Assessment of the Profitability of a Photovoltaic Installation Cooperating with Energy Storage Using an Example of a Medium-Sized Production Company

Abstract

1. Introduction

2. Background

2.1. PV Photovoltaic Installations

2.2. Energy Storage

- Depth of Discharge (DoD)—describes how deeply the battery is discharged. A DoD value of 0% means fully charged and a DoD of 100% means fully discharged battery.

- State of Charge (SOC)—is a parameter determining how charged the battery is; it is a parameter opposite to DoD, so SOC 100% means a fully charged battery.

- Number of charging cycles—determines the battery life. As cycles increase, battery capacity decreases. Each charge and discharge results in the degradation of the cell. The deeper it discharges, the faster its service life decreases.

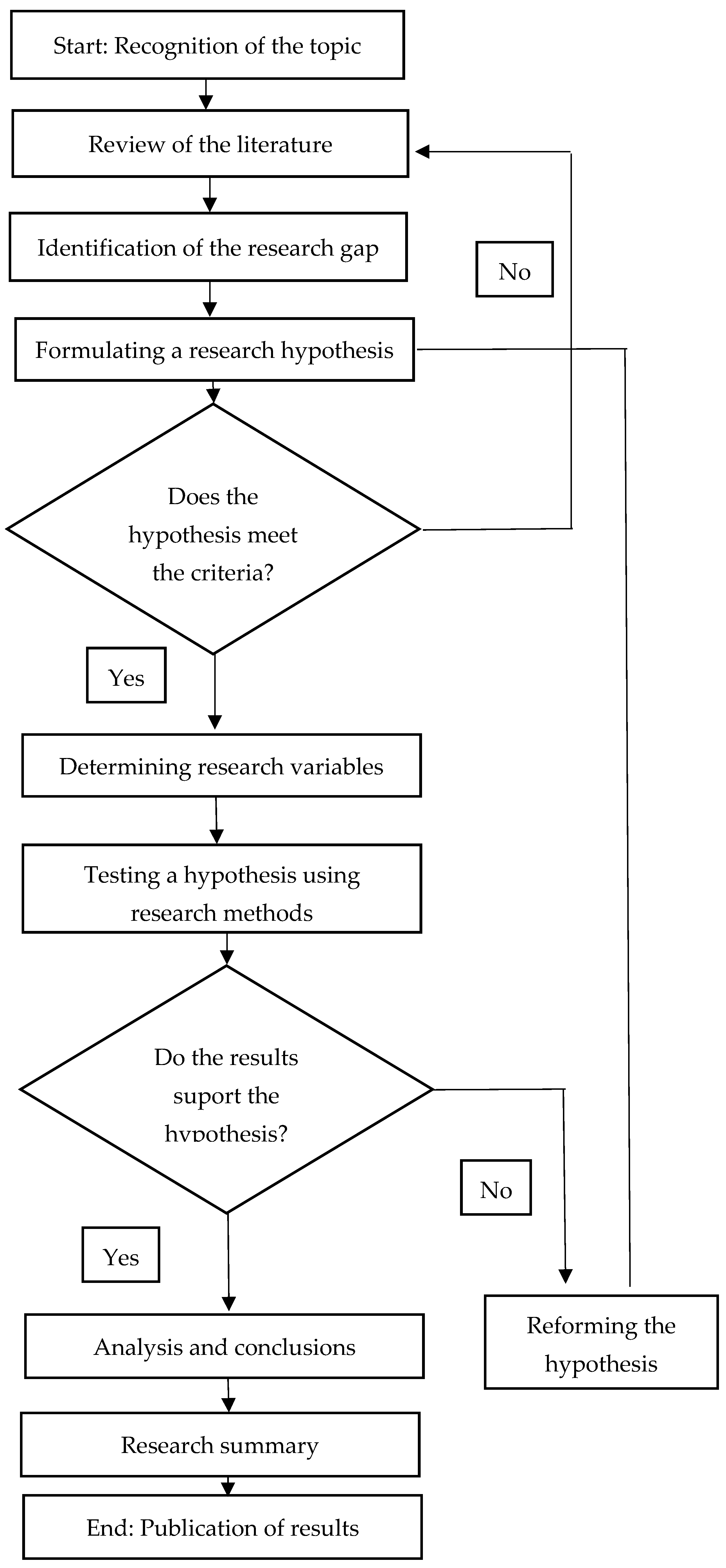

3. Materials and Methods

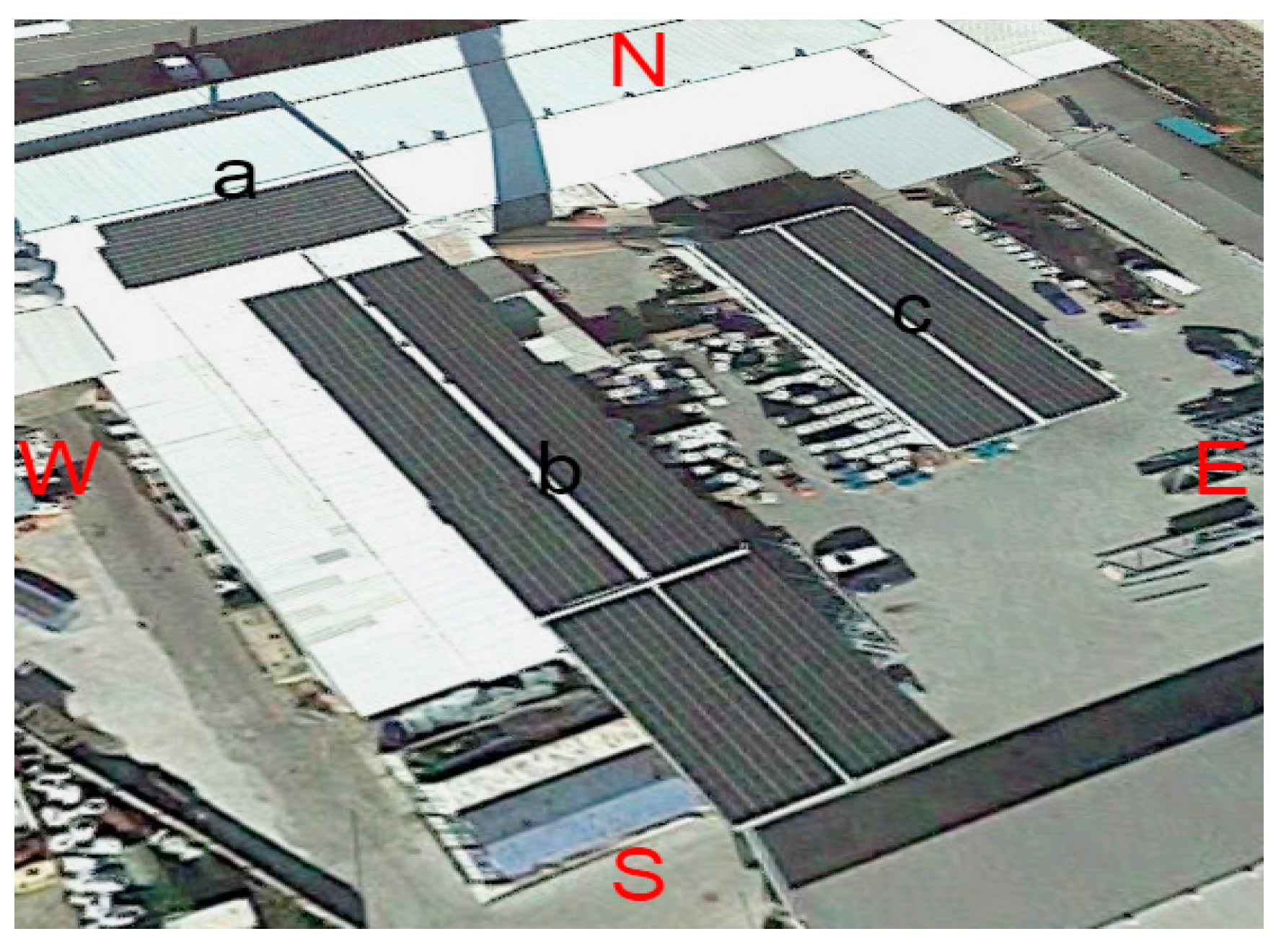

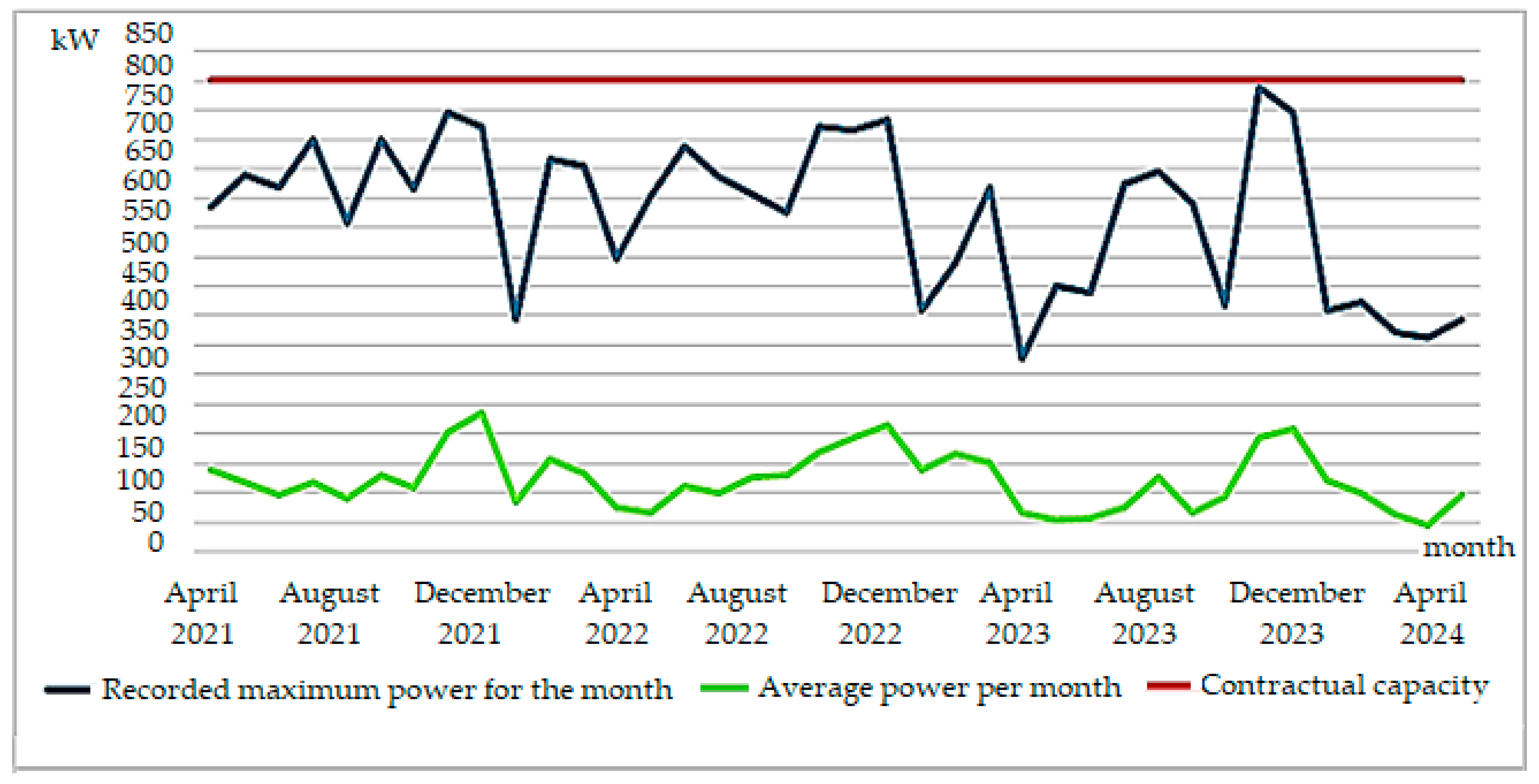

3.1. Characteristics of the Examined Enterprise

3.2. Technical Parameters of the Energy Storage

- ➢

- Technical parameters of this device:

- Rated power: 500 kW with the possibility of expansion every 100 kW;

- Battery capacity: 1000 kWh, expandable every 150 kWh or 200 kWh;

- Efficiency: >94%;

- Input voltage: 3 × 400 VAC ± 10%;

- Input voltage frequency: 50 Hz ± 5%;

- Response time to load change: 200 μs;

- Battery technology: LFP;

- Battery management system: three-level BMS with active correction;

- Phase load symmetrization: yes.

- ➢

- Energy management module:

- Bidirectional converter power scalability every 100 kW, 250 kW, 500 kW;

- LCL anti-interference filter;

- Bidirectional converter;

- Short-circuit, overload, temperature, and overvoltage protection;

- Modbus RTU, TCP/IP communication enabling integration with superior SCADA systems.

- ➢

- Battery module parameters:

- Number of charging cycles: >4000 cycles;

- Single module capacity: 150 kWh;

- The operator panel on each cabinet allows viewing and configuration of basic parameters;

- Three-level BMS protection.

3.3. Economic Analysis of Return on Investment

4. Results and Discussion

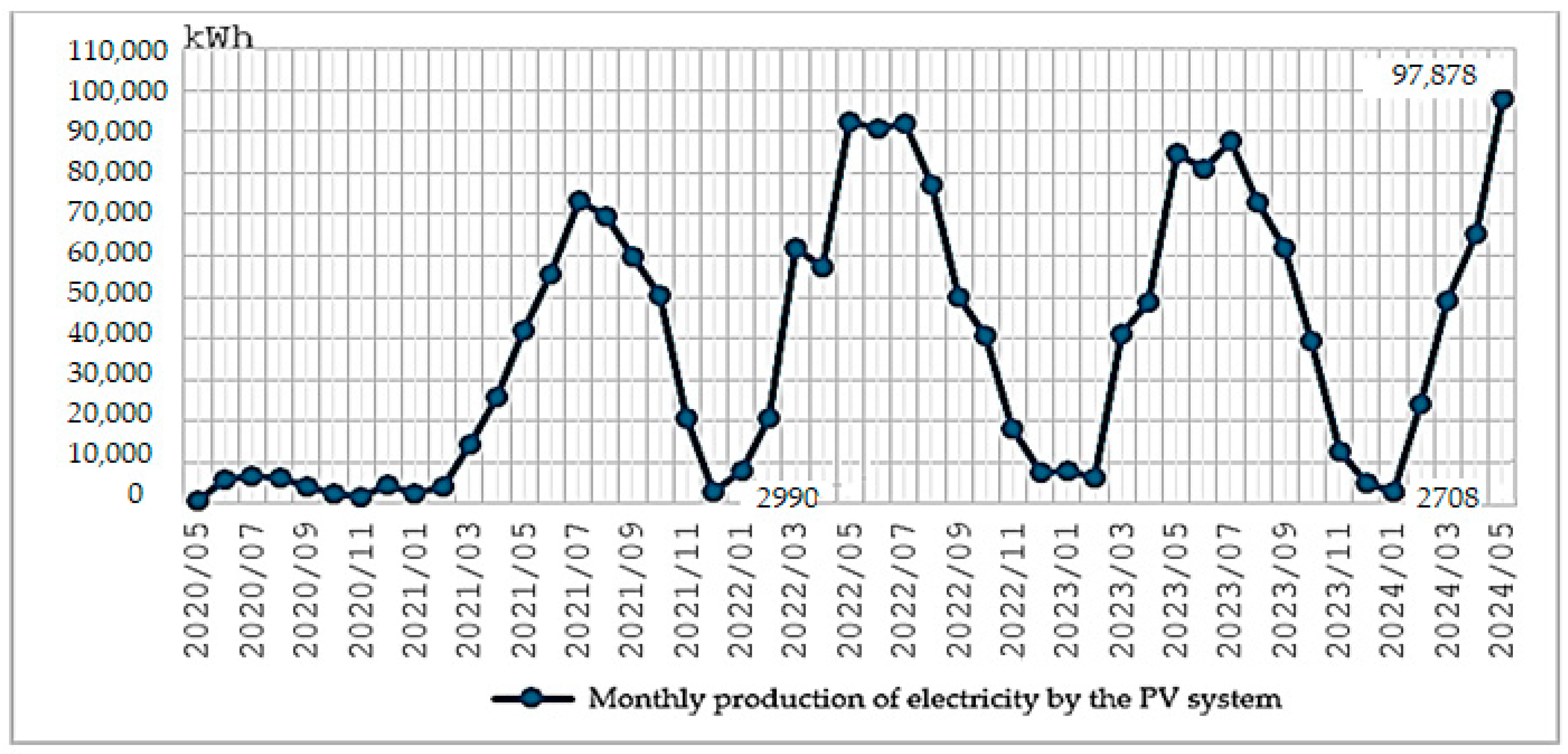

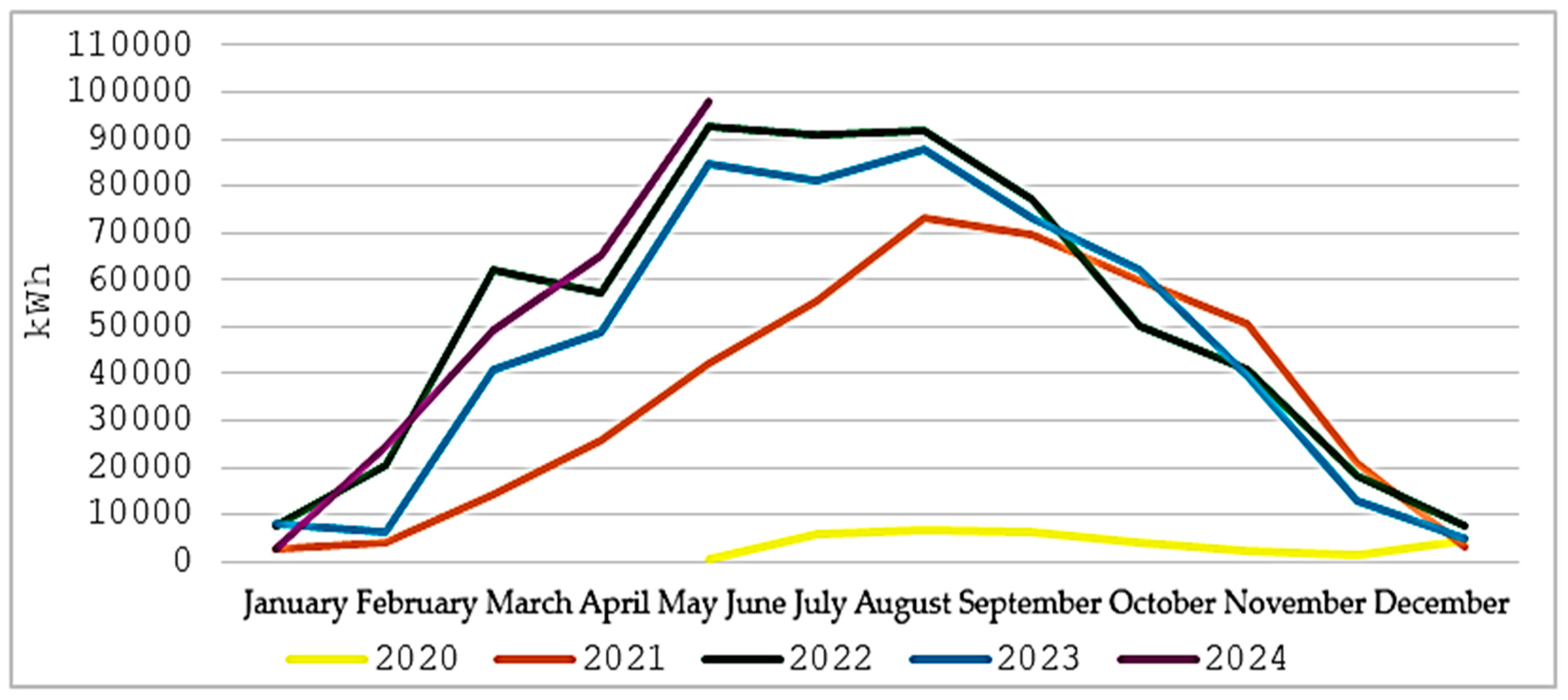

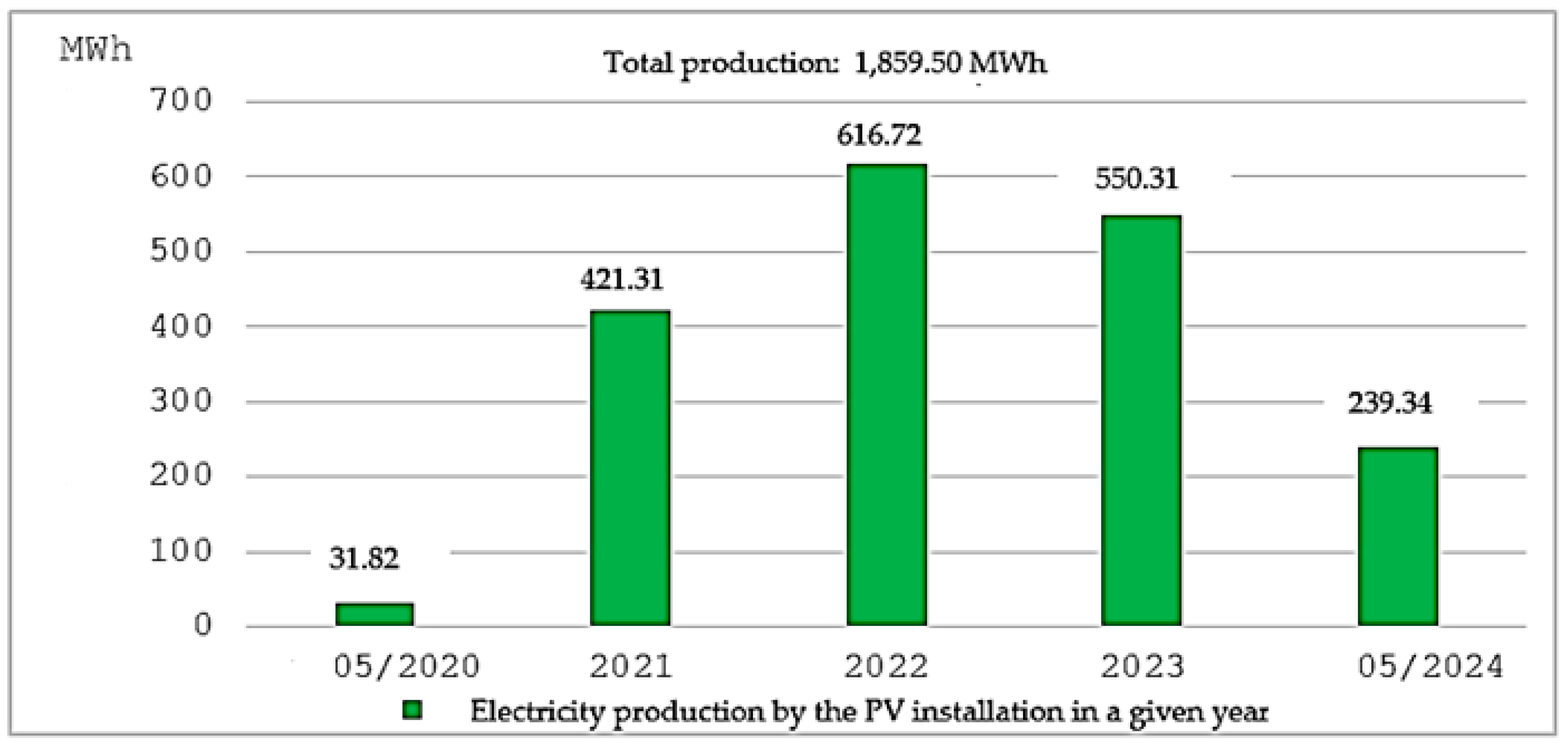

4.1. Total Electricity Production in the PV Installation

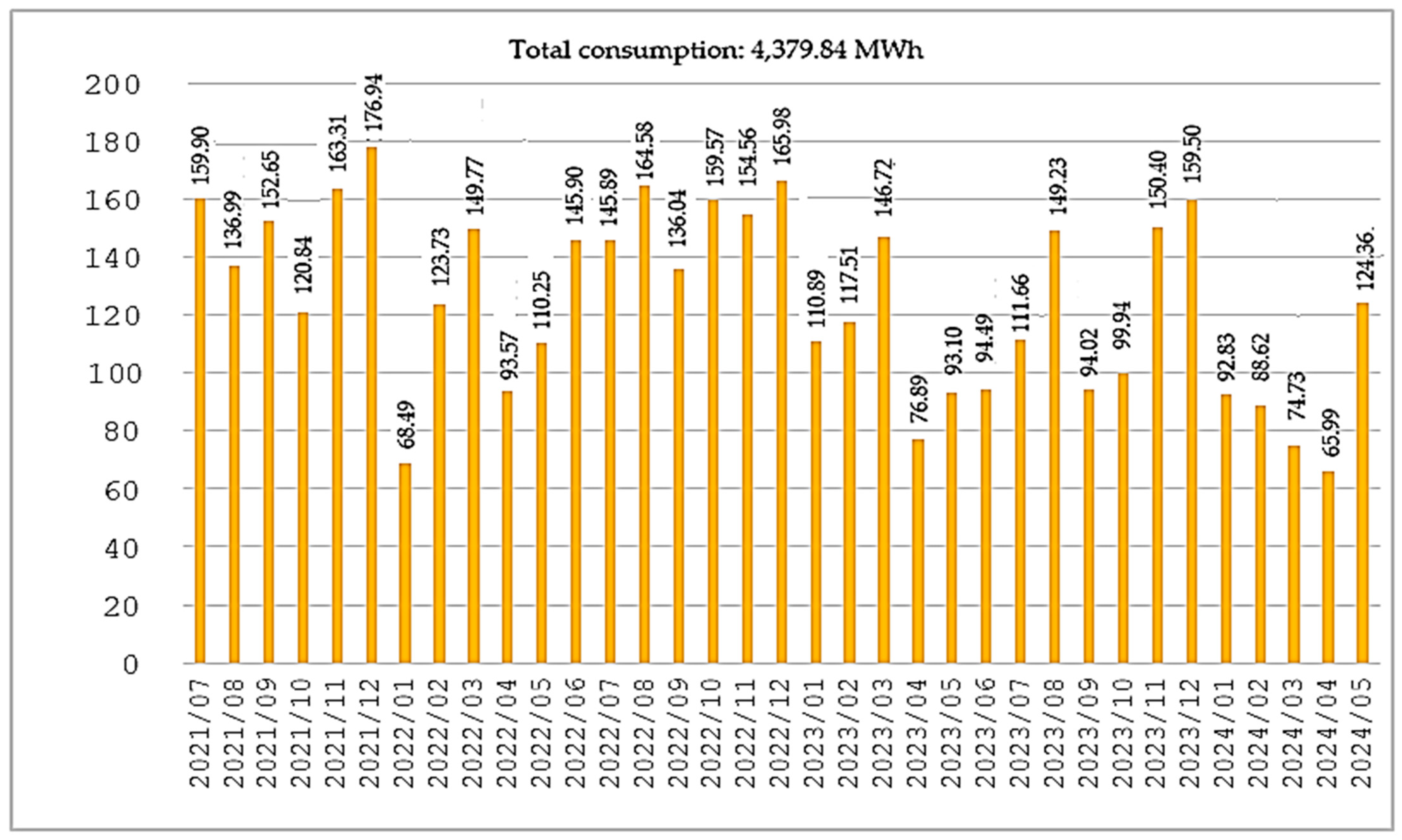

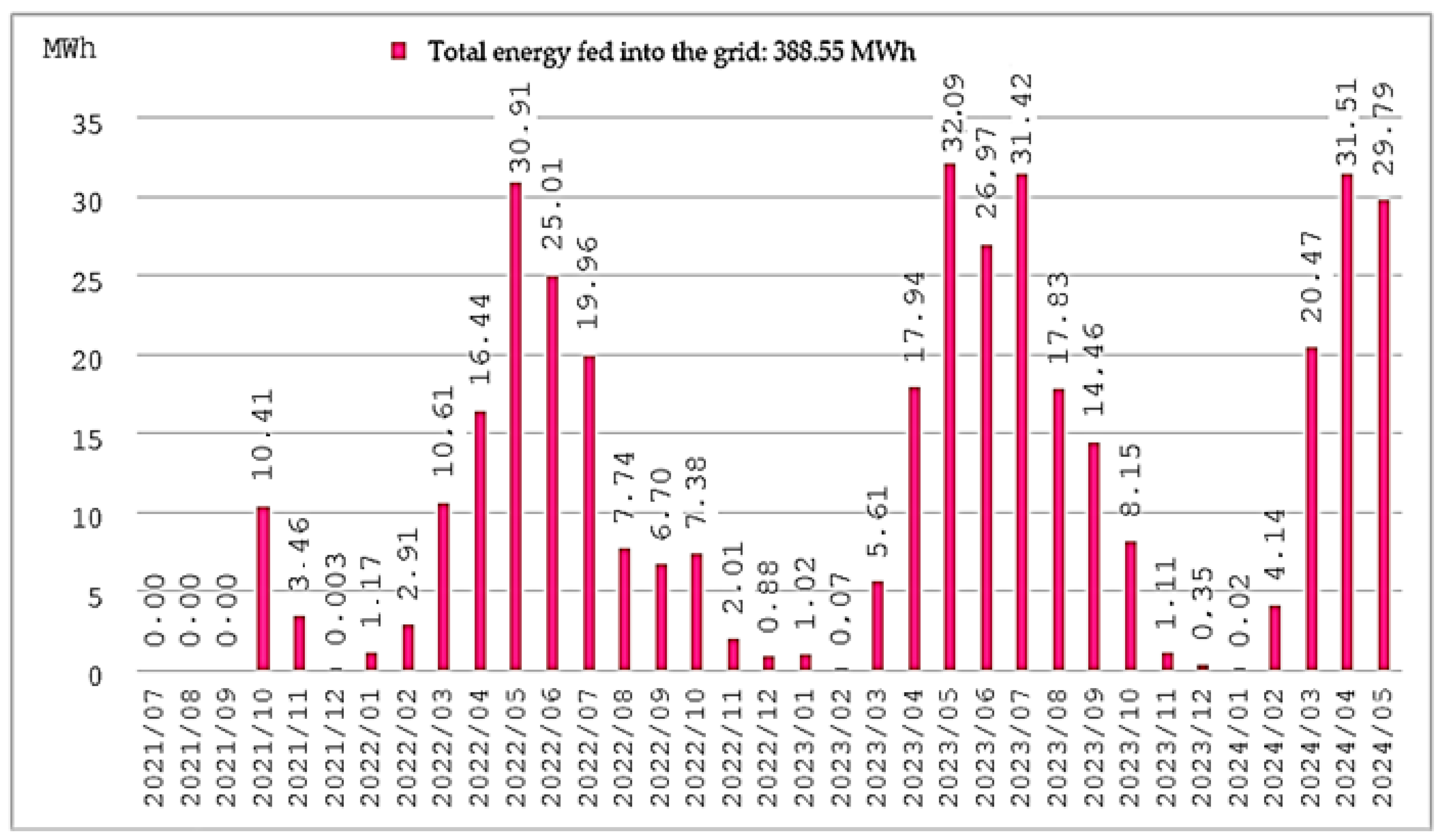

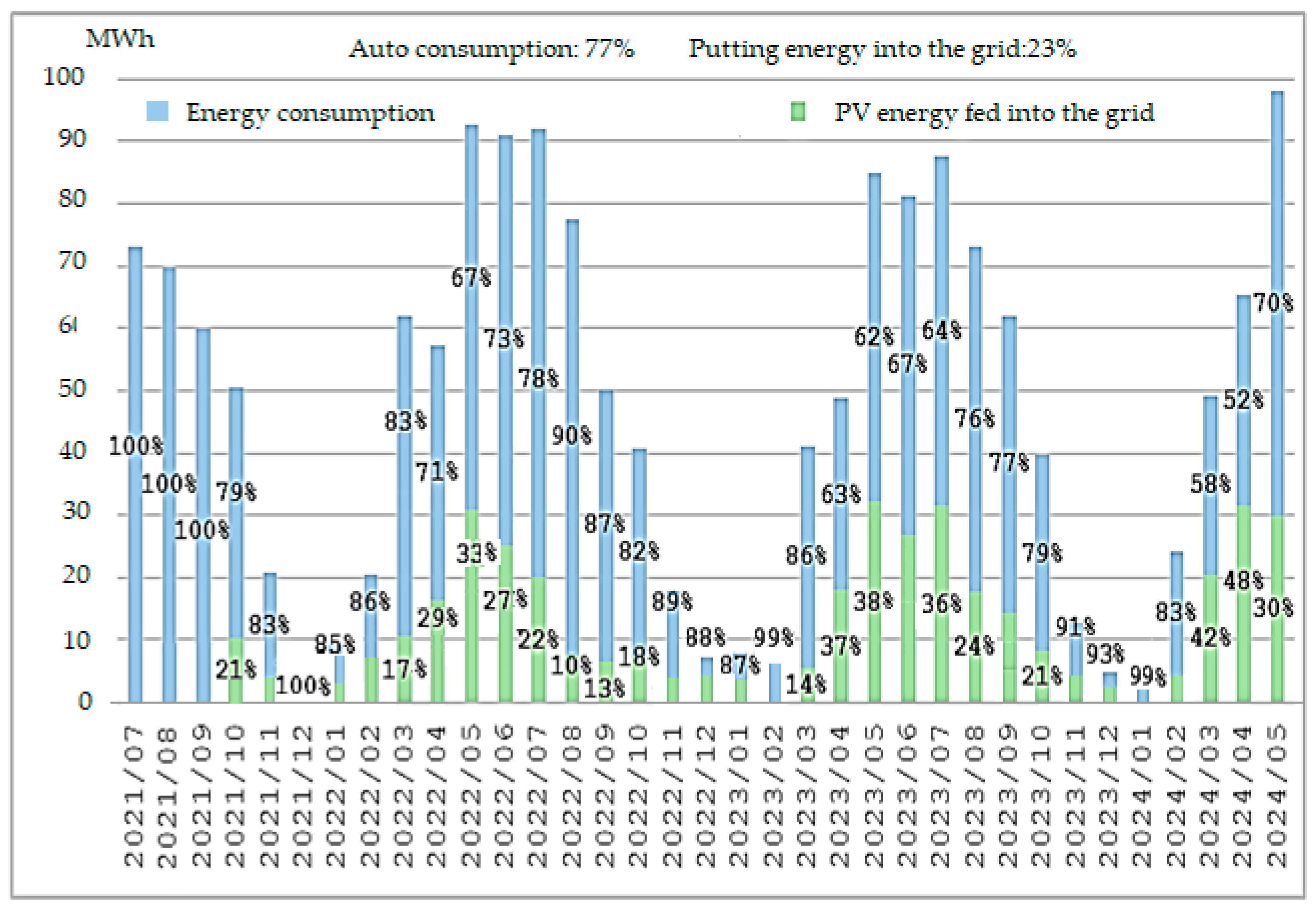

4.2. The Balance of Electricity Consumed, Transferred to the Grid, and Its Overall Production

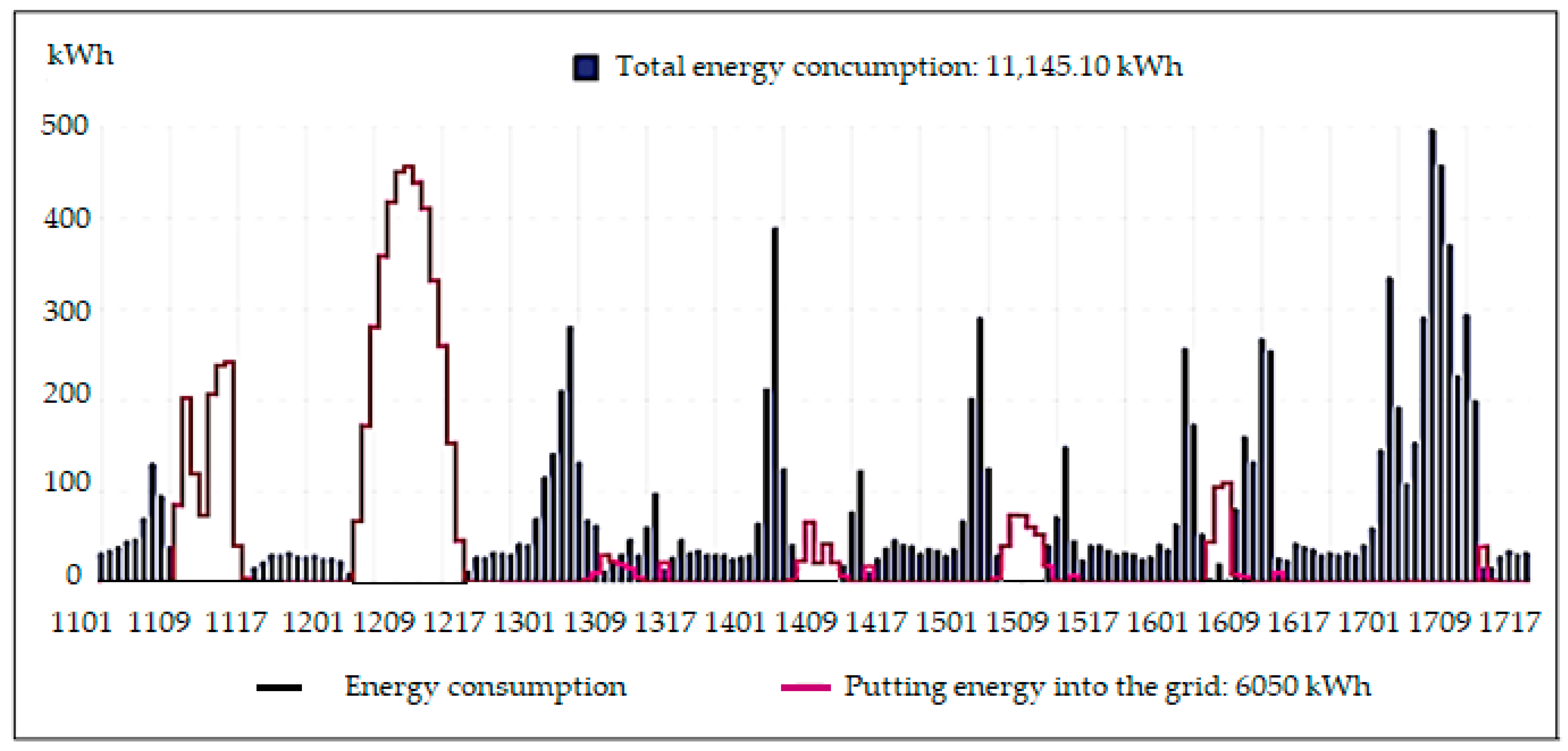

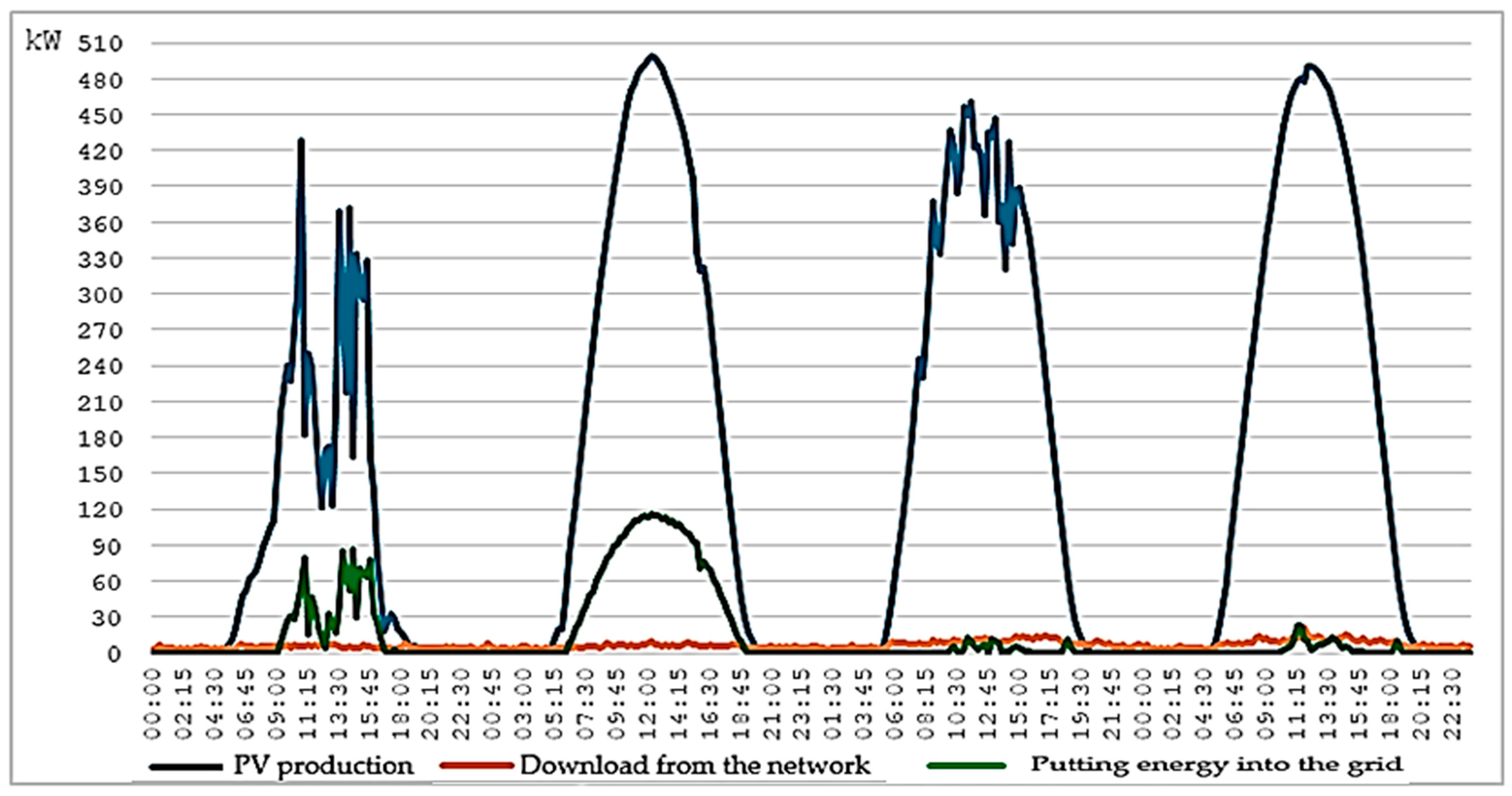

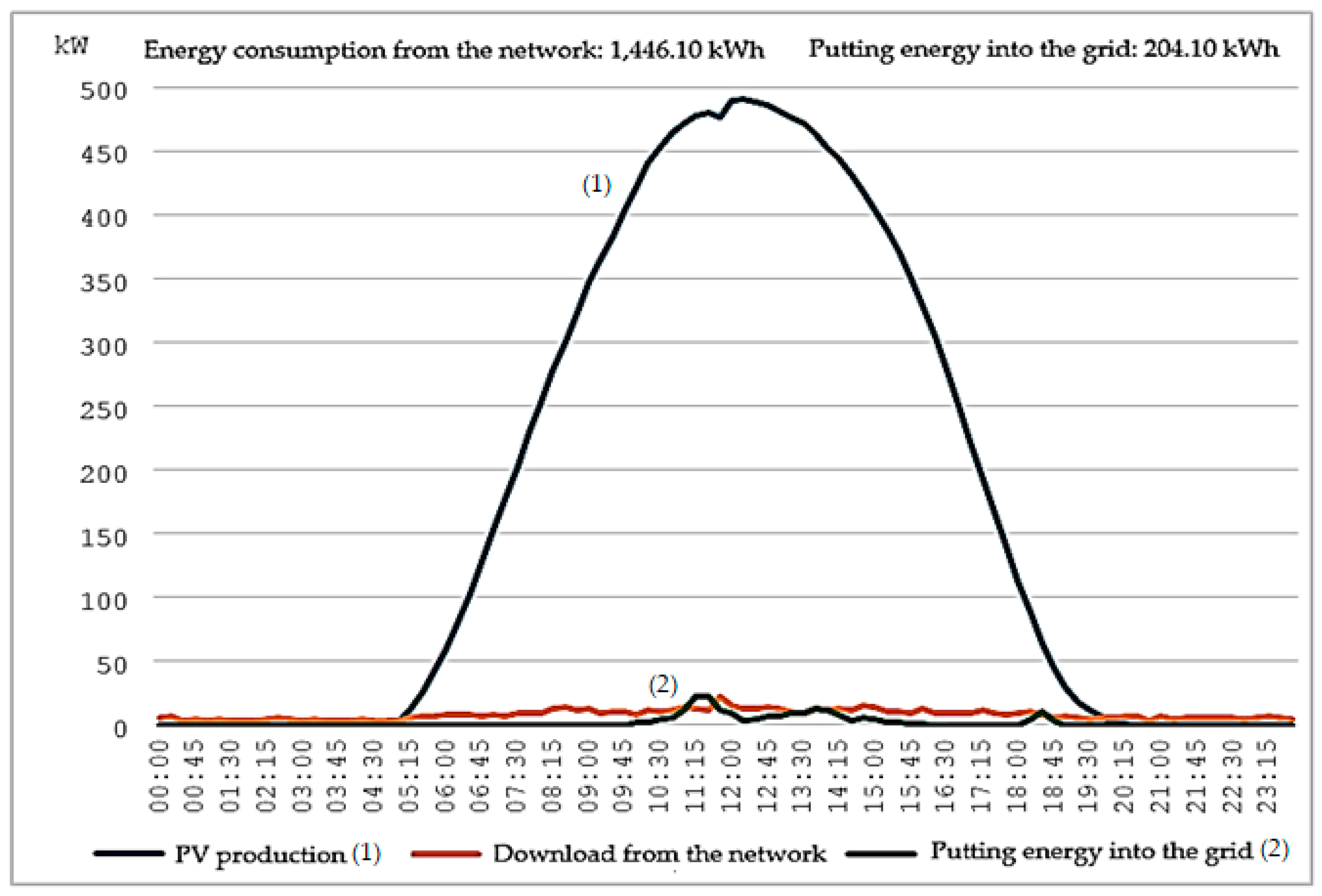

4.3. Electricity Storage for PV—Measurement and Analysis

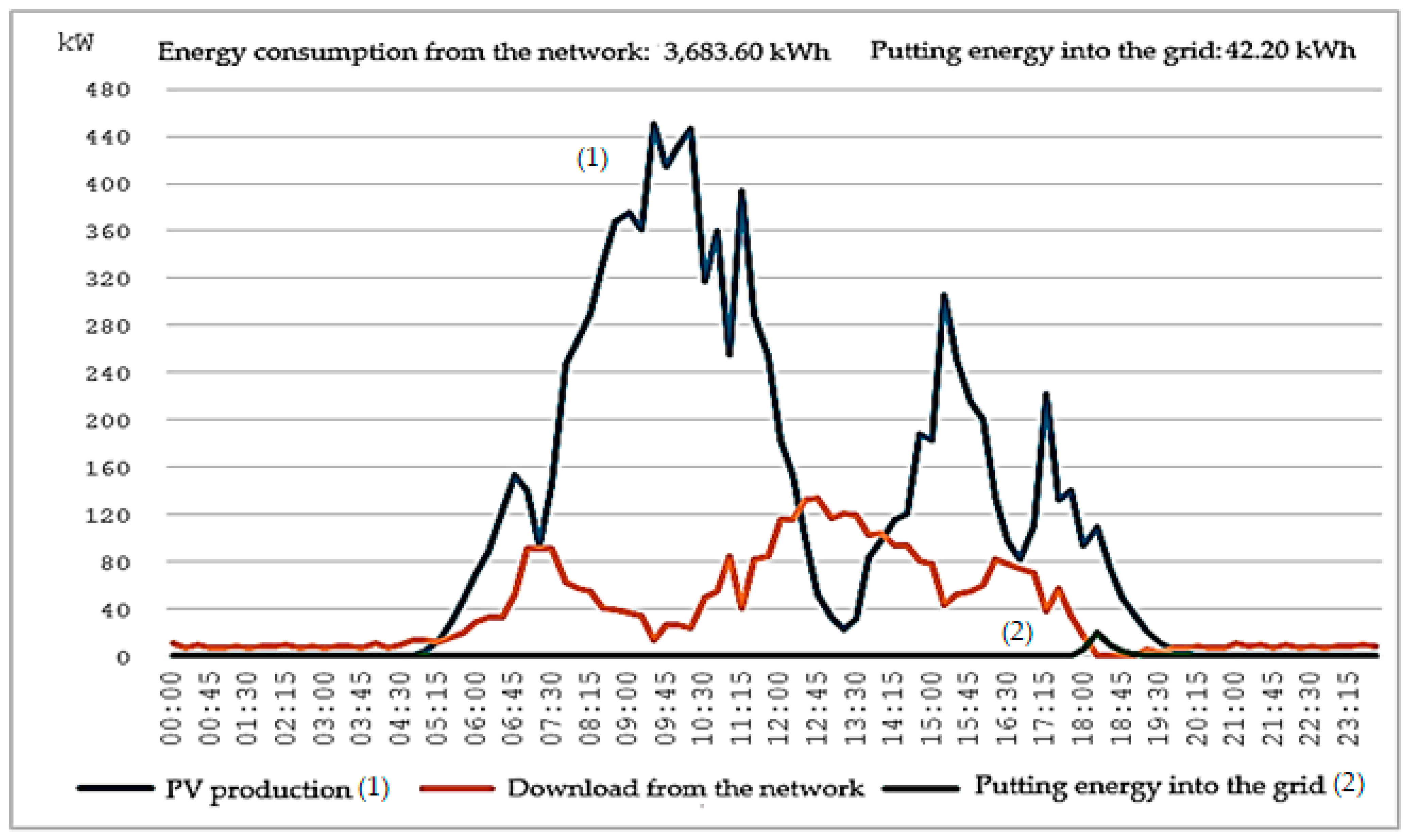

- -

- Higher consumption from the grid starts in the afternoon between 4 and 8 p.m.—the situation occurs when PV production drops in the afternoon and the energy demand is the same all day long until the machines are turned off.

- -

- During the night, the consumption from the network is small but constant—the PV installation does not work, and the energy needed to maintain the operation of the devices is taken entirely from the network.

- -

- The next increase in grid consumption is in the morning between 6 a.m. and 9 a.m.—in this situation, when the company’s production starts around 6 a.m., PV production does not yet produce enough energy, so it must be taken from the grid.

- -

- Between 9 a.m. and 4 p.m., consumption from the grid decreases to low values and feeding into the grid increases, PV production is high and meets most of the demand, and temporary, dynamic spikes result from the current PV production and demand. Sometimes, at a given moment, the installation has higher production than demand and the energy must be sent to the grid, but there are also temporary drops in PV production when the network makes up for the shortage.

- -

- An exceptional situation took place on Friday, 17 May, when the grid consumption during the day was high and the transfer practically did not occur—in the week in question, there was one day with less favorable weather conditions, which translated into low PV production and immediately the electricity consumption from the grid increased to the highest level throughout the week.

4.4. Economic Assessment of the Use of Energy Storage—Calculation

5. Conclusions

- -

- The base values of the calculation reports were the results generated by the PV installation and the energy balance enterprises throughout 2023. Calculations have shown that supplementing the described PV installation with an energy storage facility will increase the current level of auto-consumption of PV energy by over 14%.

- -

- The increase in self-consumption of electricity produced by PV means a decrease in the amount of electricity purchased from the grid and a reduction in the amount of energy sold, the sale of which is less profitable, which translates into overall savings for the company.

- -

- The benefits translate into the final effect of the energy storage operation, which brings additional annual savings for the company of approximately EUR 23,000 for a weaker device and approximately EUR 40,000 for a more powerful energy storage. Such values, interpreted only in the context of the efficiency and effectiveness of the photovoltaic energy storage for the company, provide grounds for stating that the use of such a device is justified and can significantly improve the efficiency of the entire photovoltaic system.

- -

- On the other hand, if the investment profitability factor is taken into account, which in the case of an enterprise is as important as the previous one, the final decision indicating the validity of investing in an electricity storage facility for a PV system is not obvious.

- -

- With the assumptions defined in this way, for which calculations were made, among others: (device parameters, current electricity prices, amount of distribution fees, and energy storage costs) it can be concluded that despite the relatively high savings generated annually by the electricity storage for the company, this investment is unprofitable. The basis for such a statement is carried out financial calculations, taking into account the necessary financial outlays and the potential profits generated by the device on an annual basis, which showed that the payback period for such an investment is 9 years.

- -

- Taking into account the specificity of battery devices, which lose their efficiency over time, and also remembering that the manufacturer’s warranty for the devices is only two years, it can be concluded that such a payback period is unfavorable and therefore the investment is not justified in practice. This final decision is influenced primarily by the high price of the electricity storage itself and the currently unpredictable factor of reliability of battery devices over a long period of operation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Derski, B. Power Industry in Poland in 2019—Power and Energy Production According to Data PSE. 2019. Available online: https://wysokienapiecie.pl/27524-energetyka-w-polsce-w-2019-roku-moc-produkcja-energii-wg-danych-pse/ (accessed on 31 January 2023).

- Fic, K. The Use of a Photovoltaic Installation in the Company. Master’s Thesis, AGH University of Krakow, Kraków, Poland, 2023. [Google Scholar]

- Worku, M.Y.; Hassan, M.A.; Abido, M.A. Real-Time Energy Management and Control of Renewable Energy based Microgrid in Grid Connected and Island Modes. Energies 2019, 12, 276. [Google Scholar] [CrossRef]

- Benalcazar, P.; Suski, A.; Kamiński, J. The Effects of Capital and Energy Subsidies on the Optimal Design of Microgrid Systems. Energies 2020, 13, 955. [Google Scholar] [CrossRef]

- Marszałek, K.; Dyndał, K.; Lewińska, G. Fotowoltaika; Akademia Górniczo-Hutnicza im. St. Staszica w Krakowie: Krakow, Poland, 2021. [Google Scholar]

- Szymański, B. Instalacje Fotowoltaiczne; Globenergia: Kraków, Poland, 2018. [Google Scholar]

- Gancarczyk, P.; Kielin, J.; Kołodziejczyk, T.; Piasecki, M.; Zboina, J. Selected Usage and Safety Issues in Photovoltaic Installations (Wybrane Zagadnienia Użytkowe i Bezpieczeństwa w Instalacjach Fotowoltaicznych); CNBOP-PIB: Józefów, Poland, 2021. [Google Scholar]

- Al Shaqsi, A.Z.; Sopian, K.; Al-Hinai, A. Review of energy storage services, applications, limitations, and benefits. Energy Rep. 2020, 6, 288–306. [Google Scholar] [CrossRef]

- Mikulik, J.; Niekurzak, M. Impact of a Photovoltaic Installation on Economic Efficiency on the Example of a Company with High Energy Consumption; Zeszyty Naukowe, Organizacja i Zarządzanie Seria Nr 169; Politechnika Śląska: Gliwice, Poland, 2023. [Google Scholar]

- Krawczak, E. Trends in Silicon Solar Cell Technologies (Trendy w Technologiach Krzemowych Ogniw Słonecznych). Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2020. Interdisciplinarity in Scientific Research. [Google Scholar]

- Flizikowski, J.; Mroziński, A. Photovoltaic Installation Engineering; A Publication Co-Financed from National and Norwegian Funds; Grafpol Agnieszka Blicharz-Kurpińska: Bydgoszcz, Poland, 2016. [Google Scholar]

- Kebede, A.A.; Kalogiannis, T.; Van Mierlo, J.; Berecibar, M. A comprehensive review of stationary energy storage devices for large-scale renewable energy sources grid integration. Renew. Sustain. Energy Rev. 2022, 159, 112213. [Google Scholar] [CrossRef]

- Niekurzak, M.; Lewicki, W.; Drożdż, W.; Miązek, P. Measures for assessing the effectiveness of investments for electricity and heat generation from the hybrid cooperation of a photovoltaic installation with a heat pump on the example of a household. Energies 2022, 16, 6089. [Google Scholar] [CrossRef]

- Höfer, T.; Madlener, R. A participatory stakeholder process for evaluating sustainable energy transition scenarios. Energy Policy 2020, 139, 111277. [Google Scholar] [CrossRef]

- Tan, K.M.; Babu, T.S.; Ramachandaramurthy, V.K.; Kasinathan, P.; Solanki, S.G.; Raveendran, S.K. Empowering smart grid: A comprehensive review of energy storage technology and application with renewable energy integration. J. Energy Storage 2021, 39, 102591. [Google Scholar] [CrossRef]

- Niekurzak, M. The Potential of Using Renewable Energy Sources in Poland Taking into Account the Economic and Ecological Conditions. Energies 2021, 14, 7525. [Google Scholar] [CrossRef]

- Hayibo, K.S.; Pearce, J.M. A review of the value of solar methodology with a case study of the US VOS. Renew. Sustain. Energy Rev. 2021, 137, 110599. [Google Scholar] [CrossRef]

- Georgious, R.; Refaat, R.; Garcia, J.; Daoud, A.A. Review on Energy Storage Systems in Microgrids. Electronics 2021, 10, 2134. [Google Scholar] [CrossRef]

- Chakraborty, P.; Baeyens, E.; Khargonekar, P.P.; Poolla, K.; Varaiya, P. Analysis of solar energy aggregation under various billing mechanisms. IEEE Trans. Smart Grid 2019, 10, 4175–4187. [Google Scholar] [CrossRef]

- Rouzbahani, H.M.; Karimipour, H.; Lei, L. A review on virtual power plant for energy management. Sustain. Energy Technol. Assess. 2021, 47, 101370. [Google Scholar] [CrossRef]

- Hossain, E.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N.; Nawar, N. A Comprehensive Review of Energy Storage Systems: Types, Comparison, Current Scenario, Applications, Barriers, and Potential Solutions, Policies, and Future Prospects. Energies 2020, 13, 3651. [Google Scholar] [CrossRef]

- Zimm, C.; Goldemberg, J.; Nakicenovic, N.; Busch, S. Is the renewables transformation a piece of cake or a pie in the sky? Energy Strategy Rev. 2019, 26, 100401. [Google Scholar] [CrossRef]

- Burgio, A.; Menniti, D.; Sorrentino, N.; Pinnarelli, A.; Leonowicz, Z. Influence and impact of data averaging and temporal resolution on the assessment of energetic, economic and technical issues of hybrid photovoltaic-battery systems. Energies 2020, 13, 354. [Google Scholar] [CrossRef]

- Niekurzak, M. Development Directions of Low and Zero Emission Sources in the Transformation of the Energy Sector in Poland Based on the Scenario Method Based on Intuitive Logic; Energetyka/Centralny Zarząd Energetyki, Stowarzyszenie Elektryków Polskich: Warszawa, Poland, 2022; Volume 4, pp. 181–192. ISSN 0013-7294. [Google Scholar]

- Shahzad, U.; Radulescu, M.; Rahim, S.; Isik, C.; Yousaf, Z.; Ionescu, S. Do Environment-Related Policy Instruments and Technologies Facilitate Renewable Energy Generation? Exploring the Contextual Evidence from Developed Economies. Energies 2021, 14, 690. [Google Scholar] [CrossRef]

- Rangel-Martinez, D.; Nigam, K.; Ricardez-Sandoval, L.A. Machine learning on sustainable energy: A review and outlook on renewable energy systems, catalysis, smart grid and energy storage. Chem. Eng. Res. Des. 2021, 174, 414–441. [Google Scholar] [CrossRef]

- Rahman, M.; Oni, A.O.; Gemechu, E.; Kumar, A. Assessment of energy storage technologies: A review. Energy Convers. Manag. 2020, 223, 113295. [Google Scholar] [CrossRef]

- Aneke, M.; Wang, M. Energy storage technologies and real-life applications—A state of the art review. Appl. Energy 2016, 179, 350–377. [Google Scholar] [CrossRef]

- Salkuti, S.R.; Jung, C.M. Comparative analysis of storage techniques for a grid with renewable energy sources. Int. J. Eng. Technol. 2018, 7, 970–976. [Google Scholar] [CrossRef]

- Arsad, A.Z.; Hannan, M.; Al-Shetwi, A.Q.; Mansur, M.; Muttaqi, K.; Dong, Z.; Blaabjerg, F. Hydrogen energy storage integrated hybrid renewable energy systems: A review analysis for future research directions. Int. J. Hydrogen Energy 2022, 47, 17285–17312. [Google Scholar] [CrossRef]

- SolarPower Europe. Leading the Energy Transition. Available online: https://www.thesmartere.com/publications/emo2024 (accessed on 14 January 2023).

- Dogan, E.; Ulucak, R.; Kocak, E.; Isik, C. The Use of Ecological Footprint in Estimating the Environmental Kuznets Curve Hypothesis for BRICST by Considering Cross-Section Dependence and Heterogeneity. Sci. Total Environ. 2020, 723, 138063. [Google Scholar] [CrossRef]

- Alvarado, R.; Tillaguango, B.; Dabar, V.; Ahmad, M.; Isik, C. Ecological footprint, economic complexity and natural resources rents in Latin America: Empirical evidence using quantile regressions. J. Clean. Prod. 2021, 318, 128585. [Google Scholar] [CrossRef]

- Isik, C.; Ahmad, M.; Ongan, S.; Ozdemir, D.; Ifran, M.; Alvarado, R. Convergence Analysis of the Ecological Footprint: Theory and Empirical Evidence from the USMCA Countries. Environ. Sci. Pollut. Res. 2021, 28, 32648–32659. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.; Isik, C.; Jabeen, G.; Ali, T.; Ozturk, I.; Atchike, D. Heterogeneous links among urban concentration, non-renewable energy use intensity, economic development, and environmental emissions across regional development levels. Sci. Total Environ. 2021, 765, 144527. [Google Scholar] [CrossRef] [PubMed]

- Hargreaves, J.J.; Jones, R.A. Long-Term Energy Storage in Highly Renewable Systems. Front. Energy Res. 2020, 8, 219. [Google Scholar] [CrossRef]

- Jafari, M.; Botterud, A.; Sakti, A. Decarbonizing power systems: A critical review of the role of energy storage. Renew. Sustain. Energy Rev. 2022, 158, 112077. [Google Scholar] [CrossRef]

- Kraan, O.; Chappin, E.; Kramer, G.J.; Nikolic, I. The influence of the energy transition on the significance of key energy metrics. Renew. Sustain. Energy Rev. 2019, 111, 215–223. [Google Scholar] [CrossRef]

- Niekurzak, M. The use of quantitative methods as measures for forecast electricity demand on the local market in a short time horizon. Przegląd Elektrotech. Stow. Elektr. Pol. 2023, 99, 86–93. [Google Scholar] [CrossRef]

- Bhuiyan, E.A.; Hossain, Z.; Muyeen, S.; Fahim, S.R.; Sarker, S.K.; Das, S.K. Towards next generation virtual power plant: Technology review and frameworks. Renew. Sustain. Energy Rev. 2021, 150, 111358. [Google Scholar] [CrossRef]

- Niekurzak, M.; Kubińska-Jabcoń, E. Analysis of the Return on Investment in Solar Collectors on the Example of a Household: The Case of Poland. Front. Energy Res. 2021, 9, 660140. [Google Scholar] [CrossRef]

- Koohi-Fayegh, S.; Rosen, M. A review of energy storage types, applications and recent developments. J. Energy Storage 2020, 27, 101047. [Google Scholar] [CrossRef]

- Kochanek, E. Regional cooperation on gas security in Central Europe. Energy Policy J. 2019, 22, 19–38. [Google Scholar] [CrossRef]

- Niekurzak, M.; Mikulik, J. Modelling of Energy Consumption and Reduction of Pollutant Emissions in a Walking Beam Furnace Using the Expert Method—Case Study. Energies 2021, 14, 8099. [Google Scholar] [CrossRef]

- Wróblewski, P.; Niekurzak, M. Assessment of the possibility of using various types of renewable energy sources installations in single-family buildings as part of saving final energy consumption in Polish conditions. Energies 2022, 15, 1329. [Google Scholar] [CrossRef]

- Versaci, M.; La Foresta, F. Fuzzy Approach for Managing Renewable Energy Flows for DC-Microgrid with Composite PV-WT Generators and Energy Storage System. Energies 2024, 17, 402. [Google Scholar] [CrossRef]

- Ali, A.; Aftab, A.; Akram, M.N.; Awan, S.; Muqeet, H.A.; Arfeen, Z.A. Residential Prosumer Energy Management System with Renewable Integration Considering Multi-Energy Storage and Demand Response. Sustainability 2024, 16, 2156. [Google Scholar] [CrossRef]

- Ahmad, N.I.; Ali, Z.; Ab. Kadir, M.Z.A.; Osman, M.; Zaini, N.H.; Roslan, M.H. Impacts of Lightning-Induced Overvoltage on a Hybrid Solar PV–Battery Energy Storage System. Appl. Sci. 2021, 11, 3633. [Google Scholar] [CrossRef]

- Lu, D.; Peng, Y.; Sun, J. Dual-Stage Optimization Scheduling Model for a Grid-Connected Renewable Energy System with Hybrid Energy Storage. Energies 2024, 17, 737. [Google Scholar] [CrossRef]

- Alqahtani, B.; Yang, J.; Paul, M.C. Reliability and dispatchability improvement of a hybrid system consisting of PV, wind, and bio-energy connected to pumped hydropower energy storage. Energy Convers. Manag. 2024, 304, 118212. [Google Scholar] [CrossRef]

- Al-Othman, A.; Tawalbeh, M.; Martis, R.; Dhou, S.; Orhan, M.; Qasim, M.; Olabi, A.G. Artificial intelligence and numerical models in hybrid renewable energy systems with fuel cells: Advances and prospects. Energy Convers. Manag. 2022, 253, 115154. [Google Scholar] [CrossRef]

- Javed, M.S.; Ma, T.; Jurasz, J.; Canales, F.A.; Lin, S.; Ahmed, S.; Zhang, Y. Economic analysis and optimization of a renewable energy-based power supply system with different energy storages for a remote island. Renew. Energy 2021, 164, 1376–1394. [Google Scholar] [CrossRef]

- Bistline, J.; Blanford, G.; Mai, T.; Merrick, J. Modelling variable renewable energy and storage in the power sector. Energy Policy 2021, 156, 112424. [Google Scholar] [CrossRef]

- De Rosa, M.; Afanaseva, O.; Fedyukhin, A.V.; Bianco, V. Prospects and characteristics of thermal and electrochemical energy storage systems. J. Energy Storage 2021, 44, 103443. [Google Scholar] [CrossRef]

- Niekurzak, M.; Lewicki, W.; Brelik, A. The challenges for social and economic policy related to the energy transformation—Analysis of profitability and minimizing the risk of deciding to invest in a home micro-installation. Eur. Res. Stud. J. 2022, 25, 144–159. [Google Scholar] [CrossRef]

| Year 2023 | Demand [kWh] | PV Production [kWh] | Auto-Consumption [kWh] | Level of Self-Consumption [%] | Energy Consumption [kWh] | (Surplus) Putting in Energy [kWh] | Energy Purchase Price [EUR/kWh] | Energy Sales Price [EUR/kWh] | Contractual Capacity | Energy Purchase [EUR] | Energy Sales [EUR] | Total Energy Cost [EUR] | Saving [EUR] | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [kW] | Fee [EUR] | |||||||||||||

| I | 110,889 | 8008 | 6984 | 87 | 103,905 | 1023 | 0.21 | 0.10 | 800 | 3210 | 21,181 | 100 | 24,390 | 1524 |

| II | 117,508 | 6269 | 6201 | 99 | 111,307 | 68 | 0.21 | 0.10 | 800 | 3210 | 22,691 | 6.8 | 25,901 | 1271 |

| III | 146,714 | 40,969 | 35,357 | 86 | 111,358 | 5612 | 0.20 | 0.10 | 800 | 3210 | 22,717 | 549.0 | 25,927 | 7761 |

| IV | 76,884 | 48,666 | 30,727 | 63 | 46,156 | 17,938 | 0.20 | 0.10 | 800 | 3210 | 9352 | 1753.0 | 12,562 | 7978 |

| V | 93,074 | 84,781 | 52,693 | 62 | 40,382 | 32,089 | 0.20 | 0.10 | 800 | 3210 | 8195 | 3135.0 | 11,404 | 13,827 |

| VI | 94,480 | 81,194 | 54,219 | 67 | 40,261 | 26,975 | 0.20 | 0.10 | 800 | 3210 | 8174 | 2635.0 | 11,384 | 13,643 |

| VII | 111,656 | 87,738 | 56,315 | 64 | 55,341 | 31,422 | 0.20 | 0.10 | 800 | 3210 | 11,247 | 3070.0 | 14,456 | 14,514 |

| VIII | 149,224 | 73,153 | 55,319 | 76 | 93,905 | 17,834 | 0.21 | 0.10 | 800 | 3210 | 19,166 | 1742.0 | 22,376 | 13,033 |

| IX | 94,010 | 62,085 | 47,621 | 77 | 46,389 | 14,464 | 0.21 | 0.10 | 800 | 3210 | 9408 | 1413.0 | 12,617 | 11,070 |

| X | 99,931 | 39,536 | 31,388 | 79 | 68,544 | 8148 | 0.21 | 0.10 | 800 | 3210 | 13,951 | 796.0 | 17,161 | 7185 |

| XI | 150,400 | 12,823 | 11,712 | 91 | 138,687 | 1110 | 0.21 | 0.10 | 800 | 3210 | 28,313 | 109.0 | 31,522 | 2500 |

| XII | 159,492 | 5090 | 7742 | 93 | 154,750 | 348 | 0.21 | 0.10 | 800 | 3210 | 31,598 | 34.0 | 34,807 | 1003 |

| SUM | 1,404,263 | 550,310 | 393,279 | - | 1,010,984 | 157,031 | - | - | - | 38,520 | 205,993 | 15,337.8 | 244,507 | 95,309 |

| Energy Storage | PV Installation | Network Connection | Financing |

|---|---|---|---|

| Power: 500 kW Capacity: 1000 kWh | Current PV power: 655 kWp Planned PV power: 0 kWp Sum: 655 kWp | Power ordered: 800 kW Planned reduction: 15% Rate: 4.10 [EUR/kW] | Own contribution: 100% |

| Year 2023 | Demand [kWh] | PV Production [kWh] | Auto-Consumption [kWh] | Level of Self-Consumption [%] | Energy Consumption [kWh] | (Surplus) Putting in Energy [kWh] | Energy Purchase Price [EUR/kWh] | Energy Sales Price [EUR/kWh] | Contractual Capacity | Energy Purchase [EUR] | Energy Sales [EUR] | Total Energy Cost [EUR] | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [kW] | Fee [EUR] | ||||||||||||

| I | 110,889 | 8008 | 8008 | 100 | 102,882 | 0 | 0.21 | 0.10 | 680 | 2728 | 20,972 | 0 | 23,700 |

| II | 117,508 | 6269 | 6269 | 100 | 111,239 | 0 | 0.21 | 0.10 | 680 | 2728 | 22,677 | 0 | 25,405 |

| III | 146,714 | 40,969 | 39,187 | 96 | 107,527 | 1782 | 0.20 | 0.10 | 680 | 2728 | 21,936 | 174 | 24,664 |

| IV | 76,884 | 48,666 | 43,727 | 90 | 33,156 | 4938 | 0.20 | 0.10 | 680 | 2728 | 6718 | 483 | 9446 |

| V | 93,074 | 84,781 | 66,693 | 79 | 26,382 | 18,089 | 0.20 | 0.10 | 680 | 2728 | 5354 | 1767 | 8082 |

| VI | 94,480 | 81,194 | 63,219 | 78 | 31,261 | 17,975 | 0.20 | 0.10 | 680 | 2728 | 6347 | 1756 | 9075 |

| VII | 111,656 | 87,738 | 67,915 | 77 | 43,741 | 19,822 | 0.20 | 0.10 | 680 | 2728 | 8890 | 1937 | 11,618 |

| VIII | 149,224 | 73,153 | 62.319 | 85 | 86,905 | 10,834 | 0.21 | 0.10 | 680 | 2728 | 17,737 | 1059 | 20,465 |

| IX | 94,010 | 62,085 | 58,621 | 94 | 35,389 | 3464 | 0.21 | 0.10 | 680 | 2728 | 7177 | 339 | 9905 |

| X | 99,931 | 39,536 | 37,388 | 95 | 62,544 | 2148 | 0.21 | 0.10 | 680 | 2728 | 12,730 | 210 | 15,458 |

| XI | 150,400 | 12,823 | 12,823 | 100 | 137,577 | 0 | 0.21 | 0.10 | 680 | 2728 | 20,086 | 0 | 30,814 |

| XII | 159,492 | 5090 | 5090 | 100 | 154,402 | 0 | 0.21 | 0.10 | 680 | 2728 | 31,527 | 0 | 34,255 |

| SUM | 1,404,263 | 550,310 | 471,259 | - | 933,003 | 79,051 | - | - | - | 32,736 | 182,151 | 7725 | 222,887 |

| PV installation Value of PV energy—direct self-consumption: EUR 80 Sale of PV Energy: EUR 8 | Level of PV self-consumption Without warehouse: 71.46% With stock: 85.64% |

| Energy storage Increase in self-consumption of PV energy: EUR 16 Strategy for reducing the ordered power: EUR 6 Energy optimization strategy: EUR 19 | Structure in zones Tariff: B23 S1 S2 RD network only: 38% 39% 23% network + PV: 24% 22% 54% network + PV + ME: 8% 3% 89% |

| Total effect of the energy storage: EUR 40 | |

| Total PV + Energy storage: EUR 128 |

| Year of Calculation | Start | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Expected Increase in Energy Costs | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | |

| Investment costs | |||||||||||

| Cost of PV installation | −364,047 | ||||||||||

| Cost of purchasing energy storage | −412,745 | ||||||||||

| Cost of installing an energy storage facility | −11,628 | ||||||||||

| Total capital expenditure | −788,419 | ||||||||||

| Own a share of the investment 100% | −788,419 | ||||||||||

| Service, annual inspections, and software updates 1.5% | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 |

| Total costs/expenses | 800,245 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 | −11,827 |

| Costs/expenses when ordering | −800,245 | ||||||||||

| Savings of PV installation | |||||||||||

| Savings on purchasing energy from the grid—auto-consumption of PV energy | 0 | 79,967 | 87,964 | 96,760 | 106,436 | 117,080 | 128,788 | 141,667 | 155,833 | 171,416 | 188,558 |

| Revenues from the sale of surplus PV energy | 7722 | 8494 | 9343 | 10,277 | 11,305 | 12,436 | 13,679 | 15,047 | 16,551 | 18,207 | |

| Energy storage savings | |||||||||||

| Increase in self-consumption of PV energy | 0 | 15,842 | 17,426 | 19,169 | 21,086 | 23,194 | 25,514 | 28,065 | 30,871 | 33,958 | 37,354 |

| Savings on reduction in contracted capacity | 0 | 5777 | 6355 | 6990 | 7689 | 8458 | 9304 | 10,234 | 11,258 | 12,384 | 13,622 |

| Savings on energy optimization | 0 | 18,264 | 20,090 | 22,099 | 24,309 | 26,740 | 29,414 | 32,355 | 35,591 | 39,150 | 43,065 |

| Annual financial benefits | 0 | 127,570 | 140,327 | 154,360 | 169,796 | 186,775 | 205,453 | 225,998 | 248,598 | 273,458 | 300,803 |

| Annual balance of PV + energy storage | 0 | 115,744 | 128,501 | 142,534 | 157,970 | 174,949 | 193,627 | 214,172 | 236,772 | 261,631 | 288,977 |

| Cumulative score | −800,245 | −684,502 | −556,001 | −413,701 | −255,499 | −80,550 | 113,077 | 327,248 | 563,090 | 825,650 | 1,114,626 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikulik, J.; Niekurzak, M. Assessment of the Profitability of a Photovoltaic Installation Cooperating with Energy Storage Using an Example of a Medium-Sized Production Company. Energies 2024, 17, 4740. https://doi.org/10.3390/en17184740

Mikulik J, Niekurzak M. Assessment of the Profitability of a Photovoltaic Installation Cooperating with Energy Storage Using an Example of a Medium-Sized Production Company. Energies. 2024; 17(18):4740. https://doi.org/10.3390/en17184740

Chicago/Turabian StyleMikulik, Jerzy, and Mariusz Niekurzak. 2024. "Assessment of the Profitability of a Photovoltaic Installation Cooperating with Energy Storage Using an Example of a Medium-Sized Production Company" Energies 17, no. 18: 4740. https://doi.org/10.3390/en17184740

APA StyleMikulik, J., & Niekurzak, M. (2024). Assessment of the Profitability of a Photovoltaic Installation Cooperating with Energy Storage Using an Example of a Medium-Sized Production Company. Energies, 17(18), 4740. https://doi.org/10.3390/en17184740