reservoir protectant: individually synthesized supper-amphiphobic (SA) agent | (a) Inhibition of clay minerals by cation exchange and by preventing water contact through the adsorption of SA agent onto rock surfaces (b) Reducing fluid loss by wettability alteration due to the adsorption of SA agent onto rock surfaces (c) Eliminated fluid loss of working fluids by plugging agents |

| [10] | Gas reservoir, Linxing District, Ordos Basin, Inner Mongolia, China | Drilling fluid | Water + 1.0% bentonite + 0.3% filtration reducer: LV-CMC + 0.1% 0.5% rheological regulator: XC + 2.5% filtration reducer: starch + 3.0% plugging agent: white asphalt + 2.0% CaCO3 + 1.5% reservoir protectant: SA agent + 5% density regulator and inhibitor: KCl + density regulator: BaSO4 | |

| [11] | Under-pressure zone of oil reservoir | Drilling fluid | Water + 3% bentonite + 0.2% pH buffer: Na2CO3 + 0.5~1.5% foam stabilizer: individually synthesized XG-AA/AM/AMPS + 0.286% foaming agent: SDS + air | (a) Temporary plugging and facilitated flowback of working fluids by foaming (b) Eliminated fluid loss of working fluids by foaming |

| [12] | Coalbed methane reservoir, Qingshui Basin, Shanxi, China | Fracturing fluid | Water + 0.2% foaming agent: SK-1 + 0.3% foaming agent: SK-2 + 0.2% foam stabilizer: WP-11 + 2.0% inhibitor: KCl + N2 | (a) Eliminated fluid loss of working fluids by foaming (b) Inhibition of clay minerals by cation exchange |

| [13] | Weizhou oil reservoir, Weizhou Depression, Beibu Gulf Basin, South China Sea | Drilling fluid | Water + 3.0% pH adjuster: NaOH + 2.0% PF-FLOTROL + 20% PF-GBL + 1.5% PF-LPFH + PF-CONA + PF-HCOOK + 0.7% PF-VIS + 2% PF-GJC + 3% CaCO3 | (a) Eliminated solid plugging due to no clay solids (b) Inhibition of clay minerals by cation exchange and by the sealing between water and mineral surfaces (c) Eliminated fluid loss of working fluids by plugging agents |

| [14] | Daniudi gas reservoir, Yishan Slope, Ordos Basin, Inner Mongolia, China | Drilling fluid | Water + 0.3~0.8% filtration reducer: LV-CMC + tackifier, shear strength improving agent and temporary plugging agent: 1~2% starch and 0.1~0.3% HV-CMC + 2~3% lubricant: vegetable oil + 0.05~0.1% fungicide: glutaraldehyde + 0.05~0.1% pH adjuster: NaOH | (a) No solid plugging due to no solids (b) Temporary plugging due to soluble and degradable properties of working fluids (c) Eliminated fluid loss of working fluids by plugging agents |

| [15] | Oil and gas reservoir, South China Sea | Drill-in fluid | Sea water + 0.2% pH adjuster: NaOH + 0.2% pH buffer: Na2CO3 + 2.85% filtration reducer + 0.82% lubricant + 1.63% inhibitor + 0.49% tackifier and shear strength improving agent: individually synthesized modified xanthan gum XC-LT + density regulator: KCl |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, O.; Cao, L.; Zhu, W.; Zheng, X. Review of Reservoir Damage Mechanisms Induced by Working Fluids and the Design Principles of Reservoir Protection Fluids: From Oil–Gas Reservoirs to Geothermal Reservoirs. Energies 2024, 17, 4895. https://doi.org/10.3390/en17194895

Jiang O, Cao L, Zhu W, Zheng X. Review of Reservoir Damage Mechanisms Induced by Working Fluids and the Design Principles of Reservoir Protection Fluids: From Oil–Gas Reservoirs to Geothermal Reservoirs. Energies. 2024; 17(19):4895. https://doi.org/10.3390/en17194895

Chicago/Turabian StyleJiang, Ou, Ling Cao, Wenxi Zhu, and Xiuhua Zheng. 2024. "Review of Reservoir Damage Mechanisms Induced by Working Fluids and the Design Principles of Reservoir Protection Fluids: From Oil–Gas Reservoirs to Geothermal Reservoirs" Energies 17, no. 19: 4895. https://doi.org/10.3390/en17194895

APA StyleJiang, O., Cao, L., Zhu, W., & Zheng, X. (2024). Review of Reservoir Damage Mechanisms Induced by Working Fluids and the Design Principles of Reservoir Protection Fluids: From Oil–Gas Reservoirs to Geothermal Reservoirs. Energies, 17(19), 4895. https://doi.org/10.3390/en17194895