Thermodynamic Comparative Analysis of Cascade Refrigeration System Pairing R744 with R404A, R448A, and R449A with Internal Heat Exchanger: Part 1—Coefficient of Performance Characteristics

Abstract

1. Introduction

2. Mathematical Model

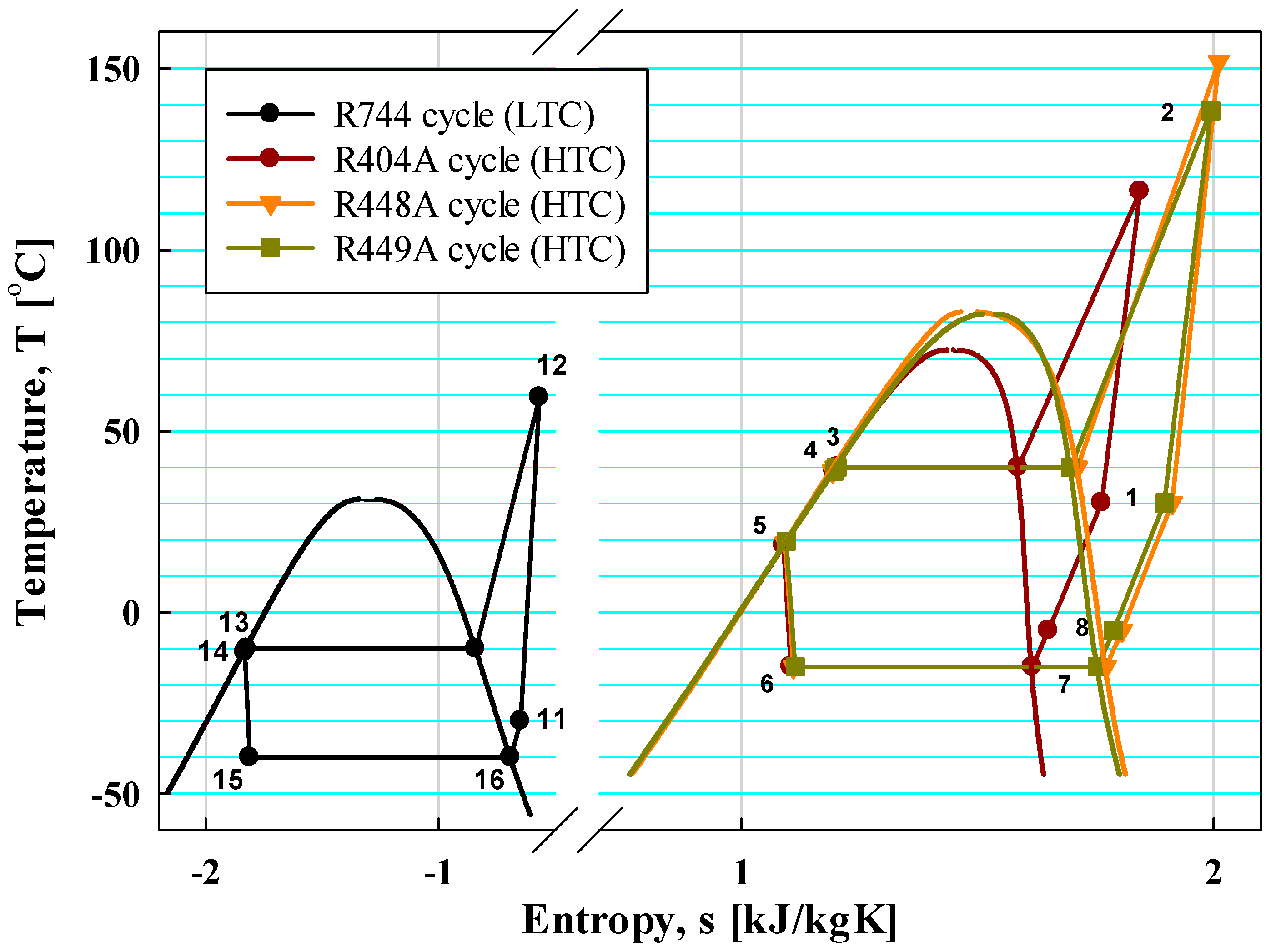

2.1. System Description

2.2. Thermodynamic Analysis

- Negligible pressure drop and heat loss in the tube and heat exchangers (evaporator, condenser, cascade heat exchanger, and internal heat exchanger) of both cycles;

- Isenthalpic process with adiabatic expansion in expansion valves of both cycles;

- Negligible changes in kinetic and potential energy;

- Operating under steady-state conditions of all system components.

2.2.1. Compressor Modeling and Validation

2.2.2. Performance Analysis of CRS

2.2.3. Analysis Conditions

3. Analysis Results and Discussions

3.1. Effect of DSC and DSH

3.1.1. Effect of DSC in the HTC

3.1.2. Effect of DSH in the HTC

3.1.3. Effect of DSH in the LTC

3.2. Effect of CT and ET

3.2.1. Effect of CT

3.2.2. Effect of ET

3.3. Effect of CET and Temperature Difference in CHX

3.3.1. Effect of CET

3.3.2. Effect of Temperature Difference in CHX

3.4. Effect of IHX Efficiency of the HTC

4. Future Scope and Recommendations

5. Conclusions

- To improve COP for R404A, R448A and R449A, it must increase subcooling degree of HTC, superheating of HTC, ET, CET, and IHX efficiencies of HTC, and reduce super-heating degree of LTC, CT, and temperature difference of CHX.

- Through this study, it was confirmed that R448A and R449A can be replaced as replacement refrigerants for R404A without significant changes, simply by making appropriate changes to the refrigerant charging rate.

- In order of greatest changing rate in terms of COP, for R404A, it is ET, CT, CET, the temperature difference in CHX, subcooling degree of HTC, IHX efficiency of HTC, superheating degree of HTC, and superheating degree of LTC. For R448A, it is ET, CT, CET, the temperature difference in CHX, subcooling degree of HTC, superheating degree of LTC, IHX efficiency of HTC, and superheating degree of HTC. And for R449A, it is ET, CT, CET, the temperature difference in CHX, subcooling degree of HTC, IHX efficiency of HTC, superheating degree of LTC, and superheating degree of HTC. Therefore, priorities one to five are the same regardless of the refrigerant and are in order of caution when designing a refrigeration system. In addition, it is considered to be less than 1.5% in the sixth rank and below, so it is not something that requires much attention.

- In order of greatest change rate in terms of MFR, for R404A, it is CT, IHX efficiency of HTC, ET, superheating degree of HTC, subcooling degree of HTC, CET, temperature difference in CHX, and superheating degree of LTC; for R448A and R449A, it is CT, ET, IHX efficiency of HTC, superheating degree of HTC, CET, subcooling degree of HTC, temperature difference in CHX, and superheating degree of LTC. In order to minimize the refrigerant charging rate from both environmental and economic perspectives, you should consider them in order of priority.

- The order of greatest influence on reducing the system PCC is CT, ET, CET, temperature difference in CHX, and subcooling degree of HTC from first to fifth place, regardless of the type of refrigerant, and the change was minimal at less than 1.45% for the sixth place and below. Therefore, if you want to reduce the system PCC in terms of energy saving, you should consider them in order from first to fifth place

- In this study, when the ratios of R448A and R449A compared to R404A were calculated as the arithmetic mean according to the changes in the eight parameters, the system COP was 99.30–102.07% and 98.22–100.66%, respectively, the system PCC was 98.08–100.71% and 99.40–101.81%, respectively, and the MFR was 72.60–74.96% and 75.96–78.03%, respectively. As can be seen from the research results, the system COP and system PCC are less than about 2% of R404A, so it is judged that there is no problem in using them as a replacement for R404A. In addition, since R448A and R449A are more economical and environmentally friendly than R404A in terms of MFR, their replacement is recommended.

- Also, in the case of the change rates of R448A and R449A compared to R404A, the system COP changed by 69.22–76.38% and 73.34–79.15%, respectively, the system PCC changed by 68.61–74.84% and 72.57–79.24%, respectively, and the MFR changed by 86.36–94.43% and 88.69–97.89%, respectively. Through this, it is judged that the system applying R448A and R449A will operate more stably than the system applying R404A because there is a low change in the system depending on the external load or environment. In addition, since R448A is more stable than R449A, the R744/R448A CRS is recommended.

- When applying IHX with 80% efficiency to HTC, the COP according to the three refrigerants increased by 0.063, 0.017, and 0.029 from 1.051, 1.056, and 1.041, respectively. In other words, applying IHX with 80% efficiency helps improve the COP, but R448A and R449A only increase by 26.98% and 46.03%, respectively, compared to R404A, so the increase rate is quite low. Therefore, if you want to apply IHX to a system that uses R448A and R449A, you should take this into consideration.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | ||

| CE | Cascade evaporator | |

| CEC | Cascade evaporation capacity | |

| CET | Cascade evaporation temperature | |

| CT | Condensation temperature | |

| CR | Compression ratio | |

| CHX | Cascade heat exchanger | |

| COP | Coefficient of performance | |

| CRS | Cascade refrigeration system | |

| DSC | Degree of subcooling | |

| DSH | Degree of superheating | |

| EC | Evaporation capacity | |

| EES | Engineering equation solver | |

| ET | Evaporation temperature | |

| GWP | Global warming potential | |

| HTC | High-temperature cycle | |

| IE | Inlet enthalpy | |

| IHX | Internal heat exchanger | |

| LT | Low-temperature level | |

| LTC | Low-temperature cycle | |

| MFR | Mass flow rate | |

| MT | Medium-temperature level | |

| OE | Outlet enthalpy | |

| PCC | Power consumption of compressor | |

| Symbols | ||

| h | Enthalpy | kJ/kg |

| Mass flow rate | kg/s | |

| Q | Heat capacity | kW |

| T | Temperature | °C |

| W | Power consumption | kW |

| Greek Symbols | ||

| Difference | ||

| Efficiency | ||

| Subscripts | ||

| C | Condensation, Condenser | |

| CAS | Cascade heat exchanger | |

| COM | Compression | |

| E | Evaporation, Evaporator | |

| HTC | High-temperature cycle | |

| IHX | Internal heat exchanger | |

| ISO | Isentropic | |

| LTC | Low-temperature cycle | |

| RATIO | Ratio | |

| R404A | R404A refrigerant | |

| R448A | R448A refrigerant | |

| R449A | R449A refrigerant | |

| R744 | R744 cycle | |

| SUC | Degree of subcooling | |

| SUH | Degree of superheating | |

| SYS | Total system | |

| VOL | Volumetric | |

| MAX | Maximum | |

References

- Sawalha, S. Using CO2 in supermarket refrigeration. Am. Soc. Heat. Refrig. Air-Cond. Eng. 2005, 47, 26–30. [Google Scholar]

- Veiby, O.J. Internal Records, Documentation in the ICA Supermarket Chain in Norway 2003, Oslo, Norway, 2003.

- Queiroz, M.V.A.; Panato, V.H.; Antunes, A.H.P.; Parise, J.A.R.; Filho, E.P.B. Experimental comparison of a cascade refrigeration system operating with R744/R134a and R744/R404A. In Proceedings of the International Refrigeration and Air-Conditioning Conference, West Lafayette, IN, USA, 11–14 July 2016; pp. 1–10. Available online: http://docs.lib.purdue.edu/iracc/1785 (accessed on 3 September 2024).

- Citarella, B.; Viscito, L.; Mochizuki, K.; Mauro, A.W. Multi-Criteria (thermo-economic) optimization and environmental analysis of a food refrigeration system working with low environmental impact refrigerants. Energy Convers. Manag. 2022, 253, 115152. [Google Scholar] [CrossRef]

- Alam, M.S.; Jeong, J.H. Calculation of the thermodynamic properties of R448A and R449A in a saturation temperature range of 233.15 K to 343.15 K using molecular dynamics simulations. Int. Commun. Heat Mass Transf. 2020, 116, 104717. [Google Scholar] [CrossRef]

- Rogstam, J.; Bolteau, S.; Makhnatch, P.; Khodabandeh, R. Evaluation of a Potential R404A Replacement—Field Test with R449A, Project (Systemlösningar Med Naturliga Köldmedier i Serverhallar/Datacenters), Kylbranschens Samarbetsstiftelse, Stockholm, Sverige, 28 November 2016. Available online: https://www.kys.se/wp-content/uploads/F%C3%A4ltm%C3%A4tning-R449A-28NOV16.pdf (accessed on 3 September 2024).

- Kedzierski, M.A.; Kang, D. Horizontal convective boiling of R448A, R449A, and R452B within a micro-fin tube. Sci. Technol. Built Environ. 2016, 22, 1090–1103. [Google Scholar] [CrossRef] [PubMed]

- Lillo, G.; Mastrullo, R.; Mauro, A.W.; Pelella, F.; Viscito, L. Experimental thermal and hydraulic characterization of R448A and comparison with R404A during flow boiling. Appl. Therm. Eng. 2019, 161, 114146. [Google Scholar] [CrossRef]

- Kim, C.H.; Kim, N.H. Evaporation heat transfer of the low GWP alternative refrigerants (R-448A, R-449A, R-455A, R-454C) for R-404A in a microfin tube. Int. J. Refrig. 2021, 128, 118–128. [Google Scholar] [CrossRef]

- Lee, B.M.; Gook, H.H.; Lee, S.B.; Lee, Y.W.; Park, D.H.; Kim, N.H. Condensation heat transfer and pressure drop of low GWP R-404A alternative refrigerants (R-448A, R-449A, R-455A, R-454C) in a 5.6 mm inner diameter horizontal smooth tube. Int. J. Refrig. 2021, 128, 71–82. [Google Scholar] [CrossRef]

- Jacob, T.A.; Matty, E.P.; Fronk, B.M. Comparison of R404A condensation heat transfer and pressure drop with low global warming potential replacement candidates R448A and R452A. Int. J. Refrig. 2020, 116, 9–22. [Google Scholar] [CrossRef]

- Ghanbarpour, M.; Mota-Babiloni, A.; Makhnatch, P.; Badran, B.E.; Rogstam, J.; Khodabandeh, R. ANN Modeling to analyze the R404A replacement with the low GWP alternative R449A in an indirect supermarket refrigeration system. Appl. Sci. 2021, 11, 11333. [Google Scholar] [CrossRef]

- Makhnatch, P.; Mota-Babiloni, A.; Rogstam, J.; Khodabandeh, R. Retrofit of lower GWP alternative R449A into an existing R404A indirect supermarket refrigeration system. Int. J. Refrig. 2017, 76, 184–192. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Gimenez-Prades, P.; Makhnatch, P.; Rogstam, J.; Fernandez-Moreno, A.; Navarro-Esbri, J. Semi-Empirical analysis of HFC supermarket refrigeration retrofit with advanced configurations from energy, environmental, and economic perspectives. Int. J. Refrig. 2022, 137, 257–271. [Google Scholar] [CrossRef]

- Giménez-Prades, P.; Navarro-Esbrí, J.; Udroiu, C.M.; Mota-Babiloni, A. Influence of subcooling in R-449A supermarket refrigeration system and screening of refrigerant mixtures for its energetic and environmental improvement. Appl. Therm. Eng. 2024, 236, 121787. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Navarro-Esbrí, J.; Peris, B.; Molés, F.; Verdú, G. Experimental evaluation of R448A as R404A lower-GWP alternative in refrigeration systems. Energy Convers. Manag. 2015, 105, 756–762. [Google Scholar] [CrossRef]

- Kim, S.G.; Kim, Y.J.; Lee, G.; Kim, M.S. The performance of a transcritical CO2 cycle with an internal heat exchanger for hot water heating. Int. J. Refrig. 2005, 28, 1064–1072. [Google Scholar] [CrossRef]

- Zhang, F.Z.; Jiang, P.X.; Lin, Y.S.; Zhang, Y.W. Efficiencies of subcritical and transcritical CO2 inverse cycles with and without an internal heat exchanger. Appl. Therm. Eng. 2011, 31, 432–438. [Google Scholar] [CrossRef]

- Llopis, R.; Sanz-Kock, C.; Cabello, R.; Sánchez, D.; Nebot-Andrés, L.; Catalán-Gil, J. Effects caused by the internal heat exchanger at the low temperature cycle in a cascade refrigeration plant. Appl. Therm. Eng. 2016, 103, 1077–1086. [Google Scholar] [CrossRef]

- Diario Oficial de la Unión Europea. REGLAMENTO (UE) 2019/1781 DE LA COMISIÓN de 1 de octubre de 2019. Diario Oficial De La Unión Europea, 25 October 2019.

- Calm, J.M.; Hourahan, G.C. Physical, safety, and environmental data for current and alternative refrigerants. In Proceedings of the 23rd International Congress of Refrigeration, Prague, Czech Republic, 21–26 August 2011; Available online: http://www.hourahan.com/wp/wp-content/uploads/2010/08/2011-Physical-Safety-and-Environmental-Data2.pdf (accessed on 3 September 2024).

- Australian-Government. Global Warming Potential Values of Hydrofluorocarbon Refrigerants; Department of Climate Change, Energy, the Environment and Water, Refrigeration and air conditioning; 2021. Available online: https://www.dcceew.gov.au/environment/protection/ozone/rac/global-warming-potential-values-hfc-refrigerants#daff-page-main (accessed on 3 September 2024).

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP; version 9.0; National Institute of Standards and Technology: Boulder, CO, USA, 2010. Available online: https://pages.nist.gov/REFPROP-docs/ (accessed on 3 September 2024).

- Wikipedia. List of Refrigerants. Available online: https://en.wikipedia.org/wiki/List_of_refrigerants (accessed on 3 September 2024).

- Euro Refrigerant—Refrigerant Gas and Tools. Available online: https://www.eurorefrigerant.com (accessed on 3 September 2024).

- Refrigerantionline. Available online: https://refrigerantionline.com/en/ (accessed on 3 September 2024).

- Dopazo, J.A.; Fernandez-Seara, J.; Sieres, J.; Uhia, F.J. Theoretical analysis of a CO2-NH3 cascade refrigeration system for cooling applications at low temperatures. Appl. Therm. Eng. 2009, 29, 1577–1583. [Google Scholar] [CrossRef]

- Getu, H.M.; Bansal, P.K. Thermodynamic analysis of an R744-R717 cascade refrigeration system. Int. J. Refrig. 2008, 31, 45–54. [Google Scholar] [CrossRef]

- Bai, T.; Yu, J.; Yan, G. Advanced exergy analysis on a modified auto-cascade freezer cycle with an ejector. Energy 2016, 113, 385–398. [Google Scholar] [CrossRef]

- Sun, Z.; Liang, Y.; Liu, S.; Ji, W.; Zang, R.; Liang, R.; Guo, Z. Comparative analysis of thermodynamic performance of a cascade refrigeration system for refrigerant couples R41/R404A and R23/R404A. Appl. Energy 2016, 184, 19–25. [Google Scholar] [CrossRef]

- Morosuk, T.; Tsatsaronis, G. Advanced exergetic evaluation of refrigeration machines using different working fluids. Energy 2009, 34, 2248–2258. [Google Scholar] [CrossRef]

- Jeon, M.-J. Experimental Analysis of the R744/R404A Cascade Refrigeration System with Internal Heat Exchanger. Part 1: Coefficient of Performance Characteristics. Energies 2021, 14, 6003. [Google Scholar] [CrossRef]

- Altinkaynak, M. Exergetic performance analysis of low GWP alternative refrigerants for R404A in a refrigeration system. Int. J. Low-Carbon Technol. 2021, 16, 842–850. [Google Scholar] [CrossRef]

- Nicola, G.D.; Giuliani, G.; Polonara, F.; Stryjek, R. Blends of carbon dioxide and HFCs as a working fluids for the low-temperature circuit in cascade refrigerating systems. Int. J. Refrig. 2005, 28, 130–140. [Google Scholar] [CrossRef]

- Yun, R.; Cho, Y. Evaluation of the performance for the CO2-NH3 cascade system and the two stage CO2 systems. In Proceedings of the 2010 SAREK Summer Annual Conference, Pyeongchang, Republic of Korea, 23–25 June 2010; pp. 824–829. [Google Scholar]

- Yılmaz, D.; Sınar, Ü.; Özyurt, A.; Yılmaz, B.; Mancuhan, E. Ultra Düşük Sıcaklıklarda Çalışan İki Kademeli Bir Soğutma Sisteminde Aşırı Soğutma ve Isıtmanın Performansa Etkilerinin Sayısal İncelenmesi. Afyon Kocatepe Univ. J. Sci. Eng. 2017, 17, 1172–1180. [Google Scholar]

- Parmar, G.G.; Kapadia, R.G. Thermodynamic Analysis of Cascade Refrigeration System using a Natural Refrigerants for Supermarket Application. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 1839–1846. [Google Scholar]

- Messineo, A.; Panno, D. Performance evaluation of cascade refrigeration systems using different refrigerants. Int. J. Air-Cond. Refrig. 2012, 20, 1250010. [Google Scholar] [CrossRef]

- Parekh, A.D.; Tailor, P.R. Thermodynamic analysis of cascade refrigeration, system using R12-R13, 290-R23 and R404A-R23, World Academy of Science. Eng. Technol. Int. J. Mech. Mechatron. Eng. 2014, 8, 1351–1356. [Google Scholar]

- Dokandari, D.A.; Hagh, A.S.; Mahmoudi, S.M.S. Thermodynamic investigation and optimization of novel ejector-expansion CO2/NH3 cascade refrigeration cycles (novel CO2/NH3 cycle). Int. J. Refrig. 2014, 46, 26–36. [Google Scholar] [CrossRef]

| System | R404A | R449A |

|---|---|---|

| MT | VOL = −0.0379CR + 0.9944 | VOL = −0.0412CR + 0.9865 |

| ISO = −0.0213CR2 + 0.2293CR + 0.0045 | ISO = −0.0079CR2 + 0.105CR + 0.2718 | |

| LT | VOL = −0.0271CR + 0.9835 | VOL = −0.0313CR + 0.9741 |

| ISO = −0.0002CR2 + 0.0124CR + 0.4965 | ISO = −0.0011CR2 + 0.0353CR + 0.419 | |

| ISO,R744 = −0.0046CR2 − 0.0073CR + 0.7253 | ||

| Parameters | MT Circuit | LT Circuit |

|---|---|---|

| Middle evaporating temperature [°C] | −20 and −10 | −40 and −30 |

| Middle condensing temperature [°C] | 25 and 40 | 20 and 40 |

| Total superheating degree [K] | 7 | 10 |

| Condenser subcooling degree [K] | 0 | 0 |

| Subcooler subcooling degree [K] | 2 |

| Refrigerant | R404A | R448A | R449A |

|---|---|---|---|

| Molar mass (kg/kmol) | 97.6 | 86.3 | 87.2 |

| Boiling point (°C) | −46.2 | −46.0 | −46.0 |

| Critical temperature (°C) | 72 | 83.7 | 81.5 |

| Critical pressure (kPa) | 3730 | 4660 | 4450 |

| ODP | 0 | 0 | 0 |

| GWP (100 yr) | 3700 | 1387 | 1397 |

| Safety class | A1 | A1 | A1 |

| Cp (kJ/kg∙°C) | 1.54 | 1.56 | 1.55 |

| k (W/mK) | 0.067 | 0.088 | 0.080 |

| Cost (€/kg) [27,28] Β | 38.9 | 29.9 | 30.9 |

| Chemical formula | R125/143a/134a | R32/R125/R134a/R1234yf/R1234ze | R32/R125/R134a/R1234yf |

| (44%/52%/4%) | (26%/26%/21%/20%/7%) | (24.3%/24.7%/25.7%/25.3%) |

| Cycle | Component | Energy | Mass |

|---|---|---|---|

| HTC (R404A/R448A/R449A) | Compressor (1→2) | ||

| Condenser (2→4) | |||

| DSC (3→4) | |||

| IHX (4→5 and 8→1) | |||

| Expansion valve (5→6) | |||

| Cascade evaporator (6→8) | |||

| DSH (7→8) | |||

| Low Temperature cycle (R744) | Compressor (11→12) | ||

| Cascade condenser (12→14) | |||

| DSC (13→14) | |||

| Expansion valve (14→15) | |||

| Evaporator (15→11) | |||

| DSH (16→11) |

| Cycle | Parameter | Range | Unit |

|---|---|---|---|

| HTC (R404A/R448A/R449A) | 30, 35, 40 *, 45, 50 | °C | |

| 0 *, 0.2, 0.4, 0.6, 0.8 | -. | ||

| 1 *, 3, 5, 5, 7, 9 | °C | ||

| 0, 5, 10 *, 15, 20 | °C | ||

| −25, −20, −15 *, −10, −5 | °C | ||

| 1, 3, 5 *, 7, 9 | °C | ||

| LTC (R744) | |||

| −50, −45, −40 *, −35, −30 | °C | ||

| 0 * | -. | ||

| 1 * | °C | ||

| 0, 5, 10 *, 15, 20 | °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, M.-J.; Lee, J.-H. Thermodynamic Comparative Analysis of Cascade Refrigeration System Pairing R744 with R404A, R448A, and R449A with Internal Heat Exchanger: Part 1—Coefficient of Performance Characteristics. Energies 2024, 17, 4481. https://doi.org/10.3390/en17174481

Jeon M-J, Lee J-H. Thermodynamic Comparative Analysis of Cascade Refrigeration System Pairing R744 with R404A, R448A, and R449A with Internal Heat Exchanger: Part 1—Coefficient of Performance Characteristics. Energies. 2024; 17(17):4481. https://doi.org/10.3390/en17174481

Chicago/Turabian StyleJeon, Min-Ju, and Joon-Hyuk Lee. 2024. "Thermodynamic Comparative Analysis of Cascade Refrigeration System Pairing R744 with R404A, R448A, and R449A with Internal Heat Exchanger: Part 1—Coefficient of Performance Characteristics" Energies 17, no. 17: 4481. https://doi.org/10.3390/en17174481

APA StyleJeon, M.-J., & Lee, J.-H. (2024). Thermodynamic Comparative Analysis of Cascade Refrigeration System Pairing R744 with R404A, R448A, and R449A with Internal Heat Exchanger: Part 1—Coefficient of Performance Characteristics. Energies, 17(17), 4481. https://doi.org/10.3390/en17174481