Comparative and Sensibility Analysis of Cooling Systems

Abstract

:1. Introduction

2. Methodology

- Development of the dynamic heat transfer model

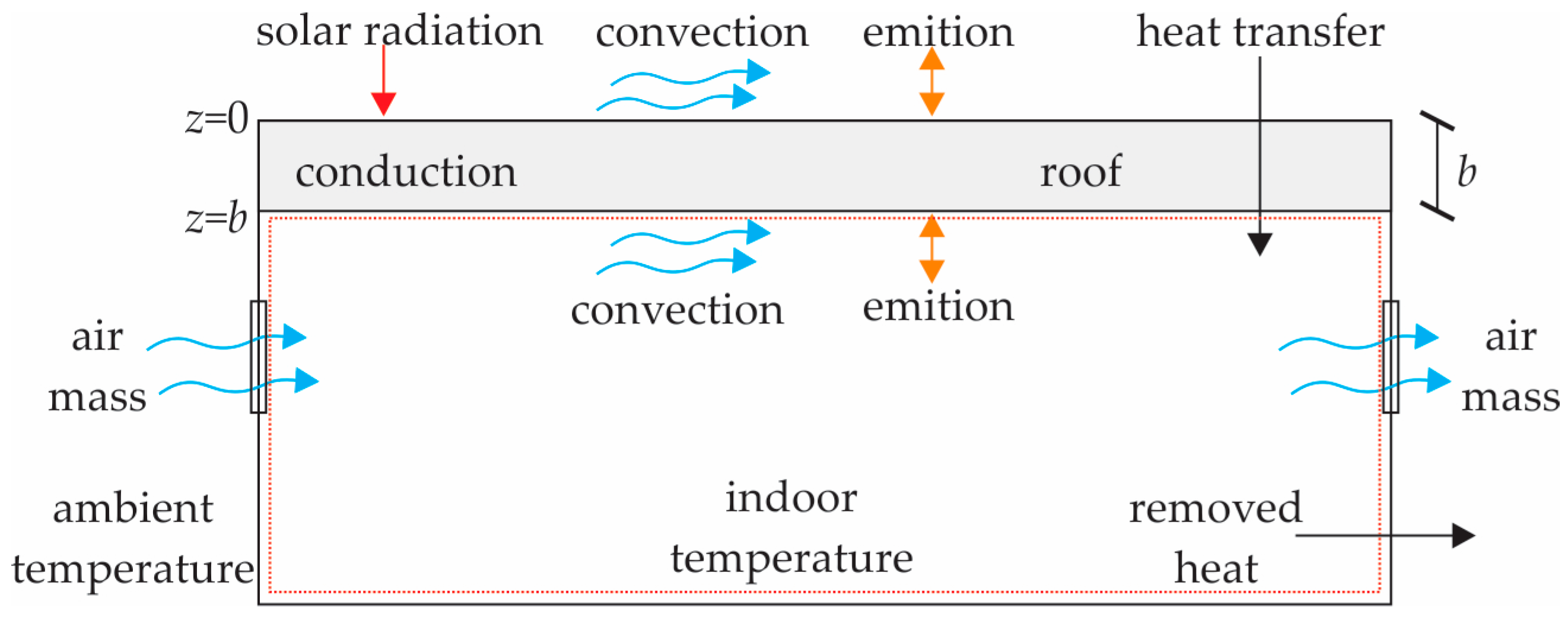

- In this step, we first describe the dynamic model of one-dimensional heat transfer via conduction through the roof of the building. The boundary conditions are given, and the equations necessary to calculate the heat fluxes are presented.

- Subsequently, the energy balance for the interior of the building, considering an open system, is presented, and the equations that couple this balance with the heat transfer model are shown.

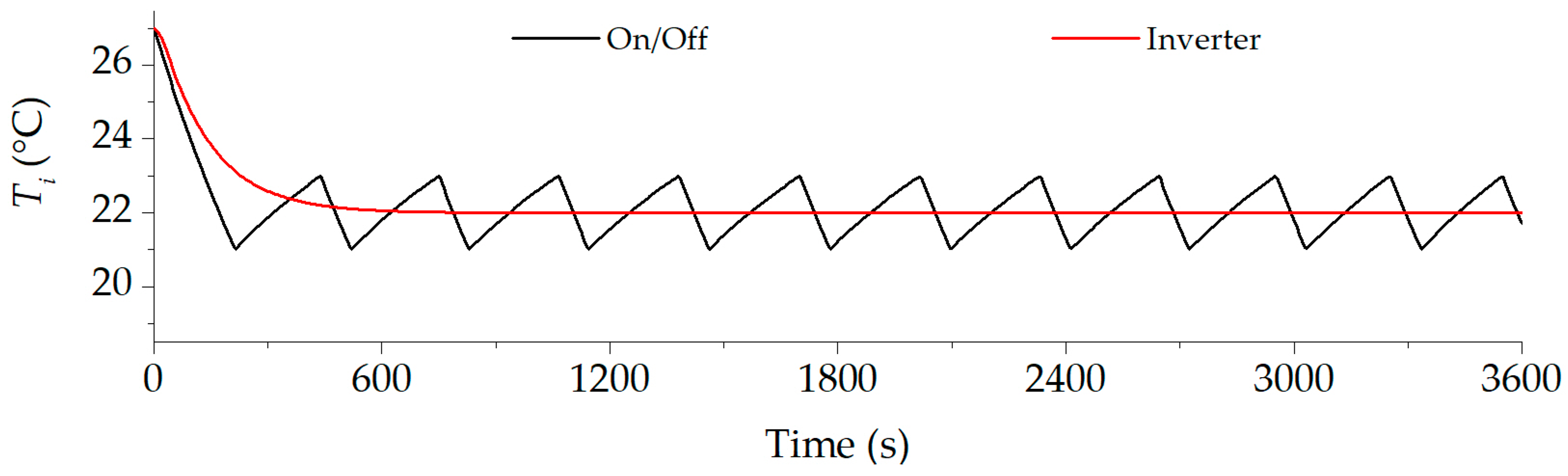

- The energy balance shows how the temperature inside the building changes, which is desired to control by means of AC equipment. Therefore, two control strategies are presented that are coupled to the energy balance to remove heat from the building if necessary. The first strategy is the on/off control; the second strategy is a PID control to simulate the behavior of inverter equipment.

- Numerical solution method

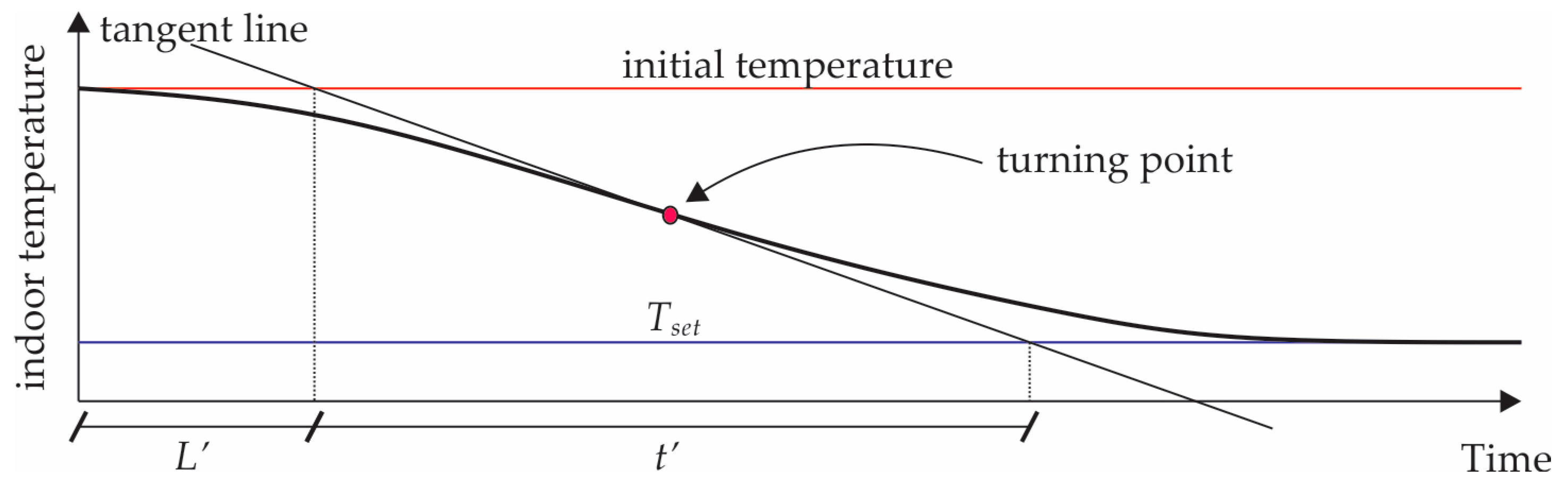

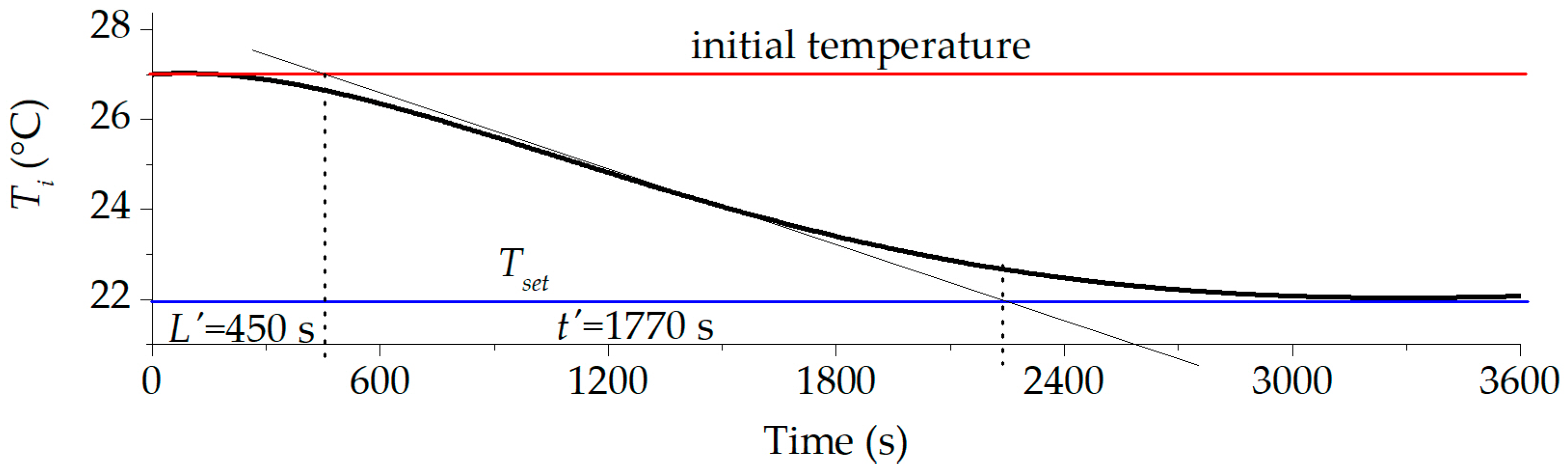

- In this step, the discrete form of the differential equations previously presented is shown. The Euler method is implemented in Python to obtain the interior temperature of the building for different times. The control strategies are coupled, and the PID strategy is tuned; that is, the values of the proportional, integral, and derivative constants are determined. The use of Python is highly advantageous due to its open-source nature and the extensive range of libraries that facilitate modeling in engineering. In this study, thermal properties of air and refrigerants libraries were used. Unlike licensed software, which often incurs high costs, these types of models can be implemented and executed on any device, regardless of its operating system or computing capacity. This feature is particularly beneficial for on-site testing and trials with short periods of time.

- Application to the base case

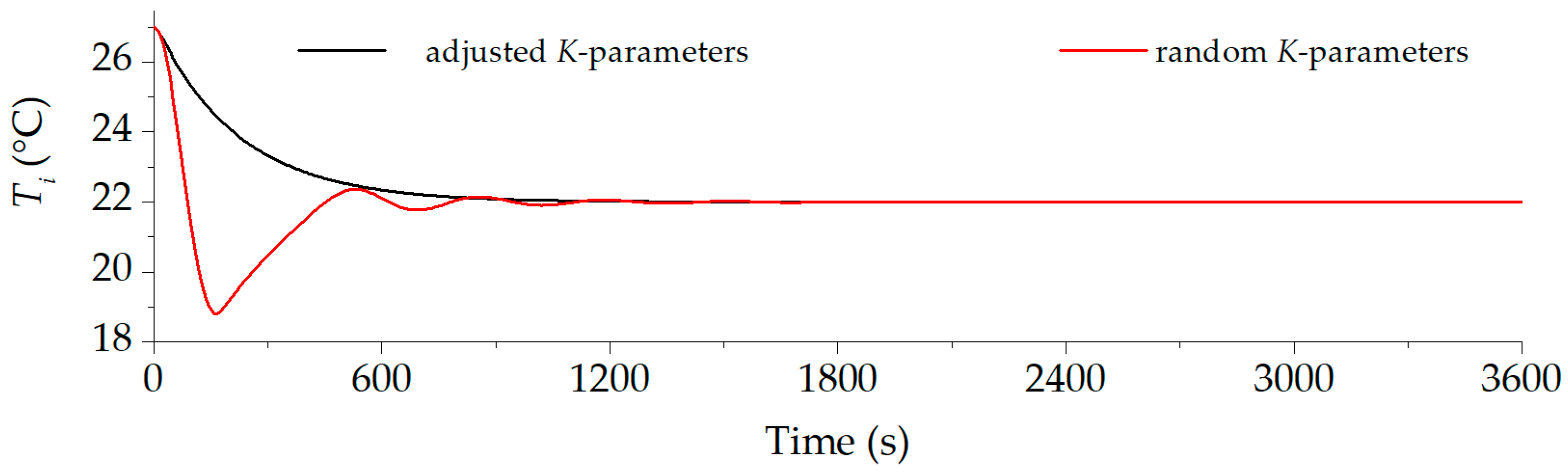

- The variables of the base case are taken to verify that the control strategies work properly; this can be seen by analyzing the evolution over time of the temperature inside the building.

- Once the correct operation of the control strategies has been verified, the electricity consumption of the two control strategies for the base case is compared.

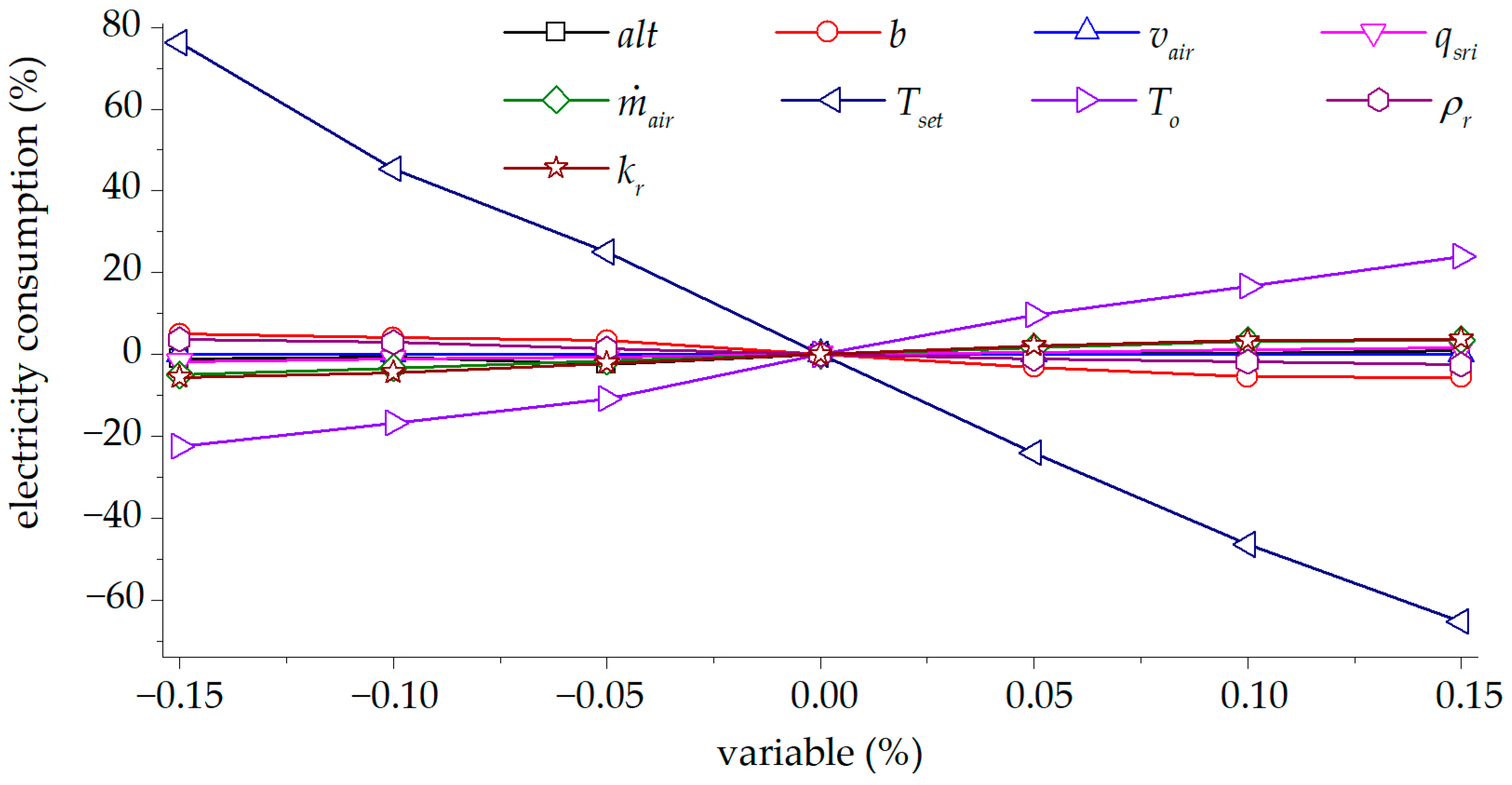

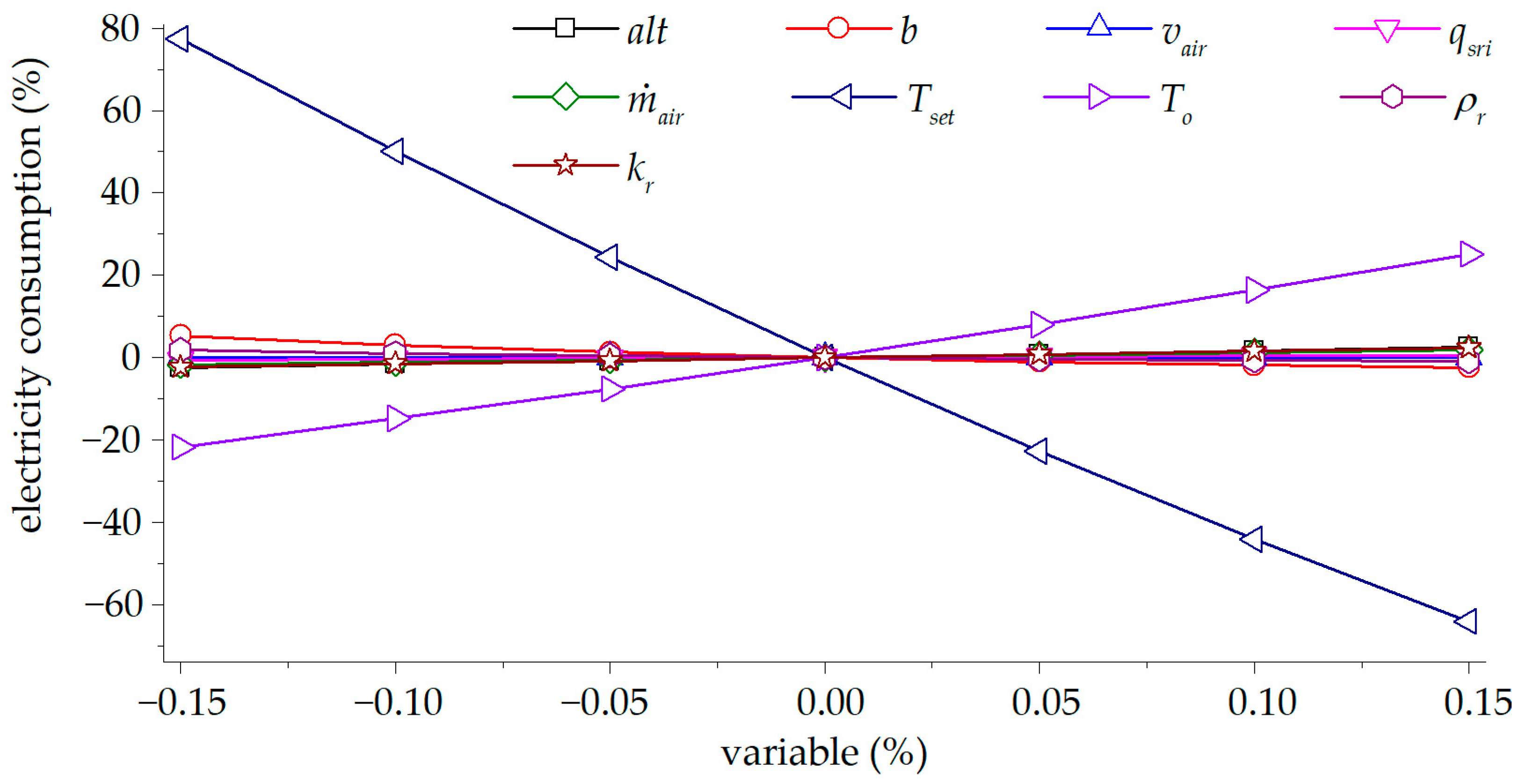

- Finally, a sensitivity analysis is performed to determine the variables that have the greatest impact on electricity consumption.

2.1. Dynamic Heat Transfer Model

2.2. Numerical Solution Method

3. Results and Discussion

3.1. Results

3.2. Discussion

4. Conclusions

- Inverter systems can bring the indoor temperature of the building closer to the comfort temperature.

- Inverter systems reduce electricity consumption by about 7% with respect to equipment with on/off control.

- The most important variable is desired comfort temperature. A variation of this variable by 15% impacts electricity consumption by up to 80%. Therefore, increasing the comfort temperature by 1 °C represents a significant electricity saving for both control strategies.

- The next most important variable is ambient temperature; a 15% variation in this variable can impact electricity consumption by about 20%.

- A 15% variation in the values of incident solar radiation, roof thickness, incoming air flow, enclosure height, external wind speed, and the thermal properties of the building materials has an impact on electricity consumption of less than 10%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| area of the roof [m2] | |

| b | roof thickness [m] |

| COP | coefficient of performance [dimensionless] |

| coefficient of performance for the ideal refrigeration cycle [dimensionless] | |

| Cp | specific heat [J kg−1 °C−1] |

| Einverter | electric power consumption with PID control [J] |

| Eon/off | electric power consumption with on/off control [J] |

| error [°C] | |

| g | acceleration constant of gravity [m s−2] |

| convective heat transfer coefficient [W m−2 °C−1] | |

| Kd | derivative constant [J °C−1] |

| Kit | integral constant [s °C W−1] |

| Kp | proportional constant [W °C−1] |

| k | thermal conductivity [W m−1 °C−1] |

| PID control response constant [s] | |

| characteristic length of the heat transfer [m] | |

| air mass inside the building [kg] | |

| mass flow of air entering and leaving the building [kg s−1] | |

| Nu | Nusselt number [dimensionless] |

| n | number of nodes [dimensionless] |

| Pr | Prandtl number [dimensionless] |

| p | perimeter [m] |

| heat removed by the AC equipment [W] | |

| internal heat sources [W] | |

| heat transferred by convection [W m−2] | |

| heat flux by emission [W m−2] | |

| heat gained by solar radiation [W m−2] | |

| incident solar irradiance [W m−2] | |

| Ra | Rayleigh number [dimensionless] |

| Re | Reynolds number [dimensionless] |

| T | temperature [°C] |

| Tj | temperature evaluated at the j-th node [°C] |

| temperature of the surroundings [K] | |

| film temperature [°C] | |

| thermal comfort temperature [°C] | |

| sky temperature [K] | |

| t | time [s] |

| PID control response constant [s] | |

| total operating time of the AC equipment [s] | |

| v | mean velocity [m s−1] |

| z | direction of heat transfer [m] |

| Greek symbols | |

| thermal absorptivity [dimensionless] | |

| coefficient of volumetric expansion [K−1] | |

| variation of heat removed [W] | |

| temporary integration step [s] | |

| spatial integration step [m] | |

| thermal emissivity [dimensionless] | |

| equipment efficiency [dimensionless] | |

| dynamic viscosity [kg m−1 s−1] | |

| kinematic viscosity [m2 s−1] | |

| density [kg m−3] | |

| Stefan-Boltzmann constant [W m−2 K−4] | |

| Subscript | |

| air | refers to the properties of the air |

| el | electrical appliances |

| i | the inside of the building |

| o | the outside of the building |

| pp | people |

| r | refers to the roof material |

| w | walls |

References

- Hassanpour, H.; Hamedi, A.H.; Mhaskar, P.; House, J.M.; Salsbury, T.I. A hybrid clustering approach integrating first-principles knowledge with data for fault detection in HVAC systems. Comput. Chem. Eng. 2024, 187, 108717. [Google Scholar] [CrossRef]

- Shah, I.H.; Manzoor, M.A.; Jinhui, W.; Li, X.; Hameed, M.K.; Rehaman, A.; Li, P.; Zhang, Y.; Niu, Q.; Chang, L. Comprehensive review: Effects of climate change and greenhouse gases emission relevance to environmental stress on horticultural crops and management. J. Environ. Manag. 2024, 351, 119978. [Google Scholar] [CrossRef]

- Bai, Y.; Yu, C.; Pan, W. Systematic examination of energy performance gap in low-energy buildings. Renew. Sustain. Energy Rev. 2024, 202, 114701. [Google Scholar] [CrossRef]

- Mirnaghi, M.S.; Haghighat, F. Fault detection and diagnosis of large-scale HVAC systems in buildings using data-driven methods: A comprehensive review. Energy Build. 2020, 229, 110492. [Google Scholar] [CrossRef]

- Ma, N.; Aviv, D.; Guo, H.; Braham, W.W. Measuring the right factors: A review of variables and models for thermal comfort and indoor air quality. Renew. Sustain. Energy Rev. 2021, 135, 110436. [Google Scholar] [CrossRef]

- Pahlavikhah Varnosfaderani, M.; Heydarian, A.; Jazizadeh, F. A longitudinal study of IAQ metrics and the efficacy of default HVAC ventilation. Build. Environ. 2024, 254, 111353. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Shchegolkov, A.V.; Galunin, E.V.; Popova, A.A.; Krivosheev, R.M.; Memetov, N.R.; Tkachev, A.G. Graphene-Modified Heat-Accumulating Materials and Aspects of their Application in Thermotherapy and Biotechnologies. Nano Hybrids Compos. 2017, 13, 21–25. [Google Scholar] [CrossRef]

- OECD/IEA. The Future of Cooling Opportunities for Energy–Efficient Air Conditioning. 2018. Available online: https://www.iea.org/reports/the-future-of-cooling (accessed on 1 May 2024).

- Tumminia, G.; Guarino, F.; Longo, S.; Aloisio, D.; Cellura, S.; Sergi, F.; Brunaccini, G.; Antonucci, V.; Ferraro, M. Grid interaction and environmental impact of a net zero energy building. Energy Convers. Manag. 2020, 203, 112228. [Google Scholar] [CrossRef]

- Ou, Y.; Bao, Z.; Ng, S.T.; Song, W.; Chen, K. Land-use carbon emissions and built environment characteristics: A city-level quantitative analysis in emerging economies. Land Use Policy 2024, 137, 107019. [Google Scholar] [CrossRef]

- Heidarykiany, R.; Ababei, C. HVAC energy cost minimization in smart grids: A cloud-based demand side management approach with game theory optimization and deep learning. Energy AI 2024, 16, 100362. [Google Scholar] [CrossRef]

- Wang, H.; Lin, J.; Zhang, Z. Single imbalanced domain generalization network for intelligent fault diagnosis of compressors in HVAC systems under unseen working conditions. Energy Build. 2024, 312, 114192. [Google Scholar] [CrossRef]

- Babadi Soultanzadeh, M.; Ouf, M.M.; Nik-Bakht, M.; Paquette, P.; Lupien, S. Fault detection and diagnosis in light commercial buildings’ HVAC systems: A comprehensive framework, application, and performance evaluation. Energy Build. 2024, 316, 114341. [Google Scholar] [CrossRef]

- Hosseini Gourabpasi, A.; Nik-Bakht, M. BIM-based automated fault detection and diagnostics of HVAC systems in commercial buildings. J. Build. Eng. 2024, 87, 109022. [Google Scholar] [CrossRef]

- Bi, J.; Wang, H.; Yan, E.; Wang, C.; Yan, K.; Jiang, L.; Yang, B. AI in HVAC fault detection and diagnosis: A systematic review. Energy Rev. 2024, 3, 100071. [Google Scholar] [CrossRef]

- Khan, O.; Parvez, M.; Seraj, M.; Yahya, Z.; Devarajan, Y.; Nagappan, B. Optimising building heat load prediction using advanced control strategies and Artificial Intelligence for HVAC system. Therm. Sci. Eng. Prog. 2024, 49, 102484. [Google Scholar] [CrossRef]

- Adli, M.I.; Hernandez, M.; Patino-Echeverri, D. Estimating unserved residential space-cooling needs without assuming arbitrary indoor set point temperatures: The case of Mexico. Energy Sustain. Dev. 2024, 79, 101379. [Google Scholar] [CrossRef]

- Davis, L.W.; Martinez, S.; Taboada, B. How effective is energy-efficient housing? Evidence from a field trial in Mexico. J. Dev. Econ. 2020, 143, 102390. [Google Scholar] [CrossRef]

- Hernandez, M.; Patino-Echeverri, D. Electricity consumption, subsidies, and policy inequalities in Mexico: Data from 100,000 households. Energy Sustain. Dev. 2022, 71, 186–199. [Google Scholar] [CrossRef]

- Adesanya, M.A.; Obasekore, H.; Rabiu, A.; Na, W.-H.; Ogunlowo, Q.O.; Akpenpuun, T.D.; Kim, M.-H.; Kim, H.-T.; Kang, B.-Y.; Lee, H.-W. Deep reinforcement learning for PID parameter tuning in greenhouse HVAC system energy Optimization: A TRNSYS-Python cosimulation approach. Expert Syst. Appl. 2024, 252, 124126. [Google Scholar] [CrossRef]

- Oropeza-Perez, I.; Østergaard, P.A. Energy saving potential of utilizing natural ventilation under warm conditions—A case study of Mexico. Appl. Energy 2014, 130, 20–32. [Google Scholar] [CrossRef]

- Evangelisti, L.; Guattari, C.; Asdrubali, F. On the sky temperature models and their influence on buildings energy performance: A critical review. Energy Build. 2019, 183, 607–625. [Google Scholar] [CrossRef]

- Churchill, S.W.; Ozoe, H. Correlations for laminar forced convection in flow over an isothermal flat plate and in developing and fully developed flow in an isothermal tube. J. Heat Transf. 1973, 95, 78–84. [Google Scholar] [CrossRef]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena; Wiley: New York, NY, USA, 1924. [Google Scholar]

- Nakamura, H.; Igarashi, T.; Tsutsui, T. Local heat transfer around a wall-mounted cube in the turbulent boundary layer. Int. J. Heat Mass Transf. 2001, 44, 3385–3395. [Google Scholar] [CrossRef]

- Liu, Y.; Harris, D.J. Full-scale measurements of convective coefficient on external surface of a low-rise building in sheltered conditions. Build. Environ. 2007, 42, 2718–2736. [Google Scholar] [CrossRef]

- Montazeri, H.; Blocken, B. Extension of generalized forced convective heat transfer coefficient expressions for isolated buildings taking into account oblique wind directions. Build. Environ. 2018, 140, 194–208. [Google Scholar] [CrossRef]

- Cengel, Y.A. Transferencia de Calor Y Masa, un Enfoque Práctico, 3rd ed.; Mc Graw Hill: Mexico City, México, 2007. [Google Scholar]

- Dormido-Bencomo, S.; Morilla-García, F. Controladores PID, Fundamentos, Sintonía y Autosintonía; Departamento de Informática y Automática UNED: Salamanca, Spain, 2001. [Google Scholar]

- Ziegler, J.G.; Nichols, N.B. Optimum Settings for Automatic Controllers. J. Fluids Eng. 1942, 64, 759–765. [Google Scholar] [CrossRef]

- Ziegler, J.G.; Nichols, N.B. Process Lags in Automatic-Control Circuits. J. Fluids Eng. 1943, 65, 433–440. [Google Scholar] [CrossRef]

- Ogata, K. Modern Control Engineering, 5th ed.; Pearson: London, UK, 2009. [Google Scholar]

| Parameter | Value | Units |

|---|---|---|

| 101.3 | kPa | |

| 32 | °C | |

| °C | ||

| 2.0 | m s−1 | |

| 0.01 | kg s−1 | |

| 800 | W m−2 | |

| L | 5 | m |

| w | 5 | m |

| alt | 2.7 | m |

| b | 0.15 | m |

| 1.4 | W m−1 °C−1 | |

| 2300 | kg m−3 | |

| 880 | J kg−1 K−1 | |

| 0.9 | Dimensionless | |

| 0.9 | Dimensionless | |

| 22 | °C | |

| n | 15 | Dimensionless |

| 0.1 | s | |

| m | ||

| 0.011 | W °C−1 | |

| - | J °C−1 | |

| - | s °C W−1 |

| Parameter | Value | Units |

|---|---|---|

| 4.72 | W °C−1 | |

| 225 | J °C−1 | |

| 900 | s °C W−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Espinosa-Martínez, É.-G.; Quezada-García, S.; Escobedo-Izquierdo, M.A.; Cázares-Ramírez, R.I. Comparative and Sensibility Analysis of Cooling Systems. Energies 2024, 17, 4452. https://doi.org/10.3390/en17174452

Espinosa-Martínez É-G, Quezada-García S, Escobedo-Izquierdo MA, Cázares-Ramírez RI. Comparative and Sensibility Analysis of Cooling Systems. Energies. 2024; 17(17):4452. https://doi.org/10.3390/en17174452

Chicago/Turabian StyleEspinosa-Martínez, Érick-G., Sergio Quezada-García, M. Azucena Escobedo-Izquierdo, and Ricardo I. Cázares-Ramírez. 2024. "Comparative and Sensibility Analysis of Cooling Systems" Energies 17, no. 17: 4452. https://doi.org/10.3390/en17174452

APA StyleEspinosa-Martínez, É.-G., Quezada-García, S., Escobedo-Izquierdo, M. A., & Cázares-Ramírez, R. I. (2024). Comparative and Sensibility Analysis of Cooling Systems. Energies, 17(17), 4452. https://doi.org/10.3390/en17174452