Performance of a Methanol-Fueled Direct-Injection Compression-Ignition Heavy-Duty Engine under Low-Temperature Combustion Conditions

Abstract

1. Introduction

2. Experimental and Numerical Setup

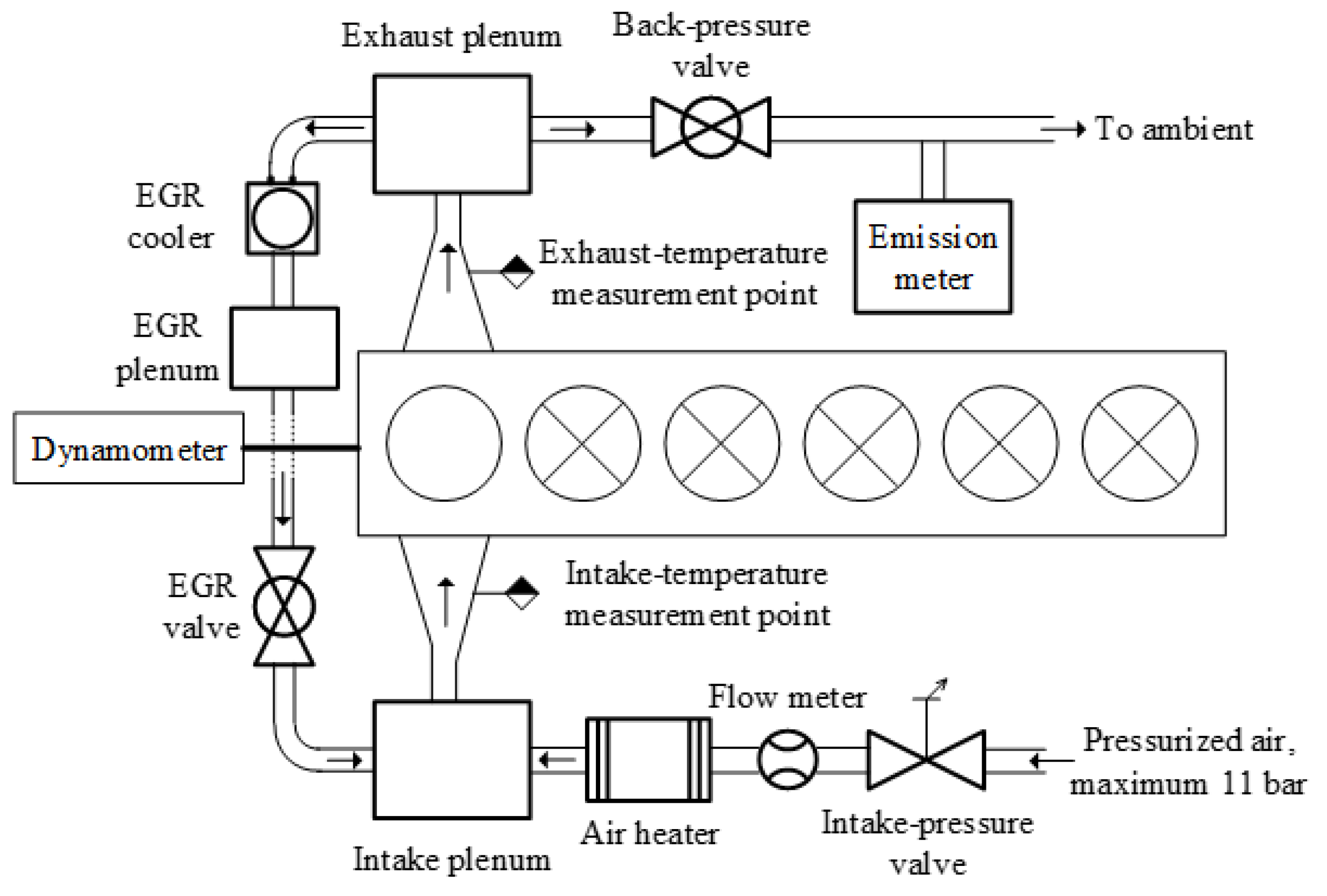

2.1. Test Cell Setup

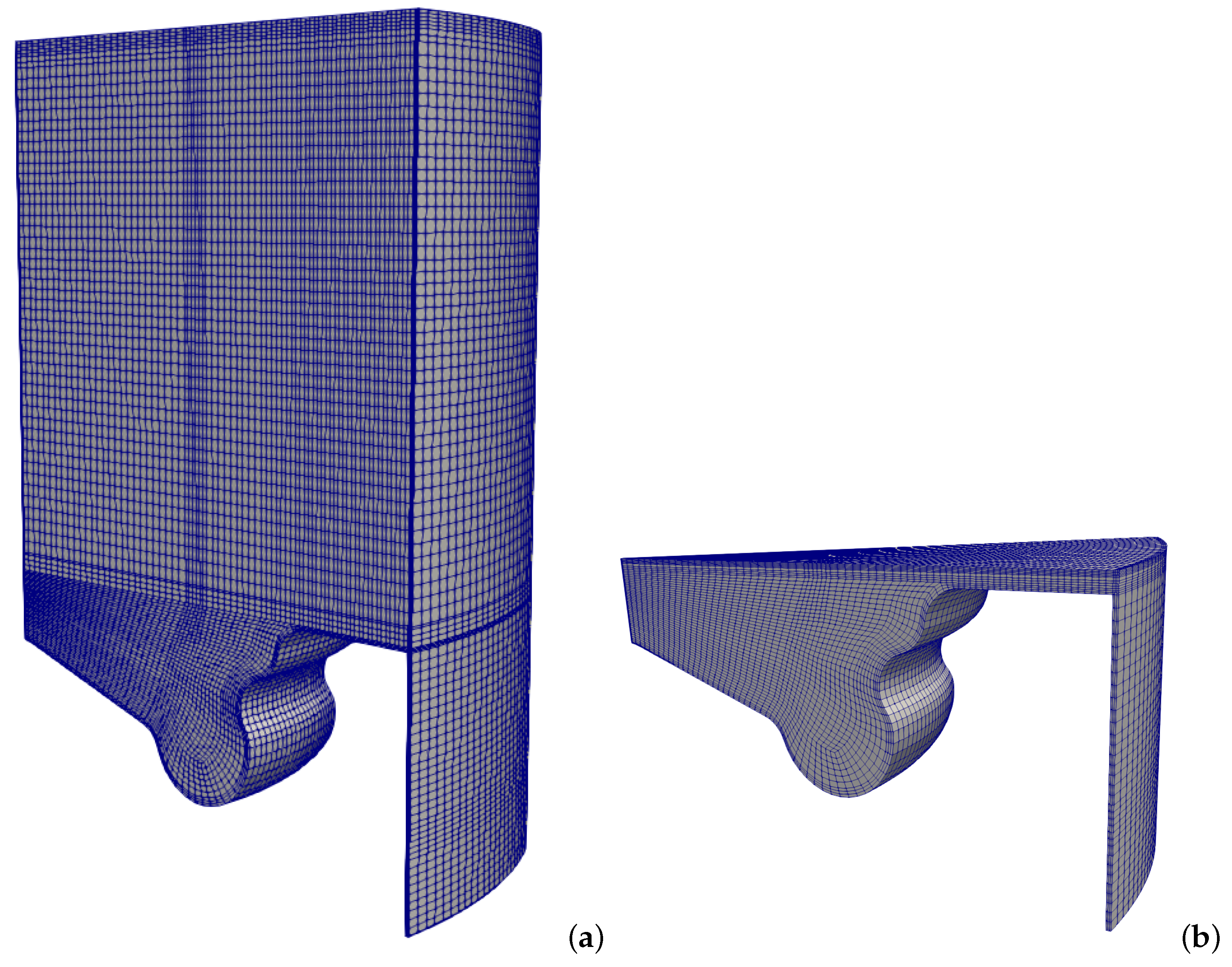

2.2. Simulation Setup

3. Results and Discussion

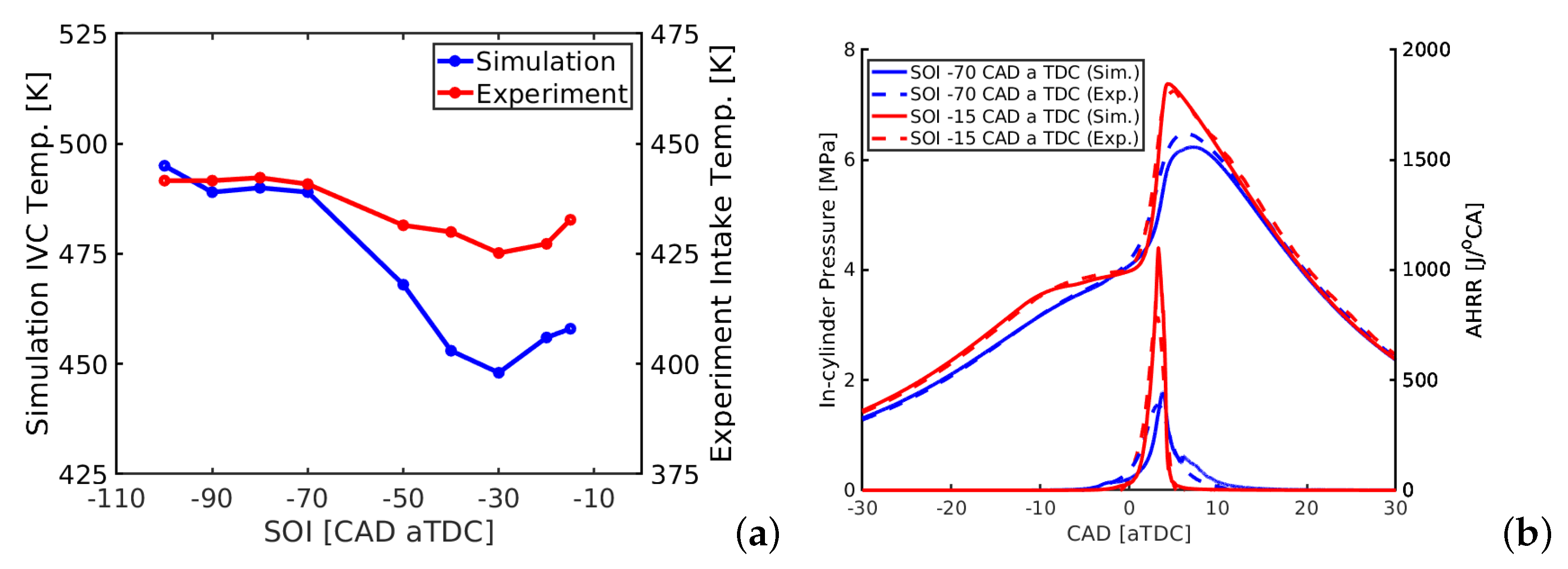

3.1. In-Cylinder Pressure and Heat Release Process

3.2. Engine Performance under HCCI and PPC Operation Conditions

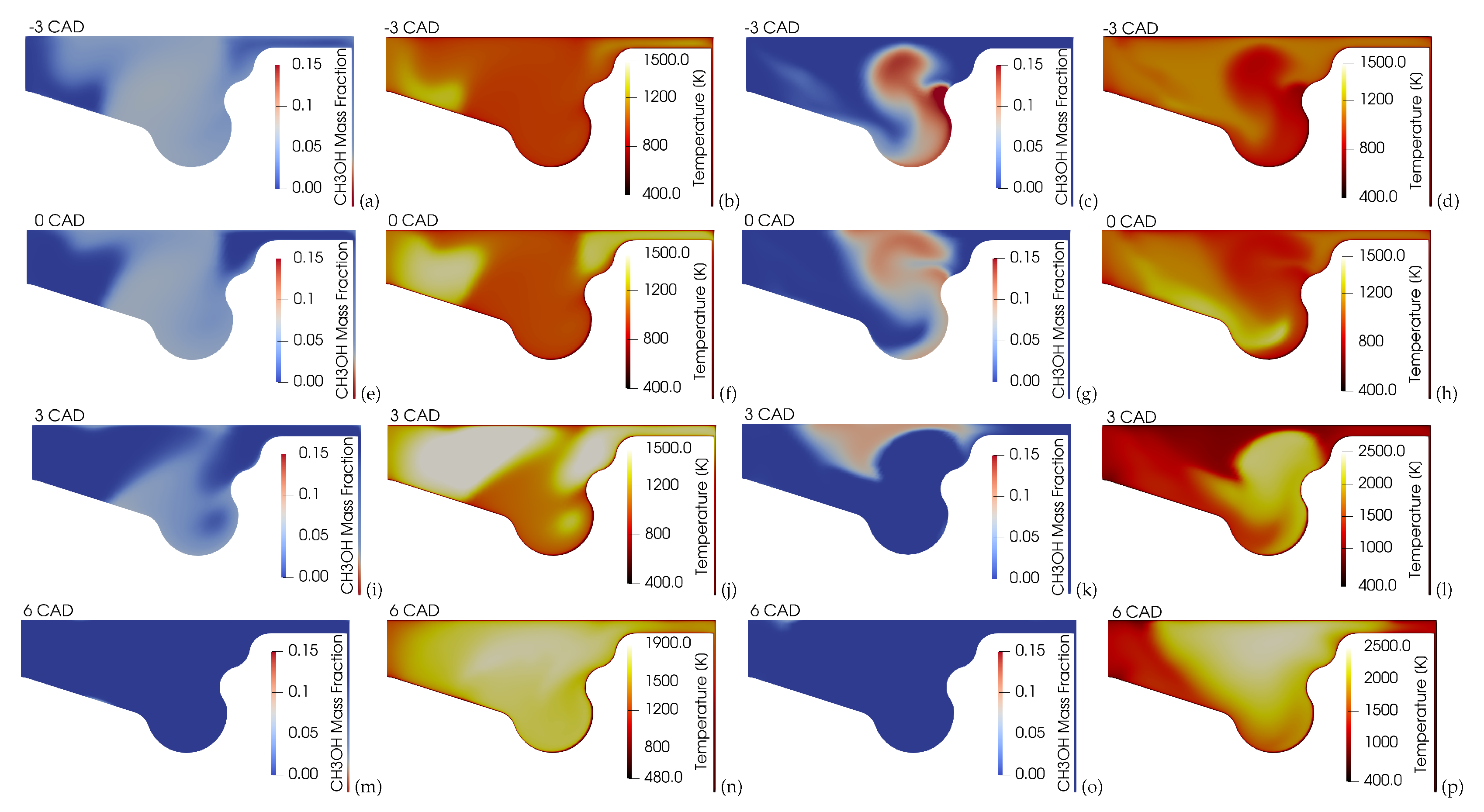

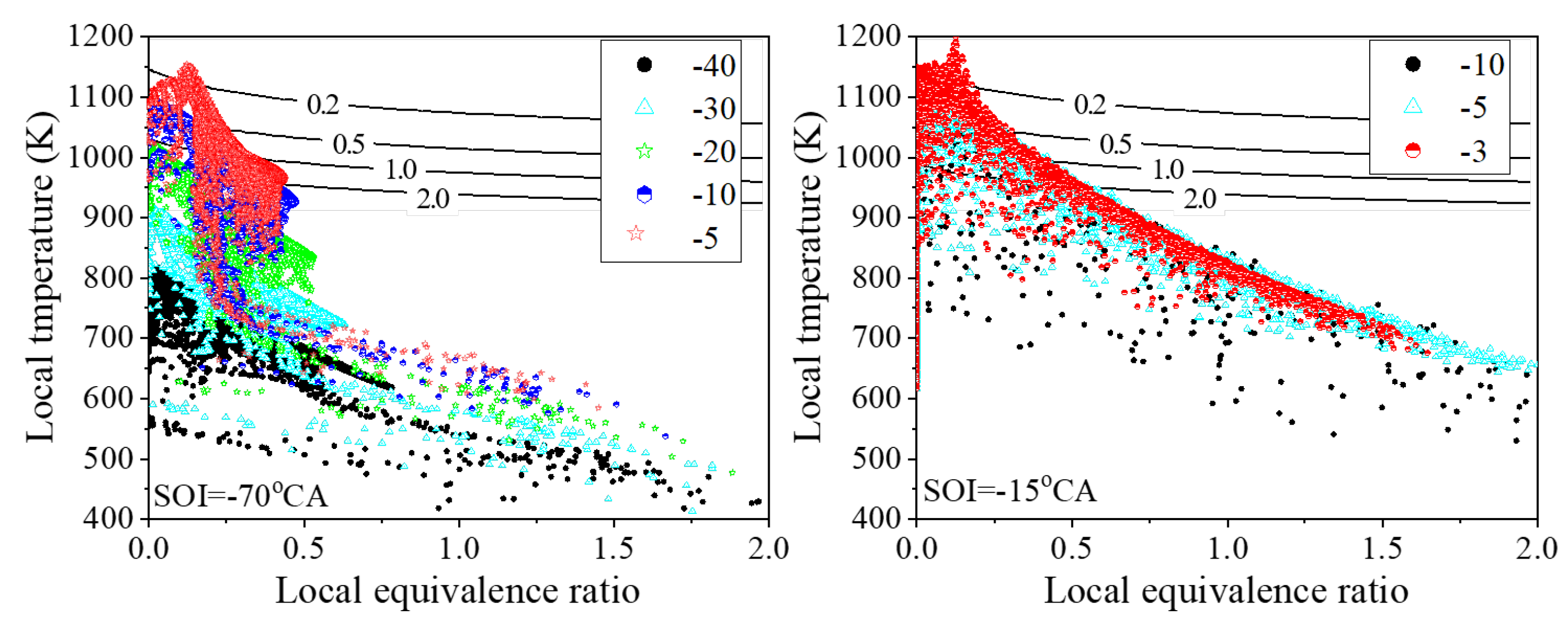

3.3. Combustion Characteristics

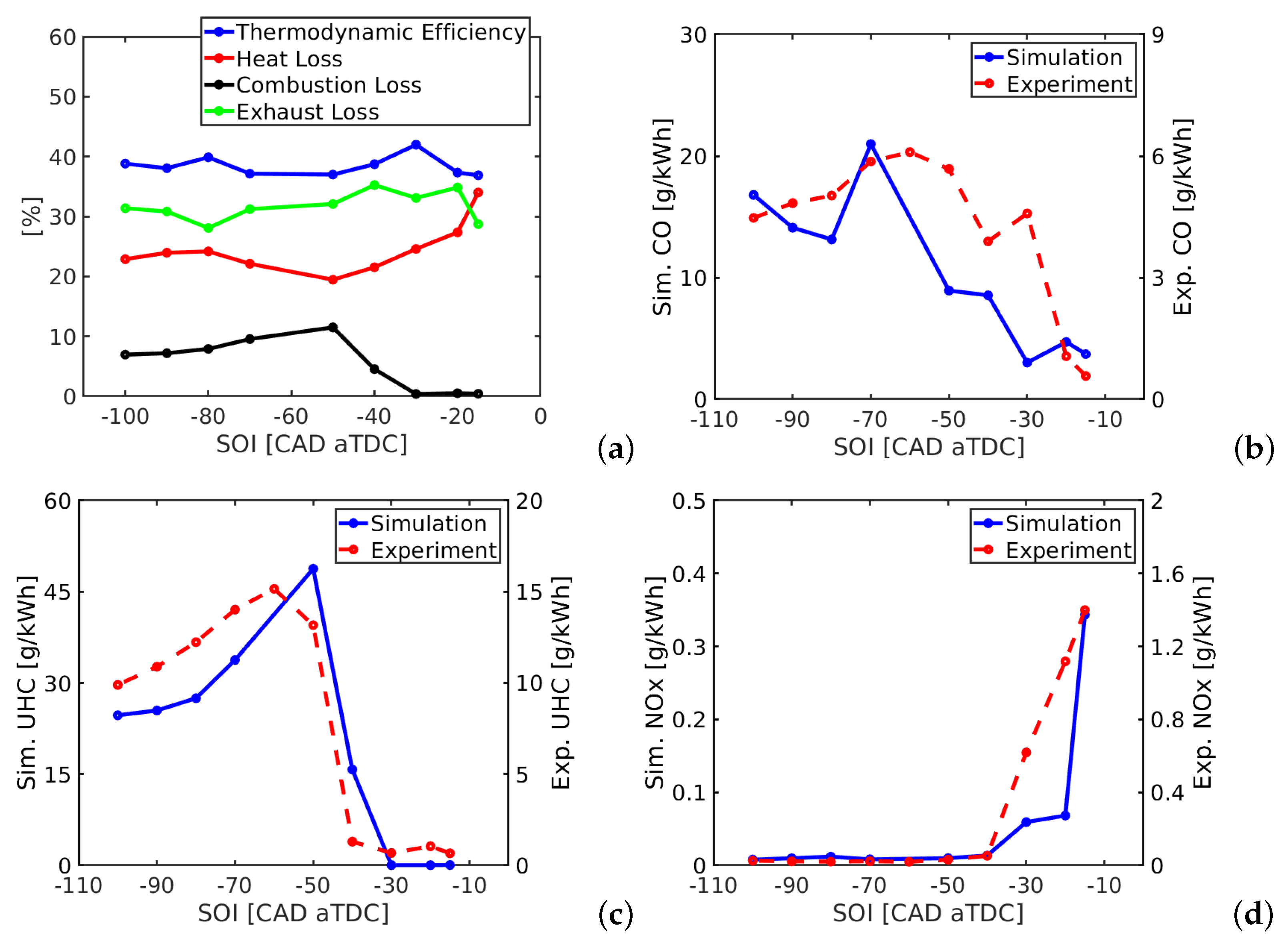

3.4. Engine-Out Emissions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AHRR | Apparent heat release rate |

| CAD | Crank angle degree |

| HCCI | Homogeneous charge compression ignition |

| HRR | Heat release rate |

| LTC | Low-temperature combustion |

| PPC | Partially premixed combustion |

| SOI | Start of injection |

| TDC | Top dead center |

| UHCs | Unburned hydrocarbons |

| °CA aTDC | Crank-angle degree after TDC |

References

- Reitz, R.D.; Ogawa, H.; Payri, R.; Fansler, T.; Kokjohn, S.; Moriyoshi, Y.; Zhao, H.; Arcoumanis, D.; Assanis, D.; Bae, C.; et al. IJER editorial: The future of the internal combustion engine. Int. J. Engine Res. 2020, 21, 3–10. [Google Scholar] [CrossRef]

- Milojević, S.; Glišović, J.; Savić, S.; Bošković, G.; Bukvić, M.; Stojanović, B. Particulate Matter Emission and Air Pollution Reduction by Applying Variable Systems in Tribologically Optimized Diesel Engines for Vehicles in Road Traffic. Atmosphere 2024, 15, 184. [Google Scholar] [CrossRef]

- Yip, H.L.; Srna, A.; Yuen, A.C.Y.; Kook, S.; Taylor, R.A.; Yeoh, G.H.; Medwell, P.R.; Chan, Q.N. A review of hydrogen direct injection for internal combustion engines: Towards carbon-free combustion. Appl. Sci. 2019, 9, 4842. [Google Scholar] [CrossRef]

- Verhelst, S.; Turner, J.W.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2019, 70, 43–88. [Google Scholar] [CrossRef]

- Xu, L.; Xu, S.; Bai, X.S.; Repo, J.A.; Hautala, S.; Hyvönen, J. Performance and emission characteristics of an ammonia/diesel dual-fuel marine engine. Renew. Sustain. Energy Rev. 2023, 185, 113631. [Google Scholar] [CrossRef]

- Kaario, O.T.; Karimkashi, S.; Bhattacharya, A.; Vuorinen, V.; Larmi, M.; Bai, X.S. A comparative study on methanol and n-dodecane spray flames using Large-Eddy Simulation. Combust. Flame 2024, 260, 113277. [Google Scholar] [CrossRef]

- Bao, J.; Wang, H.; Wang, R.; Wang, Q.; Di, L.; Shi, C. Comparative experimental study on macroscopic spray characteristics of various oxygenated diesel fuels. Energy Sci. Eng. 2023, 11, 1579–1588. [Google Scholar] [CrossRef]

- Shi, C.; Chai, S.; Wang, H.; Ji, C.; Ge, Y.; Di, L. An insight into direct water injection applied on the hydrogen-enriched rotary engine. Fuel 2023, 339, 127352. [Google Scholar] [CrossRef]

- Milojević, S.; Savić, S.; Marić, D.; Stopka, O.; Krstić, B.; Stojanović, B. Correlation between emission and combustion characteristics with the compression ratio and fuel injection timing in tribologically optimized diesel engine. Teh. Vjesn. 2022, 29, 1210–1219. [Google Scholar]

- Tian, Z.; Wang, Y.; Zhen, X.; Liu, Z. The effect of methanol production and application in internal combustion engines on emissions in the context of carbon neutrality: A review. Fuel 2022, 320, 123902. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Maurya, R.K. Evolution, challenges and path forward for low temperature combustion engines. Prog. Energy Combust. Sci. 2017, 61, 1–56. [Google Scholar] [CrossRef]

- Pachiannan, T.; Zhong, W.; Rajkumar, S.; He, Z.; Leng, X.; Wang, Q. A literature review of fuel effects on performance and emission characteristics of low-temperature combustion strategies. Appl. Energy 2019, 251, 113380. [Google Scholar] [CrossRef]

- Lachaux, T.; Musculus, M.P. In-cylinder unburned hydrocarbon visualization during low-temperature compression-ignition engine combustion using formaldehyde PLIF. Proc. Combust. Inst. 2007, 31, 2921–2929. [Google Scholar] [CrossRef]

- Yao, M.; Zheng, Z.; Liu, H. Progress and recent trends in homogeneous charge compression ignition (HCCI) engines. Prog. Energy Combust. Sci. 2009, 35, 398–437. [Google Scholar] [CrossRef]

- Sharma, T.K.; Rao, G.A.P.; Murthy, K.M. Homogeneous Charge Compression Ignition (HCCI) Engines: A Review. Arch. Comput. Methods Eng. 2016, 23, 623–657. [Google Scholar] [CrossRef]

- Noehre, C.; Andersson, M.; Johansson, B.; Hultqvist, A. Characterization of Partially Premixed Combustion. SAE Technical Paper 2006-01-3412. 2006. Available online: https://www.sae.org/publications/technical-papers/content/2006-01-3412/ (accessed on 14 August 2024).

- Kalghatgi, G.T.; Risberg, P.; Ångström, H.E. Partially Pre-Mixed Auto-Ignition of Gasoline to Attain Low Smoke and Low NOx at High Load in a Compression Ignition Engine and Comparison with a Diesel Fuel. SAE Technical Paper 2007-01-0006. 2007. Available online: https://www.sae.org/publications/technical-papers/content/2007-01-0006/ (accessed on 14 August 2024).

- Manente, V.; Johansson, B.; Tunestal, P. Partially Premixed Combustion at High Load using Gasoline and Ethanol, a Comparison with Diesel. SAE Technical Paper 2009-01-0944. 2009. Available online: https://www.sae.org/publications/technical-papers/content/2009-01-0944/ (accessed on 14 August 2024).

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef]

- Shen, M.; Tuner, M.; Johansson, B.; Cannella, W. Effects of EGR and Intake Pressure on PPC of Conventional Diesel, Gasoline and Ethanol in a Heavy Duty Diesel Engine. SAE Technical Paper 2013-01-2702. 2013. Available online: https://www.sae.org/publications/technical-papers/content/2013-01-2702/ (accessed on 14 August 2024).

- Ravaglioli, V.; Ponti, F.; Silvagni, G.; Moro, D.; Stola, F.; De Cesare, M. Performance Assessment of Gasoline PPC in a Light-Duty CI Engine. SAE Technical Paper 2022-01-0456. 2022. Available online: https://www.sae.org/publications/technical-papers/content/2022-01-0456/ (accessed on 14 August 2024).

- Li, C.; Yin, L.; Shamun, S.; Tuner, M.; Johansson, B.; Solsjo, R.; Bai, X.-S. Transition from HCCI to PPC: The Sensitivity of Combustion Phasing to the Intake Temperature and the Injection Timing with and without EGR. SAE Technical Paper 2016-01-0767. 2016. Available online: https://www.sae.org/publications/technical-papers/content/2016-01-0767/ (accessed on 14 August 2024).

- Svensson, M.; Tuner, M.; Verhelst, S. Low Load Ignitability of Methanol in a Heavy-Duty Compression Ignition Engine. SAE Technical Paper 2022-01-1093. 2022. Available online: https://www.sae.org/publications/technical-papers/content/2022-01-1093/ (accessed on 14 August 2024).

- Zincir, B.; Shukla, P.; Shamun, S.; Tuner, M.; Deniz, C.; Johansson, B. Investigation of Effects of Intake Temperature on Low Load Limitations of Methanol Partially Premixed Combustion. Energy Fuels 2019, 33, 5695–5709. [Google Scholar] [CrossRef]

- Svensson, E.; Verhelst, S. Numerical Optimization of Compression Ratio for a PPC Engine Running on Methanol. SAE Technical Paper 2019-01-2168. 2019. Available online: https://www.sae.org/publications/technical-papers/content/2019-01-2168/ (accessed on 14 August 2024).

- Johansson, B.; Shamun, S.; Shen, M.; Tuner, M.; Pagels, J.; Gudmundsson, A.; Tunestal, P. Exhaust PM Emissions Analysis of Alcohol Fueled Heavy-Duty Engine Utilizing PPC. SAE Int. J. Engines 2016, 9, 2142–2152. [Google Scholar]

- Svensson, E.; Li, C.; Shamun, S.; Johansson, B.; Tuner, M.; Perlman, C.; Lehtiniemi, H.; Mauss, F. Potential Levels of Soot, NOx, HC and CO for Methanol Combustion. SAE Technical Paper 2016-01-0887. 2016. Available online: https://www.sae.org/publications/technical-papers/content/2016-01-0887/ (accessed on 14 August 2024).

- Pucilowski, M.; Jangi, M.; Shamun, S.; Li, C.; Tuner, M.; Bai, X.S. Effect of Start of Injection on the Combustion Characteristics in a Heavy-Duty DICI Engine Running on Methanol. SAE Technical Paper 2017-01-0560. 2017. Available online: https://www.sae.org/publications/technical-papers/content/2017-01-0560/ (accessed on 14 August 2024).

- Matamis, A.; Lonn, S.; Luise, L.; Vaglieco, B.M.; Tuner, M.; Andersson, O.; Alden, M.; Richter, M. Optical characterization of methanol compression-ignition combustion in a heavy-duty engine. Proc. Combust. Inst. 2021, 38, 5509–5517. [Google Scholar] [CrossRef]

- Xu, L.; Treacy, M.; Zhang, Y.; Aziz, A.; Tuner, M.; Bai, X.S. Comparison of efficiency and emission characteristics in a direct-injection compression ignition engine fuelled with iso-octane and methanol under low temperature combustion conditions. Appl. Energy 2022, 312, 118714. [Google Scholar] [CrossRef]

- Aziz, A.; Xu, L.; Garcia, A.; Tuner, M. Influence of Injection Timing on Equivalence Ratio Stratification of Methanol and Isooctane in a Heavy-Duty Compression Ignition Engine. SAE Technical Paper 2020-01-2069. 2020. Available online: https://www.sae.org/publications/technical-papers/content/2020-01-2069/ (accessed on 14 August 2024).

- Svensson, M.; Tuner, M.; Verhelst, S. Experimental Investigation of Pilot Injection Strategies to Aid Low Load Compression Ignition of Neat Methanol. SAE Technical Paper 2024-01-2119. 2024. Available online: https://www.sae.org/publications/technical-papers/content/2024-01-2119/ (accessed on 14 August 2024).

- Lucchini, T.; D’Errico, G.; Jasak, H.; Tukovic, Z. Automatic Mesh Motion with Topological Changes for Engine Simulation. SAE Technical Paper 2007-01-0170. 2007. Available online: https://www.sae.org/publications/technical-papers/content/2007-01-0170/ (accessed on 14 August 2024).

- Wang, B.L.; Lee, C.W.; Reitz, R.D.; Miles, P.C.; Han, Z. A generalized renormalization group turbulence model and its application to a light-duty diesel engine operating in a low-temperature combustion regime. Int. J. Engine Res. 2013, 14, 279–292. [Google Scholar] [CrossRef]

- Xu, L.; Bai, X.S.; Jia, M.; Qian, Y.; Qiao, X.; Lu, X. Experimental and modeling study of liquid fuel injection and combustion in diesel engines with a common rail injection system. Appl. Energy 2018, 230, 287–304. [Google Scholar] [CrossRef]

- Beale, J.C.; Reitz, R.D. Modeling spray atomization with the Kelvin-Helmholtz/Rayleigh-Taylor hybrid model. At. Spray 1999, 9, 623–650. [Google Scholar]

- Spalding, D.B. The combustion of liquid fuels. Symp. (Int.) Combust. 1953, 4, 847–864. [Google Scholar] [CrossRef]

- Ranz, W.; Marshall, W.R. Evaporation from drops: Part 2. Chem. Eng. Prog. 1952, 48, 173–180. [Google Scholar]

- Liu, X.; Wang, H.; Wei, L.; Liu, J.; Reitz, R.D.; Yao, M. Development of a reduced toluene reference fuel (TRF)-2, 5-dimethylfuran-polycyclic aromatic hydrocarbon (PAH) mechanism for engine applications. Combust. Flame 2016, 165, 453–465. [Google Scholar] [CrossRef]

- Zeldovich, Y.B. The oxidation of nitrogen in combustion and explosions. J. Acta Physicochimica 1946, 21, 577. [Google Scholar]

- Glarborg, P.; Miller, J.A.; Ruscic, B.; Klippenstein, S.J. Modeling nitrogen chemistry in combustion. Prog. Energy Combust. Sci 2018, 67, 31–68. [Google Scholar] [CrossRef]

- Andruskiewicz, P.; Najt, P.; Durrett, R.; Biesboer, S.; Schaedler, T.; Payri, R. Analysis of the effects of wall temperature swing on reciprocating internal combustion engine processes. Int. J. Engine Res. 2018, 19, 461–473. [Google Scholar] [CrossRef]

- Li, C.; Xu, L.; Bai, X.S.; Tunestal, P.; Tuner, M. Effect of Piston Geometry on Stratification Formation in the Transition from HCCI to PPC. SAE Technical Paper 2018-01-1800. 2018. Available online: https://www.sae.org/publications/technical-papers/content/2018-01-1800/ (accessed on 14 August 2024).

- Xu, L.; Bai, X.S.; Li, Y.; Treacy, M.; Li, C.; Tunestål, P.; Tunér, M.; Lu, X. Effect of piston bowl geometry and compression ratio on in-cylinder combustion and engine performance in a gasoline direct-injection compression ignition engine under different injection conditions. Appl. Energy 2020, 280, 115920. [Google Scholar] [CrossRef]

- Kim, D.; Ekoto, I.; Colban, W.F.; Miles, P.C. In-cylinder CO and UHC Imaging in a Light-Duty Diesel Engine during PPCI Low-Temperature Combustion. SAE Int. J. Fuels Lubr. 2008, 1, 933–956. [Google Scholar] [CrossRef]

| Property | Model Name |

|---|---|

| Turbulence Model | gRNG |

| Injection Profiles | Xu et al. |

| Spray Breakup | KH-RT model |

| Reaction Mechanism | Liu et al. and extended Zeldovich |

| Evaporation Model | Spalding |

| Spray/Wall Interaction | Stick/rebound |

| Heat Transfer | Ranz–Marshall correlations |

| Turbulence Chemistry Interaction | Partially stirred reactor (PaSR) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Treacy, M.; Xu, L.; Fatehi, H.; Kaario, O.; Bai, X.-S. Performance of a Methanol-Fueled Direct-Injection Compression-Ignition Heavy-Duty Engine under Low-Temperature Combustion Conditions. Energies 2024, 17, 4307. https://doi.org/10.3390/en17174307

Treacy M, Xu L, Fatehi H, Kaario O, Bai X-S. Performance of a Methanol-Fueled Direct-Injection Compression-Ignition Heavy-Duty Engine under Low-Temperature Combustion Conditions. Energies. 2024; 17(17):4307. https://doi.org/10.3390/en17174307

Chicago/Turabian StyleTreacy, Mark, Leilei Xu, Hesameddin Fatehi, Ossi Kaario, and Xue-Song Bai. 2024. "Performance of a Methanol-Fueled Direct-Injection Compression-Ignition Heavy-Duty Engine under Low-Temperature Combustion Conditions" Energies 17, no. 17: 4307. https://doi.org/10.3390/en17174307

APA StyleTreacy, M., Xu, L., Fatehi, H., Kaario, O., & Bai, X.-S. (2024). Performance of a Methanol-Fueled Direct-Injection Compression-Ignition Heavy-Duty Engine under Low-Temperature Combustion Conditions. Energies, 17(17), 4307. https://doi.org/10.3390/en17174307