Abstract

This study investigates the effects of the co-combustion of coal and açai seed in circulating fluidized bed (CFB) boilers, highlighting the increase in thermal efficiency and relevance of a less-polluting source of energy. Using the computer software 1.5D CeSFaMB™® v4.3.0, simulations of the co-combustion process of coal and biomass were carried out in a CFB boiler, obtaining results such as the temperature profile, boiler efficiency and emissions. The work acquired data regarding the equipment in real operational conditions, consisting of the fundamental geometric and operational parameters used in the simulation campaign. The thermal and chemical properties of the fuels were analyzed by carrying out proximate, ultimate, heating value, particle size and specific mass analyses. The model validation was achieved by simulating the boiler in its real operating conditions and comparing the obtained results with the real data; the obtained error was below 10%. Simulations with different fractions of açai seed for energy replacement (10% and 30%) were carried out. As a result, an increase in the average temperature of the bed was observed, highlighting the region immediately above the dense bed. An increase in boiler efficiency was verified from 56% to 85% with 10% açai and to 83% with 30% açai seed. Decreases in SO2 and CO emissions with the insertion of açai were obtained, showing that co-combustion is more complete, while CO2 emissions were increased due to the higher quantity of fuel inserted into the equipment. The fossil CO2 emissions were reduced.

1. Introduction

The current global scenario seeks energy transition and decarbonization together with economic development and the increasing demand for electrical energy [1]. In Brazil, CONAMA regulation 382 establishes the maximum atmospheric pollutant emissions by fixed source, while in the European Union, the Industrial Emissions Directive (IED) regulates this sector. In such contexts, companies are forced to comply with regulations that aim to mitigate greenhouse gas (GHG) emissions through renewable and sustainable sources in the most efficient way possible, increasing the search for and identification of new sources.

Brazil is one of the leaders in renewable energy generation in its electrical matrix, where around 88% comes from hydroelectric, wind, solar and biomass power plants [2]. Despite biomass representing 8.8% of the matrix, much of the energy potential is not properly used, according to the Global Energy Network Institute (GENI). It is known that this country has a biomass energy potential of around 250 and 500 EJ. However, a conservative bioenergy potential of 11.69–13.93 PJ has also been reported, based on the typical productivity of 20 to 80 tons of agricultural crop per hectare [3]. It is in the abundant Amazonian biodiversity that a singular opportunity is found, the açai seed, which has the potential to be used as an energy fuel [4].

Brazil produced around 1.7 million tons of açai fruit in 2022, and the state of Para was the largest producer, being responsible for around 94% of production [5]. Studies have shown that approximately 85% of the fruit weight is its seed, the main processing residue, providing an availability of around 1.45 million tons of seed. Most of this agro-industrial residue is not collected properly (63%) [6]; it is left open in landfills for a degradation process to occur that releases methane gas, another greenhouse gas that is worse than CO2, into the environment.

In this context, the co-combustion of coal and another solid waste, such as sludge, urban solid waste and biomass, has been considered an economical and environmentally correct approach for both waste mitigation and energy production [7,8,9,10]. Therefore, the choice of açai seed as the biomass to be mixed with coal is consistent, since it is a material found in abundance in the region and since the results of other research [4], carried out by the biomass energy characterization laboratory at the Federal University of Pará, showed that the açai stone has excellent properties for generating energy. This synergy of fuels creates an opportunity to mitigate environmental impacts with the partial replacement of a fossil fuel by an agro-industrial residue. Furthermore, previous studies indicate that açai seed has compatible thermochemical properties for co-combustion such as its high heating value (HHV) of 19.23 MJ/kg [4] when compared to other agroforestry residues used for energy generation in various regions across the globe, Table 1.

Table 1.

High heating value of different agroforestry residues commonly used for energy generation.

Among various technologies available to obtain energy from a solid fuel, combustion is still the most used process in the world. Boilers with fluidized bed technology stand out for having the capacity to burn a wide range of fuels with a high combustion efficiency: in the case of circulating fluidized bed (CFB) boilers, it ranges from 97.5 to 99.5% [15]. The CFB boiler’s high performance, together with its capability of burning a variety of fuels, such as coal, organic material, biomass from agroforestry residues and mixtures of these fuels, with low emissions of sulfur and nitrogen monoxide, suggests its use for the co-combustion of coal and açai seed.

The Hydro/Alunorte industry, located in Barcarena PA, in the north region of Brazil, seeks to reduce its emissions of CO2 equivalents (CO2eq) as part of a plan to achieve carbon neutrality in the future. Near the plant location, there is large amount of açai seed residue, which could be used in co-combustion in the CFB boiler that operates with bituminous coal for fossil fuel reductions. The company primarily used coal as an energy source for the boiler under this study. Despite all the environmental problems, coal is still a very important source of energy, is used in several Latin American countries [16] and is China’s main source of energy. Due to its widespread use, it is common to find studies that focus on the characterization and use of coal in industry. As an example of characterization, ref. [16] carried out petrography and geochemistry analyses of Colombian coal, which is similar to the coal studied in this article, namely, bituminous coal. According to the author of [17], who classified the types of coal, bituminous coal is the second type with the highest calorific content and the highest concentration of fixed carbon, Table 2.

Table 2.

Types of coal according to stage of formation [17].

The co-combustion in fluidized bed combustors (FBCs) has proven effective with the application of many types of waste. This process has two clear advantages: the extensive existing experience in combustion technology, and the fact that it can be applied to waste considered to have combustion power characteristics. Existing FBC facilities promise to burn a wide variety of wastes; however, the influences of co-combustion on the operation and on the emissions may be a potential disadvantage and should be investigated [7].

To gain deeper insight into the impact of the fuel mixture on boiler operation, it is necessary to use computer simulation, which, in addition to being economically cheaper, is safer than practical tests. Among the software options for studying the co-combustion of bituminous coal and açai seed, the software chosen was the Comprehensive Simulator of Fluidized and Moving Bed Equipment (CeSFaMB™® v4.3.0, Campinas, Brazil), as it is a broad simulator for equipment that uses fluidized circulating and bubbling beds [7]. Previous applications on furnaces, boilers, dryers and gasifiers presented error ranges below 10% when comparing the results from simulation and real measurements. CeSFaMB™® v4.3.0 includes phenomena relevant to the process but presents important simplifications such as steady state and one-dimensional flow. Furthermore, it considers that diffusive phenomena are negligible compared to convective ones, due to the flow speed in the combustion chamber [18]. This simulator provides information at each point of the unit, and the results obtained are dimensional simulations and consider the differential mass and energy balances for all phases along the bed and freeboard [19].

The CeSFaMB™® v4.3.0 software is capable of handling a wide variety of carbonaceous materials and sorbents (limestone or dolomite). However, the range of possible chemical reactions for a single solid is extensive, with a broad spectrum of kinetic rates reported in the literature for the same reaction, since fuels, tar and sorbents are not pure chemical species. The software allows for the application of any factor but strongly advises against applying any values, thus utilizing data from its own database. The primary chemical reactions used in the software have been demonstrated by the program’s developer in several articles [20,21,22]. The program operates in a steady state, employing differential equations to define the system’s mass and energy balance. The program functions in one-and-a-half dimensions (1.5D), whereby changes are assumed to occur in the vertical direction. It is important to note that this is the first work to use CeSFaMB™® v4.3.0 to simulate the co-combustion process of coal–biomass in a CFB boiler and is not limited to theoretical simulation. This study incorporates an experimental validation using real industrial equipment, increasing the reliability of the results calculated by the simulator. Furthermore, this study stands out as the first to effectively employ an agro-industrial residual biomass, açai seed, as a fuel associated with bituminous coal in a circulating fluidized bed (CFB) boiler, expanding the application horizons of a residual biomass as a fuel.

2. Materials and Methods

In this work, the co-combustion process of açai seed and bituminous coal is assessed based on the temperature and chemical species profiles, efficiency and emissions. In order to achieve this objective, the methodology consisted of the equipment analysis, thermochemical fuel analysis, computational model validation, simulations campaign and results interpretation.

In order to simulate the co-combustion process in the Hydro/Alunorte CFB, the CeSFaMB™® v4.3.0 software was chosen. Initially, it was necessary to obtain several input parameters related to the fuel used and equipment operation; therefore, its daily operation was monitored. The main operational parameters that were obtained were the mass flow rate of fuel, primary and secondary air, absorbent and extra solids and steam. In addition, the dense and diluted bed temperature profiles, as the main equipment geometric parameters, were also obtained.

Secondly, the thermochemical properties of the coal and the açai seed were obtained. The proximate and ultimate analyses and the high heating value for both fuel samples were performed, as well as the density and particle size quantifications. Thermogravimetric analysis of the fuels was also carried out, in order to obtain fundamental information on the behavior fuels in the combustion process.

Once the boiler and fuel parameters were consolidated, a procedure to validate the computational model was performed. Only coal as the fuel was simulated in the CeSFaMB™® v4.3.0, and the results obtained by the simulation were compared with real data from boiler operation. Thus, with the results obtained from coal as the fuel, a baseline was fixed to compare the co-combustion results. With this validation, simulations of the co-combustion process with bituminous coal and açai seed were performed with two energy proportions. Assuming that the amount energy introduced in the boiler when consuming only coal was constant, the first case assumes that 10% of such amount of energy comes from açai seed and 90% from coal. Similarly, the second case assumes that 30% comes from açai seed and 70% from coal. The initial total equivalence ratio (only coal) was kept constant in both co-firing cases.

2.1. Equipment Data

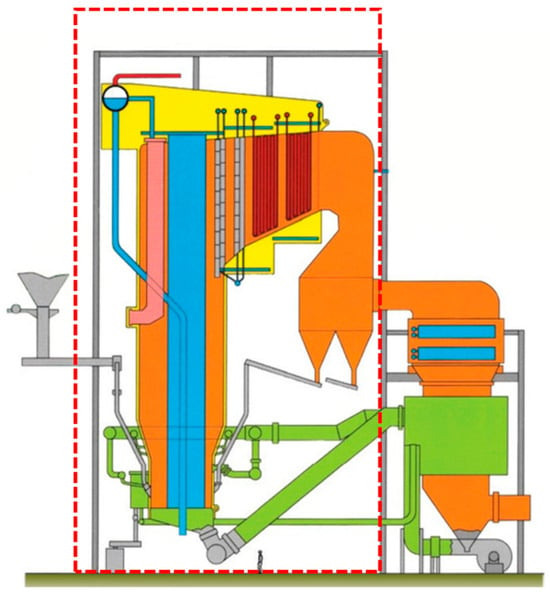

The studies were carried out on the Circulating Fluidized Bed (CFB) Boiler manufactured by Babcock & Wilcox Company, which has the capacity to process 250 MW of inlet fuel energy. The equipment is 32 m high, 12.9 m wide and 6.73 m deep. The primary air inlet comes from the distributor located in the lower region of the bed, which is made up of 4508 flutes with 14 holes each. The secondary air inlet is provided by pipes distributed at two different heights: 4.81 and 5.55 m. However, fuel is injected pneumatically at a height of 1.81 m; therefore, a small amount of air is also injected. The equipment has four multicyclones for solids recycling, each with 160 cyclones.

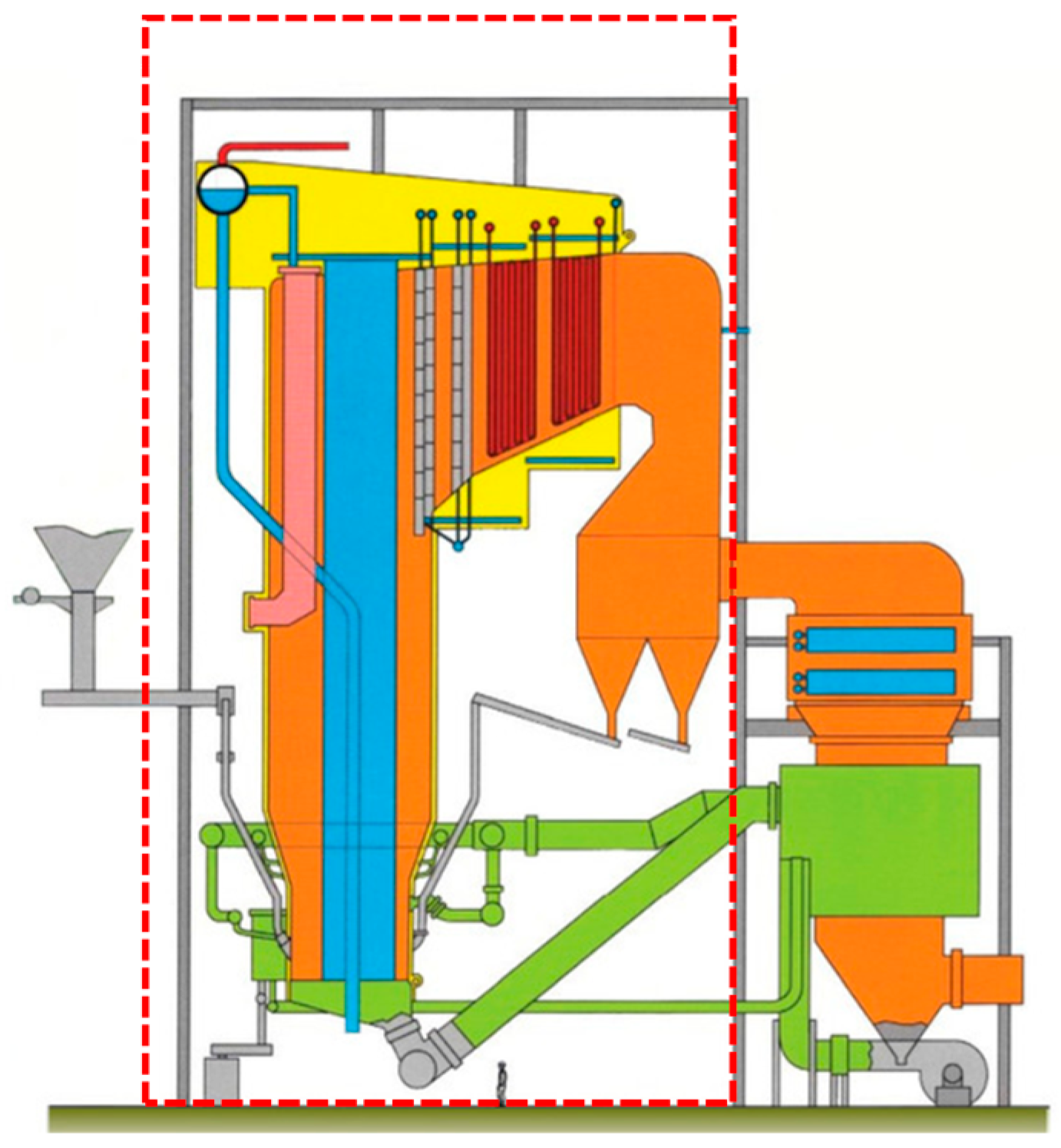

The experiments were conducted under operational conditions representative of the Hydro/Alunorte unit. Operational data were collected over 24 h, with hourly measurements obtained that included parameters such as the fuel flow, air flow, feed water flow, steam production and furnace temperature profile. The equipment scheme is shown in Figure 1.

Figure 1.

Circulating fluidized bed (CFB) boiler.

The circulating fluidized bed boiler is divided into two main regions: CFB loop and back pass [21]. The CFB loop is the volume simulated with CeSFaMB™® v4.3.0 in this work and is limited in Figure 1 by the red dashed line. This volume contains the riser, cyclones and solids recycling system. The back-pass region contains the superheaters, reheaters, economizer and air heater and is outside the red dashed line and simulated in this work.

CeSFaMB™® v4.3.0 imposes constrains when simulating CFB boilers. It simulates only the CFB loop region, disregarding the back-pass. This must be taken into account in the results, as it significantly reduces the boiler’s efficiency [22].

2.2. Fuel Analysis

2.2.1. Materials

The açai seed samples were obtained from companies specializing in managing such residue in the Igarapé-Miri-Pa region. Samples of bituminous coal were obtained through the Hydro-Alunorte industry, Barcarena, PA, Brazil.

The samples were subjected to the standardization process for chemical and thermochemical analyses, including a drying process, in accordance with the NBR-16508:2017 [23] standard for coal and CEN/TS 14774-1:2004 [24] for biomass; a grinding process in a bench knife mill; and standardization of the dimensions on sieves between 30 and 60 mesh.

The determinations of the proximate and ultimate analyses, higher heating value, specific mass and particle size were carried out. Due to the different combustion characteristics between coal and açai seed, a thermogravimetric analysis was also carried out, which aimed to understand the behavior of each fuel during the burning process. Since in general, biomass has a higher volatile content and lower heating value, when compared to coal, açai seed’s main heat release comes from the homogeneous combustion of volatiles [25].

2.2.2. Chemical Characterization and Thermochemical Properties Analysis

The procedure for the proximate analysis of coal followed standards NBR 16508:2017 [23], 16587:2017 [26] and 16586:2017 [27]. For biomass samples, the standards followed were CEN\TS 14774-1:2004 [24], 15148:2005 [28] and 14775:2004 [29]. Initially, the samples were separated and passed through the process of analysis of the moisture, while the remainder was placed in the oven for the moisture removal process. The results obtained were the moisture, volatile, fixed carbon and ash contents on a mass basis.

The ultimate analysis was performed on a PERKIN-ELMER Series 2400.1 ultimate analyzer. This made it possible to generate quantitative data in mass percentages of carbon, hydrogen, nitrogen, sulfur and oxygen (by difference).

The higher heating value (HHV) analysis was carried out using a calorimetric bomb model C2000, brand Ika Werke. All analyses were performed in triplicate to ensure the consistency and reliability of the results. The reproducibility of the experiments demonstrates the robustness of the obtained data. To obtain the lower heating value (LHV), Equation (1) was used [30].

In which the LHV is the lower heating value (kJ/kg); HHV is the higher heating value (kJ/kg); is the moisture content on a wet basis; h is the hydrogen content in the biomass; and is the enthalpy of water vaporization (2453 kJ/kg).

2.2.3. Thermogravimetry

A thermogravimetric analysis was carried out on a vacuum-sealed thermo-microbalance (Libra-Neitzsch, TG 209 F1, NETZSCH, Selb, Germany). Graphs of the mass loss as a percentage (TG) and the mass loss rate as a percentage per minute (DTG) were then obtained, with variations in the temperature. The parameters used in the analysis were a temperature range of 25–800 °C, heating rate of 10 °C/min, oxidative atmosphere with volumetric flow of 40 mL/min of O2, sample mass of 10 mg and particle size of 30 to 60 mesh.

Through thermogravimetric analysis, it is also possible to obtain chemical kinetic data; however, these data were not used, as the program strongly indicates that the kinetic data should not be altered. Thus, the fuel type was defined as general biomass, and through the wide range of chemical reactions contained in the software database, the simulation was carried out.

2.2.4. Physical Characterization Analysis

A particle size analysis of the açai seed and coal was carried out according to the standard NBR NM 248:2003 [31]. This analysis was performed with dry samples in triplicate, and an average of 500 g was used for coal and 300 g for the açai seed.

The apparent and real density were obtained by adapting the standard NBR NM-52:2003 [32]. For this work, samples of coal and açai seed (with average diameters of 15 and 12 mm, respectively) were crushed and sieved with a 16-mesh sieve, which is within the range stipulated in the standard. Isopropyl alcohol was also used as a penetrating liquid due to its capillary properties.

2.3. Simulation Conditions

After the main input data were obtained, the developed model was validated using real data obtained from boiler operation. The temperature and superficial velocity results were compared, as they are the most reliable parameters related to the equipment. The aim was to keep the error range below 10% in order to maintain the reliability of the calculation.

Once the validation was achieved, the co-combustion process between coal and açai seed was simulated in the energy proportions shown in Table 3, keeping the same equivalence ratio applied in its standard operation with only bituminous coal.

Table 3.

Energy fractions of açai seed and bituminous coal adopted in each simulation.

2.3.1. Fuel Flow

The açai seed LHV is smaller than that of bituminous coal; therefore, the same amount of energy requires more mass of açai seed then coal. Replacing a certain percentage of coal energy with açai seed energy implies an increase in the inlet fuel flow when feeding coal and açai seed together. Knowing the reference case coal mass flow rate (, the actual flows of coal, açai seed and the total inlet fuel rate can be obtained through Equations (2)–(5).

In which is the total mass flow for each simulated case (Table 3), and are the bituminous coal and açai seed mass flow rates, respectively, is the fraction of coal replaced for açai seed, and the LHV is the lower heating value.

2.3.2. Air Flow

The air mass flow rate required for each simulating condition is obtained though the mass conservation. Keeping in mind that the reference case (SIM0) equivalence ratio is kept constant, it was evaluated using Reaction (6) and Equation (7).

In which Φ is the equivalence ratio, is the ratio between the air and fuel mass stoichiometric flow rate, and is the ratio between the air and fuel real mass flow rate. Knowing the reference equivalence ratio, it is possible to calculate the air flow for each of the mixtures of coal and açai seed.

The chemical reaction equation of the co-combustion process must initially be developed for each proportion of coal and açai seed, and using the equivalence ratio, the air flow rate for the mixture conditions can be calculated using Reaction (8) and Equations (9) and (10).

where ABC and AAS are the number of mols of bituminous coal and açai seed per second, respectively, and are the coal and açai seed mass flow rates, respectively, and MWi is the fuel molecular weight.

3. Results

3.1. Equipment Operational Data

The fuel flow was carefully recorded throughout the experimentation period of a continuous 24 h. The day average results obtained are presented in Table 4 and Table 5.

Table 4.

Operating input parameters of the boiler for the reference case (SIM0).

Table 5.

Operating output parameters of the boiler for the reference case (SIM0).

The furnace temperature was recorded in the dense and diluted bed regions, allowing an analysis of both regions over time. In parallel, the steam production, a crucial indicator of the thermal efficiency of the system, was continuously monitored (Table 5).

3.2. Fuel Analysis Results

3.2.1. Thermochemical Characterization

The proximate analysis in Table 6 shows the high volatiles content for açai seed in relation to coal. It causes an initial faster combustion for the açai and therefore a greater reactivity [25].

Table 6.

Fuel analysis.

It was also observed that açai has a smaller amount of ash than coal in its composition, which causes difficulty in the bed fluidization process. The seed ash composition has a reduced amount of SiO2 and an increased amount of K2O when compared with coal ash. As a consequence, the seed ash has a melting temperature that is lower than that of coal, which can cause the agglomeration phenomenon and compromise the bed fluidization. Despite the seed ash having a lower melting temperature than coal ash, it is above the dense bed temperature, allowing its utilization as a fuel in fluidized bed boilers.

The heating value analysis demonstrated that the greater moisture in the açai seed results in a reduction in the LHV of the biomass, which implies a trend to reduce boiler efficiency.

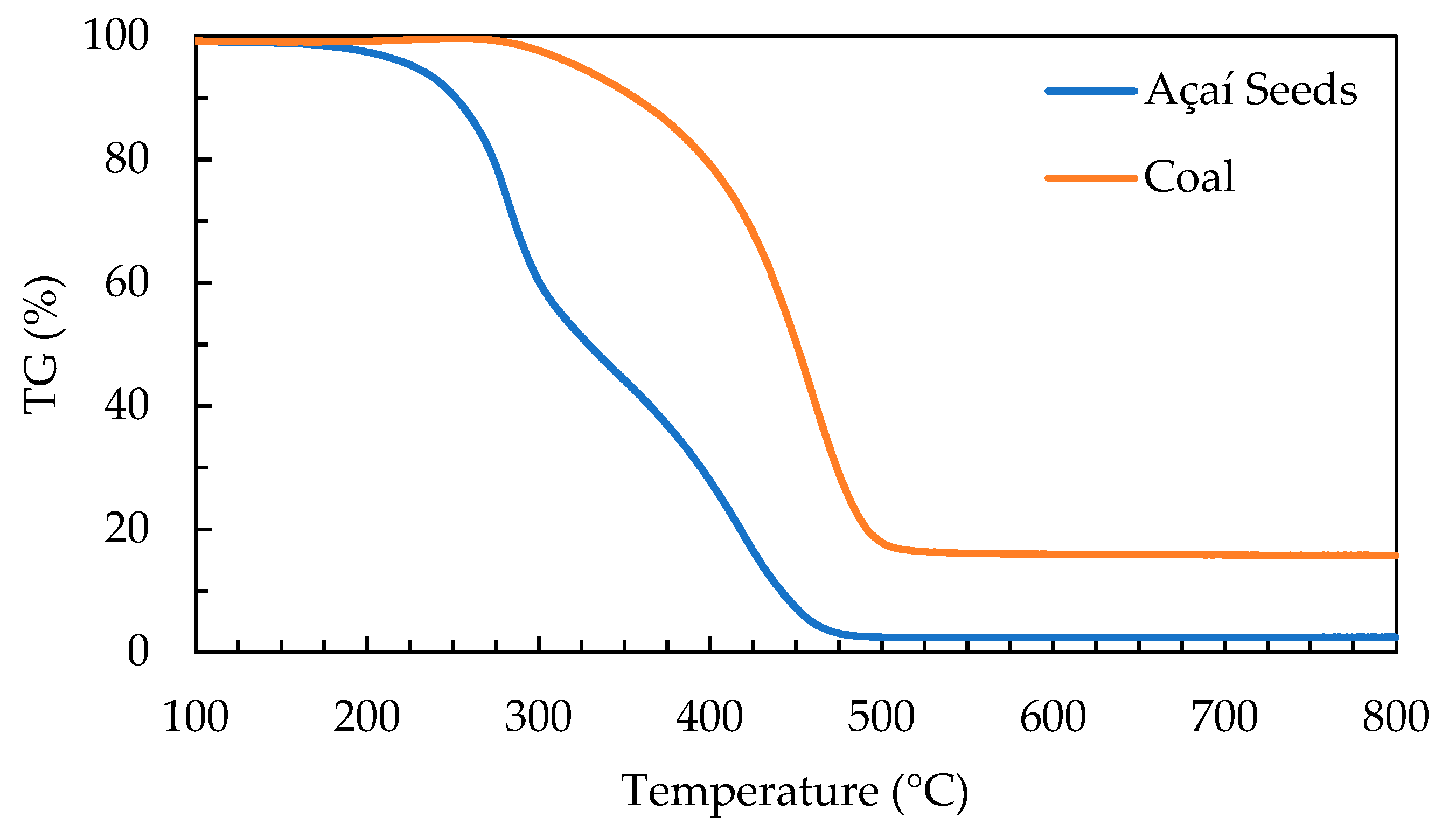

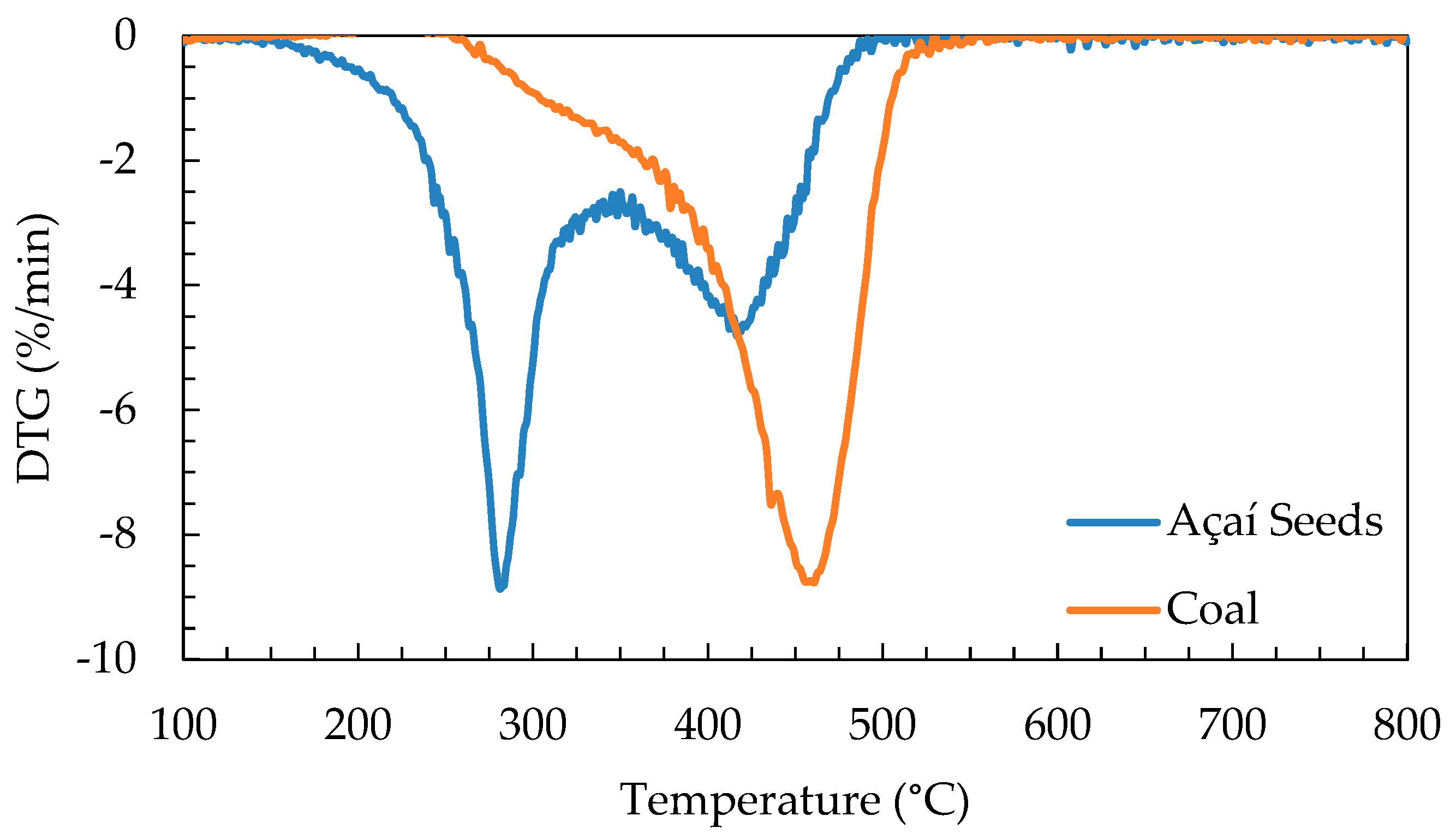

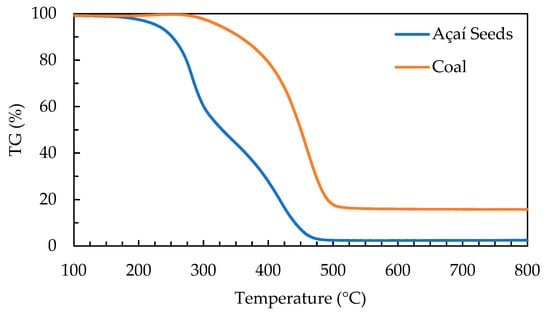

3.2.2. Thermogravimetric Analysis

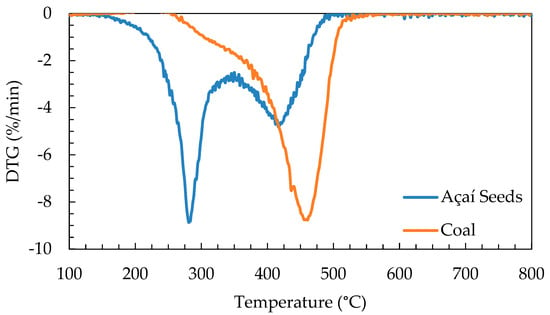

Figure 2 shows the graphs of the mass loss (TG) for the coal and açai seed samples. Both samples were analyzed on a dry basis, and no significant signs of mass loss due to moisture were identified up to 105 °C. For the coal sample, a typical reaction stage of char oxidation was observed between 378 and 501 °C (first DTG peak in Figure 3), due to the higher fixed carbon content (49.7%). For the açai seed sample, the mass loss process occurs in two stages within the range of 251–457 °C. The first stage of mass loss occurs due to volatile release (first DTG peak in Figure 3), while the second stage occurs due to char oxidation (second DTG peak in Figure 3). For the açai seed, this behavior is characteristic of biomasses in which the first stage is typical of the hemicellulose and cellulose reaction, while the second stage is characteristic of the lignin reaction and coal oxidation [33]. It is important to keep in mind that the high level of volatiles results in lower ignition temperatures. The residual mass was 15.74% for coal and 2.43% for açai seed. Both values are similar to the ash content from the proximate analysis: 15.45% for coal and 2.29% for açai seed.

Figure 2.

TG graphs for açai seed and bituminous coal fuel.

Figure 3.

DTG graphs for açai seed and bituminous coal fuel.

The mass loss rate or DTG graph, shown in Figure 3, allows the quantification of sample reactivity. For the açai seed, greater reactivity can be seen in the volatile release stage due to the high peak value of DTG of −8.9%/min, while the second stage has a peak value of −4.8%/min, which makes the release of volatiles the most relevant stage in the combustion of açai seed.

For coal, the DTG peak value was −8.9%/min, a value higher than that of the second DTG peak for the açai seed related to char oxidation, which makes the coal reaction stage more intense than the açai seed stage. Table 7 presents the temperature data for the mass loss range and the DTG peak.

Table 7.

TGA temperatures values.

3.2.3. Physical Characterization

The particle size analysis of the fuels was performed, and the following particle size distribution was obtained as shown in Table 8.

Table 8.

Particle size analysis of fuels.

It was observed that açai seed has a very uniform distribution, with most of it being retained only in two sieves. As for coal, it was observed that the average particle size was around 2.41 mm, which is within the average particle size range for CFB boilers, as a reduced diameter is necessary to facilitate the fluidization process. The determination of the bulk and true densities produced the results shown in Table 9.

Table 9.

Specific mass of fuels.

It is noted that both fuels have a very similar true density. However, when comparing the bulk density, a large difference is noticed. This is due to the natural shape of the açai seed, which has a more spherical shape that causes a greater fraction of voids.

3.3. Fuel Flow Results

Based on the LHV and coal mass flow rate for reference case (SIM0), it was possible to calculate the amount of energy received by the boiler: 231 MW. The case of SIM10 considers açai seed providing 10% of the reference energy. It is similar for SIM30 but with 30% of 231 MW. The mass flow rate of açai seed required for each coal energy replacement was then calculated using Equation (2), as shown in Table 10.

Table 10.

Fuel flow in each proportion.

3.4. Equivalence Ratio

To set up the chemical reaction for the combustion, it was necessary to know the relative moisture in the air at the plant location; thus, the air composition used is presented in Table 11.

Table 11.

Local air composition.

From the coal ultimate analysis and the air parameters at the plant location, it was possible to set up the equation for a stoichiometric combustion chemical reaction, shown in Reaction (11), in order to obtain the stoichiometric air flow rate and the equivalence ratio applied in the boiler.

The stoichiometric air flow rate was calculated as 78.2 kg/s and compared with the real air flow in the boiler, which is 129.6 kg/s. Therefore, the total equivalence ratio was obtained using Equation (7) and is equal to 0.6: a poor combustion.

3.5. Air Flow Results

This work chose to keep the equivalence ratio constant in all simulated cases, varying the air flow as needed. The air flow rate for each co-combustion case was obtained through coal and açai seed ultimate analysis and Reaction (12). The results are shown in Table 12.

Table 12.

Mole coefficients in Reaction (12) for each analyzed case.

Table 13 presents the reactants’ total mass flow rates as well as the air/fuel ratio. It is noted that despite the greater presence of oxygen in the açai seed, a greater air flow is still needed for combustion as the fraction of açai seed in the mixture increases. This is due to the greater total fuel flow. It was also observed that the air/fuel ratio decreases with the increase in açai seed input.

Table 13.

Fuel and air flow rates for equivalence ratio equal to 0.6.

3.6. Simulation Results

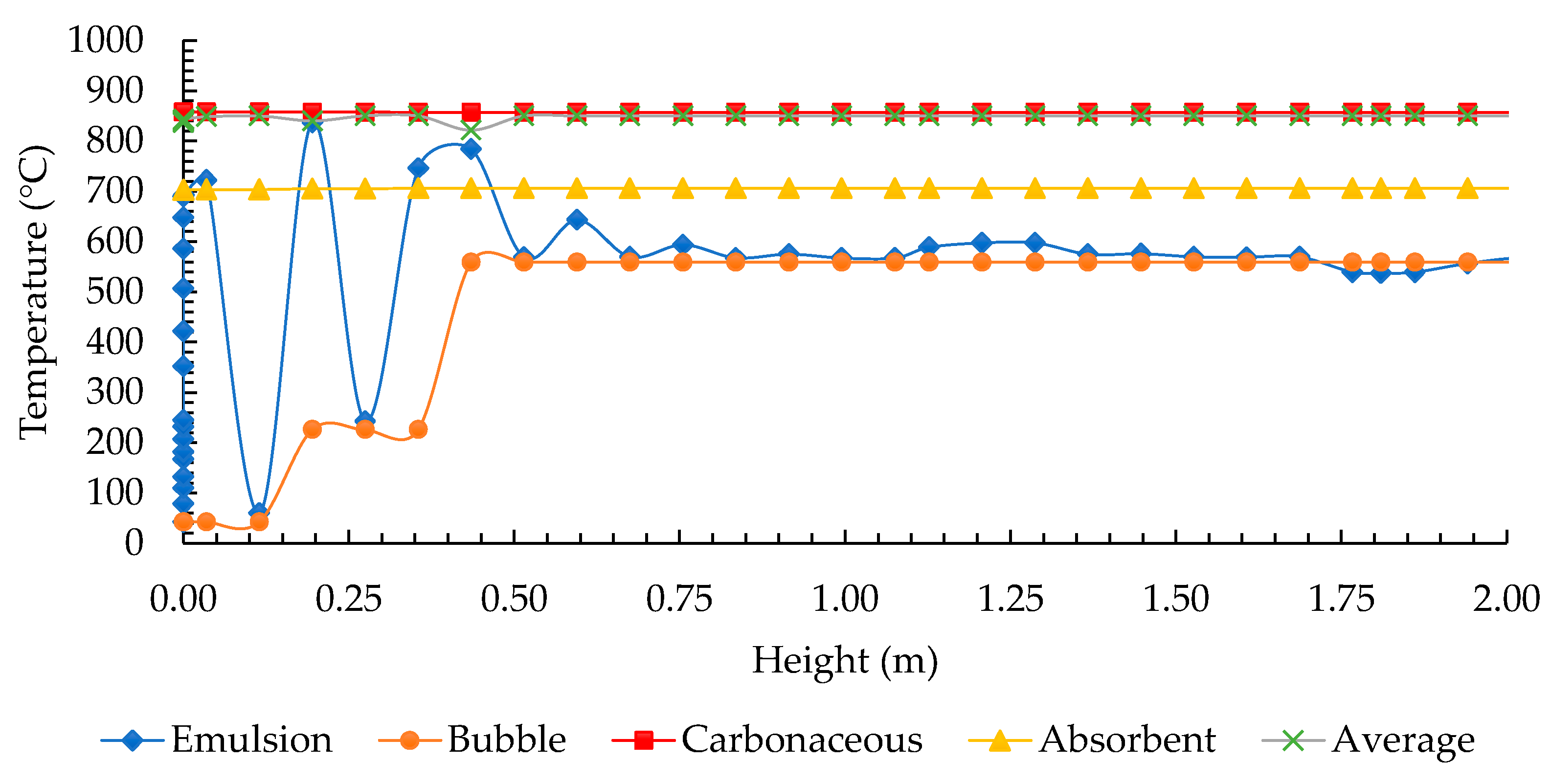

The simulation provides the temperature profile for bubbles (gas regions free of solid particles), emulsions (a phase formed by gases and solids in the fluidized bed), carbonaceous materials (complex collections of organic polymers composed mainly of aromatic chains combined with hydrocarbons and other atoms, such as oxygen, nitrogen, sulfur, potassium, sodium, etc.) and absorbents (substances that absorb liquids or gases) [20].

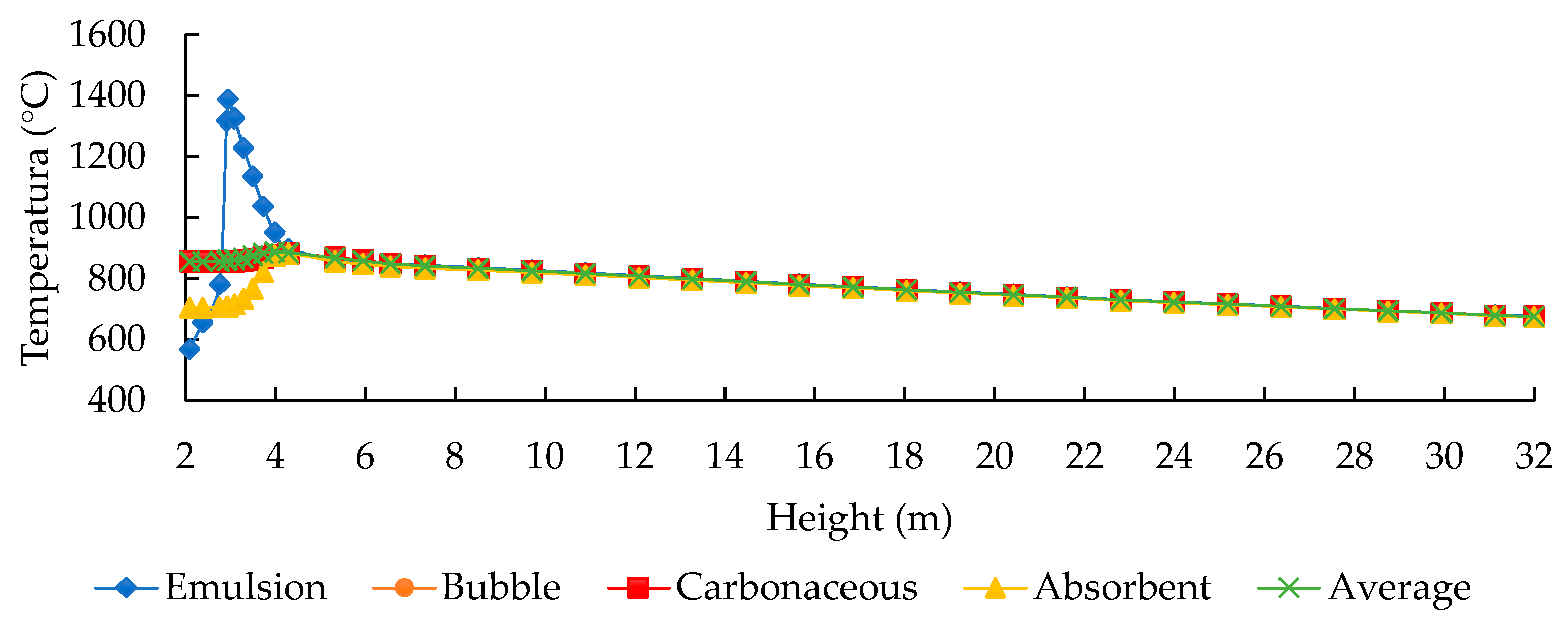

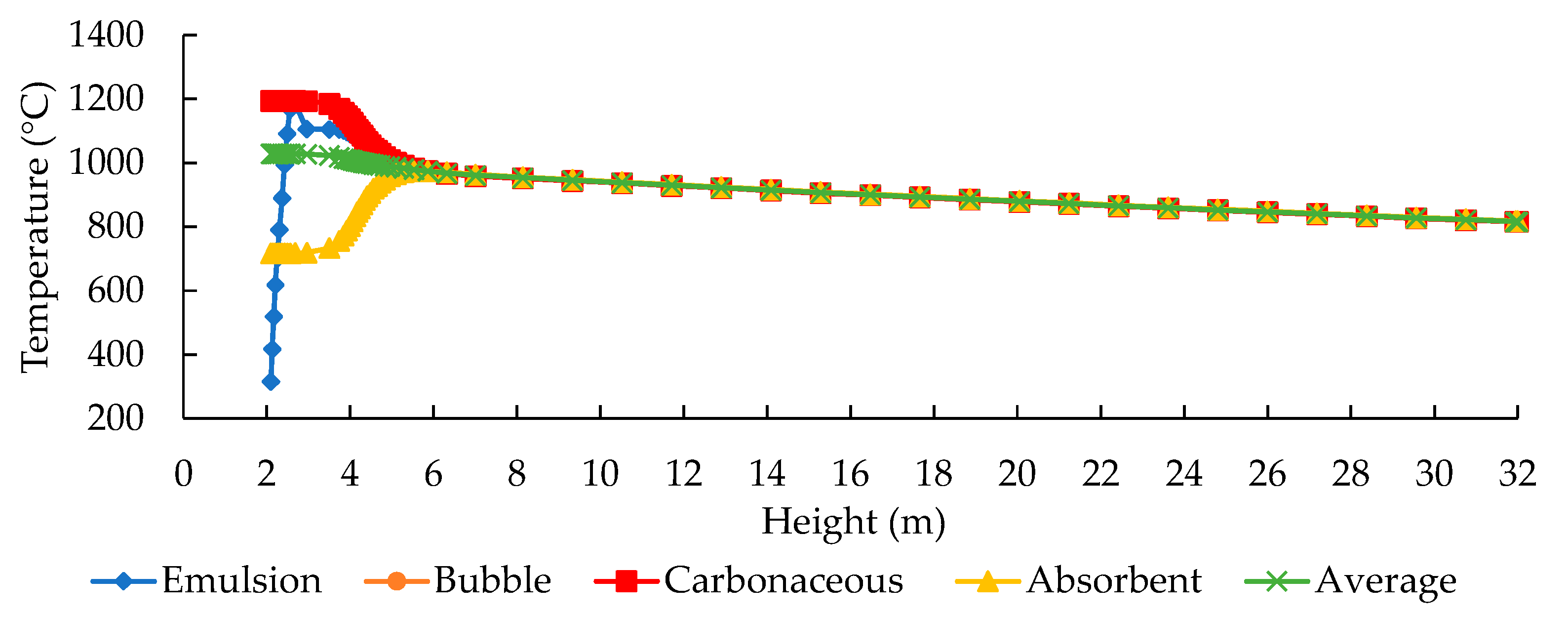

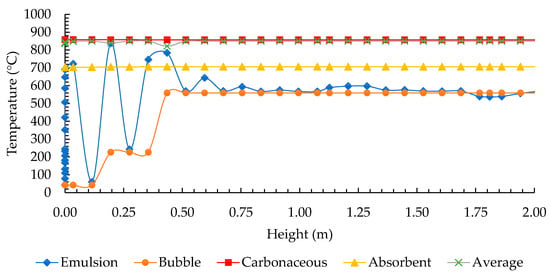

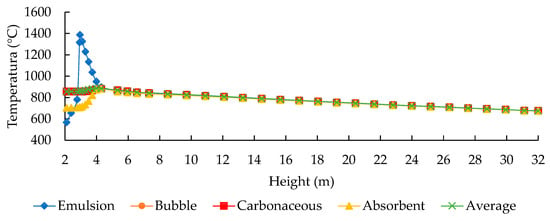

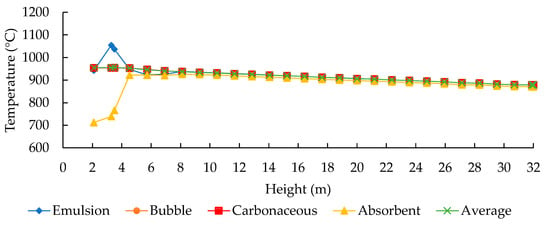

The reference case (SIM0) simulation was carried out in order to compare its results with the real operating parameters inside the boiler aiming to validate the model. Temperature was chosen to allow comparison between simulation and operation since it is the most reliable parameter obtained from boiler operation. The simulation results for the temperature profiles for the dense bed are shown in Figure 4 and for the freeboard are shown in Figure 5.

Figure 4.

Graph of temperature versus height in the dense bed.

Figure 5.

Graph of temperature versus height in the freeboard.

Figure 4 shows that combustion happens mainly before 1 m height (emulsion temp) in the dense fluid in a rich fuel combustion near stoichiometric condition. At 1.81 m high is the pneumatic fuel inlet. The air that comes with the fuel meets the residual gas coming from combustion zone increasing its O2 mole fraction but not enough to promote a flammable mixture. A rich gas mixture cross dense fluid border into the freeboard and mixes with O2 coming from secondary air inlets causing another intense combustion at 2–4 m (emulsion peak, Figure 5). This is a fast homogeneous volatile combustion. The remaining secondary inlet O2 is used to finish the secondary reactions, such as those of CO and NO.

The average temperature in the dense bed obtained in the simulation was 849 °C, which is 3.37% lower than the average measured temperature (878.6 °C). In the lean bed, the maximum simulation temperature was 887 °C, which is 9.70% lower than the measured maximum temperature (982 °C). Furthermore, the superficial velocity of the gas as it exited the dense bed for the freeboard was also compared, and the result is shown in Table 14. These results validate the boiler model.

Table 14.

Real and simulated surface speed.

The validation of the temperature profiles in the dense and lean beds also correlates with the distribution of secondary airflow across three different zones: 1.81 m, 4.81 m and 5.5 m. At 1.81 m, the airflow rate is the lowest, as the primary purpose of this air injection is to assist in the fuel injection into the bed, given that both are introduced through the same inlet. At the heights of 4.81 m and 5.5 m, the diluted bed has a negative temperature gradient as a consequence of heat exchange between the bed and wall. Once these two secondary air targets quench the secondary reactions, the gradient is kept constant for the remaining freeboard. These observations reinforce the accuracy and reliability of the boiler model.

3.6.1. Co-Combustion Analysis

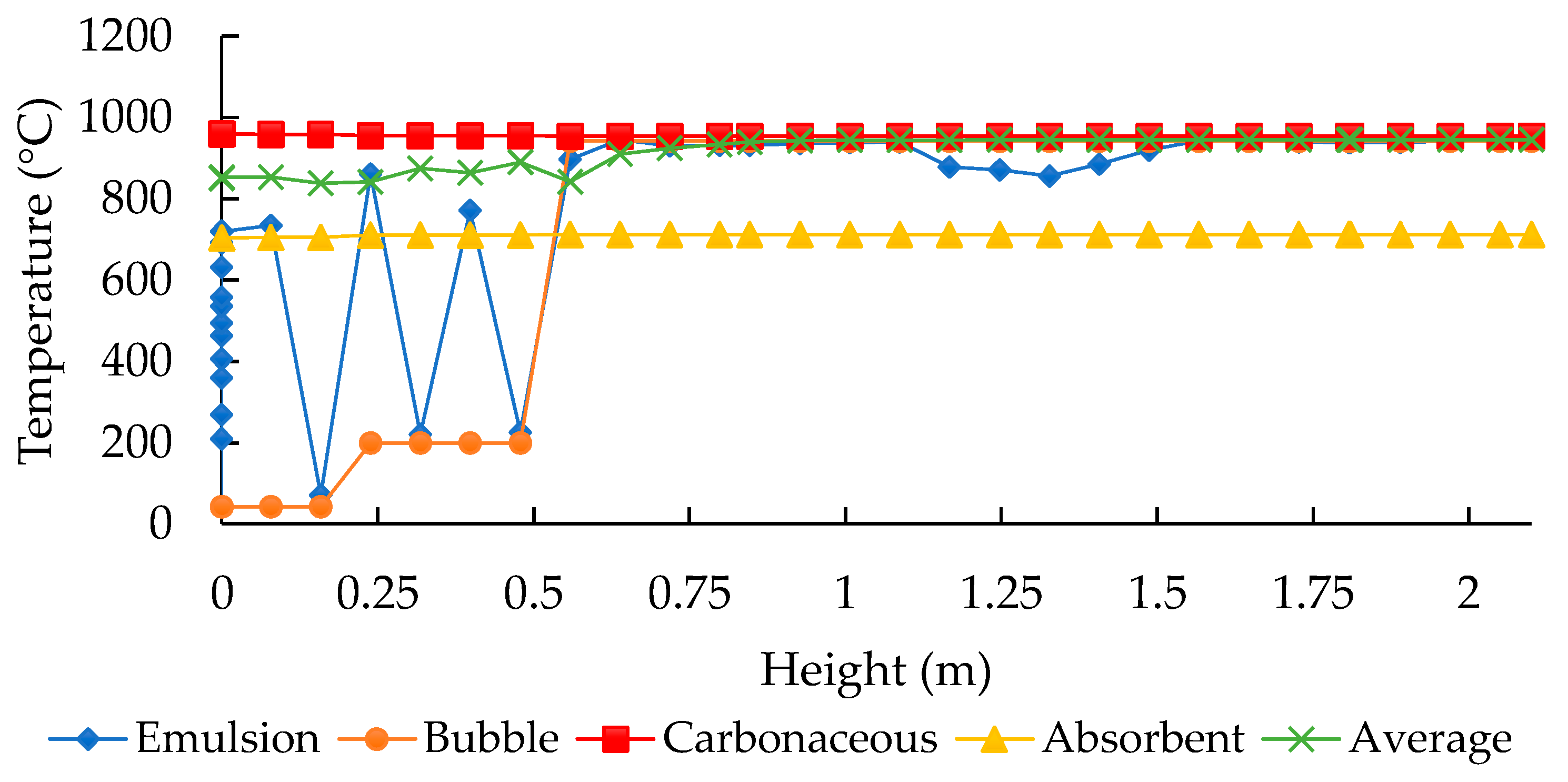

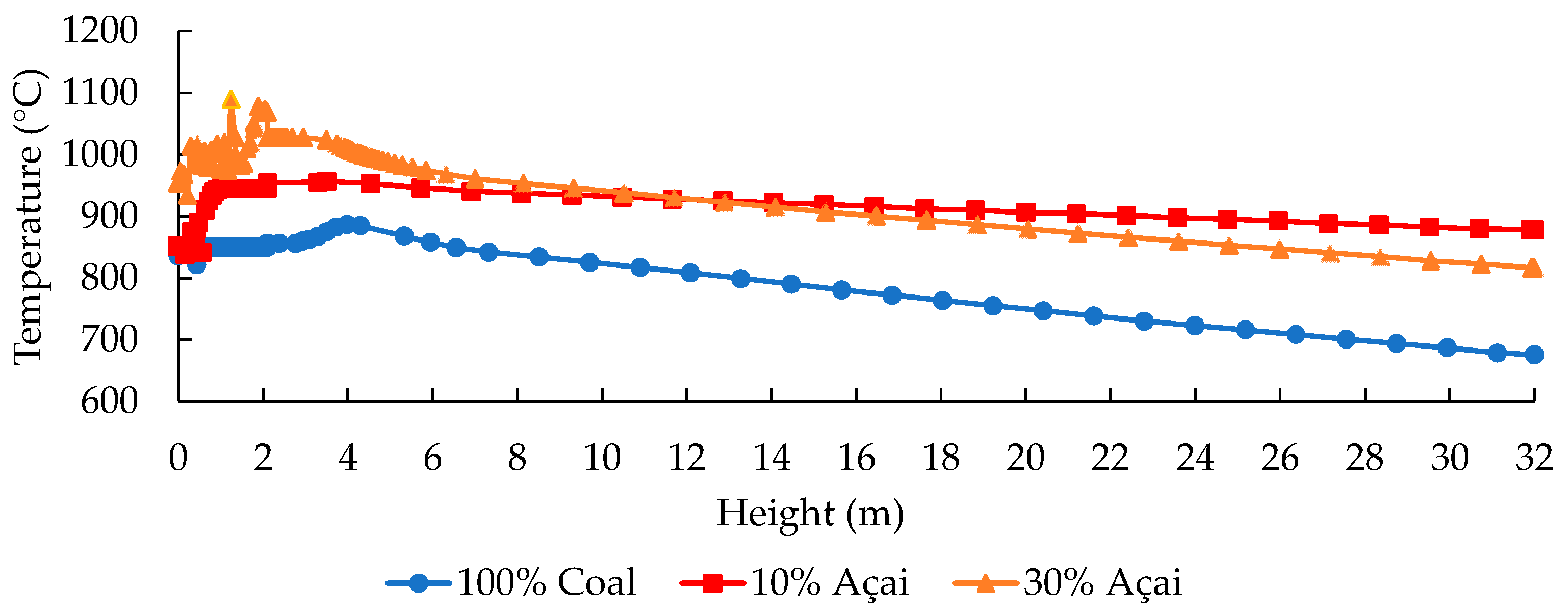

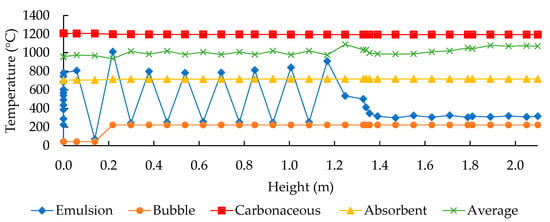

After model validation, the results of the co-combustion in the aforementioned fractions were compared and analyzed in order to understand how the açai seed impacts the boiler temperature, steam production and emissions. Figure 6 and Figure 7 show the temperature profile of the dense bed and freeboard, respectively, for the 10% energy fraction from açai seed.

Figure 6.

Graph of temperature versus height in the dense bed for 10% açai seed.

Figure 7.

Graph of temperature versus height in the freeboard for 10% açai seed.

In Figure 6, we can see that the behavior is similar to what happened with the 100% coal simulation. The emulsion and bubble phases in the dense bed stabilize at around 0.5 m high, and another observation is the increase in average temperature, which stabilized at 945 °C, unlike the coal in Figure 4, which stabilized at 849 °C.

In Figure 7, the absorbent and the emulsion stabilize around 8 m high but at higher temperatures when compared to coal; for example, the temperature at 32 m is 676 °C for 100% coal and 878 °C for 10% açai. With the flue gas coming out at higher temperatures, the equipment in the boiler back-pass can operate at higher efficiency levels.

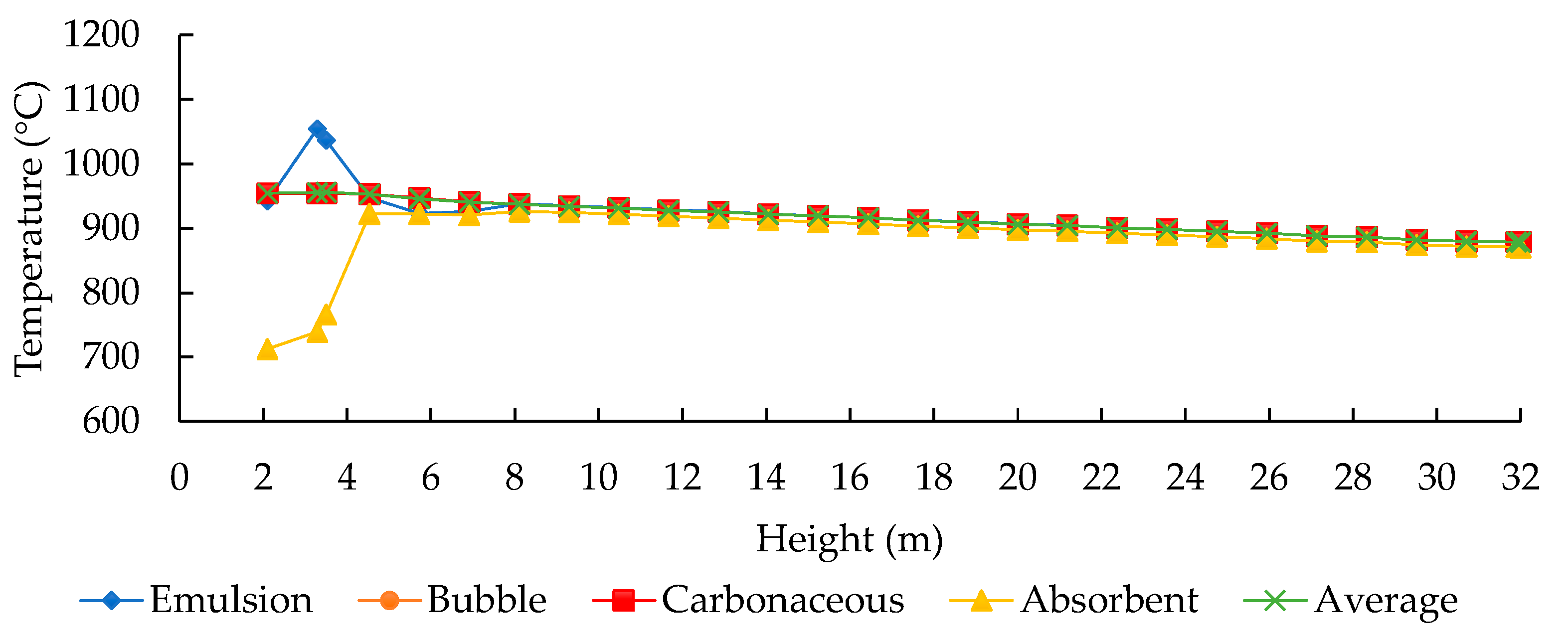

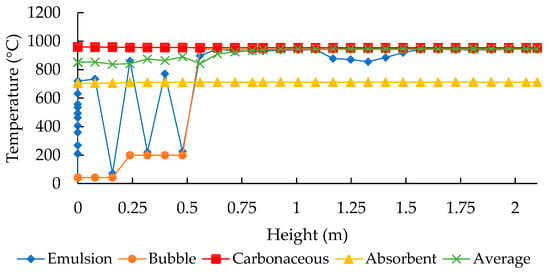

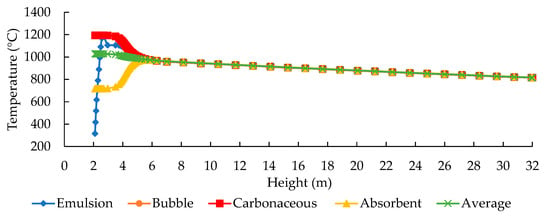

Figure 8 and Figure 9 show the same for 30% açai seed. Figure 8 shows that the increase in the percentage of açai caused the process to stabilize at 1.5 m in the dense bed, and again, there was an increase in temperature.

Figure 8.

Graph of temperature versus height in the dense bed for 30% açai seed.

Figure 9.

Graph of temperature versus height in the freeboard for 30% açai seed.

In Figure 9, stabilization occurs around 5 m, where this time carbonaceous, emulsion and absorbents play a role.

In summary, Figure 4 and Figure 9 show that in the dense bed, the introduction of açai seed caused a delay in the increase in the bubble’s temperature, suggesting that the açai seed heating and volatilization processes require more energy than similar conditions for coal. In the dense bed, shown in Figure 4, Figure 6 and Figure 8, the temperatures of the co-combustion emulsions exhibited similar initial oscillatory behavior as when only coal is burned, but it takes longer to stabilize, suggesting a significant influence of this material on the thermal dynamics of the system. This detail was not a significant concern due to the size of the boiler. It varies between the temperatures of the carbonaceous and bubbles before reaching stabilization, which can be explained by the definition of emulsions themselves, which are gas bubbles that carry solid materials. As for the absorbent, it remained stable in terms of temperature, exhibiting intermediate values between carbonaceous and bubbles. This thermal stabilization of the absorbent, even in the presence of açai seed, indicates its ability to effectively regulate the temperature in the bed, which is important in the efficiency and operational safety of the circulating fluidized bed boiler.

Figure 4, Figure 6 and Figure 8 show that the temperature at the bottom of the dense bed is stabilized quickly. However, when more açai seeds are added, there is a noticeable delay in the temperature stabilization. This delay is due to the increase in primary air injection into the bed and the presence of volatiles in the biomass. The greater quantity of gas injected into the boiler and generated from the biomass takes longer to heat, leading to a prolonged stabilization period. In Figure 4 and Figure 6, this stabilization zone is 0.5 m long, while in Figure 8, it extends approximately 1.4 m, reflecting the influence of increased biomass and air injection.

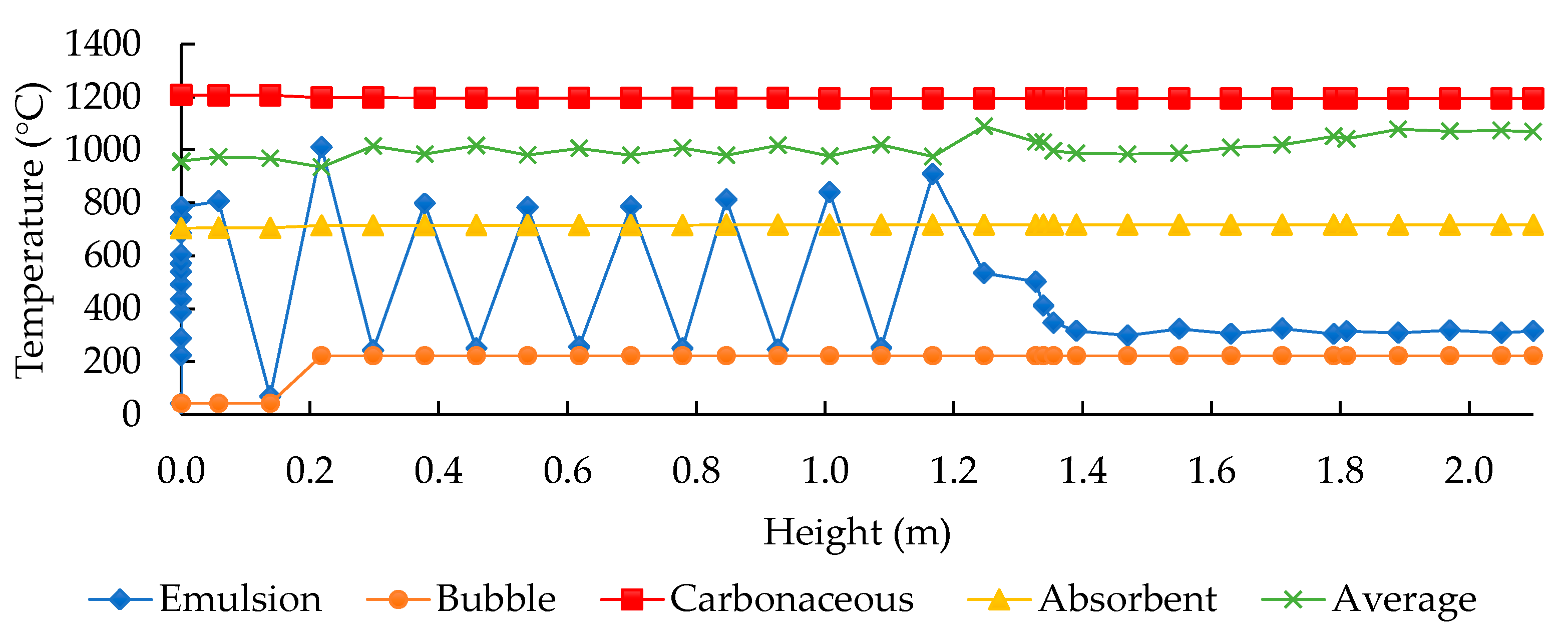

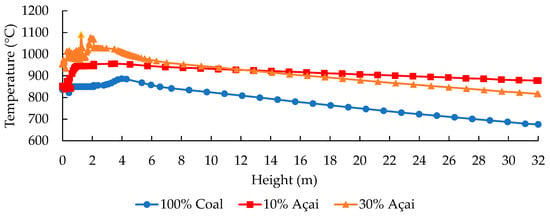

Figure 10 compares the average temperature profiles for all three cases. It shows that the mixture of açai seed and coal as energy increases both the dense bed and freeboard temperatures. In the freeboard, the temperature decreasing with height occurred more gradually compared to the coal-only burn, suggesting a favorable influence of the açai seed presence on the heat transfer rate to the boiler wall and, therefore, to the liquid water.

Figure 10.

Comparison of average temperature profile for each fraction of açaí seed in the fuel.

The temperature growth in the dense bed can be explained due to the greater reactivity of the açai seed, as observed in the thermogravimetric analyses, resulting from the increase in the volatile content, which caused an increase in the percentage of fuel burned before passing through the cyclone; thus, with more energy released, there is an increase in temperature.

The program calculates the percentage of fuel burned in the dense bed. For combustion using only coal, the fuel consumption rate is 82%. When 10% açai seed is added to the fuel mix, the percentage of fuel burned increases to 94%. With 30% açai seed, the fuel consumption rate further increases to 97%.

The insertion of the açai seed resulted in significant improvements in the efficiency of the steam generation process. While exclusively burning coal had an efficiency of 57%, the introduction of just 10% açai seed increased this efficiency to 85%, allowing the generation of up to 178 kg/s of steam at 84 bar and 485 °C. It is important to emphasize that the efficiency calculation performed by the program considers the amount of energy generated by combustion and the amount of energy transferred to water for steam generation. However, the software is restricted to the CFB loop region (Figure 1) and disregards the back-pass region, where the economizer and superheater are used precisely to increase the efficiency of the system, which justifies the efficiency obtained being lower than normal for this type of equipment.

This increase in the efficiency can be attributed to the higher rate of energy released during co-combustion, as well as the additional presence of solids in the bed. The increased density in the freeboard region facilitated heat exchange with the pipes, optimizing the transfer of energy to the water and, consequently, increasing the steam generation capacity. It was also observed that the efficiency remained approximately constant when increasing the proportion of açai seed to 30%, with an efficiency of 83%, and that the steam generation capacity remained high, reaching up to 173 kg/s. These results highlight the potential of the co-combustion of coal and açai seed to improve not only energy efficiency but also the economic and environmental viability of the steam generation process in circulating fluidized bed boilers.

3.6.2. Mole Fraction Profiles in the System

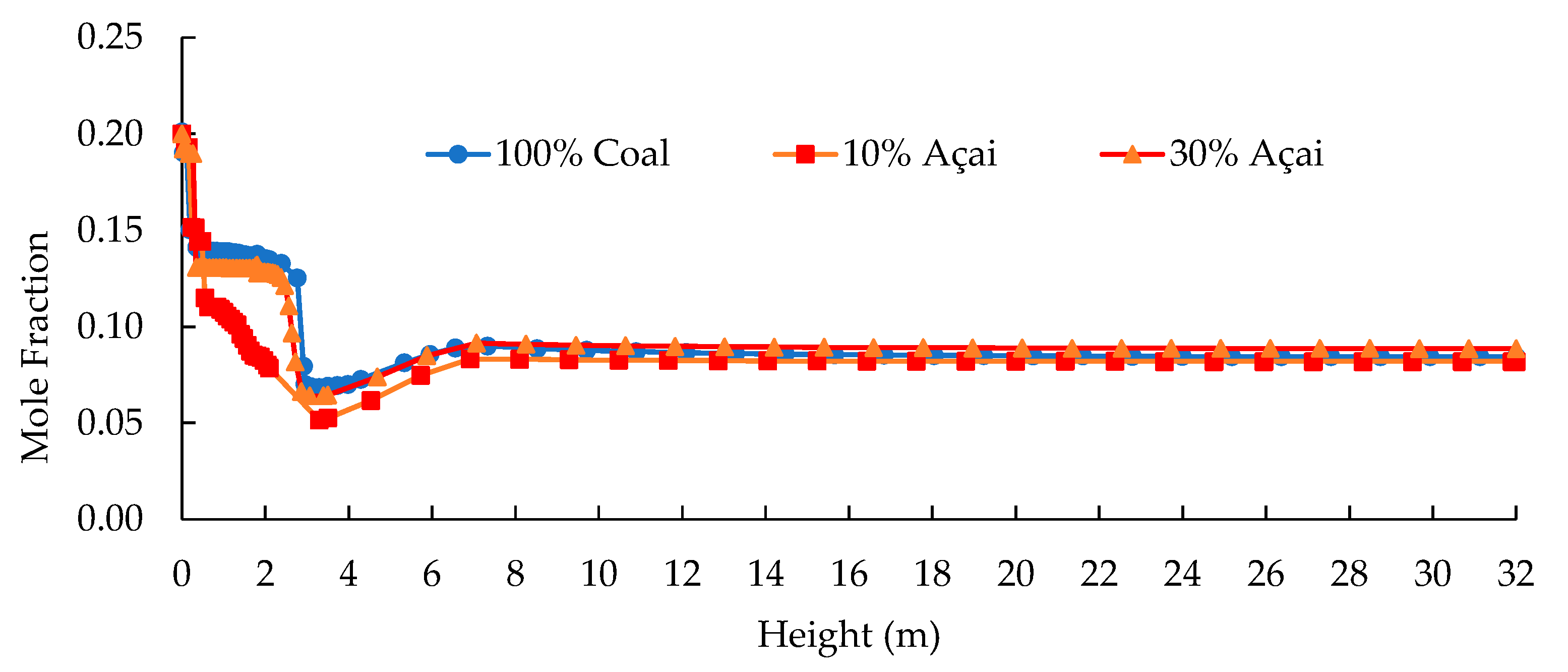

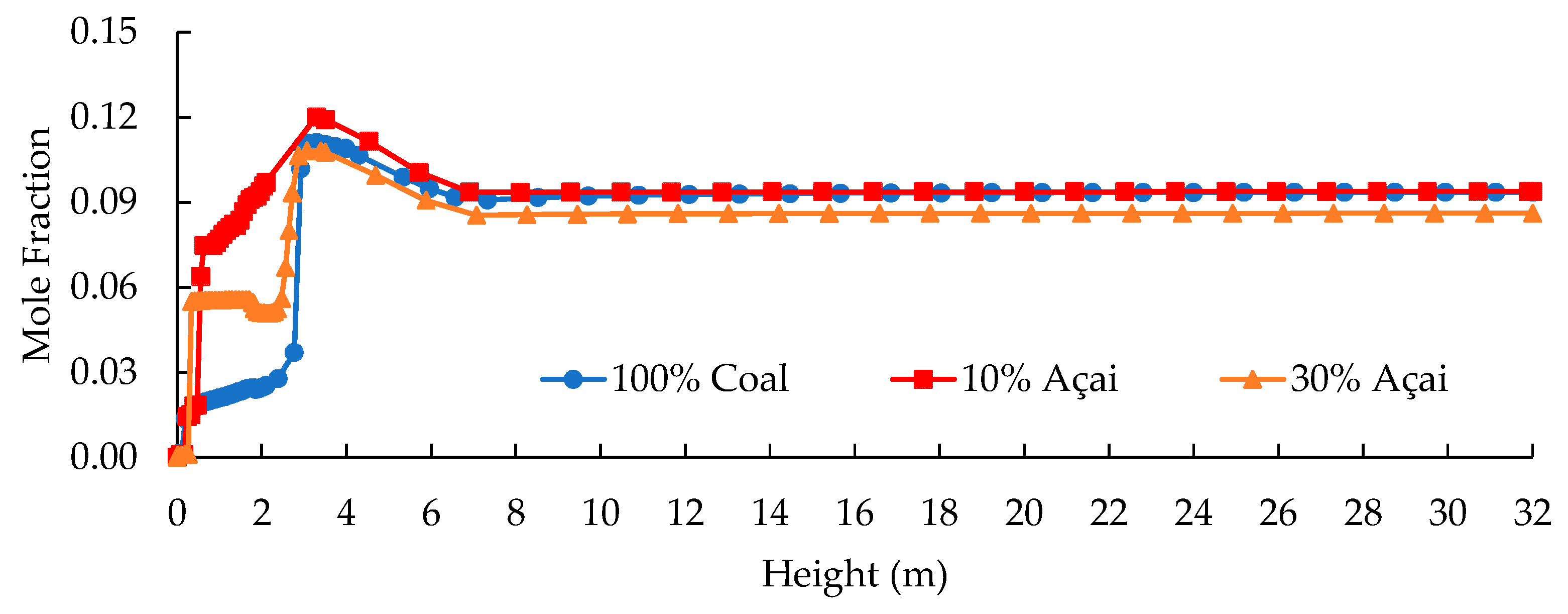

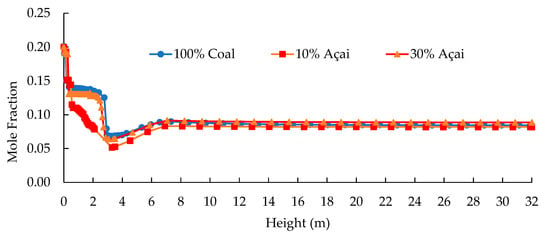

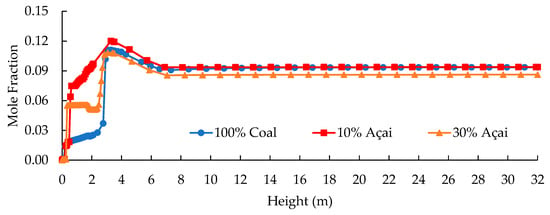

To better understand the behavior of combustion in the equipment, the variation in the mole fraction of CO2 and O2 was analyzed, as shown in Figure 11 and Figure 12, respectively.

Figure 11.

O2 mole fraction profile in combustion chamber. Primary air at 0 m, secondary air at 1.81, 4.81 and 5.5 m.

Figure 12.

CO2 mole fraction profile in the combustion chamber. Primary air at 0 m, secondary air at 1.81, 4.81 and 5.5 m.

The O2 and CO2 mol fraction profiles for all cases have a similar behavior, with small variations. However, it is noted that with the presence of açai seed in the mixture, the production of CO2 and the consumption of O2 occurs more rapidly up to 4 m in height, which supports the conclusion that in the initial stages, the açai seed volatiles combustion is predominant, increasing the rate of CO2 production and O2 consumption. This is shown by the temperature increase in the region.

3.6.3. Emissions Analysis

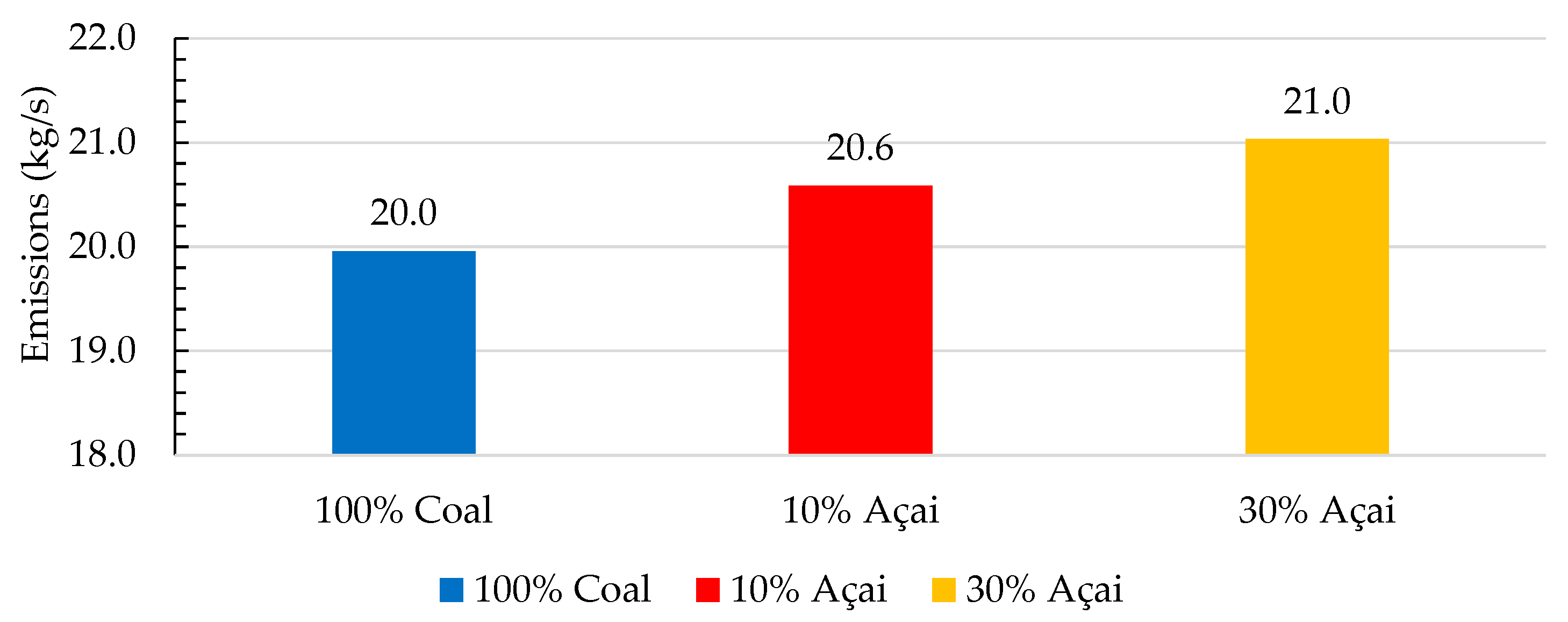

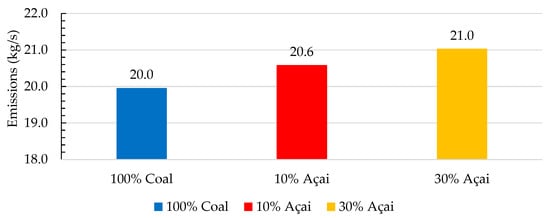

Gas emission analysis was carried out in the CFB loop, without considering the chimney filters due to the limitations of the simulation software. Therefore, the results only reflect the emissions generated during the combustion process in the circulating fluidized bed, without taking into account any reductions that could occur in the chimney filters. The CO2 emission is shown in Figure 13.

Figure 13.

CO2 emissions.

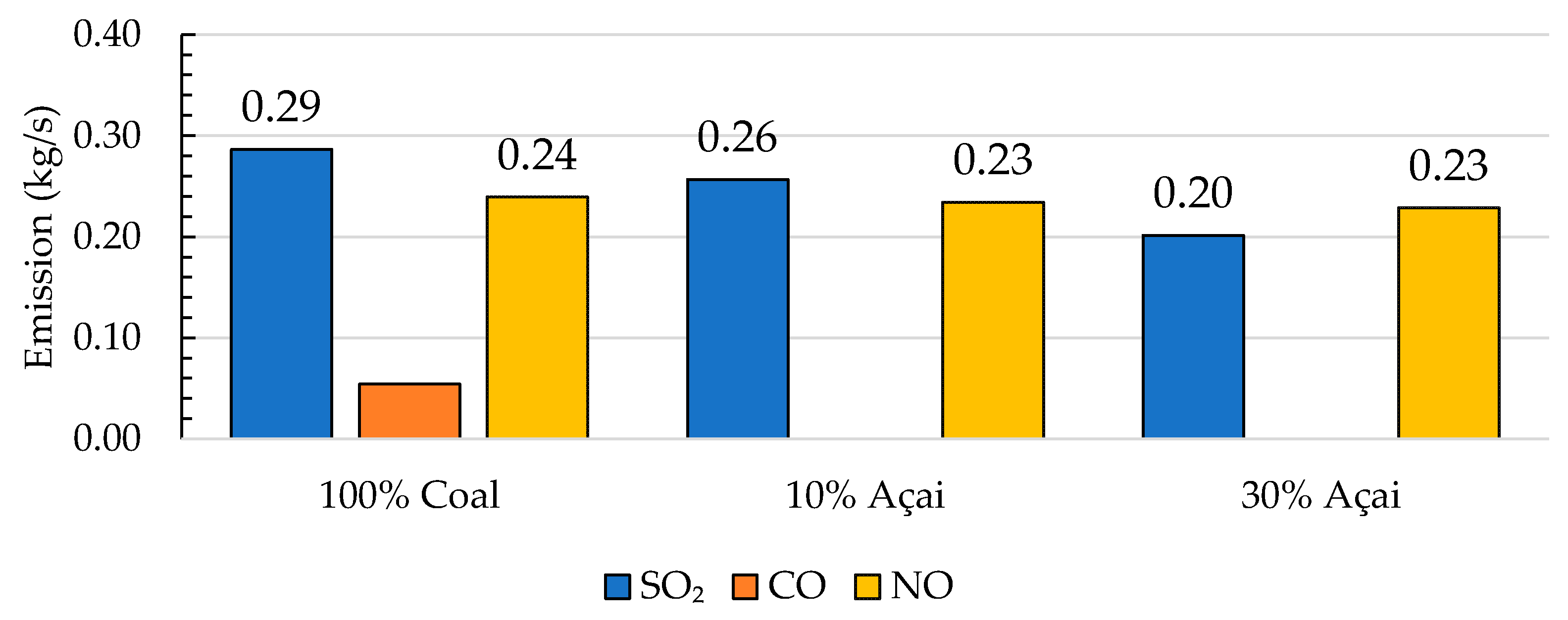

An increase in CO2 emissions was observed with the presence of açai seed, caused by the need for a greater amount of fuel to compensate for its lower LHV compared to coal. Specifically, while the exclusive burning of coal resulted in a CO2 production of 20.0 kg/s, the addition of 10% and 30% açai seed increased this production to 20.6 kg/s and 21.0 kg/s, respectively. The production of CO, NOx and SO2, which are also polluting gases, was also analyzed, and the production of each is shown in Figure 14.

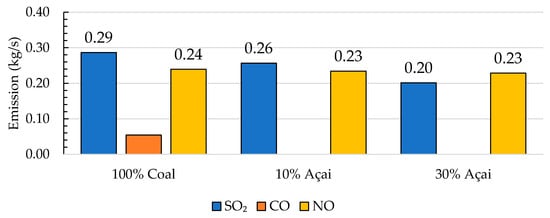

Figure 14.

SO2, CO and NO emissions.

CO emissions were reduced with the inclusion of açai seed, suggesting a more effective combustion.

For the NO emissions, on CFB combustion, thermal NO is not the major source of NO once the combustion average temperature is around 800 °C. The amount of nitrogen added with the fuel is the main cause [34]. Once the coal and açai seed have similar mass fractions of nitrogen, the second is smaller in Table 5, a stabilization was observed regardless of the amount of açai seed in the mixture.

Regarding the SO2 emissions, a reduction was recorded. Despite the sulfur mass fraction being around ten times larger in the coal compared with the açai seed, such a difference did not impact SO2 emission on the same scale. It is due to the fact that a minor fraction of coal was replaced by açai seed, causing a small reduction [35]. Once the açai seed fraction increases, such emissions are reduced.

4. Conclusions

Previous research has explored the utilization of biomass as a co-fuel in various combustion systems. The present study built upon this foundation by specifically investigating the impact of açai seed on the co-combustion performance with bituminous coal. The results align with previous findings that biomass co-combustion can enhance efficiency and reduce emissions. However, the unique characteristics of açai seed, such as its shape, composition and reactivity, contribute to distinct combustion dynamics, as evidenced by the combustion chamber temperature increase and faster O2 consumption. The results indicated that sulfur monoxide emissions declined by 31% in the fuel blend with 30% açai seed. Furthermore, the addition of açai to the fuel mix resulted in a reduction in CO2 emissions from fossil fuels. Additionally, the presence of açai seed in the fuel mix was found to effectively control nitrogen monoxide emissions, which is a significant contributor to acid rain. This evidence demonstrates that co-firing biomass and coal can facilitate the transition to cleaner energy sources.

The co-combustion of açai seed and coal in circulating fluidized bed boilers showed greater efficiency, proving that co-combustion has the capacity to produce more steam when compared to the combustion of coal alone. Reduced SO2 emissions were also found due to greater limestone conversion, with a reduction from 0.29 kg/s in an environment with 100% coal to 0.20 kg/s in an environment with 30% açai seed. The incorporation of the residue resulted in a marginal decline in NOx emissions. However, its primary benefit lies in its stability, as even with the addition of more mass to the system, emissions of nitrogen monoxide remained consistently stable. As for CO2 production, as the flow of fuel increased, it was to be expected that an increase in emissions would occur. However, with the greater participation of biomass, a considerable part of the emissions will no longer come from fossil fuels but from renewable sources that are part of the natural carbon cycle, thus showing that açai seed is a viable alternative to coal.

Author Contributions

G.C.P.S., J.V.R.M. and F.H.B.S. carried out field research to obtain boiler geometrical as well as its operational parameters. G.C.P.S. and J.V.R.M. performed data implementation in CeSFaMB™® v4.3.0, results consistency and obtained conclusions. J.V.R.M. performed laboratory analysis, namely, ultimate, proximate, calorimetric, thermogravimetric, density and size analysis. Conceptualization and methodology: D.R.S.G. and M.F.M.N.; software, validation: D.R.S.G.; formal analysis, investigation, resources and data curation: G.C.P.S., J.V.R.M., F.H.B.S., D.R.S.G. and M.F.M.N.; writing—original draft preparation, writing—review and editing, visualization: G.C.P.S., J.V.R.M., D.R.S.G. and M.F.M.N.; supervision: M.F.M.N. and D.R.S.G.; project administration: M.F.M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This work received funding support from Norsky Hydro, Brazil, within the scope of the project “Estudo logístico e energético para combustão de caroço de açai” (UFPA 036046/2021—HYDRO TAC-01 4600009900). Fundação Amazônia de Amparo a Estudos e Pesquisa—FAPESPA sponsored scholarships for Gabriel da Cruz Pereira Soares and Fernando Henrique de Barbosa dos Santos through UFPA/PPGEM. Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brazil (CAPES) sponsored scholarships for João Victor Ribeiro Moreira through UFPA/PPGEM.

Data Availability Statement

Data available on request because of project policies.

Acknowledgments

Thanks to Marcio L. de Souza-Santos from University of Campinas (UNICAMP), Faculty of Mechanical Engineering, Department of Energy, CP 6122, Campinas, SP 13083-970, Brazil, who is the owner of the CeSFaMB™® v4.3.0 software and kindly allowed its use in this research. The Graduate Program in Mechanical Engineering-PPGEM at UFPA.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Varapiang, T.; Rangton, N.; Nukkhong, W.; Wises, P.; Piumsomboon, P.; Piemjaiswang, R.; Chalermsinsuwan, B. Digital twin of biomass/coal co-firing circulating fluidized bed boiler by using computational fluid dynamics simulation. Energy Rep. 2023, 9, 6–9. [Google Scholar] [CrossRef]

- Empresa de Pesquisa Energética (EPE). Brazilian Energy Balance: Year 2023. Available online: https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/balanco-energetico-nacional-2023 (accessed on 16 July 2023).

- Alves, E.P.R.; Salcedo-Puerto, O.; Nuncira, J.; Emebu, S.; Mendoza-Martinez, C. Renewable Energy Potential and CO2 Performance of Main Biomasses Used in Brazil. Energies 2023, 16, 3959. [Google Scholar] [CrossRef]

- Moreira, J.; Carneiro, A.; Oliveira, D.; Santos, F.; Guerra, D.; Nogueira, M.; Rocha, H.; Charvet, F.; Tarelho, L. Thermochemical Properties for Valorization of Amazonian Biomass as Fuel. Energies 2022, 15, 7343. [Google Scholar] [CrossRef]

- Brazilian Institute of Geography and Statistics (IBGE). Agricultural Production: Brazil and Federation Units. 2022. Available online: https://www.ibge.gov.br/explica/producao-agropecuaria/acai-cultivo/br (accessed on 16 July 2023).

- Miranda, L.d.V.A.; Mochiutti, S.; da Cunha, A.C.; Cunha, H.F.A. Discarding and final destination of açai lumps in the Oriental Amazon—Brazil. Ambiente Soc. 2022, 25, e01382. [Google Scholar] [CrossRef]

- Dong, H.; Jiang, X.; Lv, G.; Chi, Y.; Yan, J. Co-combustion of tannery sludge in a commercial circulating fluidized bed boiler. Waste Manag. 2015, 46, 227–233. [Google Scholar] [CrossRef] [PubMed]

- Sami, M.; Annamalai, K.; Wooldridge, M. Co-Firing of Coal and Biomass Fuel Blends. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0360128500000204 (accessed on 4 May 2024).

- Liu, J.; Jiang, X.; Zhou, L.; Wang, H.; Han, X. Co-firing of oil sludge with coal-water slurry in an industrial internal circulating fluidized bed boiler. J. Hazard. Mater. 2009, 167, 817–823. [Google Scholar] [CrossRef] [PubMed]

- Hagman, H.; Backman, R.; Boström, D. Effects on a 50 MWth circulating fluidized-bed boiler co-firing animal waste, sludge, residue wood, peat, and forest fuels. Energy Fuels 2013, 27, 6146–6158. [Google Scholar] [CrossRef]

- de Almeida, S.G.; Tarelho, L.A.; Hauschild, T.; Costa, M.A.M.; Dussán, K.J. Biochar production from sugarcane biomass using slow pyrolysis: Characterization of the solid fraction. Chem. Eng. Process.-Process Intensif. 2022, 179, 109054. [Google Scholar] [CrossRef]

- Gani, A.; Erdiwansyah; Desvita, H.; Munawar, E.; Mamat, R.; Nizar, M.; Darnas, Y.; Sarjono, R.E. Comparative analysis of HHV and LHV values of biocoke fuel from palm oil mill solid waste. Case Stud. Chem. Environ. Eng. 2024, 9, 100581. [Google Scholar] [CrossRef]

- Nanda, S.; Swain, B.; Priyadarsini, A.; Mishra, A.; Parida, M.R.; Jena, P.K.; Mohanty, M.K.; Dash, M. Thermodynamic, spectroscopic, and molecular characterization of rice straw biomass for use as biofuel feedstock. Can. J. Chem. Eng. 2024, 102, 1842–1851. [Google Scholar] [CrossRef]

- Salhi, M.; Berrich, E.; Romdhane, M.; Aloui, F. Experimental investigation of additives effect on olive pomaces pyrolysis: Oyster shells and olive mill waste water. Biomass Bioenergy 2023, 175, 106815. [Google Scholar] [CrossRef]

- Tsai, W.-T.; Han, J.-W. Thermochemical characterization of husk biomass resources with relevance to energy use. J. Therm. Anal. Calorim. 2023, 148, 8061–8069. [Google Scholar] [CrossRef]

- Akinyemi, S.A.; Bohórquez, F.; Islam, N.; Saikia, B.K.; Sampaio, C.H.; Crissien, T.J.; Silva, L.F. Petrography and geochemistry of exported Colombian coals: Implications from correlation and regression analyses. Energy Geosci. 2021, 2, 201–210. [Google Scholar] [CrossRef]

- Breeze, P. Coal-Fired Generation; Elsevier Science: Amsterdam, The Netherlands; Academic Press: Cambridge, MA, USA, 2015; 98p. [Google Scholar]

- de Souza-Santos, M.L.; Chavez, J.V. Preliminary studies on advanced power generation based on combined cycle using a single high-pressure fluidized bed boiler and consuming sugar-cane bagasse. Fuel 2012, 95, 221–225. [Google Scholar] [CrossRef]

- de Souza-Santos, M.L. A new version of CSFB, comprehensive simulator for fluidized bed equipment. Fuel 2007, 86, 1684–1709. [Google Scholar] [CrossRef]

- de Souza-Santos, M.L. Solid Fuels Combustion and Gasification: Modeling, Simulation, and Equipment Operations, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2010; 508p. [Google Scholar] [CrossRef]

- de Souza-Santos, M.L. Comprehensive Simulator (CSFMB) Applied to Circulating Fluidized Bed Boilers and Gasifiers. Open Chem. Eng. J. 2008, 2, 106–118. [Google Scholar] [CrossRef]

- Basu, P. Circulating Fluidized Bed Boilers Design, Operation and Maintenance; Spring: Dordrecht, The Netherlands, 2015; 370p. [Google Scholar] [CrossRef]

- ABNT NBR 16508; Matérias Primas para Fundição–Carvão Mineral–Método de Ensaio para Determinação do Teor de Umidade. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- CEN/TS 14774-1; Methods for Determination of Moisture Content–Oven Dry Method–Part 1: Total Moisture–Reference Method. European Committee for Standardization: Brussels, Belgium, 2004.

- Wardach-Święcicka, I.; Polesek-Karczewska, S.; Kardaś, D. Biomass Combustion in the Helically Coiled Domestic Boiler Combined with the Equilibrium/Chemical Kinetics CFD Approach. Appl. Mech. 2023, 4, 779–802. [Google Scholar] [CrossRef]

- ABNT NBR 16587; Matérias Primas para Fundição–Carvão Mineral–Determinação do Teor de Materiais Voláteis. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- ABNT NBR 16586; Matérias Primas para Fundição–Carvão Mineral–Métodos para Determinação do Teor de Cinzas. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- CEN/TS 15148; Methods for the Determination of the Content of Volatile Matter. European Committee for Standardization: Brussels, Belgium, 2005.

- CEN/TS 14775; Methods for Determination of Ash Content. European Committee for Standardization: Brussels, Belgium, 2004.

- Barreto, E.J.; Rendeiro, G.; Nogueira, M. Combustão e Gaseificação de Biomassa Sólida: Soluções Energéticas para a Amazônia, 1st ed.; Ministério de Minas e Energia: Brasília, Brazil, 2008; 194p. [Google Scholar]

- NBR NM 248; Agregados—Determinação da Composição Granulométrica. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2003.

- NBR NM 52; Agregado Miúdo—Determinação da Massa Específica e Massa Específica Aparente. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2003.

- Álvarez, A.; Pizarro, C.; García, R.; Bueno, J.; Lavín, A. Determination of kinetic parameters for biomass combustion. Bioresour. Technol. 2016, 216, 36–43. [Google Scholar] [CrossRef] [PubMed]

- Birley, R.I. Additives for the Reduction of NOx Emissions in Large Scale Solid Fuel Combustion. Doctoral Dissertation, University of Leeds, Leeds, UK, 2020. [Google Scholar]

- Buryan, P. Effect of biomass on the compliance with emission limits in fluidized-bed boiler desulfurization. Energy Fuels 2017, 31, 119–123. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).