Convection Heat Transfer and Performance Analysis of a Triply Periodic Minimal Surface (TPMS) for a Novel Heat Exchanger

Abstract

1. Introduction

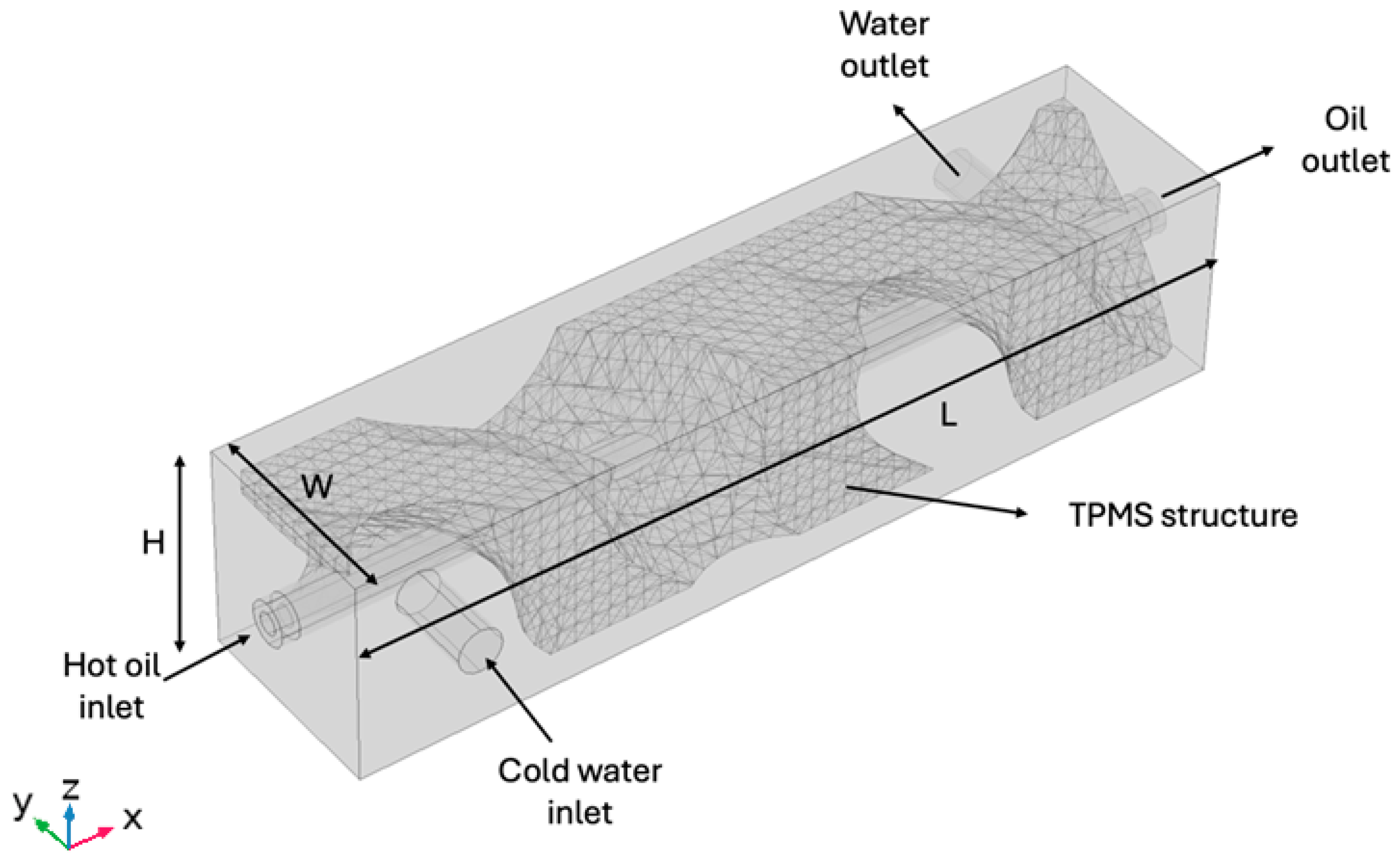

2. Problem Description

3. Finite Element Formulation and Boundary Conditions

3.1. Boundary Conditions of the System

- (i)

- The oil enters at a temperature of Tinoil = 87 degrees Celsius and a mass rate of 1 × 10−6 kg/s which correspond to a Reynolds number equal to 0.04.

- (ii)

- The water enters at a temperature Tinwater = 5 degrees Celsius and three inlet mass rates of 1 × 10−5 kg/s, 1 × 10−4 kg/s, and 1 × 10−3 kg/s which correspond to Reynolds numbers equal to 5, 50, and 500, respectively.

- (iii)

- All external surfaces are assumed adiabatic, and for the flow, no-slip boundary conditions are applied.

3.2. Non-Dimensional Parameters

3.3. Solution Technique and Convergence Criteria

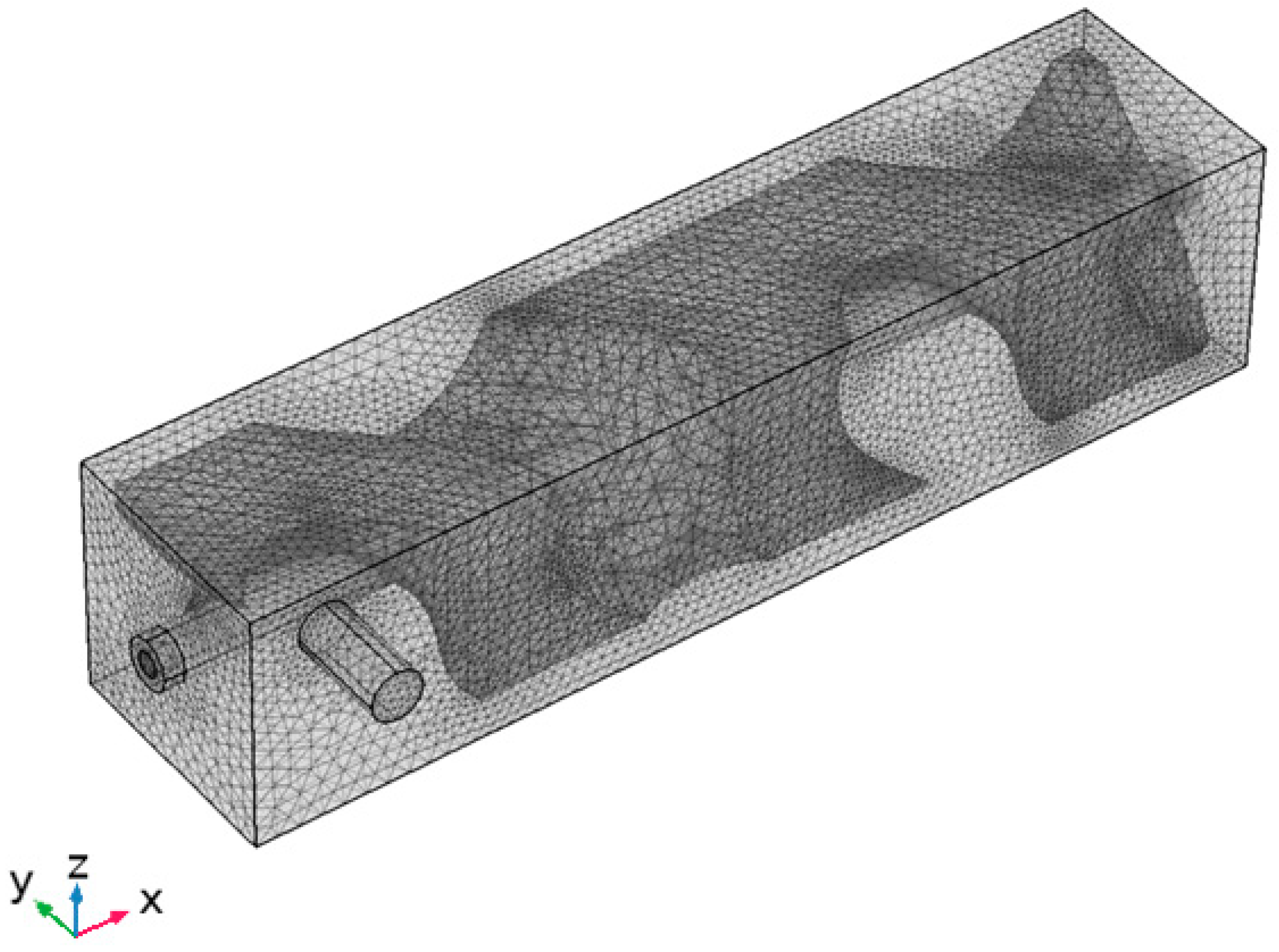

3.4. Mesh Sensitivity Analysis

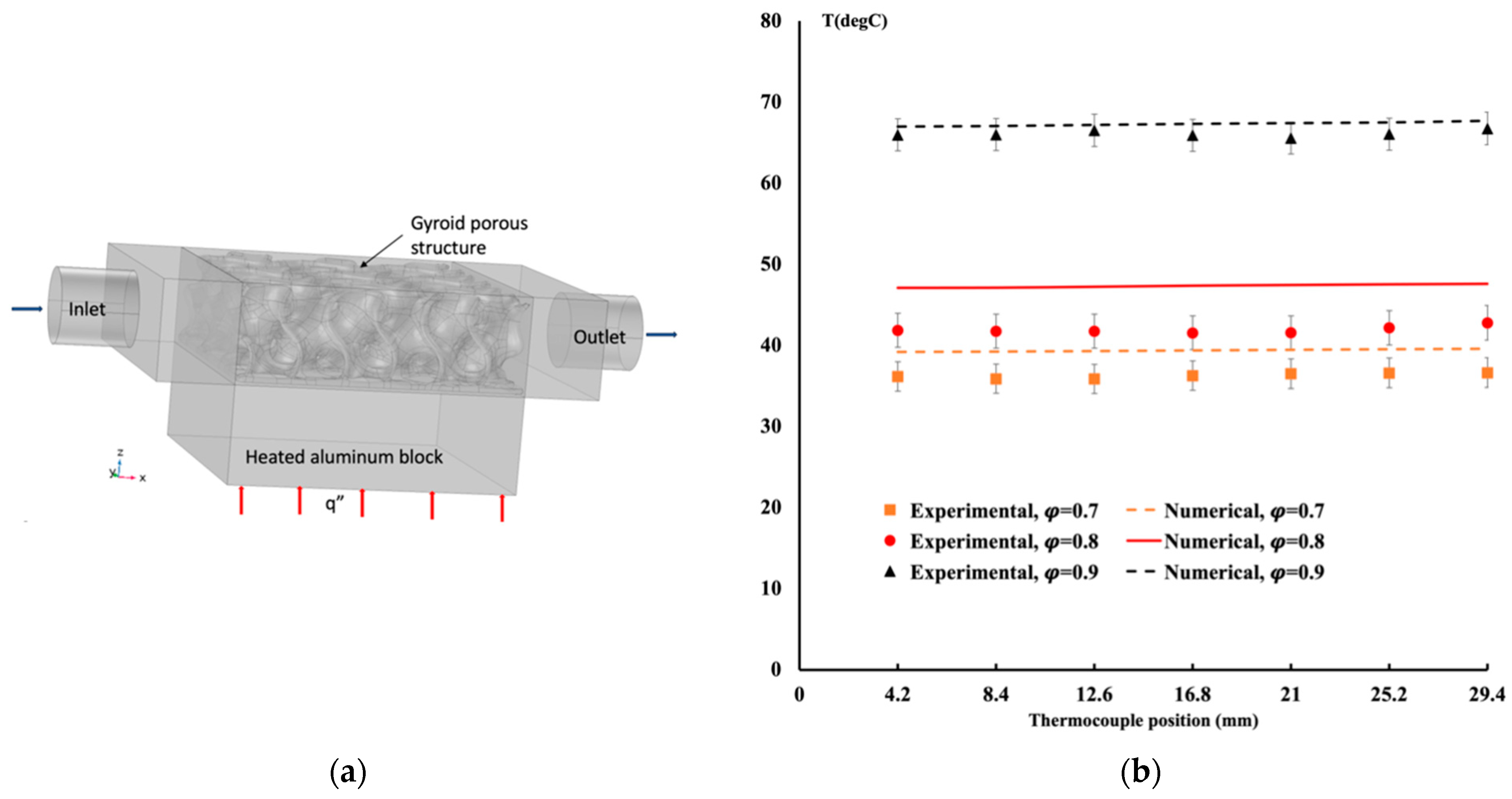

3.5. Comparison with Experimental Data

4. Results and Discussion

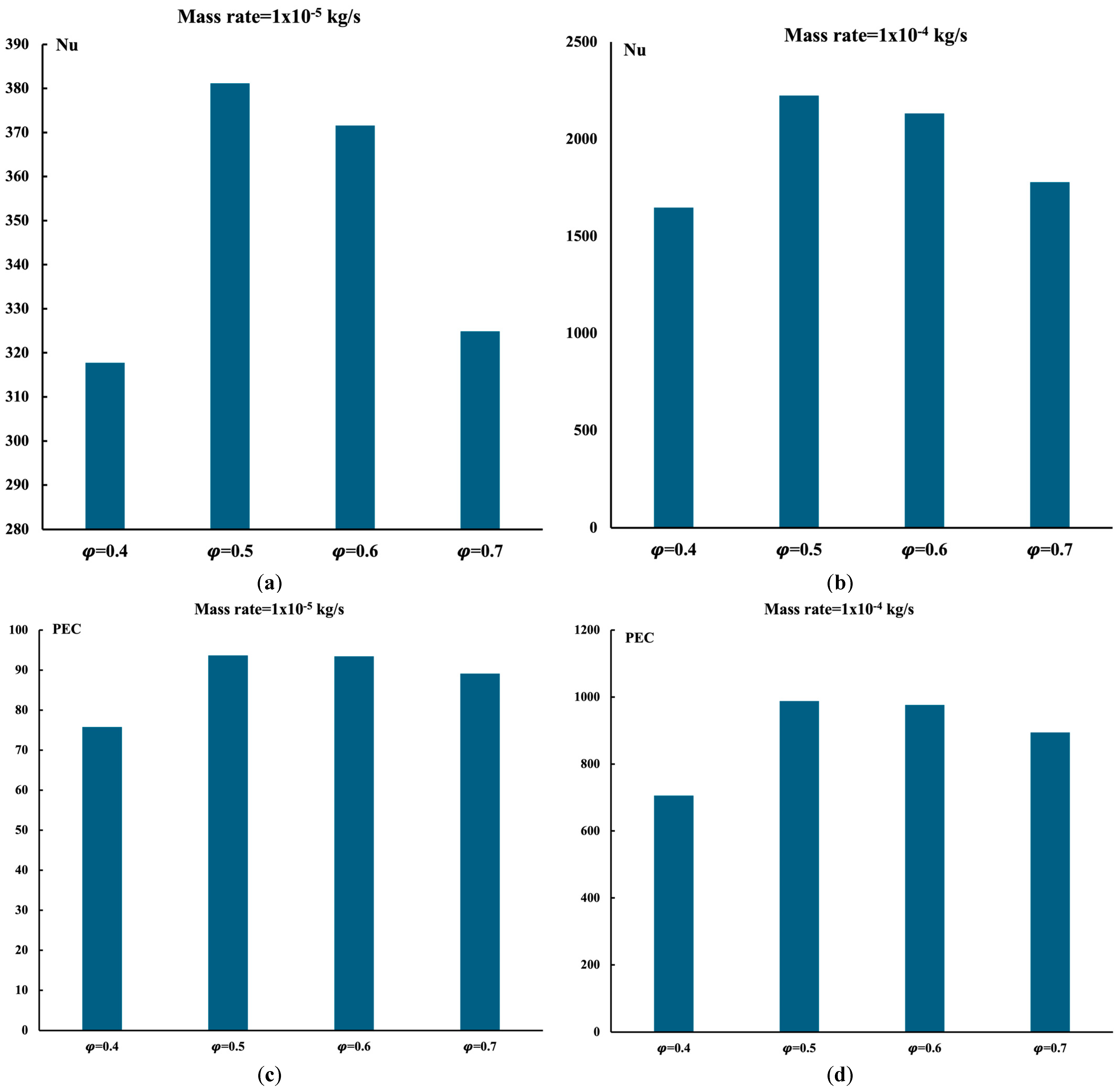

4.1. Heat Exchanger in the Presence of Gyroid TPMS

4.2. Heat Exchanger in the Presence of Diamond and FKS Structures

4.3. Comparison between Gyroid, Diamond, and FKS Structures

5. Conclusions

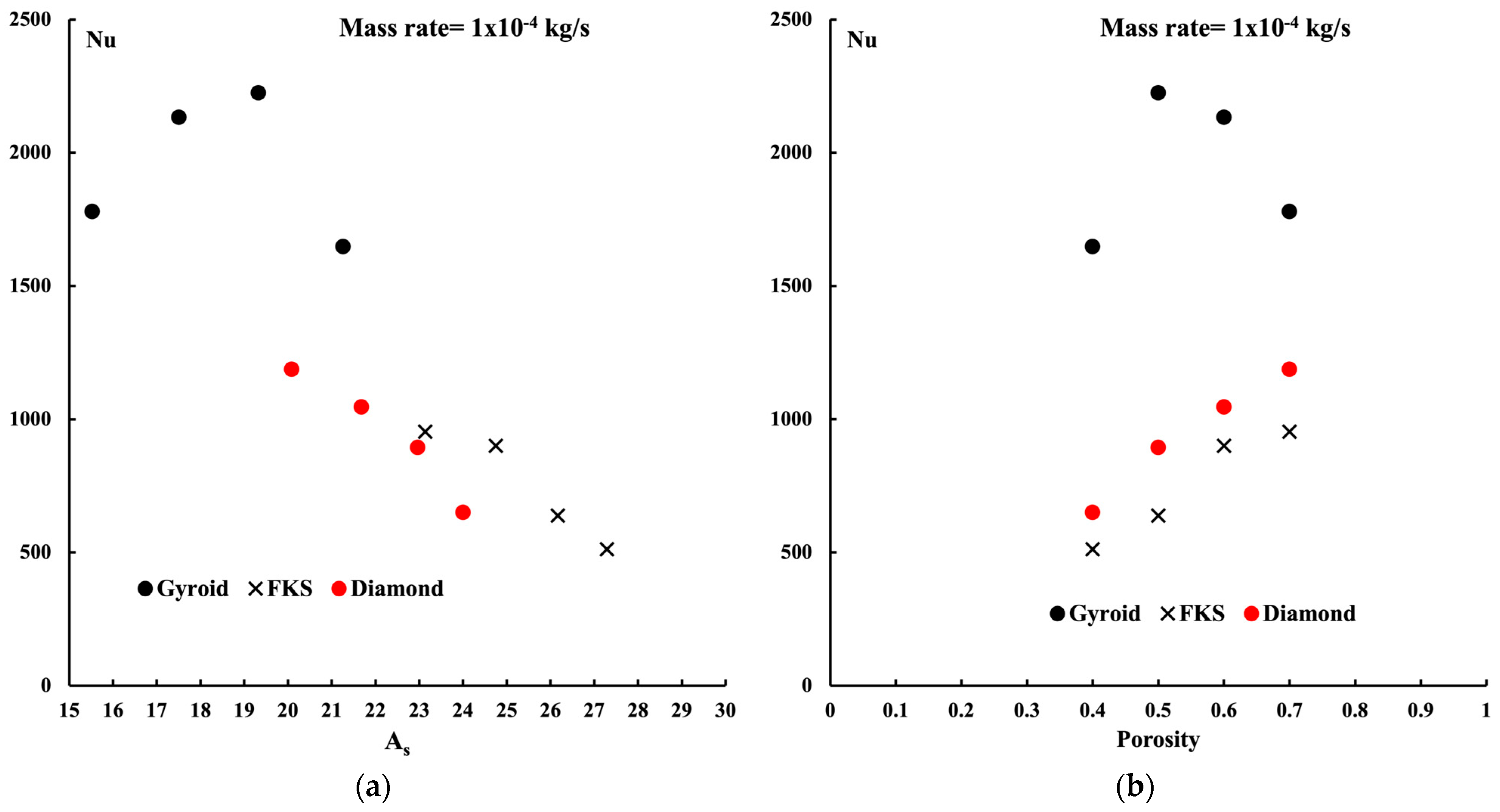

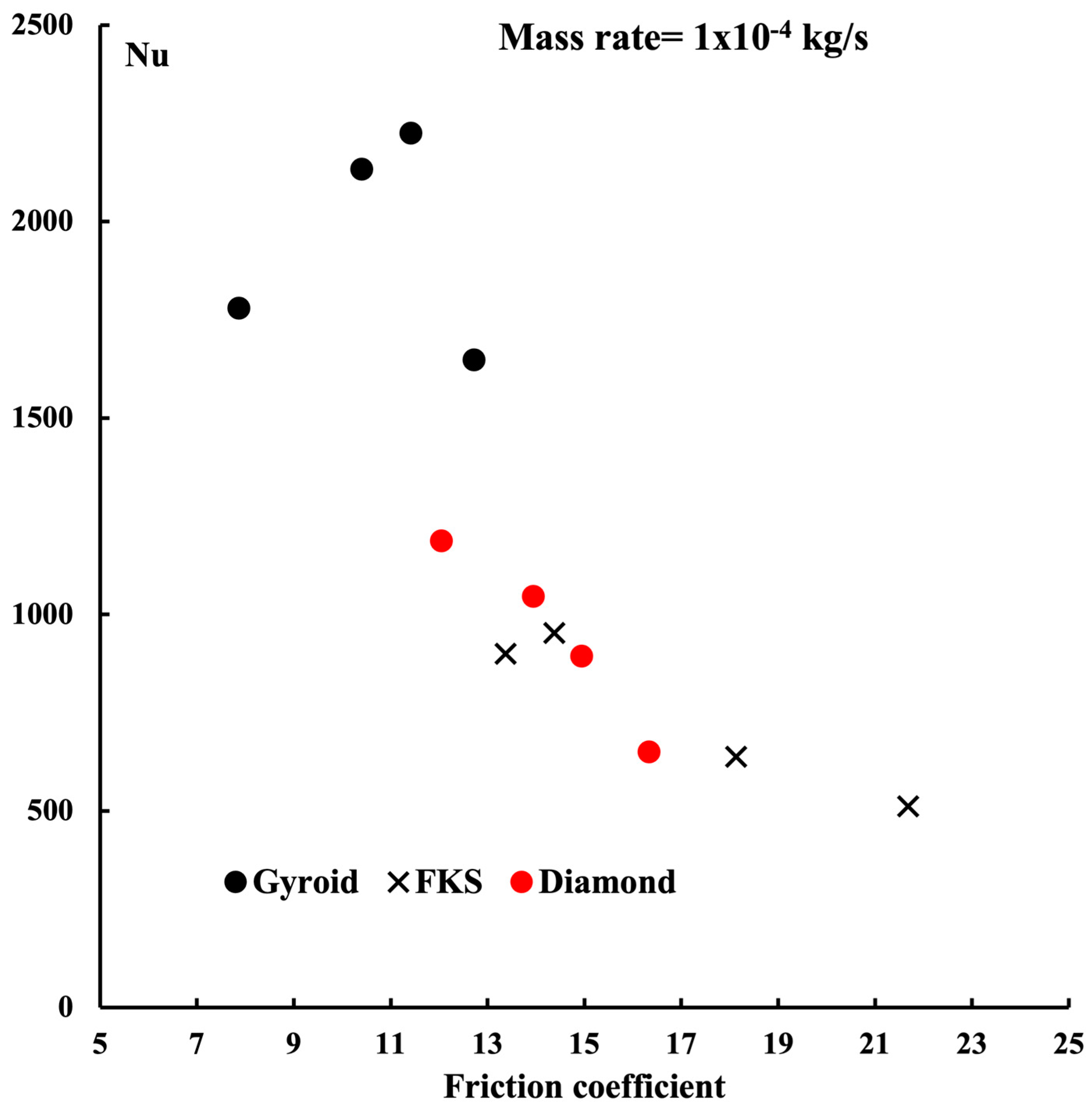

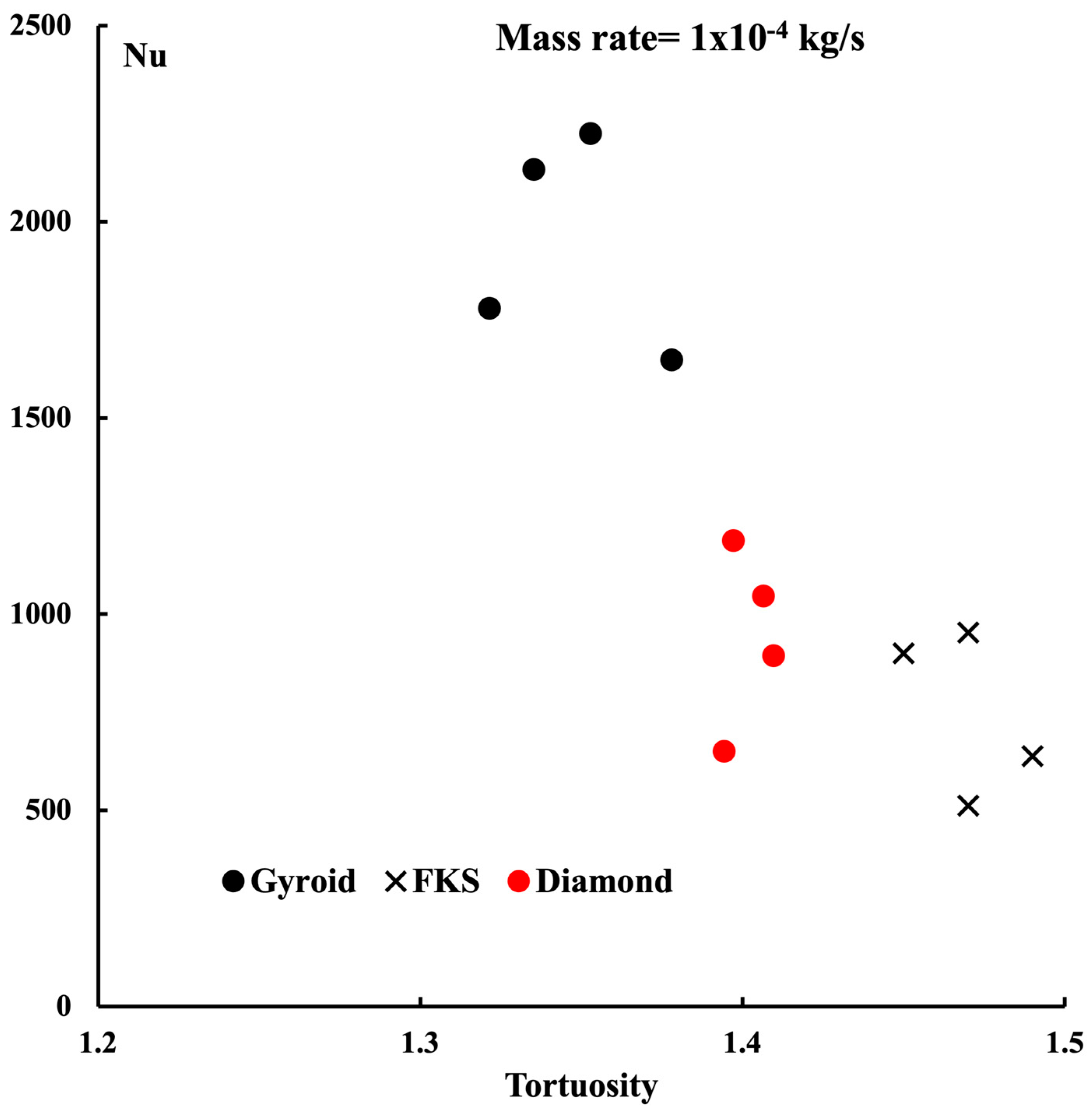

- The gyroid exhibits the highest Nusselt number toward heat removal among the three structures under investigation. The reason for this finding is the development of wavy channels inside the structure, thus allowing the fluid to circulate longer before exiting the heat sink.

- The highest Nusselt number is found at a porosity of 0.5 within the gyroid structures with different porosities. The maximum average Nusselt number is found to be near 2250.

- Pressure drop varies between structures, and the gyroids exhibit the lowest pressure drops. This lower pressure drop is the formation of a wavy and straight channel.

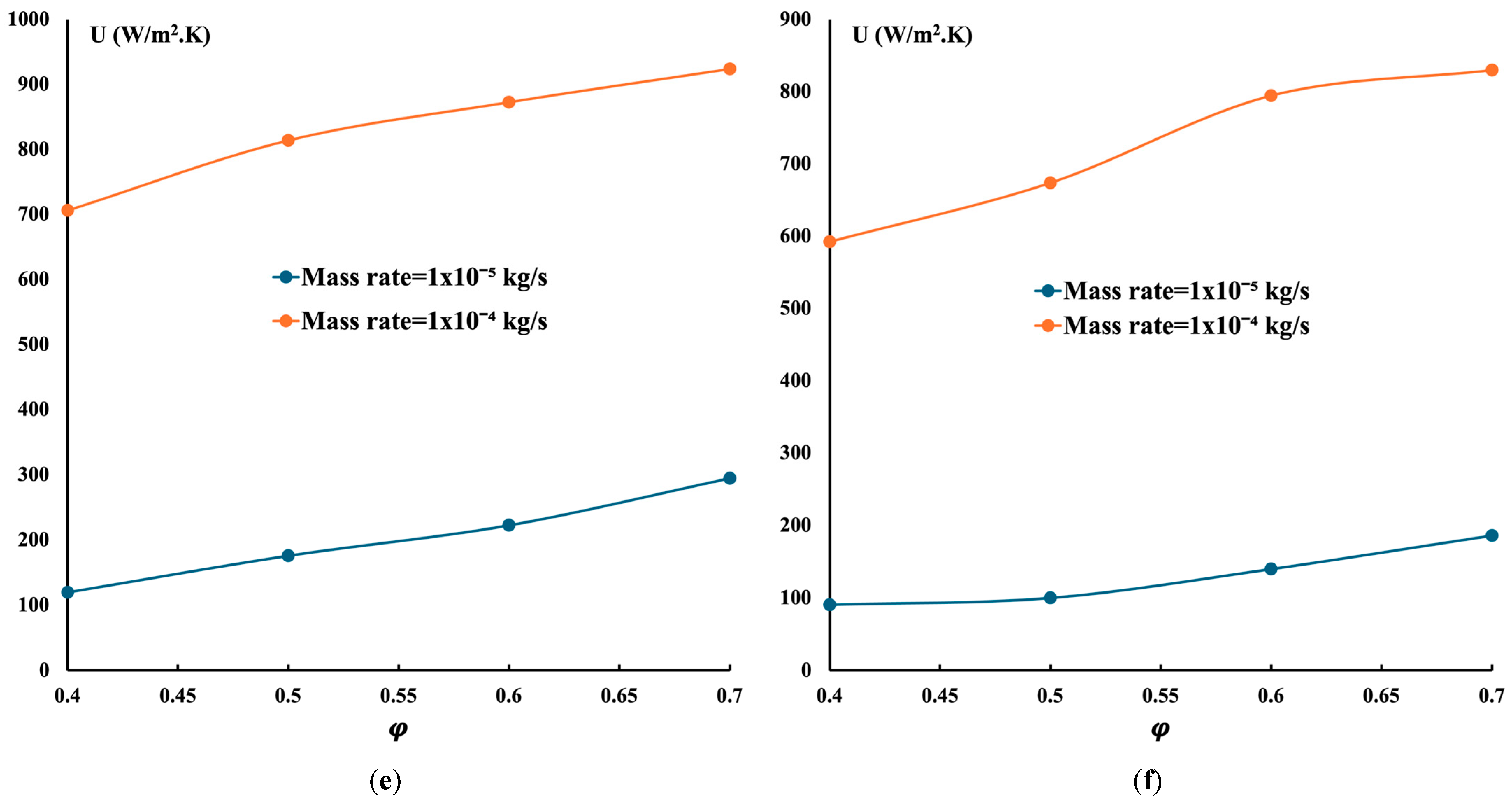

- A uniform overall heat transfer is observed for the gyroid case and has the highest value among the three structures.

- A linear variation in the average Nusselt number as a function of the structure surface area is detected for the FKS and diamond structures, contrary to the gyroid structures where nonlinearity is observed.

- A similar observation about the Nusselt number versus the surface area is detected when the Nusselt number varies with porosity.

- The overall heat transfer coefficients of the heat exchangers for the three structures have been studied. They reveal that the gyroid structure achieved the highest overall heat transfer, around 1000 W/m2·K, compared to the FKS and diamond structures. Thus, the gyroid is more suitable for heat exchangers.

- Tortuosity, unrelated to the flow, is constant for the diamond and FKS structures but nonlinear for the gyroid structure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Variables | Greek Letter | ||

| p | Fluid pressure in Pa | Fluid density in kg/m3 | |

| u,v,w | Fluid velocity in m/s | Fluid dynamic viscosity in kg/m.s | |

| x,y,z | Coordinate system in m | Permeability in m2 | |

| q″ | Heat flux in W/m2 | Porosity [17] | |

| T | Temperature in degrees C | Subscript | |

| k | Thermal conductivity in W/m.K | in | Inlet |

| Cp | Specific heat capacity in J/kg.K | out | Outlet |

| As | TPMS surface area | f | Fluid |

| Non-dimensional | s | Solid | |

| Re | Reynolds number | TPMS | Triply periodic minimum surfaces |

| Nu | Nusselt number | ||

| f | Friction coefficient | PEC | Performance evaluation criterion |

References

- Sekulic, D.P.; Shah, R.K. Fundamentals of Heat Exchanger Design; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- ScheithauerKordaß, R.; Noack, K.; Eichenauer, M.F.; Hartmann, M.; Abel, J.; Ganzer, G.; Lordick, D. Potentials and chal-lenges of additive manufacturing technologies for heat exchanger. In Advances in Heat Exchangers; IntechOpen: London, UK, 2018; Volume 4. [Google Scholar]

- Arie, M.A.; Shooshtari, A.H.; Tiwari, R.; Dessiatoun, S.V.; Ohadi, M.M.; Pearce, J.M. Experimental characterization of heat transfer in an additively manufactured polymer heat exchanger. Appl. Therm. Eng. 2017, 113, 575–584. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, P. State-of-the-art in heat exchanger additive manufacturing. Int. J. Heat Mass Transf. 2021, 178, 121600. [Google Scholar] [CrossRef]

- Kelkar, K.M.; Patankar, S.V. Numerical prediction of flow and heat transfer in a parallel plate channel with staggered fins. J. Heat Transf. 1987, 109, 25–30. [Google Scholar] [CrossRef]

- Lopez, J.; Anand, N.K.; Fletcher, L.S. Heat transfer in a three-dimensional channel with baffles. Numer. Heat Transf. Part A Appl. 1996, 30, 189–205. [Google Scholar] [CrossRef]

- Sahin, B.; Demir, A. Performance analysis of a heat exchanger having perforated square fins. Appl. Therm. Eng. 2008, 28, 621–632. [Google Scholar] [CrossRef]

- Unger, S.; Beyer, M.; Gruber, S.; Willner, R.; Hampel, U. Experimental study on the air-side thermal-flow performance of additively manufactured heat exchangers with novel fin designs. Int. J. Therm. Sci. 2019, 146, 106074. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y. A review of recent investigations on flow and heat transfer enhancement in cooling channels em-bedded with triply periodic minimal surfaces (TPMS). Energies 2022, 15, 8994. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Ali, M.; Khalil, M.; Rowshan, R.; Khan, K.A.; Abu Al-Rub, R.K. Forced convection computational fluid dynamics analysis of architected and three-dimensional printable heat sinks based on triply periodic minimal surfaces. J. Therm. Sci. Eng. Appl. 2021, 13, 021010. [Google Scholar] [CrossRef]

- Jung, Y.; Torquato, S. Fluid permeabilities of triply periodic minimal surfaces. Phys. Rev. E 2005, 72, 056319. [Google Scholar] [CrossRef]

- Dong, Z.; Zhao, X. Application of TPMS structure in bone regeneration. Eng. Regen. 2021, 2, 154–162. [Google Scholar] [CrossRef]

- Li, W.; Li, W.; Yu, Z. Heat transfer enhancement of water-cooled triply periodic minimal surface heat exchangers. Appl. Therm. Eng. 2022, 217, 119198. [Google Scholar] [CrossRef]

- Wang, J.; Chen, K.; Zeng, M.; Ma, T.; Wang, Q.; Cheng, Z. Assessment of flow and heat transfer of triply periodic minimal surface based heat exchangers. Energy 2023, 282, 128806. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Abu Al-Rub, R.K. MSLattice: A free software for generating uniform and graded lattices based on triply periodic minimal surfaces. Mater. Des. Process Commun. 2021, 3, 205. [Google Scholar] [CrossRef]

- Saghir, M.Z.; So, J.; Rasheed, H.; Ilesaliev, D. Forced Convection in Porous Medium Using Triply Periodical Minimum Surfaces. Fluids 2023, 8, 311. [Google Scholar] [CrossRef]

- Saghir, M.Z.; Kerme, E.D.; Hajialibabei, M.; Rasheed, H.; Welsford, C.; Al-Ketan, O. Study of the Thermal and Hydraulic Performance of Porous Block versus Gyroid Structure: Experimental and Numerical Approaches. Energies 2024, 17, 861. [Google Scholar] [CrossRef]

- Yan, G.; Sun, M.; Zhang, Z.; Liang, Y.; Jiang, N.; Pang, X.; Song, Y.; Liu, Y.; Zhao, J. Experimental study on flow and heat transfer performance of triply periodic minimal surface structures and their hybrid form as disturbance structure. Int. Commun. Heat Mass Transf. 2023, 147, 106942. [Google Scholar] [CrossRef]

- Iyer, J.; Moore, T.; Nguyen, D.; Roy, P.; Stolaroff, J. Heat transfer and pressure drop characteristics of heat exchangers based on triply periodic minimal and periodic nodal surfaces. Appl. Therm. Eng. 2022, 209, 118192. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, H.; Zhang, L.; Zeng, Y.; Sun, L.; Zhao, Y.; Yan, M.; Jiang, C.; Yang, P.; Li, Q.; et al. A New Method to Adjust the Lattice Structure of Gyroid-Type Triply Periodic Minimal Surfaces (TPMS) and Its Effect on Convective Heat Transfer Process. Available at SSRN, p. 4263557. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4263557 (accessed on 24 June 2024).

- Attarzadeh, R.; Rovira, M.; Duwig, C. Design analysis of the “Schwartz D” based heat exchanger: A numerical study. Int. J. Heat Mass Transf. 2021, 177, 121415. [Google Scholar] [CrossRef]

- Yan, K.; Wang, J.; Li, L.; Deng, H. Numerical investigation into thermo-hydraulic characteristics and mixing performance of triply periodic minimal surface-structured heat exchangers. Appl. Therm. Eng. 2023, 230, 120748. [Google Scholar] [CrossRef]

- Wang, J.; Chen, K.; Zeng, M.; Ma, T.; Wang, Q.; Cheng, Z. Investigation on flow and heat transfer in various channels based on triply periodic minimal surfaces (TPMS). Energy Convers. Manag. 2023, 283, 116955. [Google Scholar] [CrossRef]

- Cheng, Z.; Xu, R.; Jiang, P.-X. Morphology, flow and heat transfer in triply periodic minimal surface based porous structures. Int. J. Heat Mass Transf. 2012, 170, 120902. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, P. Flow and thermal transport characteristics of Triply-Periodic Minimal Surface (TPMS)-based gyroid and Schwarz-P cellular materials. Numer. Heat Transf. Part A Appl. 2021, 79, 553–569. [Google Scholar] [CrossRef]

- Careri, F.; Khan, R.H.; Todd, C.; Attallah, M.M. Additive manufacturing of heat exchangers in aerospace applications: A review. Appl. Therm. Eng. 2023, 235, 121387. [Google Scholar] [CrossRef]

- Thompson, S.M.; Aspin, Z.S.; Shamsaei, N.; Elwany, A.; Bian, L. Additive manufacturing of heat exchangers: A case study on a multi-layered Ti–6Al–4V oscillating heat pipe. Addit. Manuf. 2015, 8, 163–174. [Google Scholar] [CrossRef]

- Niknam, S.A.; Mortazavi, M.; Li, D. Additively manufactured heat exchangers: A review on opportunities and challenges. Int. J. Adv. Manuf. Technol. 2021, 112, 601–618. [Google Scholar] [CrossRef]

- Wei, H.; Bao, H.; Ruan, X. Machine learning prediction of thermal transport in porous media with physics-based de-scriptors. Int. J. Heat Mass Transf. 2020, 160, 120176. [Google Scholar] [CrossRef]

- Wei, H.; Zhao, S.; Rong, Q.; Bao, H. Predicting the effective thermal conductivities of composite materials and porous media by machine learning methods. Int. J. Heat Mass Transf. 2018, 127, 908–916. [Google Scholar] [CrossRef]

- Thulukkanam, K. Heat Exchanger Design Handbook; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- da Silva, M.T.Q.S.; Cardoso, M.D.R.; Veronese, C.M.P.; Mazer, W. Tortuosity: A brief review. Mater. Today Proc. 2022, 58, 1344–1349. [Google Scholar] [CrossRef]

- COMSOL Manual; COMSOL Inc.: Burlington, MA, USA, 2022.

- Ghanbarian, B.; Hunt, A.G.; Ewing, R.P.; Sahimi, M. Tortuosity in porous media: A critical review. Soil Sci. Soc. Am. J. 2013, 77, 1461–1477. [Google Scholar] [CrossRef]

- Matyka, M.; Koza, Z. How to calculate tortuosity easily? In Proceedings of the Porous Media and Its Applications in Science, Engineering, and Industry: Fourth International Conference, Potsdam, Germany, 17–22 June 2012; American Institute of Physics: College Park, MS, USA, 2012; Volume 1453, pp. 17–22. [Google Scholar]

| Gyroid | Surface Area (cm2) |

|---|---|

| Porosity φ = 70% | 15.524 |

| Porosity φ = 60% | 17.5073 |

| Porosity φ = 50% | 19.3235 |

| Porosity φ = 40% | 21.2585 |

| FKS | |

| Porosity φ = 70% | 23.1358 |

| Porosity φ = 60% | 24.748 |

| Porosity φ = 50% | 26.167 |

| Porosity φ = 40% | 27.289 |

| Diamond | |

| Porosity φ = 70% | 20.087 |

| Porosity φ = 60% | 21.679 |

| Porosity φ = 50% | 22.965 |

| Porosity φ = 40% | 24 |

| Fluid | (kg/m3) | (kg/m·s) | Cp (J/kg·K) | (W/m2·K) |

|---|---|---|---|---|

| Water | 998.2 | 0.001001 | 4128 | 0.6 |

| Engine Oil | 848 | 0.025 | 2160 | 0.137 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saghir, M.Z.; Yahya, M. Convection Heat Transfer and Performance Analysis of a Triply Periodic Minimal Surface (TPMS) for a Novel Heat Exchanger. Energies 2024, 17, 4275. https://doi.org/10.3390/en17174275

Saghir MZ, Yahya M. Convection Heat Transfer and Performance Analysis of a Triply Periodic Minimal Surface (TPMS) for a Novel Heat Exchanger. Energies. 2024; 17(17):4275. https://doi.org/10.3390/en17174275

Chicago/Turabian StyleSaghir, Mohamad Ziad, and Mohammad Yahya. 2024. "Convection Heat Transfer and Performance Analysis of a Triply Periodic Minimal Surface (TPMS) for a Novel Heat Exchanger" Energies 17, no. 17: 4275. https://doi.org/10.3390/en17174275

APA StyleSaghir, M. Z., & Yahya, M. (2024). Convection Heat Transfer and Performance Analysis of a Triply Periodic Minimal Surface (TPMS) for a Novel Heat Exchanger. Energies, 17(17), 4275. https://doi.org/10.3390/en17174275