1. Introduction

In the quest for sustainable development and climate change mitigation, improving building energy efficiency is a primary objective. Innovative paraffin-based Phase Change Materials (PCMs) offer a promising solution in this regard. PCMs have the unique capability to store and release large amounts of thermal energy during phase transitions, effectively regulating indoor temperatures [

1]. This introduction paves the way to explore how incorporating these advanced materials into building design and construction can revolutionize energy management, reduce carbon footprints, and promote environmentally conscious architecture.

Thermal Energy Storage includes various methods, such as utilizing latent heat, the sensible heat capacity of materials, or the exothermic and endothermic chemical reactions of materials [

2]. Among these, the use of PCMs for storing or releasing thermal energy through latent heat storage has proven particularly promising over the past few decades [

3]. PCMs have a significant latent heat capacity, making them highly effective for managing a building’s thermal environment. By transitioning between solid and liquid phases, PCMs can efficiently absorb and release heat, thus reducing heating and cooling loads and shifting peak energy demands [

4]. During the day, PCMs absorb excess solar energy, minimizing heat penetration into the building. At night, when temperatures drop, PCMs release stored heat, maintaining indoor thermal comfort [

5].

PCMs contribute significantly to the sustainability goals of green building certification systems like LEED and BREEAM by enhancing energy efficiency, reducing greenhouse gas emissions, and improving indoor environmental quality [

6]. By incorporating PCMs into building materials, energy consumption for heating and cooling can be substantially decreased, leading to lower operational carbon footprints. This aligns with LEED and BREEAM credits for energy optimization and reduction in environmental impacts. Additionally, the improved thermal regulation provided by PCMs enhances occupant comfort and indoor air quality, contributing to credits related to health and wellbeing. The use of PCMs also supports the efficient use of resources and materials, a key aspect of these certification systems. In general, paraffin-based PCMs help buildings achieve higher performance in energy efficiency, sustainability, and occupant comfort, thus supporting the comprehensive goals of green building certification systems. Buildings designed with PCMs contribute to reducing overall energy consumption, thereby mitigating environmental impact and promoting resource conservation. Furthermore, integrating PCMs supports the advancement of net-zero energy buildings, offering significant economic and environmental benefits for society [

7]. As PCM technology continues to evolve and gain traction, its implementation represents a critical step toward achieving energy-efficient and environmentally sustainable buildings [

8]. For example, integrating PCMs into the outer face of south-side brick walls resulted in 13.4% energy savings, although a 30 year life cycle analysis indicated that this might not be cost-effective. Similarly, PCM dry walls significantly improved energy efficiency in a Mediterranean climate like Coimbra, Portugal, with gains of up to 62%, though effectiveness varied in other climates, showing energy efficiency improvements ranging from 10% to 46% [

9,

10].

Figure 1 illustrates the categories of PCMs, focusing on paraffin-based types and their various applications in building components. The diagram categorizes PCMs into solid–solid and solid–liquid transitions, with paraffin-based PCMs highlighted for their use in construction materials [

11]. Paraffin-based PCMs, derived from organic compounds, are used due to their high latent heat storage capacity and compatibility with different building materials. The organic category encompasses fatty esters, fatty acids, alcohol/polyols, and paraffins. Compared to other PCM types such as salt hydrates and fatty acids, paraffin-based PCMs generally offer superior thermal stability and a more consistent phase change temperature, which translates to more reliable performance over time. While salt hydrates can have higher latent heat capacities, they often suffer from issues like subcooling and phase separation, which can reduce their effectiveness and reliability. Fatty acids, on the other hand, are biodegradable and environmentally friendly but may not provide the same level of thermal stability as paraffin-based PCMs. Paraffin-based PCMs strike a favorable balance between energy savings, thermal regulation, and long-term stability, making them a competitive choice compared to salt hydrates and fatty acids for building applications. The applications depicted in the figure include integration into floors, bricks, walls, roofs, and windows, showcasing the versatility of paraffin-based PCMs in enhancing the thermal performance of buildings [

12]. This integration helps reduce energy consumption by improving the thermal regulation of indoor environments, thus contributing significantly to energy-efficient building designs. The figure encapsulates the potential of paraffin-based PCMs to transform conventional building practices by incorporating advanced materials that support sustainable and energy-efficient architecture.

Advancements in PCM technology, particularly in encapsulation and the development of composite materials, have significantly enhanced the effectiveness of paraffin-based PCMs in building applications. Encapsulation techniques, such as microencapsulation and macroencapsulation, are crucial for improving the thermal stability, preventing leakage during phase transitions, and enhancing the durability of PCMs when integrated into building materials. According to [

13], incorporating additives such as expanded graphite into paraffin can increase its thermal conductivity by up to 6.5 times, addressing the low thermal conductivity that is typically a limitation of paraffin-based PCMs. Additionally, another review highlights that encapsulating PCMs within building elements not only improves their thermal performance but also facilitates easier integration into various construction materials, leading to better energy efficiency and indoor thermal comfort [

14]. The use of encapsulated PCMs in building elements helps maintain stable indoor temperatures by effectively absorbing and releasing heat, thereby reducing the load on heating and cooling systems. These advancements make paraffin-based PCMs more practical for a wide range of applications in sustainable building design, offering substantial benefits in both energy savings and improved indoor environmental quality.

Extensive research has explored the use of paraffin PCMs within building components, leading to emerging alternatives like biobased PCMs [

12]. However, much of this research has been limited to simulation studies or laboratory-scale experiments. The untapped potential lies in implementing PCMs in real-life building environments to evaluate their thermal performance in real-time scenarios. Current studies predominantly emphasize singular applications [

15,

16,

17,

18,

19,

20,

21]. However, by diversifying integration across multiple building elements—walls, ceilings, and floors—there is potential for varied outcomes that enhance building performance, aligning with sustainable efforts to transition conventional structures into net-zero energy buildings [

12].

Specifically, within civil engineering, PCM applications focus on energy-saving through temperature regulation, particularly in building walls, roofs, ceilings, and floors. For instance, research by Rathore et al. [

22] embedded PCM-filled tubes in walls, achieving a moderate reduction in peak temperatures and energy savings. Yan et al. [

23] integrated PCM systems with nocturnal sky radiators, significantly reducing indoor temperatures and energy consumption during hot weather. Lee et al. [

24] developed PCM thermal shields that reduced peak heat fluxes and delayed temperature peaks. These examples underscore PCM’s efficacy in enhancing building thermal performance and reducing energy consumption [

25,

26].

Recent studies have shown significant advancements in passive thermal management of buildings through the integration of PCMs, particularly when these materials are enhanced by innovative techniques. For instance, the use of PCM microcapsules enhanced by single-wall carbon nanotubes (SWCNTs) has been demonstrated to improve thermal performance significantly, offering better heat storage and release characteristics, which is crucial for maintaining indoor thermal comfort [

27]. Furthermore, the scaling laws for fluid transport phenomena in porous PCM media have been extensively studied, providing insights into the permeability and porosity relationships critical for optimizing PCM-based systems in building applications [

28]. Moreover, PCM applications extend beyond traditional materials like concrete walls to include innovative uses such as PCM-enhanced gypsum boards [

29,

30], wooden composites [

31], and PCM-filled double-glazed windows [

32]. These applications illustrate the potential for PCM integration to improve thermal insulation and regulate indoor temperatures effectively [

32,

33,

34,

35,

36,

37,

38]. The integration of PCMs in low-scale personal cooling systems has been experimentally validated, demonstrating enhanced efficiency and operational autonomy [

39].

In challenging environments, PCMs have been explored for their ability to mitigate temperature fluctuations and enhance structural integrity in materials like concrete and pavement [

40,

41,

42,

43]. These studies highlight PCM’s potential in diverse applications ranging from construction materials to pavement maintenance and beyond.

However, despite these advancements, practical challenges remain, including high costs, technical complexities in integration, and the need for standardized assessment methods [

44,

45,

46]. Further research and development are crucial to overcome these challenges and promote wider adoption of PCM technologies in building applications.

While paraffin-based PCMs significantly enhance thermal performance by improving energy storage and temperature regulation in building materials, their integration can present trade-offs with other critical material properties such as mechanical strength and fire resistance. The inclusion of paraffin-based PCMs in cementitious composites can lead to a reduction in mechanical strength due to the softer and more flexible nature of PCMs compared to the host matrix, which may weaken the material under stress [

47]. Additionally, paraffin-based PCMs are organic and inherently flammable, potentially compromising the fire resistance of building materials. This presents a significant safety concern, especially in applications where fire resistance is critical. However, advancements such as the incorporation of fire-resistant additives or encapsulation methods have been developed to mitigate these risks, enhancing the fire performance of PCM-enhanced materials [

48]. While these strategies can help balance thermal benefits with safety and structural integrity, they underscore the need for careful material design and selection when integrating PCMs into building applications.

The innovative application of paraffin-based PCMs for building energy efficiency can be paralleled with advancements in hydrogen storage materials. Recent advancements in PCMs, such as the integration of multi-wall carbon nanotubes to enhance photothermal conversion and storage, have shown promising results [

49]. For example, the addition of metal oxide catalysts to organic hydrogen storage materials has shown promising results in reducing dehydrogenation temperatures and enhancing thermal stability [

50]. Similar to the use of paraffin-based PCMs in building energy efficiency, the integration of metal oxide additives to improve thermal stability in hydrogen storage materials is another area of active research.

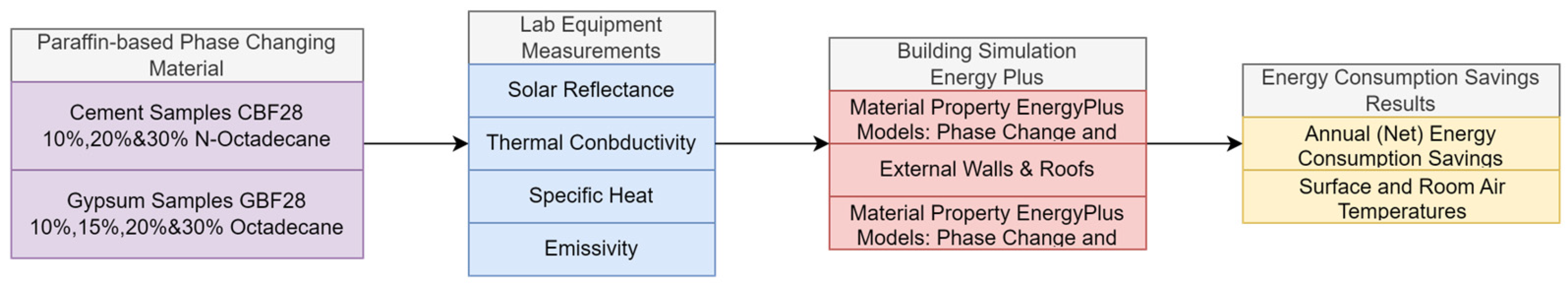

Despite extensive research on PCMs, a significant gap remains in exploring the combined use of PCMs across multiple building elements to optimize performance. Most existing studies are confined to simulations or laboratory-scale experiments, highlighting the need for real-world implementation and performance evaluation to validate PCM effectiveness in actual building environments. This study aims to address this gap by measuring the thermal properties of shape-stabilized paraffin-based PCMs and assessing their impact on building energy efficiency through comprehensive simulations using OpenStudio and EnergyPlus. By integrating PCMs into external roofs and walls, this research moves beyond singular applications to investigate the synergistic benefits of combined PCM use. The novelty of this work lies in its approach to combining paraffin-based PCMs across multiple building elements, conducting precise measurements, and utilizing advanced simulation tools to evaluate energy savings and assess practical performance.

In this section, the field, challenge, scope, solution, and novelty of this study were discussed. Following, in

Section 2, the materials and methods that are used for this study are presented, including the methodology, case study building, PCM samples, and the simulation model. Next, in

Section 3, the results from the PCM sample characteristics measurements are presented, in addition to the building energy simulation scenarios results. Last but not least, in

Section 4 and

Section 5, the discussion and conclusions are presented, respectively.

4. Discussion

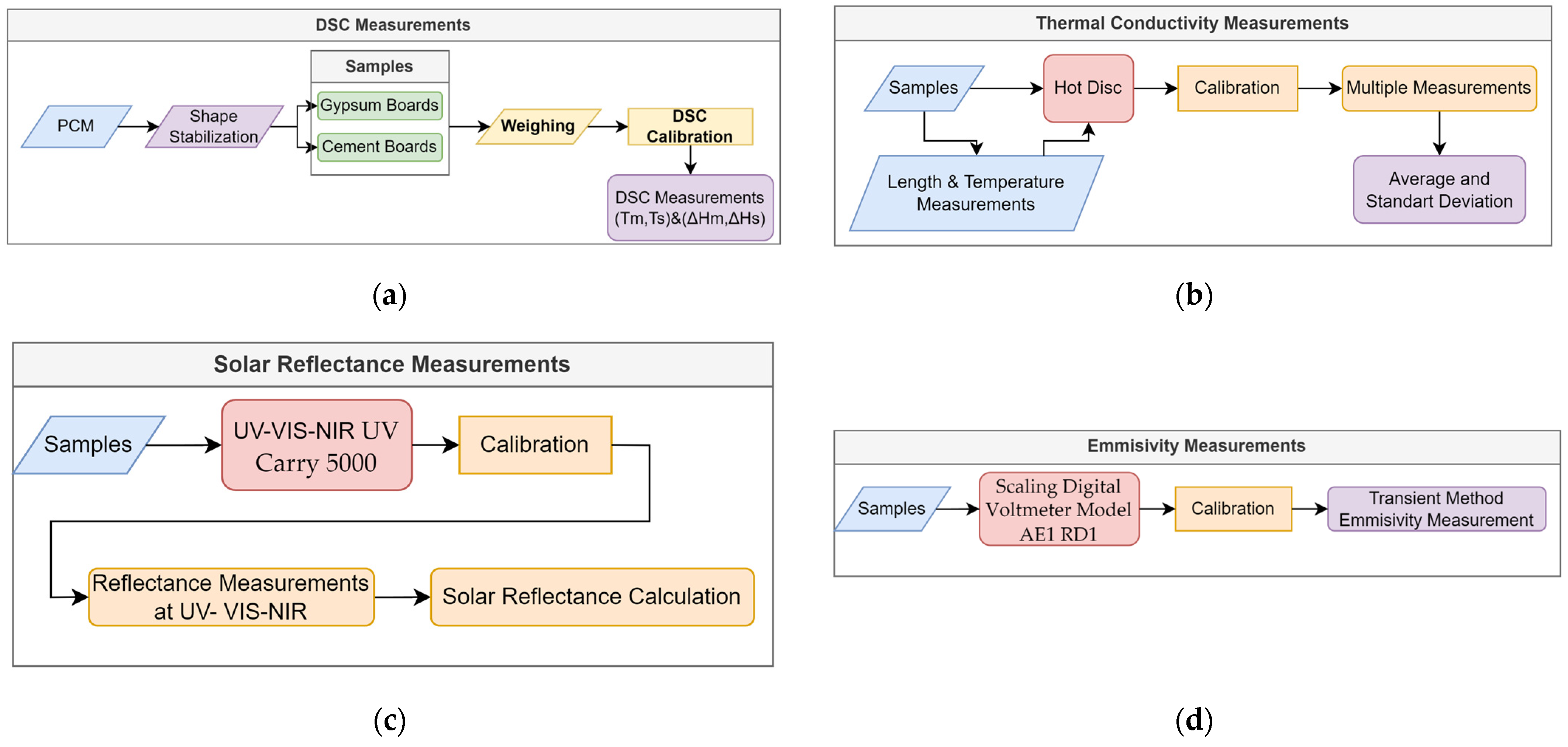

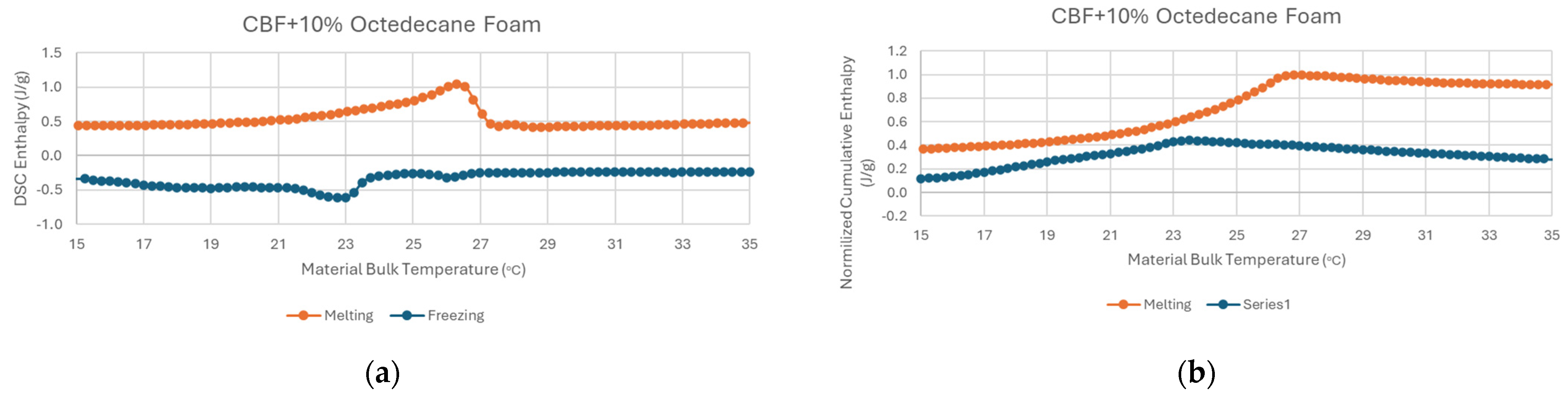

The integration of PCMs into building materials such as cement and gypsum boards has demonstrated significant impacts on thermal properties and building energy consumption. This section discusses the results of Differential Scanning Calorimetry (DSC) measurements, thermal conductivity tests, solar reflectance, and emissivity measurements, as well as the implications of these properties on the overall energy performance of buildings as determined by EnergyPlus simulations.

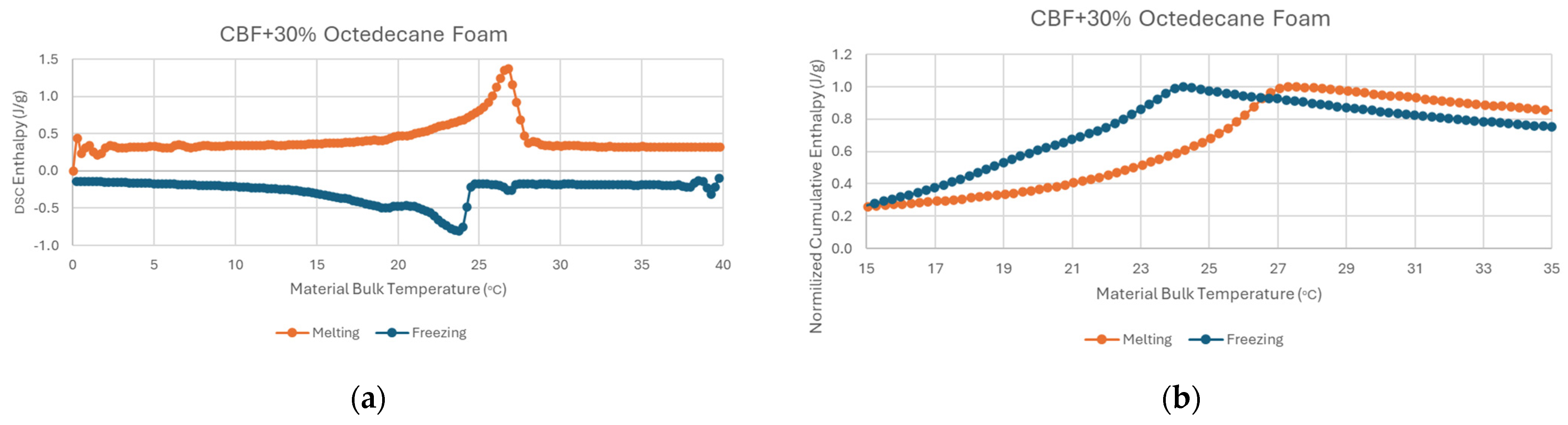

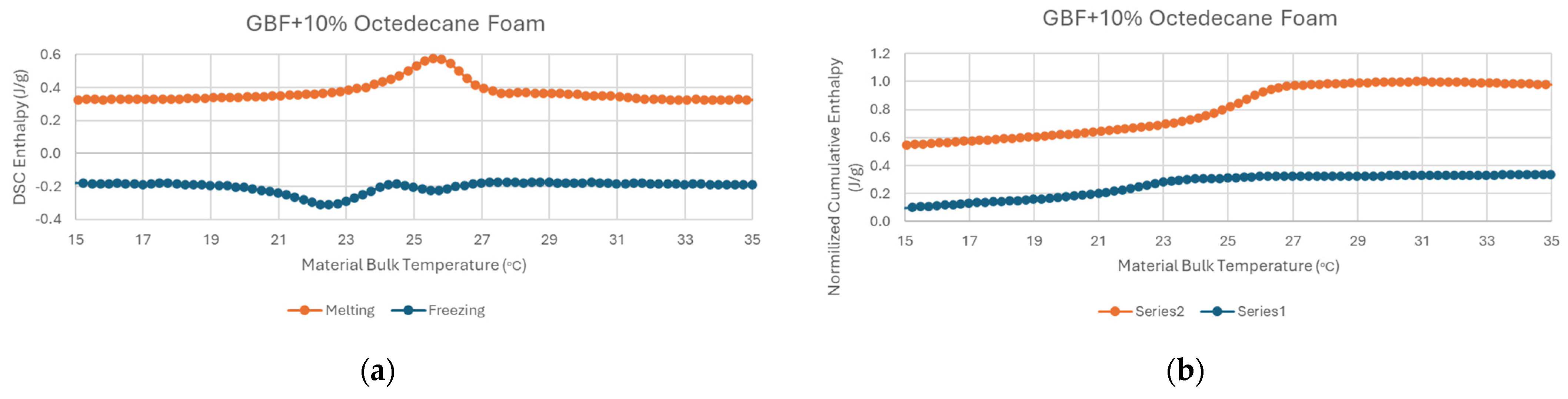

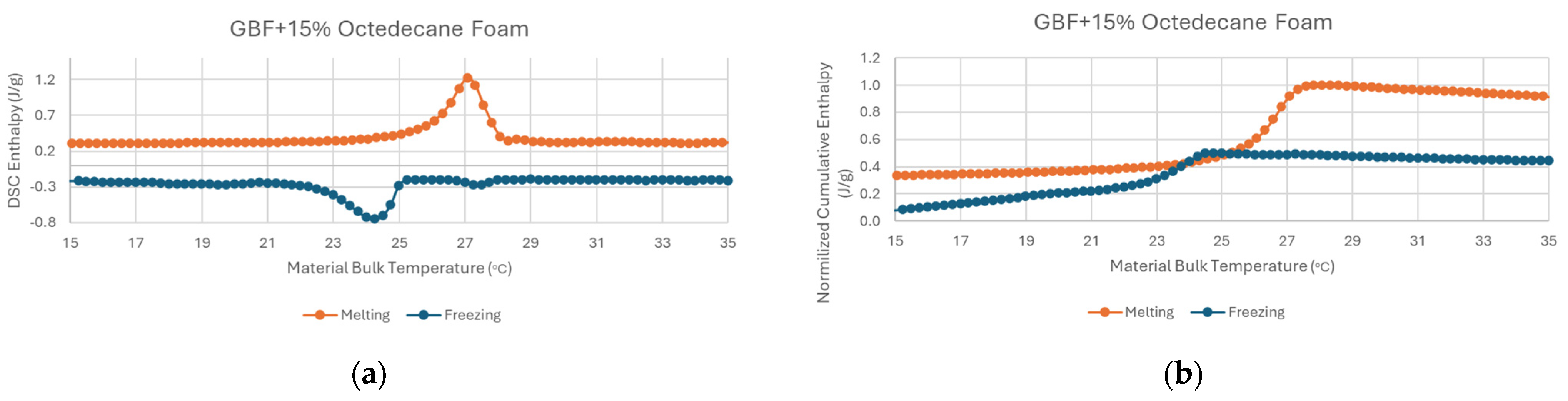

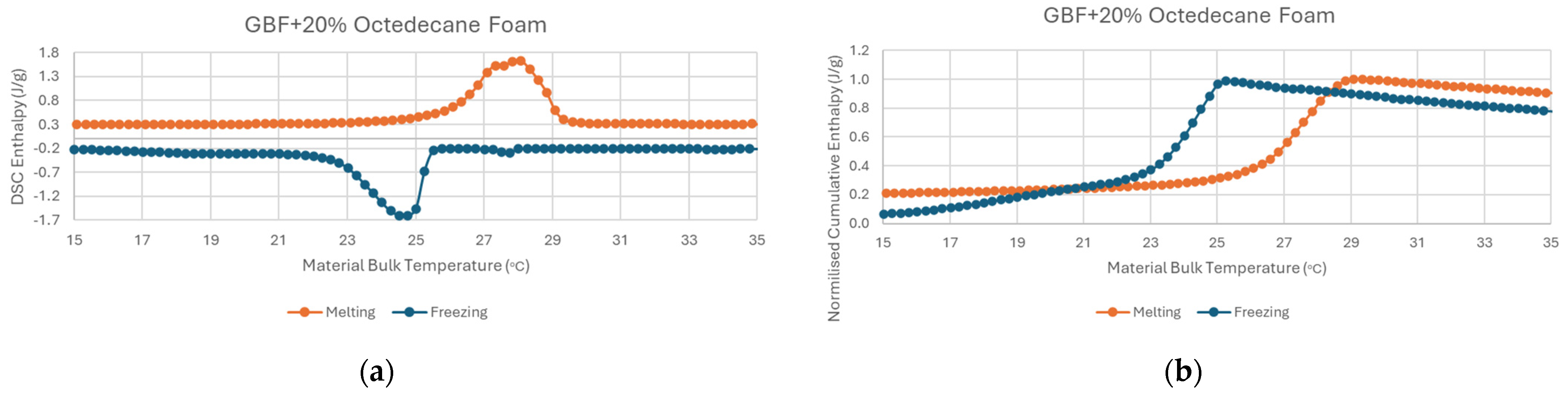

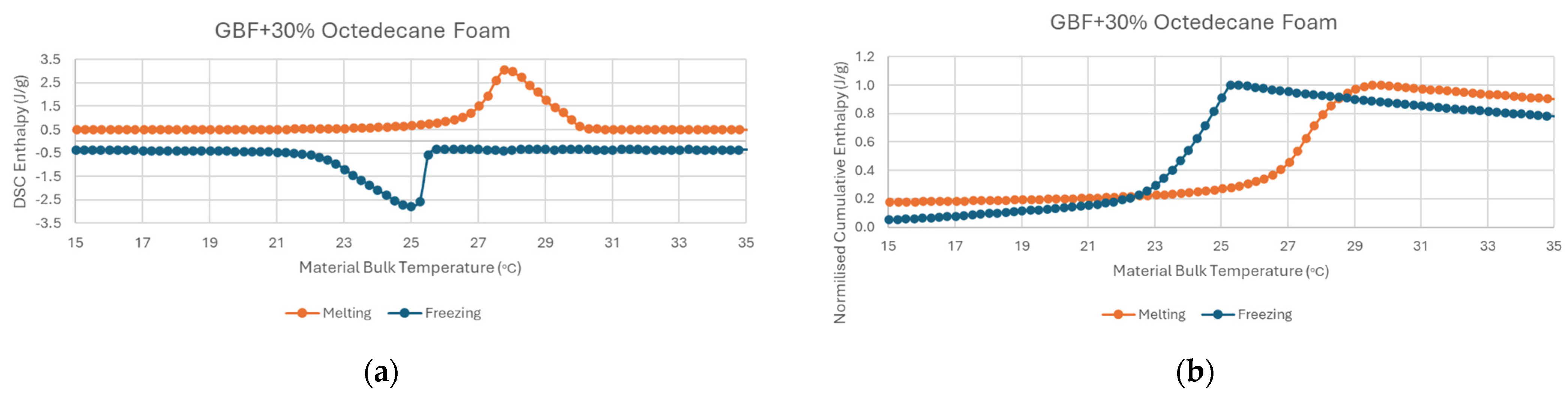

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12 illustrate the enthalpy diagrams obtained from DSC measurements for cement and gypsum boards with varying percentages of PCM foam. These diagrams show that increasing the percentage of PCM foam in the boards enhances their thermal storage capacity. The enthalpy curves for higher PCM concentrations (e.g., 30% PCM foam) more closely resemble the curves of pure PCM, indicating a significant integration of PCM characteristics into the construction materials. This enhancement in thermal storage capacity is crucial for stabilizing indoor temperatures and reducing heating and cooling demands.

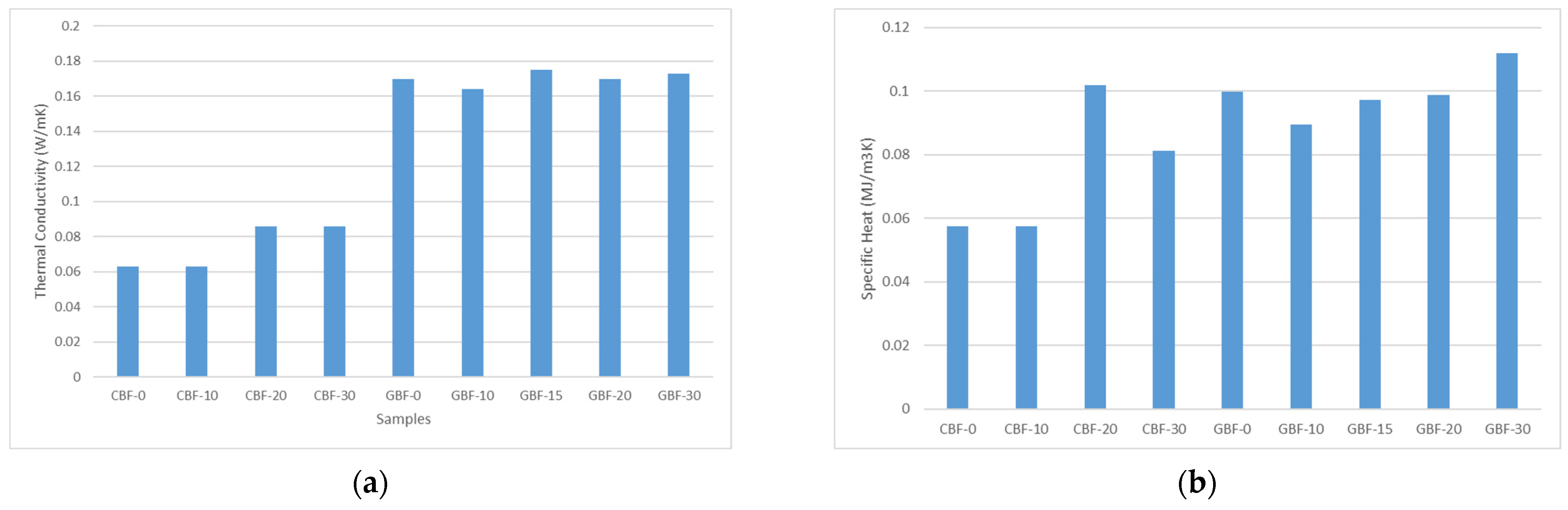

The thermal conductivity and specific heat measurements, presented in

Table 1 and depicted in

Figure 13a,b, highlight notable differences between the samples. Cement boards with lower PCM content (10%) exhibit the lowest thermal conductivity, which is advantageous for reducing heat transfer through building envelopes. Conversely, gypsum boards with higher PCM content show increased thermal conductivity but also higher specific heat values, which can be beneficial for thermal mass and energy storage purposes. Traditional materials, such as standard gypsum boards and cement, typically exhibit thermal conductivities in the range of 0.17 to 0.25 W/mK for gypsum boards and 0.29 to 1.73 W/mK for cement. In contrast, the PCM-enhanced materials in this study demonstrated a range of thermal conductivities, from 0.063 W/mK to 0.175 W/mK, depending on the PCM content and the type of material. The lower thermal conductivity values observed in the PCM-enhanced gypsum and cement samples indicate better thermal insulation compared to their traditional counterparts. This improved insulation is crucial for reducing heat transfer through building envelopes, thereby enhancing overall energy efficiency.

Similarly, the specific heat of these materials, measured in MJ/m3K, varied with the PCM content. The highest specific heat was observed in gypsum boards with 30% PCM, reflecting a greater capacity for thermal energy storage. This characteristic is crucial for stabilizing indoor temperatures, as it allows the materials to absorb excess heat during warmer periods and release it when temperatures drop. The enhanced specific heat, particularly in the gypsum boards, suggests that these materials could effectively contribute to the thermal mass of a building, thus improving its holistic energy management.

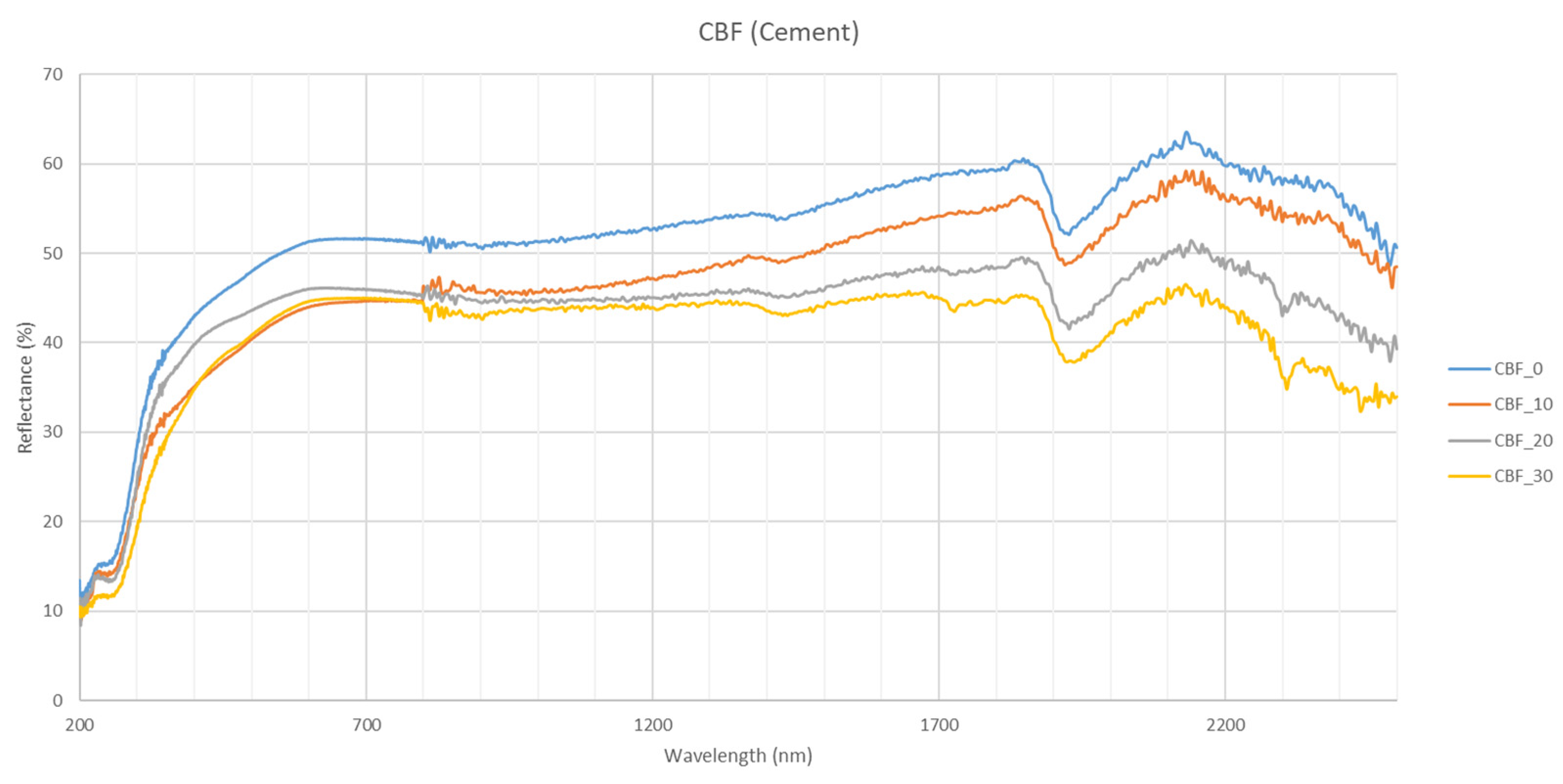

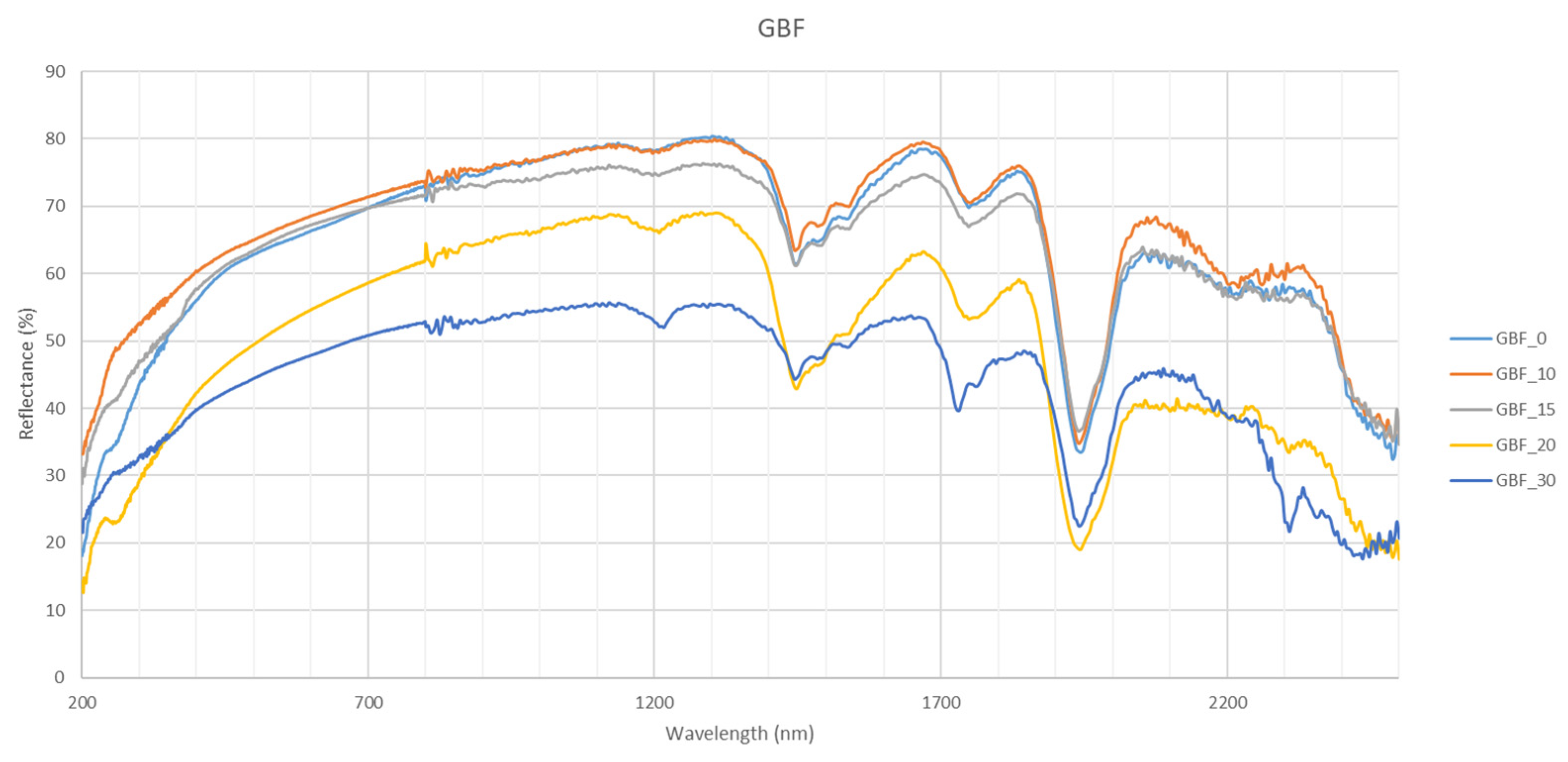

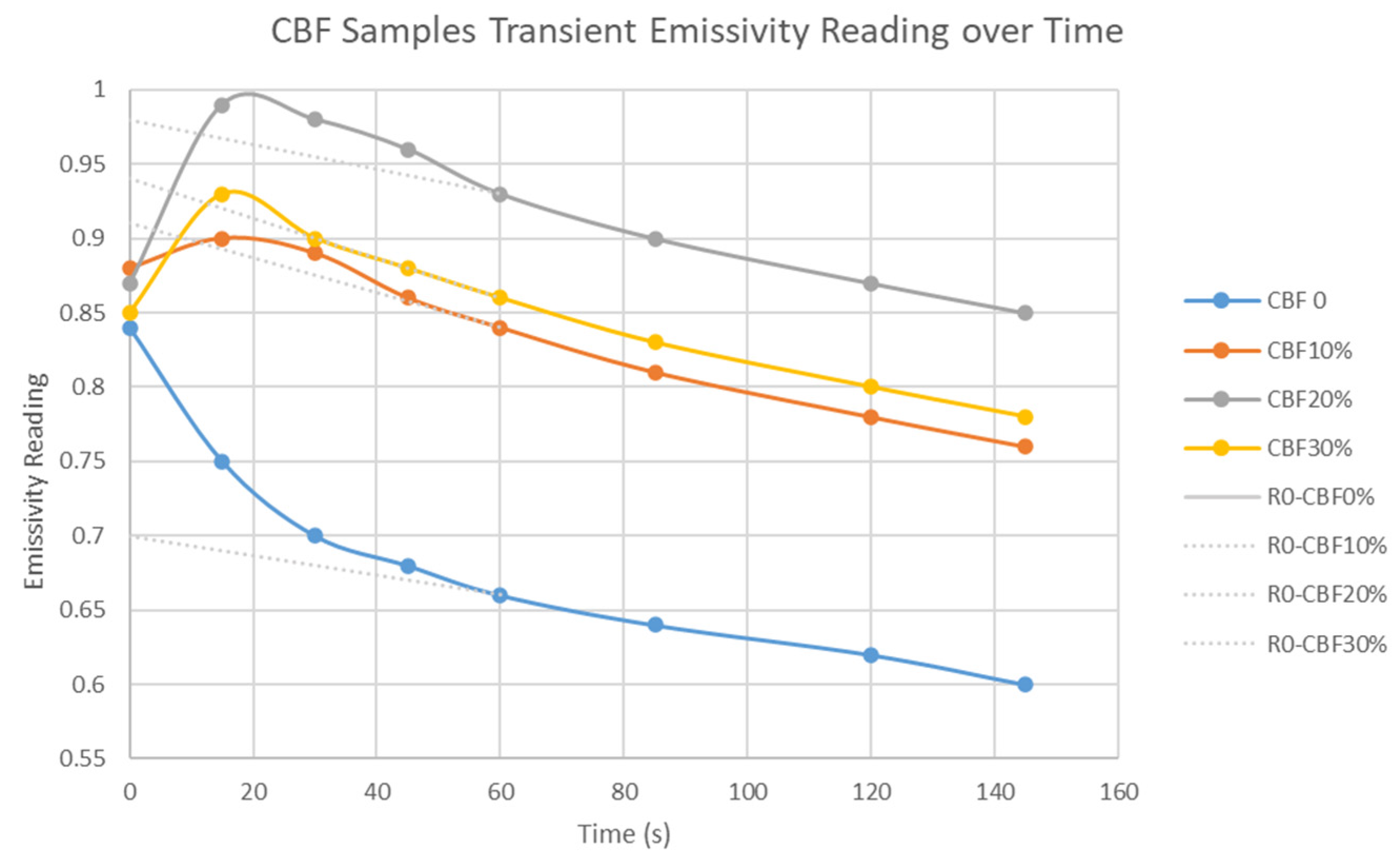

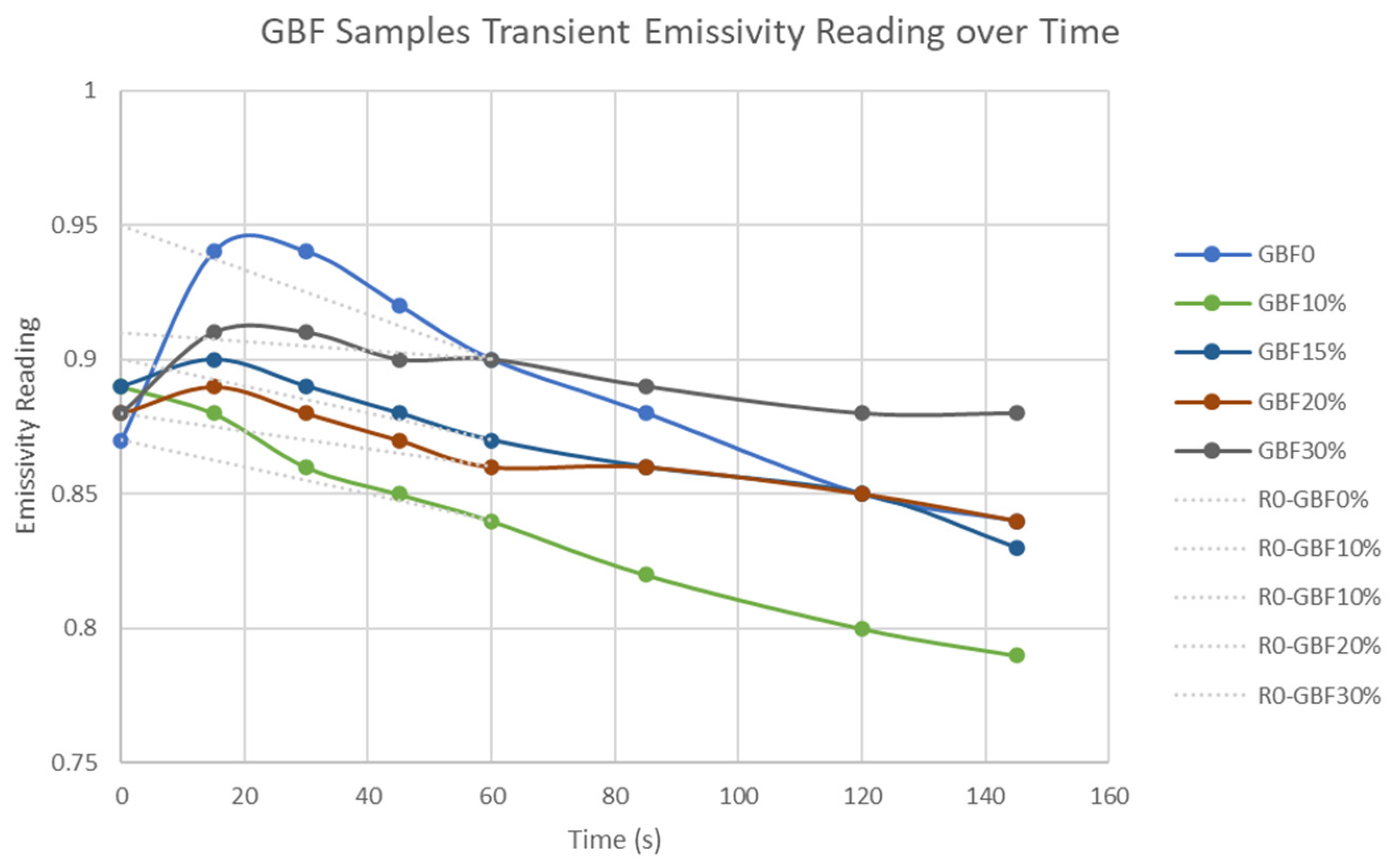

Reflectance measurements (

Figure 14 and

Figure 15) and solar reflectance data from

Table 2 reveal that gypsum boards generally exhibit higher solar reflectance compared to cement boards. This characteristic makes gypsum boards more effective in reflecting solar radiation, thereby reducing cooling loads. Emissivity measurements (

Figure 16 and

Figure 17,

Table 3) show that all samples have relatively high emissivity values, which is beneficial for releasing stored heat during cooler periods. Traditional gypsum boards generally show reflectance values around 20% to 30%, while standard gray cement typically has reflectance values between 30% and 50%. The PCM-enhanced materials in this study, however, exhibited significantly higher solar reflectance values, ranging from 42.7% to 70.31%, depending on the PCM concentration and the specific surface treatment applied. These increased solar reflectance values contribute to lower heat gain from solar radiation, reducing the cooling loads required to maintain indoor thermal comfort.

These findings highlight the dual role of PCM-enhanced materials in managing both heat gain and dissipation, making them versatile for various climatic conditions. The balance between high reflectance and high emissivity suggests that these materials can effectively reduce energy consumption by optimizing both cooling and heating needs. Further research should focus on the long-term stability of these properties in real-world conditions to confirm their practical benefits and explore the potential for further material optimization.

In summary, regarding the measurements, PCM-enhanced materials not only offer better thermal insulation by lowering thermal conductivity but also enhance solar reflectance, making them more effective in reducing energy consumption compared to traditional building materials. This dual benefit underlines the potential of PCM-enhanced materials to contribute significantly to the thermal management of buildings, leading to improved energy efficiency and sustainability in building design.

Measuring the thermal conductivity and solar reflectance of PCM-enhanced materials using the Hot Disc TPS1500 and UV-Vis-NIR spectrophotometer presents specific challenges that must be carefully managed to ensure accurate results. One primary challenge in measuring thermal conductivity is ensuring the uniform dispersion of PCM within the material matrix, as any inhomogeneity can lead to inconsistent results due to the PCM’s phase change behavior, which can cause localized variations in thermal conductivity. Additionally, the phase change nature of the PCM, which involves latent heat absorption and release, complicates the measurement process, particularly if the material’s temperature nears the PCM’s phase transition point. To address these issues, it is crucial to thoroughly prepare the samples to ensure uniform PCM distribution and to maintain a stable measurement temperature, avoiding the PCM’s phase change region. For solar reflectance measurements, challenges arise due to the PCM’s optical properties, which can vary with temperature, and surface irregularities caused by PCM integration that might influence the reflectance readings. To mitigate these challenges, measurements should be conducted under controlled temperature conditions to keep the PCM in a single phase and ensure a smooth, uniform surface finish to reduce the impact of surface irregularities. These strategies help ensure that the measurements of thermal conductivity and solar reflectance accurately reflect the properties of PCM-enhanced materials. Both measurement equipments used are high-end and comply with standards that minimize the errors and result in accurate results.

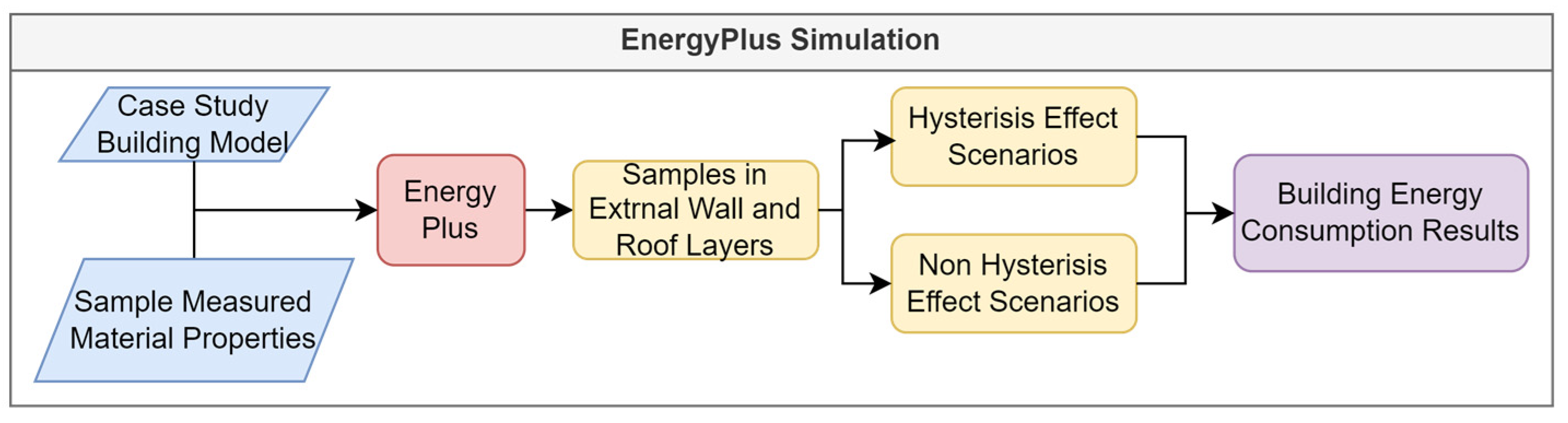

The EnergyPlus simulations provide a comprehensive analysis of the energy performance of buildings utilizing PCM-enhanced materials. Scenarios with hysteresis models consistently outperform those without hysteresis, as evidenced by the greater energy savings (

Table 4 and

Table 5). Specifically, Scenario S14, involving gypsum board with 30% PCM foam, demonstrates the highest energy savings of 12.8% compared to the baseline scenario at standard setpoints (20 °C for heating and 26 °C for cooling). This scenario also shows substantial net annual energy consumption savings, 22.3% (

Table 6 and

Table 7), indicating the significant potential of PCM-enhanced materials in reducing energy usage. The increase in the savings percentage from annual energy consumption to the net annual energy consumption indicates the compatibility of RES like PV panels with the PCMs as TES. The scenarios running on PCMs melting and freezing points as cooling and heating setpoints did not reach high percentages of savings.

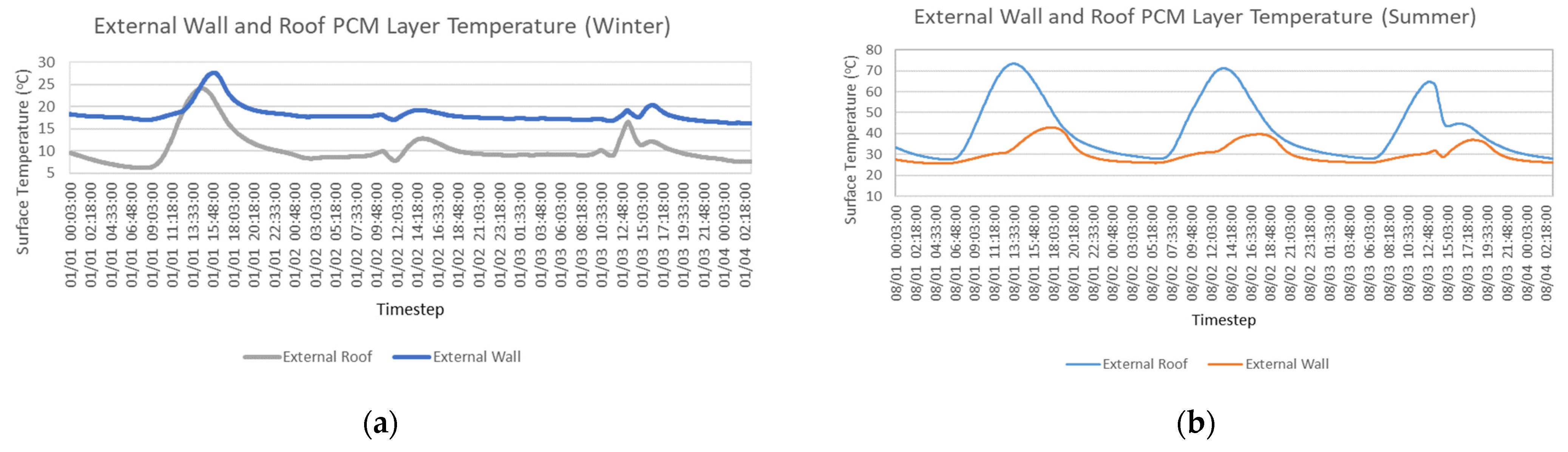

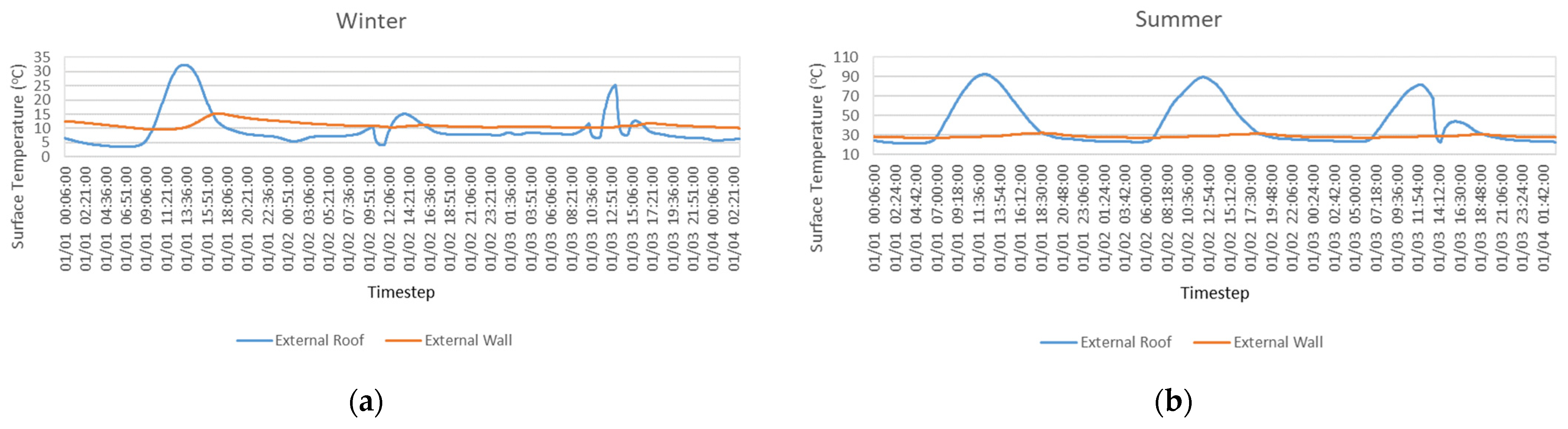

Figure 18 illustrates the PCM layer node temperatures for the external roof and walls in Scenario 14 (Prominent GBF 30% Hysteresis) during winter (a) and summer (b). The data reveal that the PCM layers significantly moderate temperature fluctuations, maintaining more stable temperatures compared to non-PCM-enhanced materials. This stability is crucial in reducing thermal stress on building materials and maintaining indoor thermal comfort.

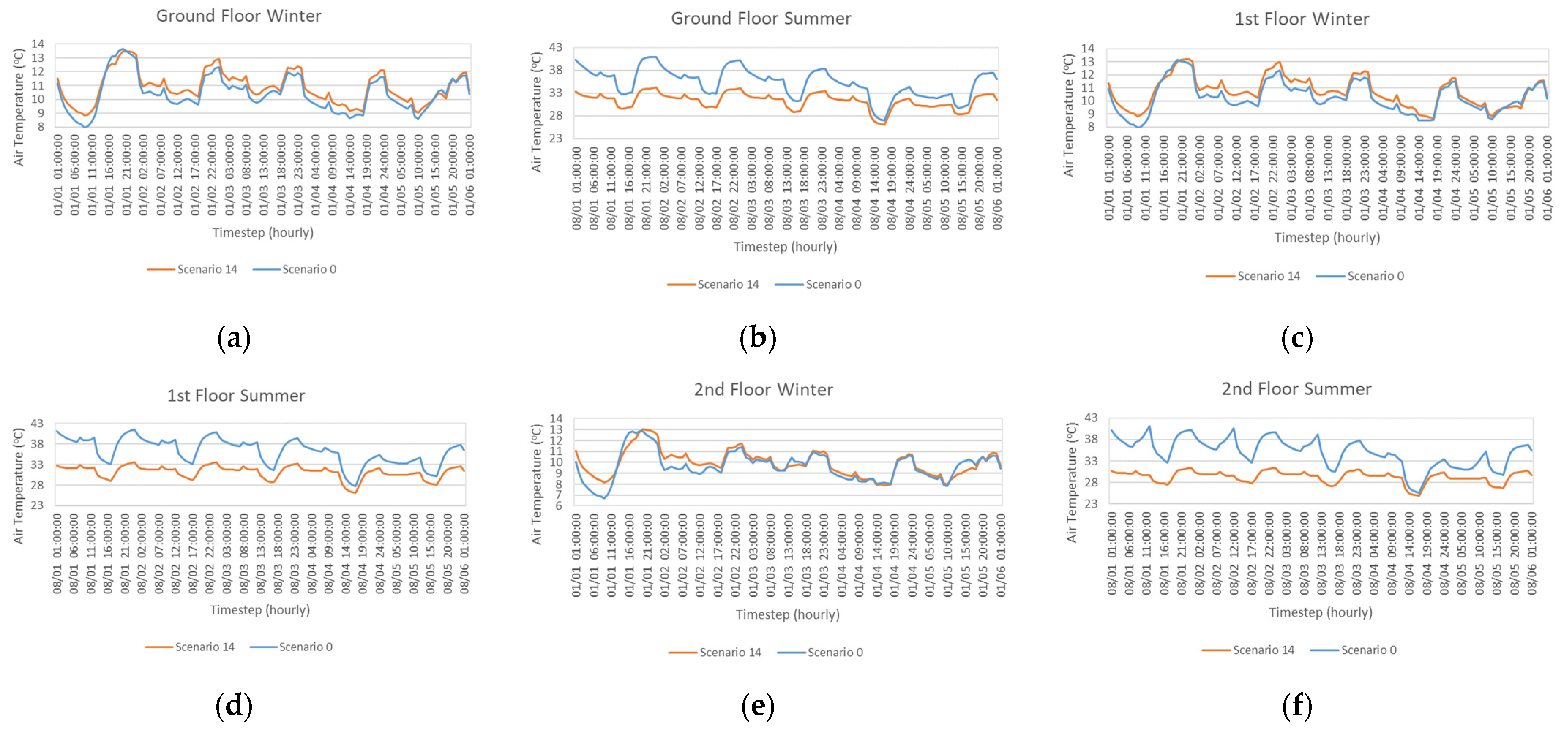

Figure 19 compares room air temperatures between the baseline scenario (S0) and the prominent PCM-enhanced scenario (S14) for different floors (ground, first, and second) during both winter and summer under free-running conditions (no HVAC). The results demonstrate that PCM-enhanced materials help in maintaining indoor temperatures closer to the desired comfort range without active heating or cooling. This suggests that PCMs can passively enhance thermal comfort, reducing the dependency on HVAC systems and potentially lowering energy consumption.

Figure 20 shows the temperature fluctuations within a test room equipped with PCM-enhanced materials compared to a control room for both winter (a) and summer (b), also under free-running conditions (no HVAC). The PCM-enhanced room experiences significantly dampened temperature peaks and valleys, indicating that PCMs effectively mitigate extreme indoor temperatures. This capacity for thermal regulation is particularly beneficial in maintaining occupant comfort and reducing the overall load on HVAC systems when they are in use, especially during peak heating and cooling periods.

Findings align with several studies that have investigated the use of PCMs in building materials. For instance, results showing up to 12.8% annual energy savings with 30% PCM-enhanced gypsum boards are comparable to the 10–46% energy efficiency improvements reported by studies in various climates [

9,

10,

23]. Additionally, the integration of PCM into walls and roofs has demonstrated similar benefits in terms of thermal regulation and energy reduction [

24,

29,

30]. However, it is noteworthy that the specific conditions under which these savings were achieved, such as the climatic context and the PCM concentrations, vary across studies. This suggests that while the trend in PCM effectiveness is consistent, the magnitude of energy savings is highly dependent on specific implementation details, such as the type of PCM, building design, and local climate conditions.

PCMs show varying performance across different climate conditions. In hot climates, they effectively absorb and release heat to reduce cooling needs, offering significant energy savings. In temperate climates, they provide year-round thermal regulation by adapting to seasonal temperature variations, ensuring frequent phase changes. In cold climates, their effectiveness is limited due to fewer phase changes, focusing more on heat retention to maintain indoor warmth. In general, the performance of paraffin-based PCMs hinges on selecting materials with appropriate melting points and optimizing thermal properties to match specific climate conditions.

Moreover, the performance of PCM-enhanced materials in this study, particularly in temperate and hot climates, supports the conclusions of Yan et al. [

23] and Lee et al. [

24], who demonstrated significant reductions in cooling loads when PCMs were integrated into building envelopes. The energy savings reported in this study, especially under hysteresis scenarios, are slightly higher than those reported by Lee et al. [

24], which could be attributed to differences in the PCM content, the specific materials used, or the simulation settings.

In terms of thermal regulation and the maintenance of indoor comfort, the results of this work are consistent with the findings of Kuznik and Virgone [

15], who also observed that PCM integration into building materials helps maintain stable indoor temperatures and reduces reliance on HVAC systems. However, while this study focuses on cement and gypsum boards, Kuznik and Virgone [

15] primarily examined PCM-impregnated concrete walls, which may offer different thermal dynamics due to the inherent properties of concrete compared to gypsum and cement.

It is also important to address the trade-offs observed in our study between thermal benefits and other material properties, such as mechanical strength. Rostami et al. [

48] and Miccoli et al. [

40] have similarly reported that while PCMs improve thermal performance, they may compromise other material characteristics, highlighting the need for balanced material design. Our findings corroborate these observations, suggesting that while PCM-enhanced materials offer substantial energy savings, careful consideration of their mechanical properties is essential, particularly in load-bearing applications.

The study’s findings have significant implications for both the design and construction of new buildings and the retrofitting of existing buildings with PCM-enhanced materials. For new buildings, incorporating paraffin-based PCMs into the initial design allows for optimal placement and integration, maximizing energy efficiency and thermal performance from the outset. This proactive approach can result in substantial long-term energy savings, improved occupant comfort, and enhanced sustainability credentials, making it easier to achieve green building certifications. Conversely, retrofitting existing buildings with PCM-enhanced materials provides a viable path to improve energy efficiency without the need for major structural changes. This can be particularly beneficial for older buildings, where adding PCM-enhanced gypsum boards, walls, or roofs can significantly reduce energy consumption for heating and cooling. Both strategies demonstrate that PCM technology can be flexibly applied to improve building performance, whether in new constructions designed with energy efficiency in mind or in existing structures seeking to enhance their thermal regulation and reduce energy costs.

Overall, while paraffin-based PCMs may not have the highest thermal properties among the different PCM types, their favorable characteristics, such as chemical stability, ease of integration, and cost-effectiveness, make them a highly practical choice for building applications. The energy savings and thermal regulation achieved in this study align well with the results observed in studies using other PCM types, reaffirming the potential of PCMs in enhancing building energy efficiency.

The potential for scalability and mass adoption of paraffin-based PCM technology in the building industry is strong due to its cost-effectiveness, abundant availability, and established manufacturing processes. Paraffin-based PCMs offer significant energy savings and improved thermal regulation, making them attractive for both new constructions and retrofits. As demand for sustainable, energy-efficient building solutions grows, driven by stringent building codes and green certification requirements, the adoption of PCM technology is likely to increase. Collaborative efforts between manufacturers, builders, and policymakers can further support widespread implementation, making paraffin-based PCMs a mainstream solution in the building industry.

Future work should involve testing the replication of this methodology by subjecting the samples to stress under a weather simulation station. This approach will reveal how these materials behave and what their properties become after prolonged exposure to environmental conditions. Additionally, implementing these materials in a pilot building will be crucial to validating the findings of this study, providing also practical insights into their long-term performance and effectiveness. Furthermore, the impact of the integration of paraffin-based PCMs on the structural integrity and durability of building components over long-term use should be examined in future work. Moreover, the economic feasibility of using paraffin-based PCMs in building components should be explored in future work.

5. Conclusions

The study demonstrates that integrating paraffin-based Phase Change Materials (PCMs) into building materials such as cement and gypsum boards significantly en-hances thermal performance and energy efficiency. Differential Scanning Calorimeter (DSC) measurements show that increasing PCM content in the boards enhances their thermal storage capacity, essential for stabilizing indoor temperatures and reducing heating and cooling demands, with enthalpy values increasing from 45,851 J/kg to 80,042 J/kg as PCM content increases to 30%. Thermal conductivity tests revealed that cement boards with 10% PCM content exhibited the lowest thermal conductivity at 0.063 W/mK, which is beneficial for reducing heat transfer. Gypsum boards, on the other hand, with 30% PCM content showed a higher thermal conductivity of 0.173 W/mK, enhancing thermal mass and energy storage. So, lower PCM content in cement boards reduces heat transfer, while higher PCM content in gypsum boards enhances thermal mass and energy storage. Solar reflectance measurements showed that gypsum boards with 10% PCM content had the highest solar reflectance at 70.31%, effectively reducing cooling loads. Emissivity data, measured across different samples, indicated high heat release during cooler periods, with values ranging from 0.78 to 0.91.

EnergyPlus simulations based on these measured properties demonstrated that PCM-enhanced materials can effectively moderate indoor temperatures, reducing the reliance on HVAC systems. Specifically, the use of 30% PCM-enhanced gypsum boards resulted in a 12.8% reduction in annual energy consumption, from 121.63 kWh/m2 to 106.05 kWh/m2, and a 22.3% reduction in net annual energy consumption, from 69.80 kWh/m2 to 54.23 kWh/m2, compared to baseline scenarios. Additionally, scenarios that incorporated PCMs with hysteresis models showed up to 19.5% energy savings, highlighting the importance of accounting for thermal cycling in PCM applications.

Key findings include:

PCM-enhanced gypsum boards with 30% PCM content resulted in the highest energy savings, achieving a reduction of up to 12.8% in annual energy consumption and 22.3% in net annual energy consumption compared to baseline.

Scenarios incorporating PCMs with hysteresis outperformed those without, indicating the importance of considering thermal cycling in PCM applications.

The use of PCM-enhanced materials in building components can lead to significant improvements in indoor thermal comfort by maintaining more stable temperatures and reducing thermal stress on building materials.

These findings indicate that PCM-enhanced materials hold significant potential for improving indoor thermal comfort by stabilizing temperatures and reducing thermal stress on building components. To advance the adoption of PCM technologies in energy-efficient and sustainable building designs, future research should prioritize long-term performance testing of these materials under real environmental conditions and explore their implementation in pilot buildings. Additionally, it is crucial to examine the long-term effects of integrating paraffin-based PCMs on the structural integrity and durability of building components. Moreover, assessing the economic feasibility of using paraffin-based PCMs in building materials will be essential for evaluating their practical application and widespread adoption.