Experimental Investigation of R404A Indirect Refrigeration System Applied Internal Heat Exchanger: Part 2—Exergy Characteristics

Abstract

1. Introduction

2. Test Apparatus and Data Analysis

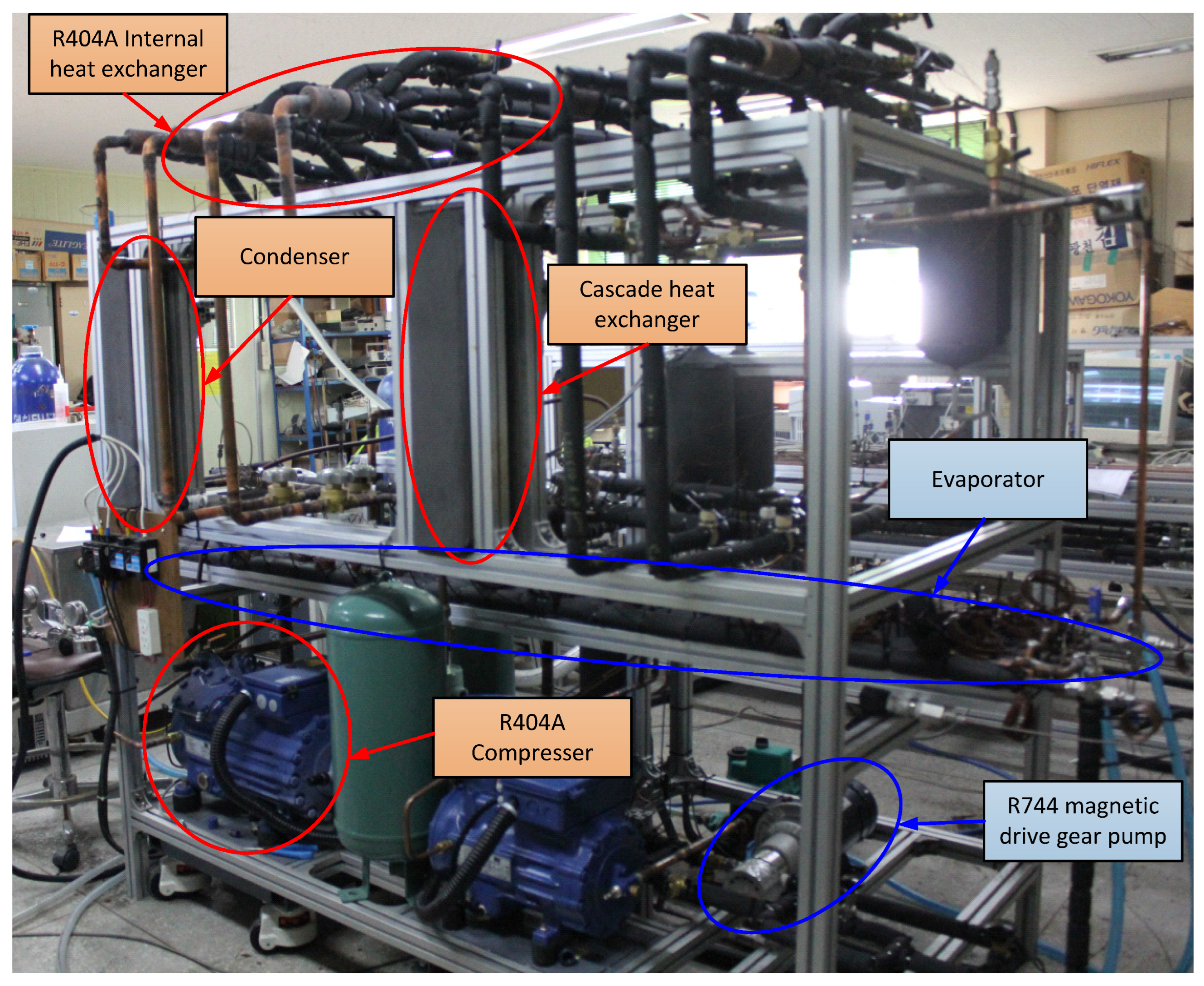

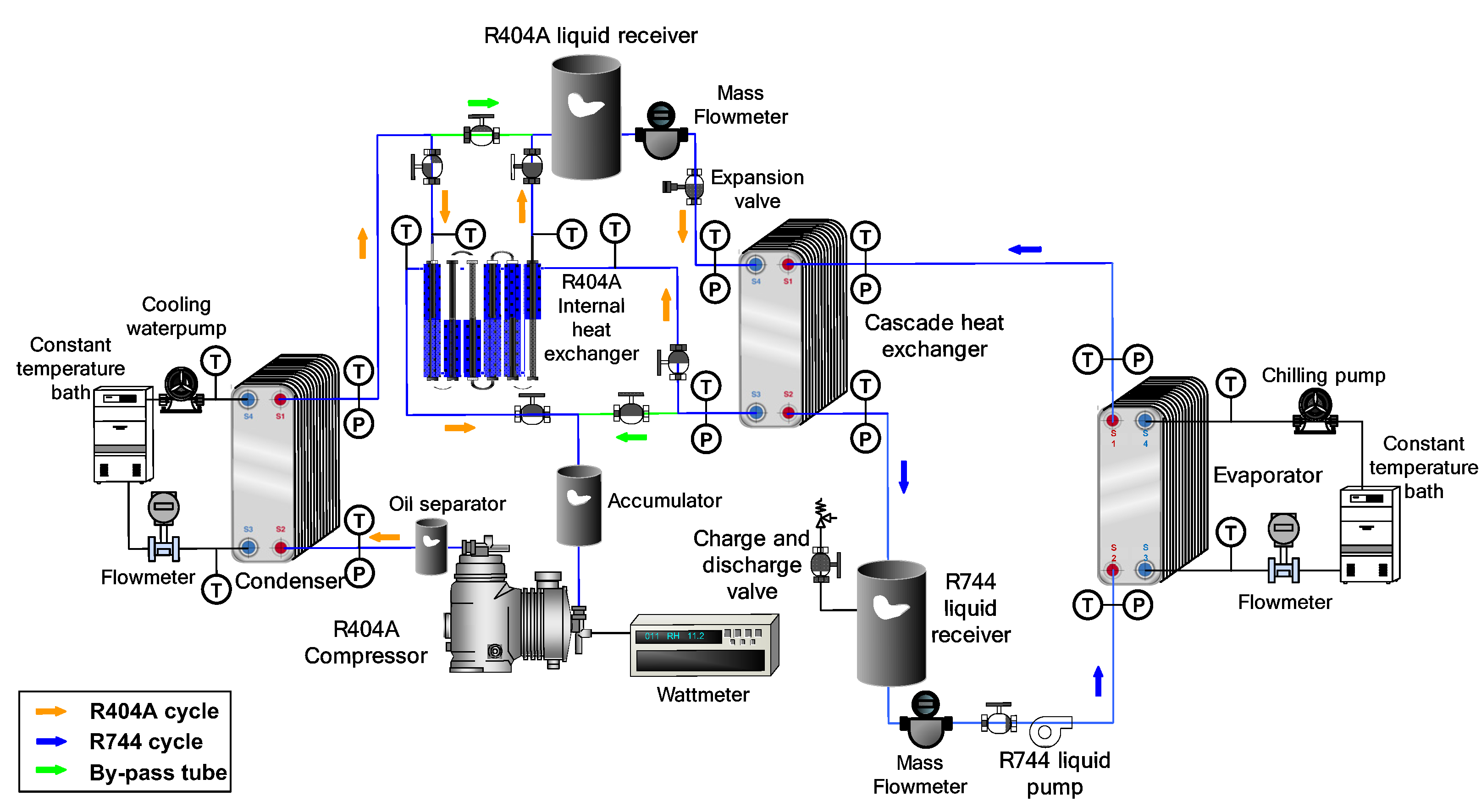

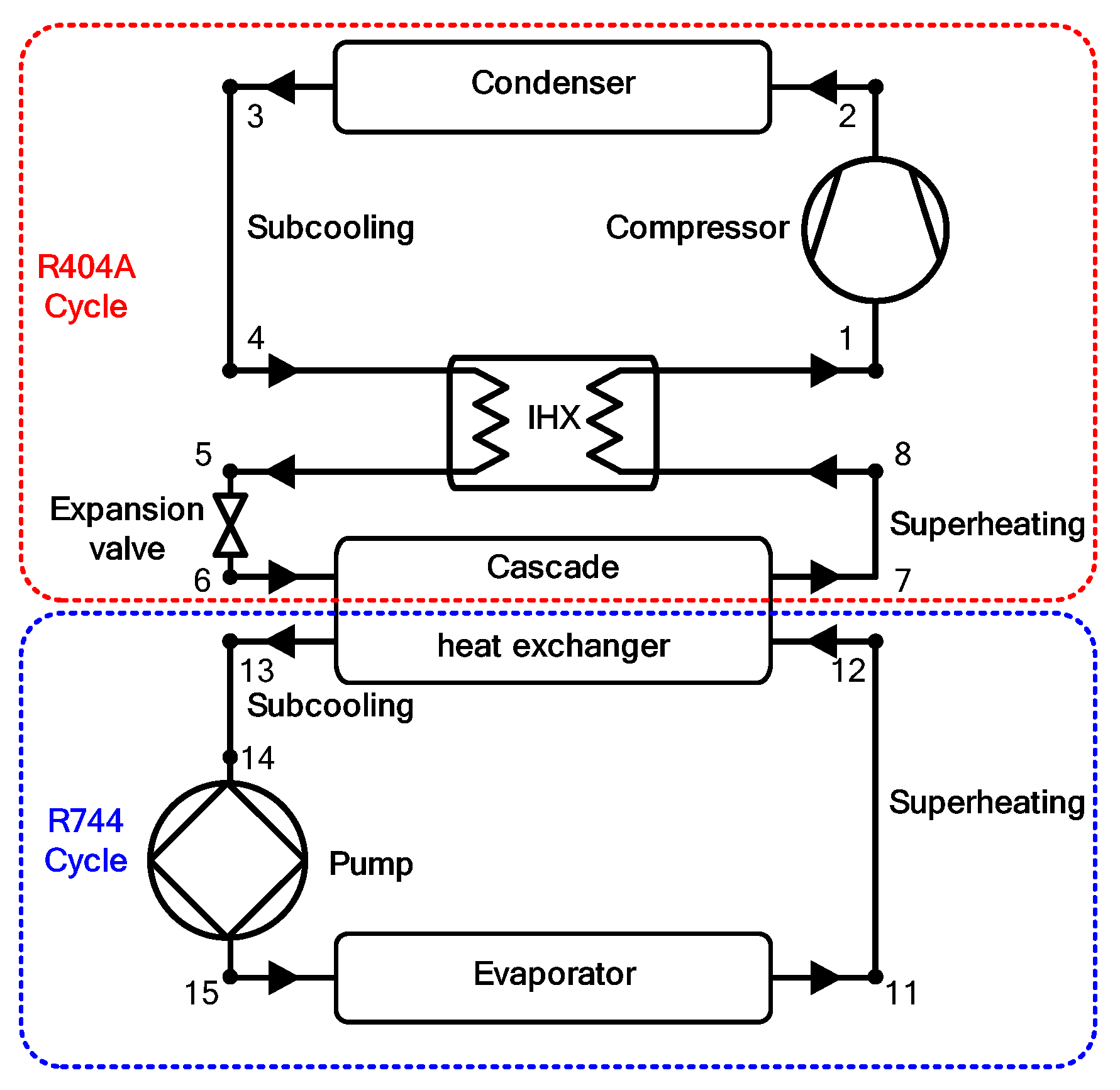

2.1. Test Apparatus

2.2. Data Reduction

2.3. Uncertainties

3. Results

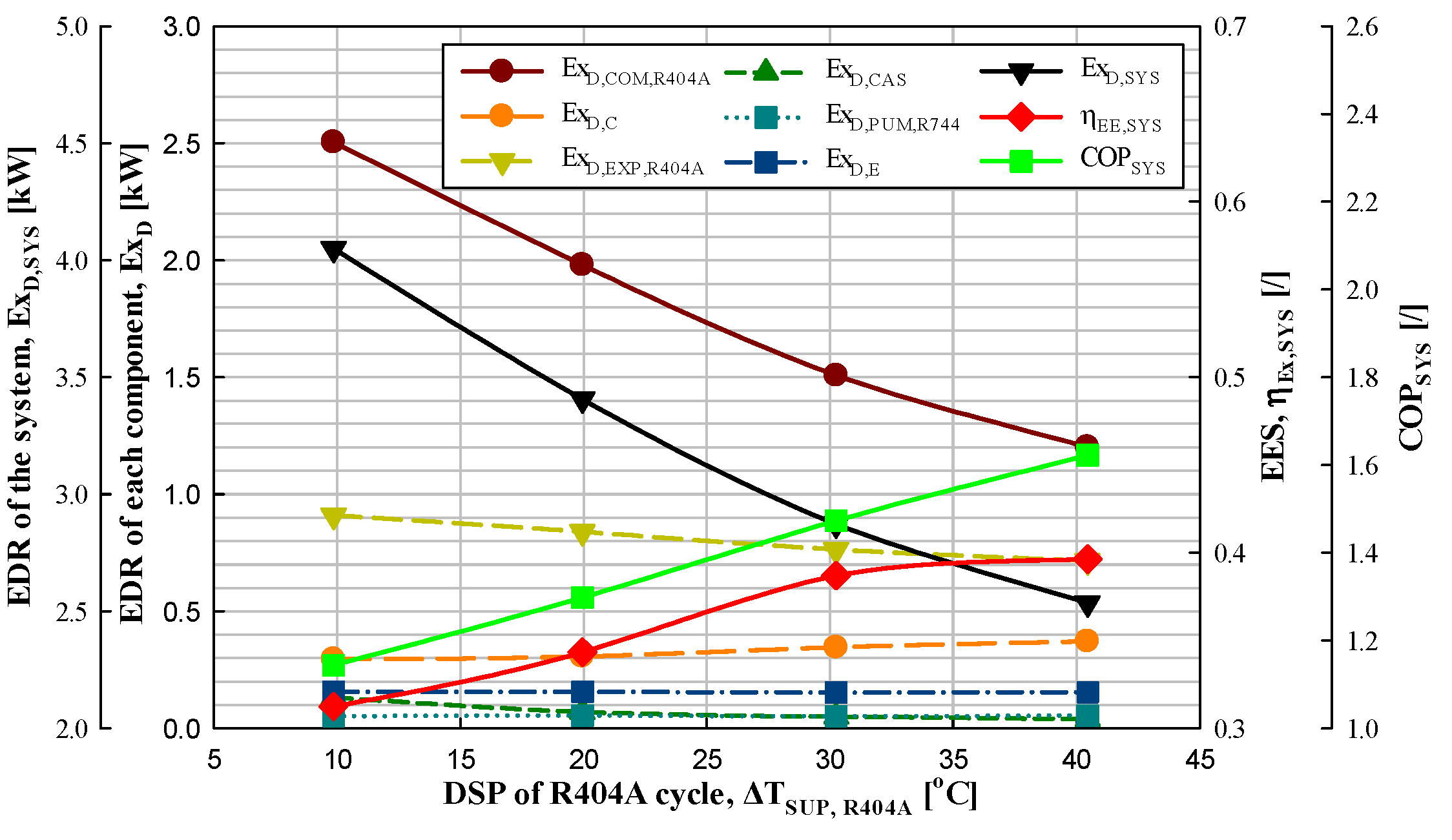

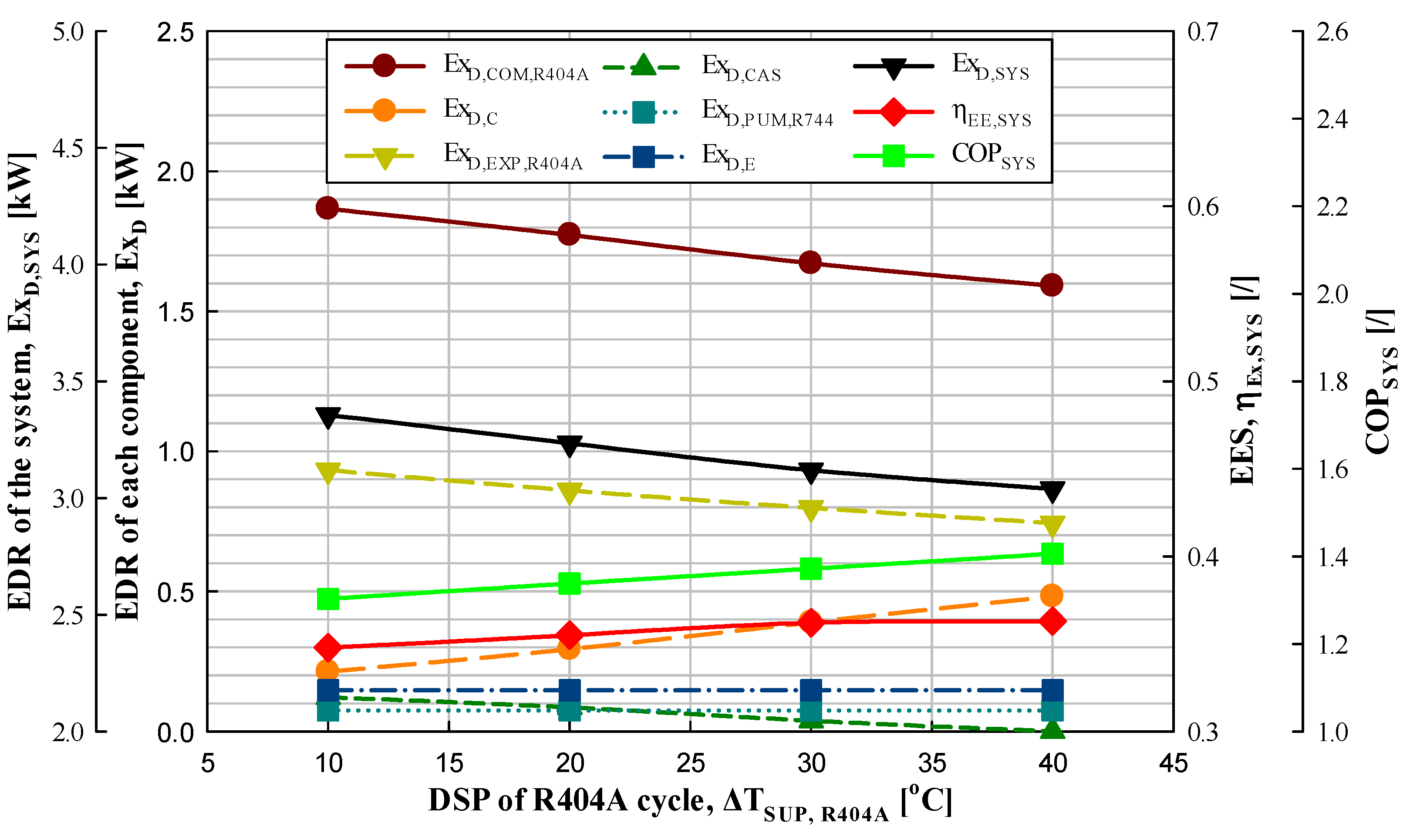

3.1. Effect of the DSP

3.1.1. Effect of the DSP of the R404A Cycle

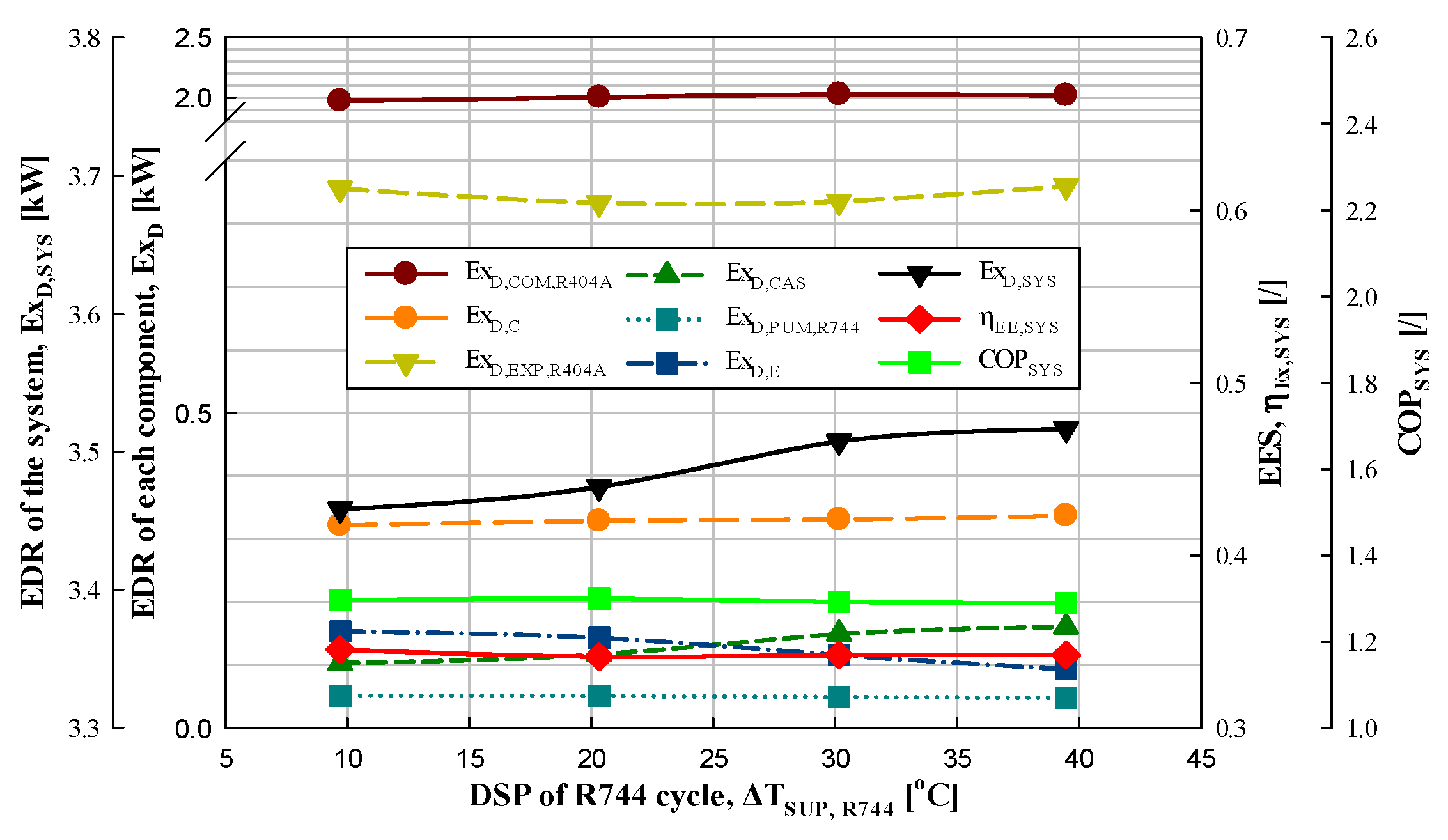

3.1.2. Effect of the DSP of the R744 Cycle

3.2. Effect of the DSB

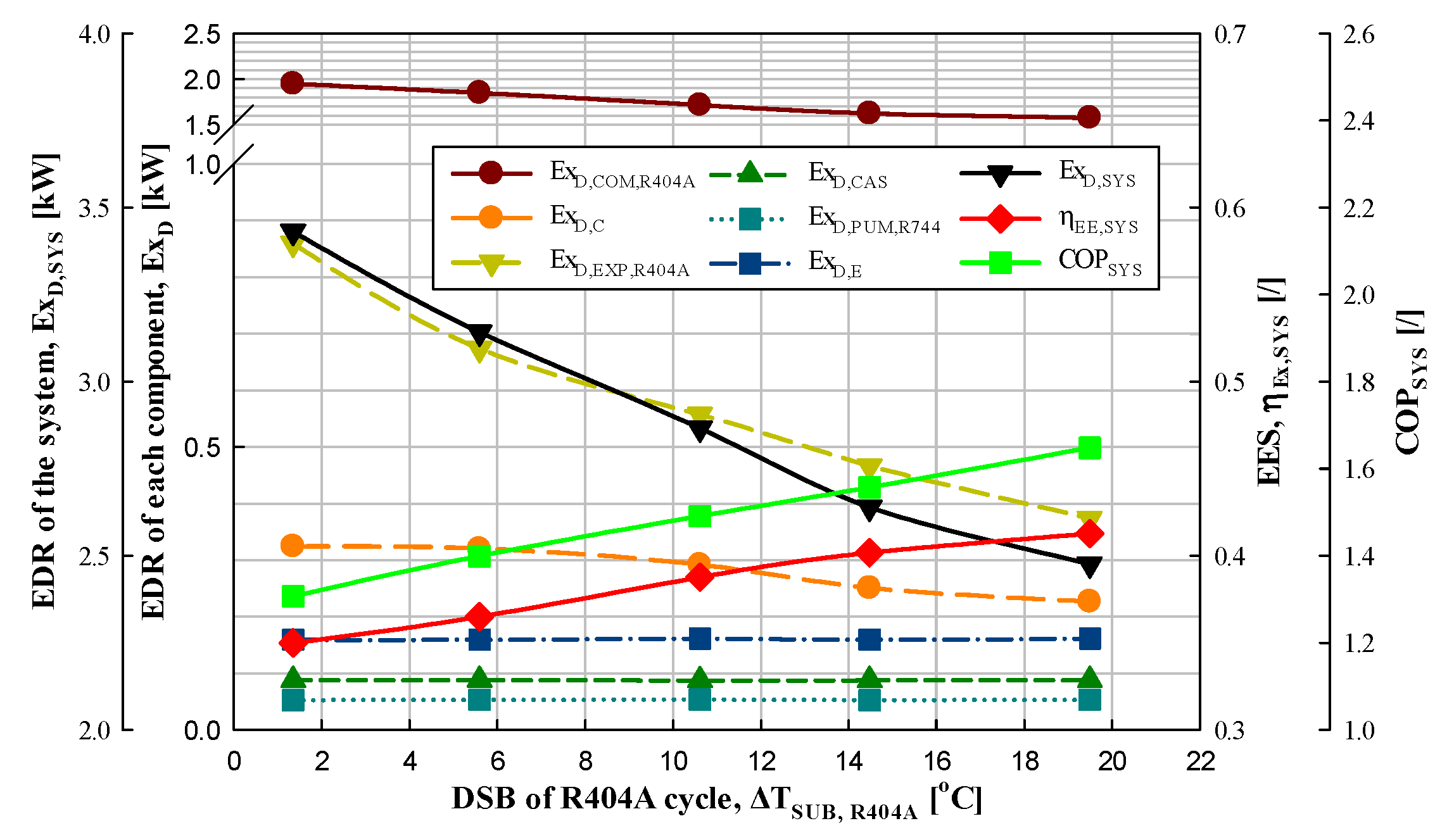

Effect of the DSB of the R404A Cycle

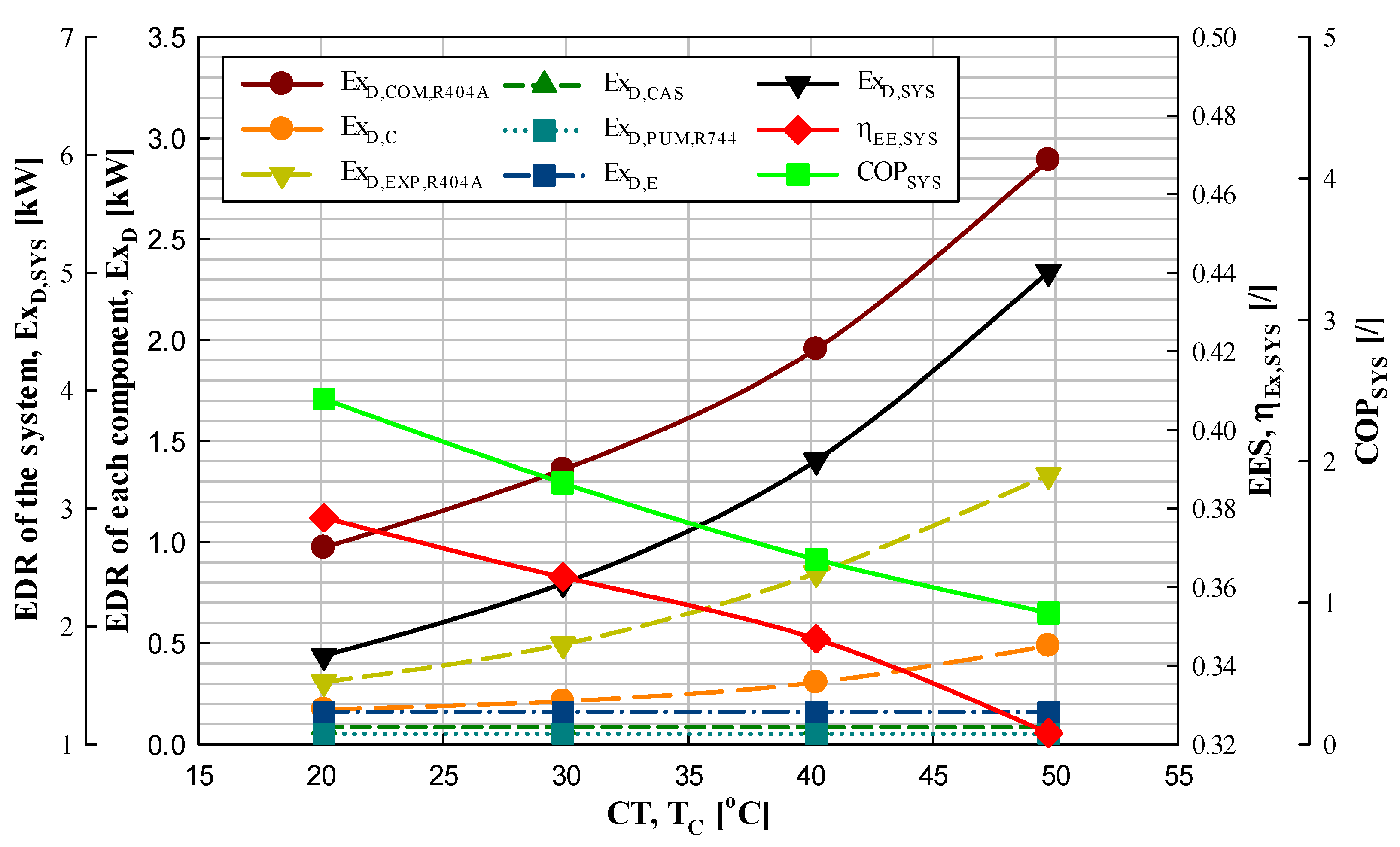

3.3. Effect of CT

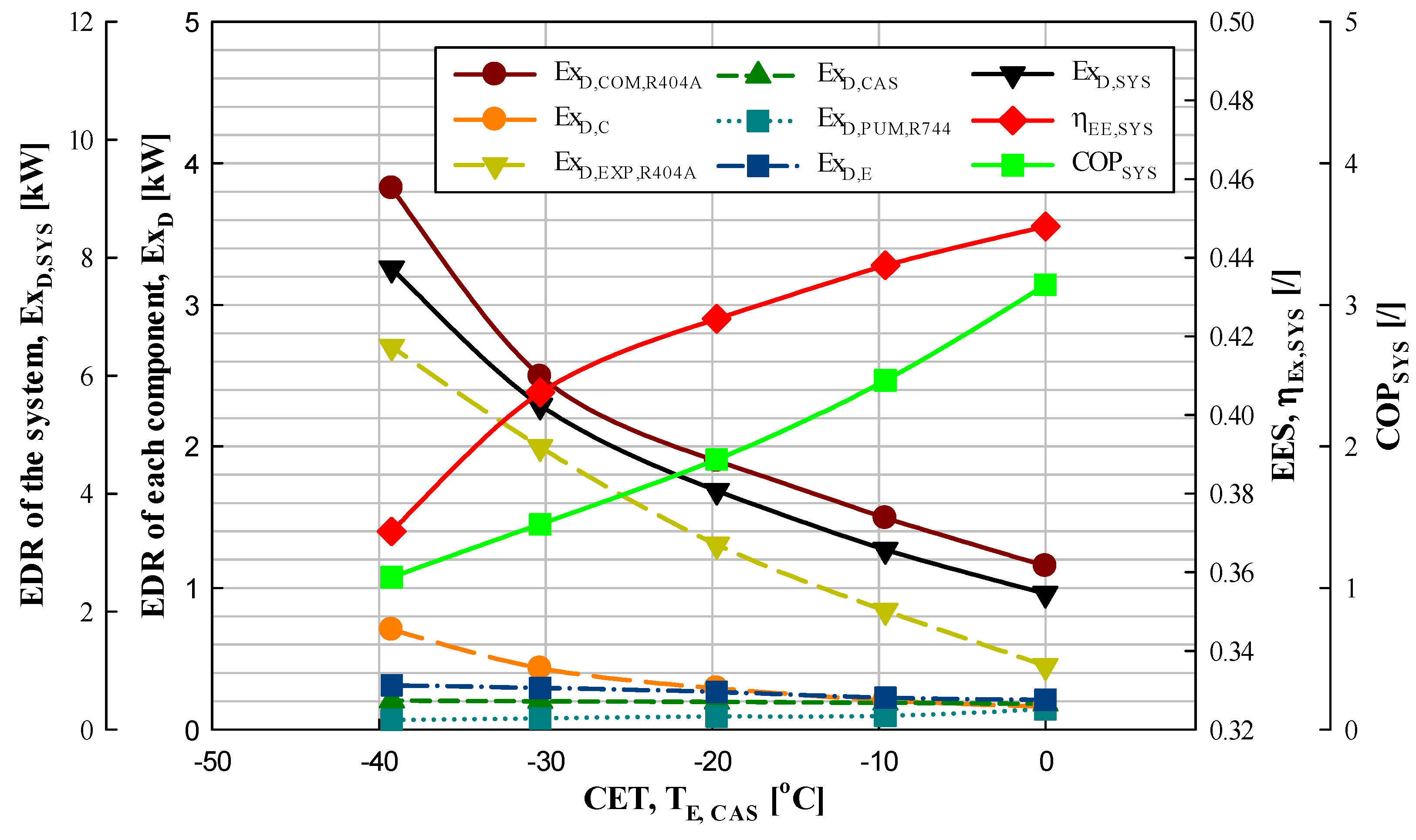

3.4. Effect of the CET

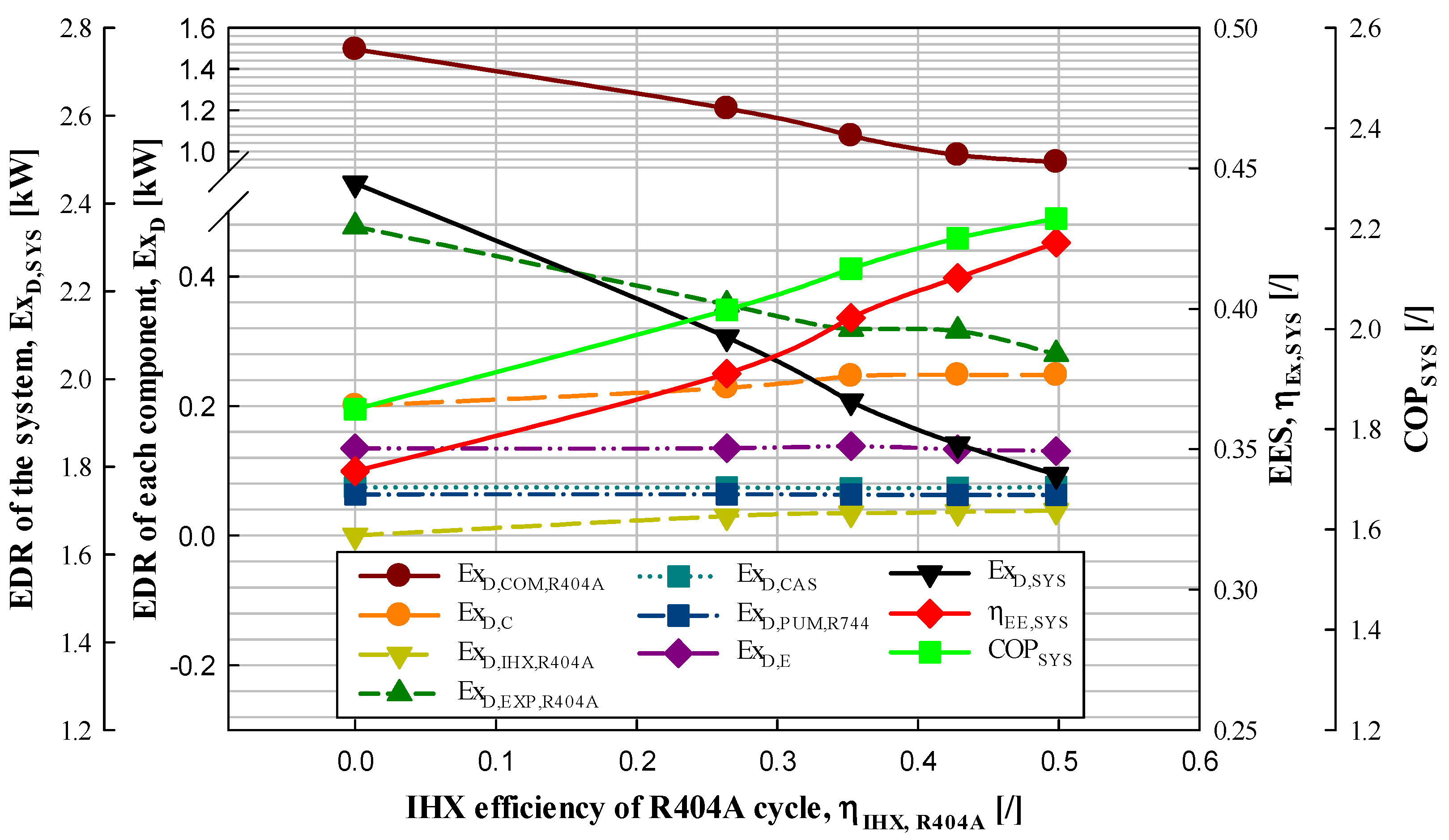

3.5. Effect of IHX Efficiency

3.6. Comparison of Experimental and Performance Analysis Data

4. Conclusions

- In order to lower the system EDR, the DSP, DSB, IHX efficiency and CET of the R404A cycle must be increased to the maximum, and the DSP of the R744 cycle and CT must be reduced to the minimum.

- Under the given conditions, the smallest change in the system EDR according to the change in each parameter is the DSP of the R744 cycle (0.3–1%), followed by the DSB of the R404A cycle (6.1–8.8%), IHX efficiency of the R404A cycle (3.8–14.3%), DSP of the R404A cycle (11.7–15.9%), CET (29.4–41.9%), and CT (35–47%).

- Also, in terms of the EES, the largest value obtained was the DSP of the R404A cycle (2.4–12.7%), followed by the IHX efficiency of the R404A cycle (3–10.2%), CET (2.2–8.7%), CT (4–6.9%), DSB of the R404A cycle (2.7–6.2%), and DSP of the R744 cycle (0.04–1.2%).

- The DSP of the R744 cycle does not need to be considered when designing the R404A IRS using R744 as a secondary fluid because the changes in the EDR of the IRS and EES are insignificant, with ranges of 0.3–1% and 0.04–1.2%, respectively.

- Among the EDRs of the components of the IRS, the largest one is the compressor, followed by the expansion valve, condenser, evaporator, CHX, pump, and IHX. Therefore, from energy and environmental aspects, great efforts must be made to reduce the EDR in the compressor and expansion valve when designing the R404A IRS using R744 as a secondary fluid.

- The trend of the system EDR shows the exact opposite of that of the system exergy efficiency and COP. The EES and COP of the system increase with a decrease in the system EDR.

- The EES can replace the COP of the system.

- The position and size of energy inefficiency, which cannot be identified via COP analysis, can be identified by evaluating the EDR of each component, thereby making it possible to maximize energy efficiency.

- Energy efficiency can be maximized via detailed, quantitative, and advanced exergy analysis. This may be considered in future work.

- The R404A refrigerant is regulated in developed countries, including Europe. Therefore, novel alternatives such as R448A and R449A must be examined.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ABBREVIATIONS | ||

| CC | Cascade condenser | |

| CE | Cascade evaporator | |

| CET | Cascade evaporation temperature | |

| CHX | Cascade heat exchanger | |

| COP | Coefficient of performance | |

| CRS | Cascade refrigeration system | |

| CT | Condensation temperature | |

| DSB | Degree of subcooling | |

| DSP | Degree of superheating | |

| DX | Direct expansion | |

| EDR | Exergy destruction rate | |

| EES | Exergy efficiency of the system | |

| EHC | Evaporation heat capacity | |

| ET | Evaporation temperature | |

| EV | Expansion valve | |

| IE | Inlet entropy | |

| IHX | Internal heat exchanger | |

| IRS | Indirect refrigeration system | |

| IX | Indirect expansion | |

| MFR | Mass flow rate | |

| OE | Outlet entropy | |

| PCC | Power consumption of the compressor | |

| PCP | Power consumption of the pump | |

| SYMBOLS | ||

| Exergy rate | kW | |

| Q | Heat capacity | kW |

| T | Temperature | °C |

| W | Power consumption | kW |

| S | Entropy | kJ/(kg·K) |

| GREEK SYMBOLS | ||

| Difference | ||

| Efficiency | ||

| SUPERSCRIPTS | ||

| M | Mechanical | |

| T | Thermal | |

| SUBSCRIPTS | ||

| C | Condensation or condenser | |

| CAS | Cascade heat exchanger | |

| COM | Compression | |

| D | Destruction | |

| E | Evaporation or evaporator | |

| Exergy | ||

| Exergy rate | kW | |

| EXP | Expansion valve | |

| F | Fuel | |

| IHX | Internal heat exchanger | |

| P | Product | |

| PUM | Pump | |

| R404A | R404A cycle | |

| R744 | R744 cycle | |

| SUB | Degree of subcooling | |

| SUP | Degree of superheating | |

| SYS | Total indirect refrigeration system | |

References

- Cabello, R.; Andreu-Nácher, A.; Sánchez, D.; Llopis, R.; Vidan-Falomir, F. Energy comparison based on experimental results of a cascade refrigeration system pairing R744 with R134a, R1234ze(E) and the natural refrigerants R290, R1270, R600a. Int. J. Refrig. 2023, 148, 131–142. [Google Scholar] [CrossRef]

- Vaishak, S.; Singha, P.; Dasgupta, M.S.; Hafner, A.; Widell, K.; Bhattacharyya, S.; Saini, S.K.; Arun, B.S.; Samuel, M.P.; Ninan, G. Performance analysis of a CO2/NH3 cascade refrigeration system with subcooling for low temperature freezing applications. Int. J. Refrig. 2023, 153, 140–154. [Google Scholar] [CrossRef]

- Staubach, D.; Michel, B.; Revellin, R. Refrigerant selection from an economic and TEWI analysis of cascade refrigeration systems in Europe based on annual weather data. Appl. Therm. Eng. 2023, 230, 120747. [Google Scholar] [CrossRef]

- Shi, R.; Bai, T.; Wan, J. Performance analysis of a dual-ejector enhanced two-stage auto-cascade refrigeration cycle for ultra-low temperature refrigeration. Appl. Therm. Eng. 2024, 240, 122152. [Google Scholar] [CrossRef]

- Hinde, D.; Zha, S.; Lan, L. Carbon dioxide in north American supermarkets. ASHRAE J. 2009, 51, 18–26. [Google Scholar]

- Kruse, H. Refrigerant use in Europe. ASHRAE J. 2000, 42, 16–25. [Google Scholar]

- Birndt, R.; Riedel, R.; Schenk, J. Dichtheit von Gewerbekälteanlagen (Tightness of Commercial Refrigeration Systems). Die Kälte- Und Klimatech. 2000, 9, 56–63. (In German) [Google Scholar]

- Bivens, D.; Gage, C. Commercial Refrigeration Systems Emissions. In Proceedings of the 15th Annual Earth Technologies Forum, Washington, DC, USA, 13–15 April 2004. [Google Scholar]

- Haaf, S.; Heinbokel, B. Alternative Kaltemittel fur Supermarkt-Kalteanlagen (Alternative Refrigerants for Supermarket Refrigeration Installations). In Proceedings of the Deutsche Kälte-Klima-Tagung, Magdeburg, Germany, 21–22 November 2002; Deutscher Kälte- und Klimatechnischer Verein DKV: Stuttgart, Germany, 2002; pp. 29–42. (In German). [Google Scholar]

- van den Hoogen, B.; van der Ree, H. The Dutch Approach to Reduce Emissions of Fluorinated Greenhouse Gases. In Proceedings of the IIR Conference on “Zero Leakage—Minimum Charge. Efficient Systems for Refrigeration, Air Conditioning and Heat Pumps”, Stockholm, Seden, 26–28 August 2002; International Institute of Refrigeration (IIR/IIF): Paris, France, 2002. [Google Scholar]

- Pedersen, P.H. Evaluation of the Possibilities of Substituting Potent Greenhouse Gases (HFCs, PFCs and SF6); Environmental Project No. 771; Danish Environmental Protection Agency: Copenhagen, Denmark, 2003. [Google Scholar]

- Radford, P. The Benefits of Refrigerant Inventory Control. In Proceedings of the Institute of Refrigeration Conference: R22 Phase Out–Impact on End Users Today; Institute of Refrigeration: London, UK, 1998. [Google Scholar]

- IPCC/TEAP; Metz, B.; Kuijpers, L.; Solomon, S.; Andersen, S.O.; Davidson, O.; Pons, J.; de Jager, D.; Kestin, T.; Manning, M.; et al. (Eds.) Safeguarding the Ozone Layer and the Global Climate System; Cambridge University Press: Cambridge, UK, 2005; p. 478. [Google Scholar]

- Available online: https://e360blog.copeland.com/ten-tips-for-preventing-refrigerant-leaks-in-supermarket-systems/ (accessed on 12 August 2024).

- Available online: https://www.coolingpost.com/world-news/us-supermarket-to-pay-400k-for-refrigerant-leaks/ (accessed on 12 August 2024).

- Queiroz, M.V.A.; Panato, V.H.; Antunes, A.H.P.; Parise, J.A.R.; Filho, E.P.B. Experimental comparison of a cascade refrigeration system operating with R744/R134a and R744/R404A. In Proceedings of the International Refrigeration and Air-Conditioning Conference, West Lafayette, IN, USA, 11–13 July 2016; Paper 1785. pp. 1–10. Available online: http://docs.lib.purdue.edu/iracc/1785 (accessed on 19 September 2020).

- Wikipedia. List of Refrigerants. Available online: https://en.wikipedia.org/wiki/List_of_refrigerants#cite_note-ASHRAE2007-34m-v-10 (accessed on 25 July 2021).

- Pearson, S.F. Cooling Method and Apparatus. British Patent Number 2258298, January 1995. [Google Scholar]

- Pearson, A. Carbon dioxide—New uses for an old refrigerant. Int. J. Refrig. 2005, 28, 1140–1148. [Google Scholar] [CrossRef]

- Pachai, A.C. Experience with CO2 as refrigerant in supermarkets. In Proceedings of the Sixth IIR-Gustav Lorentzen Conference on Natural Working Fluids, Glasgow, UK, 29 August–1 September 2004. [Google Scholar]

- Nilsson, P.O.; Rogstam, J.; Sawalha, S.; Shahzad, K. Ice rink refrigeration system with carbon dioxide as secondary fluid in copper tubes. In Proceedings of the Seventh IIR-Gustav Lorentzen Conference on Natural Working Fluids, Trondheim, Norway, 29–31 May 2006. [Google Scholar]

- Jahn, K. Natural refrigerants in dairy processing, supermarket refrigeration and air conditioning. In GTZ Proklima: Natural Refrigerants-Sustainable Ozone-and Climate-Friendly Alternatives to HCFCs Eschborn Germany; Deutsche Gesellschaft fur Technische Zusammenarbeit (GTZ) GmbH, German Technical Cooperation—Programme Proklima: Eschborn, Germany, 2008; pp. 313–317. [Google Scholar]

- Kaga, S.; Nomura, T.; Seki, K.; Hirano, A. Development of compact inverter refrigerating system using R600a/CO2 by Thermo Siphon. In Proceedings of the Eighth IIR-Gustav Lorentzen Conference on Natural Working Fluids, Copenhagen, Denmark, 7–10 September 2008; pp. 1011–1018. [Google Scholar]

- Sawalha, S.; Palm, B. Energy comsumption evaluation of indirect systems with CO2 as secondary refrigerant in supermarket refrigeration. In Proceedings of the International Congress of Refrigeration, Washington, DC, USA, 17–22 August 2003. ICR0434. [Google Scholar]

- Jeon, M.J.; Lee, J.H. Experimental investigation of R404A indirect refrigeration system applied internal heat exchanger. Part 1—Coefficient of performance characteristics. Energies 2024, 17, 4127. [Google Scholar] [CrossRef]

- Jeon, M.J. Experimental Analysis of the R744/R404A Cascade Refrigeration System with Internal Heat Exchanger. Part 2: Exergy Characteristics. Energies 2022, 15, 1251. [Google Scholar] [CrossRef]

- Bai, T.; Yu, J.; Yan, G. Advanced exergy analysis on a modified auto-cascade freezer cycle with an ejector. Energy 2016, 113, 385–398. [Google Scholar] [CrossRef]

- Sun, Z.; Liang, Y.; Liu, S.; Ji, W.; Zang, R.; Liang, R.; Guo, Z. Comparative analysis of thermodynamic performance of a cascade refrigeration system for refrigerant couples R41/R404A and R23/R404A. Appl. Energy 2016, 184, 19–25. [Google Scholar] [CrossRef]

- Morosuk, T.; Tsatsaronis, G. Advanced exergetic evaluation of refrigeration machines using different working fluids. Energy 2009, 34, 2248–2258. [Google Scholar] [CrossRef]

- Kline, S.J.; McClintock, F.A. Describing Uncertainties in Single Sample Experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- Moffat, R. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Yılmaz, D.; Sınar, Ü.; Özyurt, A.; Barış, Y.; Mancuhan, E. Ultra Düşük Sıcaklıklarda Çalışan İki Kademeli Bir Soğutma Sisteminde Aşırı Soğutma ve Isıtmanın Performansa Etkilerinin Sayısal İncelenmesi. AKU J. Sci. Eng. 2017, 17, 1172–1180. [Google Scholar] [CrossRef]

- Mosaffa, A.H.; Farshi, L.G.; Ferreira, C.A.I.; Rosen, M.A. Exergoeconomic and environmental analyses of CO2/NH3 cascade refrigeration systems equipped with different types of flash tank intercoolers. Energy Convers. Manag. 2016, 117, 442–453. [Google Scholar] [CrossRef]

- Nurhasanah, H.R.; Suhengki, P. Energy and Exergy Analysis of Cascade Refrigeration System Using MC22 and MC134 on HTC, R404A and R502 on LTC. J. Adv. Res. Fluid Mech. Therm. Sci. 2021, 80, 73–83. [Google Scholar] [CrossRef]

- Parekh, A.D.; Tailor, P.R. Thermodynamic analysis of cascade refrigeration, system using R12-R13, 290-R23 and R404A-R23. Int. J. Mech. Mechatron. Eng. 2014, 8, 1351–1356. [Google Scholar]

- Kilicarslan, A.; Hosoz, M. Energy and irreversibility analysis of a cascade refrigeration system for various refrigerant couples. Energy Convers. Manag. 2010, 51, 2947–2954. [Google Scholar] [CrossRef]

- Shilliday, J.A.; Tassou, S.A.; Shilliday, N. Comparative energy and exergy analysis of R744, R404A and R290 refrigeration cycles. Int. J. Low-Carbon Technol. 2009, 4, 104–111. [Google Scholar] [CrossRef]

- Yi, W.B. An Experimental Analysis on the Performance of Indirect Refrigeration System Using CO2 as a Secondary Refrigerant. Master’s Thesis, Pukyong National University, Busan, Republic of Korea, 2014. [Google Scholar]

| Country | Year(s) | Annual Refrigerant Loss | References |

|---|---|---|---|

| The Netherlands | 1999 | 3.2% | Hoogen et al., 2002 [10] |

| Germany | 2000–2000 | 5–10% | Birndt et al., 2000 [7]; Haaf and Heinbokel, 2002 [9] |

| Denmark | 2003 | 10% | Pedersen, 2003 [11] |

| Norway | 2002–2003 | 14% | Bivens and Gage, 2004 [8] |

| Sweden | 1993 1998 2001 | 14% 12.5% 10.4% | Bivens and Gage, 2004 [8] |

| United Kingdom | 1998 | 14.4% | Radford, 1998 [12] |

| USA | 2000–2002 | 13% and 18%, 19% and 22% | Bivens and Gage, 2004 [8] |

| USA | 2020 | 25% | [14] |

| USA | 2019–2021 | 40%, 59%, and 46% | [15] |

| Authors | Year | Primary Fluid | Secondary Fluid | Analysis Method |

|---|---|---|---|---|

| Sawalha and Palm [24] | 2003 | R404A | R744 | Experiment and Simulation |

| Pachai [20] | 2004 | R290 + R170 | R744, PG | Experiment |

| Pearson [19] | 2005 | - | R744 | Review |

| Nilsson et al. [21] | 2006 | R744 | Experiment | |

| Jahn [22] | 2008 | - | R744 | Experiment |

| Hinde et al. [5] | 2008 | R404A, R507 | R744, PG | Experiment |

| Kaga et al. [23] | 2008 | R600a | R744 | Experiment |

| Cycle | Component | Range | Unit |

|---|---|---|---|

| R404A cycle | CT | 20, 30, 40 *, 50 | °C |

| IHX efficiency | 0 *, 1, 2, 3, 4 | stage | |

| DSB | 0 *, 5, 10, 15, 20 | °C | |

| DSP | 10, 20 *, 30, 40 | °C | |

| CET | −40, −30, −25 *, −20, −10, 0 | °C | |

| Temperature difference of the cascade heat exchanger | 5 * | °C | |

| R744 cycle | |||

| ET and cascade CT | −35, −25, −20 *, −15, −5, 5 | °C | |

| DSB | 1 * | °C | |

| DSP | 10 *, 20, 30, 40 | °C |

| Component | Characteristics |

|---|---|

| R404A compressor | Bock; model: HGX34P/380-4S. Displacement with 1450 min−1:33.1 m3 h−1. Number of cylinders: 4. Weight: 96 kg. Max. power consumption: 11.1 kW |

| R744 magnetic drive gear pump | Micropump; model: Series 5000. Flow range: 0–13.5 L/min. Maximum system pressure: 103 bar (1500 psi). Temperature range: −46 to 121 °C |

| Evaporator | Custom-built; type: horizontal double tube. Material: copper tube. Internal diameter of the inner tube: 11.46 mm. Internal diameter of the outer tube: 33.27 mm. Length of the evaporator: 8000 mm |

| Condenser | Alfa Laval; model: ACH-70X-50H-F. Heat exchanged: 38.44 kW. Heat transfer area: 2.45 m2 |

| Cascade heat exchanger | Alfa Laval; model: ACH-70X-50H-F. Heat exchanged: 10.86 kW. Heat transfer area: 2.45 m2 |

| Cycle | Component | , kW | , kW | , kW |

|---|---|---|---|---|

| R404A cycle | Compressor (1→2) | (- | ||

| Condenser (2→4) | () | |||

| IHX (4→5, 8→1) | () | |||

| EV (5→6) | ()() | |||

| Cascade heat exchanger (6→8, 12→14) | () () | |||

| R744 cycle | ||||

| Pump (14→15) | () | |||

| Evaporator (15→12) | () |

| Parameter | Unit | Uncertainty |

|---|---|---|

| MFR | [kg/min] | 0.0100 |

| PCC | [kW] | 0.0350 |

| PCP | [W] | 0.2350 |

| COP of the total IRS | [/] | 0.0135 |

| EDR of the system | [kW] | 0.0175 |

| Temperature | [°C] | 0.2000 |

| [°C] | 0.4000 | |

| Pressure | [kPa] | 5.2700 |

| (Pressure drop) | [kPa] | 0.0100 |

| MFR of coolant | [kg/h] | 7.5300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, M.-J.; Lee, J.-H. Experimental Investigation of R404A Indirect Refrigeration System Applied Internal Heat Exchanger: Part 2—Exergy Characteristics. Energies 2024, 17, 4143. https://doi.org/10.3390/en17164143

Jeon M-J, Lee J-H. Experimental Investigation of R404A Indirect Refrigeration System Applied Internal Heat Exchanger: Part 2—Exergy Characteristics. Energies. 2024; 17(16):4143. https://doi.org/10.3390/en17164143

Chicago/Turabian StyleJeon, Min-Ju, and Joon-Hyuk Lee. 2024. "Experimental Investigation of R404A Indirect Refrigeration System Applied Internal Heat Exchanger: Part 2—Exergy Characteristics" Energies 17, no. 16: 4143. https://doi.org/10.3390/en17164143

APA StyleJeon, M.-J., & Lee, J.-H. (2024). Experimental Investigation of R404A Indirect Refrigeration System Applied Internal Heat Exchanger: Part 2—Exergy Characteristics. Energies, 17(16), 4143. https://doi.org/10.3390/en17164143