Abstract

Advances in numerical modeling are essential for heat-transfer applications in electronics cooling, renewable energy, and sustainable construction. This review explores key methods like Computational Fluid Dynamics (CFD), the Finite Element Method (FEM), the Finite Volume Method (FVM), and multiphysics modeling, alongside emerging strategies such as Adaptive Mesh Refinement (AMR), machine learning (ML), reduced-order modeling (ROM), and high-performance computing (HPC). While these techniques improve accuracy and efficiency, they also increase computational energy demands, contributing to a growing carbon footprint and sustainability concerns. Sustainable computing practices, including energy-efficient algorithms and renewable-powered data centers, offer potential solutions. Additionally, the increasing energy consumption in numerical modeling highlights the need for optimization strategies to mitigate environmental impact. Future directions point to quantum computing, adaptive models, and green computing as pathways to sustainable thermal management modeling. This study systematically reviews the latest advancements in numerical heat-transfer modeling and, for the first time, provides an in-depth exploration of the roles of computational energy optimization and green computing in thermal management. This review outlines a roadmap for efficient, environmentally responsible heat-transfer models to meet evolving demands.

1. Introduction

Effective heat transfer and thermal management are essential across various industries, from electronics and automotive to renewable energy and building systems. As modern technology evolves, so does the need for efficient thermal control to prevent overheating, ensure safety, and maximize energy efficiency. The field of heat-transfer modeling has responded to these demands by adopting and advancing sophisticated computational techniques, making numerical modeling a cornerstone for understanding and controlling thermal behaviors in complex systems. This review focuses on the latest developments in numerical modeling for heat transfer, with particular attention to computational techniques and their environmental implications.

Traditionally, thermal transfer processes are delineated by three fundamental mechanisms: conduction, convection, and radiation [1]. Each mechanism performs an essential function depending on the material characteristics, the configurations of the system, and the operational conditions. However, the solutions to practical thermal transfer challenges are often complicated due to the interrelations of numerous factors, which encompass intricate geometries, transient boundary conditions, and coupled physical phenomena [2]. Numerical modeling has empowered researchers to address these complexities with increased precision, adaptability, and computational efficiency. Principal numerical methodologies, such as Finite-Difference Method (FDM), Finite Element Method (FEM), Finite Volume Method (FVM), Computational Fluid Dynamics (CFD), Lattice Boltzmann Method (LBM), and Smoothed-Particle Hydrodynamics (SPH) have become extensively employed in the discipline due to their capacity to effectively simulate fluid dynamics and thermal interactions. These methodologies, combined with multiphysics modeling, allow researchers to incorporate interactions among fluid, thermal, and structural phenomena, thereby enhancing the predictive capability of simulations.

Recent advances in computational methodologies have further augmented the capabilities of thermal management modeling [3]. AMR techniques, for example, have improved the simulation precision and efficiency of the simulation by refining the density of the mesh in regions characterized by elevated thermal gradients [4]. Furthermore, machine learning (ML) and artificial intelligence (AI) are making substantial contributions by providing data-driven methodologies that optimize computational resources, reduce simulation durations, and facilitate predictive maintenance [5]. Reduced-order modeling (ROM) has also attracted attention, as it simplifies intricate models while preserving fundamental dynamics, making real-time applications more practicable [6]. Ultimately, the function of high-performance computing (HPC) has been transformative, allowing extensive simulations that were previously unattainable due to computational constraints [7]. Specifically, constraints refer to the significant computational resources required, including high memory demands, processing power, and execution time, which previously limited the feasibility of extensive simulations. The implementation of high-performance computing (HPC) has helped to overcome these barriers, enabling more complex simulations.

Despite these advances, the environmental impact of computational modeling for heat transfer has raised growing concerns. High-fidelity modeling techniques frequently require considerable computational resources, which can result in significant energy expenditure and an increased carbon footprint [8]. The rapid expansion of AI-driven computations and data centers exacerbates these concerns, as highlighted in the International Energy Agency (IEA) report “Energia 2024”, which predicts that global energy demand for AI and cryptocurrency could double by 2026, equaling the electricity consumption of Japan. Major tech companies—Microsoft, Meta, Google, and Amazon—are rapidly expanding data center infrastructure, contributing to unprecedented power demands. A 2024 Goldman Sachs report forecasts that U.S. data centers will consume 8% of the country’s electricity by 2030, up from 3% in 2022, straining existing power grids. This surge in energy demand has driven corporations toward nuclear power, with Amazon acquiring a nuclear-powered data center in Pennsylvania, and Microsoft securing a 20-year nuclear energy deal. However, concerns over grid stability have led to regulatory pushback, such as the U.S. Federal Energy Regulatory Commission (FERC) rejecting a proposal for Amazon to source energy from a nuclear plant. These developments emphasize the urgent need for sustainable computing solutions, including energy-efficient algorithms, low-power hardware, and the integration of renewable energy sources in data centers, to mitigate the growing environmental impact of high-performance simulations. This review examines not only the technical advancements in numerical modeling but also the sustainability issues that accompany them. Efforts to mitigate ecological consequences, such as energy-conserving algorithms, low-power hardware, and the implementation of renewable energy-powered data centers, are progressively significant. These practices, known as sustainable computing, aim to balance computational accuracy with environmental responsibility, helping to mitigate the carbon footprint associated with high-performance simulations.

In addition to sustainability concerns, several challenges remain in the field. Balancing the compromises between precision and computational expense is a persistent concern, particularly in simulations that require elevated spatial and temporal resolutions. Capturing real-world conditions accurately in models—such as transient heat flows, variable boundary conditions, and multi-physics interactions—remains a complex task. Furthermore, the integration of AI and ML into heat-transfer modeling presents its own set of challenges, particularly with respect to data quality and availability. High-quality data are essential for training robust machine learning models, but obtaining accurate and diverse datasets can be difficult in many engineering applications [9]. These include turbulent convection, phase-change processes such as boiling and condensation, and radiative heat transfer in participating media. In these cases, experimental measurements are often limited by sensor accuracy, spatial and temporal resolution constraints, and complex boundary conditions.

Looking ahead, the promising future directions in numerical modeling for heat transfer include quantum computing, which has the potential to revolutionize thermal simulations by offering computational power beyond traditional HPC systems. While quantum computers are expected to provide advantages only for certain types of computationally intensive problems, some heat-transfer phenomena, such as nanoscale thermal transport, fall into this category. Specifically, solving the Boltzmann transport equation (BTE) for phonon transport in semiconductors or addressing quantum many-body interactions in thermal systems are areas where quantum computing could be beneficial. These applications involve complex, high-dimensional calculations that are challenging for classical methods, making them potential candidates for quantum acceleration [10]. Quantum algorithms could provide faster solutions to complex heat-transfer problems, opening new possibilities for adaptive models functioning in real time that respond to dynamic environmental conditions [11]. Green computing initiatives are also expected to play an important role, with advances in low-energy processors, optimized algorithms, and collaborative open-source platforms that foster environmentally responsible practices [12]. These developments signify a shift toward a more sustainable approach to computational modeling, one that seeks to minimize environmental impact, while advancing technical capabilities.

This review presents a thorough examination of the current progress in numerical modeling methodologies pertaining to heat transfer and thermal management. It discusses their applications, emerging technologies, environmental challenges, and potential future directions, offering researchers and engineers insights into the development of efficient and sustainable thermal management solutions.

2. Overview of Numerical Modeling Techniques in Heat Transfer

Numerical modeling methodologies in the domain of heat transfer are essential for the precise forecasting and regulation of thermal phenomena across a multitude of applications. These methodologies inspire engineers and scholars to replicate intricate thermal scenarios, refine designs, and increase system efficiency. Among the foremost techniques, FDM systematically discretizes heat-transfer equations over a well-structured grid, making it particularly effective for conduction-dominant scenarios within simplistic, uniform geometries [13]. However, the dependency of FDM on structured grids limits its flexibility in handling highly irregular geometries and complex boundary problems, making it less suitable for such scenarios, compared to other methods such as FEM. FEM mitigates this constraint by partitioning the domain into smaller interconnected elements, thus providing enhanced adaptability for intricate geometries and transient heat phenomena [14]. FEM is widely utilized in sectors such as automotive [15] and aerospace [16] engineering, in which precise modeling of unconventional structures and boundary conditions is of critical importance.

For scenarios that encompass substantial fluid–thermal interactions, CFD proves to be invaluable, as it effectively simulates convective heat transfer and the interactions that occur between fluids and surfaces. CFD is routinely employed in the domains of electronics cooling, HVAC systems, and energy systems, in which it facilitates the analysis and optimization of fluid–thermal behavior to enhance heat dissipation and energy efficiency. In recent years, innovative techniques have further propelled advancements within the realm of heat-transfer modeling. AMR, for instance, dynamically modifies grid resolution to effectively capture regions characterized by high thermal gradients, thereby improving model precision without incurring excessive computational burdens. Moreover, ML methodologies have introduced data-driven models that facilitate rapid predictions for complex thermal systems, significantly decreasing computational time while maintaining acceptable accuracy levels. Additionally, ROM simplifies comprehensive simulations into lower-dimensional constructs, allowing for faster analyses without sacrificing critical dynamic characteristics.

Each of these methodologies has distinct advantages and limitations, and their applications are selected based on system complexity, precision requirements, and the computational resources at hand. The selection of the most suitable technique is highly dependent on the specific challenges presented by the thermal management issue and the performance expectations related to the application in question. To provide a clearer understanding of the strengths and limitations of the methods presented in the subsequent parts of Section 2, Table 1 has been added to summarize their key characteristics.

Table 1.

Structured comparison of the methods.

2.1. Finite-Difference Method (FDM)

The FDM constitutes a numerical approach extensively employed for the resolution of heat conduction phenomena, primarily owing to its inherent simplicity and efficacy in accommodating various boundary conditions and structured geometrical configurations. This technique involves discretization of the heat equation across a grid in which derivatives are approximated using finite differences, thereby facilitating the numerical resolution of intricate conduction issues. FDM proves particularly beneficial in contexts in which analytical solutions are challenging to derive or are altogether nonexistent. In the subsequent discussion, the implementation and merits of FDM in modeling conduction phenomena are elaborated on comprehensively.

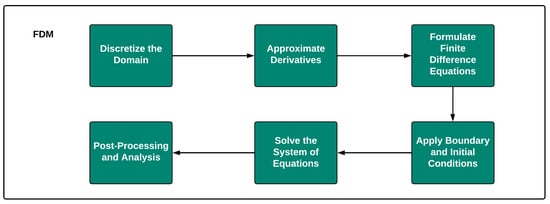

FDM is a numerical approach to solving partial differential equations (PDEs) by approximating derivatives with finite differences. The process begins with discretization of the domain, dividing the problem into a grid of discrete points in 1D, 2D, or 3D. Derivatives in the governing equations are replaced by finite-difference approximations obtained from Taylor series expansions, such as forward, backward, or central difference schemes. These approximations are then substituted into the PDE to form a discrete system of algebraic equations. This system is formulated as Au = b, where u is the vector of unknowns, A is the coefficient matrix, and b contains the source terms and boundary conditions. Boundary conditions are applied by modifying the equations at the boundaries. Finally, numerical techniques such as Gaussian elimination, LU decomposition, or iterative solvers (e.g., Jacobi or Gauss–Seidel) are applied to solve the system for the unknowns. The solution is then analyzed and refined by adjusting the grid space or time steps, and the convergence and precision are then verified [17,18]. The flowchart of the steps in the FDM is presented in Figure 1. For a detailed introduction to finite-difference methods in heat transfer, readers may refer to Ozisik et al. [19].

Figure 1.

Flowchart of FDM.

FDM is used in solving inverse boundary value problems in 2D steady-state anisotropic heat conduction. It helps reconstruct missing boundary conditions and thermal fields from over-prescribed data, demonstrating its utility in complex boundary scenarios [20]. The FDM is proficiently utilized in addressing two-dimensional heat conduction challenges, yielding commendable outcomes across a spectrum of boundary conditions and geometries. The methodology is executed through algorithms, such as those devised in Matlab (version 2017b), to tackle issues related to temperature distributions in plates with and without heat generation. The numerical solutions derived through FDM have exhibited remarkable precision, with the relative errors recorded being as minimal as 0.003 or 0.03 for scenarios without or including heat generation, respectively, in the steady-state case [21]. The FDM is further adapted to encompass transient heat conduction issues, wherein time-dependent fluctuations in temperature are taken into account. An innovative space–time generalized FDM incorporates direct space–time discretization, facilitating the investigation of transient heat conduction in both homogeneous and heterogeneous materials. This methodology has evidenced superior accuracy and efficiency, as corroborated through comparative analyses with both analytical and alternative numerical outcomes [22]. The FDM is employed to address hyperbolic heat conduction equations which consider the finite velocity of heat propagation. Both explicit and implicit FDM calculation schemes are used, the technique demonstrating its efficacy in approximating time derivatives and managing the boundary and initial conditions [23].

The FDM is characterized by its straightforward implementation and adaptability to a diverse range of boundary conditions, including Neumann, Dirichlet, and mixed conditions. This inherent flexibility makes it applicable to a wide spectrum of heat conduction challenges [24]. The methodology shows proficiency in addressing irregular geometrical configurations, particularly when combined with meshless techniques. For example, a meshless variant of FDM has been developed for conjugate heat-transfer challenges, facilitating the resolution of heat conduction in complex geometries without the need for structured grids [24]. FDM can be customized to simulate heat conduction in materials characterized by varying properties, such as functionally graded materials (FGMs). This adaptation capacity is essential for the accurate representation of real materials that possess spatially heterogeneous thermal properties [25,26]. FDM has been compared with the Smoothed Particle Hydrodynamics (SPH) method, which is another numerical approach used to solve heat conduction problems. Although SPH offers advantages in certain scenarios, FDM remains a robust choice due to its established framework and ease of use. Although previous studies have explored comparisons between these methods, including the analysis in [27], a more comprehensive evaluation considering computational cost and accuracy is necessary for a rigorous assessment.

Recent innovations in FDM include the development of hybrid methods that integrate FDM with other numerical techniques to enhance performance. For example, the hybrid Restarting FDM–SVR–Lanczos method combines FDM with machine learning to solve heat flow problems in welding more effectively [28].

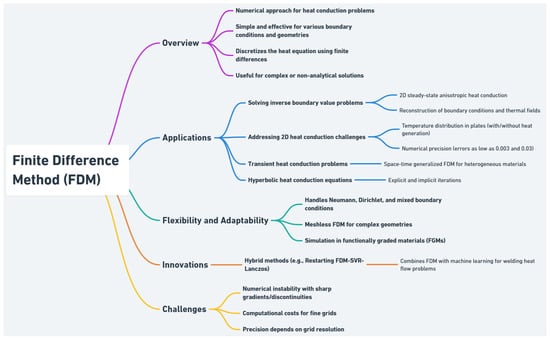

Figure 2 presents a summary of the individual topics discussed in relation to FDM.

Figure 2.

Summary of the key considerations related to the FDM method.

Although FDM represents a formidable instrument for modeling conduction phenomena, it is not devoid of limitations. The method may experience numerical instability and inaccuracies, particularly in scenarios that involve sharp gradients or discontinuities. However, recent advances, such as unconditionally stable explicit FD methods [29], have addressed this limitation. These methods maintain second-order accuracy even when applied to heterogeneous media, enhancing the reliability of FDM in complex heat-transfer problems. Furthermore, recent studies [30,31] have extended and applied FD-type methods in various engineering applications, demonstrating their practical utility. Despite these developments, the precision of FDM solutions is intricately linked to grid resolution, potentially resulting in increased computational expenditures for fine grids. Notwithstanding these challenges, FDM remains an invaluable methodology for addressing a wide array of heat conduction issues, especially when integrated with contemporary computational techniques; for example, it is widely used in LBM.

2.2. Finite Element Method (FEM)

FEM represents a sophisticated numerical approach that is used to address the intricate problems associated with heat transfer, particularly in scenarios in which analytical solutions are impractical. FEM is of significant importance within the domain of heat transfer as a result of its proficiency in managing complex geometries, boundary conditions, and variations in material properties. This methodology involves the discretization of a domain into smaller, manageable elements, thereby facilitating the approximation of solutions to the PDEs that govern heat-transfer phenomena. The adaptability and accuracy of FEM renders it essential in both engineering and scientific endeavors related to heat transfer.

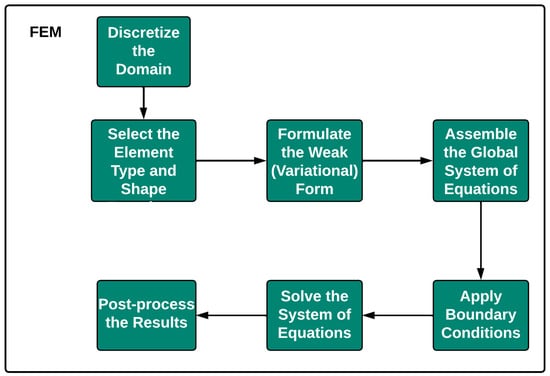

FEM is a numerical technique for solving PDEs by dividing the domain into smaller, simpler parts, called elements, and defined by the nodes. The process begins by discretizing the domain; in this, the problem is divided into a finite number of elements that collectively form a mesh. An appropriate element type (e.g., linear, quadratic) and corresponding shape functions are selected to approximate the distribution of unknown variables within each element on the basis of values on the nodes. The governing PDE is then rewritten in its weak (variational) form by integrating against a test function, ensuring that the solution satisfies the equation in an average sense. For each element, the element stiffness matrix and the load vector are computed using the shape functions and the weak form of the PDE, and these contributions are assembled into a global system of algebraic equations (a stiffness matrix is the left part of the system K, and the load vector f is the right part). Boundary conditions (e.g., Dirichlet or Neumann) are incorporated to modify the global system, resulting in a linear system of equations, Ku = f, where u represents unknown nodal values. The system is solved using numerical techniques, and the solution is post-processed to compute derived quantities (e.g., temperature or heat fluxes) and to visualize or interpret the results [32,33]. The individual stages of the FEM modeling process are presented in Figure 3.

Figure 3.

Flowchart of the FEM modeling process.

FEM is particularly useful for solving heat conduction problems in complex 3D geometries, in which traditional analytical methods fall short. For example, it can model intricate shapes such as L-shaped blocks, effectively capturing localized temperature gradients and discontinuities [34].

In the context of natural convection, FEM has been used to study the heat transfer between a cold circular cylinder and a heated corrugated cylinder, demonstrating sensitivity to parameters such as Rayleigh number and cylinder inclination [35].

FEM excels at addressing heat transfer in irregularly shaped domains, which are common in real-world applications. By partitioning these domains into smaller elements, FEM can systematically solve heat-transfer equations, as demonstrated in studies involving irregular 2D geometries [13].

The method’s ability to model non-stationary heat conduction in composite materials further highlights its adaptability to complex material properties and geometries [36].

The application of open-source computational tools in FEM facilitates the effective modeling of thermal transfer phenomena within intricate systems, exemplified by heat sinks utilized in the electronics sector. This methodological framework capitalizes on advanced computing capabilities to address the challenges associated with conduction, convection, and radiation, providing a financially viable substitute for proprietary software solutions [37].

FEM can be integrated with the Boundary Element Method (BEM) to enhance the examination of structures across multiple scales. This integration improves the precision of solutions and reduces computational expenses, establishing it as a formidable option for complicated heat-transfer challenges [38].

FEM is applied in various fields, including bio-heat transfer for medical treatments such as Magnetic Fluid Hyperthermia, in which it helps to target cancerous tissues without harming healthy ones [39].

In the automotive industry, automated meshing techniques have been developed to handle complex geometrical configurations efficiently. This automation is crucial to keeping up with the fast-paced development cycles in motorsports and other automotive applications [40]. Transient thermal simulations are vital to managing the thermal behavior of the automotive underhood and underbody components. FEM helps to accurately model the thermal mass and interactions between different materials, which is essential for vehicle development [41].

FEM is widely used for transient thermal analysis in aerospace, such as in the design of permanent magnet motors and induction motors. These analyses are critical to the optimization of motor performance under varying load conditions and ambient temperatures [42,43].

Inverse heat conduction analysis using FEM is applied to atmospheric reentry vehicles to predict aerodynamic heating and ensure structural integrity under extreme conditions [44]. The inverse method has been used to identify the heat-transfer coefficient under different conditions of water spray pressure, water flux, and nozzle-to-surface distance [45]. Additionally, the solution strategy for the inverse determination of the specially-varying heat-transfer coefficient on the water-cooled plate has been developed [46]. Inverse solutions to vertical plate cooling in air were applied in a comparative study [47].

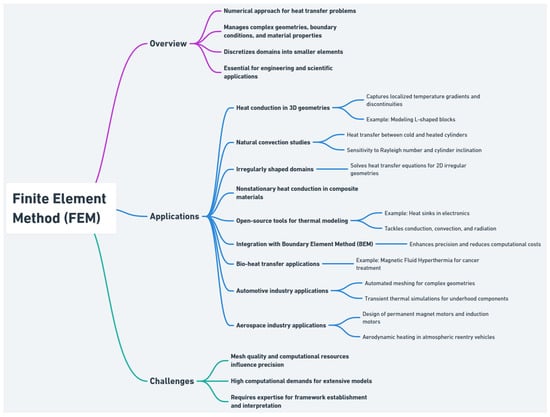

Figure 4 presents a summary of the individual topics discussed in relation to FEM.

Figure 4.

The key considerations related to FEM.

Although FEM serves as a robust instrument for the analysis of heat-transfer phenomena, it is not devoid of inherent constraints. The precision of FEM-derived solutions is profoundly influenced by the quality of the mesh configuration and the computational resources at one’s disposal. In certain instances, the methodology may require substantial computational capacity, particularly when dealing with highly detailed or intricate models. Furthermore, the establishment and interpretation of FEM frameworks can be complex and require a high level of expertise in both the technique and the specific area of application. Notwithstanding these obstacles, FEM continues to be a fundamental element in the analysis and simulation of heat-transfer challenges across diverse industries and scholarly fields. FEM requires large, or even huge, computational resources and simulations can take a long time. Often, results of FEM calculation serve as databases for AI, including ANN, ML, and DL, and further application of trained ANN as ROM.

2.3. Computational Fluid Dynamics (CFD)

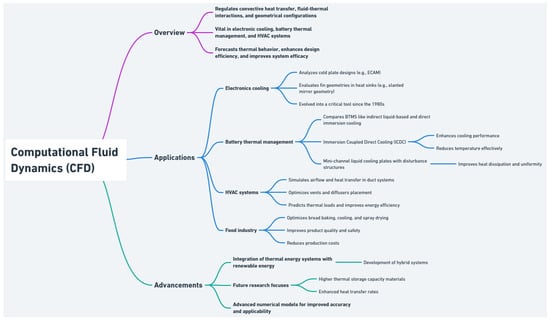

CFD is integral to the regulation of convective heat transfer, fluid–thermal interactions, and intricate geometrical configurations in a range of applications. Its importance is particularly pronounced in domains such as electronic cooling, battery thermal management, and HVAC (heating, ventilation, and air conditioning) systems, in which meticulous thermal regulation is vital for optimal performance and safety. CFD facilitates comprehensive simulations that can forecast thermal behavior, improve design efficiency, and improve overall system efficacy. A detailed examination of CFD applications in these specific areas is provided in the following.

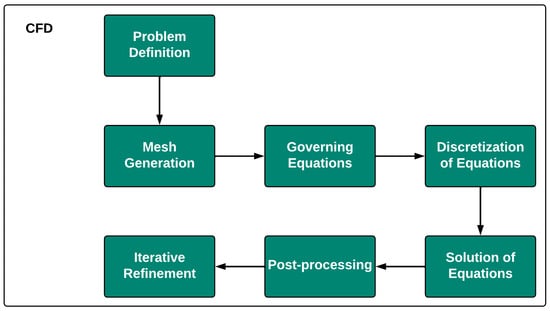

CFD is a numerical approach to the analysis and prediction of fluid behavior; it solves governing equations of fluid motion, such as the Navier–Stokes equations. The process begins with problem definition, which involves specifying the geometry, fluid properties, boundary conditions (e.g., inlets, outlets, walls) and initial conditions for time-dependent problems. The domain is then discretized into a mesh of control volumes or elements, ensuring adequate refinement in critical regions such as boundaries or areas with steep gradients. The governing equations, including the continuity, momentum, and energy equations, are defined, together with any necessary models, such as turbulence or multiphase flow models. These equations are discretized using numerical methods such as FVM, which convert partial differential equations into algebraic equations at each point in the grid. The resulting equations are solved using iterative techniques (e.g., explicit or implicit methods), ensuring convergence and proper coupling between pressure and velocity fields via algorithms like SIMPLE or PISO. The results are then post-processed using visualization tools to analyze velocity fields, pressure distributions, and derived quantities like drag or heat-transfer rates. Finally, iterative refinement of the mesh, boundary conditions, or models is performed to improve accuracy, repeating the process until the desired solution is achieved [48,49]. The stages of the CFD modeling process are presented in Figure 5.

Figure 5.

Flowchart of the CFD modeling process.

Turbulence modeling is a fundamental aspect of CFD simulations, particularly in engineering applications in which fluid flow exhibits chaotic and unsteady behavior. Accurate prediction of turbulence is essential for applications such as aerodynamics, HVAC systems, and thermal management in electronics. Various turbulence models are used in CFD to address different flow regimes, including Reynolds-Averaged Navier–Stokes (RANS) models, Large Eddy Simulation (LES), and Direct Numerical Simulation (DNS) [50,51]. RANS models, such as the k-ε and k-ω models, offer a balance between computational cost and accuracy, which make them widely used in industrial applications such as HVAC systems and vehicle aerodynamics [52,53]. LES provides greater accuracy by resolving large-scale turbulent structures while modeling smaller eddies, making it suitable for indoor environment control and aerospace applications [54]. On the contrary, DNS offers the highest fidelity by directly solving all turbulent scales, but it comes at a significantly higher computational cost, making it practical only for small-scale turbulence studies [55].

Additionally, multi-physics coupling plays a vital role in numerous real-world applications, where CFD must be integrated with other physical models. Fluid–solid coupling is critical in structural integrity analysis, in which fluid forces interact with deformable structures, leading to applications in aerospace, biomedical devices, and civil engineering [56,57].

Multiphase flow modeling is another key aspect; in this application, CFD is utilized to simulate interactions between different fluid phases, such as liquid–gas and liquid–solid flows. This is particularly important in processes such as fuel injection, boiling, and slurry transport [58,59]. CFD models such as Volume of Fluid (VOF) [60], Eulerian–Eulerian [61], and Eulerian–Lagrangian [62] approaches are commonly employed to handle these complex interactions by tracking phase boundaries and interfacial dynamics.

Furthermore, CFD is extensively used in modeling chemically reactive flows, such as combustion processes and electrochemical reactions in batteries and fuel cells, in which the couplings between fluid flow, chemical kinetics, and heat transfer are crucial to accurate predictions [63]. The Eulerian–Eulerian two-phase flow model has been widely adopted to model solid oxide fuel cells and proton exchange membrane fuel cells (PEMFCs), allowing for detailed resolution of electrochemical reaction zones and gas-phase transport phenomena [64].

CFD is used to analyze cold plate designs for electronics cooling, particularly those produced by electrochemical additive manufacturing (ECAM). These designs offer improved thermal performance compared to traditional methods by enabling complex geometries that improve heat dissipation [65]. CFD and conjugate heat-transfer analyses are used to evaluate different fin geometries in heat sinks. This helps identify configurations that minimize thermal resistance and pressure drop, such as slanted mirror geometry, which provides superior performance [66]. The role of thermal design with CFD in electronics has evolved significantly since the 1980s; it has become a critical tool for predicting operating temperatures and refining thermal designs during product development [67].

CFD simulations are used to compare different battery thermal management systems (BTMS), such as indirect liquid-based cooling and direct immersion cooling. These simulations help assess thermal gradients and identify hotspots, which are crucial for maintaining battery safety and performance [68]. The immersion coupled direct cooling (ICDC) method, analyzed through CFD, shows enhanced cooling performance by extending the optimal working duration of batteries. This method reduces battery temperature more effectively than natural convection or traditional immersion cooling [69]. CFD is utilized to design and optimize mini-channel liquid cooling plates with disturbance structures. These designs improve heat dissipation and flow field performance, ensuring uniform temperature distribution throughout the battery module [70].

CFD can simulate airflow and heat transfer in complex duct systems, optimize the placement of vents and diffusers, and improve energy efficiency by predicting thermal loads and system responses. The food industry uses CFD to optimize processes such as bread baking, cooling, and spray drying. This improves the quality and safety of food products while reducing production costs [71].

Recent advances in CFD include the integration of thermal energy systems with renewable energy sources, leading to the development of hybrid systems [72]. Future research in CFD aims to develop materials with higher thermal storage capacity and enhance heat-transfer rates, further optimizing system designs [72]. Additionally, the continuous development of advanced numerical models will further enhance the accuracy and applicability of CFD simulations in thermal management and other fields [73].

Figure 6 presents a summary of the individual topics discussed in relation to the CFD method.

Figure 6.

Key considerations related to CFD.

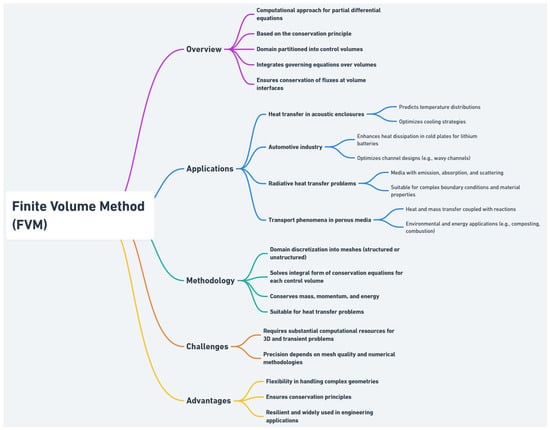

2.4. Finite Volume Method (FVM)

FVM constitutes a computational approach extensively employed for the resolution of partial differential equations, especially within the realms of thermal transfer and fluid dynamics. This methodology is predicated upon the conservation principle, whereby the spatial domain is partitioned into a finite set of control volumes and the governing equations are systematically integrated over these defined volumes. The efficacy of this method is particularly pronounced in its ability to adeptly manage intricate geometries while simultaneously ensuring the conservation of fluxes at the interfaces of control volumes. The application of FVM spans a diverse array of heat-transfer contexts, encompassing acoustic enclosures, cold plates, and porous media, thereby illustrating its remarkable versatility and operational effectiveness.

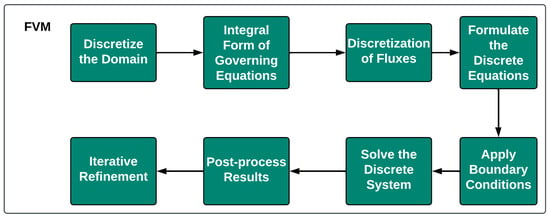

FVM divides the domain into discrete “control” volumes. The integral form of the conservation equations is applied to each control volume, ensuring that the flux entering a volume equals the flux leaving it, taking into account any sources or sinks within the volume [74]. The method involves discretizing the spatial domain into a mesh, in which the governing equations are solved. This can be accomplished using structured or unstructured meshes, allowing for flexibility in the handling of complex geometries [75]. FVM inherently conserves mass, momentum, and energy, making it particularly suitable for heat-transfer problems in which these principles are critical [76]. The flowchart of the FVM modeling process is presented in Figure 7.

Figure 7.

Flowchart of the FVM modeling process.

FVM has been used to model heat transfer in acoustic enclosures, helping to predict temperature distributions and optimize cooling strategies to prevent the overheating of machinery [77]. In the automotive industry, FVM is applied to enhance heat dissipation on cold plates for lithium batteries. By optimizing channel designs, such as by using wavy channels, FVM helps improve thermal performance significantly [78]. The FVM is also employed to solve radiative heat-transfer problems, particularly in media that emit, absorb, and scatter radiation. This application is crucial in systems with complex boundary conditions and varying material properties [79]. The method is effective in predicting transport phenomena in porous media, including heat and mass transfer coupled with chemical and biological reactions. This is particularly useful in environmental and energy applications, such as composting and combustion processes [80].

Figure 8 presents a summary of the individual topics discussed in relation to FVM.

Figure 8.

The key considerations related to FVM.

Although FVM is exceedingly effective in guaranteeing conservation and managing intricate geometries, it may necessitate substantial computational resources, particularly for three-dimensional and transient issues. Furthermore, the precision of FVM can be affected by the caliber of the mesh and the numerical methodologies used for discretization [74,76]. Notwithstanding these obstacles, FVM continues to be a favored selection in numerous engineering applications owing to its resilience and flexibility.

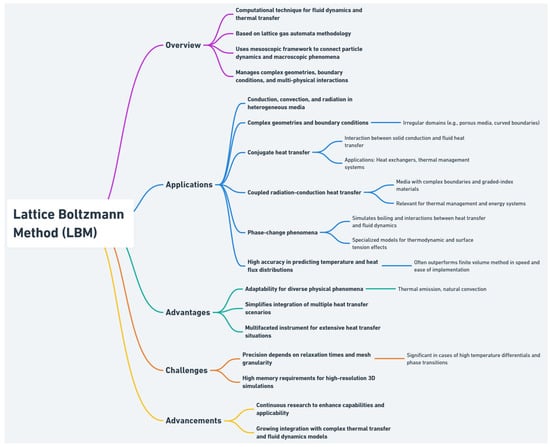

2.5. Lattice Boltzmann Method (LBM)

LBM is a computational technique that has acquired significance for modeling fluid dynamics and thermal transfer phenomena. Deriving from the lattice gas automata methodology, LBM employs a mesoscopic framework to represent the distribution of particle velocities across a lattice framework, thereby enabling the recovery of macroscopic transport equations. Its pertinence to thermal transfer is emphasized by its capacity to manage intricate geometries, boundary conditions, and multi-physical field interactions with relative simplicity, in comparison to conventional computational fluid dynamics techniques. This makes LBM especially apt for simulating a variety of thermal transfer phenomena, encompassing conduction, convection, and radiation, in heterogeneous media and configurations. It also allows for simulations of complex problems in conjunction with chemical reactions, diffusion, etc.

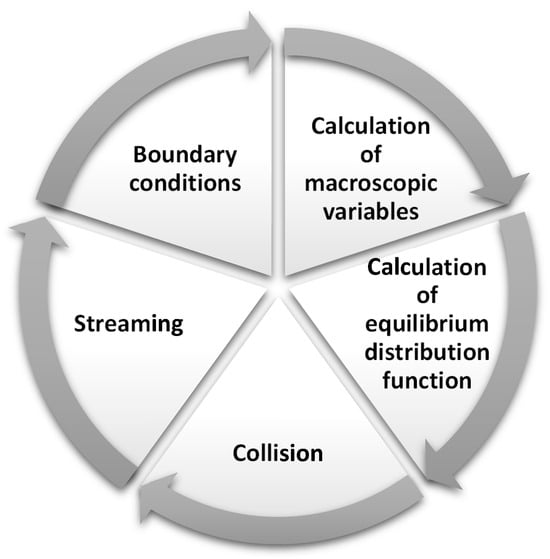

The same LBM algorithm is applied to all cases of modeled problems, following a cyclic process (Figure 9) that includes the following steps:

Figure 9.

Structure of the LBM calculation algorithm.

- Calculation of macroscopic variables such as density (ρ), velocity (u), temperature (T), concentration (C), and others.

- Evaluation of the equilibrium distribution function feq for the modeled variables.

- Collision operation, which involves the determination of the output distribution function fout.

- Streaming operation, which transfers the distribution function to the appropriate cells, sites, or nodes.

- Application of boundary conditions.

The cycle typically begins with the calculation of macroscopic variables and equilibrium distribution functions, as well as the assignment of output functions, and can technically start at any stage.

The method is fundamentally based on the discretization of space and time. A regular grid is applied to the domain, in which the grid is square in two dimensions or cubic in three dimensions, with the spacing between adjacent nodes set to one. Similarly, the time step length is also set to one. A crucial component of the system is the choice of velocity model. In one-dimensional space, models such as D1Q2 and D1Q3 are commonly used; in two-dimensional space, D2Q4, D2Q5, and D2Q9 are employed. For three-dimensional problems, models such as D3Q6, D3Q7, D3Q15, D3Q19, and others are utilized. Here, “D” represents the dimensionality, while “Q” denotes the number of velocity directions. Additional details about LBM can be found in [81].

LBM functions on a mesoscopic scale, facilitating the connections between microscopic particle dynamics and macroscopic fluid phenomena. This enables the proficient simulation of intricate fluid flows and thermal transfer mechanisms without the need to directly solve the Navier–Stokes equations [82]. LBM is adept at managing complex geometries and boundary conditions, which is crucial to accurately modeling heat transfer in irregular domains such as porous media and curved boundaries [82,83]. LBM has been effectively applied to simulate conjugate heat transfer, in which heat conduction in solids interacts with fluid flow and heat transfer in adjacent fluids. This is particularly useful in engineering applications that involve heat exchangers and thermal management systems [84]. The method has been extended to handle coupled radiation-conduction heat-transfer problems, especially in media with complex boundaries and graded-index materials. This capability is crucial for applications in thermal management and energy systems in which radiative heat transfer plays an important role [83,85]. LBM has been adapted to simulate phase-change phenomena, such as boiling, which involve complex interactions between heat transfer and fluid dynamics. This is achieved through specialized models that account for the effects of thermodynamic and surface tension on phase-change processes [86]. This method was also applied to the modeling of heat transfer during the phase transformations that occur in materials [87,88].

LBM provides high accuracy in predicting temperature and heat-flux distributions, often outperforming traditional methods such as FVM in terms of computational speed and ease of implementation [89]. The adaptability of the approach facilitates the integration of various physical phenomena, such as thermal emission and natural convection, within a cohesive framework. This makes it a multifaceted instrument usable for modeling an extensive array of heat-transfer situations [90].

The current status of LBM applied to aerodynamic, aeroacoustic, and thermal flows was presented in [91]. The modeling of natural convection heat transfer on a large scale became possible due to new calculation schemes applied in thermal LBM [92].

Figure 10 presents a summary of the individual topics discussed in relation to LBM.

Figure 10.

The key considerations related to LBM.

Although LBM presents numerous benefits, it is not devoid of constraints. The precision of the methodology can be susceptible to the selection of relaxation durations and mesh granularity, particularly in simulations encompassing substantial temperature differentials or intricate phase-transition phenomena. Moreover, although LBM is computationally proficient, it may require considerable memory resources for high-resolution simulations, especially in three-dimensional contexts. Notwithstanding these obstacles, ongoing research and advancement continues to expand the capabilities and applicability of LBM in thermal transfer and fluid dynamics. A very important feature of the method is its adaptability to parallelization, which opens wide possibilities for fast and effective calculations.

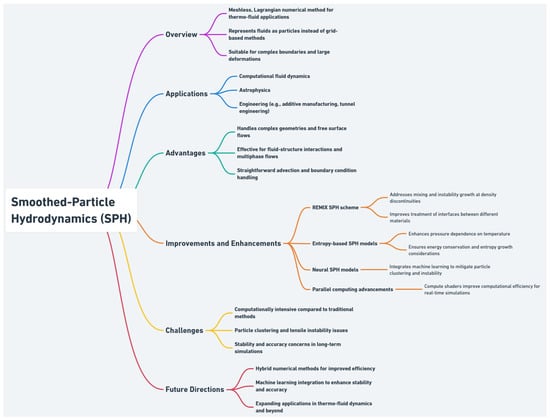

2.6. Smoothed-Particle Hydrodynamics (SPH)

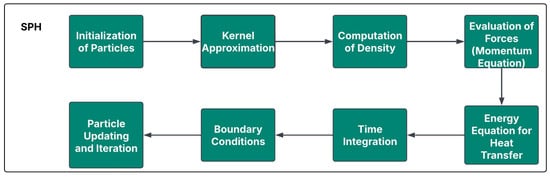

Smoothed Particle Hydrodynamics (SPH) is a mesh-free, Lagrangian method for solving fluid dynamics and heat-transfer problems by representing a continuum as discrete particles. Each particle carries properties such as mass, velocity, and temperature, interacting with its neighbors via a smoothing kernel function. The process begins with particle initialization, assigning properties and discretizing the domain. The kernel approximation estimates field variables, while density computation ensures mass conservation. Forces are evaluated by solving the Navier–Stokes equations, incorporating pressure, viscosity, and external forces. If heat transfer is modeled, the energy equation updates the temperatures. The system evolves through time integration using explicit schemes like Euler or Verlet. Boundary conditions are enforced via ghost particles or repulsive forces, and particle properties are iteratively updated until the simulation reaches convergence [93].

The flowchart of the steps in the SPH is presented in Figure 11.

Figure 11.

Flowchart of SPH.

This method has been applied across various fields, including Computational Fluid Dynamics, astrophysics, and engineering, demonstrating its adaptability and efficiency in handling diverse thermo-fluid challenges.

The SPH meshless approach allows it to handle complex geometries and free surface flows effectively, making it suitable for applications such as fluid–structure interactions and multiphase flows [94,95]. The Lagrangian framework of SPH enables a straightforward handling of advection and complex boundary conditions, which is beneficial in simulating multiphase flows and fluid–solid interactions [94,96]. SPH has been successfully applied in various fields, from tunnel engineering to astrophysics, demonstrating its ability to model a wide range of fluid dynamics scenarios [95].

Almério et al. provided a detailed explanation of the implementation of the SPH method to solve the heat equation in an unsteady state [97]. In addition, they compared the SPH with the FDM in terms of accuracy and computational cost. Similarly, K.C. Ng et al. applied the SPH method to estimate heat transfer in complex geometries [98]. The SPH method has also been utilized in various engineering applications, such as additive manufacturing [99].

The REMIX SPH scheme addresses problems related to mixing and instability growth in density discontinuities, improving the treatment of interfaces between dissimilar materials, and capturing hydrodynamic behaviors with greater precision [100]. Incorporating entropy into SPH allows for pressure dependence on temperature, enhancing the method’s capability to simulate thermo-fluid dynamics with energy conservation and entropy growth considerations [101].

SPH simulations can suffer from particle clustering due to tensile instabilities, which can affect the accuracy and stability of long-term predictions. Recent advancements in neural SPH models aim to mitigate these issues by integrating machine learning techniques [102]. Although SPH is computationally intensive, advances in parallel computing, such as the use of compute shaders, have improved its performance, making real-time simulations more feasible [103].

SPH continues to evolve; ongoing research addresses its limitations and expands its applicability. While it offers significant advantages in handling complex thermo-fluid scenarios, challenges such as computational efficiency and stability remain areas of active development. The integration of machine learning and hybrid numerical methods presents promising avenues for enhancing SPH’s capabilities, potentially leading to more accurate and efficient simulations in the future.

Figure 12 presents a summary of the individual topics discussed in relation to the SPH method.

Figure 12.

The key considerations related to the SPH method.

3. Recent Advances in Computational Approaches for Heat Transfer

3.1. Adaptive Mesh Refinement (AMR)

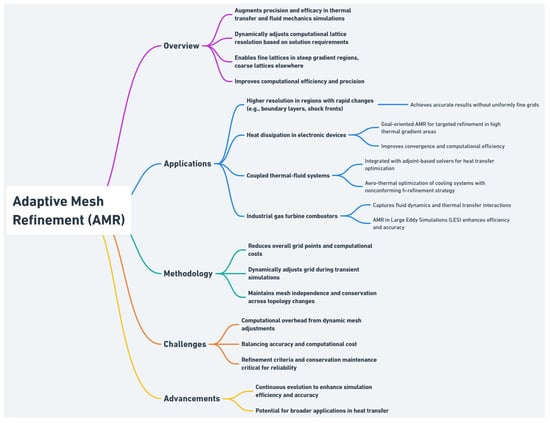

AMR is a computational methodology employed to increase the precision and efficacy of numerical simulations in thermal transfer and fluid mechanics. AMR dynamically modifies the resolution of the computational lattice in accordance with the solution’s exigencies, permitting finer lattices in regions characterized by steep gradients or intricate features, while coarser lattices are utilized in other areas. This versatility engenders substantial advances in computational efficacy and precision, making AMR an invaluable instrument in the domain of computational thermal transfer.

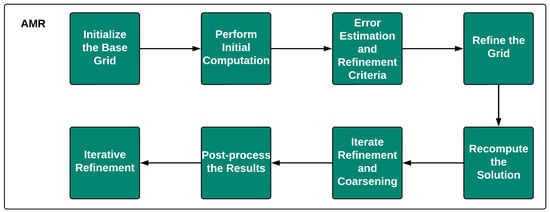

The AMR process begins by initializing a base grid, where the problem domain is defined and discretized into a coarse and uniform grid with initial values for key variables such as velocity, pressure, or temperature [104]. An initial computation is performed to solve the governing equations, identifying regions requiring higher resolution, such as areas with steep gradients or shock waves [105]. Based on error estimation and refinement criteria, such as gradient-based or residual-based methods, regions exceeding a defined threshold are refined by the subdivision of cells into smaller cells while ensuring smooth transitions between coarse and fine regions [106]. The governing equations are then recomputed on the refined grid, using interpolation or reconstruction to transfer information between the grids [107]. This process of iterative refinement and coarsening continues, dynamically refining regions with persistent errors and coarsening those in which high resolution is no longer needed, optimizing computational efficiency [108]. Once the simulation reaches the desired accuracy, post-processing is performed to analyze and visualize the results, highlighting the refined regions and the behavior of the solution, the refinement being repeated as necessary to meet the convergence and accuracy requirements [104]. The flowchart of the AMR is presented in Figure 13.

Figure 13.

Flowchart of AMR.

AMR allows for higher resolution in areas in which the solution exhibits rapid changes, such as boundary layers or shock fronts, leading to more accurate results without the need for a uniformly fine grid throughout the domain [109,110]. By concentrating computational resources only where needed, AMR reduces the total number of points in the grid and the computational cost, making it feasible to solve large-scale problems with limited computational resources [111,112]. AMR can dynamically adjust the grid during simulation, responding to evolving features in the flow field or thermal field, which is particularly useful in transient simulations in which regions of interest can change over time [113].

AMR is utilized in electronic devices to effectively manage heat dissipation, which is crucial to maintaining device performance and longevity. The goal-oriented AMR algorithm proposed by Wang et al. [114] focuses on specific metrics rather than global error, allowing for targeted refinement in areas with high thermal gradients, such as surface mount packages. This approach eliminates unnecessary refinement, improving convergence behavior and computational efficiency. In coupled thermal–fluid systems, AMR is integrated with adjoint-based solvers to optimize heat transfer while controlling mechanical power dissipation. Gallorini et al. [115] demonstrate the use of AMR in a finite volume solver for aero-thermal optimization of cooling systems. The hierarchical nonconforming h-refinement strategy ensures mesh independence and conservation across topology changes, as validated through two- and three-dimensional test cases. Adaptive Mesh Refinement (AMR) is utilized in the computational modeling of industrial gas turbine combustors to effectively capture the intricate interactions between fluid dynamics and thermal transfer. McManus et al. implement AMR within the framework of Large Eddy Simulations (LES) to dynamically optimize the computational mesh in response to variations in mixture fraction and reaction progress. This methodology facilitates a double improvement in computational efficiency compared to static mesh configurations, while simultaneously preserving precision in the prediction of flow characteristics and flame temperatures [116].

Figure 14 presents a summary of the individual topics discussed in relation to FDM.

Figure 14.

The key considerations related to AMR.

Although AMR offers significant advantages in handling high thermal gradients, it is essential to consider the computational overhead associated with dynamic mesh adjustments. The balance between precision and computational cost is a critical factor in the successful implementation of AMR. Additionally, the choice of refinement criteria and the ability to maintain conservation across mesh changes are crucial for achieving reliable results. As AMR techniques continue to evolve, they hold the potential to further enhance the efficiency and accuracy of simulations in various heat-transfer applications.

3.2. Artificial Intelligence and Machine Learning (AI/ML)

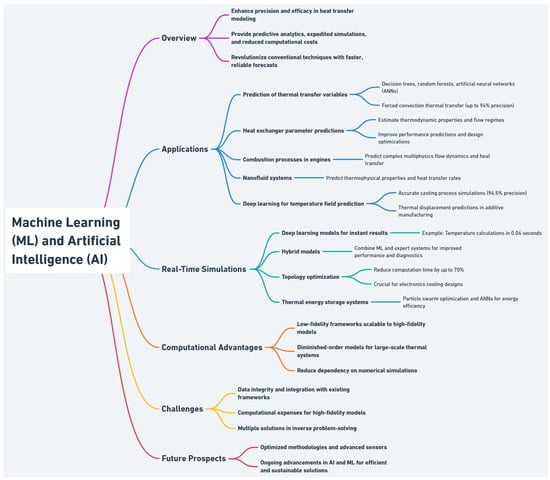

AI and ML have become essential in the progress of heat-transfer modeling, providing innovative solutions for predictive analytics and accelerated simulations, and reducing computational costs. These technologies use data-centric methodologies to improve the precision and efficacy of heat-transfer simulations, which are vital for optimizing thermal systems. The incorporation of AI and ML into heat-transfer modeling is revolutionizing conventional techniques by delivering faster and more reliable forecasts, thus facilitating improved design and operational determinations.

The sudden successes of ML and then deep learning (DL) from 2012 to 2015 were not due to some new discovery or breakthrough in theory (many people were describing deep neural networks and backpropagation as far back as the 1950s), but occurred for two reasons: the massive increase in computer power (including a 100x speed increase achieved by moving to GPUs) and the availability of massive amounts of training data. However, in engineering applications, obtaining such large, high-quality datasets is challenging. Experimental data are often limited by sensor inaccuracies, sparse measurements, and high costs, while numerical datasets require computationally expensive simulations that may not provide full-coverage data for complex scenarios. These limitations impact the generalization capabilities of AI/ML models, as insufficient or biased training data can lead to overfitting and reduced performance in real-world applications.

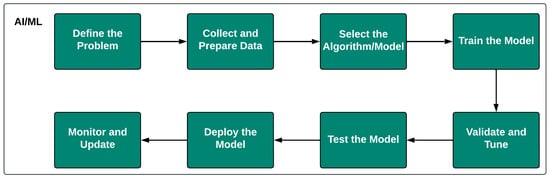

ML involves a systematic process used to develop models that make predictions or decisions based on data. The process starts by defining the problem, identifying the type of task (e.g., supervised learning for predictions, unsupervised learning for pattern discovery, or reinforcement learning for decision optimization), and establishing performance metrics such as accuracy or precision [117]. Next, data collection and preparation involve the gathering of raw data, cleaning it to address missing values or outliers, engineering relevant features, and splitting the data into training, validation, and test sets [118]. To address data limitations, techniques such as transfer learning can be employed, in which a pre-trained model from a related domain is fine-tuned with a limited amount of new data to enhance performance. This approach has been particularly useful in cases where the acquisition of large-scale experimental datasets is impractical. Additionally, domain adaptation and physics-informed machine learning methods help improve model generalization by incorporating physical constraints into AI predictions. Then, an appropriate algorithm or model is selected based on the problem, ranging from linear models and tree-based methods to neural networks or clustering algorithms [119]. The chosen model is trained on the training data by optimizing its parameters to minimize a loss function. During validation and tuning, the model is evaluated on validation data, hyperparameters are optimized, and techniques such as cross-validation or regularization are used to prevent overfitting [120]. The final model is tested on the test dataset to ensure that it generalizes well to unseen data. Once validated, the model is deployed in production systems (e.g., APIs or embedded devices) and is monitored in real time for performance [121]. Finally, monitoring and updating ensure that the model remains accurate over time, with periodic retraining on new data to handle changes or mitigate performance degradation. Individual steps in AI/ML are presented in Figure 15.

Figure 15.

Flowchart of AI/ML.

ML frameworks, including decision trees, random forests, and artificial neural networks, are utilized in an innovative application to forecast thermal transfer variables. These frameworks possess the ability to scrutinize extensive datasets derived from empirical investigations and simulations to anticipate results with considerable precision, as evidenced by their application in forced convection thermal transfer with nanoparticles, attaining precisions of up to 94% [122,123]. ML models have been used effectively to predict heat exchanger parameters, offering robust performance in estimating thermodynamic properties and flow regimes. These models are built on experimental or numerical data, improving the accuracy of performance predictions and design optimizations [124]. AI/ML models, particularly artificial neural networks (ANNs), have been developed to predict combustion processes in internal combustion engines. These models utilize historical performance data to characterize complex multiphysics flow dynamics, heat transfer, and chemical kinetics, achieving high prediction accuracy [125]. ML techniques are applied to predict thermophysical characteristics and heat-transfer rates in nanofluid systems, aiding in understanding and optimizing these advanced cooling technologies [126]. Deep learning, a subset of ML, is particularly effective in handling complex datasets, and has been applied to predict temperature fields in casting processes with an accuracy of 94.5% [127]. It also facilitates the rapid prediction of thermal displacement in metal additive manufacturing, showing a strong correlation with high-fidelity models [128].

AI methods, including DL, enable real-time simulations and analysis of heat-transfer processes. For example, a deep learning model can calculate temperature variations in less than 0.04 s, providing instant results for online thermal monitoring [129]. Combining different AI techniques, such as machine learning and expert systems, can enhance the flexibility and performance of heat-transfer simulations. These hybrid models are capable of integrating domain expertise with data-driven insights to optimize performance and diagnostics [130]. ML has been integrated into topology optimization for heat conduction problems, significantly reducing computation time by up to 70% while maintaining high-fidelity solutions. This approach is particularly beneficial for cooling designs in electronics, for which rapid simulation results are crucial [131]. AI techniques, such as particle swarm optimization and ANNs, are used to optimize thermal energy storage systems, improving their design and control. These methods improve energy efficiency and reduce environmental impacts by optimizing system performance [132].

AI models significantly reduce computational costs by offering low-fidelity frameworks that can be scaled to high-fidelity models for increased accuracy. This methodology reduces the need for comprehensive numerical simulations, thus saving time and resources [128]. Using machine learning algorithms, scholars can formulate diminished-order models that elucidate intricate thermal transfer phenomena, making them more manageable and computationally efficient [133]. This is particularly beneficial for large-scale thermal systems, for which traditional methods may be computationally prohibitive.

Figure 16 presents a summary of the individual topics discussed in relation to ML and AI.

Figure 16.

The key considerations related to AI/ML.

While machine learning and artificial intelligence provide considerable advantages in thermal transfer simulation, obstacles such as data integrity, assimilation with pre-existing frameworks, and computational expenses persist. Addressing these issues requires optimized computational methodologies and sophisticated sensor technologies [130]. Furthermore, the potential for multiple solutions in inverse problem solving using deep learning poses a challenge that requires further research to refine these models [134]. Despite these challenges, ongoing advances in AI and ML continue to drive innovation in heat-transfer modeling, promising more efficient and sustainable solutions in the future. Furthermore, AI, ML, and DL are very fishable for ROM (see below).

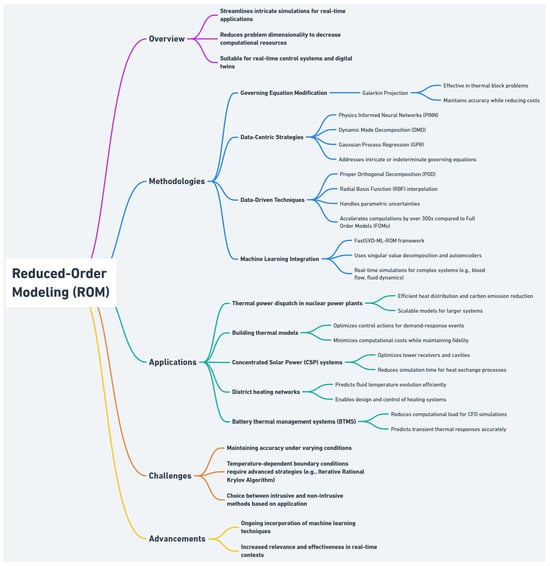

3.3. Reduced-Order Modeling (ROM)

ROM constitutes a sophisticated computational methodology employed to streamline intricate simulations, rendering them viable for immediate applications, especially within the domain of heat transfer. ROMs accomplish this by diminishing the dimensionality of the problem, which leads to a substantial reduction in the computational resources necessary while preserving an acceptable degree of accuracy. This methodology is particularly advantageous in situations where swift simulations are imperative, such as in real-time control systems and digital twins. The following sections offer a comprehensive overview of various ROM methodologies and their implementations in the context of heat transfer. The first ROMs included the use of simple approximation methods, a tactic widely used in industrial applications even in the first half of the twentieth century.

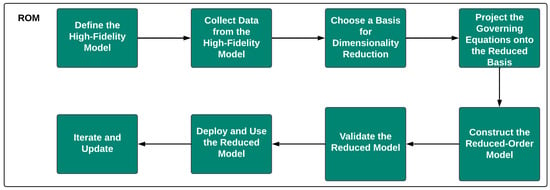

ROM begins by defining the high-fidelity model, typically a detailed simulation using methods like finite element or finite volume, and identifying the governing equations (e.g., Navier–Stokes for fluid flow). Next, data collection involves performing simulations or experiments to generate training data, capturing key states of the system such as velocity, pressure, or displacement fields. The basis for dimensionality reduction is then chosen by using techniques like Proper Orthogonal Decomposition (POD) or Dynamic Mode Decomposition (DMD) to extract dominant features. The governing equations are projected on a reduced basis, resulting in a low-dimensional system of ordinary differential equations (ODEs) or algebraic equations [135]. This forms the reduced-order model, which operates efficiently in a reduced space. The model is validated against the high-fidelity model or experimental data to ensure accuracy, speedup, and stability. Once validated, the ROM is deployed for fast simulations, optimization, control design, or real-time applications [136]. The process is iterative, with updates to the model or reduced basis to improve accuracy or adapt to new scenarios, ensuring that ROM remains effective and reliable [137]. The flowchart of steps in the ROM is presented in Figure 17.

Figure 17.

Flowchart of ROM.

These methods involve modifying the governing equations of the system. A common approach is the Galerkin projection, which projects the full-order model (FOM) onto a reduced subspace. This technique is effective in applications such as the thermal block problem, in which it has been shown to maintain accuracy while reducing computational costs [138,139].

Recent advancements have led to the emergence of non-intrusive ROM techniques, which do not require modifications to the governing equations but instead rely on data-driven methods to construct reduced models. Physics-Informed Neural Networks (PINNs) and Autoencoder-based ROMs are among the most prominent of these techniques. PINNs incorporate physical constraints into neural network architectures, allowing them to model complex heat-transfer problems while preserving physical laws. This approach eliminates the need for explicit equation reformulation and has demonstrated advantages in solving parameterized problems and cases with limited training data. Autoencoder-based ROMs, on the other hand, utilize deep learning frameworks to extract dominant features from high-fidelity simulations, reducing dimensionality while retaining predictive accuracy. These methods are particularly useful for large-scale, nonlinear thermal systems, cases where traditional ROMs may struggle to maintain efficiency and accuracy [140,141].

While non-intrusive ROMs offer significant advantages in scalability and flexibility, they also introduce challenges. Traditional ROMs, such as Proper Orthogonal Decomposition (POD) and Dynamic Mode Decomposition (DMD), are computationally efficient, mathematically well established, and require minimal training data. However, they may struggle with high-dimensional nonlinear systems and often necessitate intrusive modifications to the governing equations. In contrast, non-intrusive ROMs excel in handling complex, data-driven problems without requiring equation reformulation, making them ideal for modern AI-enhanced simulations. However, their main limitations include the need for extensive training datasets and the high computational costs of neural network-based approaches.

ROMs have been effectively utilized to replicate thermally interconnected flow phenomena, including natural convection within a thermally energized cavity. These mathematical constructs are capable of achieving speed improvements exceeding 300 times in comparison to Full Order Models (FOMs), making the former appropriate for applications that require real-time processing [138]. Data-driven ROMs have been formulated for the analysis of convective heat-transfer phenomena within porous media, employing methodologies such as POD and Radial Basis Function (RBF) interpolation techniques. These advanced models have the ability to accommodate parametric uncertainties and have shown substantial improvements in computational efficiency [142]. The integration of machine learning with ROMs, such as in the FastSVD-ML-ROM framework, enhances the ability to handle large-scale nonlinear problems. This approach uses techniques such as singular value decomposition and convolutional autoencoders for dimensionality reduction, allowing real-time simulations in complex systems such as blood flow and fluid dynamics around cylinders [143].

Although ROMs offer significant computational advantages, they also present challenges, particularly in maintaining accuracy under varying conditions. For example, handling temperature-dependent boundary conditions in thermal systems can be complex, requiring advanced reduction strategies such as the Iterative Rational Krylov Algorithm [144]. Additionally, the choice between intrusive and non-intrusive methods depends on the specific application and the availability of system equations [140]. With the increasing role of machine learning in ROM development, hybrid approaches that combine physics-based reduction with data-driven techniques are expected to play a critical role in future heat-transfer simulations. In summary, ROMs establish a comprehensive framework for the simplification of intricate heat-transfer simulations, making them suitable for real-time implementations. Nevertheless, the selection of methodology, be it intrusive or non-intrusive, hinges upon the requirements and limitations of the application in question. As ROMs progressively advance, especially with the incorporation of machine learning techniques, their relevance and effectiveness in real-time contexts are expected to increase significantly. Also, ROM has been applied to an online control system that optimizes the design of the rolling schedule in view of the flatness of the plate. The thermal roll profile during hot rolling was modeled by FEM and then the results were approximated using a time series function or different equations with their numerical solutions [145].

ROM is used to model the dispatch of thermal power in nuclear power plants, allowing efficient heat distributions within industrial processes while reducing carbon emissions. The reduced-order model simplifies complex interactions within the plant, allowing scalability and integration into larger-power models of the system [146]. ROM is applied to the construction of thermal models to optimize control actions during demand–response events. By reducing the order of the model, computational costs are minimized while maintaining model fidelity, which is essential for real-time applications in building energy management [147]. The methodology allows for the automatic identification of key parameters, ensuring that the reduced models accurately capture the thermal dynamics of buildings. In CSP systems, ROM is used to optimize the design and operation of tower receivers and their cavities. The method reduces computational time by orders of magnitude, allowing efficient simulation of heat exchange processes under varying conditions [148]. This efficiency is paramount to enhancing the thermal efficacy of Concentrated Solar Power (CSP) systems, which operate under elevated thermal conditions. ROM is used in district heating networks to efficiently predict evolution of fluid temperature. Reduced models provide accurate simulations of temperature responses, facilitating the design and control of heating systems with significantly reduced computational costs [149]. In battery thermal management systems (BTMS) for electric vehicles, ROM significantly reduces the computational loads of CFD simulations, which are typically resource intensive. Using projection-based methods, ROM can predict transient thermal responses with high accuracy, facilitating rapid design and control optimizations [150].

Figure 18 presents a summary of the individual topics discussed in relation to the ROM.

Figure 18.

The key considerations related to the ROM.

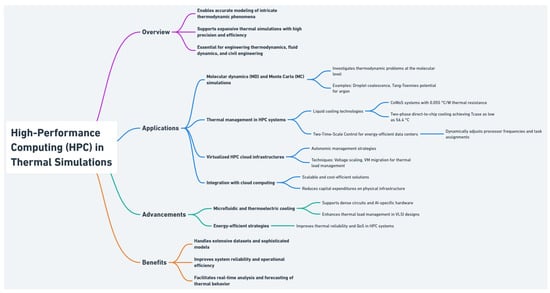

3.4. High-Performance Computing (HPC)

HPC assumes a crucial position in expansive thermal simulations by offering the requisite computational capabilities to accurately model intricate thermodynamic phenomena with exceptional precision and operational efficiency. Such simulations are imperative in numerous disciplines, including engineering thermodynamics, fluid dynamics, and civil engineering, in which they facilitate the comprehension and forecasting of system behavior under various thermal conditions. HPC allows for the management of extensive datasets and sophisticated models, which are indispensable for achieving precise simulations. The following sections will explore the specific functions and advantages of HPC in large-scale thermal simulations.

HPC allows for the execution of molecular dynamics (MD) and Monte Carlo (MC) simulations, which are essential for investigating thermodynamic problems at the molecular level. These simulations provide insight into phenomena such as droplet coalescence and the development of potential models for thermodynamic properties, such as the Tang–Toennies potential for argon [151].

Advancements in HPC have been significantly influenced by developments in cloud computing and parallel processing, particularly in the realm of thermal management. As computational demands increase, effective thermal management becomes crucial to maintaining system reliability and efficiency. Recent research highlights various strategies and technologies that address these challenges, focusing on liquid cooling, energy-efficient management, and the integration of HPC with cloud computing.

Liquid cooling has emerged as a key technology for managing the thermal output of high-performance systems. For example, the use of liquid cooling in CoWoS (Chip on Wafer on Substrate) systems has demonstrated significant improvements in thermal resistance, with direct liquid cooling achieving junction-to-ambient thermal resistance of 0.055 °C/W at a flow rate of 40 mL/s [152]. A study of two-phase direct-to-chip liquid cooling systems showed that these systems could handle high thermal demands effectively, achieving a Tcase as low as 56.4 °C, which is crucial to maintaining performance in data centers [153].

The Two-Time-Scale Control (TTSC) approach optimizes energy consumption in HPC data centers by dynamically adjusting processor frequencies and task assignments based on thermal conditions. This method has been shown to improve energy efficiency while maintaining thermal constraints [154]. Virtualized HPC cloud infrastructures benefit from autonomic management strategies that use techniques such as voltage scaling and VM migration to manage thermal loads. These methodologies guarantee the optimization of energy utilization while preserving quality of service (QoS) through their ability to adapt to fluctuating thermal environments [155].

The amalgamation of HPC with cloud computing presents scalable and economically efficient solutions for performing intricate simulations and analyses. Cloud platforms provide on-demand resources, mitigating the need for substantial capital expenditures in tangible infrastructure [156]. Advanced VLSI design methodologies, including microfluidic and thermoelectric cooling, are crucial for managing thermal loads in dense circuits. These innovations support the development of AI-specific hardware and other specialized processors, further improving HPC capabilities [157].

Figure 19 presents a summary of the individual topics discussed in relation to HPC.

Figure 19.

The key considerations related to the HPC.

4. Applications of Numerical Modeling in Thermal Management

This section presents selected applications from among many others and is not a complete list of possible applications.

4.1. Electronics Cooling

Modeling serves an essential function in the governance of thermal dynamics within microelectronics, notably for central processing units (CPUs), graphics processing units (GPUs), and power electronics, by facilitating the design and enhancement of proficient cooling mechanisms. As electronic apparatuses advance in capability and miniaturization, the difficulty of effectively dissipating heat becomes increasingly evident. Modeling offers a systematic approach to forecasting thermal performance, refining cooling methodologies, and ensuring the dependability and efficacy of electronic components. This discourse examines the significance of modeling in thermal management, with an emphasis on CPUs, GPUs, and power electronics.

Thermal models allow for the prediction of temperature distributions and heat flows within electronic devices, which is essential for designing effective cooling solutions. These models help to understand the thermal behavior of complex systems, such as 3D circuits and power electronics [158]. By simulating various cooling scenarios, thermal models enable the optimization of cooling designs, ensuring that devices operate within safe temperature limits. This is especially significant for high-power density utilizations such as Central Processing Units (CPUs) and Graphics Processing Units (GPUs), for which effective thermal dissipation is paramount [159]. For devices experiencing time-varying workloads, such as microprocessors and power electronics, transient thermal models are crucial. These models help to design cooling solutions that can respond quickly to temperature fluctuations, ensuring the reliability and performance of the device [160].

Equation-Based Modeling (EBM) enables the amalgamation of thermal models with conventional 3D chip simulators, permitting an extensive simulation of on-chip thermal occurrences and heat dissipation mechanisms. This methodology has been a transformative factor in addressing the thermal difficulties of nanoscale integrated circuits [161]. Modeling facilitates the advancement and assessment of sophisticated cooling technologies, such as microchannel heat exchangers, phase transition substances, and thermal conduits. These technologies are simulated to evaluate their duration of thermal response and suitability for particular applications [162].

The difficulties associated with the escalation of power densities and the trend toward miniaturization in electronic devices are substantial, as these factors result in heightened thermal burdens that conventional cooling techniques find arduous to control. Sophisticated CFD and ML methodologies are currently being employed to enhance cooling solutions, effectively addressing these issues by improving the efficiency and efficacy of thermal management systems. This analysis investigates the obstacles presented by elevated power densities and miniaturization, as well as the application of advanced CFD and ML methodologies in the optimization of cooling solutions.

As electronic devices become more compact, the power density increases, leading to significant thermal management challenges. For example, high-performance processors can reach power densities of 1–2 kW/cm2, creating localized hot spots that degrade performance and reliability [163]. In integrated circuits, rapid temperature swings and sub-millimeter hot spots necessitate sophisticated cooling strategies. Traditional methods often do not address these rapid and localized thermal changes effectively [161]. Miniaturization of components limits the space available for cooling solutions, necessitating innovative designs that can fit within these constraints while still providing effective thermal management [164].

CFD models are crucial to understanding and optimizing the cooling systems of high-power devices. For example, CFD analysis of electric motors has been used to identify and mitigate overheating problems by optimizing airflow and reducing temperature by up to 120 K [165]. The combination of traditional 3D chip simulators with heat dissipation models in EBM languages allows for a comprehensive simulation of on-chip thermal phenomena, facilitating better cooling assessments [161].

Artificial Neural Networks (ANNs) serve as surrogate models to predict thermal resistance and pressure drop, allowing the rapid optimization of cooling systems for high heat-flux applications [166]. DL models, specifically convolutional neural networks (CNNs), are used to forecast cooling effectiveness and improve design variables, considerably reducing computational demands compared to conventional CFD simulations [167]. ML workflows can rapidly explore extensive design spaces, optimizing cooling solutions for power modules and heat sinks. This approach has led to significant improvements in thermal performance and cost efficiency [168].

Although advanced CFD and ML models offer promising solutions for the challenges of increasing power densities and miniaturization, they also introduce new complexities. Integration of these models requires significant computational resources and expertise in both fluid dynamics and machine learning. Additionally, the rapid pace of technological advancement means that cooling solutions must continually evolve to keep up with the new device architectures and power profiles. Despite these challenges, the potential for improved thermal management through these advanced models is substantial, offering pathways to more efficient and reliable electronic devices.

4.2. Energy Systems

Heat-transfer modeling plays a crucial role in optimizing the performance of renewable energy systems such as solar thermal panels, wind turbines, and geothermal setups. By improving the efficiency of heat-transfer processes, these models help maximize energy production, reduce costs, and improve the overall sustainability of renewable energy systems. The integration of advanced materials, innovative design strategies, and sophisticated control mechanisms is one key to achieving these optimizations. Below, the specific contributions of heat-transfer modeling to each type of renewable system are discussed.