Life Cycle Assessment of Plug-In Hybrid Electric Vehicles Considering Different Vehicle Working Conditions and Battery Degradation Scenarios

Abstract

1. Introduction

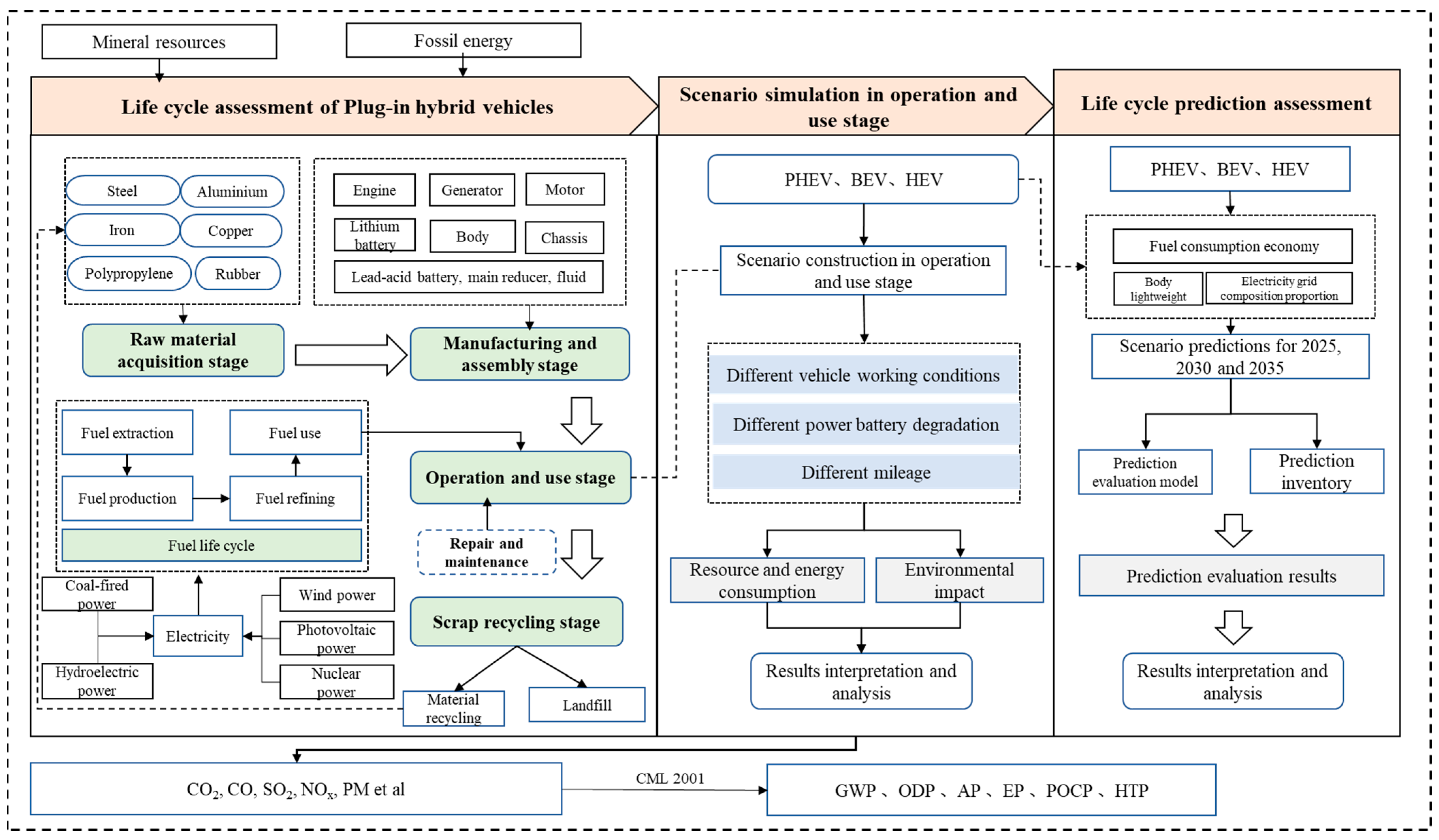

2. Life Cycle Assessment Model for PHEVs

2.1. Assessment Objectives

2.2. System Boundary and Functional Unit

2.3. Mathematical Assessment Model

2.3.1. Material Resource Consumption Assessment Model

2.3.2. Fossil Energy Consumption Assessment Model

2.3.3. Environmental Emissions Assessment Model

2.4. Inventory

2.4.1. Raw Material Acquisition Stage

2.4.2. Manufacturing and Assembly Stage

2.4.3. Operation and Use Stage

2.4.4. Scrap Recycling Stage

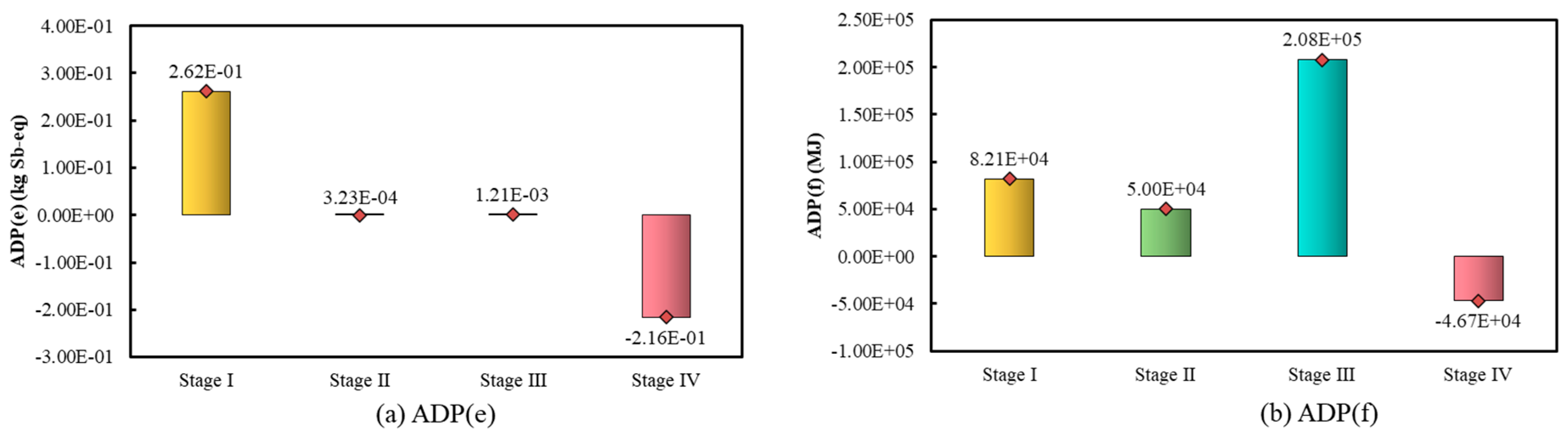

3. Assessment Result Analysis for PHEVs

4. Analysis and Discussion of Environmental Benefits in Different Scenarios

4.1. Vehicle Model Specification

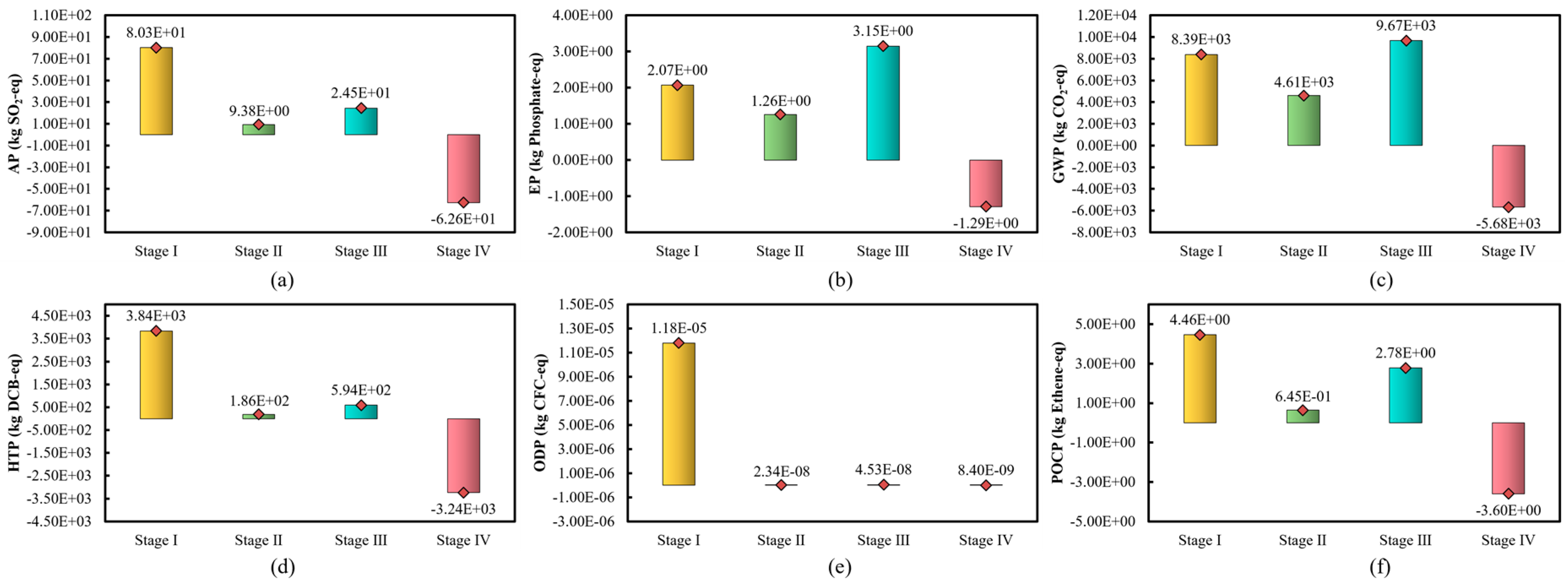

4.2. Working Conditions Scenario Analysis

4.2.1. Construction of Vehicle Working Conditions Scenario

4.2.2. Assessment Results and Analysis of Working Conditions Scenario

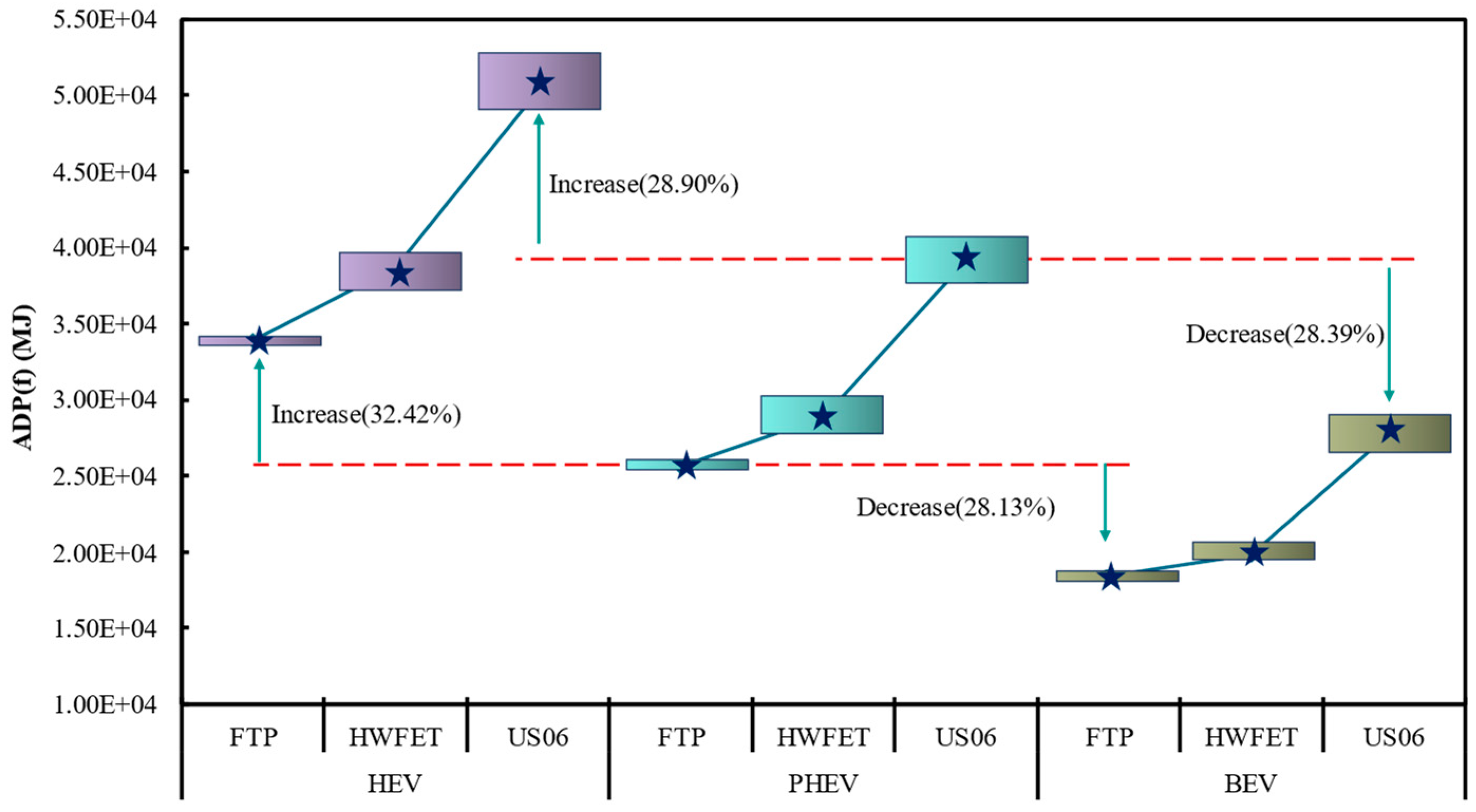

4.3. Power Battery Degradation Scenario Analysis

4.3.1. Construction of Power Battery Degradation Scenario

4.3.2. Assessment Results and Analysis of Power Battery Degradation Scenario

4.4. Mileage Scenario Analysis

4.4.1. Construction of Mileage Scenario Analysis

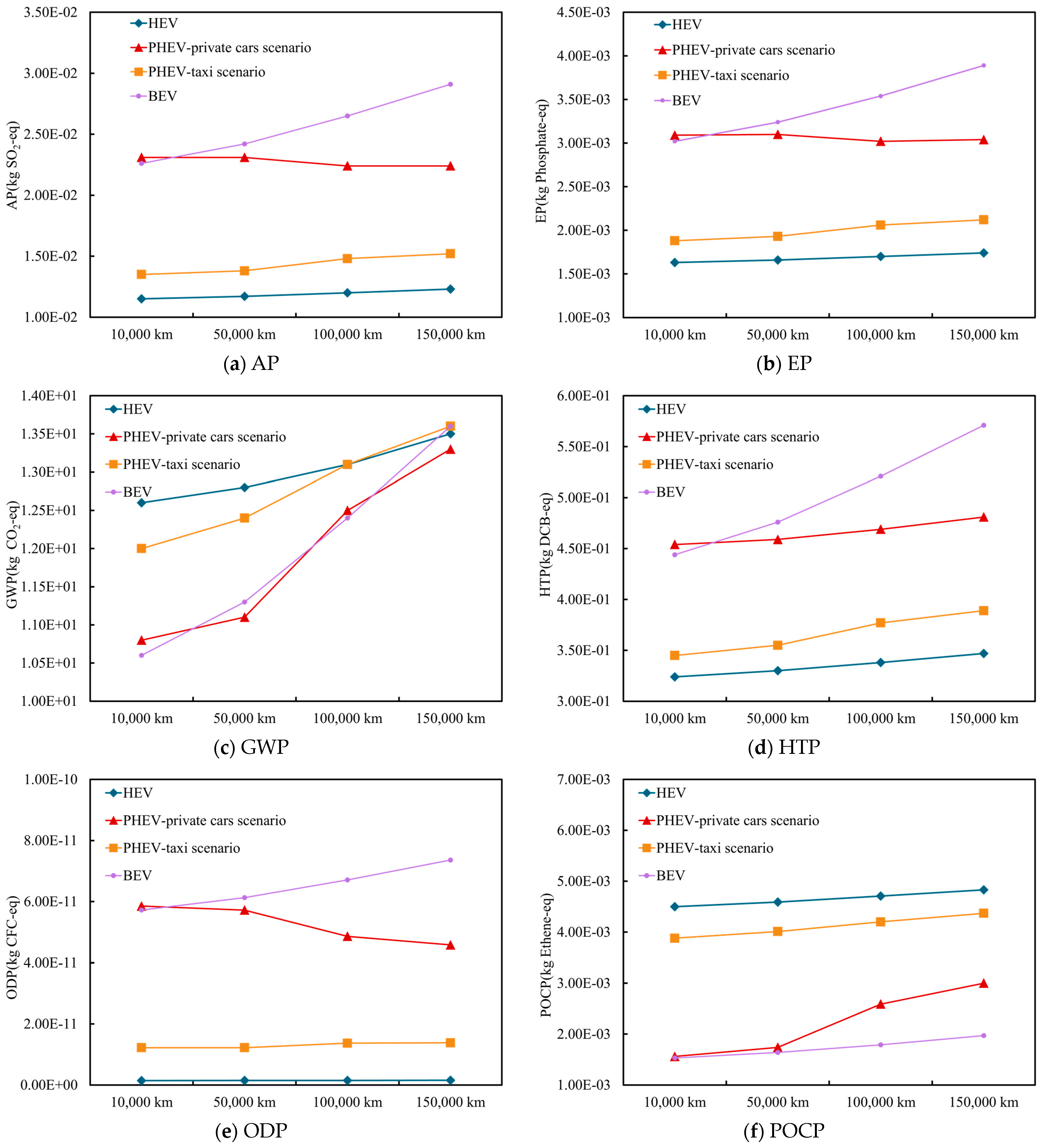

4.4.2. Assessment Results and Analysis of Mileage Scenario

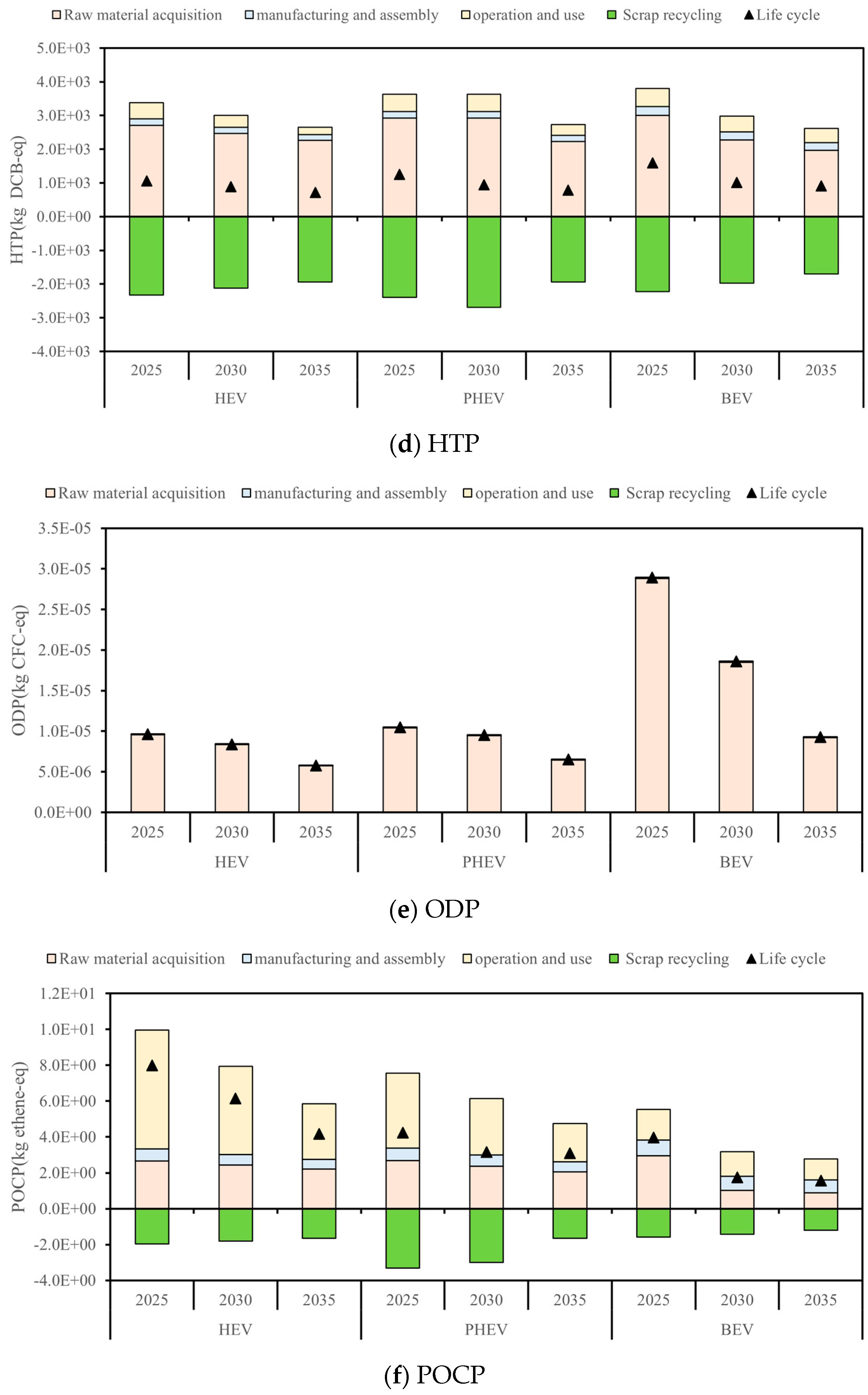

5. Prediction Assessment for 2025, 2030 and 2035

5.1. Prediction Scenarios

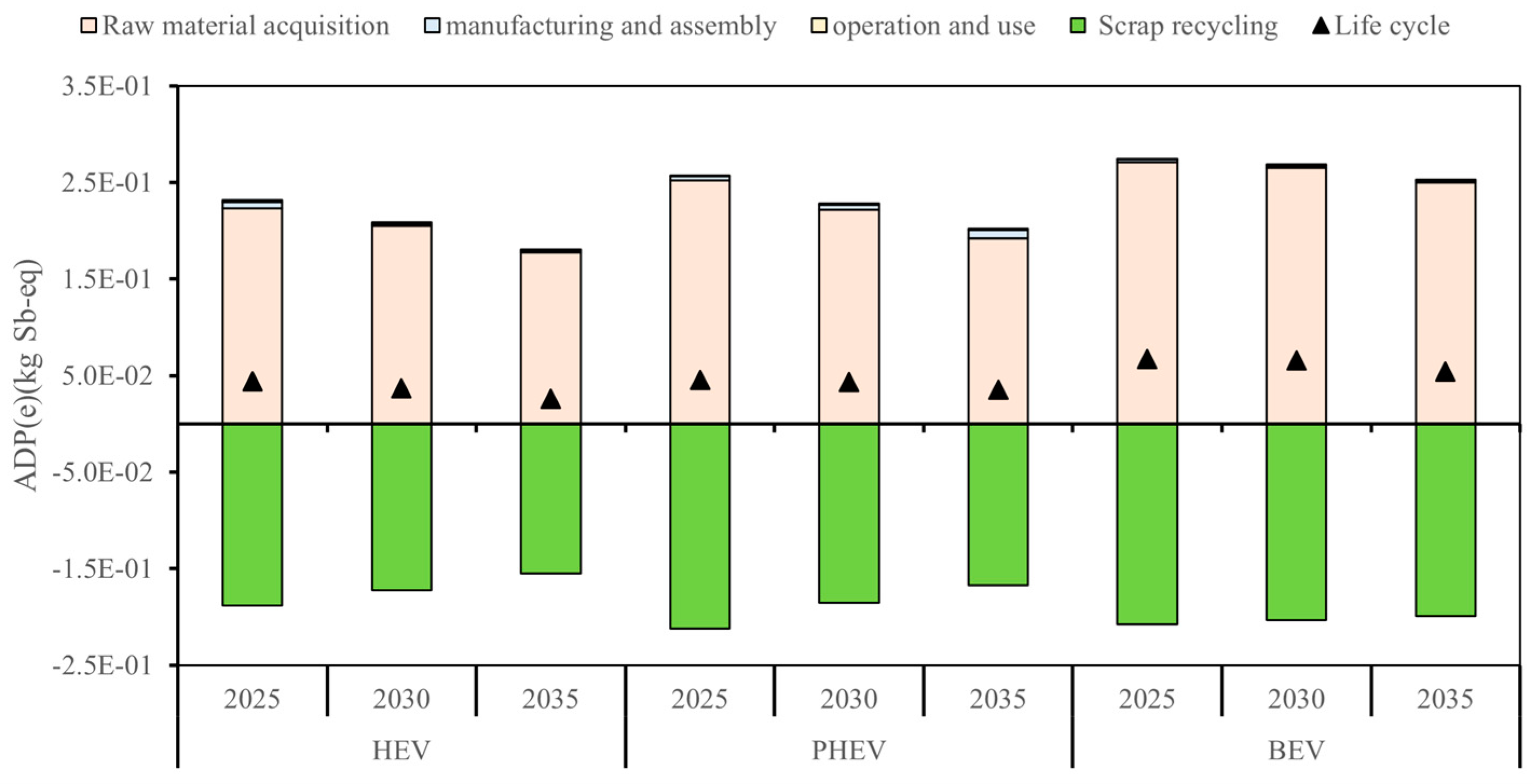

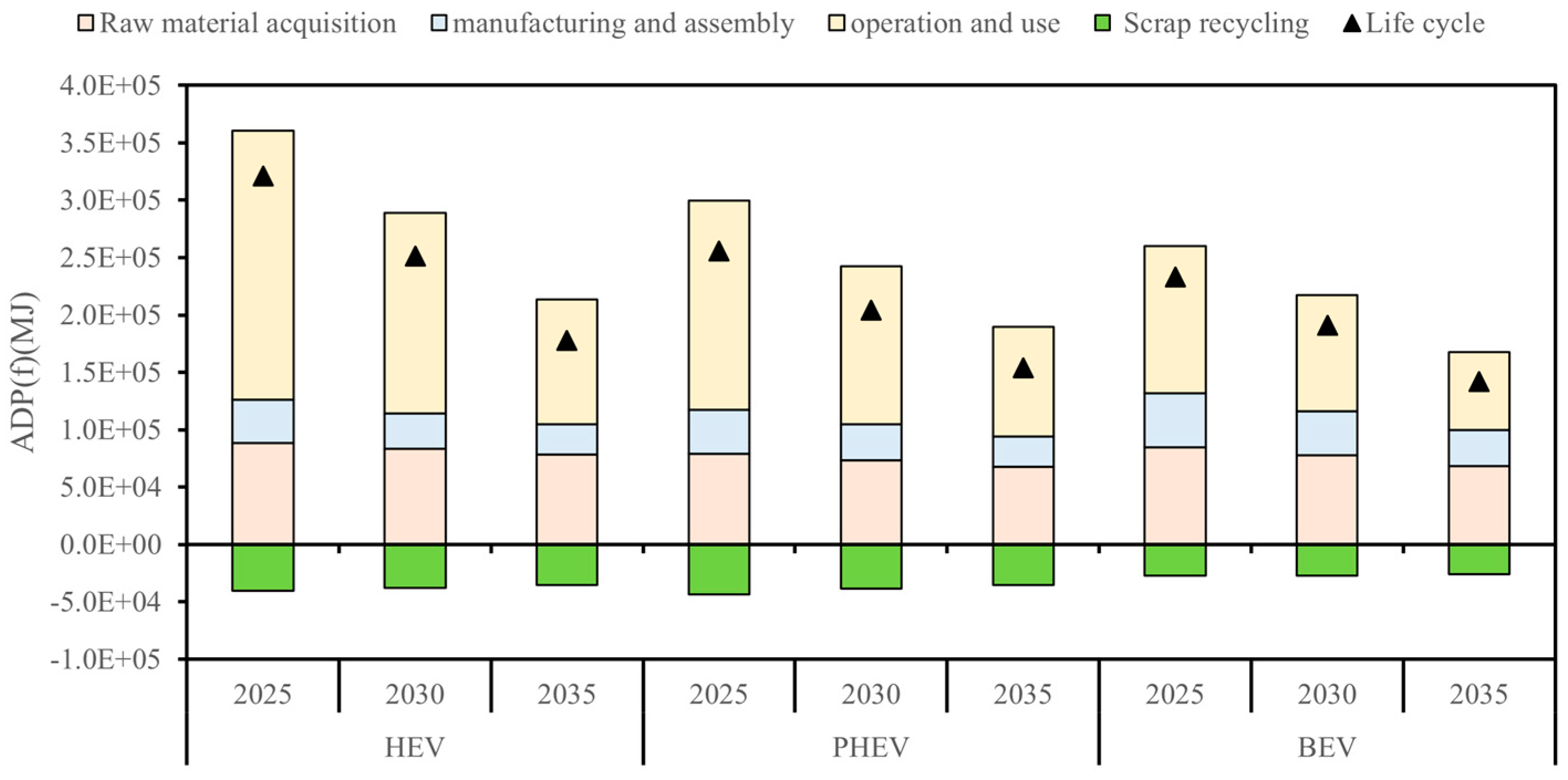

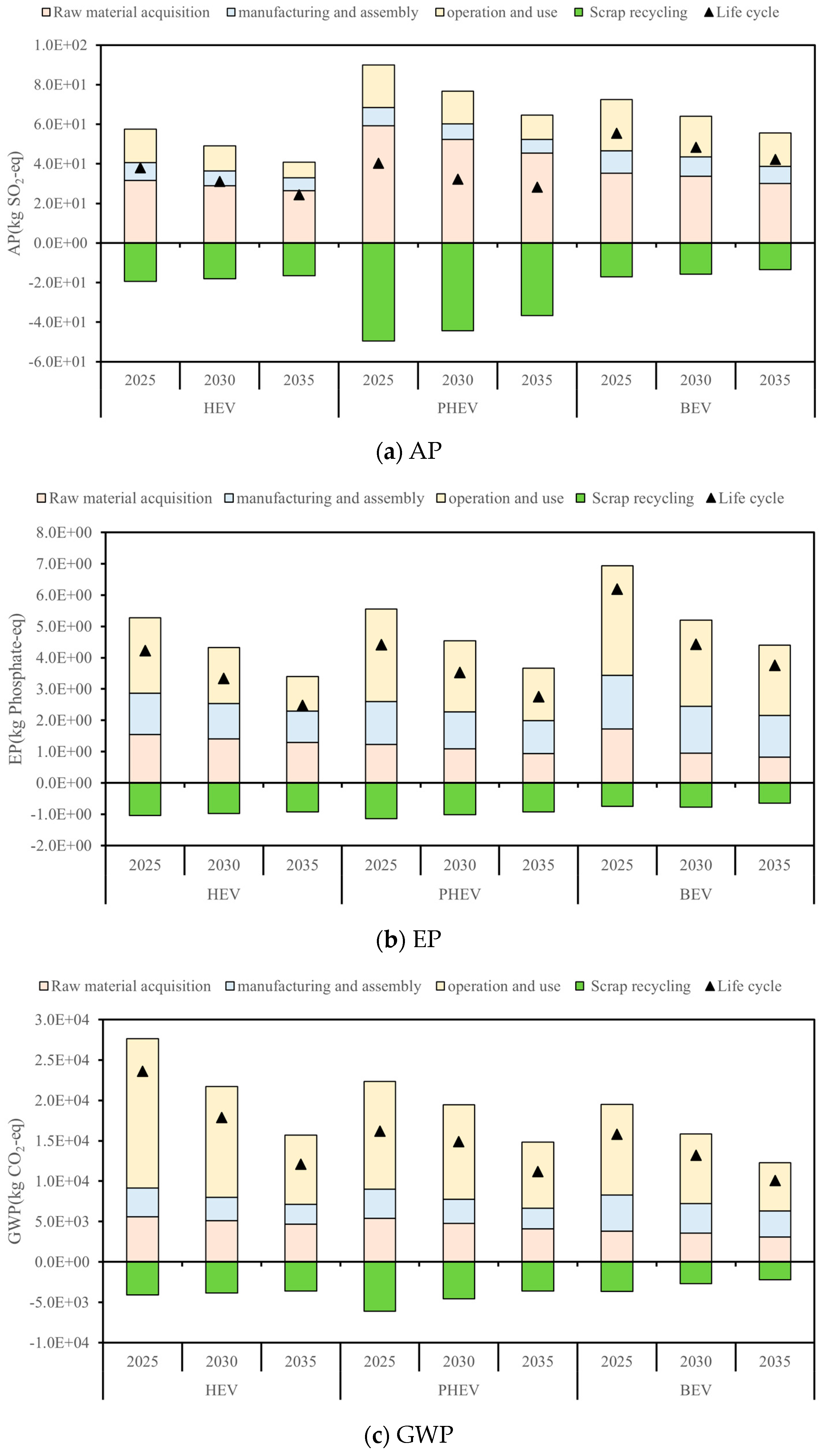

5.2. Predictive Results and Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADP(e) | Abiotic depletion (element) |

| ADP(f) | Abiotic depletion (fossil) |

| AER | All electric range |

| AP | Acidification potential |

| BEV | Battery electrical vehicle |

| CD | Charge depleting |

| CS | Charge sustaining |

| EP | Eutrophication potential |

| EPA | Environmental protection agency |

| FCV | Fuel cell vehicles |

| FTP | Federal Test Procedure |

| GWP | Global warming potential |

| HEV | Hybrid electric vehicles |

| HTP | Human toxicity potential |

| HWFET | Highway fuel economy testing |

| ICEV | Internal combustion engine vehicles |

| LCA | Life cycle assessment |

| NCM | Lithium-ion nickel–cobalt–manganese |

| ODP | Ozone depletion potential |

| PHEV | Plug-in hybrid electric vehicles |

| POCP | Photochemical ozone creation potential |

| PVDF | Polyvinylidene fluoride |

References

- The State Council of China. Action Plan for Peak Carbon by 2030. Beijing, 2021. Available online: https://www.gov.cn/zhengce/content/2021-10/26/content_5644984.htm (accessed on 23 June 2023).

- García, A.; Monsalve-Serrano, J.; Martinez-Boggio, S.; Tripathi, S. Techno-Economic Assessment of Vehicle Electrification in the Six Largest Global Automotive Markets. Energy Convers. Manag. 2022, 270, 116273. [Google Scholar] [CrossRef]

- Zackrisson, M.; Avellán, L.; Orlenius, J. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles–Critical issues. J. Clean. Prod. 2010, 18, 1519–1529. [Google Scholar] [CrossRef]

- Bauer, C.; Hofer, J.; Althaus, H.J.; Del Duce, A.; Simons, A. The Environmental Performance of Current and Future Passenger Vehicles: Life Cycle Assessment Based on a Novel Scenario Analysis Framework. Appl. Energy 2015, 157, 871–883. [Google Scholar] [CrossRef]

- Miotti, M.; Hofer, J.; Bauer, C. Integrated Environmental and Economic Assessment of Current and Future Fuel Cell Vehicles. Int. J. Life Cycle Assess. 2015, 22, 94–110. [Google Scholar] [CrossRef]

- Ambrose, H. Understanding the Future of Lithium: Part 2, Temporally and Spatially Resolved Life-Cycle Assessment Modeling. J. Ind. Ecol. 2020, 24, 88–89. [Google Scholar] [CrossRef]

- Shimizu, T.; Ihara, M.; Kikuchi, Y. A Region-Specific Environmental Analysis of Technology Implementation of Hydrogen Energy in Japan Based on Life Cycle Assessment. J. Ind. Ecol. 2020, 28, 217–233. [Google Scholar] [CrossRef]

- Liang, L.; Fu, G.Z. Comparative Analysis of Life Cycle Energy Consumption and Emissions of Plug-in Hybrid Electric Vehicles with Different Power Systems. Shanghai Automob. 2016, 45–50. [Google Scholar] [CrossRef]

- Fu, P.; Lan, L.B.; Chen, Y.; Hao, Z.; Xing, Y.X.; Cai, X.; Zhang, C.M.; Chen, Y.S. Life Cycle Carbon Emission Prediction and Assessment of Energy-Saving and New Energy Vehicles for 2035. Environ. Sci. 2023, 44, 2365–2374. [Google Scholar]

- Qiao, Q.; Zhao, F.; Liu, Z.; Jiang, S.; Hao, H. Cradle-to-Gate Greenhouse Gas Emissions of Battery Electric and Internal Combustion Engine Vehicles in China. Appl. Energy 2017, 204, 1399–1411. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, M.; Zheng, J.; Sun, X.; Zhao, M.; Wang, X. Life Cycle Greenhouse Gas Emission Reduction Potential of Battery Electric Vehicle. J. Clean. Prod. 2018, 190, 462–470. [Google Scholar] [CrossRef]

- Shi, S.; Zhang, H.; Yang, W.; Zhang, Q.; Wang, X. A Life-Cycle Assessment of Battery Electric and Internal Combustion Engine Vehicles: A Case in Hebei Province, China. J. Clean. Prod. 2019, 228, 606–618. [Google Scholar] [CrossRef]

- Chen, Y.S.; Ding, Z.S.; Wang, W.J.; Liu, J.H. Life Cycle Assessment and Scenario Simulation of Different Hydrogen Production Schemes for Hydrogen Fuel Cell Vehicles. China J. Highw. Transp. 2019, 32, 172–180. [Google Scholar]

- Andersson, Ö.; Börjesson, P. The Greenhouse Gas Emissions of An Electrified Vehicle Combined with Renewable Fuels: Life Cycle Assessment and Policy Implications. Appl. Energy 2021, 289, 116621. [Google Scholar] [CrossRef]

- Yang, L.; Yu, B.; Yang, B.; Chen, H.; Malima, G.; Wei, Y.M. Life Cycle Environmental Assessment of Electric and Internal Combustion Engine Vehicles In China. J. Clean. Prod. 2021, 285, 124899. [Google Scholar] [CrossRef]

- Yuksel, T.; Tamayao, M.A.M.; Hendrickson, C.; Azevedo, I.M.; Michalek, J.J. Effect of Regional Grid Mix, Driving Patterns and Climate on the Comparative Carbon Footprint of Gasoline and Plug-In Electric Vehicles in the United States. Environ. Res. Lett. 2016, 11, 044007. [Google Scholar] [CrossRef]

- Bickert, S.; Kampker, A.; Greger, D. Developments of CO2-Emissions and Costs for Small Electric and Combustion Engine Vehicles in Germany. Transp. Res. Part D 2015, 36, 138–151. [Google Scholar] [CrossRef]

- Hooftman, N.; Messagie, M.; Joint, F.; Segard, J.B.; Coosemans, T. In-Life Range Modularity for Electric Vehicles: The Environmental Impact of A Range-Extender Trailer System. Appl. Sci. 2018, 8, 1016. [Google Scholar] [CrossRef]

- Sen, B.; Kucukvar, M.; Onat, N.C.; Tatari, O. Life Cycle Sustainability Assessment of Autonomous Heavy-Duty Trucks. J. Ind. Ecol. 2020, 24, 149–164. [Google Scholar] [CrossRef]

- Usai, L.; Hung, C.R.; Vásquez, F.; Windsheimer, M.; Burheim, O.S.; Strømman, A.H. Life Cycle Assessment of Fuel Cell Systems for Light Duty Vehicles, Current State-of-the-Art and Future Impacts. J. Clean. Prod. 2021, 280, 125086–125097. [Google Scholar] [CrossRef]

- Benitez, A.; Wulf, C.; de Palmenaer, A.; Lengersdorf, M.; Röding, T.; Grube, T.; Robinius, M.; Stolten, D.; Kuckshinrichs, W. Ecological Assessment of Fuel Cell Electric Vehicles with Special Focus on Type Iv Carbon Fiber Hydrogen Tank. J. Clean. Prod. 2021, 278, 123277–123289. [Google Scholar] [CrossRef]

- Requia, W.J.; Adams, M.D.; Arain, A.; Koutrakis, P.; Ferguson, M. Carbon dioxide emissions of plug-in hybrid electric vehicles: A life-cycle analysis in eight Canadian cities. Renew. Sustain. Energy Rev. 2017, 78, 1390–1396. [Google Scholar] [CrossRef]

- De Souza, L.L.P.; Lora, E.E.S.; Palacio, J.C.E.; Rocha, M.H.; Renó, M.L.G.; Venturini, O.J. Comparative environmental life cycle assessment of conventional vehicles with different fuel options, plug-in hybrid and electric vehicles for a sustainable transportation system in Brazil. J. Clean. Prod. 2018, 203, 444–468. [Google Scholar] [CrossRef]

- Hao, H.; Cheng, X.; Liu, Z.; Zhao, F. Electric Vehicles for Greenhouse Gas Reduction in China: A Cost-Effectiveness Analysis. Transp. Res. Part D 2017, 56, 68–84. [Google Scholar] [CrossRef]

- Held, M.; Schücking, M. Utilization effects on battery electric vehicle life-cycle assessment: A case-driven analysis of two commercial mobility applications. Transp. Res. Part D Transp. Environ. 2019, 75, 87–105. [Google Scholar] [CrossRef]

- Shafique, M.; Luo, X. Environmental life cycle assessment of battery electric vehicles from the current and future energy mix perspective. J. Environ. Manag. 2022, 303, 114050. [Google Scholar] [CrossRef]

- Bhosale, A.; Mastud, S. Comparative environmental impact assessment of battery electric vehicles and conventional vehicles: A case study of India. Int. J. Eng. 2023, 36, 965–978. [Google Scholar] [CrossRef]

- Burton, T.; Powers, S.; Burns, C.; Conway, G.; Leach, F.; Senecal, K. A data-driven greenhouse gas emission rate analysis for vehicle comparisons. SAE Int. J. Electrified Veh. 2022, 12, 91–127. [Google Scholar] [CrossRef]

- Wong, E.Y.C.; Ho, D.C.K.; So, S.; Tsang, C.W.; Chan, E.M.H. Life cycle assessment of electric vehicles and hydrogen fuel cell vehicles using the greet model—A comparative study. Sustainability 2021, 13, 4872. [Google Scholar] [CrossRef]

- Peng, T.; Ou, X.; Yan, X. Development and application of an electric vehicle life-cycle energy consumption and greenhouse gas emissions analysis model. Chem. Eng. Res. Des. 2018, 131, 699–708. [Google Scholar] [CrossRef]

- Cai, Y.; Applegate, S.; Yue, W.; Cai, J.; Wang, X.; Liu, G.; Li, C. A hybrid life cycle and multi-criteria decision analysis approach for identifying sustainable development strategies of Beijing’s taxi fleet. Energy Policy 2017, 100, 314–325. [Google Scholar] [CrossRef]

- Yu, R.; Cong, L.; Hui, Y.; Zhao, D.; Yu, B. Life cycle CO2 emissions for the new energy vehicles in China drawing on the reshaped survival pattern. Sci. Total Environ. 2022, 826, 154102. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, K.; Zhao, J.; Li, G.; Johnson, J.; Zietsman, J. In-Use Energy and CO2 Emissions Impact of a Plug-in Hybrid and Battery Electric Vehicle Based on Real-World Driving. Int. J. Environ. Sci. Technol. 2018, 15, 1001–1008. [Google Scholar] [CrossRef]

- Karabasoglu, O.; Michalek, J. Influence of Driving Patterns on Life Cycle Cost and Emissions of Hybrid and Plug-in Electric Vehicle Powertrains. Energy Policy 2013, 60, 445–461. [Google Scholar] [CrossRef]

- Chen, Y.; Lan, L.; Hao, Z.; Fu, P. Cradle-grave energy consumption, greenhouse gas and acidification emissions in current and future fuel cell vehicles: Study based on five hydrogen production methods in China. Energy Rep. 2022, 8, 7931–7944. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lan, L.B.; Hao, Z.; Fu, P. Life Cycle Assessment and Key Parameter Comparison of Hydrogen Fuel Cell Vehicles Power Systems. Environ. Sci. 2022, 43, 4402–4412. (In Chinese) [Google Scholar]

- Ding, Z.C.; Chen, Y.S.; Liu, J.H. Comparative Life Cycle Assessment of Fuel Cell Vehicles and Plug-in Hybrid Electric Vehicles. In Proceedings of the 2018 National Academic Annual Conference on “Environmental Engineering” (Volume 1), Beijing, China, 20 August 2018; School of Automotive Engineering, Chang’an University: Xi’an, China, 2018; p. 5. [Google Scholar]

- Yang, Y. Research on the Green Assessment of Life Cycle Assessment of Urban Traffic and Its Multi-Scenario Simulation Prediction. Ph.D. Thesis, Chang’an University, Xi’an, China, 2021. [Google Scholar]

- Yang, S. Research on Energy Management Strategy of Hybrid Electric Vehicle Based on Working Condition Recognition. Master’s Thesis, Jilin University, Changchun, China, 2023. [Google Scholar]

- Ren, C.L.; Liu, H.J. Study on Energy Management Control Strategy of Plug-In Parallel Hybrid Electric Vehicle Based on Dynamic Planning. J. Hefei Univ. Technol. (Nat. Sci. Ed.) 2021, 44, 1157–1164. [Google Scholar]

- Peterson, S.B.; Apt, J.; Whitacre, J.F. Lithium-ion battery cell degradation resulting from realistic vehicle and vehicle-to-grid utilization. J. Power Sources 2010, 195, 2385–2392. [Google Scholar] [CrossRef]

- Li, X.Y.; Liao, Y.M.; Zhang, Y.H.; Yu, G.H. Life cycle assessment of passenger car body considering the influence of vehicle type difference. J. Environ. Sci. 2024, 44, 462–476. [Google Scholar]

- Guinée, J.B. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Springer Science & Business Media: Berlin, Germany, 2002. [Google Scholar]

| Key Parameters | Values | Unit |

|---|---|---|

| vehicle dimensions (length × width × height) | 4645 × 1775 × 1480 | mm |

| curb weight | 1540 | kg |

| engine displacement | 1.8 | L |

| maximum engine power | 73 | kW |

| maximum engine torque | 142 | N·m |

| battery capacity | 10.5 | kWh |

| electric range | 72 | km |

| nominal electricity consumption | 14.42 | kWh/100 km |

| nominal fuel consumption (fuel feed) | 4.3 | L/100 km |

| nominal fuel consumption | 1.3 | L/100 km |

| battery type | Lithium-ion battery | \ |

| Component | Material | Value (kg) | Component | Material | Value (kg) |

|---|---|---|---|---|---|

| Engine | Steel | 26.2 | Lithium battery | NCM | 33.8 |

| Aluminum | 78.6 | Aluminum | 23.6 | ||

| Cast iron | 131.0 | PVDF | 2.8 | ||

| Copper | 2.6 | Graphite | 22.0 | ||

| Rubber | 11.8 | Copper | 13.7 | ||

| Plastic | 11.8 | Polypropylene | 3.9 | ||

| Generator | Steel | 11.6 | Steel | 1.8 | |

| Aluminum | 11.6 | Fiberglass | 0.4 | ||

| Copper | 8.8 | Polyethylene | 0.4 | ||

| Lead-acid battery | Lead | 11.6 | LiPF6 | 2.3 | |

| Sulfuric acid | 1.4 | Ethylene carbonate | 6.5 | ||

| Polypropylene | 1.1 | Dimethyl carbonate | 6.5 | ||

| Fiberglass | 0.4 | Transistor | 0.6 | ||

| Water | 2.5 | Resistor | 0.6 | ||

| Motor | Steel | 11.6 | Ethylene glycol | 1.1 | |

| Aluminum | 11.6 | ||||

| Copper | 8.8 | ||||

| Main reducer | Steel | 57.6 | Fluid | Lubricating fluid | 0.9 |

| Aluminum | 19.0 | Braking fluid | 1.0 | ||

| Copper | 18.1 | Cooling fluid | 8.0 | ||

| Plastic | 0.2 | Windshield washer fluid | 3.0 | ||

| Organics | 0.2 | Additive | 15.1 | ||

| Body | Steel | 432.1 | Chassis | Steel | 266.7 |

| Aluminum | 5.0 | Cast iron | 20.4 | ||

| Magnesium | 0.6 | Aluminum | 3.2 | ||

| Fiberglass | 41.5 | Copper | 7.5 | ||

| Plastic | 109.4 | Plastic | 10.7 | ||

| Copper | 12.0 | Rubber | 13.6 | ||

| Others | 28.3 | Carbon black | 1.9 |

| Replacement Component | Replacement Cycle (km) | Replacement Number | Mass (kg) |

|---|---|---|---|

| Tire | 75,000 | 1 | 76.9 |

| Lubricating fluid | 6250 | 23 | 20.7 |

| Braking fluid | 40,000 | 3 | 3 |

| Cooling fluid | 55,500 | 2 | 16 |

| Windshield washer fluid | 12,500 | 11 | 33 |

| Unit | Life Cycle | Raw Material Acquisition | Manufacturing and Assembly | Operation and Use | Scrap Recycling | |

|---|---|---|---|---|---|---|

| ADP(e) | kg Sb-eq | 4.82 × 10−2 | 2.62 × 10−1 | 3.23 × 10−4 | 1.21 × 10−3 | −2.16 × 10−1 |

| ADP(f) | MJ | 2.93 × 105 | 8.21 × 104 | 5.00 × 104 | 2.08 × 105 | −4.67 × 104 |

| AP | kg SO2-eq | 5.15 × 101 | 8.03 × 101 | 9.38 × 100 | 2.45 × 101 | −6.26 × 101 |

| EP | kg Phosphate-eq | 5.20 × 100 | 2.07 × 100 | 1.26 × 100 | 3.15 × 100 | −1.29 × 100 |

| GWP | kg CO2-eq | 1.70 × 104 | 8.39 × 103 | 4.61 × 103 | 9.67 × 103 | −5.68 × 103 |

| HTP | kg DCB-eq | 1.38 × 103 | 3.84 × 103 | 1.86 × 102 | 5.94 × 102 | −3.24 × 103 |

| ODP | kg CFC-eq | 1.19 × 10−5 | 1.18 × 10−5 | 2.34 × 10−8 | 4.53 × 10−8 | 8.40 × 10−9 |

| POCP | kg Ethene-eq | 4.28 × 100 | 4.46 × 100 | 6.45 × 10−1 | 2.78 × 100 | −3.60 × 100 |

| Name | Unit | PHEV | HEV | BEV |

|---|---|---|---|---|

| Curb quality | kg | 1540.0 | 1650.0 | 1650.0 |

| Engine displacement | L | 1.8 | 2.5 | \ |

| Power battery capacity | kWh | 10.5 | 1.3 | 57.0 |

| Engine maximum power | kW | 73.0 | 131.0 | \ |

| Motor maximum power | kW | \ | \ | 100.0 |

| gasoline consumption economy | L·(100 km)−1 | 4.3 | 4.4 | \ |

| Electricity consumption economy | kWh·(100 km)−1 | 14.42 | \ | 14.10 |

| Battery type | \ | Lithium-ion nickel–cobalt–manganese battery | Ni-MH battery | Lithium iron phosphate battery |

| Name | Unit | FTP | HWFET | US06 |

|---|---|---|---|---|

| Maximum speed | km/h | 90 | 97 | 129 |

| Average speed | km/h | 32 | 77 | 77 |

| Maximum acceleration | m/s2 | 1.48 | 1.43 | 3.78 |

| Driving distance | km | 17 | 16 | 13 |

| Driving time | min | 31 | 12.5 | 10 |

| Brake times | \ | 23 | 0 | 4 |

| Idle time | % | 18 | 0 | 7 |

| Engine start-up | °C | 20 | 30 | 30 |

| Name | Unit | FTP | HWFET | US06 |

|---|---|---|---|---|

| HEVs gasoline consumption | L·(100 km)−1 | 5.17 | 5.91 | 7.69 |

| PHEVs electricity consumption | kWh·(100 km)−1 | 14.88 | 15.67 | 19.43 |

| PHEVs gasoline consumption | L·(100 km)−1 | 4.67 | 5.52 | 7.83 |

| PHEVs AER | km | 70.56 | 67.00 | 54.04 |

| BEVs power consumption | kWh·(100 km)−1 | 14.20 | 14.60 | 20.86 |

| BEVs AER | km | 427.74 | 290.42 | 273.22 |

| Name | Energy Source | Unit | FTP | HWFET | US06 |

|---|---|---|---|---|---|

| HEV | gasoline | L | 927.50 | 1060.25 | 1379.59 |

| PHEV | gasoline | L | 292.07 | 345.23 | 489.70 |

| electricity | kWh | 1738.85 | 1831.17 | 2270.56 | |

| BEV | electricity | kWh | 2407.55 | 2619.24 | 3742.28 |

| Name | Scenario | AER (km) | Rate of Increase in Energy Consumption (%) | Energy Consumption per 100 km (kWh/(100 km)) |

|---|---|---|---|---|

| BEV | No degradation (scenario 1) | 390.42 | 0 | 14.60 |

| Degrate to 90% (scenario 2) | 309.10 | 26.30 | 18.44 | |

| Degrate to 85% (scenario 3) | 226.31 | 72.53 | 25.19 | |

| PHEV | No degradation (scenario 1) | 70.56 | 0 | 14.88 |

| Degrate to 90% (scenario 2) | 53.98 | 30.71 | 19.45 | |

| Degrate to 85% (scenario 3) | 39.51 | 78.63 | 26.58 |

| Vehicle Type | Scenario | ADP(e) (kg Sb-eq) | ADP(f) (MJ) | AP (kg SO2-eq) | EP (kg Phosphate-eq) | GWP (kg CO2-eq) | HTP (kg DCB-eq) | ODP (kg CFC-eq) | POCP (kg Ethene-eq) |

|---|---|---|---|---|---|---|---|---|---|

| BEV | No degradation (scenario 1) | 1.40 × 10−4 | 2.05 × 104 | 4.20 × 100 | 5.61 × 10−1 | 1.96 × 103 | 8.25 × 101 | 1.06 × 10−8 | 2.84 × 10−1 |

| Degrate to 90% (scenario 2) | 1.77 × 10−4 | 2.60 × 104 | 5.30 × 100 | 7.09 × 10−1 | 2.48 × 103 | 1.04 × 102 | 1.34 × 10−8 | 3.59 × 10−1 | |

| Degrate to 85% (scenario 3) | 2.42 × 10−4 | 3.54 × 104 | 7.25 × 100 | 9.68 × 10−1 | 3.38 × 103 | 1.42 × 102 | 1.83 × 10−8 | 4.90 × 10−1 | |

| PHEV | No degradation (scenario 1) | 1.43 × 10−4 | 2.43 × 104 | 3.55 × 100 | 4.81 × 10−1 | 2.14 × 103 | 7.65 × 101 | 7.15 × 10−9 | 4.88 × 10−1 |

| Degrate to 90% (scenario 2) | 1.65 × 10−4 | 2.90 × 104 | 3.89 × 100 | 5.29 × 10−1 | 2.50 × 103 | 8.60 × 101 | 7.19 × 10−9 | 6.20 × 10−1 | |

| Degrate to 85% (scenario 3) | 1.85 × 10−4 | 3.31 × 104 | 4.18 × 100 | 5.70 × 10−1 | 2.83 × 103 | 9.44 × 101 | 7.23 × 10−9 | 7.35 × 10−1 |

| Mileage | Scenario | HEV/Gasoline | PHEV/Gasoline | PHEV/Electricity | BEV/Electricity |

|---|---|---|---|---|---|

| 10,000 km | Private car (scenario 1) | 440.0 L | \ | 1442.0 kWh | 1410.0 kWh |

| Taxi (scenario 2) | 349.0 L | 271.5 kWh | |||

| 50,000 km | Private car (scenario 1) | 2244.4 L | 185.4 L | 7047.1 kWh | 7560.7 kWh |

| Taxi (scenario 2) | 1807.5 L | 1357.7 kWh | |||

| 100,000 km | Private car (scenario 1) | 4603.3 L | 1272.2 L | 11,893.5 kWh | 16,540.9 kWh |

| Taxi (scenario 2) | 3771.2 L | 3075.3 kWh | |||

| 150,000 km | Private car (scenario 1) | 7082.5 | 2616.9 L | 16,739.7 kWh | 27,206.5 kWh |

| Taxi (scenario 2) | 5891.8 L | 4613.0 kWh |

| Mileage | Scenario | HEV/Gasoline (L/100 km) | PHEV/Gasoline (L/100 km) | PHEV/Power (kWh/100 km) | BEV/Power (kWh/100 km) |

|---|---|---|---|---|---|

| 10,000 km | Private car (scenario 1) | 4.40 | \ | 14.42 | 14.10 |

| Taxi (scenario 2) | 3.49 | 2.72 | |||

| 50,000 km | Private car (scenario 1) | 4.49 | 0.21 | 14.09 | 15.12 |

| Taxi (scenario 2) | 3.62 | 2.72 | |||

| 100,000 km | Private car (scenario 1) | 4.60 | 1.27 | 11.89 | 16.54 |

| Taxi (scenario 2) | 3.77 | 3.08 | |||

| 150,000 km | Private car (scenario 1) | 4.72 | 1.74 | 11.16 | 18.14 |

| Taxi (scenario 2) | 3.93 | 3.08 |

| Mileage | Scenario | HEV | PHEV | BEV |

|---|---|---|---|---|

| 10,000 km | Private car (scenario 1) | 7.50 × 10−7 | 7.71 × 10−7 | 7.54 × 10−7 |

| Taxi (scenario 2) | 7.46 × 10−7 | |||

| 50,000 km | Private car (scenario 1) | 7.66 × 10−7 | 7.90 × 10−7 | 8.09 × 10−7 |

| Taxi (scenario 2) | 7.69 × 10−7 | |||

| 100,000 km | Private car (scenario 1) | 7.84 × 10−7 | 8.54 × 10−7 | 8.84 × 10−7 |

| Taxi (scenario 2) | 8.14 × 10−7 | |||

| 150,000 km | Private car (scenario 1) | 8.05 × 10−7 | 8.9 × 10−7 | 9.70 × 10−7 |

| Taxi (scenario 2) | 8.41 × 10−7 |

| Mileage | Scenario | HEV | PHEV | BEV |

|---|---|---|---|---|

| 10,000 km | Private car (scenario 1) | 1.58 × 102 | 1.13 × 102 | 1.11 × 102 |

| Taxi (scenario 2) | 1.49 × 102 | |||

| 50,000 km | Private car (scenario 1) | 1.61 × 102 | 1.18 × 102 | 1.19 × 102 |

| Taxi (scenario 2) | 1.53 × 102 | |||

| 100,000 km | Private car (scenario 1) | 1.65 × 102 | 1.40 × 102 | 1.30 × 102 |

| Taxi (scenario 2) | 1.62 × 102 | |||

| 150,000 km | Private car (scenario 1) | 1.70 × 102 | 1.51 × 102 | 1.42 × 102 |

| Taxi (scenario 2) | 1.68 × 102 |

| Name | Year | Energy Consumption of 100 km (kWh) | Fuel Consumption of 100 km (L) | Curb Weight (kg) |

|---|---|---|---|---|

| PHEV | 2025 | 13.0 | 4.3 | 1309.0 |

| 2030 | 12.50 | 3.2 | 1155.0 | |

| 2035 | 12.00 | 2.0 | 1001.0 | |

| HEV | 2025 | \ | 4.3 | 1485.0 |

| 2030 | \ | 3.2 | 1353.0 | |

| 2035 | \ | 2.0 | 1237.5 | |

| BEV | 2025 | 13.00 | \ | 1402.5 |

| 2030 | 12.50 | \ | 1237.5 | |

| 2035 | 12.00 | \ | 1072.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Cao, Z.; Zhang, C.; Chen, Y. Life Cycle Assessment of Plug-In Hybrid Electric Vehicles Considering Different Vehicle Working Conditions and Battery Degradation Scenarios. Energies 2024, 17, 4283. https://doi.org/10.3390/en17174283

Zhang Y, Cao Z, Zhang C, Chen Y. Life Cycle Assessment of Plug-In Hybrid Electric Vehicles Considering Different Vehicle Working Conditions and Battery Degradation Scenarios. Energies. 2024; 17(17):4283. https://doi.org/10.3390/en17174283

Chicago/Turabian StyleZhang, Yaning, Ziqiang Cao, Chunmei Zhang, and Yisong Chen. 2024. "Life Cycle Assessment of Plug-In Hybrid Electric Vehicles Considering Different Vehicle Working Conditions and Battery Degradation Scenarios" Energies 17, no. 17: 4283. https://doi.org/10.3390/en17174283

APA StyleZhang, Y., Cao, Z., Zhang, C., & Chen, Y. (2024). Life Cycle Assessment of Plug-In Hybrid Electric Vehicles Considering Different Vehicle Working Conditions and Battery Degradation Scenarios. Energies, 17(17), 4283. https://doi.org/10.3390/en17174283