Abstract

Small modular reactors (SMRs) are currently advancing towards increased degrees of automation and intelligence, with intelligent control emerging as a prominent trend in SMR development. SMRs exhibit significant variations in design specifications and safety auxiliary system design as compared to conventional commercial nuclear power reactors. Consequently, defect diagnostic techniques that rely on commercial nuclear power plants are not appropriate for SMRs. This study designed a defect detection system for the System-integrated Modular Advanced ReacTor SMR by utilizing the PCTRAN/SMR V1.0 software and a deep learning neural network structure. Through the comparison of several neural network designs, it was discovered that the CNN-BiLSTM model, which utilizes bidirectional data processing, obtained a fault diagnostic accuracy of 97.33%. This result confirms the accuracy and effectiveness of the fault diagnosis system. This strongly supports the eventual implementation of autonomous control for SMRs.

1. Introduction

To meet market demands for “safety, flexibility, and multipurpose use”, small modular reactors (SMRs) with their high safety, modular design, and wide range of applications have become a research hotspot in the nuclear industry. Currently, 11 countries worldwide are engaged in SMR research, with over 50 publicly disclosed reactor designs [,,]. Compared to large reactors, SMRs have lower investment costs and shorter construction periods. They can be built in phases, enabling a two-step approach of construction and operation, allowing for operational revenues to fund further construction.

Moreover, SMRs have versatile applications. By increasing the number of modules, they can achieve centralized power generation to meet the output demands of large nuclear power plants. Additionally, they can establish medium- and small-sized power grids, providing electricity to remote mountainous areas, islands, industrial parks, offshore oil platforms, and nuclear-powered ships. SMRs can also supply heating and power to cities, provide industrial heat and steam, and facilitate seawater desalination and the treatment of inland brackish water [,,,,].

Compared to traditional commercial nuclear power plants, SMRs exhibit strong coupling characteristics, nonlinearity, and complex dynamic behaviors. The small capacity and high heat exchange capability of direct-current steam generators, as well as the sensitivity of steam pressure and superheat to feedwater flow rate, endow SMRs with rapid feedback mechanisms. At the same time, the IAEA report indicates that human error remains the leading cause of operational events in nuclear power plants [,]. Consequently, high demands are placed on decision making and automatic control performance. The design parameters of SMRs differ significantly from those of traditional commercial nuclear power plants, and there are substantial changes in safety and auxiliary systems, making traditional fault diagnosis systems unsuitable for SMRs.

Therefore, researching SMR fault diagnosis models and methods and developing practical and effective fault detection and diagnosis systems is of paramount importance. These advancements can reduce the need for operational staff to make judgments and decisions or to perform manual operations, thereby lowering the likelihood of misjudgments and operational errors. Additionally, they can reduce requirements regarding the number and skill level of operational personnel and decrease operating costs [,,].

This research employs a data-driven fault diagnostic approach to create an intelligent fault detection system for small modular reactors (SMRs). The arrangement of the paper’s structure is as follows: Section 1 provides an overview of the research history and present status of small modular reactors (SMRs) both locally and globally. It succinctly highlights the distinctions between SMRs and standard commercial nuclear power facilities. Additionally, it establishes the format of the study. Section 2 presents a concise overview of the chosen System-integrated Modular Advanced Reactor (SMART) SMR system and its simulation software, PCTRAN/SMR. It also provides a brief analysis of how parameters vary under fault conditions for SMRs in comparison to conventional commercial nuclear power plants. Section 3 outlines the fundamental concepts of the deep learning neural network employed in this paper. Section 4 provides an elaborate account of the architecture of the created neural network model, along with an examination of its performance testing and accuracy in defect diagnosis. Section 5 provides a summary of the paper’s findings, examines the limitations of the intelligent accident fault diagnostic system for SMRs that was built, and proposes areas for further research.

2. Small Modular Reactor Simulator Introduction

2.1. System-Integrated Modular Advanced ReacTor

SMART, also known as the System-integrated Modular Advanced ReacTor, is a highly promising small-scale nuclear reactor. The reactor is a comprehensive system that incorporates well-developed technology and sophisticated design elements, with the goal of improving both safety and economic effectiveness. The combination of intrinsic safety enhancement features with dependable passive safety systems leads to an improvement in both safety and dependability. Economic enhancements are attained by streamlining the system, using modular components, shortening building time, and improving plant availability. The initial safety evaluations of certain critical mishaps guarantee the dependability of the SMART reactor system.

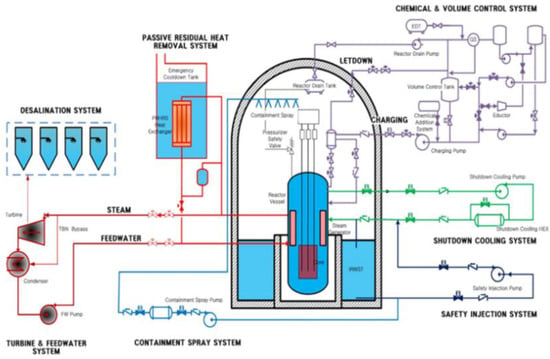

The SMART reactor is a highly sophisticated small modular reactor that has a rated thermal output of 330 MWt. The design of the system primarily incorporates intrinsic safety elements, such as the integrated layout of the reactor coolant system and greater natural circulation capabilities, which contribute to better safety. By implementing a passive residual heat removal system and an advanced LOCA (loss-of-coolant accident) mitigation system, substantial improvements in safety are achieved. Figure 1 displays the design flow diagram of the system [].

Figure 1.

Flowchart of the SMR system.

2.2. PCTRAN Software

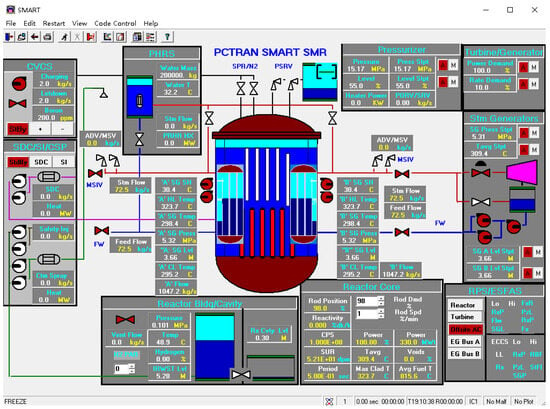

Figure 2 illustrates the PCTRAN/SMART graphical user interface, showing the positioning of a heater at the middle top of the reactor vessel. The Chemical and Volume Control System (CVCS) is tasked with the regulation of the liquid level in the pressurizer and the management of the chemical composition of the coolant. This is accomplished by employing charging pumps and relief valves. The boron concentration can be increased or decreased by simply hitting the “+” or “−” buttons, respectively. The pressurizer indicates the liquid level, pressure, setpoints, and flow rates of the safety release valve. The control panels for the Shutdown Cooling System (SDC), the Safety Injection (SI) System, and the Containment Spray (CS) System may be found beneath the CVCS [,,,].

Figure 2.

PCTRAN/SMART running interface.

The turbine/generator control panel is located in the upper right corner. By manipulating the demand and rate of change, the turbine power may be regulated to guarantee that both the reactor and the entire plant function in accordance with the predetermined design specifications. Immediately behind this is the pressure regulator for the steam generator. The pace at which feedwater flows can be modified in order to sustain the required amount of steam generator (SG). Below is the Reactor Protection System (RPS), which consists of buttons for controlling the reactor vessel limit, trip, and AC power. Trip buttons that have been activated are visually highlighted in the color red. The Emergency Safety Features Actuation System (ESFAS), responsible for initiating Safety Injection (SI) and Containment Spray (CS) excursions, is likewise indicated by the color red.

The reactor core controller, located in the center of the bottom right portion, allows for the adjustment of the total withdrawal ratio of control rod assemblies. This adjustment is used to manage the power of the core. In this operational mode, the turbine closely tracks the functioning of the reactor. The display indicates the levels of neutron flux, reactivity, core fuel temperature, and void fraction. On the left side, there is a containment panel that shows the thermohydraulic conditions. The In-Containment Refueling Water Storage Tank (IRWST) is responsible for providing water to the Safety Injection (SI) and Containment Spray (CS) pumps. Additionally, it serves as a collection point for any excess water that may occur during coolant leakage incidents. During the process of managing a core meltdown, a protective mechanism is activated to transport water into the reactor cavity in order to cool the bottom of the vessel.

The PCTRAN/SMART V1.0 software closely adheres to the requirements of the Korean APR1400 and OPR1000 versions. The Korea Institute of Nuclear Safety (KINS), the Korea Electric Power Corporation (KEPCO), the Korea Hydro & Nuclear Power (KHNP), and five institutions have granted authorization for the usage of these models. SMART incorporates both passive and active heat dissipation devices, along with hydrogen recombiners for mitigating catastrophic accidents. These systems have undergone comprehensive simulations in both normal and accident scenarios.

2.3. SMR and PWR LOCA Accident Simulation Analysis

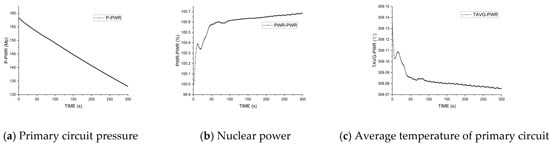

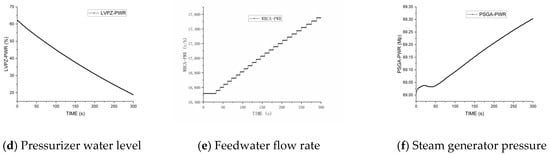

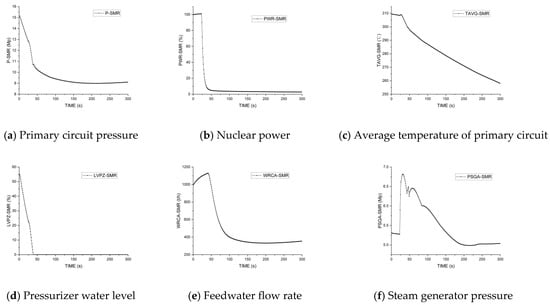

Using PCTRAN/PWR V1.0 and PCTRAN/SMR V1.0 software, we simulated a LOCA scenario with a 5 cm2 break at the cold leg during normal operation. The key parameters analyzed included the primary circuit pressure, the nuclear power, the average temperature of the primary circuit, the pressurizer water level, the feedwater flow rate, and the steam generator pressure. The operational trends are illustrated in the figures. A comparison of Figure 3 and Figure 4 reveals significant differences in the response of commercial pressurized water reactors (PWRs) and SMRs under identical LOCA conditions.

Figure 3.

Operation trend diagrams of commercial pressurized water reactor.

Figure 4.

Operation trend diagrams of small modular reactor.

In a commercial PWR experiencing a LOCA with a 5 cm2 break at the cold leg, the primary loop pressure and pressurizer water level drop due to the breach. The CVCS triggers a protection mechanism that increases the charging flow to compensate for the coolant lost through the break, resulting in an upward trend in primary coolant flow. The excess subcooled water added causes the coolant temperature to drop. Due to the reactor’s negative feedback mechanism, the decrease in coolant temperature leads to an increase in nuclear power. To dissipate the additional heat generated by the increased nuclear power, the heat transfer rate in the steam generator rises, causing the steam generator pressure to increase.

In the case of an SMR experiencing a 5 cm2 LOCA at the cold leg, the pressure and pressurizer water level also drop, prompting the CVCS to activate and compensate for the lost coolant. However, due to the difference in design scale between SMRs and commercial PWRs, the CVCS in an SMR cannot fully compensate for the coolant lost in a 5 cm2 LOCA. Consequently, the rate of decrease in the pressure and the pressurizer water level is more rapid in an SMR compared to a commercial PWR. About 25 s after the incident, the pressure drops below the reactor protection threshold, triggering a reactor shutdown signal. Before shutdown, the parameter trends are consistent with those in a commercial PWR; after shutdown, nuclear power drops sharply but remains at about 7% due to decay heat. Concurrently, the primary loop pressure, the average primary loop temperature, and the feedwater flow rate decrease as nuclear power declines. Steam generator pressure initially rises due to the rapid drop in feedwater flow post-shutdown, then follows a decreasing trend, with brief rises when the primary-loop safety relief valves close, but overall continues to decline.

Analysis of the operational data from commercial PWRs and SMRs demonstrates that the design and operational parameters differ significantly between these reactor types. The parameter change gradients are more pronounced in SMRs under the same fault conditions, indicating that fault diagnosis systems developed for commercial PWRs are not suitable for SMRs.

3. CNN-BILSTM Neural Network Model

3.1. CNN Neural Network

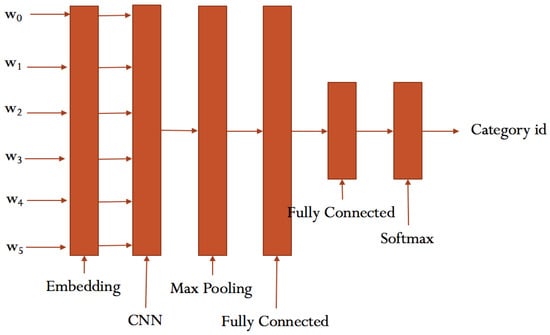

A Convolutional Neural Network (CNN) is a type of deep neural network in which neuron structures adjust their weights and biases through learning. Figure 5 depicts the basic structure of a CNN []. It consists of an input layer, an output layer, and several hidden layers, typically including convolutional layers, pooling layers, and fully connected layers.

Figure 5.

CNN network basic structure diagram.

The input layer of CNNs [] is capable of processing multidimensional data. A multidimensional array is fed into the input layer of the CNN, as expressed in Equation (1):

In the equation, represents the initial input data and and are the learnable parameters (biases and weights) associated with the th layer. The functions and represent the respective functions at level and step , with their outputs structured as feature mapping matrices.

The convolutional layer of a CNN is composed of feature maps obtained through convolution operations with several convolutional kernels. Its essence lies in extracting relevant features, as represented by Equation (2):

where represents the th feature map in the th layer, denotes the activation function, is the number of feature maps, denotes the convolution operation, is the number of the convolution kernel, is the bias of the th feature map in layer , and represents the weight of the th convolutional kernel of layer .

The pooling layer of a CNN, also known as the downsampling layer, follows directly after the convolutional layer. Its main function is to appropriately compress the model, thereby enhancing robustness and computational speed, while also helping to prevent overfitting to some extent. The formula for the max pooling method is shown as Equation (3):

where represents the output of the pooling layer at position , denotes the input from the previous layer, and the max operation computes the maximum value within the pooling window.

After the pooling layer comes the fully connected layer in a Convolutional Neural Network (CNN). The data output from the pooling layer is flattened into a one-dimensional vector, which is then fed into the fully connected layer for feature extraction. Subsequently, the output from the fully connected layer is input into a Softmax classifier for classification [,,].

3.2. BiLSTM Neural Network

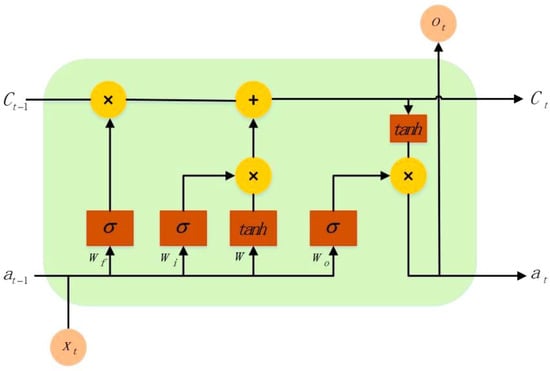

Recurrent Neural Networks (RNNs) are a type of neural networks specifically created to handle consecutive data samples. In an RNN, each layer not only transmits information to the next layer, but also transfers a hidden state to the same layer for the purpose of processing the following sample. Just like how Convolutional Neural Networks (CNNs) can be readily expanded to accommodate pictures with huge dimensions and some CNNs can handle images of variable sizes, Recurrent Neural Networks (RNNs) can be expanded to handle longer sequences of data, and most RNNs can process data with varying sequence lengths. An RNN may be conceptualized as a neural network that is completely linked and has self-recurrent feedback. The network architecture is depicted in Figure 6, with W representing the self-recurrent parameter matrix from the hidden layer to itself, U representing the parameter matrix from the input layer to the hidden layer, and V representing the parameter matrix from the hidden layer to the output layer.

Figure 6.

LSTM network basic structure diagram.

Nevertheless, Recurrent Neural Networks (RNNs) commonly encounter the challenge of long-term dependencies, resulting in the occurrence of disappearing and bursting gradients. In 1997, Sepp Hochreiter introduced the Long Short-Term Memory (LSTM) network as a solution to this issue [,]. The LSTM neural network cell consists of a forget gate (), an input gate (), and an output gate (). The input gate is utilized to modify the structural state value of the unit being incorporated into the cell. The forget gate controls the proportion of the cell value from the previous time step that is retained. The output gate produces a concealed state value () that functions as a supplementary input for the subsequent time step. The LSTM cell produces the structural state value and the hidden state value at time , based on the signal. These values are then used as extra inputs at time . This technique enables the network to autonomously and internally regulate the updating of each unit value during training, providing the network with a memory that may vary in length. The cellular architecture of the Long Short-Term Memory (LSTM) model is illustrated in Figure 4, while the corresponding mathematical expressions may be found in Equations (4)–(9) [].

where represents the input vector at time step ; is the weight matrix; denotes the bias vector; represents the activation function; and are, respectively, the cell-state and hidden-state values at time steps and ; tanh is the hyperbolic tangent activation function; is the input gate; is the forget gate; is the output gate; and represents the output value at time step .

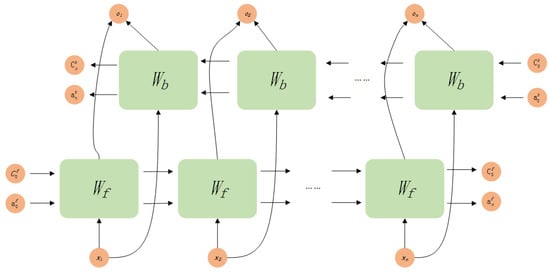

The Bidirectional Long Short-Term Memory (BiLSTM) network is an extension of the LSTM network introduced to capture hidden relationships in sequential data more effectively []. Unlike unidirectional LSTM networks, BiLSTM networks can recursively process and provide feedback for both past and future hidden states. This capability allows BiLSTM networks to uncover intrinsic connections between current data and data from both past and future time steps, thereby enhancing model prediction accuracy and data utilization.

As shown in Figure 7, the BiLSTM network structure comprises two LSTM layers: one for forward propagation and another for backward propagation. From a temporal perspective, BiLSTM adds a reverse data flow from future to past to the unidirectional flow from past to future in traditional LSTM networks. The hidden layers used for past and future data are independent of each other, enabling BiLSTM to better exploit the temporal characteristics of the data. As depicted, the forward and backward hidden layers do not interact and can be considered as two independent networks with opposite data flows.

Figure 7.

BiLSTM network basic structure diagram.

4. Nuclear Power Plant Accident Diagnosis

4.1. Data Preprocessing

In this model selection process, six different operational conditions were chosen: normal operation, in-containment loss of coolant, ex-containment loss of coolant, containment steam pipe rupture, main pump failure, and turbine trip. Using the PCTRAN/SMR software, various accident scenarios for a nuclear power plant were simulated, and data were extracted for these conditions [,].

Six features were selected for this experiment: nuclear power, pressurizer pressure, pressurizer water level, coolant flow rate, average coolant temperature, and steam generator pressure. Due to the wide range of values for each feature, a linear normalization method [] (i.e., min–max normalization) was used to normalize the features to improve the model’s accuracy. The normalization formula is given in Equation (6), where and are the minimum and maximum values of the feature, is the initial feature value, and is the normalized feature value [].

For each of the six operational conditions (normal operation, in-containment loss of coolant, ex-containment loss of coolant, containment steam pipe rupture, main pump failure, and turbine trip), 500 continuous data sets with a time length of 5 s were randomly sampled. After preprocessing, the data were split into training, validation, and test sets in a ratio of 7:1:2 []. One-hot encoding was used to encode the operational conditions. This method uses an N-bit status register to encode N states, where each state has its own independent register bit, and, at any time, only one bit is active. A total of 3000 data sets (each being a six-dimensional array with a time length of 7 s) were randomly sampled across the six conditions. These were then divided into 2100 training sets, 300 validation sets, and 600 test sets.

4.2. Model Training and Prediction

This study evaluated the model’s performance using accuracy and the categorical cross-entropy loss function. Accuracy measures the ratio of correctly classified samples to the total number of samples. The categorical cross-entropy loss function assesses the discrepancy between the probability distribution predicted by the model and the true distribution. Let denote the total number of samples and denote the number of correctly classified samples. The accuracy is calculated as shown in Equation (11):

The categorical cross-entropy loss function is computed using Equation (12), where represents the total number of classes for motion images, denotes the predicted values, and represents the true values:

Through these formulas, a value closer to 1 indicates higher accuracy, while a value closer to 0 indicates better prediction performance [,].

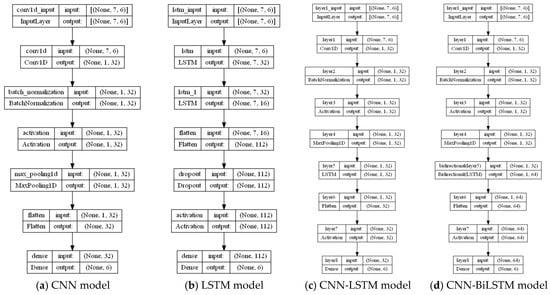

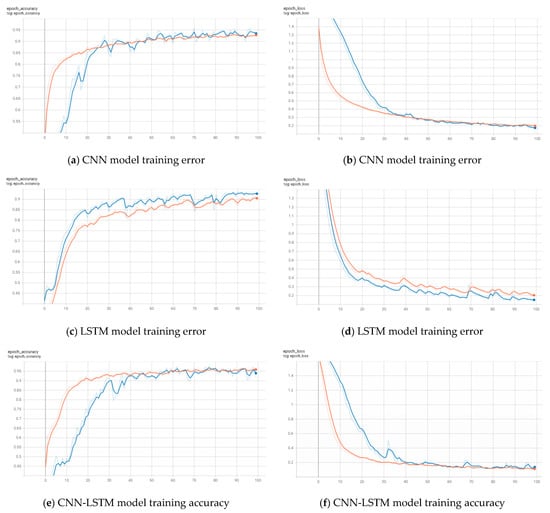

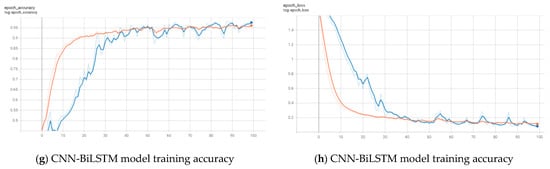

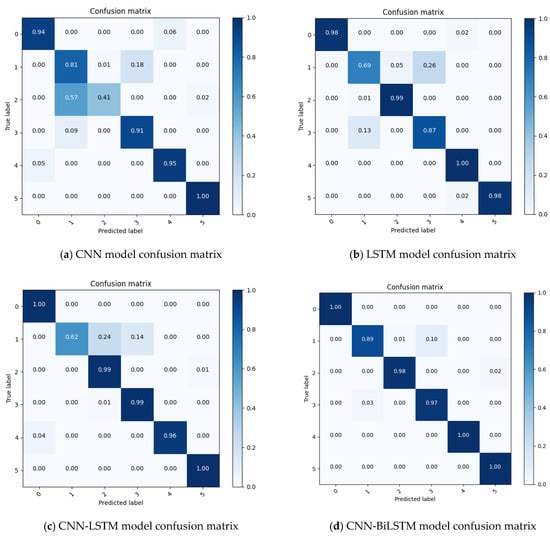

Four different models, namely, the CNN model, the LSTM model, the CNN-LSTM model, and the CNN-BiLSTM model, were employed to conduct modeling on the training and validation sets [,,,]. The outcomes of this analysis are presented in Figure 8. The training process was supervised by invoking the Tensorboard module, and the outcomes are displayed in Figure 9 (the training process is depicted by the orange curve, while the validation process is represented by the blue curve). Figure 9 demonstrates that the accuracy of all four models improves and the loss lowers as the number of training iterations rises. After 100 repetitions, the accuracy and loss trends reach a state of relative stability. The CNN model in the trained models achieved a training accuracy of 93.05%, a training loss of 0.2138, a validation accuracy of 82.67%, and a validation loss of 0.3408. The LSTM model attained a training accuracy of 90.24%, a training loss of 0.2391, a validation accuracy of 93.67%, and a validation loss of 0.1570. The CNN-LSTM model attained a training accuracy of 95.76%, a training loss of 0.1143, a validation accuracy of 92.00%, and a validation loss of 0.1545. The CNN-BiLSTM model attained a training accuracy of 96.19%, a training loss of 0.1170, a validation accuracy of 96.33%, and a validation loss of 0.0963. The analysis of the findings indicated that both the CNN and CNN-LSTM models have limited generalization capabilities and face challenges in adapting to unfamiliar inputs. The validation accuracy of the LSTM model surpasses its training accuracy, suggesting potential over-regularization. The CNN-BiLSTM model has nearly equal accuracies in both training and validation, suggesting a high level of stability. Table 1 and Figure 10 provide the prediction results and confusion matrices for the four models that were evaluated using the test set. As seen in Figure 10, when the predicted results align with the actual results, they are located on the diagonal. Conversely, if they do not align, they are situated in different places.

Figure 8.

Model structure diagrams.

Figure 9.

Neural network training diagrams.

Table 1.

Model prediction results table.

Figure 10.

Prediction confusion matrix graphs.

Through testing on the validation set, the CNN model achieved a minimum diagnostic accuracy of 83.67%, whereas the CNN-BiLSTM model achieved the highest accuracy of 97.33%. Analysis of the confusion matrix (Figure 8) revealed that for Label 1 (loss of coolant inside the containment vessel), all four models exhibited higher misclassification rates compared to the other five operational states. This suggests that the trends in operation for the six key parameters may be similar between Label 2 (loss of coolant outside the containment vessel) and Label 3 (rupture of the steam pipe in the containment vessel). However, the CNN-BiLSTM model, leveraging bidirectional data patterns, demonstrated a superior ability to differentiate between different operational modes compared to the other models.

These results indicate that the CNN-BiLSTM neural network-based fault diagnostic model for nuclear power plants can accurately assess operational conditions. In the event of a nuclear power plant accident, this model can effectively assist operators in rapidly identifying the type of fault, thereby enhancing the overall safety of SMRs (small modular reactors).

4.3. Discussion

The objective of this work was to develop a data-driven intelligent system for diagnosing faults in small modular reactors (SMRs). Through the utilization of deep learning neural network modeling using datasets acquired from simulators, we have drawn several significant conclusions. Firstly, this study provides evidence that small modular reactors (SMRs) may greatly enhance the efficiency of defect identification for operators. The CNN fault diagnosis model has a prediction accuracy of 83.67%, the LSTM fault diagnostic model has a prediction accuracy of 91.83%, the CNN-LSTM fault diagnosis model has a prediction accuracy of 92.67%, and the CNN-BiLSTM fault diagnosis model has a prediction accuracy of 97.33%. The observed outcomes may be ascribed to the neural network models’ capacity to analyze substantial quantities of intricate sensor data and autonomously extract valuable characteristics from them. This allows the algorithms to recognize subtle patterns and trends that are hard to identify using conventional approaches. Furthermore, throughout the training process, the models acquire the ability to discern distinctions among different failure modes and promptly detect these patterns in real-time data. This feature enhances the efficiency and precision of defect diagnostics. Incorporating several data sources, such as vibration, temperature, pressure, etc., enables a thorough analysis, enhancing the precision and comprehensiveness of the diagnosis. This study provides more evidence to support the effectiveness and feasibility of intelligent fault diagnostic systems in comparison to the previous literature. Notwithstanding the favorable findings, there are still certain constraints. Initially, the research exclusively centered on SMART small reactors; hence, the findings may not have universal applicability. Furthermore, the data utilized in this study were only obtained from simulation software. While the physical processes in the simulation program generally align with real events, there may be variations in individual parameter values. Hence, it is imperative for future research to take into account model migration and employ authentic accident records to authenticate the findings of this study. This study offers operators a potent tool to bolster the advancement of intelligent fault diagnostic systems in SMR operational monitoring. Furthermore, policymakers might utilize the findings of this study to develop appropriate policies aimed at fostering the digitalization of SMRs.

5. Conclusions

For the small modular reactor SMART, this paper establishes four different neural networks based on a deep learning framework: CNN, LSTM, CNN-LSTM, and CNN-BiLSTM. These networks were trained and tested using fault data generated by PCTRAN/SMR, achieving prediction accuracies of 83.67%, 91.83%, 92.67%, and 97.33%, respectively. The results indicate that all four intelligent fault diagnosis models can effectively achieve the goal of accident diagnosis, with the CNN-BiLSTM neural network model performing the best. This demonstrates the importance of bidirectional data modes in time-series prediction. Despite the positive conclusions, there are still some limitations. Firstly, the study focused only on a single small reactor and lacks generalizability. Secondly, only simulated data were used in this study. Although the physical processes in the simulation software align with real-world trends, the specific parameter values may differ. Therefore, future research should consider data model transfer and the use of real accident data to further validate the conclusions of this study.

Author Contributions

Conceptualization, J.L. (Jichong Lei), X.F. and C.Y.; Methodology, C.R. and Z.P.; Software, J.L. (Jichong Lei); Validation, J.L. (Jichong Lei) and H.H.; Formal analysis, C.R.; Investigation, J.L. (Jie Liu) and J.H.; Resources, H.H. and C.Y.; Data curation, J.L. (Jichong Lei); Writing—original draft, C.R. and J.L. (Jichong Lei); Writing—review & editing, J.L. (Jichong Lei); Visualization, J.L. (Jie Liu) and Z.P.; Supervision, X.Y. and T.Y.; Project administration, J.H., X.F., X.Y. and T.Y.; Funding acquisition, X.Y. and T.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (no. U2267207), the Open Fund of the State Key Laboratory (KFKT-24-2021006), and the Scientific Fund of Hunan Provincial Education Department (23A0629).

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Abbreviations

| Abbreviations | Definitions |

| SMR | Small modular reactor |

| SMART | System-integrated Modular Advanced ReacTor |

| LOCA | Loss-of-coolant accident |

| CVCS | Chemical and Volume Control System |

| CDS | Shutdown Cooling System |

| SG | Steam generator |

| SI | Safety Injection |

| CS | Containment Spray |

| RPS | Reactor Protection System |

| ESFAS | Emergency Safety Features Actuation System |

| IRWST | In-Containment Refueling Water Storage Tank |

| KINS | Korea Institute of Nuclear Safety |

| KEPCO | Korea Electric Power Corporation |

| KHNP | Korea Hydro & Nuclear Power |

| PWR | Pressurized water reactor |

| CNN | Convolutional Neural Network |

| RNN | Recurrent Neural Network |

| LSTM | Long Short-Term Memory |

| BILSTM | Bidirectional Long Short-Term Memory |

References

- Locatelli, G.; Bingham, C.; Mancini, M. Small modular reactors: A comprehensive overview of their economics and strategic aspects. Prog. Nucl. Energy 2014, 73, 75–85. [Google Scholar] [CrossRef]

- Cooper, M. Small modular reactors and the future of nuclear power in the United States. Energy Res. Soc. Sci. 2014, 3, 161–177. [Google Scholar] [CrossRef]

- Shobeiri, E.; Genco, F.; Hoornweg, D.; Tokuhiro, A. Small modular reactor deployment and obstacles to Be overcome. Energies 2023, 16, 3468. [Google Scholar] [CrossRef]

- Zarębski, P.; Katarzyński, D. Small Modular Reactors (SMRs) as a Solution for Renewable Energy Gaps: Spatial Analysis for Polish Strategy. Energies 2023, 16, 6491. [Google Scholar] [CrossRef]

- Temiz, M.; Dincer, I. Development of a hybridized small modular reactor and solar-based energy system for useful commodities required for sustainable cities. Energy 2024, 286, 129562. [Google Scholar] [CrossRef]

- Vujić, J.; Bergmann, R.M.; Škoda, R.; Miletić, M. Small modular reactors: Simpler, safer, cheaper? Energy 2012, 45, 288–295. [Google Scholar] [CrossRef]

- Mignacca, B.; Locatelli, G. Economics and finance of Small Modular Reactors: A systematic review and research agenda. Renew. Sustain. Energy Rev. 2020, 118, 109519. [Google Scholar] [CrossRef]

- Zohuri, B.; McDaniel, P. Advanced Smaller Modular Reactors; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Calle, V. Applicability of the IAEA Safety Standards to Non-Water-Cooled Reactors and Small Modular Reactors; International Atomic Energy Agency: Vienna, Austria, 2024. [Google Scholar]

- International Atomic Energy Agency. Instrumentation and Control Systems for Advanced Small Modular Reactors; International Atomic Energy Agency: Vienna, Austria, 2017. [Google Scholar]

- Bhowmik, P.K.; Perez, C.E.E.; Fishler, J.D.; Prieto, S.A.B.; Reichow, I.D.; Johnson, J.T.; Sabharwall, P.; O’Brien, J.E. Integral and separate effects test facilities to support water cooled small modular reactors: A review. Prog. Nucl. Energy 2023, 160, 104697. [Google Scholar] [CrossRef]

- Saeed, H.A.; Peng, M.; Wang, H.; Rasool, A. Autonomous control model for emergency operation of small modular reactor. Ann. Nucl. Energy 2023, 190, 109874. [Google Scholar] [CrossRef]

- Xie, W.; Atherton, J.; Bai, J.; Farazi, F.; Mosbach, S.; Akroyd, J.; Kraft, M. A nuclear future? Small Modular Reactors in a carbon tax-driven transition to clean energy. Appl. Energy 2024, 364, 123128. [Google Scholar] [CrossRef]

- Kim, K.K.; Lee, W.; Choi, S.; Kim, H.R.; Ha, J. SMART: The first licensed advanced integral reactor. J. Energy Power Eng. 2014, 8, 94. [Google Scholar]

- Liu, B.; Lei, J.; Xie, J.; Zhou, J. Development and Validation of a Nuclear Power Plant Fault Diagnosis System Based on Deep Learning. Energies 2022, 15, 8629. [Google Scholar] [CrossRef]

- Gu, H.; Liu, G.; Li, J.; Xie, H.; Wen, H. A Framework Based on Deep Learning for Predicting Multiple Safety-Critical Parameter Trends in Nuclear Power Plants. Sustainability 2023, 15, 6310. [Google Scholar] [CrossRef]

- Wang, L.; Sun, W.; Zhao, J.; Liu, D. A speed-governing system model with over-frequency protection for nuclear power generating units. Energies 2019, 13, 173. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, J.; Liu, D.; Lin, Y.; Zhao, Y.; Lin, Z.; Zhao, T.; Lei, Y. Parameter identification with the random perturbation particle swarm optimization method and sensitivity analysis of an advanced pressurized water reactor nuclear power plant model for power systems. Energies 2017, 10, 173. [Google Scholar] [CrossRef]

- Lu, J.; Tan, L.; Jiang, H. Review on convolutional neural network (CNN) applied to plant leaf disease classification. Agriculture 2021, 11, 707. [Google Scholar] [CrossRef]

- Ren, C.; Li, H.; Lei, J.; Liu, J.; Li, W.; Gao, K.; Huang, G.; Yang, X.; Yu, T. A CNN-LSTM–Based Model to Fault Diagnosis for CPR1000. Nucl. Technol. 2023, 209, 1365–1372. [Google Scholar] [CrossRef]

- Salehi, A.W.; Khan, S.; Gupta, G.; Alabduallah, B.I.; Almjally, A.; Alsolai, H.; Siddiqui, T.; Mellit, A. A study of CNN and transfer learning in medical imaging: Advantages, challenges, future scope. Sustainability 2023, 15, 5930. [Google Scholar] [CrossRef]

- Santos, A.A.; Marcato Junior, J.; Araújo, M.S.; Di Martini, D.R.; Tetila, E.C.; Siqueira, H.L.; Aoki, C.; Eltner, A.; Matsubara, E.T.; Pistori, H.; et al. Assessment of CNN-based methods for individual tree detection on images captured by RGB cameras attached to UAVs. Sensors 2019, 19, 3595. [Google Scholar] [CrossRef]

- Tropea, M.; Fedele, G.; De Luca, R.; Miriello, D.; De Rango, F. Automatic stones classification through a CNN-based approach. Sensors 2022, 22, 6292. [Google Scholar] [CrossRef] [PubMed]

- Ghimire, S.; Deo, R.C.; Wang, H.; Al-Musaylh, M.S.; Casillas-Pérez, D.; Salcedo-Sanz, S. Stacked LSTM sequence-to-sequence autoencoder with feature selection for daily solar radiation prediction: A review and new modeling results. Energies 2022, 15, 1061. [Google Scholar] [CrossRef]

- Lei, J.; Ren, C.; Li, W.; Fu, L.; Li, Z.; Ni, Z.; Li, Y.; Liu, C.; Zhang, H.; Chen, Z.; et al. Prediction of crucial nuclear power plant parameters using long short-term memory neural networks. Int. J. Energy Res. 2022, 46, 21467–21479. [Google Scholar] [CrossRef]

- Siami-Namini, S.; Tavakoli, N.; Namin, A.S. The performance of LSTM and BiLSTM in forecasting time series. In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 3285–3292. [Google Scholar]

- Lei, J.; Chen, Z.; Zhou, J.; Yang, C.; Ren, C.; Li, W.; Xie, C.; Ni, Z.; Huang, G.; Li, L.; et al. Research on the preliminary prediction of nuclear core design based on machine learning. Nucl. Technol. 2022, 208, 1223–1232. [Google Scholar] [CrossRef]

- Lei, J.C.; Zhou, J.D.; Zhao, Y.N.; Chen, Z.P.; Zhao, P.C.; Xie, C.; Ni, Z.N.; Yu, T.; Xie, J.S. Prediction of burn-up nucleus density based on machine learning. Int. J. Energy Res. 2021, 45, 14052–14061. [Google Scholar] [CrossRef]

- Rezaeian, N.; Gurina, R.; Saltykova, O.A.; Hezla, L.; Nohurov, M.; Kashyzadeh, K.R. Novel GA-Based DNN Architecture for Identifying the Failure Mode with High Accuracy and Analyzing Its Effects on the System. Appl. Sci. 2024, 14, 3354. [Google Scholar] [CrossRef]

- Lei, J.; Yang, C.; Ren, C.; Li, W.; Liu, C.; Sun, A.; Li, Y.; Chen, Z.; Yu, T. Development and validation of a deep learning-based model for predicting burnup nuclide density. Int. J. Energy Res. 2022, 46, 21257–21265. [Google Scholar] [CrossRef]

- AL-Ghamdi, M.; AL-Ghamdi AA, L.M.; Ragab, M. A Hybrid DNN Multilayered LSTM Model for Energy Consumption Prediction. Appl. Sci. 2023, 13, 11408. [Google Scholar] [CrossRef]

- Ren, C.; He, L.; Lei, J.; Liu, J.; Huang, G.; Gao, K.; Qu, H.; Zhang, Y.; Li, W.; Yang, X.; et al. Neutron transport calculation for the BEAVRS core based on the LSTM neural network. Sci. Rep. 2023, 13, 14670. [Google Scholar] [CrossRef] [PubMed]

- Aksan, F.; Li, Y.; Suresh, V.; Janik, P. CNN-LSTM vs. LSTM-CNN to predict power flow direction: A case study of the high-voltage subnet of northeast Germany. Sensors 2023, 23, 901. [Google Scholar] [CrossRef] [PubMed]

- Khorram, S.; Jehbez, N. A hybrid CNN-LSTM approach for monthly reservoir inflow forecasting. Water Resour. Manag. 2023, 37, 4097–4121. [Google Scholar] [CrossRef]

- Méndez, M.; Merayo, M.G.; Núñez, M. Long-term traffic flow forecasting using a hybrid CNN-BiLSTM model. Eng. Appl. Artif. Intell. 2023, 121, 106041. [Google Scholar] [CrossRef]

- Fu, G.; Wei, Q.; Yang, Y.; Li, C. Bearing fault diagnosis based on CNN-BiLSTM and residual module. Meas. Sci. Technol. 2023, 34, 125050. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).