Abstract

Bioethanol, an alcohol produced by microbial fermentation, is traditionally produced from sugar-rich plants such as sugar cane, sugar beet and maize. However, there is growing interest in the use of lignocellulose, an abundant and inexpensive renewable energy source, as a potential substitute for the production of biofuels and biochemicals. Yeast Saccharomyces cerevisiae, which is commonly used for ethanol fermentation, cannot cope with lignocellulose due to a lack of lignocellulolytic enzymes and the inefficient functioning of the pentose phosphate pathway. The aim of this research was to isolate yeasts that can efficiently produce bioethanol and valuable byproducts from both glucose and xylose in a two-stage fermentation process using brewer’s spent grains. This approach should maximize sugar utilization and improve the economic viability of bioethanol production while contributing to waste valorization and sustainability. Kluyveromyces marxianus and Candida krusei were identified and tested with different initial concentrations of glucose and xylose. The results showed that both yeasts produced bioethanol from glucose but were inefficient with xylose, yielding valuable compounds, such as 2,3-butanediol and glycerol instead. A two-stage fermentation was then carried out with weak acidic hydrolysate from brewer’s spent grain. In the first stage, glucose was fermented by S. cerevisiae to produce bioethanol; in the second stage, xylose was fermented by K. marxianus and C. krusei to obtain other valuable products.

1. Introduction

Bioethanol, a renewable energy source produced by microbial fermentation, plays an important role in reducing dependence on fossil fuels and mitigating greenhouse gas emissions [1,2,3]. Traditionally, bioethanol production has relied on feedstocks such as sugar cane, sugar beet and maize, which are rich in easily fermentable sugars [4,5].

However, this traditional approach has raised concerns about the competition between food and fuel, land use and the sustainability of using edible crops for biofuel production. As a result, there is growing interest in the use of lignocellulosic biomass as an alternative feedstock. Lignocellulosic biomass, derived from agricultural residues, forestry waste and dedicated energy crops, is abundant, cost-effective, and does not compete with food resources, making it a promising candidate for sustainable bioethanol production [6,7,8,9].

Brewer’s spent grain (BSG) is a major byproduct of the beer brewing process. Every hectoliter of beer produces 15–20 kg of BSG, which means that around 34 million tons of wet BSG are produced worldwide every year [10]. In Europe, breweries produce around 3.5 million tons of BSG per year [11]. BSG is rich in cellulose (12–25%), hemicellulose (20–25%), lignin (12–28%) and protein (19–30%). It is an underutilized resource that is mainly used as animal feed or disposed of in landfills and has a market value of 35 euros per ton [12]. The rich chemical composition and high fiber content of BSG make it an excellent feedstock for a wide range of commercial processes [9,13]. Its applications extend to biotechnology, as well as thermochemical and biochemical process technologies. BSG can be used to produce renewable energy, the cultivation of substrates, enzyme production and the food industry, e.g., for bread production. It can also be converted into valuable products such as ethanol, butanol, xylitol, activated carbon, charcoal, lignin and oligosaccharides [9,10].

The efficient conversion of BSG into fermentable sugars requires the breakdown of cellulose and hemicellulose into their constituent monosaccharides: hexoses (such as glucose) and pentoses (such as xylose) [6,14]. This poses a challenge, as the conventional yeast Saccharomyces cerevisiae, widely used for industrial ethanol production, is optimized for hexose fermentation [15]. S. cerevisiae is unsuitable for the conversion of lignocellulosic biomass into bioethanol because it lacks lignocellulolytic enzymes, which are necessary to break down complex polymers such as cellulose and hemicellulose into fermentable sugars. In addition, S. cerevisiae has an inefficient pentose phosphate pathway, which limits its ability to ferment pentoses such as xylose. These enzymatic limitations result in lower ethanol yields, require extensive pretreatment processes and lead to incomplete sugar utilization, making S. cerevisiae less effective and economical for the conversion of lignocellulosic biomass.

These limitations significantly hinder the efficient utilization of lignocellulosic biomass for bioethanol production. To address these challenges, investigations are focused on the identification and development of alternative microorganisms that can efficiently ferment both hexoses and pentoses [16]. Various non-conventional yeasts, including Schizosaccharomyces pombe, Kluyveromyces lactis and species from the genera Candida and Pichia, have shown potential due to their diverse metabolic capabilities. These yeasts have enzymatic pathways that can process the complex sugar mixtures from lignocellulosic hydrolysates more effectively [17,18].

In this study, two promising strains, Kluyveromyces marxianus and Candida krusei, were isolated and evaluated as yeast strains capable of efficiently producing bioethanol and valuable byproducts from both glucose and xylose. This approach should maximize sugar utilization and improve the economic viability of bioethanol production while contributing to waste valorization and sustainability. To further investigate and optimize the fermentation process, a two-stage fermentation strategy using weak acidic hydrolysate from BSG was applied. In the first stage, S. cerevisiae was used to ferment glucose, efficiently producing bioethanol. In the second stage, the remaining xylose was fermented by K. marxianus and C. krusei, resulting in the production of additional valuable bioproducts. This two-stage approach aims not only to maximize the utilization of all fermentable sugars in lignocellulosic biomass, but also to improve the economics of the bioethanol production process by diversifying the range of valuable bioproducts obtained. By integrating the metabolic strengths of different yeast species, more efficient and sustainable bioprocesses can be developed for bioethanol production from lignocellulosic biomass. This approach contributes to the advancement of renewable energy technologies while addressing waste management issues in the brewing industry, creating a more circular and sustainable bioeconomy.

2. Materials and Methods

2.1. Materials

The following chemicals were used to perform the experiments: 2,3-butanediol was purchased from Acros Organics (Waltham, MA, USA); 3,5-dinitrosalicylic acid, diammonium hydrogen phosphate and potassium sodium tartrate tetrahydrate were purchased from Fluka (Buchs, Switzerland). Malt extract agar, potato dextrose agar and yeast extract were purchased from Biolife Italiana (Milan, Italy) and activated charcoal from Lach-Ner (Zagreb, Croatia). Ammonium sulfate was procured from Kemika (Zagreb, Croatia), and the Analytical Profile Index (API 20 C AUX) from BioMérieux® (Marcy-l’Étoile, France). D(+)-glucose, ethanol, glycerol, calcium hydroxide, and sodium hydroxide were supplied by Gram mol (Zagreb, Croatia). Disodium hydrogen phosphate and D(+)-xylose were supplied by VWR Chemicals (Radnor, PA, USA). Glucose GOD-PAP assay was purchased from Greiner (Bahlingen, Germany). Sodium dihydrogen phosphate monohydrate was purchased from Merck (Darmstadt, Germany).

All chemicals and reagents were of analytical grade and were used without any further purification.

The materials used for yeast isolation, biowaste consisting of fruit and vegetable, was collected from markets in Zagreb, Croatia, while the piece of rotten wood was collected from a forest near Zagreb, Croatia.

The acidic hydrolysate of BSG was obtained from the University of Zagreb, Faculty of Food Technology and Biotechnology. Acid hydrolysis of BSG was performed by mixing 1 kg of dry BSG and 10 L of 0.5% H2SO4 in a high-pressure reactor constructed as a double-jacket vessel (total volume of 20 L). The process was carried out at 180 °C for 10 min. After processing, 6.8 L of the acidic hydrolysate was cooled, centrifuged at 5000 rpm for 30 min, and the supernatant was separated and used for further experiments [19].

The enzymatic hydrolysate of BSG was obtained from the Josip Juraj Strossmayer University of Osijek, Faculty of Food Technology Osijek. Briefly, the BSG was dried at 60 °C and stored at room temperature (T = 25 °C). An amount of 30 g of BSG was mixed with 55 mL of distilled water in 720 mL laboratory glassware. The prepared sample was sterilized at a temperature of 121 °C for 15 min. After cooling to room temperature (T = 25 °C), the substrate was inoculated with five mycelial plugs (diameter 1 cm) of the fungus Thermomyces lanuginosus growing on a culture medium containing potato dextrose agar and yeast extract suspended in 5 mL of sterile distilled water. After inoculation, enzymatic hydrolysis of the lignocellulose was carried out at 45 °C for 7 days in an incubator [20]. The extraction of the biologically treated BSG was performed in distilled water at a solid/liquid ratio of 1:7. The extraction was carried out at 25 °C for 1 h at 200 rpm on a laboratory shaker. After extraction, the samples were filtered by vacuum filtration, sterilized at 121 °C for 15 min and stored at 4 °C before further use.

2.2. Methods

2.2.1. Analytical Methods

Glucose was determined according to the glucose GOD-PAP assay [21], and total sugars were determined by the DNS method [22]. Ethanol was analyzed by GC (Shimadzu GC-2014, Kyoto, Japan) according to the method described elsewhere [23]. The concentrations of 2,3-butanediol and glycerol were determined according to the method described by Budžaki et al. [24]. The biomass concentration was determined gravimetrically [25].

2.2.2. Yeasts Isolation from Biowaste and Rotten Wood

Yeasts were isolated from biowaste and rotten wood. Briefly, dry biowaste (10 g) was added to 100 mL of sterile water. This mixture was homogenized at room temperature (T = 25 °C) for 60 min on a rotary shaker at 160 rpm. Subsequently, 1 mL of the homogenized sample was transferred to a Petri dish and mixed with malt extract agar. The rotten wood was crushed and added to 50 mL of liquid potato dextrose agar medium with added xylose. The prepared suspension was homogenized for 24 h at room temperature (T = 25 °C) on a rotary shaker at 160 rpm. After homogenization, 1 mL of the suspension was transferred to a Petri dish, and potato dextrose agar was added. The samples were incubated at 28 °C for 3–5 days. After incubation, the number of colonies grown on the malt/potato dextrose agar was determined. A yeast colony that was morphologically distinct and represented a dominant colony was repeatedly subcultured using the streak plate method to obtain a separate and pure colony. Once a pure colony was obtained, the yeast was examined under a light microscope (Motic B1-220A, Binocular, Weltzar, Germany) and identified using API 20 C AUX.

2.2.3. Single-Substrate Fermentation in a Batch Reactor

The fermentation of glucose and xylose with the yeasts S. cerevisiae, K. marxianus and C. krusei at an initial biomass concentration of γ = 1 g/L was carried out on nutrient media with different initial concentrations of glucose (γG = 5 g/L, γG = 10 g/L and γG = 50 g/L) or xylose (γXy = 5 g/L, γXy = 10 g/L and γXy = 20 g/L). In addition to sugars, culture media with a volume of 200 mL contained ultrapure water, yeast extract (γ = 1.5 g/L), salts: (NH4)2HPO4 (γ = 1.0 g/L) and (NH4)2SO4 (γ = 1.0 g/L). The prepared culture media were sterilized in Erlenmeyer flasks at T = 121 °C and cooled to room temperature (T = 25 °C). Fermentation started by adding selected yeast to the medium. The process was carried out in a batch reactor at room temperature (T = 25 °C) on a laboratory shaker at 100 rpm. Sterile samples were taken from the flasks at various time intervals. The biomass concentration was determined in each sample and then the sample was filtered (CHROMAFIL Xtra PTFE-45/25, MACHEREY-NAGEL GmbH & Co. KG, Düren, Germany) to determine the concentration of sugar and bioethanol. The bioprocess efficiency parameters were calculated based on the values obtained.

2.2.4. Two-Substrate Fermentation with K. marxianus and C. krusei Yeasts in a Batch Reactor

The one-stage fermentation (Figure 1a) of a model solution containing glucose and xylose in two batch reactors was carried out in a culture medium with the following composition: ultrapure water, yeast extract (γ = 1.5 g/L), salts: (NH4)2HPO4 (γ = 1.0 g/L) and (NH4)2SO4 (γ = 1.0 g/L), glucose (γG = 18 g/L) and xylose (γXy = 12 g/L). After the sterilization of the medium (30 min at T = 121 °C), 1 g/L K. marxianus or C. krusei in combination with S. cerevisiae was inoculated sterilely into the cooled medium. The process was carried out at room temperature (T = 25 °C) on a laboratory shaker, at 100 rpm. At different time intervals, sterile samples were taken from the flasks at various time intervals and the concentrations of biomass, sugar and bioethanol were determined. The bioprocess efficiency parameters were calculated on the basis of the values obtained.

Figure 1.

(a) One- and (b) two-stage fermentation.

The two-stage fermentation (Figure 1b) of a model solution of glucose and xylose in a batch reactor was carried out on a culture medium with the same composition as in the one-stage fermentation. After the sterilization of the medium, the cooled medium was sterilely inoculated with the yeast S. cerevisiae γ = 3.6 g/L. The process was carried out at room temperature (T = 25 °C) on a laboratory shaker at 100 rpm. Sterile samples were taken from the flasks at various time intervals, and the concentrations of biomass, sugar and bioethanol were determined. Based on the values obtained, the bioprocess efficiency parameters were calculated. When all the glucose was consumed, the entire medium was centrifuged (10 min at 5000 rpm) to remove the yeast cells. In the next step, 1 g/L of K. marxianus or C. krusei yeast was added to the same medium. The experiment was continued under the same process conditions. At various time intervals, sterile samples were taken from the flasks and the concentrations of biomass, sugar and bioethanol were determined. The bioprocess efficiency parameters were calculated on the basis of the values obtained.

2.2.5. Two-Stage Fermentation of the Acidic Hydrolysate of BSG

Prior to fermentation, the obtained acidic hydrolysate of BSG was neutralized in four different ways to determine the best neutralization procedure. An amount of 800 mL of the hydrolysate was additionally centrifuged at 5000 rpm for 10 min. After centrifugation, the supernatant was divided into four parts, each with a volume of 200 mL. Two hydrolysates were treated for 1 h with 18 g/L activated charcoal. The activated charcoal was then removed by vacuum filtration through a Büchner funnel. One charcoal treated hydrolysate and one untreated hydrolysate were treated with NaOH to obtain a pH of 5.8, as the initial pH was 1.9. Two other hydrolysates were treated by adding Ca(OH)2 until the same pH was reached. The Ca(OH)2-treated hydrolysate was then centrifuged for 10 min to remove the precipitate formed.

After neutralization, γ = 1.5 g/L yeast extract and γ = 1.0 g/L of the salts (NH4)2HPO4 and (NH4)2SO4 were added to all hydrolysates. The resulting medium was sterilized at a temperature of 121 °C for 15 min. After cooling, a two-stage process was carried out as described in Section 2.2.4.

2.2.6. Mathematical Modelling and Calculation of Bioprocess Efficiency Parameters

The evaluation of the success of the fermentation process was based on the following indicators (Equations (1)–(4)) [5]:

Product yield (YP):

Conversion coefficient of substrate to product (YP/S):

Bioprocess efficiency (E):

Bioprocess productivity (Pr):

where is the final concentration of the product (ethanol, 2,3-butanediol or glycerol) (g/L), is the initial concentration of the product (g/L), is the final concentration of the substrate (glucose or xylose) (g/L), is the initial concentration of the substrate (g/L), is the theoretical conversion coefficient of the substrate into ethanol (g/g), and t is time (h).

The mathematical model of the fermentation process comprises a reactor and a kinetic model. In order to develop a mathematical model of fermentation, it was necessary to set mass balances for the substrates glucose (G), xylose (Xy), the product bioethanol (E) and the microbial biomass (X) (Equations (5)–(8)) [26].

where μ is specific growth rate described by the extended Monod’s equation (Equation (9)). Monod’s equation is extended by the expression for the inhibition of the substrate, since high concentrations of bioethanol in the mixture inhibit the growth of the yeast cells and the product formation rate [27].

where γP′ is the ethanol concentration above which cells do not produce ethanol and μmax and KS are empirical coefficients of the Monod equation.

2.2.7. Data Processing

The experimental data were obtained in the form of the time dependence of the concentration of biomass, substrate and product under the conditions the experiments were carried out. The parameters of the mathematical model of the process were estimated from the experimental results by non-linear regression, i.e., using the simplex method and the least squares method integrated in the Scientist software package (MicroMath® Scientist® for WindowsTM, version 2.0, Salt Lake City, UT, USA). The difference between the values of the experimental data and the values of the data calculated by the model is given as the sum of the squares of the deviations. The Scientist program package also provides other statistical parameters that indicate the success of the assessment, such as standard deviation, R2, correlation and model selection criteria. In addition, the Scientist program package provides the standard deviations of the estimated parameters, which indicate that the value of the parameter lies within the specified range with a probability of 95%.

3. Results and Discussion

3.1. Batch Fermentation of Brewer’s Spent Grain Hydrolysate Obtained by Weak Acid Pretreatment

According to the data available in the literature [28,29], the most common average composition of BSG (% dry matter) is as follows: cellulose (25.4%), hemicellulose (21.8%), lignin (11.9%), proteins (24%), lipids (10.6%) and ash (2.4%), the rest being secondary constituents such as ferulic acid, coumaric acid, etc. The high proportion of polysaccharides in BSG makes it an interesting substrate for the production of bioethanol. When using lignocellulosic feedstocks for biofuel production, processing is required to extract lignin and break down cellulose and hemicellulose into simpler sugars [30]. Two types of hydrolysis of BSG were carried out during the investigations.

The first method was enzymatic hydrolysis with the fungus T. lanuginosus, as described in Section 2.1. At the end of the process (t = 7 days), the concentration of total reducing sugars in the sterilized hydrolysates was 0.5 mg/mL, while in the non-sterilized samples, it was 1 mg/mL. The amount of sugar obtained was low, making this hydrolysate unsuitable for further studies. The second process of BSG hydrolysis was carried out by adding weak acid. After processing the BSG with weak acid, the hydrolysate obtained contained the highest amount of glucose (18.3 g/L; 60.61%), followed by xylose (7.90 g/L; 26.16%) and arabinose (3.99 g/L; 13.21%). In addition to carbohydrates, organic acids were also present in the samples, namely formic acid (1.45 g/L) and acetic acid (1.6 g/L). The obtained concentrations were below reported inhibitory concentrations [9]. It should be noted that hydrolysates may also contain various toxic substances that were not detected but may inhibit the growth of yeasts [19,31]. For this reason, part of the hydrolysate obtained was treated with activated charcoal to remove potentially harmful compounds (detoxification) [9]. In addition, the pH of the droplet after acid hydrolysis was 1.9. To adjust the pH to 5.8, which is optimal for carrying out the fermentation process, the samples were treated in two ways: by adding NaOH or by adding Ca(OH)2. In addition to increasing the pH, the addition of Ca(OH)2 could lead to the removal of some compounds that are undesirable for fermentation, as they are absorbed by Ca(OH)2 and removed from the substrate by precipitation. Among the many factors that affect fermentation are the type of microorganism, temperature, pH, size of substrate particles and nutrients [32]. To promote yeast growth and support its physiological activity, a source of phosphorus and nitrogen, yeast extract and the salts (NH4)2HPO4 and (NH4)2SO4 were added to the substrate during the fermentation process in addition to fermentable sugar [33]. Phosphorus is contained in nucleic acids and phospholipids and is therefore necessary for the growth of all yeasts [34]. In addition, the addition of phosphorus and nitrogen to the culture media improves the utilization of sugars and increases the production of bioethanol. Yeast extract is also an important source of peptides, amino acids and vitamins, so its addition should increase the bioethanol yield [35].

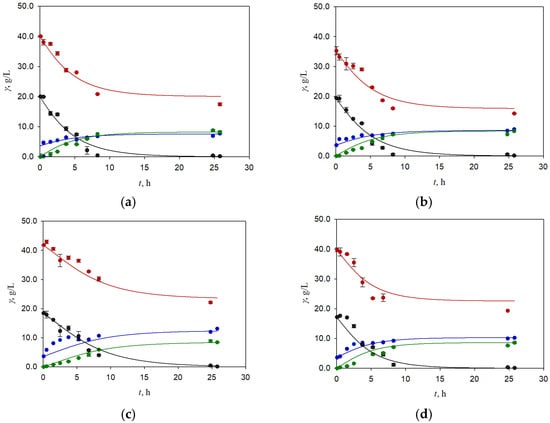

The dynamic change in the concentration of biomass, bioethanol, glucose and total sugars during the S. cerevisiae fermentation of BSG neutralized in the four ways is shown in Figure 2.

Figure 2.

Dynamic change in the concentration of microbial biomass (●), bioethanol (●), glucose (●) and total sugars (●) for the acid hydrolysate of BSG treated with (a) NaOH, (b) activated charcoal and NaOH, (c) Ca(OH)2, (d) activated charcoal and Ca(OH)2 ((-) mathematical model of the process).

As can be seen from the experimental results, the total sugar consumption corresponds in all cases to the total glucose consumption, since S. cerevisiae does not ferment the other sugars present in the hydrolysate (pentose, arabinose and xylose). Most of the glucose was consumed within the first 10 h of the process. Thereafter, a slight decrease in the total sugar concentration was observed, possibly due to the presence of other hexoses in the hydrolysate. The microbial biomass concentration increased during the first 2.5 h, probably due to the presence of dissolved oxygen. During this time, bioethanol production was low. After the oxygen is consumed, alcoholic fermentation starts and the bioethanol concentration increases. The maximum bioethanol concentrations achieved in the experiments conducted with all hydrolysates were similar and amounted to 8.192 ± 0.251 g/L (a), 8.335 ± 0.015 g/L (b), 8.403 ± 0.114 g/L (c) and 8.576 ± 0.247 g/L (d), respectively. In recent years, the use of BSG as a substrate for ethanol production has been explored. Various pretreatment methods, such as alkaline, acidic and hydrothermal processes, are commonly used to break down the lignocellulosic structure and make the sugars in the cellulose fraction accessible [36,37,38,39,40,41]. These methods have resulted in ethanol concentrations ranging from 4.3 to 22.0 g/L, with yields between 23% and 81% [36,37,38,39,40,41,42,43,44]. The results of this study are consistent with these results, but similar concentrations were also observed when the rice straw was treated with S. cerevisiae, Bacillus subtilis NA15 and Phanerochaete chrysosporium 787 after a microwave–alkali–acid treatment (8.97 g/L) [45]; wheat straw fermented with S. cerevisiae (6.3 g/L) [46]; tofu waste fermented with S. cerevisiae and A. niger (7.69 g/L) [47]; newspaper waste fermented with S. cerevisiae (7.3 g/L) [48], etc. Despite this progress, these yields are still considered insufficient for large-scale bioethanol production, and further work is needed.

Table 1 shows the indicators of the success of the process, allowing a comparison of the experiments carried out in different ways with the acid hydrolysates produced.

Table 1.

Bioprocess efficiency parameters of batch fermentation carried out with acidic hydrolysate of BSG.

According to the bioprocess efficiency parameters, the acidic hydrolysates treated with activated charcoal show slightly higher efficiency and productivity, which can be explained by the fact that the activated carbon probably bound some of the minor components present in the hydrolysate, which can act as inhibitors. In acidic hydrolysate treated with activated charcoal and Ca(OH)2 (Figure 2d), the glucose was consumed more slowly at the beginning of the process, i.e., the yeast needed a longer time to adapt [9]. Nevertheless, this system showed high efficiency E = 98.148 ± 2.829% and productivity Pr = 0.332 ± 0.010 g/(L·h).

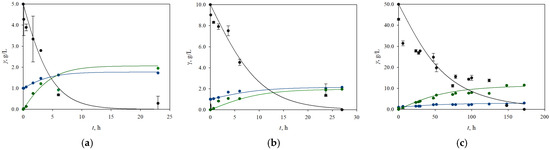

To better understand the process, a mathematical model was proposed to describe the dynamics of the process. Three independent experiments were proposed, in which the influence of the initial glucose concentration on bioethanol production was monitored (Figure 3).

Figure 3.

Dynamic change in the concentration of microbial biomass (●), bioethanol (●) and glucose (●) during the anaerobic fermentation of Saccharomyces cerevisiae for different initial concentrations of glucose: (a) 5 g/L, (b) 10 g/L, (c) 50 g/L ((-) mathematical model of the process).

Based on the results obtained, the kinetic parameters of the Monod model were estimated: µmax (maximum specific growth rate of yeast cells) and KS (saturation constant) using Equations (5)–(9). In all three cases, Ks was estimated to be 12.603 g/L, while µmax was estimated to be 0.502 1/h, 0.222 1/h and 0.022 1/h for glucose concentrations 5, 10 and 50 g/L, respectively. As can be observed, the glucose concentration has an effect on growth kinetics, and it can be observed that µmax decreases with increasing glucose concentration at the same initial cell concentration. The highest value of µmax = 0.502 1/h was obtained in the experiment with an initial glucose concentration of 5.0 g/L, while the lowest value of µmax = 0.022 1/h was obtained in the experiment with an initial glucose concentration of 50 g/L. The estimated parameters and the proposed mathematical models (Equations (5)–(9)) were used to describe the dynamic change in the concentration of microbial biomass, bioethanol, glucose and total sugars, and as can be seen, a good agreement between the model and the experimental results was obtained, indicating that the proposed model can be used for further process optimization.

On the other hand, there was still the issue of the unused sugars that remained in the medium. In order to utilize the remaining sugars in the next stage, two promising strains, Kluyveromyces marxianus and Candida krusei, were isolated as described in Section 2.2.2. and evaluated as yeast strains capable of efficiently producing bioethanol from both glucose and xylose.

3.2. The Influence of Different Initial Concentrations of Glucose and Xylose on the Process Productivity and Growth of the Yeasts K. marxianus and C. krusei

After the yeasts K. marxiansus and C. krusei were isolated and identified, their ability to metabolize hexose and pentose was tested. K. marxiansus was selected because the growth of this yeast at temperatures up to 52 °C and the ability to ferment at temperatures above 40 °C are very important from an industrial point of view. Fast fermentation at elevated temperatures can reduce the cost of refrigeration and the continuous transition from fermentation to distillation, reduce the risk of contamination and allow simultaneous saccharification and fermentation. In addition, K. marxianus can use a wide range of cheap substrates, such as molasses and whey for bioethanol production and, unlike S. cerevisiae, can also use xylose as a substrate for bioethanol production. Its disadvantage is that its growth is inhibited even at low concentrations of bioethanol in the mixture [49]. Despite the above-mentioned properties, K. marxianus has only recently been studied more intensively, and the results so far show that it has the potential to become a leading yeast for many biotechnological processes. In addition to bioethanol production, this yeast also produces other industrially important compounds such as 2,3-butanediol and glycerol [50]. C. krusei is attracting the attention of more and more scientists due to its biotechnological potential, but still has limited applications due to its pathogenic nature. The maximum temperature at which it can grow is 43–45 °C, which is desirable for fermentation. This yeast is also resistant to various inhibitors obtained by the pretreatment of lignocellulosic biomass. It is tolerant to the presence of acetic acid (up to 75 mmol/L) and formic acid (up to 10 mmol/L). It is also resistant to various environmental conditions, such as pH changes, high salt concentrations and high temperatures. Due to its high resistance, it is considered a promising alternative for sustainable bioethanol production [51]. In addition, bioethanol production does not generate byproducts such as succinic acid produced by S. cerevisiae or glycerol and 2,3-butanediol produced by K. marxianus [52].

In the alcoholic fermentation of glucose, the initial concentration of γG = 1 g/L should ultimately yield about 0.47 g/L of bioethanol. An identical amount of bioethanol should result from the fermentation of 1 g/L xylose. However, too high sugar concentrations in the substrate can have a negative, i.e., inhibitory effect on the yeasts, i.e., on the entire process [53]. It is therefore necessary to find the optimum sugar concentration. To investigate the influence of the initial concentration of glucose and xylose on the efficiency and productivity of the process, experiments were carried out with different initial concentrations of glucose (5 g/L, 10 g/L and 50 g/L) and xylose (5, 10 and 20 g/L). All experiments were carried out in such a way that fermentation was stopped when the concentration of glucose and xylose dropped to zero.

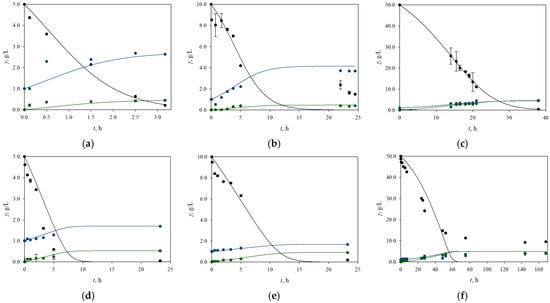

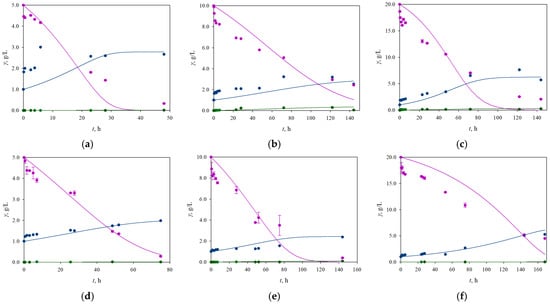

Figure 4 shows that the yeast K. marxianus consumes the glucose contained in the substrate at a high rate and that the amount of bioethanol obtained increases proportionally depending on the sugar consumed. The results also show that the yeast C. krusei produces approximately the same concentration of bioethanol in the culture media as the yeast K. marxianus. However, a major difference between the two isolated yeasts is the growth rate and the microbial biomass concentration at the end of the process. The biomass concentration of the C. krusei yeast after 5 h was 1.689 g/L, while the biomass concentration of the K. marxianus yeast was 2.634 g/L. The results obtained were expected, considering that K. marxianus is the fastest growing eukaryote on earth [54].

Figure 4.

Changes in the concentrations of glucose (●), bioethanol (●) and microbial biomass (●) described using a mathematical model (-) during the fermentation process by K. marxianus (a–c) and C. krusei (d–f) yeast for different initial glucose concentrations: (a) 5 g/L, (b) 10 g/L, (c) 50 g/L, (d) 5 g/L, (e) 10 g/L, (f) 50 g/L.

The maximum bioethanol concentration in the experiment conducted with K. marxianus and the initial glucose concentration of γG = 5 g/L was γE = 0.446 ± 0.031 g/L, at an initial glucose concentration of γG = 10 g/L it was γE = 0.395 ± 0.001 g/L, and at an initial glucose concentration of γG = 50 g/L it was γE = 4.546 ± 0.324 g/L. The highest substrate-to-product conversion coefficient (YP/S = 0.093 ± 0.006 g/g), process efficiency (E = 18.194 ± 1.278%) and process productivity (Pr = 0.141 ± 0.009 g/(L·h)) were achieved in the process where the initial glucose concentration was 5 g/L (Table 2). Similar results, i.e., the best process parameters, were also obtained in previous studies when S. cerevisiae was used to obtain bioethanol and the initial glucose concentration was γG = 5 g/L. However, when comparing the bioethanol yield at an initial glucose concentration of γG = 5 g/L with S. cerevisiae, the bioethanol concentration was γE = 1.946 ± 0.014 g/L, while in the experiment conducted with an initial glucose concentration of γG = 10 g/L, the bioethanol concentration was γE = 1.950 ± 0.035 g/L, which is significantly higher than in this study.

Table 2.

Bioprocess efficiency parameters and Monod constants of batch fermentation of glucose and xylose carried out with the yeasts K. marxianus and C. krusei.

The bioprocess efficiency parameters for both yeasts are listed in Table 2.

During the fermentation of K. marxianus, it can also be observed (Figure 4) that the concentration of bioethanol produced quickly reaches its maximum value. The reason for this is probably the low tolerance of K. marxianus yeast to bioethanol, resulting in low productivity. The low productivity and low tolerance to higher bioethanol concentrations are the reason why K. marxianus is still not an industrially interesting yeast [55].

To describe the dynamics of the process, the kinetic parameters of the Monod model were estimated. The results show that the yeasts grow at different rates depending on the initial glucose concentration in the medium, i.e., the glucose concentration influences the growth kinetics (Table 2). The highest growth rate was achieved during fermentation with a culture medium containing 5 g/L glucose, while the lowest value was achieved during the process with an initial glucose concentration of 50 g/L.

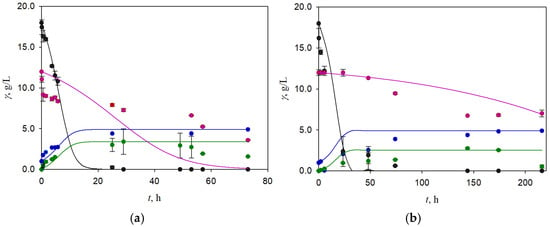

When carrying out the xylose fermentation process with K. marxianus and C. krusei yeast at different initial concentrations (5, 10 and 20 g/L), it was found that the process is not efficient from the point of view of bioethanol production. Regardless of the sugar concentration in the substrate, the bioethanol concentration obtained was only γE = 0.02 g/L. Considering the very low concentrations, the efficiency of the process was consequently very low, i.e., in the range of E = 0.418–6.728%. The results obtained are shown in Figure 5.

Figure 5.

Change in the concentrations of xylose (●), bioethanol (●) and microbial biomass (●) described using a mathematical model (-) during the fermentation process by K. marxianus (a–c) and C. krusei (d–f) yeast for different initial xylose concentrations: (a) 5 g/L, (b) 10 g/L, (c) 20 g/L, (d) 5 g/L, (e) 10 g/L, (f) 20 g/L.

On the other hand, as already mentioned, K. marxianus and C. krusei have metabolic pathways for the production of other industrially important compounds such as 2,3-butanediol and glycerol. The results of measuring the concentration of 2,3-butanediol and glycerol at the end of the fermentation process are shown in Table 3.

Table 3.

Concentrations of glycerol (GL) and 2,3-butanediol (BT) produced by the fermentation of glucose and xylose of different initial concentrations with the yeasts K. marxianus and C. krusei.

When K. marxianus was used, the highest glycerol concentration was formed during the fermentation of 50 g/L glucose and amounted to γGL = 5.309 ± 0.481 g/L. In xylose fermentation, the highest concentration (γGL = 0.348 ± 0.012 g/L) was also achieved at the highest xylose concentration of 20 g/L. The formation of 2,3-butanediol was also observed during the fermentation of both sugars. In glucose fermentation, the highest concentration of 2,3-butanediol (γBT = 0.131 ± 0.008 g/L) was achieved at the fermentation of 50 g/L glucose and in xylose fermentation (γBT = 0.412 ± 0.018 g/L) at a concentration of 10 g/L. It can be seen from the results that the concentrations of 2,3-butanediol are significantly higher in xylose fermentation.

As with sugar fermentation by K. marxianus yeasts, the maximum glycerol concentration of 0.657 ± 0.119 g/L was achieved by the fermentation of 50 g/L glucose with C. krusei, and the maximum concentration of 2,3-butanediol formed (γBT = 1.860 ± 0.044 g/L) was achieved by the fermentation of 20 g/L xylose.

In order to describe the process mathematically, the KS value for K. marxianus was taken from the literature (KS = 13.4 g/L) [54], while the µmax values were estimated as 0.178 1/h, 0.049 1/h and 0.028 1/h for xylose concentrations of 5, 10 and 20 g/L, respectively. The Ks values indicate that K. marxianus has a higher affinity for glucose than for xylose. The results clearly show that both xylose and glucose concentrations influence the growth kinetics, i.e., the µmax values decrease with increasing sugar concentration for the same initial microbial biomass concentration.

For C. krusei, the highest growth rate during fermentation was achieved with a culture medium containing 5 g/L xylose (µmax = 0.022 1/h), followed by a medium containing 10 g/L (µmax = 0.016 1/h), while the lowest value (µmax = 0.013 1/h) was achieved during the process with an initial xylose concentration of 20 g/L. The comparison of the growth rates of the yeast C. krusei on two different sugars shows that the growth rate of the yeast on xylose is significantly lower than on glucose.

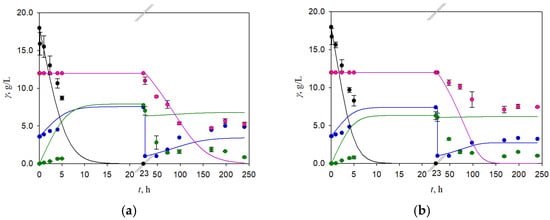

After investigating the influence of different initial concentrations of glucose and xylose on the process productivity and growth of the yeasts K. marxianus and C. krusei, a model solution containing 18 g/L glucose and 12 g/L xylose was prepared. The results of the fermentation of the model solution with the yeasts K. marxianus and C. krusei are shown in Figure 6.

Figure 6.

Change in the concentrations of glucose (●), xylose (●), bioethanol (●) and microbial biomass (●) described by the mathematical model (-) during the fermentation of model solution (18 g/L glucose and 12 g/L xylose) by the yeasts (a) K. marxianus and (b) C. krusei.

The results show that the biomass grows in both processes right at the beginning (t = 4 h), which is due to the presence of dissolved oxygen in the substrate. During this time, bioethanol production is low. With the consumption of oxygen, alcoholic fermentation begins and the bioethanol concentration increases. During the fermentation of the sugar mixture with the yeast K. marxianus, both sugars, glucose and xylose, are consumed in parallel, with the glucose consumption rate being significantly higher. In contrast, during the fermentation of the sugar mixture with the yeast C. krusei, the glucose is consumed first and then the xylose. In both cases, the bioethanol concentration increased as a function of the glucose consumed, and the maximum value was reached after 29 h in the sugar fermentation with the yeast K. marxianus (γE = 3.403 ± 1.561 g/L), while it was reached after 144 h in the process with C. krusei (γE = 2.754 ± 0.084 g/L). After this time, the bioethanol concentration slowly decreases, which is probably related to the transition from the production phase to the death phase of the yeast cells. The fact that the cells died before the end of the process can also be seen from the xylose concentration at the end of the process. In both cases, the xylose was only consumed at the end, i.e., at the end of the fermentation with K. marxianus it was γXy = 3.580 ± 0.075 g/L, while in the process in which the yeast C. krusei was used, it was γXy = 7.013 ± 0.416 g/L. The bioprocess efficiency parameters are shown in Table 4.

Table 4.

Bioprocess efficiency parameters of the one-stage and two-stage batch fermentation of a model medium and BSG carried out with the yeasts K. marxianus and C. krusei.

Comparing the productivity of the two processes, the productivity of the process was significantly higher when the yeast K. marxianus was used in the fermentation process (Pr = 0.117 ± 0.054 g/(L·h)) compared to the fermentation process where the yeast C. krusei was used (Pr = 0.019 ± 0.001 g/(L·h)), making it a better choice for the production of bioethanol. However, compared to S. cerevisiae yeast, both achieved productivities are low. Since the aim of bioethanol production is to develop an economically viable process, i.e., to produce a high concentration of bioethanol in a short time, it can be concluded that none of the isolated yeasts is satisfactory in terms of productivity.

In view of the results obtained and the low productivity of the bioethanol, a two-stage fermentation of a model sugar solution (18 g/L glucose and 12 g/L xylose) was carried out. In the first stage, glucose fermentation was carried out with the yeast S. cerevisiae. After the glucose concentration had dropped to 0 g/L, the S. cerevisiae yeast was removed from the mixture (Figure 1b). The yeasts K. marxianus and C. krusei were then added, initiating the second fermentation stage, xylose fermentation. The results obtained are shown in Figure 7 and Table 4.

Figure 7.

Changes in the concentrations of glucose (●), xylose (●), bioethanol (●) and microbial biomass (●) described by the mathematical model (-) during the two-stage fermentation process of a model sugar solution (18 g/L glucose and 12 g/L xylose) by the yeasts (a) S. cerevisiae and K. marxianus and (b) S. cerevisiae and C. krusei.

As can be seen from the experimental results, the yeast S. cerevisiae only consumed glucose, and most of it was consumed within the first 10 h of the process. In both experiments, the microbial biomass concentration increased in the first 5 h due to the dissolved oxygen in the medium, after which the growth slowed down significantly. During the biomass growth phase, the bioethanol production was low. After the consumption of oxygen, when alcoholic fermentation started, the bioethanol concentration also increased significantly. The maximum ethanol concentrations measured in both processes were similar, and amounted to γE = 7.751 ± 0.001 g/L and γE = 6.293 ± 0.538 g/L, respectively.

After consumption of glucose, the experiments were terminated by removing the S. cerevisiae yeast from the medium by centrifugation. The yeast K. marxianus was then added to one substrate and the C. krusei yeast to the other. In this way, the second fermentation stage, i.e., the fermentation of xylose, was initiated. As can be seen from the results, both yeasts consume xylose, and at the beginning of each process, the xylose consumption follows biomass growth. Comparing the biomass concentration of the two yeasts, it can be seen that more biomass was produced in the process in which the K. marxianus yeast was used. The bioethanol concentration decreased over time in both processes. The reason for this is probably the consumption of bioethanol as a substrate for the formation of new compounds. Although both processes are unfavorable for the production of bioethanol, the formation of 2,3-butanediol and glycerol was observed in the second fermentation stage. The concentrations obtained are shown in Table 5.

Table 5.

Concentrations of glycerol and 2,3-butanediol produced during the fermentation of model medium and BSG with the yeasts K. marxianus and C. krusei.

As can be seen, the fermentation of sugar in the culture medium by the yeast K. marxianus produces larger amounts of glycerol, while the fermentation of sugar by the yeast C. krusei produces larger amounts of 2,3-butanediol as industrially interesting compounds. By further optimizing the process conditions, the concentrations obtained could be increased, which would ensure economically viable production of both compounds.

The results obtained show the potential to produce bioethanol and other industrially interesting compounds through the fermentation of glucose and xylose in a two-stage process. If the bioethanol obtained in the first stage is removed together with the yeast and the production of other valuable raw materials continues in the second stage, it is possible to develop a sustainable process.

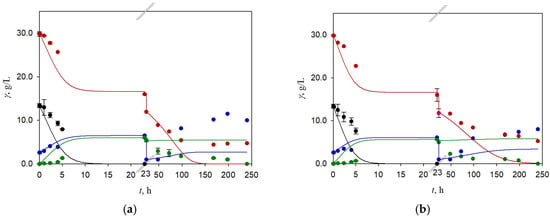

3.3. Two-Stage Fermentation of BSG

After the two-stage fermentation of the model solution, a two-stage fermentation of the hydrolysate of BSG was performed. The results obtained are shown in Figure 8.

Figure 8.

Changes in the concentrations of glucose (●), total sugars (●), bioethanol (●) and microbial biomass (●) described using a mathematical model (-) during the process of two-stage fermentation of acidic hydrolysate of BSG with the yeasts (a) S. cerevisiae and K. marxianus and (b) S. cerevisiae and C. krusei.

As can be seen from the experimental results, the total sugar consumption corresponds to the total consumption of glucose in both cases, since S. cerevisiae does not ferment the other sugars present in the hydrolysate (pentose, arabinose and xylose). In both experiments, the biomass concentration increased in the first 5 h due to the oxygen dissolved in the medium, after which growth slowed down significantly. During the biomass growth phase, bioethanol production was low. After the consumption of oxygen, when the alcoholic fermentation started, the bioethanol concentration also increased significantly. The maximum ethanol concentrations observed in both processes were similar and amounted to γE = 6.024 ± 0.326 g/L in the process using the yeasts S. cerevisiae and K. marxianus and γE = 5.632 ± 0.193 g/L in the process using the yeasts S. cerevisiae and C. krusei, respectively. Comparing the concentrations of the resulting microbial biomass and bioethanol with the concentrations obtained in the experiments using a model solution, it can be seen that the concentration of bioethanol is lower, but the efficiency and productivity are higher when the hydrolysate of the BSG was used as a substrate. The reason for this is that the model solutions contained more glucose than the BSG hydrolysate, as they were prepared according to the previously obtained results on the composition of the BSG hydrolysate (γG = 18 g/L), while the subsequent experiments showed that the hydrolysate contained significantly less glucose (γG = 13.50 g/L). It can be assumed that glucose consumption took place in the stored sample over time. Table 4 shows the bioprocess efficiency parameters. The formation of glycerol and 2,3-butanediol was also recorded during the fermentation of BSG hydrolysate, and their concentrations are shown in Table 5.

4. Conclusions

Brewer’s spent grain (BSG) hydrolysates show significant potential for bioethanol production when pretreated with a weak acid and properly detoxified, although further optimization is needed, especially in the use of pentose sugars and the improvement of yeast tolerance.

In this study, both enzymatic and acidic hydrolysis processes were investigated for the degradation of BSG. Hydrolysis with a weak acid yielded significant amounts of glucose (18.3 g/L) and smaller amounts of xylose (7.90 g/L) and arabinose (3.99 g/L). Fermentation with Saccharomyces cerevisiae showed the importance of detoxifying the hydrolysate using activated charcoal and Ca(OH)2, as well as optimizing the pH for effective fermentation. In detoxified hydrolysates, efficiencies of up to 98.148 ± 2.829% and productivities of 0.332 ± 0.010 g/(L·h) were achieved.

In addition, the fermentation capabilities of Kluyveromyces marxianus and Candida krusei were investigated in this study. The performance comparison between the yeast strains K. marxianus and C. krusei revealed their different capabilities and limitations. K. marxianus showed rapid growth but low bioethanol tolerance, fermenting mainly glucose and producing significant amounts of glycerol and 2,3-butanediol. In contrast, C. krusei showed higher resistance to environmental stress and inhibitors, with a remarkable production of 2,3-butanediol, especially from xylose, although it also showed inefficient xylose fermentation for bioethanol production.

The analysis of the Monod model showed that the glucose concentration had a significant effect on yeast growth rates, with both yeasts showing optimal growth at lower initial glucose concentrations (5 g/L). On the other hand, K. marxianus produced up to 4.546 g/L bioethanol at a glucose concentration of 50 g/L, while C. krusei reached up to 3.936 g/L. Despite the effective glucose fermentation, this study showed that the utilization of xylose was a challenge, as both yeasts only achieved low bioethanol yields during xylose fermentation. However, significant production of other valuable compounds, such as glycerol and 2,3-butanediol was observed, especially at higher sugar concentrations, suggesting a potential for byproduct production.

The results show the importance of selecting suitable yeast strains and optimizing the initial sugar concentration to increase the efficiency of bioethanol production. This study also suggests the potential for a two-stage fermentation process combining different yeast strains to further improve bioethanol yields and maximize substrate utilization. Overall, the practical implications of this research are significant for industrial bioethanol production. It underlines the potential of BSG hydrolysates as a sustainable feedstock for bioethanol while highlighting the need for further optimization, especially in the efficient use of pentose sugars and the improvement of yeast tolerance to inhibitors. This study contributes to the development of sustainable biofuel technologies by providing valuable insights into the use of alternative substrates and yeast strains and paving the way for more efficient and resilient bioethanol production processes.

Author Contributions

Conceptualization, A.Š. and B.Z.; methodology, A.Š., R.V., M.B. and N.Z.; software, R.V. and M.B.; validation, A.Š., R.V., M.B. and N.Z.; formal analysis, A.Š., R.V., M.B. and N.Z.; investigation, R.V., M.B., M.N., D.K.G. and N.Z.; resources, B.Z.; data curation, R.V., M.B., M.N., D.K.G. and N.Z.; writing—original draft preparation, A.Š.; writing—review and editing, R.V., M.B., M.N., D.K.G., B.Z. and N.Z; visualization, A.Š., R.V. and M.B.; supervision, A.Š.; project administration, B.Z.; funding acquisition, B.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the University of Zagreb’s short-term financial support for research for 2023.

Data Availability Statement

The data will be available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zheng, J.; Negi, A.; Khomlaem, C.; Kim, B.S. Comparison of Bioethanol Production by Candida Molischiana and Saccharomyces Cerevisiae from Glucose, Cellobiose, and Cellulose. J. Microbiol. Biotechnol. 2019, 29, 905–912. [Google Scholar] [CrossRef] [PubMed]

- Sharker, B.; Islam, M.A.; Hossain, M.A.A.; Ahmad, I.; Al Mamun, A.; Ghosh, S.; Rahman, A.; Hossain, M.S.; Ashik, M.A.; Hoque, M.R.; et al. Characterization of Lignin and Hemicellulose Degrading Bacteria Isolated from Cow Rumen and Forest Soil: Unveiling a Novel Enzymatic Model for Rice Straw Deconstruction. Sci. Total Environ. 2023, 904, 166704. [Google Scholar] [CrossRef] [PubMed]

- Merritt, H.; Barragán-Ocaña, A. The Impact of Market Factors on the Development of Eco-Friendly Energy Technologies: The Case of Bioethanol. Clean Technol. Environ. Policy 2021, 52, 313–321. [Google Scholar] [CrossRef] [PubMed]

- Kazemi Shariat Panahi, H.; Dehhaghi, M.; Kinder, J.E.; Ezeji, T.C. A Review on Green Liquid Fuels for the Transportation Sector: A Prospect of Microbial Solutions to Climate Change. Biofuel Res. J. 2019, 6, 995–1024. [Google Scholar] [CrossRef]

- Novak, M.; Marđetko, N.; Trontel, A.; Pavlečić, M.; Kelemen, Z.; Perković, L.; Petravić Tominac, V.; Šantek, B. Development of an Integrated Bioprocess System for Bioethanol and Arabitol Production from Sugar Beet Cossettes. Food Technol. Biotechnol. 2024, 62, 89–101. [Google Scholar] [CrossRef] [PubMed]

- Phitsuwan, P.; Sakka, K.; Ratanakhanokchai, K. Structural Changes and Enzymatic Response of Napier Grass (Pennisetum Purpureum) Stem Induced by Alkaline Pretreatment. Bioresour. Technol. 2016, 218, 247–256. [Google Scholar] [CrossRef] [PubMed]

- Tursi, A. A Review on Biomass: Importance, Chemistry, Classification, and Conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Rosado, M.J.; Marques, G.; Rencoret, J.; Gutiérrez, A.; del Río, J.C. Chemical Composition of Lipophilic Compounds from Rice (Oryza Sativa) Straw: An Attractive Feedstock for Obtaining Valuable Phytochemicals. Front. Plant. Sci. 2022, 13, 868319. [Google Scholar] [CrossRef] [PubMed]

- Didak Ljubas, B.; Novak, M.; Trontel, A.; Rajković, A.; Kelemen, Z.; Marđetko, N.; Grubišić, M.; Pavlečić, M.; Tominac, V.P.; Šantek, B. Production of Different Biochemicals by Paenibacillus Polymyxa DSM 742 From Pretreated Brewers’ Spent Grains. Front. Microbiol. 2022, 13, 812457. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, S.; Abu-Ghannam, N.; Jaiswal, A.K. A Comparative Analysis of Pretreatment Strategies on the Properties and Hydrolysis of Brewers’ Spent Grain. Bioresour. Technol. 2018, 248, 272–279. [Google Scholar] [CrossRef]

- Pinheiro, T.; Coelho, E.; Romaní, A.; Domingues, L. Intensifying Ethanol Production from Brewer’s Spent Grain Waste: Use of Whole Slurry at High Solid Loadings. New Biotechnol. 2019, 53, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ Spent Grain: A Review with an Emphasis on Food and Health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Z.; Huang, Y.; Wang, H.; Xiao, Q.; Ye, H.; Huang, X. Extraction and Preparation of Cellulose Nanocrystal from Brewer’s Spent Grain and Application in Pickering Emulsions. Bioact. Carbohydr. Diet. Fibre 2024, 31, 100418. [Google Scholar] [CrossRef]

- Vargas-Tah, A.; Moss-Acosta, C.L.; Trujillo-Martinez, B.; Tiessen, A.; Lozoya-Gloria, E.; Orencio-Trejo, M.; Gosset, G.; Martinez, A. Non-Severe Thermochemical Hydrolysis of Stover from White Corn and Sequential Enzymatic Saccharification and Fermentation to Ethanol. Bioresour. Technol. 2015, 198, 611–618. [Google Scholar] [CrossRef] [PubMed]

- Parra-Ramírez, D.; Martinez, A.; Cardona, C.A. Technical and Economic Potential Evaluation of the Strain Escherichia Coli MS04 in the Ethanol Production from Glucose and Xylose. Biochem. Eng. J. 2018, 140, 123–129. [Google Scholar] [CrossRef]

- Wagner, E.; Sierra-Ibarra, E.; Rojas, N.L.; Martinez, A. One-Pot Bioethanol Production from Brewery Spent Grain Using the Ethanologenic Escherichia Coli MS04. Renew. Energy 2022, 189, 717–725. [Google Scholar] [CrossRef]

- Kręgiel, D.; Pawlikowska, E.; Antolak, H. Non-Conventional Yeasts in Fermentation Processes: Potentialities and Limitations. In Old Yeasts—New Questions; InTech: London, UK, 2017. [Google Scholar]

- Bergmann, J.C.; Trichez, D.; de Morais Junior, W.G.; Ramos, T.G.S.; Pacheco, T.F.; Carneiro, C.V.G.C.; Honorato, V.M.; Serra, L.A.; Almeida, J.R.M. Biotechnological Application of Non-Conventional Yeasts for Xylose Valorization. In Non-Conventional Yeasts: From Basic Research to Application; Springer International Publishing: Cham, Switzerland, 2019; pp. 23–74. [Google Scholar]

- Marđetko, N.; Novak, M.; Trontel, A.; Grubišić, M.; Galić, M.; Šantek, B. Bioethanol Production from Dilute-Acid Pre-Treated Wheat Straw Liquor Hydrolysate by Genetically Engineered Saccharomyces Cerevisiae. Chem. Biochem. Eng. Q 2018, 32, 483–499. [Google Scholar] [CrossRef]

- Tišma, M.; Jurić, A.; Bucić-Kojić, A.; Panjičko, M.; Planinić, M. Biovalorization of Brewers’ Spent Grain for the Production of Laccase and Polyphenols. J. Inst. Brew. 2018, 124, 182–186. [Google Scholar] [CrossRef]

- Rascón-Careaga, A.; Corella-Madueño, M.A.G.; Pérez-Martínez, C.J.; García-Rojas, A.M.; Souflé-Vásquez, S.Z.; García-Moroyoqui, M.T.; Córdoba-Beltrán, L.J.; Cáñez-Carrasco, M.G.; García-Alegría, A.M. Validation and Estimation of Uncertainty for a Glucose Determination Method GOD-PAP Using a Multi-Calibrator as Reference. Mapan J. Metrol. Soc. India 2021, 36, 269–278. [Google Scholar] [CrossRef]

- Du, R.; Guo, W.; Shen, Y.; Dai, J.; Zhang, H.; Fu, M.; Wang, X. In Situ Assay of the Reducing Sugars in Hydrophilic Natural Deep Eutectic Solvents by a Modified DNS Method. J. Mol. Liq. 2023, 385, 122286. [Google Scholar] [CrossRef]

- Šalić, A.; Faletar, P.; Zelić, B. NAD+ Regeneration in a Microreactor Using Permeabilized Baker’s Yeast Cells. Biochem. Eng. J. 2013, 77, 88–96. [Google Scholar] [CrossRef]

- Budžaki, S. Enzyme-Catalysed Biodiesel Production from Edible and Waste Cooking Oils. Chem. Biochem. Eng. Q 2015, 29, 329–333. [Google Scholar] [CrossRef]

- Sonnleitner, B.; Locher, G.; Fiechter, A. Biomass Determination. J. Biotechnol. 1992, 25, 5–22. [Google Scholar] [CrossRef] [PubMed]

- Foutch, G.L.; Johannes, A.H. Reactors in Process Engineering. In Encyclopedia of Physical Science and Technology; Elsevier: Amsterdam, The Netherlands, 2003; pp. 23–43. [Google Scholar]

- Ghose, T.K.; Tyagi, R.D. Rapid Ethanol Fermentation of Cellulose Hydrolysate. II. Product and Substrate Inhibition and Optimization of Fermentor Design. Biotechnol. Bioeng. 1979, 21, 1401–1420. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Dragone, G.; Roberto, I.C. Brewers’ Spent Grain: Generation, Characteristics and Potential Applications. J. Cereal Sci. 2006, 43, 1–14. [Google Scholar] [CrossRef]

- Karlović, A.; Jurić, A.; Ćorić, N.; Habschied, K.; Krstanović, V.; Mastanjević, K. By-Products in the Malting and Brewing Industries—Re-Usage Possibilities. Fermentation 2020, 6, 82. [Google Scholar] [CrossRef]

- Kucharska, K.; Rybarczyk, P.; Hołowacz, I.; Łukajtis, R.; Glinka, M.; Kamiński, M. Pretreatment of Lignocellulosic Materials as Substrates for Fermentation Processes. Molecules 2018, 23, 2937. [Google Scholar] [CrossRef] [PubMed]

- Jönsson, L.J.; Alriksson, B.; Nilvebrant, N.O. Bioconversion of Lignocellulose: Inhibitors and Detoxification. Biotechnol. Biofuels 2013, 6, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Fathin Ruslan, N. Sustainable Bioethanol Production by Solid State Fermentation: A Systematic Review. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Pavlečić, M.; Novak, M.; Trontel, A.; Marđetko, N.; Grubišić, M.; Ljubas, B.D.; Tominac, V.P.; Rakovac, R.Č.; Šantek, B. Mathematical Modelling of Bioethanol Production from Raw Sugar Beet Cossettes in a Horizontal Rotating Tubular Bioreactor. Fermentation 2022, 8, 13. [Google Scholar] [CrossRef]

- Graeme, M. Yeast Physiology and Biotechnology; John Wiley & Sons: Hoboken, NJ, USA, 1998; Volume 1. [Google Scholar]

- Tesfaw, A.; Assefa, F. Current Trends in Bioethanol Production by Saccharomyces Cerevisiae: Substrate, Inhibitor Reduction, Growth Variables, Coculture, and Immobilization. Int. Sch. Res. Notices 2014, 2014, 532852. [Google Scholar] [CrossRef] [PubMed]

- Xiros, C.; Topakas, E.; Katapodis, P.; Christakopoulos, P. Hydrolysis and Fermentation of Brewer’s Spent Grain by Neurospora Crassa. Bioresour. Technol. 2008, 99, 5427–5435. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, S.; Smart, K.A.; Cook, D.J. Optimisation of Alkaline Reagent Based Chemical Pre-Treatment of Brewers Spent Grains for Bioethanol Production. Ind. Crops Prod. 2014, 62, 219–227. [Google Scholar] [CrossRef]

- White, J.S.; Yohannan, B.K.; Walker, G.M. Bioconversion of Brewer’s Spent Grains to Bioethanol. FEMS Yeast Res. 2008, 8, 1175–1184. [Google Scholar] [CrossRef] [PubMed]

- Xiros, C.; Christakopoulos, P. Enhanced Ethanol Production from Brewer’s Spent Grain by a Fusarium Oxysporum Consolidated System. Biotechnol. Biofuels 2009, 2, 4. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, S.; Smart, K.A.; Cook, D.J. A Comparison of Dilute Acid- and Alkali-Catalyzed Hydrothermal Pretreatments for Bioethanol Production from Brewers’ Spent Grains. J. Am. Soc. Brew. Chem. 2014, 72, 143–153. [Google Scholar] [CrossRef]

- Xiros, C.; Topakas, E.; Katapodis, P.; Christakopoulos, P. Evaluation of Fusarium Oxysporum as an Enzyme Factory for the Hydrolysis of Brewer’s Spent Grain with Improved Biodegradability for Ethanol Production. Ind. Crops Prod. 2008, 28, 213–224. [Google Scholar] [CrossRef]

- Wilkinson, S.; Smart, K.A.; Cook, D.J. Optimising the (Microwave) Hydrothermal Pretreatment of Brewers Spent Grains for Bioethanol Production. J. Fuels 2015, 2015, 369283. [Google Scholar] [CrossRef]

- Heredia-Olea, E.; Pérez-Carrillo, E.; Serna-Saldívar, S.O. Effect of Extrusion Conditions and Hydrolysis with Fiber-Degrading Enzymes on the Production of C5 and C6 Sugars from Brewers’ Spent Grain for Bioethanol Production. Biofuel Res. J. 2015, 2, 203–208. [Google Scholar] [CrossRef]

- Kemppainen, K.; Rommi, K.; Holopainen, U.; Kruus, K. Steam Explosion of Brewer’s Spent Grain Improves Enzymatic Digestibility of Carbohydrates and Affects Solubility and Stability of Proteins. Appl. Biochem. Biotechnol. 2016, 180, 94–108. [Google Scholar] [CrossRef]

- Khaleghian, H.; Karimi, K.; Behzad, T. Ethanol Production from Rice Straw by Sodium Carbonate Pretreatment and Mucor Hiemalis Fermentation. Ind. Crops Prod. 2015, 76, 1079–1085. [Google Scholar] [CrossRef]

- Kwak, S.; Jin, Y.-S. Production of Fuels and Chemicals from Xylose by Engineered Saccharomyces Cerevisiae: A Review and Perspective. Microb. Cell Fact. 2017, 16, 82. [Google Scholar] [CrossRef] [PubMed]

- Febrianti, F. Bioethanol Production from Tofu Waste by Simultaneous Saccharification and Fermentation (SSF) Using Microbial Consortium. Int. J. Technol. 2017, 8, 898–908. [Google Scholar] [CrossRef]

- Byadgi, S.A.; Kalburgi, P.B. Production of Bioethanol from Waste Newspaper. Procedia Environ. Sci. 2016, 35, 555–562. [Google Scholar] [CrossRef]

- Karim, A.; Gerliani, N.; Aïder, M. Kluyveromyces Marxianus: An Emerging Yeast Cell Factory for Applications in Food and Biotechnology. Int. J. Food Microbiol. 2020, 333, 108818. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, G.G.; Heinzle, E.; Wittmann, C.; Gombert, A.K. The Yeast Kluyveromyces Marxianus and Its Biotechnological Potential. Appl. Microbiol. Biotechnol. 2008, 79, 339–354. [Google Scholar] [CrossRef] [PubMed]

- Zwirzitz, A.; Alteio, L.; Sulzenbacher, D.; Atanasoff, M.; Selg, M. Ethanol Production from Wheat Straw Hydrolysate by Issatchenkia Orientalis Isolated from Waste Cooking Oil. J. Fungi 2021, 7, 121. [Google Scholar] [CrossRef] [PubMed]

- Yadav, J.S.S.; Bezawada, J.; Yan, S.; Tyagi, R.D.; Surampalli, R.Y. Candida Krusei: Biotechnological Potentials and Concerns about Its Safety. Can. J. Microbiol. 2012, 58, 937–952. [Google Scholar] [CrossRef]

- Chang, Y.-H.; Chang, K.-S.; Chen, C.-Y.; Hsu, C.-L.; Chang, T.-C.; Jang, H.-D. Enhancement of the Efficiency of Bioethanol Production by Saccharomyces Cerevisiae via Gradually Batch-Wise and Fed-Batch Increasing the Glucose Concentration. Fermentation 2018, 4, 45. [Google Scholar] [CrossRef]

- Dasgupta, D.; Junghare, V.; Nautiyal, A.K.; Jana, A.; Hazra, S.; Ghosh, D. Xylitol Production from Lignocellulosic Pentosans: A Rational Strain Engineering Approach toward a Multiproduct Biorefinery. J. Agric. Food Chem. 2019, 67, 1173–1186. [Google Scholar] [CrossRef]

- Mo, W.; Wang, M.; Zhan, R.; Yu, Y.; He, Y.; Lu, H. Kluyveromyces Marxianus Developing Ethanol Tolerance during Adaptive Evolution with Significant Improvements of Multiple Pathways. Biotechnol. Biofuels 2019, 12, 63. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).