Novel Recuperated Power Cycles for Cost-Effective Integration of Variable Renewable Energy

Abstract

1. Introduction

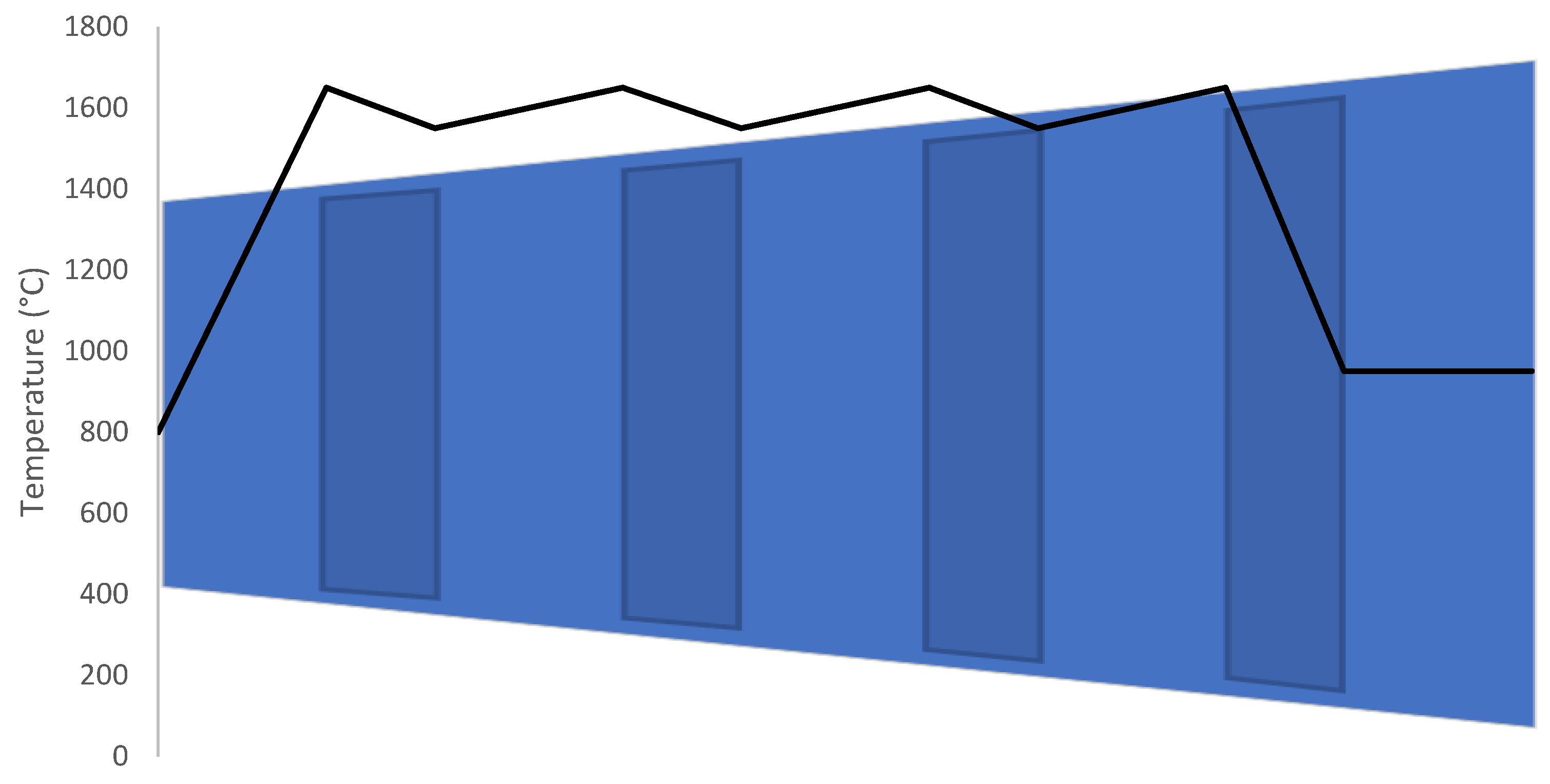

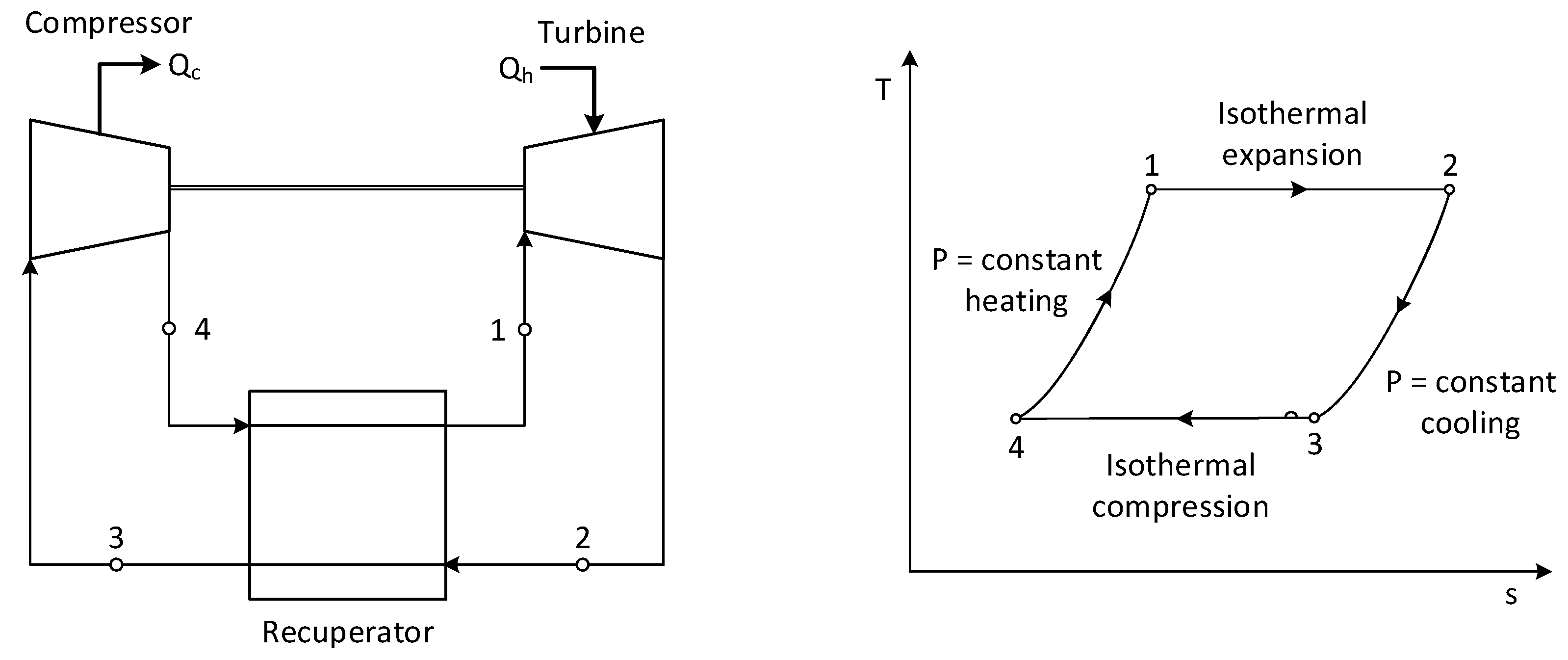

1.1. Near-Isothermal Hydrogen Turbine (NIHT)

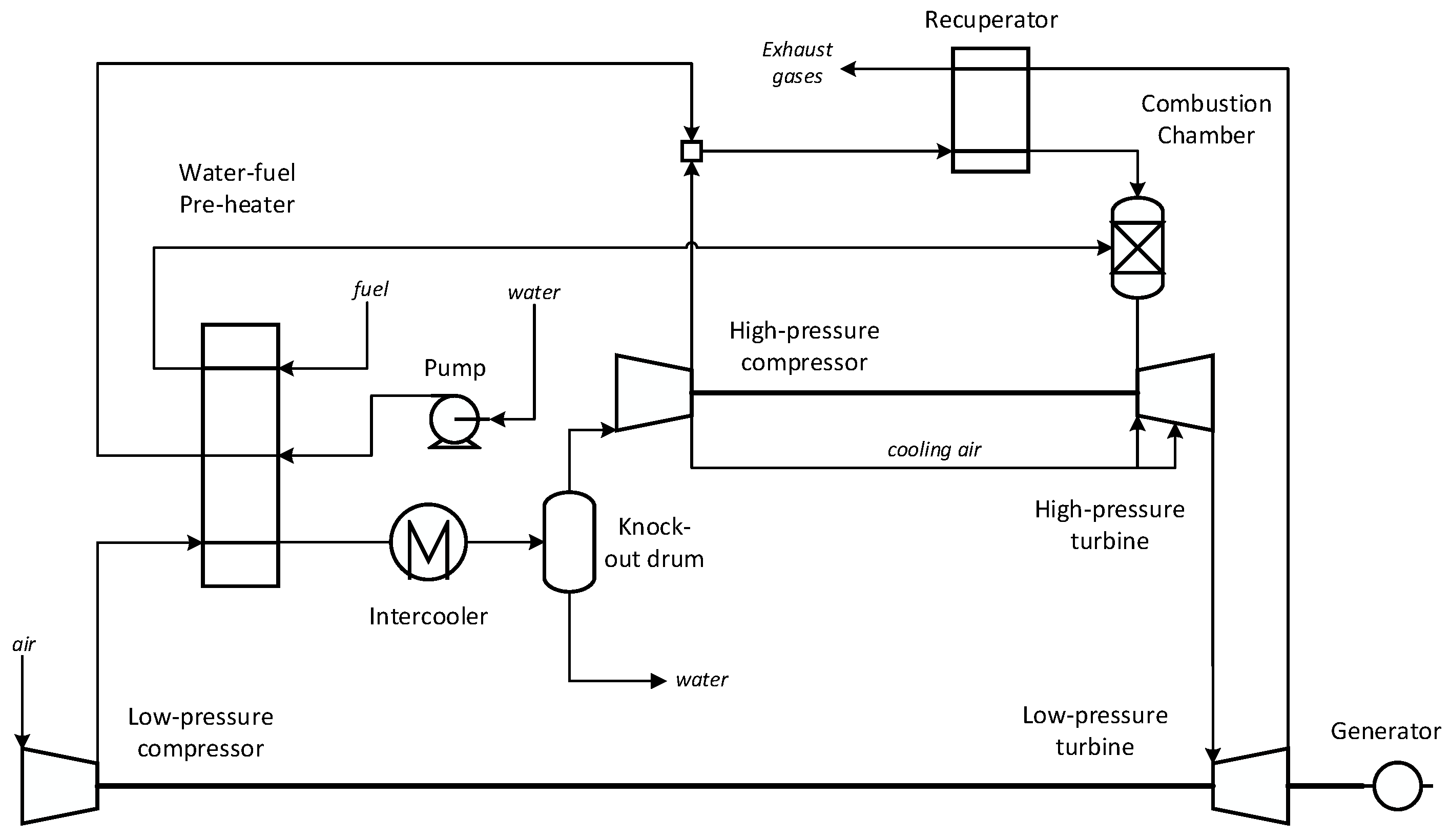

1.2. Intercooled Recuperated Water-Injected Cycle

2. Methodology

2.1. Process Modelling

2.2. Blade Cooling Flow Model

2.3. Economic Assessment

3. Results

3.1. Technical Performance

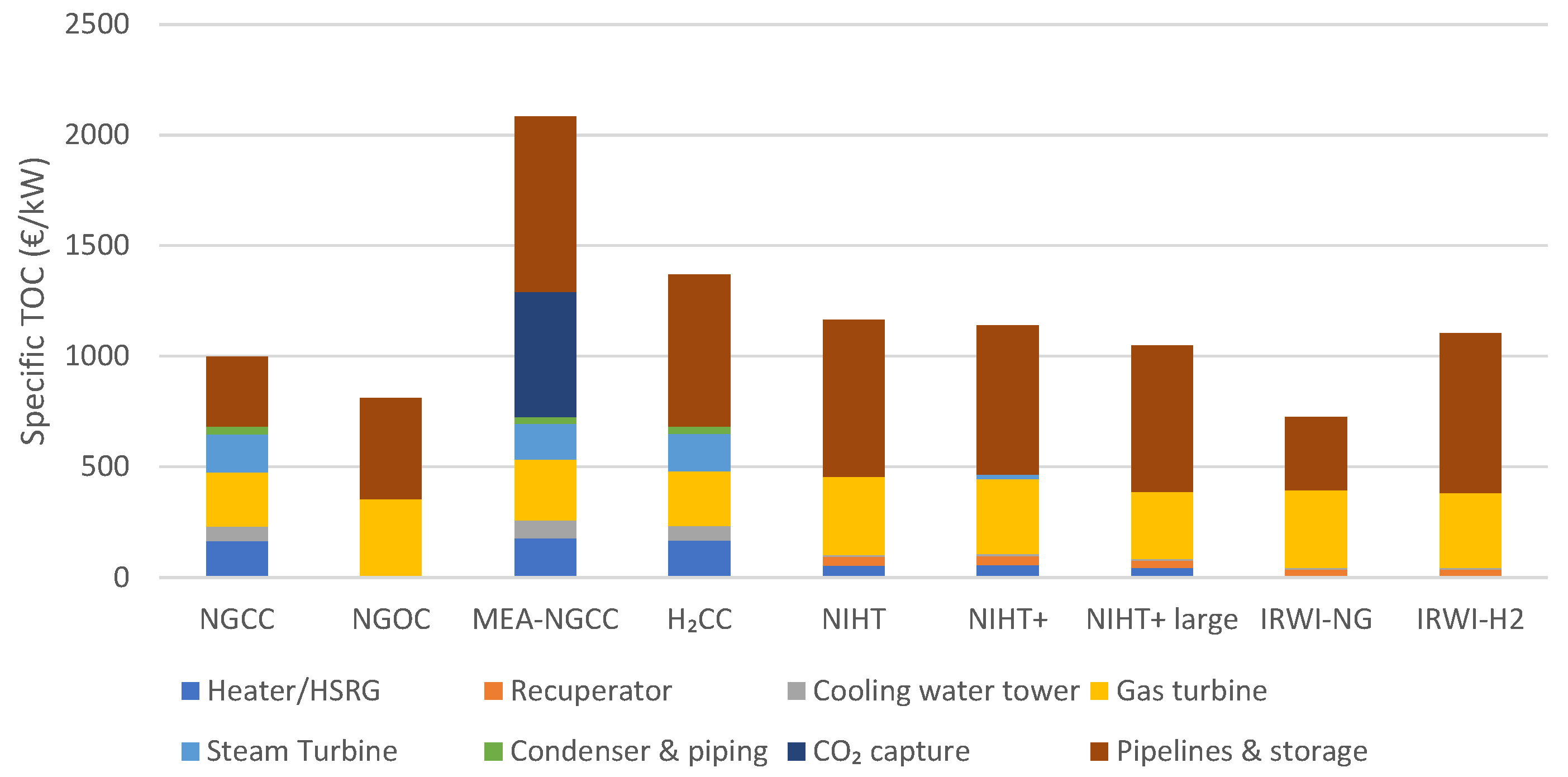

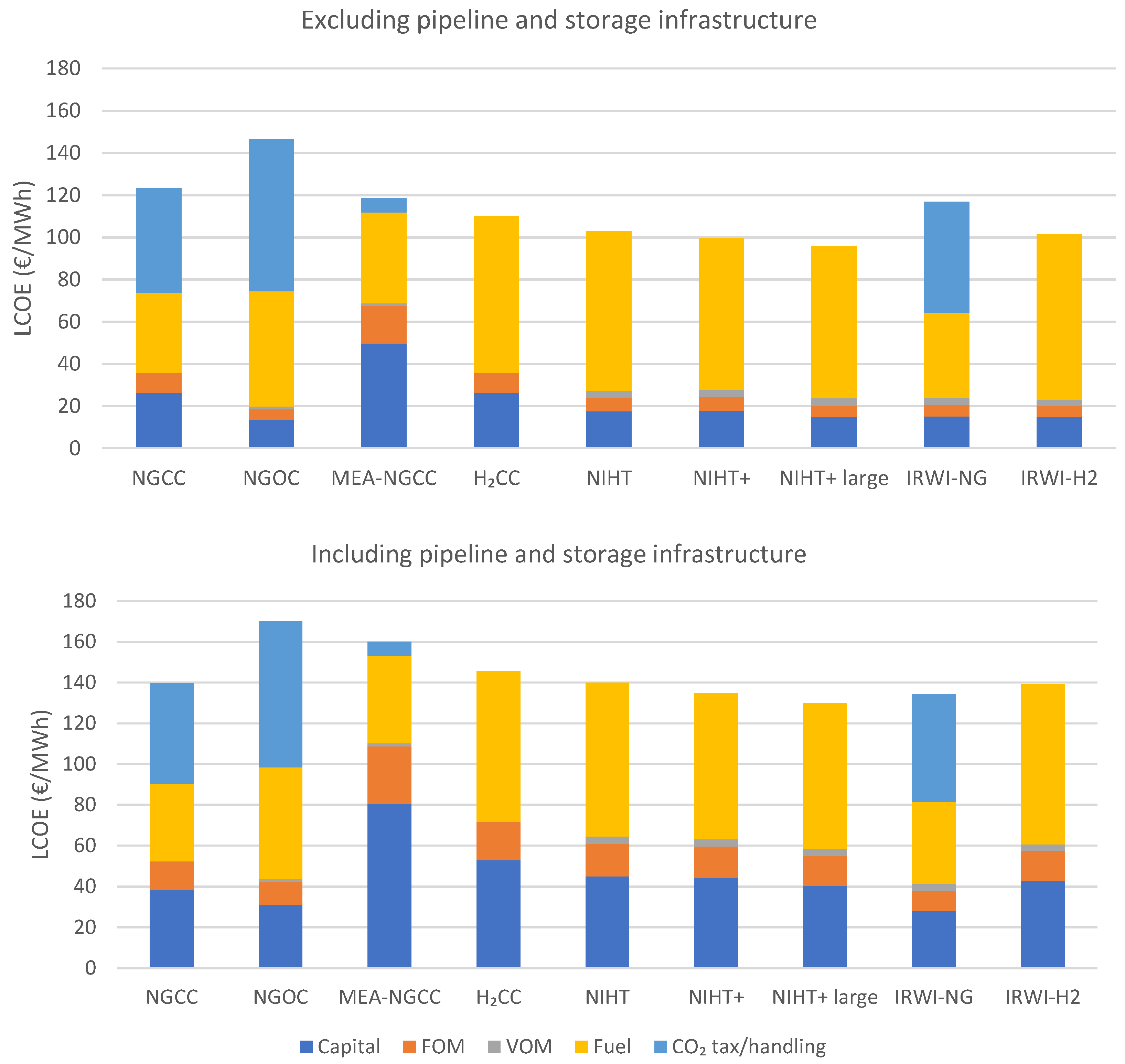

3.2. Economic Performance

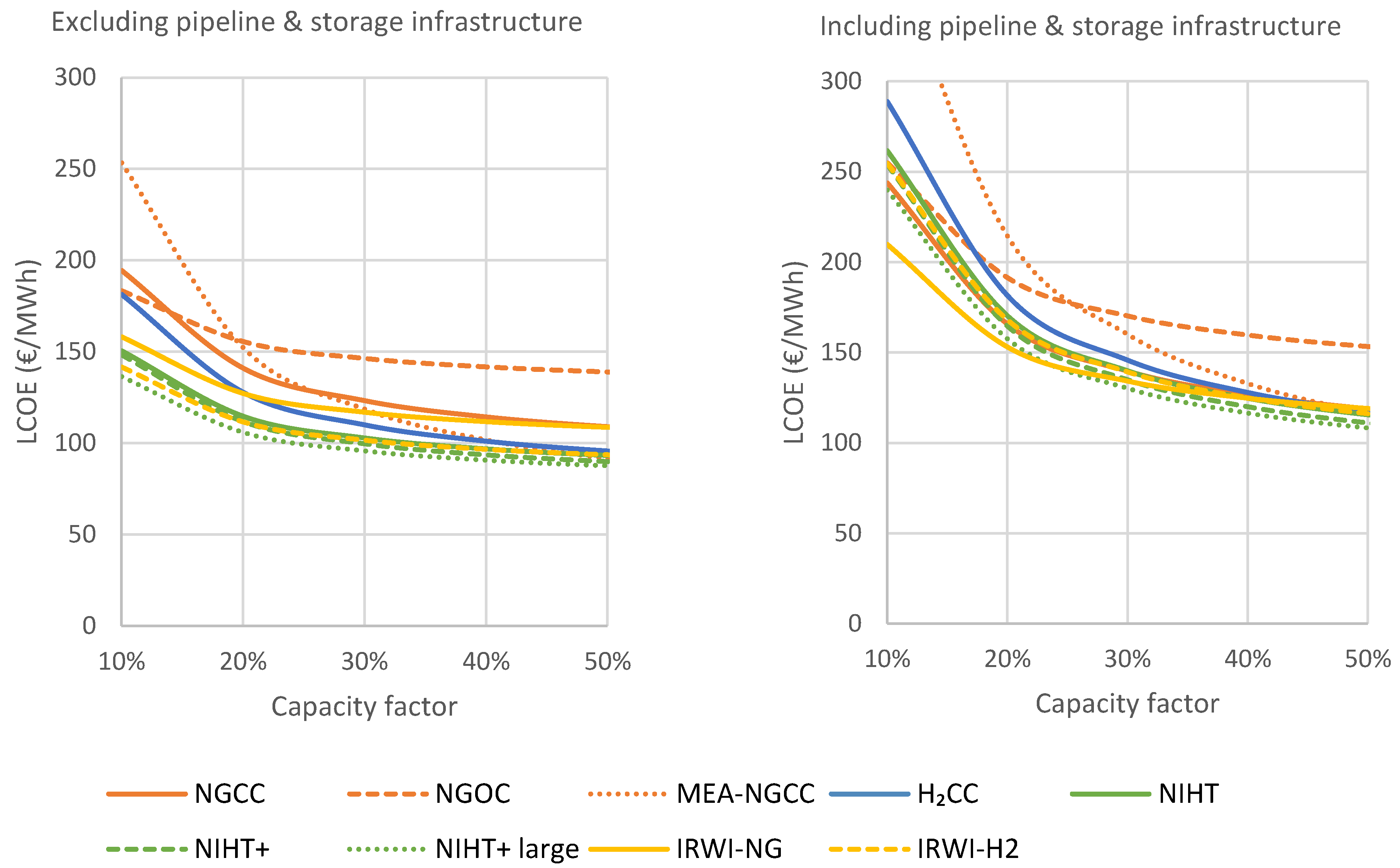

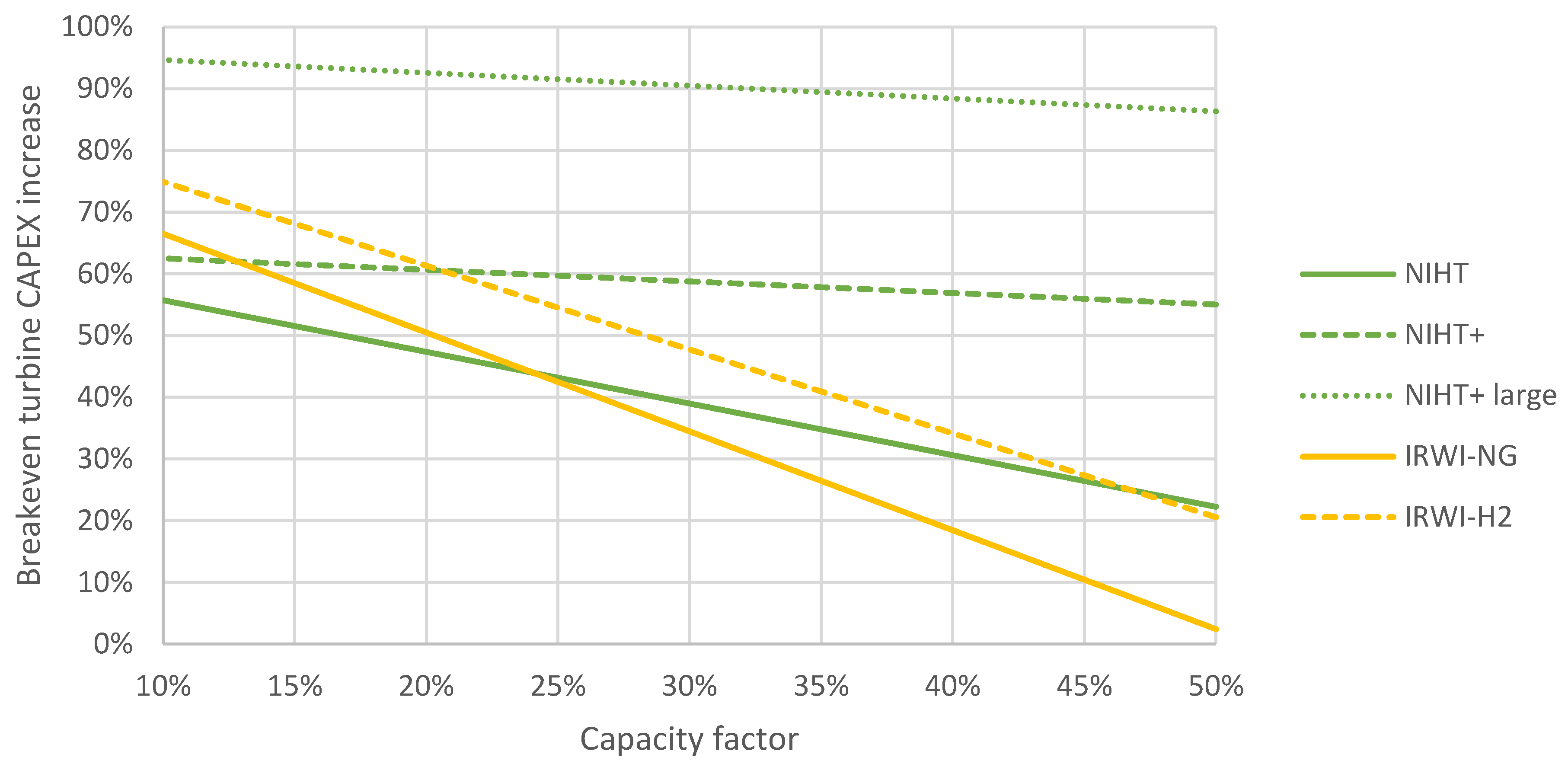

3.3. Effect of Capacity Factor

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Acronyms: | |

| BEC | Bare erected cost |

| CC | Combined cycle |

| CCS | Carbon capture and storage |

| COT | Combustor outlet temperature |

| EPC | Engineering procurement and construction |

| FOM | Fixed operating and maintenance |

| HSRG | Heat recovery steam generator |

| IRWI | Intercooled recuperated water-injected cycle |

| LCOE | Levelized cost of electricity |

| LHV | Lower heating value |

| MEA | Monoethanolamine |

| NG | Natural gas |

| NGCC | Natural gas combined cycle |

| NGOC | Natural gas open cycle |

| NIHT | Near isothermal hydrogen turbine |

| OC | Owner’s costs |

| PT | Project contingency |

| SEA | Standardized economic assessment |

| TIT | Turbine inlet temperature |

| TOC | Total overnight cost |

| VOM | Variable operating and maintenance |

| List of symbols | |

| Blade cooling empirical constant (-) | |

| Temperature (K) | |

| Heat duty (MW) | |

| Mass flow (kg/s) | |

| Specific heat capacity (kJ/kgK) | |

| Geometric mean pressure (bar) | |

| Compressor extraction pressure (bar) | |

| Gas turbine power density (kJ/kg) | |

| Gas turbine pressure ratio (-) | |

| Subscripts/Superscripts | |

| Blade | |

| Hot gases | |

| Coolant | |

References

- IEA. World Energy Outlook; International Energy Agency: Paris, France, 2023. [Google Scholar]

- IPCC. Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2022. [Google Scholar]

- NREL. Annual Technology Baseline: Natural Gas Plants. 2019. Available online: https://atb-archive.nrel.gov/electricity/2019/index.html?t=cg (accessed on 18 January 2024).

- Cloete, S.; Ruhnau, O.; Hirth, L. On capital utilization in the hydrogen economy: The quest to minimize idle capacity in renewables-rich energy systems. Int. J. Hydrog. Energy 2021, 46, 169–188. [Google Scholar] [CrossRef]

- van der Wijk, P.C.; Brouwer, A.S.; van den Broek, M.; Slot, T.; Stienstra, G.; van der Veen, W.; Faaij, A.P.C. Benefits of coal-fired power generation with flexible CCS in a future northwest European power system with large scale wind power. Int. J. Greenh. Gas Control 2014, 28, 216–233. [Google Scholar] [CrossRef]

- Oates, D.L.; Versteeg, P.; Hittinger, E.; Jaramillo, P. Profitability of CCS with flue gas bypass and solvent storage. Int. J. Greenh. Gas Control 2014, 27, 279–288. [Google Scholar] [CrossRef]

- Zaman, M.; Lee, J.H. Optimization of the various modes of flexible operation for post-combustion CO2 capture plant. Comput. Chem. Eng. 2015, 75, 14–27. [Google Scholar] [CrossRef]

- Mac Dowell, N.; Staffell, I. The role of flexible CCS in the UK’s future energy system. Int. J. Greenh. Gas Control 2016, 48, 327–344. [Google Scholar] [CrossRef]

- Cloete, S.; Hirth, L. Flexible power and hydrogen production: Finding synergy between CCS and variable renewables. Energy 2020, 192, 116671. [Google Scholar] [CrossRef]

- de Boer, H.S.; Grond, L.; Moll, H.; Benders, R. The application of power-to-gas, pumped hydro storage and compressed air energy storage in an electricity system at different wind power penetration levels. Energy 2014, 72, 360–370. [Google Scholar] [CrossRef]

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. Int. J. Hydrog. Energy 2019, 44, 12254–12269. [Google Scholar] [CrossRef]

- Cloete, S.; Arnaiz del Pozo, C.; Jiménez Álvaro, Á. System-friendly process design: Optimizing blue hydrogen production for future energy systems. Energy 2022, 259, 124954. [Google Scholar] [CrossRef]

- Nazir, H.; Muthuswamy, N.; Louis, C.; Jose, S.; Prakash, J.; Buan, M.E.; Flox, C.; Chavan, S.; Shi, X.; Kauranen, P.; et al. Is the H2 economy realizable in the foreseeable future? Part II: H2 storage, transportation, and distribution. Int. J. Hydrog. Energy 2020, 45, 20693–20708. [Google Scholar] [CrossRef]

- Arnaiz del Pozo, C.; Jiménez Álvaro, Á.; Cloete, S.; García del Pozo Martín de Hijas, J.A. The Potential of Chemically Recuperated Power Cycles in Markets with High Shares of Variable Renewables. Energies 2023, 16, 7046. [Google Scholar] [CrossRef]

- Kraszewski, B. On an improvement of Carnot-like cycles devoted to turbines with isothermal expansion. Trans. Inst. Fluid-Flow Mach. 2018, 140, 3–21. [Google Scholar]

- Rice, M. Simulation of Isothermal Combustion in Gas Turbines; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 2004. [Google Scholar]

- El-Masri, M.A.; Magnusson, J.H. Thermodynamics of an Isothermal Gas Turbine Combined Cycle. J. Eng. Gas Turbines Power 1984, 106, 743–749. [Google Scholar] [CrossRef]

- Shah, P.N.; Tan, C.S. Effect of Blade Passage Surface Heat Extraction on Axial Compressor Performance. J. Turbomach. 2005, 129, 457–467. [Google Scholar] [CrossRef]

- Kim, T.; Lee, C.-Y.; Hwang, Y.; Radermacher, R. A review on nearly isothermal compression technology. Int. J. Refrig. 2022, 144, 145–162. [Google Scholar] [CrossRef]

- El-Masri, M.A. Thermodynamics and Performance Projections for Intercooled/Reheat/Recuperated Gas Turbine Systems. In Proceedings of the GT1987, Volume 2: Aircraft Engine; Marine; Microturbines and Small Turbomachinery, Anaheim, CA, USA, 31 May–4 June 1987. [Google Scholar] [CrossRef]

- El-Masri, M.A. A Modified, High-Efficiency, Recuperated Gas Turbine Cycle. J. Eng. Gas Turbines Power 1988, 110, 233–242. [Google Scholar] [CrossRef]

- Chiesa, P.; Lozza, G.; Macchi, E.; Consonni, S. An Assessment of the Thermodynamic Performance of Mixed Gas–Steam Cycles: Part B—Water-Injected and HAT Cycles. J. Eng. Gas Turbines Power 1995, 117, 499–508. [Google Scholar] [CrossRef]

- English, C.R.; McCarthy, S.J. Qualification Testing the WR21 Intercooled and Recuperated Gas Turbine. In Proceedings of the GT2001, Volume 1: Aircraft Engine; Marine; Turbomachinery; Microturbines and Small Turbomachinery, New Orleans, LA, USA, 4–7 June 2001. [Google Scholar] [CrossRef]

- Little, G.T.; Erskine, P.A.; Norton, P. Demonstrating the Electric Ship. Nav. Eng. J. 2003, 115, 91–105. [Google Scholar] [CrossRef]

- Nakhamkin, M.; Swensen, E.C.; Scheibel, J.R.; Cohn, A. CHAT Technology: An Alternative Approach to Achieve Advanced Turbine Systems Efficiencies With Present Combustion Turbine Technology. In Proceedings of the GT1998, Volume 3: Coal, Biomass and Alternative Fuels; Combustion and Fuels; Oil and Gas Applications; Cycle Innovations, Stockholm, Sweden, 2–5 June 1998. [Google Scholar] [CrossRef]

- Jonsson, M.; Bolland, O.; Bücker, D.; Rost, M. Gas turbine cooling model for evaluation of novel cycles. Proc. ECOS 2005, 2005, 641–650. [Google Scholar]

- Franco, F.; Anantharaman, R.; Bolland, O.; Booth, N.; van Dorst, E.; Ekstrom, C.; Sanchez Fernandez, E.; Macchi, E.; Manzolini, G.; Nikolic, D.; et al. European Best Practice Guidelines for CO2 Capture Technologies. 2011. Available online: https://www.ctc-n.org/sites/default/files/resources/d_4_9_best_practice_guide.pdf (accessed on 18 January 2024).

- El-Masri, M.A. On Thermodynamics of Gas-Turbine Cycles: Part 2—A Model for Expansion in Cooled Turbines. J. Eng. Gas Turbines Power 1986, 108, 151–159. [Google Scholar] [CrossRef]

- Unnikrishnan, U.; Yang, V. A review of cooling technologies for high temperature rotating components in gas turbine. Propuls. Power Res. 2022, 11, 293–310. [Google Scholar] [CrossRef]

- Vaferi, K.; Vajdi, M.; Nekahi, S.; Nekahi, S.; Sadegh Moghanlou, F.; Shahedi Asl, M.; Mohammadi, M. Thermo-mechanical simulation of ultrahigh temperature ceramic composites as alternative materials for gas turbine stator blades. Ceram. Int. 2021, 47, 567–580. [Google Scholar] [CrossRef]

- Martelli, E.; Girardi, M.; Chiesa, P. Breaking 70% Net Electric Combined Cycle Efficiency With CMC Gas Turbine Blades. In Proceedings of the GT2022, Volume 4: Cycle Innovations; Cycle Innovations: Energy Storage, Rotterdam, The Netherlands, 13–17 June 2022. [Google Scholar] [CrossRef]

- Arnaiz del Pozo, C.; Cloete, S.; Jiménez Álvaro, Á. Standard Economic Assessment (SEA) Tool. 2021. Available online: https://bit.ly/3IXPWC8 (accessed on 18 January 2024).

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A. Analysis, Synthesis and Design of Chemical Processes: Appendix A; Pearson Education: London, UK, 2008. [Google Scholar]

- GTW. Gas Turbine World Handbook; Pequot Publishing: Essex, CT, USA, 2020. [Google Scholar]

- DeSantis, D.; James, B.D.; Houchins, C.; Saur, G.; Lyubovsky, M. Cost of long-distance energy transmission by different carriers. iScience 2021, 24, 103495. [Google Scholar] [CrossRef] [PubMed]

- Walker, I.; Madden, B.; Tahir, F. Hydrogen Supply Chain Evidence Base; Elemental Energy: Vancouver, BC, Canada, 2018. [Google Scholar]

- Ahluwalia, R.K.; Papadias, D.D.; Peng, J.-K.; Roh, H.S. System Level Analysis of Hydrogen Storage Options; US Department of Energy: Washington, DC, USA, 2019.

- Abudu, K.; Igie, U.; Roumeliotis, I.; Szymanski, A.; Di Lorenzo, G. Aeroderivative gas turbine back-up capability with compressed air injection. Appl. Therm. Eng. 2020, 180, 115844. [Google Scholar] [CrossRef]

- Beck, A.; Sevault, A.; Drexler-Schmid, G.; Schöny, M.; Kauko, H. Optimal Selection of Thermal Energy Storage Technology for Fossil-Free Steam Production in the Processing Industry. Appl. Sci. 2021, 11, 1063. [Google Scholar] [CrossRef]

- Nazir, S.M.; Cloete, J.H.; Cloete, S.; Amini, S. Pathways to low-cost clean hydrogen production with gas switching reforming. Int. J. Hydrog. Energy 2020, 46, 20142–20158. [Google Scholar] [CrossRef]

- Cloete, S.; Khan, M.N.; Amini, S. Economic assessment of membrane-assisted autothermal reforming for cost effective hydrogen production with CO2 capture. Int. J. Hydrog. Energy 2019, 44, 3492–3510. [Google Scholar] [CrossRef]

- Pruvost, F.; Cloete, S.; Arnaiz del Pozo, C.; Zaabout, A. Maximizing the Techno-Economic Performance of Steam Methane Reforming for Near-Term Blue Hydrogen Production. Int. J. Hydrog. Energy 2021. preprint. Available online: https://bit.ly/3lViy4r (accessed on 18 January 2024). [CrossRef]

- Szima, S.; Arnaiz del Pozo, C.; Cloete, S.; Chiesa, P.; Jiménez Alvaro, Á.; Cormos, A.-M.; Amini, S. Finding synergy between renewables and coal: Flexible power and hydrogen production from advanced IGCC plants with integrated CO2 capture. Energy Convers. Manag. 2021, 231, 113866. [Google Scholar] [CrossRef]

| Specification | Value | Units |

|---|---|---|

| Turbine inlet temperature (TIT) | 1550 | °C |

| Pressure ratio | 23.6 | - |

| Filter pressure loss | 0.75 | % |

| Heat losses | 0.4 | %LHV |

| Combustor pressure drop | 3 | % |

| Turbine backpressure | 3.5 | kPa |

| Compressor leakage | 0.4 | % |

| Gas turbine auxiliaries | 2.2 | MW |

| Fuel temperature | 220 | °C |

| Air flow at compressor inlet | 956.1 | kg/s |

| Generator efficiency | 98.7 | % |

| Mechanical efficiency | 99.865 | % |

| Calibrated Parameter | Value | Units |

|---|---|---|

| Combustor outlet temperature (COT) | 1651 | °C |

| Turbine outlet temperature (TOT) | 638.3 | °C |

| Gas turbine open cycle net efficiency | 42.78 | % |

| Gas turbine net power | 513.8 | MW |

| Compressor polytropic efficiency | 92.86 | % |

| Expansion stage polytropic efficiency | 87.58 | % |

| Design Parameter | Value | Units |

|---|---|---|

| Recuperator temperature approach (IRWI) | 40 | °C |

| Economizer temperature approach (IRWI) | 15 | °C |

| Intercooler outlet temperature | 30 | °C |

| Maximum air preheat temperature | 800 | °C |

| NIHT HSRG pinch point | 10 | °C |

| Steam coolant temperature | 350 | °C |

| Backpressure steam turbine polytropic efficiency | 85 | % |

| Pump hydraulic efficiency | 80 | % |

| Fuel | Cavern Storage ($/kWh) | Pipeline Scale (GW) | Pipeline Cost (M$/km) |

|---|---|---|---|

| H2 | 2.1 | 8.36 | 1.29 |

| NG | 0.7 | 17.39 | 1.57 |

| Capital Estimation Methodology | ||

|---|---|---|

| Bare erected cost (BEC) | SEA tool or GT correlation | |

| Engineering, procurement, and construction (EPC) | 10% BEC | |

| Project contingency (PT) | 20% (BEC+EPC) | |

| Owner’s costs (OC) | 15% (BEC+EPC+PT) | |

| Total overnight costs (TOC) | BEC+EPC+PT+OC | |

| Operating and maintenance costs | ||

| Fixed | ||

| Maintenance | 2.6 | %TOC |

| Insurance | 1 | %TOC |

| Variable | ||

| NG fuel | 6.5 | €/GJLHV |

| H2 fuel | 13 | €/GJLHV |

| CO2 tax | 150 | €/ton |

| Process water | 6 | €/ton |

| Cooling water | 0.35 | €/ton |

| Cash flow analysis assumptions | ||

| Discount rate | 8 | % |

| Construction period | 2 | Years |

| Plant Lifetime | 25 | Years |

| NGCC | NGOC | MEA-NGCC | H2CC | NIHT | NIHT+ | IRWI-NG | IRWI-H2 | ||

|---|---|---|---|---|---|---|---|---|---|

| Heat input | 1201.0 | 1201.0 | 1201.0 | 1180.5 | 832.5 | 850.2 | 1504.1 | 1546.1 | MW |

| Compression | 441.0 | 441.0 | 441.0 | 433.4 | 179.4 | 182.5 | 443.0 | 454.3 | MW |

| Expansion | 963.5 | 963.5 | 963.5 | 968.1 | 707.1 | 722.9 | 1336.4 | 1392.7 | MW |

| Gas turbine net | 513.8 | 513.8 | 513.8 | 523.3 | 519.7 | 532.2 | 879.4 | 922.0 | MW |

| Steam turbine | 241.8 | 179.6 | 232.8 | 0.0 | 24.8 | 0.0 | 0.0 | MW | |

| Auxiliaries | −10.0 | −41.4 | −10.3 | −2.8 | −3.3 | −3.0 | −3.1 | MW | |

| Net power | 745.6 | 513.8 | 652.0 | 745.8 | 516.9 | 553.7 | 876.4 | 918.9 | MW |

| LHV efficiency | 62.1 | 42.8 | 54.3 | 63.2 | 62.1 | 65.1 | 58.3 | 59.4 | % |

| NGCC | MEA-NGCC | H2CC | NIHT | NIHT+ | IRWI-NG | IRWI-H2 | ||

|---|---|---|---|---|---|---|---|---|

| Air flow | 956.1 | 956.1 | 963.5 | 365 | 365 | 956.1 | 956.1 | kg/s |

| Specific power | 537.4 | 537.4 | 561.6 | 1458.1 | 1561.9 | 919.8 | 965.2 | kJ/kg |

| Pressure ratio | 23.6 | 23.6 | 23.6 | 45 | 45 | 45 | 45 | - |

| Shafts | 1 | 1 | 1 | 2 | 2 | 2 | 2 | - |

| Intercooled compression | no | no | no | yes | yes | yes | yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arnaiz del Pozo, C.; Cloete, S.; Chiesa, P.; Jiménez Álvaro, Á. Novel Recuperated Power Cycles for Cost-Effective Integration of Variable Renewable Energy. Energies 2024, 17, 4826. https://doi.org/10.3390/en17194826

Arnaiz del Pozo C, Cloete S, Chiesa P, Jiménez Álvaro Á. Novel Recuperated Power Cycles for Cost-Effective Integration of Variable Renewable Energy. Energies. 2024; 17(19):4826. https://doi.org/10.3390/en17194826

Chicago/Turabian StyleArnaiz del Pozo, Carlos, Schalk Cloete, Paolo Chiesa, and Ángel Jiménez Álvaro. 2024. "Novel Recuperated Power Cycles for Cost-Effective Integration of Variable Renewable Energy" Energies 17, no. 19: 4826. https://doi.org/10.3390/en17194826

APA StyleArnaiz del Pozo, C., Cloete, S., Chiesa, P., & Jiménez Álvaro, Á. (2024). Novel Recuperated Power Cycles for Cost-Effective Integration of Variable Renewable Energy. Energies, 17(19), 4826. https://doi.org/10.3390/en17194826