Recent Advances in Numerical Simulation of Ejector Pumps for Vacuum Generation—A Review

Abstract

1. Introduction

2. Fundamental of Ejectors

- The primary fluid’s pressure energy is converted into kinetic energy within the nozzle.

- The low-velocity secondary fluid is entrained and mixed with the high-velocity primary fluid in the mixing throat, driven by viscous friction and the suction created by the pressure drop at the nozzle exit.

- The combined fluid’s kinetic energy is transformed back into pressure energy within the diffuser.

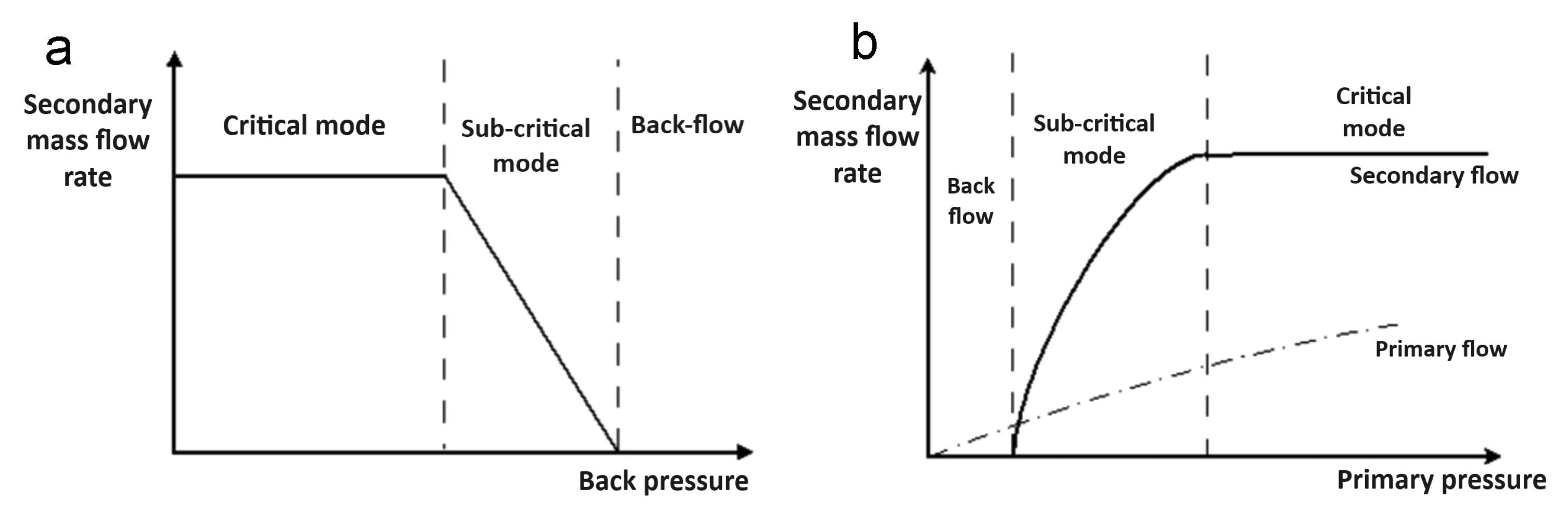

2.1. Entrainment Ratio

2.2. Pressure Ratio

2.3. Efficiency of Ejector

2.4. Subsonic Ejectors

2.5. Supersonic Ejectors

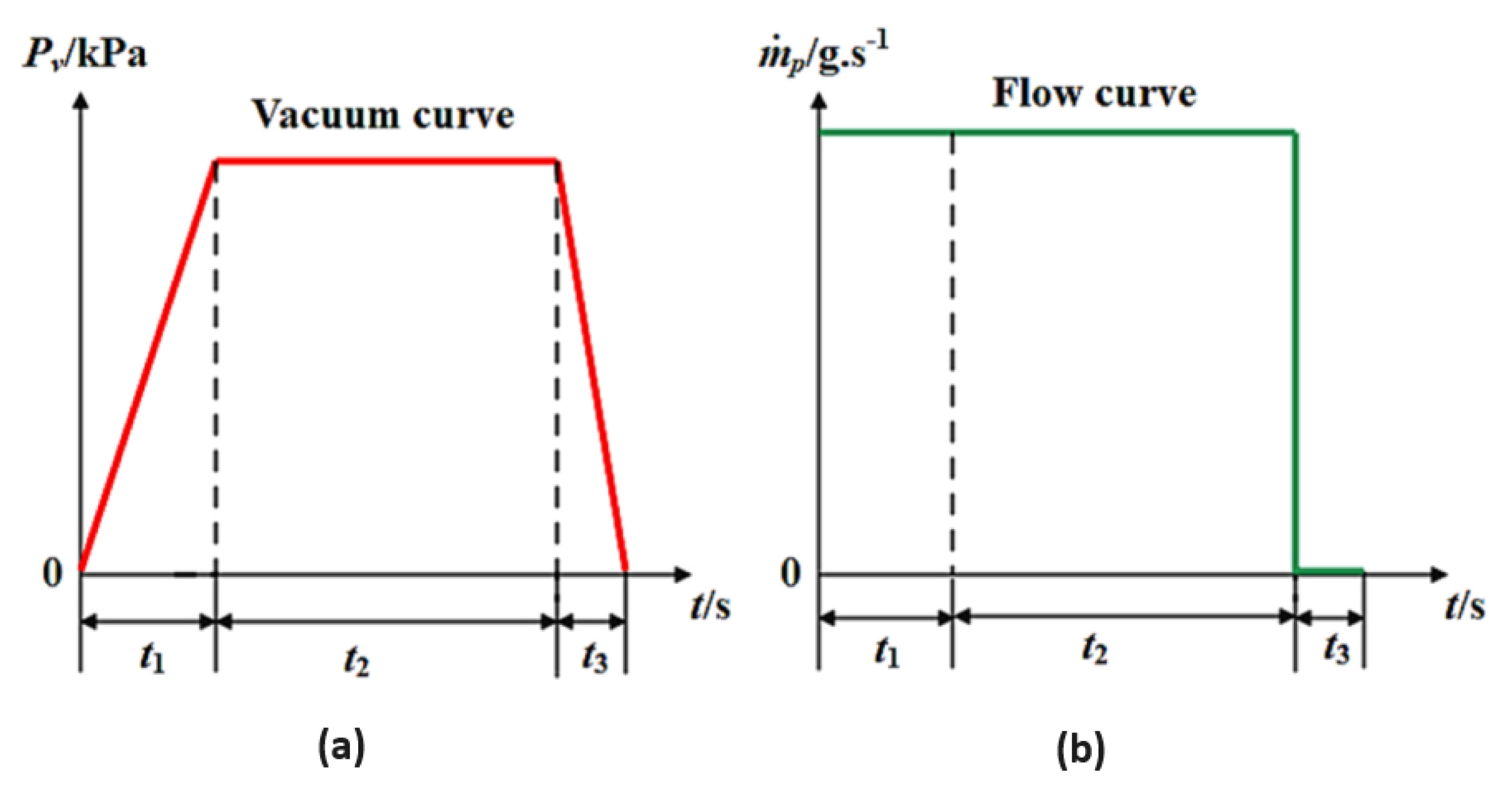

2.6. Vacuum Ejectors

- Response Time: The vacuum response time is the time at which the vacuum level reaches 63 % of the maximum vacuum level. Response time is crucial for system efficiency. A longer response time can decrease overall work efficiency and increase air consumption. Therefore, minimizing is essential for optimal performance.

- Vacuum Holding Time: This stage represents a significant portion of the work cycle, typically accounting for 50–80% of the total time. During this period, high-pressure air is continuously supplied to make up for leakage and maintain the desired vacuum level.

2.7. Applications

2.7.1. Single-Phase and Two-Phase Ejectors

2.7.2. Geography of Ejectors Research

3. Computational Fluid Dynamics Modeling of Ejectors

3.1. Single-Phase Ejector CFD Simulation

3.2. Two-Phase Ejectors CFD Simulation

- Volume of fluid (VOF): Suitable for simulating fluids with a sharp interface, such as liquid–gas flows.

- Mixture model: often used for simulating homogeneous multiphase flows or when the interface is not of primary interest.

- Lagrangian–Eulerian model: Suitable for particle-scale phenomena which can be modeled using fundamental principles of physics.

3.3. Numerical Methods

3.4. Geometry and Mesh

3.5. Boundary Conditions

3.6. Solvers and Software

3.7. Turbulence Modeling

3.8. Validation and Verification

3.9. Parametric Study

3.9.1. Nozzle Exit Position

3.9.2. Nozzle Area Ratio

3.9.3. Mixing Throat Diameter

3.9.4. Other Geometric Aspects

3.9.5. Operating Conditions

3.10. Optimization

Single-Factor and Multi-Factor Analyses of Vacuum Ejectors

3.11. Entropy Loss

- Entropy generation through viscous dissipation caused by average velocity gradients.

- Entropy generation through heat conduction resulting from average temperature gradients.

- Entropy generation through viscous dissipation caused by fluctuating velocity gradients (turbulent dissipation).

- Entropy generation through heat conduction due to fluctuating temperature gradients (turbulent heat transfer).

3.12. Entrainment Ratio Behavior

- Implementing advanced turbulence models.

- Optimizing geometry; involving nozzle design, mixing chamber shape, diffuser design.

- Adjusting operating conditions.

- Utilizing adjoint optimization.Additional factors can also be added to this list, such as:

- Incorporation of real gas effects.

- Boundary layer control involving wall treatments.

3.13. Internal Flow Visualization

3.13.1. Mixing Characteristics

3.13.2. Shock Structure

3.14. Investigation into the Properties of Heat and Mass Transfer

3.14.1. Condensation Effect

3.14.2. Nucleation

3.14.3. Droplet Growth

3.14.4. Condensing Nozzle

4. Limitations of Multiphase Flow Simulation in Ejectors

5. Conclusions

- Computational fluid dynamics (CFD) is a powerful tool for modeling and understanding complex flow phenomena in ejectors, including shock waves, mixing processes, and phase transitions.

- The accuracy of numerical predictions heavily depends on appropriate turbulence models, multiphase flow modeling, and consideration of non-equilibrium effects.

- Significant progress has been made in modeling condensation phenomena, leading to improved understanding and optimization of ejector performance parameters.

- Challenges remain in accurately modeling real gas effects, phase change kinetics, and coupled heat and mass transfer processes.

- Further validation against experimental data is needed, particularly for complex multiphase flow scenarios.

- Developing more robust multiphase flow models, incorporating advanced turbulence modeling techniques.

- Exploring adjustable, multi-nozzle designs, and specific operation conditions for practical multi-factor optimization of vacuum ejectors.

- Investigating various working fluids (e.g., real gas air, , , ) and materials (e.g., glass, wood, sponge, PVC pipes) to assess performance and applicability of vacuum ejectors.

- Integrating machine learning-based optimization methods. Exploring novel ejector configurations and applications in emerging technologies like energy storage and waste heat recovery systems.

Funding

Conflicts of Interest

References

- Chen, J.; Jarall, S.; Havtun, H.; Palm, B. A review on versatile ejector applications in refrigeration systems. Renew. Sustain. Energy Rev. 2015, 49, 67–90. [Google Scholar] [CrossRef]

- Elbel, S.; Lawrence, N. Review of recent developments in advanced ejector technology. Int. J. Refrig. 2016, 62, 1–18. [Google Scholar] [CrossRef]

- Besagni, G.; Mereu, R.; Inzoli, F. Ejector refrigeration: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 53, 373–407. [Google Scholar] [CrossRef]

- Little, A.; Garimella, S. A critical review linking ejector flow phenomena with component- and system-level performance. Int. J. Refrig. 2016, 70, 243–268. [Google Scholar] [CrossRef]

- Aidoun, Z.; Ameur, K.; Falsafioon, M.; Badache, M. Current advances in ejector modeling, experimentation and applications for refrigeration and heat pumps. Part 1: Single-phase ejectors. Inventions 2019, 4, 15. [Google Scholar] [CrossRef]

- Aidoun, Z.; Ameur, K.; Falsafioon, M.; Badache, M. Current advances in ejector modeling, experimentation and applications for refrigeration and heat pumps. Part 2: Two-phase ejectors. Inventions 2019, 4, 16. [Google Scholar] [CrossRef]

- Tashtoush, B.M.; Al-Nimr, M.A.; Khasawneh, M.A. A comprehensive review of ejector design, performance, and applications. Appl. Energy 2019, 240, 138–172. [Google Scholar] [CrossRef]

- Koirala, R.; Ve, Q.L.; Zhu, B.; Inthavong, K.; Date, A. A review on process and practices in operation and design modification of ejectors. Fluids 2021, 6, 409. [Google Scholar] [CrossRef]

- Besagni, G.; Cristiani, N.; Croci, L.; Guédon, G.R.; Inzoli, F. Computational fluid-dynamics modelling of supersonic ejectors: Screening of modelling approaches, comprehensive validation and assessment of ejector component efficiencies. Appl. Therm. Eng. 2021, 186, 116431. [Google Scholar] [CrossRef]

- Cunningham, R.G. Jet-Pump theory and performance with fluids of high viscosity. Trans. Am. Soc. Mech. Eng. 2022, 79, 1807–1819. [Google Scholar] [CrossRef]

- Kwidziński, R. Control-volume-based model of the steam-water injector flow. Arch. Thermodyn. 2010, 31, 45–59. [Google Scholar] [CrossRef]

- Grazzini, G.; Milazzo, A.; Piazzini, S. Prediction of condensation in steam ejector for a refrigeration system. Int. J. Refrig. 2011, 34, 1641–1648. [Google Scholar] [CrossRef]

- Mazzelli, F.; Giacomelli, F.; Milazzo, A. CFD modeling of condensing steam ejectors: Comparison with an experimental test-case. Int. J. Therm. Sci. 2018, 127, 7–18. [Google Scholar] [CrossRef]

- Elmore, E.; Al-Mutairi, K.; Hussain, B.; El-Gizawy, A.S. Development of analytical model for predicting dual-phase ejector performance. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar]

- Winoto, S.H.; Li, H.; Shah, D.A. Efficiency of jet pumps. J. Hydraul. Eng. 2000, 126, 150–156. [Google Scholar] [CrossRef]

- Karassik, I.J. Pump Handbook; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Niu, L.; Zhang, X. Comparison of the performance enhancement of vacuum ejector by means of structure optimization and bypass methods. Energy 2024, 297, 131263. [Google Scholar] [CrossRef]

- Niu, L.; Zhang, X. Study on energy-saving applications of vacuum ejectors across various operational demands. Vacuum 2024, 228, 113527. [Google Scholar] [CrossRef]

- Couper, J.R. Chemical Process Equipment: Selection and Design; Gulf Professional Publishing: Oxford, UK, 2005. [Google Scholar]

- Megdouli, K.; Tashtoush, B.M.; Nahdi, E.; Elakhdar, M.; Mhimid, A.; Kairouani, L. Analyse de performance d’un cycle à compression de vapeur combiné et d’un cycle à éjecteur pour la cogénération de froid. Int. J. Refrig. 2017, 74, 515–525. [Google Scholar] [CrossRef]

- Zou, L.; Yu, J. 4E assessment of ejector-enhanced R290 heat pump cycle with a sub-cooler for cold region applications. Energy 2024, 298, 131369. [Google Scholar] [CrossRef]

- Bruno, F.; Belusko, M.; Halawa, E. CO2 refrigeration and heat pump systems—A comprehensive review. Energies 2019, 12, 2959. [Google Scholar] [CrossRef]

- Mohammadi, A.; Aghaie, H.R.; Saghafian, M. Design and analysis of a suction mechanism for the vacuum degassing process. Ironmak. Steelmak. 2021, 48, 457–465. [Google Scholar] [CrossRef]

- Peris Pérez, B.; Ávila Gutiérrez, M.; Expósito Carrillo, J.A.; Salmerón Lissén, J.M. Performance of Solar-driven Ejector Refrigeration System (SERS) as pre-cooling system for air handling units in warm climates. Energy 2022, 238, 121647. [Google Scholar] [CrossRef]

- Braimakis, K. Solar ejector cooling systems: A review. Renew. Energy 2021, 164, 566–602. [Google Scholar] [CrossRef]

- Cao, Y.; Dhahad, H.A.; Hussen, H.M.; Parikhani, T. Proposal and evaluation of two innovative combined gas turbine and ejector refrigeration cycles fueled by biogas: Thermodynamic and optimization analysis. Renew. Energy 2022, 181, 749–764. [Google Scholar] [CrossRef]

- Gullo, P.; Hafner, A.; Banasiak, K.; Minetto, S.; Kriezi, E.E. Multi-Ejector Concept: A Comprehensive Review on its Latest Technological Developments. Energies 2019, 12, 406. [Google Scholar] [CrossRef]

- Liu, Y.; Tu, Z.; Chan, S.H. Applications of ejectors in proton exchange membrane fuel cells: A review. Fuel Process. Technol. 2021, 214, 106683. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Z.; Xin, X.; Yang, X. Proposal and assessment of a novel carbon dioxide energy storage system with electrical thermal storage and ejector condensing cycle: Energy and exergy analysis. Appl. Energy 2020, 269, 115067. [Google Scholar] [CrossRef]

- Moghimi, M.; Emadi, M.; Akbarpoor, A.M.; Mollaei, M. Energy and exergy investigation of a combined cooling, heating, power generation, and seawater desalination system. Appl. Therm. Eng. 2018, 140, 814–827. [Google Scholar] [CrossRef]

- Hassani, M.; Kouhikamali, R. Investigation of two phase liquid jet ejector with simultaneous air and water suction in fresh water distillation system. Energy 2024, 301, 131662. [Google Scholar] [CrossRef]

- Milow, B.; Zarza, E. Advanced MED solar desalination plants. Configurations, costs, future—Seven years of experience at the Plataforma Solar de Almeria (Spain). Desalination 1997, 108, 51–58. [Google Scholar] [CrossRef]

- Andrés-Mañas, J.; Requena, I.; Ruiz-Aguirre, A.; Zaragoza, G. Performance modelling and optimization of three vacuum-enhanced membrane distillation modules for upscaled solar seawater desalination. Sep. Purif. Technol. 2022, 287, 120396. [Google Scholar] [CrossRef]

- Ferziger, J.H.; Perić, M.; Street, R.L. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Talebiyan, M.A.; Nili-Ahmadabadi, M.; Ha, M.Y. Adjoint optimization of a supersonic ejector for under-expanded, isentropic, and over-expanded primary flow modes. Chem. Eng. Sci. 2024, 292, 119979. [Google Scholar] [CrossRef]

- Tavakoli, M.; Nili-Ahmadabadi, M.; Joulaei, A.; Ha, M.Y. Enhancing subsonic ejector performance by incorporating a fluidic oscillator as the primary nozzle: A numerical investigation. Int. J. Thermofluids 2023, 20, 100429. [Google Scholar] [CrossRef]

- Macia, L.; Castilla, R.; Gámez, P.J. Simulation of ejector for vacuum generation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 659, 012002. [Google Scholar] [CrossRef]

- Hou, Y.; Chen, F.; Zhang, S.; Chen, W.; Zheng, J.; Chong, D.; Yan, J. Numerical simulation study on the influence of primary nozzle deviation on the steam ejector performance. Int. J. Therm. Sci. 2022, 179, 107633. [Google Scholar] [CrossRef]

- Banu, J.P.; Mani, A. Numerical studies on ejector with swirl generator. Int. J. Therm. Sci. 2019, 137, 589–600. [Google Scholar] [CrossRef]

- Singer, G.; Pinsker, R.; Stelzer, M.; Aggarwal, M.; Pertl, P.; Trattner, A. Ejector validation in proton exchange membrane fuel cells: A comparison of turbulence models in computational fluid dynamics (CFD) with experiment. Int. J. Hydrogen Energy 2024, 61, 1405–1416. [Google Scholar] [CrossRef]

- Li, Z.; Xu, W.; Liang, T.; Ye, W.; Zhang, Z. Experimental and numerical studies on the performance of supersonic multi-nozzle ejector. Appl. Therm. Eng. 2024, 242, 122409. [Google Scholar] [CrossRef]

- Chai, Y.; Lin, Y.; Xiao, Q.; Huang, C.; Ke, H.; Li, B. Numerical simulation on two-phase ejector with non-condensable gas. Energies 2024, 17, 1341. [Google Scholar] [CrossRef]

- Feng, H.; Yao, A.; Han, Q.; Zhang, H.; Jia, L.; Sun, W. Effect of droplets in the primary flow on ejector performance of MED-TVC systems. Energy 2024, 293, 130741. [Google Scholar] [CrossRef]

- Kuś, T.; Madejski, P. Numerical investigation of a two-phase ejector operation taking into account steam condensation with the Presence of CO2. Energies 2024, 17, 2236. [Google Scholar] [CrossRef]

- Dadpour, D.; Lakzian, E.; Gholizadeh, M.; Ding, H.; Han, X. Numerical modeling of droplets injection in the secondary flow of the wet steam ejector in the refrigeration cycle. Int. J. Refrig. 2022, 136, 103–113. [Google Scholar] [CrossRef]

- Koirala, R.; Inthavong, K.; Date, A. Numerical study of flow and direct contact condensation of entrained vapor in water jet eductor. Exp. Comput. Multiph. Flow 2022, 4, 291–303. [Google Scholar] [CrossRef]

- Wen, C.; Gong, L.; Ding, H.; Yang, Y. Steam ejector performance considering phase transition for multi-effect distillation with thermal vapour compression (MED-TVC) desalination system. Appl. Energy 2020, 279, 115831. [Google Scholar] [CrossRef]

- Han, Y.; Wang, X.; Sun, H.; Zhang, G.; Guo, L.; Tu, J. CFD simulation on the boundary layer separation in the steam ejector and its influence on the pumping performance. Energy 2019, 167, 469–483. [Google Scholar] [CrossRef]

- Giacomelli, F.; Biferi, G.; Mazzelli, F.; Milazzo, A. CFD modeling of the supersonic condensation inside a steam ejector. Energy Procedia 2016, 101, 1224–1231. [Google Scholar] [CrossRef]

- Ariafar, K.; Buttsworth, D.; Sharifi, N.; Malpress, R. Ejector primary nozzle steam condensation: Area ratio effects and mixing layer development. Appl. Therm. Eng. 2014, 71, 519–527. [Google Scholar] [CrossRef]

- Ariafar, K.; Buttsworth, D.; Al-Doori, G.; Malpress, R. Effect of mixing on the performance of wet steam ejectors. Energy 2015, 93, 2030–2041. [Google Scholar] [CrossRef]

- Xue, W.; Wang, Y.; Liang, Y.; Wang, T.; Ren, B. Efficient hydraulic and thermal simulation model of the multi-phase natural gas production system with variable speed compressors. Appl. Therm. Eng. 2024, 242, 122411. [Google Scholar] [CrossRef]

- Fang, Y.; Sen, S.; Poncet, S.; Bartosiewicz, Y.; Nesreddine, H.; Monney, D. Advanced modelling of a transcritical CO2 ejector. In Proceedings of the 14th IIR-Gustav Lorentzen Conference on Natural Refrigerants (GL2020), Kyoto, Japon, 7–9 December 2020. [Google Scholar] [CrossRef]

- Pianthong, K.; Seehanam, W.; Behnia, M.; Sriveerakul, T.; Aphornratana, S. Investigation and improvement of ejector refrigeration system using computational fluid dynamics technique. Energy Convers. Manag. 2007, 48, 2556–2564. [Google Scholar] [CrossRef]

- Karthick, S.; Rao, S.; Jagadeesh, G.; Reddy, K. Parametric experimental studies on mixing characteristics within a low area ratio rectangular supersonic gaseous ejector. Phys. Fluids 2016, 28, 076101. [Google Scholar] [CrossRef]

- Samsam-Khayani, H.; Park, S.H.; Ha, M.Y.; Kim, K.C.; Yoon, S.Y. Design modification of two-dimensional supersonic ejector via the adjoint method. Appl. Therm. Eng. 2022, 200, 117674. [Google Scholar] [CrossRef]

- Sriveerakul, T.; Aphornratana, S.; Chunnanond, K. Performance prediction of steam ejector using computational fluid dynamics: Part 1. Validation of the CFD results. Int. J. Therm. Sci. 2007, 46, 812–822. [Google Scholar] [CrossRef]

- Zhang, Z.; Chong, D.; Yan, J. Modeling and experimental investigation on water-driven steam injector for waste heat recovery. Appl. Therm. Eng. 2012, 40, 189–197. [Google Scholar] [CrossRef]

- Sharifi, N.; Boroomand, M. An investigation of thermo-compressor design by analysis and experiment: Part 1. Validation of the numerical method. Energy Convers. Manag. 2013, 69, 217–227. [Google Scholar] [CrossRef]

- Moses, C.A.; Stein, G.D. On the growth of steam droplets formed in a laval nozzle using both static pressure and light scattering measurements. J. Fluids Eng. 1978, 100, 311–322. [Google Scholar] [CrossRef]

- Starzmann, J.; Hughes, F.R.; Schuster, S.; White, A.J.; Halama, J.; Hric, V.; Kolovratník, M.; Lee, H.; Sova, L.; Št’astný, M.; et al. Results of the international wet steam modeling project. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 550–570. [Google Scholar] [CrossRef]

- Banu, J.P.; Maharudrappa, M.; Mani, A. Experimental and Numerical Investigations of Ejector Jet Refrigeration System with Primary Stream Swirl. In International Refrigeration and Air Conditioning Conference. Paper 1576. 16 the International Refrigeration and Air Conditioning Conference at Purdue; 2016; Available online: http://docs.lib.purdue.edu/iracc/1576 (accessed on 14 July 2024).

- Moore, M. Predicting the fog-drop size in wet-steam turbines. Wet Steam 1973. Available online: https://cir.nii.ac.jp/crid/1574231874929479936 (accessed on 14 July 2024).

- Bakhtar, F.; Mohammadi Tochai, M. An investigation of two-dimensional flows of nucleating and wet steam by the time-marching method. Int. J. Heat Fluid Flow 1980, 2, 5–18. [Google Scholar] [CrossRef]

- Launder, B.; Spalding, D. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Lucas, C.; Rusche, H.; Schroeder, A.; Koehler, J. Numerical investigation of a two-phase CO2 ejector. Int. J. Refrig. 2014, 43, 154–166. [Google Scholar] [CrossRef]

- Novais, W.R.I.; Scalon, V.L. Numerical Simulation of an Ejector Using the OpenFOAM® Solvers; Associacao Brasileira de Engenharia e Ciencias Mecanicas: Rio de Janeiro, Brazil, 2018; p. 2. [Google Scholar] [CrossRef]

- Klyuyev, A.S.; Chernyshev, Y.I.; Ivanov, E.A.; Borshchev, I.O. Comparison of jet pump numerical calculation results in ansys and openfoam cfd packages. EDP Sci. 2021, 320, 04017. [Google Scholar] [CrossRef]

- Zaheer, Q.; Masud, J. Visualization of flow field of a liquid ejector pump using embedded LES methodology. J. Vis. 2017, 20, 777–788. [Google Scholar] [CrossRef]

- Croquer, S.; Lamberts, O.; Poncet, S.; Moreau, S.; Bartosiewicz, Y. Large Eddy Simulation of a supersonic air ejector. Appl. Therm. Eng. 2022, 209, 118177. [Google Scholar] [CrossRef]

- Roache, P. Verification and Validation in Computational Science and Engineering; Hermosa Publishers: Hermosa Beach, CA, USA, 1998. [Google Scholar]

- Kwidzinski, R. Experimental and theoretical investigations of two-phase flow in low pressure steam–water injector. Int. J. Heat Mass Transf. 2019, 144, 118618. [Google Scholar] [CrossRef]

- Kwidzinski, R. Condensation heat and mass transfer in steam–water injectors. Int. J. Heat Mass Transf. 2021, 164, 120582. [Google Scholar] [CrossRef]

- Karthick, S.; Rao, S.M.; Jagadeesh, G.; Reddy, K. Experiments in supersonic gaseous ejector using 2D-PIV technique. In 31st International Symposium on Shock Waves 2: Applications 31; Springer: Cham, Switzerland, 2019; pp. 785–793. [Google Scholar]

- Al-Rbaihat, R.; Saleh, K.; Malpress, R.; Buttsworth, D. Experimental investigation of a novel variable geometry radial ejector. Appl. Therm. Eng. 2023, 233, 121143. [Google Scholar] [CrossRef]

- Ahmed, F.; Chen, W. Investigation of steam ejector parameters under three optimization algorithm using ANN. Appl. Therm. Eng. 2023, 225, 120205. [Google Scholar] [CrossRef]

- Liu, G.; Pu, L.; Zhao, H.; Chen, Z.; Li, G. Multi-objective optimization of CO2 ejector by combined significant variables recognition, ANN surrogate model and multi-objective genetic algorithm. Energy 2024, 295, 131010. [Google Scholar] [CrossRef]

- Wang, K.; Wang, L.; Jia, L.; Cai, W.; Gao, R. Optimization design of steam ejector primary nozzle for MED-TVC desalination system. Desalination 2019, 471, 114070. [Google Scholar] [CrossRef]

- Llorenç Macia and Robert Castilla and Pedro Javier Gamez-Montero and Gustavo Raush. Multi-Factor Design for a Vacuum Ejector Improvement by In-Depth Analysis of Construction Parameters. Sustainability 2022, 14, 10195. [CrossRef]

- Arbel, A.; Shklyar, A.; Hershgal, D.; Barak, M.; Sokolov, M. Ejector irreversibility characteristics. J. Fluids Eng. 2003, 125, 121–129. [Google Scholar] [CrossRef]

- Sierra-Pallares, J.; García del Valle, J.; García Carrascal, P.; Castro Ruiz, F. A computational study about the types of entropy generation in three different R134a ejector mixing chambers. Int. J. Refrig. 2016, 63, 199–213. [Google Scholar] [CrossRef]

- Omidvar, A.; Ghazikhani, M.; Razavi, S.M.R.M. Entropy analysis of a solar-driven variable geometry ejector using computational fluid dynamics. Energy Convers. Manag. 2016, 119, 435–443. [Google Scholar] [CrossRef]

- Galanis, N.; Sorin, M. Ejector design and performance prediction. Int. J. Therm. Sci. 2016, 104, 315–329. [Google Scholar] [CrossRef]

- Rao, S.M.V.; Jagadeesh, G. Observations on the non-mixed length and unsteady shock motion in a two dimensional supersonic ejector. Phys. Fluids 2014, 26, 036103. [Google Scholar] [CrossRef]

- He, S.; Li, Y.; Wang, R. Progress of mathematical modeling on ejectors. Renew. Sustain. Energy Rev. 2009, 13, 1760–1780. [Google Scholar] [CrossRef]

- Śmierciew, K.; Gagan, J.; Butrymowicz, D. Application of numerical modelling for design and improvement of performance of gas ejector. Appl. Therm. Eng. 2019, 149, 85–93. [Google Scholar] [CrossRef]

- Bodys, J.; Smolka, J.; Palacz, M.; Haida, M.; Banasiak, K. Non-equilibrium approach for the simulation of CO2 expansion in two-phase ejector driven by subcritical motive pressure. Int. J. Refrig. 2020, 114, 32–46. [Google Scholar] [CrossRef]

- Smolka, J.; Bulinski, Z.; Fic, A.; Nowak, A.J.; Banasiak, K.; Hafner, A. A computational model of a transcritical R744 ejector based on a homogeneous real fluid approach. Appl. Math. Model. 2013, 37, 1208–1224. [Google Scholar] [CrossRef]

- Palacz, M.; Smolka, J.; Fic, A.; Bulinski, Z.; Nowak, A.J.; Banasiak, K.; Hafner, A. Application range of the HEM approach for CO2 expansion inside two-phase ejectors for supermarket refrigeration systems. Int. J. Refrig. 2015, 59, 251–258. [Google Scholar] [CrossRef]

- Akbarnejad, S.; Ziabasharhagh, M. A study of the application of wet steam modeling for thermocompressor simulation in TVC desalination. Desalin. Water Treat. 2024, 317, 100289. [Google Scholar] [CrossRef]

- Al-Manea, A.; Saleh, K. Supersonic steam ejectors: Comparison of dry and wet. J. Eng. Sci. Technol. 2022, 17, 1200–1212. [Google Scholar]

- Foroozesh, F.; Khoshnevis, A.B.; Lakzian, E. Improvement of the wet steam ejector performance in a refrigeration cycle via changing the ejector geometry by a novel EEC (Entropy generation, Entrainment ratio, and Coefficient of performance) method. Int. J. Refrig. 2020, 110, 248–261. [Google Scholar] [CrossRef]

- Marynowski, T.; Desevaux, P.; Mercadier, Y. Experimental and numerical visualizations of condensation process in a supersonic ejector. J. Vis. 2009, 12, 251–258. [Google Scholar] [CrossRef]

- Khalil, A.; Fatouh, M.; Elgendy, E. Ejector design and theoretical study of R134a ejector refrigeration cycle. Int. J. Refrig. 2011, 34, 1684–1698. [Google Scholar] [CrossRef]

- Carey, V.P.; Oyumi, S.M.; Ahmed, S. Post-nucleation growth of water microdroplets in supersaturated gas mixtures: A molecular simulation study. Int. J. Heat Mass Transf. 1997, 40, 2393–2406. [Google Scholar] [CrossRef]

- Banasiak, K.; Hafner, A. 1D Computational model of a two-phase R744 ejector for expansion work recovery. Int. J. Therm. Sci. 2011, 50, 2235–2247. [Google Scholar] [CrossRef]

- Grazzini, G.; Milazzo, A.; Mazzelli, F.; Grazzini, G.; Milazzo, A.; Mazzelli, F. Physics of the Ejectors. In Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2018; pp. 21–69. [Google Scholar]

- Yadav, S.K.; Pandey, K.M.; Gupta, R. Recent advances on principles of working of ejectors: A review. Mater. Today Proc. 2021, 45, 6298–6305. [Google Scholar] [CrossRef]

- Wegener, P.; Mack, L. Condensation in supersonic and hypersonic wind tunnels. Adv. Appl. Mech. 1958, 5, 307–447. [Google Scholar] [CrossRef]

- Wang, C.; Wang, L.; Zhao, H.; Du, Z.; Ding, Z. Effects of superheated steam on non-equilibrium condensation in ejector primary nozzle. Int. J. Refrig. 2016, 67, 214–226. [Google Scholar] [CrossRef]

- Hill, P.G. Condensation of water vapour during supersonic expansion in nozzles. J. Fluid Mech. 1966, 25, 593–620. [Google Scholar] [CrossRef]

- Zhou, H.; Gué, A. Simulation model and droplet ejection performance of a thermal-bubble microejector. Sens. Actuators B Chem. 2010, 145, 311–319. [Google Scholar] [CrossRef]

- Yang, Y.; Walther, J.H.; Yan, Y.; Wen, C. CFD modeling of condensation process of water vapor in supersonic flows. Appl. Therm. Eng. 2017, 115, 1357–1362. [Google Scholar] [CrossRef]

- Guo, T.; Burnett, M.; Turnquist, N.; Moraga, F. High Pressure Subsonic Nucleation in 1D Nozzles—An Experimental Study. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V01BT27A051. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Dong, J.; Wu, J.; Tu, J. Numerical study on mixing flow behavior in gas-liquid ejector. Exp. Comput. Multiph. Flow 2021, 3, 108–112. [Google Scholar] [CrossRef]

- Sommerfeld, M. Numerical methods for dispersed multiphase flows. In Particles in Flows; Springer: Cham, Switzerland, 2017; pp. 327–396. [Google Scholar] [CrossRef]

- Sommerfeld, M.; van Wachem, B.; Oliemans, R. Best Practice Guidelines for Computational Fluid Dynamics of Dispersed Multi-Phase Flows; ERCOFTAC: UK, 2008; p. 129. [Google Scholar]

| Paper | Primary–Secondary Flow | Fluid Flow | Geometry | Elements No. |

|---|---|---|---|---|

| Niu and Zhang 2024 [18] | Air–air (both ideal gas) single-phase | supersonic | 2D | 44,400 |

| Chai et al., 2024 [42] | Saturated steam–water two-phase | supersonic | 3D | 294,480 |

| Li et al., 2024 [41] | Nitrogen–air single-phase | Supersonic | 2D for single nozzle and 3D for 4-nozzles | 374,000 for single nozzle 16 million for 4-nozzles |

| Talebiyan et al., 2024 [35] | Gas–gas (both ideal gas) single-phase | supersonic | 2D with rectangular cross-section | 430,000 |

| Singer et al., 2024 [40] | Pure hydrogen-mixed H2/N2 single-phase | supersonic | 2D axis-symmetric | 330,000 |

| Feng et al., 2024 [43] | Steam–water two-phase | supersonic | 2D axis-symetric | 140,000 |

| Kus and Madejski 2024 [44] | water–CO2 two-phase | subsonic | 2D axis-symetric | 28,299 |

| Tavakoli et al., 2023 [36] | Air–air (both ideal gas) single-phase | subsonic | 2D without and with fluidic oscillator | 50,000 |

| Hou et al., 2022 [38] | Steam–steam (both ideal saturated steam) single-phase | supersonic | 3D | 982,362 |

| Dadpour et al., 2022 [45] | Wet steam–wet steam two-phase | supersonic | 2D | 40,000 |

| Koirala et al., 2022 [46] | Sub-cooled water–vapor two-phase | subsonic | 3D | 1.8 million |

| Wen et al., 2020 [47] | Vapor–liquid two-phase | supersonic | 2D | 73,000 |

| Macia et al., 2019 [37] | Air–air (both ideal gas) single-phase | supersonic | 2D axisymmetric | 20,300 |

| Han et al., 2019 [48] | Steam–steam (both ideal gas) single-phase | supersonic | 2D axisymmetric | 46,352 |

| Banu and Mani 2019 [39] | Steam–steam (both ideal gas) single-phase | - | 3D | 700,000 |

| Giacomelli et al., 2016 [49] | wet steam–wet steam two-phase | supersonic | 2D axis-symmetric | 45,000 |

| Ariafar et al., 2014 [50] | wet steam nozzle (of an ejector) two-phase | supersonic | 2D axis-symmetric with rectangular cross-section | 6510 |

| Paper | Two-Phase Model | Best Turbulence Model Reported | Entrainment Ratio Remarks | Heat and Mass Transfer Model and Parameters |

|---|---|---|---|---|

| Niu and Zhang 2024 [18] | - | - | Was analyzed using both single-factor and multi-factor approaches | - |

| Chai et al., 2024 [42] | Heterogeneous two-fluid (Eulerian) model | - | - | Non-equilibrium condensation model |

| Li et al., 2024 [41] | - | - | Reported versus compression ratio, non-mixing length | - |

| Talebiyan et al., 2024 [35] | - | k- SST | The adjoint optimization method notably improved entrainment ratio by around 20.8%, 15.3%, and 16.5% for different operating modes | - |

| Singer et al., 2024 [40] | - | RSM with adjusted GEKO parameters | Reported versus the percentage of the fuel cell stack’s maximum load point/ Generalized k- turbulence model decreases overprediction of entrainment ratio by 25% | - |

| Feng et al., 2024 [43] | Eulerian–Eulerian | - | Reported versus liquid mass fraction, droplet number/increase in droplet mass fraction led to a 9.15% decrease in M | classical homogeneous nucleation theory |

| Tavakoli et al., 2023 [36] | - | k- SST k- | Reported versus pressure ratio/Ejector with oscillator improved entrainment ratio by 38.3% | |

| Kus and Madejski 2024 [44] | Not available | - | - | Direct contact condensation and Mixture multiphase mode (MMP) |

| Hou et al., 2022 [38] | - | - | Reported versus oultlet back pressure | - |

| Dadpour et al., 2022 [45] | Eulerian-Eulerian | - | Reported versus back pressure/injection leads to a decrease in M by approximately 22.93% | - |

| Koirala et al., 2022 [46] | Eulerian multiphase model | - | Back pressure ratio on entrainment ratio Primary flow temperature on entrainment ratio Entrainment pressure on entrainment ratio Time on entrainment ratio Condensation on entrainment ratio/ | Direct contact condensation resistance models for heat transfer interaction Ranz–Marshall to zero-resistance |

| Wen et al., 2020 [47] | Not available | k- SST | Reported versus inlet pressure of suction chamber on entrainment ratio/ M grows as the pressure in the suction chamber increases | Non-equilibrium condensation model |

| Macia et al., 2019 [37] | - | - | - | - |

| Han et al., 2019 [48] | - | realizable k- | Reported versus primary fluid temperature, Back pressure, Throat diameter, NXP/ | |

| Banu and Mani 2019 [39] | - | - | Reported versus pressure drive ratio and for different sweep angles of cavity type swirl generator/ | - |

| Giacomelli et al., 2016 [49] | Eulerian multiphase model | - | Reported versus outlet pressure/HEM predicts a lower value of M | Non-equilibrium condensation model Homogeneous Non-equilibrium model |

| Ariafar et al., 2014 [51] | Eulerian–Eulerian approach | - | described without curves | - |

| Paper | Boundary Conditions | Solver and Software | Turbulence Modeling and Wall Function | Validation and Verification |

|---|---|---|---|---|

| Niu and Zhang [18] | MPa, MPa, MPa | Implicit pressure-based Ansys Fluent 19.0 | k- SST, Standard wall function | Experimental |

| Chai et al., 2024 [42] | Inlet: mass flow rate for primary and secondary, 0.6–2.9 MPa, Outlet: 500 kPa | Pressure-based Ansys CFX 18.0 | k-,Scalable wall function | - |

| Li et al., 2024 [41] | 6.84 kg/s, 316.2 K, 0.61 kg/s, K, kPa, K | coupled implicit density-based, FLUENT 19.0 | k- SST | Experimental |

| Talebiyan et al., 2024 [35] | Inlet: kPa, K, kPa, K, Outlet: kPa, K | Pressure-based Ansys Fluent 2022 R2 | k- SST | Karthick et al., 2016 (exp) [55], Samsam-Khayani et al., 2022 (Num) [56] |

| Singer et al., 2024 [40] | Inlet: , kPa Outlet: kPa with variation of pure hydrogen and mixed volume percentage | pressure-based using pressure–velocity coupling, Ansys Fluent 2023 R1 | Spallart allmaras, Standard k- wall function: Enhanced Wall Treatment, RNG k-, Realizable k-, k-, SST k-, Generalized k- (GEKO), RSM stress-BSL | Experimental |

| Feng et al., 2024 [43] | Inlet: Pa, K, kPa, K Outlet: kPa, K | density-based implicit, FLUENT 19.2 | k- SST | Experimental and CFD by Sriveerakul [57] |

| Kus and Madejski 2024 [44] | Inlet: m/s, bar, C, g/s, bar, C Outlet: bar | Segregated flow model, Siemens StarCCM+ 2022.1.1 | Realizable k- | - |

| Tavakoli et al., 2023 [36] | Inlet: kg/s, 99,961.75 Pa, Outlet: 102,161 Pa | URANS equations (unsteady) Ansys Fluent 2022 R2 | k- and k- SST | - |

| Hou et al., 2022 [38] | Inlet: 27,100 Pa, , , Outlet: : an independent variable, : saturated steam temperature corresponding to the | Pressure-based (steady state) Fluent | Realizable k-,standard wall function | Numerical |

| Dadpour et al., 2022 [45] | B-Moore nozzle: kPa, K, , K, Ejector: kPa, , kPa, K Outlet: , K | Using Gauss–Seidel method coupled with implicit scheme, Open FOAM | k- model | B-Moore nozzle |

| Koirala et al., 2022 [46] | Inlet: MPa, , MPa, Outlet: MPa | Pressure-based (steady and unsteady) Ansys Fluent 2019 R2 | k- model | Zhang et al., 2012 [58] |

| Wen et al., 2020 [47] | Total pressure and total temperature for the entrances and exit | URANS equations (unsteady) Ansys Fluent 19 | k- SST | Sharifi and Boroomand 2013 (exp) [59] Laval nozzle Moses and Stein (exp) 1978 [60] Starzman et al., 2018 [61] |

| Macia et al., 2019 [37] | Inlet: bar, Neumann condition for velocity, bar, Outlet: | Density-based explicit (rhoCentralFoam) implicit (HiSA) solvers OpenFOAM 6 | k- SST | Experimental |

| Han et al., 2019 [48] | Inlet: 310–390 kPa, 2330–3170 Pa, Outlet: 3500–7000 Pa | ANSYS Fluent 17 | Standard k-, RNG k-, realizable k-, with Standard Wall Function and Enhanced Wall Function, and k- SST | Experimental |

| Banu and Mani 2019 [39] | Inlet: , bar | Density-based (steady) Ansys Fluent 15.0 | k- SST | Experimental Banu et al., 2016 [62] as well as PIV study |

| Giacomelli et al., 2016 [49] | Inlet: , ; primary and secondary pressures are the saturation pressures corresponding to | Ansys Fluent 16.2 | - | WS model in Fluent 16.2 |

| Ariafar et al., 2014 [50] | kPa, K, Outlet: kPa | Coupled implicit solver Ansys Fluent 14.5 | Realizable k- | Two experimental cases by Moor et al. [63] and Bakhtar et al. [64] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghiseraji, J.; Garcia-Vilchez, M.; Castilla, R.; Raush, G. Recent Advances in Numerical Simulation of Ejector Pumps for Vacuum Generation—A Review. Energies 2024, 17, 4479. https://doi.org/10.3390/en17174479

Sadeghiseraji J, Garcia-Vilchez M, Castilla R, Raush G. Recent Advances in Numerical Simulation of Ejector Pumps for Vacuum Generation—A Review. Energies. 2024; 17(17):4479. https://doi.org/10.3390/en17174479

Chicago/Turabian StyleSadeghiseraji, Jaber, Mercè Garcia-Vilchez, Robert Castilla, and Gustavo Raush. 2024. "Recent Advances in Numerical Simulation of Ejector Pumps for Vacuum Generation—A Review" Energies 17, no. 17: 4479. https://doi.org/10.3390/en17174479

APA StyleSadeghiseraji, J., Garcia-Vilchez, M., Castilla, R., & Raush, G. (2024). Recent Advances in Numerical Simulation of Ejector Pumps for Vacuum Generation—A Review. Energies, 17(17), 4479. https://doi.org/10.3390/en17174479