Abstract

Climate change demands urgent action to limit greenhouse gas (GHG) emissions and explore methods for atmospheric carbon removal. Forest residues, a significant biomass resource, represent a readily available solution. With the use of life cycle assessment (LCA), this study investigates the environmental advantages of thermochemical processes utilizing forest residues to produce valuable energy-dense products, like syngas, bio-oil, and biochar, providing a carbon sink. While slow pyrolysis emphasizes biochar production for carbon sequestration, gasification focuses on bioenergy generation. This research evaluates the environmental performance of both techniques in terms of carbon sequestration and GHG emissions mitigation. This comprehensive analysis aims to identify critical factors influencing the environmental sustainability of thermochemical processes in forest management. The findings aim to contribute to achieving sustainable development goals by highlighting the environmental advantages of biochar in mitigating climate change.

1. Introduction

Global climate change is occurring at an alarming pace. To prevent a potentially catastrophic impact on global society, it is essential to prevent temperature rising no more than 1.5 °C compared to preindustrial levels [1]. In addition to swiftly decreasing human-generated GHG emissions, there is an urgent necessity to explore and implement rapid carbon dioxide removal strategies [2]. The utilization of biomass presents a readily accessible solution. Bioenergy is highly preferred as a renewable energy source due to its abundant reserves, extensive distribution, and minimal carbon emissions. Moreover, forest residues, being one of the significant biomass resources, hold substantial potential for displacing fossil fuels [3,4]. Nevertheless, on a global scale, just 65% of forest residues are employed for bioenergy, with the remaining portion often left unutilized. Unutilized forest residues left to decompose in the forest emit carbon dioxide, contributing to climate change [5]. In some regions, they are incinerated, leading to CO2 release into the atmosphere and contributing to smog and particulate matter [6]. Thermochemical processes are among the most promising technologies for converting biomass, with the potential to produce both renewable energy and valuable materials [7]. Different pyrolysis technologies can be tailored to suit various applications, considering factors like feedstock types, geographical locations, and scale [8,9]. Pyrolysis is commonly categorized into different types, ranging from slow to fast based on differences in heating rates and residence times, leading to varying proportions of primary products, such as syngas, bio-oil, and biochar [10,11,12]. Usually, fast pyrolysis follows a heating rate of 10–200 °C/s, with lower rates between 0.1–10 °C/s referred to as slow pyrolysis. Fast pyrolysis temperatures typically occur between 400 and 800 °C and slow pyrolysis between 300 and 700 °C, although some sources suggest wider ranges [12]. Slow pyrolysis, with low heating rates and moderate temperatures, promotes biochar production, while fast pyrolysis favors the generation of bio-oil and syngas. As pyrolysis temperature rises, the yield of biochar decreases, but the carbon content and aromatic condensation of the biochar increase [13]. Pyrolysis could be followed by gasification. Gasification, an industrial thermochemical process, can be used to produce energy, with biochar as a low-cost byproduct. In this process, by heating the products of pyrolysis reactions to higher temperatures and adding a gasification agent (air or oxygen), they can be further converted into a gas mixture containing carbon monoxide, carbon dioxide, hydrogen, methane, and nitrogen. Biochar is a solid carbon-rich product obtained by heating biomass in an oxygen-limited environment, such as pyrolysis [14,15,16]. In line with IPCC recognition in 2019, biochar is now acknowledged as a technology for CO2 removal. Sequestering atmospheric carbon dioxide can be achieved efficiently by producing biochar and incorporating it into the soil [17]. Biochar has shown great promise as a soil amendment in recent years due to its unique physical and chemical characteristics and interactions with soil systems. Biochar’s molecular structure, characterized by its high chemical and microbial breakdown resistance, improves soil fertility, nutrient retention, and water-holding capacity when added to soils. The porous structure of biochar provides a habitat for beneficial microorganisms, contributing to healthier soils and promoting plant growth. Moreover, biochar’s porous structure makes it a versatile material with potential applications in removing harmful chemicals from contaminated waters [18], storing hydrogen as an energy carrier [19], and serving as a carbon-activated material to enhance carbon potential capacitive performances [20]. These properties contribute to its role in promoting circular economy principles and improving ecological conditions. Demonstrating the environmental advantages of biochar applications is a crucial prerequisite before commercialization and widespread implementation [21,22,23,24]. Recently, there has been a growing focus on conducting life cycle assessments (LCAs) for large-scale biochar production, reflecting its increasing importance [25,26,27,28,29,30].

Therefore, a thorough evaluation of the impact of unused forest residues on climate change can encourage increased efforts to utilize these resources for decarbonization purposes, thereby improving economic viability, particularly if carbon trading mechanisms are implemented [31].

Life cycle assessment (LCA) stands as the most commonly employed tool for evaluating the environmental sustainability of diverse products or services. It represents a systematic approach to appraising the environmental consequences of a product over its entire life cycle. LCA’s holistic vantage point helps prevent the displacement of issues among various life cycle stages, impacts, or geographical areas [32].

Numerous field studies [33,34,35] and model-based simulations [36,37,38,39,40] have assessed the climate benefits of substituting fossil energy with forest residues.

During forest harvest operations, a significant amount of nonmerchantable woody residue is typically left in piles and burned. This burning process generates air pollution and releases CO2 into the atmosphere. Alternatively, these nonmerchantable woody residues can be converted into biochar at various scales, ranging from small-scale to large-scale bioenergy facilities, offering opportunities for both merchantable and nonmerchantable woody biomass, including integrating bioenergy production with carbon capture and sequestration. Different methods for creating biochar can generate heat and sequester carbon in different proportions [40]. Arfelli et al. [29] discussed the environmental benefits of the gasification process by using different woody biomasses and specifically residues. Carbon stock, due to the application of biochar on soil, and avoided emissions, due to energy and heat produced, have been accounted for. Safarian [41] conducted a comparative analysis of GHG emissions from traditional biomass energy production in Sweden, Italy, and Poland, considering different electricity and heat generation systems. While gasification was not evaluated, different pyrolysis temperatures were explored to identify the most effective operating conditions.

This study presents a comprehensive analysis of the environmental benefits of two different thermochemical processes applied to residual woody biomasses: one maximizing biochar production at the expense of energy production (slow pyrolysis), and one that prioritizes energy production over biochar yield (gasification) [42,43]. This analysis is conducted using a case study in Italy, a country that is not energy self-sufficient. In 2020, Italy’s energy dependence on foreign sources was approximately 75% [44]. At the same time, in Italy, the total wooded area covers almost 36 of the overall country area, of which forest covers approximately 30% and other wooded land 6.5% [44]. For these reasons, the energetic valorization of biomass in conjunction with carbon stock could be particularly significant at a national level. While there is extensive research on the potential and benefits of converting woody biomass through thermochemical processes, no articles specifically address the differences achievable by using the selected two distinct processes while considering both carbon stock and avoided emissions [41] and encompassing a full set of environmental impact categories by applying life cycle assessment methodology [29,45,46,47,48,49,50].

The primary objective of this study is to investigate and assess the key factors influencing the sustainability of thermochemical processes, focusing on biochar production and its use as a soil amendment in forest management and energy production. The aim is to thoroughly analyze the environmental benefits associated with managing forest residues, focusing on aspects like carbon sequestration from biochar and avoided emissions from energy produced from alternative renewable sources.

Ultimately, this research strives to contribute to achieving sustainable development goals by enhancing our understanding of the potential advantages offered by thermochemical processes applied to the wood residual biomasses. In particular, the renewable energy products generated from the processes make a valuable contribution to SDG 7 (Affordable and Clean Energy), which provides an environmentally positive substitute for conventional fossil fuels. Moreover, incorporating biochar into the soil is consistent with SDG 13, which aims to mitigate climate change.

2. Materials and Methods

2.1. Goal and Scope

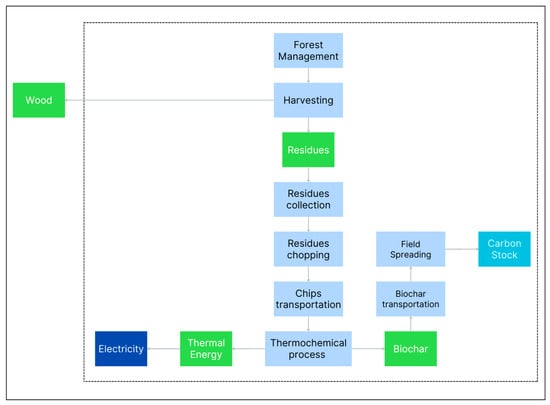

This study aims to calculate the carbon balance by quantifying the energy and material inputs and outputs associated with biochar production. Therefore, the analysis was designed to evaluate the full range of environmental benefits achievable through thermochemical processes for energy (bio-oil and syngas) and biochar production, including increased soil carbon stock and avoided impacts from alternative energy production. The scope includes two thermochemical processes, namely, the GAS and SLOW prototypes. The LCA includes the environmental impacts of input materials, such as fuels and electricity, as well as the resulting outputs, including biochar, energy, waste, and emissions. The life cycle assessments adhered to ISO 14040 and ISO 14044 standards [51,52]. SimaPro 9.4 Analyst software (PRé Consultants B.V., Amsterfoort, The Netherlands) was employed to create the life cycle inventory (LCI) models and generate results and analyses with IPCC 2021 GWP100 V1.00 and EF 3.0 methodologies [53]. The reference period is 2020–2022, and the collected data encompass both primary data (Table 1), gathered through direct surveys, and secondary data obtained from the literature, databases, technical manuals, other studies, and calculations. The functional unit (FU) for the LCAs of the selected thermochemical processes is one metric ton (1000 kg) of forest residues from a mixture of wood, mainly Turkey oak and beech. The system boundaries include the chipping phase, pyrolysis with the production of syngas and biochar, the application of biochar to forest soil, and related transportation. The chipping storage phase and the disposal of ashes produced by the pyrogasification plant are excluded (Figure 1). Ecoinvent 3.8 (Ecoinvent, Zurich, Switzerland) was used as the dataset for background data. All background data used the allocation at point of substitution (APOS) approach [54].

Table 1.

Specific inventory data (input and output) relating to the energetic valorization of residual biomasses from forests in Italy (primary data).

Figure 1.

System boundary of life cycle assessment.

2.2. Inventory

2.2.1. Harvesting, Chipping, and Transportation

The process of collecting forest residues is outlined in Table 1. The residual biomass, before chipping, has an average density of 30 kg/m3. An estimated 216 MJ/ton was calculated for the collection and chipping of residual biomass [55]. Transport from the forest road to the collection site is carried out by tractor and trailer with a load capacity of 4 tons, distance of 4 km, average forward speed of 10 km/h, and consumption of 20 L/h of diesel. Transportation from the collection point to the thermochemical process plants covers a distance of 35 km using a Euro 6-class vehicle with a load capacity of 3.5–7.5 tons.

2.2.2. Thermochemical Processes

The wood chips having various sizes (<20 mm), shapes, and an average density of 240 kg/m3 are alternately directed to the two plants. Heat, electricity, and quantities of biochar produced were obtained from primary data (Table 1). Wood chips combustion avoids the heat produced by natural gas combustion and electricity generation at the national level. The following Ecoinvent v. 3.5 processes were used as avoided processes: “Heat, district or industrial, natural gas {Europe without Switzerland}|heat production, natural gas, at industrial furnace >100 kW | APOS, U” and “Electricity, high voltage {IT}| electricity production, natural gas, conventional power plant | APOS, U”.

2.2.3. Transportation, Biochar Spreading, and CO2 Sequestration

It was assumed that the biochar would be transported back to the branch collection point (35 km from the pyrogasification site) using a Euro 6-class vehicle with a 3.5–7.5 tons load capacity. For spreading, the process from Ecoinvent v. 3.5 was used: “Solid manure loading and spreading, by hydraulic loader and spreader {GLO}| market for | APOS, U”. The stored CO2 was calculated assuming that the residual carbon in the soil after 100 years would be 80% of the applied carbon, while the C content in the biochar was derived from primary data (64.1% on dry matter biochar produced by the slow pyrolysis prototype, 63.9% on dry matter biochar produced by the fast pyrolysis prototype). The conversion factor from C to CO2 was obtained from the ratio of their molar masses. To estimate biogenic CO2 emissions, the initial C content in the woody biomass was calculated, considering a dry matter content of wood chips equal to 70% of the wet mass and a carbon content equal to 50% of the dry matter (0.35 tons of C/ton of wood chips). The difference between the initial C content and the content stored at 100 years, converted to CO2 using the factor 3.67, was considered as the total biogenic CO2 emitted in the thermochemical and soil retention phases.

3. Results and Discussion

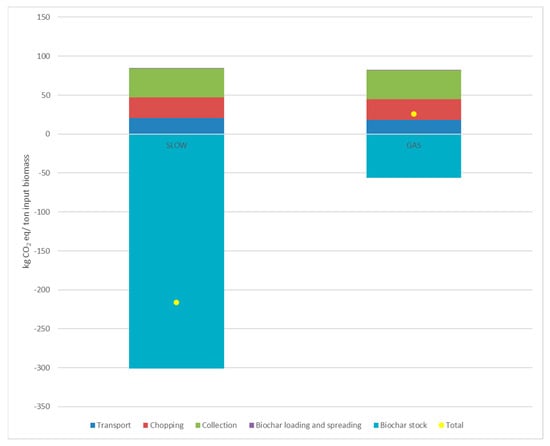

Figure 2 illustrates the global warming potential (GWP) for the two different thermochemical systems analyzed, measured per 1000 kg of input biomass. It should be noted that the GWP emissions depicted in Figure 2 exclude emissions from biogenic carbon dioxide produced. For SLOW systems, CO2 stock from biochar application compensates the total GWP emissions from the harvesting, chopping, collecting, and transporting forest residues. In contrast, for the GAS system, roughly 70% of the total GWP emissions can be compensated by biochar CO2 stock due to reduced biochar production rates. The quantities of biochar obtained from the two different thermochemical plants and relative to the input biomass are consistent with the available literature for similar processes. Biomass type, temperature, and residence time can influence the final yields [56,57,58].

Figure 2.

Global warming potential (excluding avoided impact) for the two different biochar production systems analyzed (SLOW and GAS), measured per 1000 kg of input biomass.

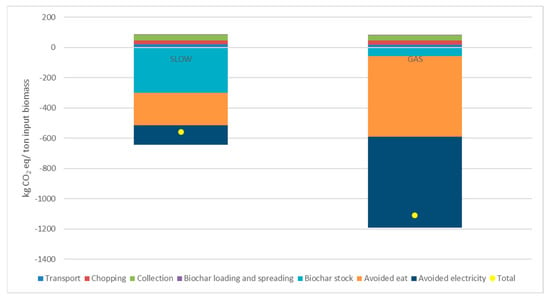

Different results are obtained when the CO2 stock resulting from biochar application in forest soils is combined with the environmental benefit of avoided emissions. In fact, the processing of residual woody biomass in the selected plants generates thermal and electrical energy in quantities gathered from primary data provided by the plants under study and reported in Table 1. These quantities are assumed to replace an equivalent amount of thermal MJ and electrical MWh that would otherwise be assumed to be produced by natural gas combustion. In this case, the higher energy yield of the GAS process scenario leads to greater benefits in terms of GHG emissions, as shown in Figure 3. In this latter case, 1 ton of residual woody mass in GAS process has negative emissions corresponding to 1110 kg CO2eq, compared to 558 obtained through slow pyrolysis.

Figure 3.

Global warming potential (including avoided impact) for the two different biochar production systems analyzed (SLOW and GAS), measured per 1000 kg of input biomass.

This study aligns with previous LCA research considering biochar’s potential to mitigate climate change through direct carbon sequestration. In fact, when residual biomass is employed in the chosen thermochemical processes, much of the carbon initially captured by plants from the atmosphere during photosynthesis is retained within the resulting products, rather than being released back into the air through combustion. When added to the soil, biochar acts as a C sink, effectively capturing and retaining C, preventing its release back into the atmosphere as CO2 [59]. Moreover, beyond direct carbon sequestration, the offset due to bioenergy production is accounted for by considering the avoided energy and heat production [60,61,62]. Our results align with those reported by Ramachandran et al. [60], who found that the net GHG emissions are −438.4 g CO2eq/FU. In Ramachandran’s study, FU was chosen to be 0.2 kg of sewage sludge and 0.8 kg of woody biomass. Beyond the biogenic emissions and carbon credits for grid electricity substitution, as in the current study for SLOW pyrolysis, the most significant contributor to negative net emissions in the proposed system is the CO2 sequestered in biochar. In fact, the codigestion of 1 kg of sewage sludge and woody biomass produces 9.8% of biochar, avoiding, at the same time, the use of direct fossil emissions for sewage sludge incineration. Usually, other potential benefits of biochar use are not considered, like the reduced fertilizer use and the increased agronomic yields [63,64,65,66,67], and in the present case, it is very difficult to estimate them due to the soil forest reuse. Moreover, in the present paper, other potential uses of biochar and possible environmental benefits are not considered. While biochar has various applications, its most notable uses include removing organic pollutants and heavy metals from wastewater and serving as a renewable carbon source in slag foaming. Research on woody biomass offers insights into producing biochar from forest residues using portable systems [42,68]. These portable systems aim to decrease the costs and environmental footprint associated with transporting forest residues to industrial sites. This is especially relevant for residual woody biomass with low bulk density [69]. The benefits of using portable systems are primarily measured by the carbon stock resulting from biochar application in forest soils. Additionally, they offer other advantages, such as avoiding emissions from open burning, which have significant implications for human health [70] and influence wildfire behavior. However, other avoided emissions cannot be considered because these systems do not produce energy.

The results of the current study, even without accounting for avoided emissions, indicate that in the case of slow pyrolysis, the distance from the collection point to the pyrolysis plant can be up to 400 km to maintain a carbon-neutral process. For GAS process, the minimal amount of biochar produced is insufficient to offset the emissions from the process. Therefore, in this specific scenario, the distance should be reduced to 6.5 km, compared to the previously estimated 35 km, to have carbon neutrality.

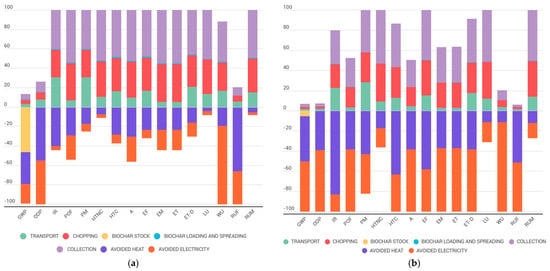

As with other studies, the EF 3.0 methodology was used to assess the environmental impacts of biochar production in various categories, considering CO2 stock and avoided impacts from produced energy (see Figure 4). In the GAS process, the avoided impacts offset the impacts in 12 out of 14 impact categories, with results mainly affected by avoided emissions (see Figure 4b). These results evidence the ability of the avoided impacts to counterbalance the produced impacts in a significant portion of the evaluated categories. The SLOW pyrolysis process demonstrates a notable environmental benefit only in 4 out of the 16 impact categories, mainly because, in this case, biochar production is maximized compared to energy production (see Figure 4a).

Figure 4.

Contribution of different processes to various EF impact categories for slow (a) and fast (b) pyrolysis.

Although the results seem more favorable with avoided impacts, it is important to emphasize that the “avoided impacts” are included in the system expansion allocation procedure. System expansion relies heavily on precise data and can be prone to significant uncertainty or inaccuracies. The implementation of this approach is difficult as the results are highly dependent on the substitute selected in the reference system. For instance, geographical location and technological level can greatly impact the outcomes [71]. This is not the case for carbon stock related to biochar. It is important to note that in the current work, only the carbon stock resulting from biochar application was considered, without considering its effect on the carbon soil pool. Some authors argue that the “carbon equivalence” between fossil and biological CO2 is debatable. In fact, carbon accounting often renders fossil and biotic forms of carbon, i.e., from fossil fuels vs. land use, land use change, and forestry, equivalent, allowing fossil fuel emissions to be “offset” by increases in biological carbon sequestration. A major issue with this equivalence lies in the different timescales: fossil carbon is essentially permanent, while biotic carbon is part of the short-term cycle. The temporal disparity between fossil and biotic carbon fundamentally limits their equivalence. In contrast, biochar contains stable carbon: 75% of biochar C consists of stable polycyclic aromatic carbon (PAC) and will persist after soil application for more than 1000 years, independent of soil texture and climate. The remaining 25% of the biochar C may be considered as semipersistent carbon (SPC), with a mean residence time in soil of 50 to 100 years, depending on soil texture and climate. In this paper, only the stable carbon has been considered of the two distinct carbon pools with different degrees of permanence [72].

4. Conclusions

This study assessed the environmental impacts of producing biochar from forest residues using two different pyrolysis systems, GAS and SLOW, located 35 km from the harvesting areas, through a cradle-to-grave life cycle assessment.

Overall, biochar production from forest residues generates GHG emissions ranging from −215 to 25 kg of CO2eq. per ton of forest residues for SLOW and GAS pyrolysis, respectively. The estimates of bioenergy production and avoided emissions are −558 and −1110 kg of CO2eq. per ton of forest residues for SLOW and GAS pyrolysis, respectively.

GAS pyrolysis is the most promising among the two biochar production systems when considering avoided impacts across the full set of impact categories. However, regarding permanent carbon stock, slow pyrolysis produces a larger share of biochar, contributing to stable carbon dioxide storage. This is true even without considering secondary effects on the soil carbon pool, crop yields, and other potential benefits that are difficult to estimate.

To summarize, both systems offer the potential for producing biochar while minimizing environmental impacts. This study provides essential insights for stakeholders and policymakers, improving the understanding of utilizing forest residues for biochar production while increasing the share of renewable energy in Italy. There are opportunities for economic development in mountainous and often marginalized regions. Establishing a sustainable bioproduct industry in Italy is feasible, especially if forest thinning is adopted for wildfire mitigation and biochar production from forest residues.

Author Contributions

Conceptualization, L.L.; methodology, L.L.; software, D.V. and L.L.; validation, D.V. and L.L.; formal analysis, D.V. and L.L.; investigation, D.V. and L.L.; resources, D.V. and L.L.; data curation, D.V. and L.L.; writing—original draft preparation, L.L.; writing—review and editing, D.V. and L.L.; visualization, D.V. and L.L.; supervision, L.L.; project funding acquisition, L.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Emilia-Romagna Region under the Rural Development Program 2014–2020, measure 16.1.01 “Operational Groups of the European Partnership for Agricultural Productivity and Sustainability”, Focus Area 5E, Research project: SMACS—Stream Management to Increase Carbon Stock in Soil and Project funded under the National Recovery and Resilience Plan (NRRP), Mission 04 Component 2 Investment 1.5—NextGenerationEU, Call for tender n. 3277 dated 30 December 2021. Award Number: 0001052 dated 23 June 2022. This work was also supported by the Project National Center for the Development of New Technologies in Agriculture (Agritech), funded under the National Recovery and Resilience Plan (NRRP), Mission 4 Component 2 Investment 1.4—Call for tender No. 3138 of 16 December 2021, rectified by Decree n. 3175 of 18 December 2021 of the Italian Ministry of University and Research, funded by the European Union, NextGenerationEU, Project code_CN 00000022, Concession Decree No. 1032 of 17 June 2022, adopted by the Italian Ministry of University and Research.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Allen, M.R.; Shine, K.P.; Fuglestvedt, J.S.; Millar, R.J.; Cain, M. A Solution to the Misrepresentations of CO2-Equivalent Emissions of Short-Lived Climate Pollutants under Ambitious Mitigation. npj Clim. Atmos. Sci. 2018, 1, 16. [Google Scholar] [CrossRef]

- Rogelj, J.; Popp, A.; Calvin, K.V.; Luderer, G.; Emmerling, J.; Gernaat, D.; Fujimori, S.; Strefler, J.; Hasegawa, T.; Marangoni, G.; et al. Scenarios towards Limiting Global Mean Temperature Increase below 1.5 °C. Nat. Clim. Chang. 2018, 8, 325–332. [Google Scholar] [CrossRef]

- Mäkipää, R.; Linkosalo, T.; Komarov, A.; Mäkelä, A. Mitigation of Climate Change with Biomass Harvesting in Norway Spruce Stands: Are Harvesting Practices Carbon Neutral? Can. J. For. Res. 2015, 225, 217–225. [Google Scholar] [CrossRef]

- Guest, G.; Bright, R.M.; Cherubini, F.; Strømman, A.H. Consistent Quanti Fi Cation of Climate Impacts Due to Biogenic Carbon Storage across a Range of Bio-Product Systems. Environ. Impact Assess. Rev. 2013, 43, 21–30. [Google Scholar] [CrossRef]

- Kukrety, S.; Wilson, D.C.; Amato, A.W.D.; Becker, D.R. Biomass and Bioenergy Assessing Sustainable Forest Biomass Potential and Bioenergy Implications for the Northern Lake States Region, USA. Biomass Bioenergy 2015, 81, 167–176. [Google Scholar] [CrossRef]

- Tagade, A.; Kirti, N.; Sawarkar, A.N. Bioresource Technology Reports Pyrolysis of Agricultural Crop Residues: An Overview of Researches by Indian Scientific Community Pyrolysis Biochar Bio-Oil Gas Soil Additive Activated Organic Acids Bio Based Chemicals. Bioresour. Technol. Rep. 2021, 15, 100761. [Google Scholar] [CrossRef]

- Zhu, X.; Labianca, C.; He, M.; Luo, Z.; Wu, C.; You, S.; Tsang, C.W. Bioresource Technology Life-Cycle Assessment of Pyrolysis Processes for Sustainable Production of Biochar from Agro-Residues. Bioresour. Technol. 2022, 360, 127601. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, Q.; Zheng, H.; Li, M.; Liu, Y.; Wang, X.; Peng, Y.; Luo, X.; Li, F.; Li, X.; et al. Soil & Environmental Health Biochar as a Sustainable Tool for Improving the Health of Salt-Affected Soils. Soil Environ. Health 2023, 1, 100033. [Google Scholar] [CrossRef]

- Chang, Z.; Tian, L.; Wu, M.; Dong, X.; Peng, J.; Pan, B. Molecular Markers of Benzene Polycarboxylic Acids in Describing Biochar Physiochemical Properties and Sorption Characteristics. Environ. Pollut. 2018, 237, 541–548. [Google Scholar] [CrossRef]

- Yang, X.; Ng, W.; Shu, B.; Wong, E.; Hun, G.; Wang, C. Characterization and Ecotoxicological Investigation of Biochar Produced via Slow Pyrolysis: Effect of Feedstock Composition and Pyrolysis Conditions. J. Hazard. Mater. 2019, 365, 178–185. [Google Scholar] [CrossRef]

- Chantanumat, Y.; Phetwarotai, W.; Sangthong, S.; Palamanit, A.; Abu Bakar, M.S.; Cheirsilp, B.; Phusunti, N. Characterization of Bio-Oil and Biochar from Slow Pyrolysis of Oil Palm Plantation and Palm Oil Mill Wastes. Biomass Convers. Biorefinery 2023, 13, 13813–13825. [Google Scholar] [CrossRef]

- Pahnila, M.; Koskela, A.; Sulasalmi, P.; Fabritius, T. A Review of Pyrolysis Technologies and the Effect of Process Parameters on Biocarbon Properties. Energies 2023, 16, 6936. [Google Scholar] [CrossRef]

- Yrjälä, K.; Ramakrishnan, M.; Salo, E. ScienceDirect Agricultural Waste Streams as Resource in Circular Economy for Biochar Production towards Carbon Neutrality. Curr. Opin. Environ. Sci. Health 2022, 26, 100339. [Google Scholar] [CrossRef]

- Moreira, M.T.; Noya, I.; Feijoo, G. Bioresource Technology The Prospective Use of Biochar as Adsorption Matrix—A Review from a Lifecycle Perspective. Bioresour. Technol. 2017, 246, 135–141. [Google Scholar] [CrossRef]

- Conte, P.; Bertani, R.; Sgarbossa, P.; Bambina, P.; Schmidt, H.-P.; Raga, R.; Lo Papa, G.; Chillura Martino, D.F.; Lo Meo, P. Recent Developments in Understanding Biochar’s Physical–Chemistry. Agronomy 2021, 11, 615. [Google Scholar] [CrossRef]

- Shah, H.H.; Amin, M.; Iqbal, A.; Nadeem, I.; Kalin, M.; Soomar, A.M.; Galal, A.M. A Review on Gasification and Pyrolysis of Waste Plastics. Front. Chem. 2023, 10, 960894. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management, 2nd ed.; Lehmann, J., Joseph, S., Eds.; Routledge: London, UK, 2015. [Google Scholar]

- Wei, S.; Tan, Z.; Liu, Z.; Zuo, H.; Xia, Y.; Zhang, Y. Removal of Methyl Orange Dye by High Surface Area Biomass Activated Carbon Prepared from Bamboo Fibers. Ind. Crops Prod. 2024, 218, 118991. [Google Scholar] [CrossRef]

- Turkyilmaz, A.; Isinkaralar, K.; Dogan, M.; Kocer Kizilduman, B.; Bicil, Z. Production, Characterization, and Hydrogen Storage Properties of Activated Carbon from Horse Chestnut Shell. Sustain. Chem. Pharm. 2024, 40, 101634. [Google Scholar] [CrossRef]

- Bao, Q.; Zhang, M.; Li, J.; Wang, X.; Zhu, M.; Sun, G. The Optimal Micro- and Meso-Pores Oriented Development of Eucommia Ulmoides Oliver Wood Derived Activated Carbons for Capacitive Performance. Renew. Energy 2024, 225, 120209. [Google Scholar] [CrossRef]

- He, M.; Xu, Z.; Hou, D.; Gao, B.; Cao, X.; Ok, Y.S.; Rinklebe, J.; Bolan, N.S.; Tsang, D.C.W. Waste-Derived Biochar for Water Pollution Control and Sustainable Development. Nat. Rev. Earth Environ. 2022, 3, 444–460. [Google Scholar] [CrossRef]

- Tiegam, T.; Raoul, D.; Tchuifon, T.; Santagata, R.; Alain, P.; Nanssou, K.; Gabche, S.; Ionel, I.; Ulgiati, S. Production of Activated Carbon from Cocoa Pods: Investigating Bene Fi Ts and Environmental Impacts through Analytical Chemistry Techniques and Life Cycle Assessment. J. Clean. Prod. 2021, 288, 125464. [Google Scholar] [CrossRef]

- Maroušek, J.; Minofar, B.; Maroušková, A.; Strunecký, O.; Gavurová, B. Environmental and Economic Advantages of Production and Application of Digestate Biochar. Environ. Technol. Innov. 2023, 30, 103109. [Google Scholar] [CrossRef]

- Li, S.; Tasnady, D. Biochar for Soil Carbon Sequestration: Current Knowledge, Mechanisms, and Future Perspectives. J. Carbon Res. 2023, 9, 67. [Google Scholar] [CrossRef]

- Hosseinian, A.; Brancoli, P.; Vali, N.; Ylä-Mella, J.; Pettersson, A.; Pongrácz, E. Life Cycle Assessment of Sewage Sludge Treatment: Comparison of Pyrolysis with Traditional Methods in Two Swedish Municipalities. J. Clean. Prod. 2024, 455, 142375. [Google Scholar] [CrossRef]

- Zhou, J.; Li, M.; Han, X.; Wang, B.; Zhang, C.; Cheng, Z.; Shen, Z.; Ogugua, P.C.; Zhou, C.; Pan, X.; et al. Environmental Sustainability Practice of Sewage Sludge and Low-Rank Coal Co-Pyrolysis: A Comparative Life Cycle Assessment Study. Sci. Total Environ. 2024, 928, 172255. [Google Scholar] [CrossRef]

- Xia, F.; Zhang, Z.; Zhang, Q.; Huang, H.; Zhao, X. Life Cycle Assessment of Greenhouse Gas Emissions for Various Feedstocks-Based Biochars as Soil Amendment. Sci. Total Environ. 2024, 911, 168734. [Google Scholar] [CrossRef]

- Papageorgiou, A.; Azzi, E.S.; Enell, A.; Sundberg, C. Biochar Produced from Wood Waste for Soil Remediation in Sweden: Carbon Sequestration and Other Environmental Impacts. Sci. Total Environ. 2021, 776, 145953. [Google Scholar] [CrossRef]

- Arfelli, F.; Tosi, C.; Ciacci, L.; Passarini, F. Life Cycle Assessment of a Wood Biomass Gasification Plant and Implications for Syngas and Biochar Utilization. Energies 2024, 17, 2599. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, W.; Wang, X.; Zhao, Q.; Han, M. Biochar Technology Cannot Offset Land Carbon Emissions in Guangdong Province, China. Carbon Res. 2024, 3, 55. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, W.; Wang, J.; Yu, W.; Luo, H.; Liu, W. A Dynamic Monetary Valuation Perspective for Carbon Sequestration: Effect on Biomass Utilization Strategy of Caragana Plantation as an Illustration. Ecol. Indic. 2021, 128, 107854. [Google Scholar] [CrossRef]

- Ita-nagy, D.; Vázquez-rowe, I.; Kahhat, R.; Quispe, I.; Chinga-carrasco, G.; Clauser, N.M.; Cristina, M. Science of the Total Environment Life Cycle Assessment of Bagasse Fi Ber Reinforced Biocomposites. Sci. Total Environ. 2020, 720, 137586. [Google Scholar] [CrossRef] [PubMed]

- Xue, S.; Lewandowski, I.; Wang, X.; Yi, Z. Assessment of the Production Potentials of Miscanthus on Marginal Land in China. Renew. Sustain. Energy Rev. 2016, 54, 932–943. [Google Scholar] [CrossRef]

- Baul, T.K.; Alam, A.; Ikonen, A.; Strandman, H.; Asikainen, A. Climate Change Mitigation Potential in Boreal Forests: Impacts of Management, Harvest Intensity and Use of Forest Biomass to Substitute Fossil Resources. Forests 2017, 8, 455. [Google Scholar] [CrossRef]

- Galik, C.S.; Benedum, M.E.; Kauffman, M.; Becker, D.R. Biomass and Bioenergy Opportunities and Barriers to Forest Biomass Energy: A Case Study of Four U. Biomass Bioenergy 2021, 148, 106035. [Google Scholar] [CrossRef]

- Cherubini, F.; Strømman, A.H.; Hertwich, E. Effects of Boreal Forest Management Practices on the Climate Impact of CO2 Emissions from Bioenergy. Ecol. Modell. 2011, 223, 59–66. [Google Scholar] [CrossRef]

- Hammar, T.; Ortiz, C.A.; Stendahl, J.; Ahlgren, S.; Hansson, P.-A. Time-Dynamic Effects on the Global Temperature When Harvesting Logging Residues for Bioenergy. BioEnergy Res. 2015, 8, 1912–1924. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Z.; Xie, X.; Yu, Z.; Von Gadow, K.; Xu, J. Analysis of the Global Warming Potential of Biogenic CO2 Emission in Life Cycle Assessments. Nat. Publ. Gr. 2017, 7, 39857. [Google Scholar] [CrossRef]

- Qin, Z.; Zhuang, Q.; Cai, X.; He, Y.; Huang, Y.; Jiang, D.; Lin, E.; Liu, Y.; Tang, Y.; Wang, M.Q. Biomass and Biofuels in China: Toward Bioenergy Resource Potentials and Their Impacts on the Environment. Renew. Sustain. Energy Rev. 2018, 82, 2387–2400. [Google Scholar] [CrossRef]

- Brandão, M.; Hjuler, S.V. Quantifying the Climate Change Effects of Bioenergy Systems: Comparison of 15 Impact Assessment Methods. GCB Bioenergy 2019, 11, 727–743. [Google Scholar] [CrossRef]

- Safarian, S. Climate Impact Comparison of Biomass Combustion and Pyrolysis with Different Applications for Biochar Based on LCA. Energies 2023, 16, 5541. [Google Scholar] [CrossRef]

- Amalina, F.; Razak, A.S.A.; Krishnan, S.; Sulaiman, H.; Zularisam, A.W.; Nasrullah, M. Biochar Production Techniques Utilising Biomass Waste-Derived Materials and Environmental Applications—A Review. J. Hazard. Mater. Adv. 2022, 7, 100134. [Google Scholar] [CrossRef]

- Broumand, M.; Albert-Green, S.; Yun, S.; Hong, Z.; Thomson, M.J. Spray Combustion of Fast Pyrolysis Bio-Oils: Applications, Challenges, and Potential Solutions. Prog. Energy Combust. Sci. 2020, 79, 100834. [Google Scholar] [CrossRef]

- Bompard, E.; Deandreis, M.; Corgnati, S.; Lo Russo, S.; Masera, M.; Profumo, F.; Scudieri, P. MED & Italian Energy Report—Geopolitics of Energy in the Mediterranean Area between International Crises and New Energy Commodities; Giannini Editore: Napoli, Italy, 2023; ISBN 978-88-6906-320-6. [Google Scholar]

- Roberts, K.G.; Gloy, B.A.; Joseph, S.; Scott, N.R.; Lehmann, J. Life Cycle Assessment of Biochar Systems: Estimating the Energetic, Economic, and Climate Change Potential. Environ. Sci. Technol. 2010, 44, 827–833. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, J.; Nascimento, L.; Soares, M.; Valério, N.; Ribeiro, A.; Faria, L.; Silva, A.; Pacheco, N.; Araújo, J.; Vilarinho, C. Life Cycle Assessment (LCA) of Biochar Production from a Circular Economy Perspective. Processes 2022, 10, 2684. [Google Scholar] [CrossRef]

- Giuliano, A.; Catizzone, E.; Freda, C.; Cornacchia, G. Valorization of OFMSW Digestate-Derived Syngas toward Methanol, Hydrogen, or Electricity: Process Simulation and Carbon Footprint Calculation. Processes 2020, 8, 526. [Google Scholar] [CrossRef]

- Koroneos, C.; Dompros, A.; Roumbas, G. Hydrogen Production via Biomass Gasification—A Life Cycle Assessment Approach. Chem. Eng. Process. Process Intensif. 2008, 47, 1261–1268. [Google Scholar] [CrossRef]

- Li, G.; Ma, S.; Liu, F.; Zhou, X.; Wang, K.; Zhang, Y. Life Cycle Water Footprint Assessment of Syngas Production from Biomass Chemical Looping Gasification. Bioresour. Technol. 2021, 342, 125940. [Google Scholar] [CrossRef]

- Marzeddu, S.; Cappelli, A.; Ambrosio, A.; Décima, M.A.; Viotti, P.; Boni, M.R. A Life Cycle Assessment of an Energy-Biochar Chain Involving a Gasification Plant in Italy. Land 2021, 10, 1256. [Google Scholar] [CrossRef]

- ISO14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Daminani, M.; Ferrara, N.; Ardente, F. Understanding Product Environmental Footprint and Organisation Environmental Footprint Methods; Publications Office of the European Union: Luxembourg, 2022; ISBN 9789276572145. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 3, 1218–1230. [Google Scholar] [CrossRef]

- Paraschiv, G.; Moiceanu, G.; Voicu, G.; Chitoiu, M.; Cardei, P.; Dinca, M.N.; Tudor, P. Optimization Issues of a Hammer Mill Working Process Using Statistical Modelling. Sustainability 2021, 13, 973. [Google Scholar] [CrossRef]

- Altıkat, A.; Alma, M.H.; Altıkat, A.; Bilgili, M.E.; Altıkat, S. A Comprehensive Study of Biochar Yield and Quality Concerning Pyrolysis Conditions: A Multifaceted Approach. Sustainability 2024, 16, 937. [Google Scholar] [CrossRef]

- Ronsse, F.; van Hecke, S.; Dickinson, D.; Prins, W. Production and Characterization of Slow Pyrolysis Biochar: Influence of Feedstock Type and Pyrolysis Conditions. GCB Bioenergy 2013, 5, 104–115. [Google Scholar] [CrossRef]

- Singh Yadav, S.P.; Bhandari, S.; Bhatta, D.; Poudel, A.; Bhattarai, S.; Yadav, P.; Ghimire, N.; Paudel, P.; Paudel, P.; Shrestha, J.; et al. Biochar Application: A Sustainable Approach to Improve Soil Health. J. Agric. Food Res. 2023, 11, 100498. [Google Scholar] [CrossRef]

- Schaffer, S.; Pröll, T.; Al Afif, R.; Pfeifer, C. A Mass- and Energy Balance-Based Process Modelling Study for the Pyrolysis of Cotton Stalks with Char Utilization for Sustainable Soil Enhancement and Carbon Storage. Biomass Bioenergy 2019, 120, 281–290. [Google Scholar] [CrossRef]

- Ramachandran, S.; Yao, Z.; You, S.; Massier, T.; Stimming, U.; Wang, C.-H. Life Cycle Assessment of a Sewage Sludge and Woody Biomass Co-Gasification System. Energy 2017, 137, 369–376. [Google Scholar] [CrossRef]

- Homagain, K.; Shahi, C.; Luckai, N.; Sharma, M. Life Cycle Environmental Impact Assessment of Biochar-Based Bioenergy Production and Utilization in Northwestern Ontario, Canada. J. For. Res. 2015, 26, 799–809. [Google Scholar] [CrossRef]

- Hudiburg, T.W.; Law, B.E.; Wirth, C.; Luyssaert, S. Regional Carbon Dioxide Implications of Forest Bioenergy Production. Nat. Clim. Chang. 2011, 1, 419–423. [Google Scholar] [CrossRef]

- Pereira, E.I.P.; Suddick, E.C.; Six, J. Carbon Abatement and Emissions Associated with the Gasification of Walnut Shells for Bioenergy and Biochar Production. PLoS ONE 2016, 11, e0150837. [Google Scholar] [CrossRef]

- Muñoz, E.; Curaqueo, G.; Cea, M.; Vera, L.; Navia, R. Environmental Hotspots in the Life Cycle of a Biochar-Soil System. J. Clean. Prod. 2017, 158, 1–7. [Google Scholar] [CrossRef]

- Peters, J.F.; Iribarren, D.; Dufour, J. Biomass Pyrolysis for Biochar or Energy Applications? A Life Cycle Assessment. Environ. Sci. Technol. 2015, 49, 5195–5202. [Google Scholar] [CrossRef]

- Rosas, J.G.; Gómez, N.; Cara, J.; Ubalde, J.; Sort, X.; Sánchez, M.E. Assessment of Sustainable Biochar Production for Carbon Abatement from Vineyard Residues. J. Anal. Appl. Pyrolysis 2015, 113, 239–247. [Google Scholar] [CrossRef]

- Wang, Z.; Dunn, J.B.; Han, J.; Wang, M.Q. Effects of Co-Produced Biochar on Life Cycle Greenhouse Gas Emissions of Pyrolysis-Derived Renewable Fuels. Biofuels Bioprod. Biorefining 2014, 8, 189–204. [Google Scholar] [CrossRef]

- Kieush, L.; Schenk, J.; Koveria, A.; Hrubiak, A.; Hopfinger, H.; Zheng, H. Evaluation of Slag Foaming Behavior Using Renewable Carbon Sources in Electric Arc Furnace-Based Steel Production. Energies 2023, 16, 4673. [Google Scholar] [CrossRef]

- Puettmann, M.; Sahoo, K.; Wilson, K.; Oneil, E. Life Cycle Assessment of Biochar Produced from Forest Residues Using Portable Systems. J. Clean. Prod. 2020, 250, 119564. [Google Scholar] [CrossRef]

- Sifford, C.N.; Pierobon, F.; Gauguly, I.; Eastin, I.; Alvarado, E.; Rogers, L. Developing an Impact Assessment of Local Air Quality as a Result of Biomass Burns. Master’s Thesis, University of Washington, Seattle, WA, USA, 2017. [Google Scholar]

- Gnansounou, E.; Dauriat, A.; Villegas, J.; Panichelli, L. Bioresource Technology Life Cycle Assessment of Biofuels: Energy and Greenhouse Gas Balances. Bioresour. Technol. 2009, 100, 4919–4930. [Google Scholar] [CrossRef]

- Schmidt, H.-P.; Abiven, S.; Hagemann, N.; Meyer zu Drewer, J. Permanence of Soil Applied Biochar. An Executive Summary for Global Biochar Carbon Sink Certification. Biochar J. 2022, 109, 69–74. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).