Analysis of the Energy Potential of Hazelnut Husk Depending on the Variety

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- There are significant differences between hazelnut varieties in terms of lower calorific value. Varieties such as ‘Olbrzymi z Halle’ (17.40 MJ·kg−1; 18.68 MJ·kg−1) and ‘Olga’ (17.39 MJ·kg−1; 18.68 MJ·kg−1) show higher calorific values, making them more energy-efficient compared to ‘Kataloński’ (17.35 MJ·kg−1; 18.63 MJ·kg−1) and ‘Webba Cenny’ (17.33 MJ·kg−1; 18.61 MJ·kg−1).

- The morphological characteristics of the hazelnut shells influence their energy value and emission factors. The ‘Webba Cenny’ (9.01%) variety is characterized by higher moisture content, which negatively affects the biomass energy value. The ‘Kataloński’ (8.64%) variety, on the other hand, showed lower moisture content and ash content, which is beneficial from the point of view of combustion efficiency.

- The analysis of emissions during the combustion of hazelnut shells showed different results depending on the variety. The ‘Olbrzymi z Halle’ variety showed the highest CO (57.94 kg·Mg−1) and CO2 (1418.83 kg·Mg−1) emissions, while the ‘Webba Cenny’ variety had higher dust and NOx (1.26 kg·Mg−1) emissions. Overall, however, emissions were comparable to other biomass types, and SO2 content was minimal.

- Analysis of the mass of shells on an area of 1 ha, depending on the variety, showed the lowest mass for the ‘Webba Cenny’ variety (1.62 t·h−1) and the highest for the ‘Catalan’ variety (1.96 t·h−1).

- The selection of a suitable variety for energy crops should take into account both calorific value and emission factors. The varieties ‘Olbrzymi z Halle’ and ‘Olga’ may be preferred due to their higher calorific value, even though they may generate higher emissions. In contrast, the varieties ‘Kataloński’ and ‘Webba Cenny’ may be chosen in the context of lower emissions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mateos, E.; Ormaetxea, L. Sustainable Renewable Energy by Means of Using Residual Forest Biomass. Energies 2019, 12, 13. [Google Scholar] [CrossRef]

- Colla, M.; Verleysen, K.; Blondeau, J.; Jeanmart, H. Navigating Bioenergy Horizons: A Critical Examination of Europe’s Potential, with Belgium as a Case. Sustain Energy Res. 2024, 11, 17. [Google Scholar] [CrossRef]

- Serocka, A. Renewable energy sources as an element of state energy security management. Zeszyty Naukowe Politechniki Częstochowskiej. Zarządzanie 2022, 88–100. [Google Scholar] [CrossRef]

- Digitemie, W.N.; Ekemezie, I. O A comprehensive review of building energy managment systems (BEMS) for Improved efficiency. World J. Adv. Res. Rev. 2024, 21, 829–841. [Google Scholar] [CrossRef]

- Gürdil, G.; DemiRel, B.; Herak, D.; Baz, Y.Ö. Performance of a Manually Fed Pelleting Machine with a Horizontal Rotating Matrix. In Current Methods of Construction Design: Proceedings of the ICMD 2018; Springer International Publishing: Cham, Switzerland, 2020; pp. 599–604. ISBN 978-3-030-33145-0. [Google Scholar]

- Carmona Rene, J.; Riquelme Alejandro, A. Gonzalez Gillian European Hazelnut Shell as a Source of Extractives and Bio-Oil. Chem. Eng. Trans. 2024, 109, 349–354. [Google Scholar] [CrossRef]

- Ceylan, F.D.; Adrar, N.; Bolling, B.W.; Capanoglu, E. Valorisation of Hazelnut By-Products: Current Applications and Future Potential. Biotechnol. Genet. Eng. Rev. 2022, 1–36. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, X.; Lin, H.; Lin, Z. Hazelnut and Its By-Products: A Comprehensive Review of Nutrition, Phytochemical Profile, Extraction, Bioactivities and Applications. Food Chem. 2023, 413, 135576. [Google Scholar] [CrossRef]

- Aydemir, B.; Yilgin, M. Findik Kabugunum Torrefaksiyon ve Yanma davransinin Incelenmesi. Karadeniz Fen Bilim. Derg. 2022, 12, 51–65. [Google Scholar] [CrossRef]

- Calà, E.; Fracchia, A.; Robotti, E.; Gulino, F.; Gullo, F.; Oddone, M.; Massacane, M.; Cordone, G.; Aceto, M. On the Traceability of the Hazelnut Production Chain by Means of Trace Elements. Molecules 2022, 27, 3854. [Google Scholar] [CrossRef]

- Solís, A.; Rocha, S.; König, M.; Adam, R.; Garcés, H.; Candia, C.; Muñoz, R.; Azócar, L. Preliminary assessment of hazelnut shell biomass as a raw material for pellet production. Fuel 2023, 333, 126517. [Google Scholar] [CrossRef]

- Ollani, S.; Peano, C.; Sottile, F. Recent Innovations on the Reuse of Almond and Hazelnut By-Products: A Review. Sustainability 2024, 16, 2577. [Google Scholar] [CrossRef]

- An, N.; Turp, M.T.; Türkeş, M.; Kurnaz, M.L. Mid-Term Impact of Climate Change on Hazelnut Yield. Agriculture 2020, 10, 159. [Google Scholar] [CrossRef]

- EN-ISO 1928:2020; Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method and Calculation of Net Calorific Value. ISO: Geneva, Switzerland, 2020.

- EN-ISO 18122:2022; Solid Biofuels. Determination of Ash Content. ISO: Geneva, Switzerland, 2022.

- EN-ISO 18123:2023; Solid Fuels—Determination of Volatile Content by Gravimetric Method. ISO: Geneva, Switzerland, 2023.

- EN-ISO 18134-1:2022; Solid Biofuels—Determination of Moisture Content—Oven Dry Method Part 1: Total Moisture—Reference Method. ISO: Geneva, Switzerland, 2022.

- Choudhury, N.D.; Saha, N.; Phukan, B.R.; Kataki, R. Characterization and Evaluation of Energy Properties of Pellets Produced from Coir Pith, Saw Dust and Ipomoea Carnea and Their Blends. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 45, 1–18. [Google Scholar] [CrossRef]

- Maj, G. Emission Factors and Energy Properties of Agro and Forest Biomass in Aspect of Sustainability of Energy Sector. Energies 2018, 11, 1516. [Google Scholar] [CrossRef]

- EN-ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. ISO: Geneva, Switzerland, 2015.

- EN-ISO 16994:2016; Solid Biofuels—Determination of Total Content of Sulphur and Chlorine. ISO: Geneva, Switzerland, 2016.

- Alves, J.L.F.; da Silva, J.C.G.; Mumbach, G.D.; Domenico, M.D.; da Silva Filho, V.F.; de Sena, R.F.; Machado, R.A.F.; Marangoni, C. Insights into the Bioenergy Potential of Jackfruit Wastes Considering Their Physicochemical Properties, Bioenergy Indicators, Combustion Behaviors, and Emission Characteristics. Renew. Energy 2020, 155, 1328–1338. [Google Scholar] [CrossRef]

- Kovacs, H.; Szemmelveisz, K.; Koós, T. Theoretical and Experimental Metals Flow Calculations during Biomass Combustion. Fuel 2016, 185, 524–531. [Google Scholar] [CrossRef]

- Paraschiv, L.S.; Serban, A.; Paraschiv, S. Calculation of Combustion Air Required for Burning Solid Fuels (Coal / Biomass / Solid Waste) and Analysis of Flue Gas Composition. Energy Rep. 2020, 6, 36–45. [Google Scholar] [CrossRef]

- Köksal, A.İ. Turkish Hazelnut Types; Hazelnut Promotion Group: Ankara, Turkey, 2002; ISBN 975-92886-0-5. (In Turkish) [Google Scholar]

- Zscheischler, J.; Orth, R.; Seneviratne, S.I. Bivariate return periods of temperature and precipitation explain a large fraction of European crop yields. Biogeosciences 2017, 14, 3309–3320. [Google Scholar] [CrossRef]

- Nazarenko, M.; Simchenko, O. Diversity of hazelnut varieties and changes in plant development during introduction in the semi-arid zone. Biosyst. Divers. 2023, 31, 313–318. [Google Scholar] [CrossRef]

- Bak, T.; Karadeniz, T. Effects of Branch Number on Quality Traits and Yield Properties of European Hazelnut (Corylus avellana L.). Agriculture 2021, 11, 437. [Google Scholar] [CrossRef]

- Çalışkan, K.; Balta, F.; Yılmaz, M.; Karakaya, O. Changes in yield and nut traits depending on the stem number per ocak in grown organically in Palaz hazelnut cultivar. Acad. J. Agr. Cilt 8 Özel Sayı 2019, 49–60. [Google Scholar] [CrossRef]

- Farinelli, D.; Tombesi, A.; Boco, M.; Trappoloni, C.S. Hazelnut (Corylusavellana L.) kernel quality during maturity in central Italy. Acta Hort. 2001, 556, 553–558. [Google Scholar] [CrossRef]

- Król, K. Qualityassessment of the Selected Hazelnut Cultivars (Corylus avellana L.) Produced in Poland; Szkoła Główna Gospodarstwa Wiejskiego w Warszawie Instytut Nauk o Żywieniu Człowieka: Warsaw, Poland, 2022. [Google Scholar]

- Güler, E.; Balta, F. Determination of yield and quality characteristics of hazelnut populations of Taskesti district (Mudurnu-Bolu). Uluslar. Tarim Ve Yaban Hayati Bilim. Derg. 2020, 6, 115–128. [Google Scholar] [CrossRef]

- Ferrão, A.C.; Guiné, R.P.F.; Ramalhosa, E.; Lopes, A.; Rodrigues, C.; Martins, H.; Gonçalves, R.; Correia, P.M.R. Chemical and Physical Properties of Some Hazelnut Varieties Grown in Portugal. Agronomy 2021, 11, 1476. [Google Scholar] [CrossRef]

- Özdemi, F.; Akinci, I. Physical and nutritional properties of four major commercial Turkish hazelnut varieties. J. Food Eng. 2004, 63, 341–347. [Google Scholar] [CrossRef]

- Ciemniewska, H.; Ratusz, K. Characteristics of hazelnuts from three hazel cultivars grown in Poland. Rośliny Oleiste 2012, 33, 273–283. [Google Scholar] [CrossRef]

- Gürdil, G.; DemiRel, B.; Baz, Y.Ö.; Demirel, C. Pelleting hazelnut husk residues for biofuel. In Proceedings of the 6th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 7–9 September 2016. [Google Scholar]

- Mladenovic, M.; Vucicevic, B.; Marinkovic, A.; Buha-Markovic, J. Combustion of Waste Solids in a Fluidized Bed to Generate Sustainable Energy. Hem. Ind. 2024, 61, 8. [Google Scholar] [CrossRef]

- Acampora, A.; Civitarese, V.; Sperandio, G.; Rezaei, N. Qualitative Characterization of the Pellet Obtained from Hazelnut and Olive Tree Pruning. Energies 2021, 14, 4083. [Google Scholar] [CrossRef]

- Güleç, F.; Pekaslan, D.; Williams, O.; Lester, E. Predictability of Higher Heating Value of Biomass Feedstocks via Proximate and Ultimate Analyses—A Comprehensive Study of Artificial Neural Network Applications. Fuel 2022, 320, 123944. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.-C.; Li, W.-Y.; Feng, J. Ash Contents and Ash-Forming Elements of Biomass and Their Significance for Solid Biofuel Combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Rahimi, Z.; Anand, A.; Gautam, S. An Overview on Thermochemical Conversion and Potential Evaluation of Biofuels Derived from Agricultural Wastes. Energy Nexus 2022, 7, 100125. [Google Scholar] [CrossRef]

- Torreiro, Y.; Pérez, L.; Piñeiro, G.; Pedras, F.; Rodríguez-Abalde, A. The Role of Energy Valuation of Agroforestry Biomass on the Circular Economy. Energies 2020, 13, 2516. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; González-Aguirre, J.A.; Poveda Giraldo, J.A.; Cardona Alzate, C.A. Thermochemical Processing of Woody Biomass: A Review Focused on Energy-Driven Applications and Catalytic Upgrading. Renew. Sustain. Energy Rev. 2021, 136, 110376. [Google Scholar] [CrossRef]

- Mitchell, E.J.S.; Gudka, B.; Whittaker, C.; Shield, I.; Price-Allison, A.; Maxwell, D.; Jones, J.M.; Williams, A. The Use of Agricultural Residues, Wood Briquettes and Logs for Small-Scale Domestic Heating. Fuel Process. Technol. 2020, 210, 106552. [Google Scholar] [CrossRef]

- Hebda, T.; Brzychczyk, B.; Francik, S.; Pedryc, N. Evaluation of Suitability of Hazelnut Shell Energy for Production of Biofuels. Eng. Rural Dev. 2018, 17, 1860–1865. [Google Scholar]

- Matin, B.; Matin, A.; Brandić, I.; DJurović, A.; Ištvanić, J.; Antonović, A. Lignocellulose composition, proximate analysis and heat value of certain forest and energy crop biomasses and their potential as raw materials for the production of solid biofuels. In Proceedings of the Wood Technology & Product Design, Proceedings of the 6th International Scientific Conference, Ohrid, North Macedonia, 13–15 September 2023; Faculty of Design and Technologies of Furniture and Interior: Skopje, North Macedonia, 2023; p. 200. [Google Scholar]

- Maj, G.; Piekut, J. Comparing Emission Factors and Physicochemical Properties of Waste-Biomass Leaves of Selected Species of Trees. Pol. J. Environ. Stud. 2018, 27, 2155–2162. [Google Scholar] [CrossRef] [PubMed]

- Malaťák, J.; Bradna, J.; Velebil, J. The Dependence of COx and NOx Emission Concentrations on the Excess Air Coefficient during Combustion of Selected Agricultural Briquetted By-Products. Agron. Res. 2017, 15, 1084–1093. [Google Scholar]

- Brunerová, A.; Malaťák, J.; Müller, M.; Valášek, P.; Roubík, H. Tropical Waste Biomass Potential for Solid Biofuels Production. Agron. Res. 2017, 15, 359–368. [Google Scholar]

- Malaták, J.; Gürdil, G.A.K.; Jevic, P.; Selvi, K.Ç. Biomass Heat-Emission Characteristics of Energy Plants. AMA Agric. Mech. Asia Afr. Lat. Am. 2008, 39, 9–13. [Google Scholar]

| Parameter | Standard | |

|---|---|---|

| Proximate analysis | Higher heating value (HHV; MJ·kg−1) | EN-ISO 1928:2020; Equipment LECO AC 600 [14] |

| Lower heating value (LHV; MJ·kg−1) | ||

| Ash (A; %) | EN-ISO 18122:2022; Equipment LECO TGA 701 [15] | |

| Volatile matter (V; %) | EN-ISO 18123:2023; Equipment LECO TGA 701 [16] | |

| Moisture (M; %) | EN-ISO 18134-1:2022; Equipment LECO TGA 701 [17] | |

| Fixed carbon (FC; %) | FC=100-V-A-M [18] | |

| Ultimate analysis (emission factors calculated according to studies [19]) | Carbon (C; %) | EN-ISO 16948:2015-07, Equipment LECO CHNS 628 [20] |

| Hydrogen (H; %) | ||

| Nitrogen (N; %) | ||

| Sulfur (S; %) | EN-ISO 16994:2016-10; Equipment LECO CHNS 628 [21] | |

| Oxygen (O; %) | O=100-A-H-C-S-N [22] | |

| Emission factors (exhaust gas composition was calculated according to [23,24]) | Carbon monoxide emission factor (Ec) of chemically pure coal (CO; kg·Mg−1) | CO—carbon monoxide emission factor (kg∙kg−1), —molar mass ratio of carbon monoxide and carbon, EC—emission factor of chemically pure coal (kg∙kg−1), C/CO—part of the carbon emitted as CO (for biomass 0.06) |

| Carbon dioxide emission factor (CO2; kg·Mg−1) | CO2—carbon dioxide emission factor (kg∙kg−1), molar mass ratio of carbon dioxide and pure coal, molar mass ratio of carbon dioxide and carbon monoxide, molar mass ratio of carbon and methane, ECH4—methane emission factor, ENMVOC—emission index of non-methane VOCs (for biomass 0.009) | |

| Sulphur dioxide emission factor (SO2; kg·Mg−1) | SO2—sulfur dioxide emission factor (kg∙kg−1), 2—molar mass ratio of SO2 and sulfur, S—sulfur content in fuel (%), r—coefficient determining the part of total sulfur retained in the ash | |

| Emission factor was calculated from (NOX; kg·Mg−1) | , NOx—NOx emission factor (kg∙kg−1), molar mass ratio of nitrogen dioxide to nitrogen; the molar mass of nitrogen dioxide was considered due to the fact that nitrogen oxide in the air oxidizes very soon to nitrogen dioxide, N/C—nitrogen to carbon ratio in biomass, /N—part of nitrogen emitted as NOx (for biomass 0.122). | |

| Exhaust gas composition | Theoretical oxygen demand (VO2; Nm3·kg−1) | , C—biomass carbon content (%), H—biomass hydrogen content (%), S—biomass sulfur content (%), O—biomass oxygen content) |

| The stoichiometric volume of dry air required to burn 1 kg of biomass (Voa; Nm3·kg−1) | Since the oxygen content in the air is 21%, which participates in the combustion process in the boiler, the stoichiometric volume of dry air required to burn 1 kg of biomass | |

| Carbon dioxide content of the combustion products (VCO2; Nm3·kg−1) | ||

| Content of sulfur dioxide (VSO2; Nm3·kg−1) | , | |

| Water vapor content of the exhaust gas (VH2O; Nm3·kg−1) | is the component of water vapor volume from the hydrogen combustion process ; and the volume of moisture contained in the combustion air ; ; M-fuel moisture content (%), air absolute humidity (kg H2O·kg−1 dry air) | |

| The theoretical nitrogen content in the exhaust gas ; Nm3 ·kg−1) | , Considering that the nitrogen in the exhaust comes from the fuel composition and the combustion air, and the nitrogen content in the air is 79% | |

| The total stoichiometric volume of dry exhaust gas Nm3 ·kg−1) | ||

| The total volume of exhaust gases ; Nm3 ·kg−1) | Assuming that biomass combustion is carried out under stoichiometric conditions, i.e., using the minimum amount of air required for combustion (λ = 1), a minimum exhaust gas volume will be obtained |

| Parameter | Hazelnut Variety | p-Value | ||||

|---|---|---|---|---|---|---|

| ‘Kataloński’ | ‘Olbrzymi z Halle’ | ‘Olga’ | ‘Webba Cenny’ | |||

|

100 pcs. (g) | husk | 209.33 ± 7.02 b * | 248.00 ± 21.00 a | 201.00 ± 3.46 b | 203.67 ± 10.69 b | 0.0054 |

| kernel | 195.67 ± 1.53 b | 207.00 ± 9.54 b | 241.00 ± 6.24 a | 197.00 ± 6.24 b | 0.0001 | |

|

1 bush (kg) | husk | 2.95 ± 0.10 a | 2.83 ± 0.24 ab | 2.50 ± 0.04 bc | 2.44 ± 0.13 a | 0.0068 |

| kernel | 2.75 ± 0.02 b | 2.37 ± 0.11 c | 3.00 ± 0.08 a | 2.36 ± 0.07 c | 0.0001 | |

|

Yeld (t·ha−1) | husk | 1.96 ± 0.07 a | 1.89 ± 0.16 ab | 1.67 ± 0.03 bc | 1.62 ± 0.09 a | 0.0049 |

| kernel | 1.83 ± 0.01 b | 1.58 ± 0.07 c | 2.00 ± 0.05 a | 1.57 ± 0.05 c | 0.0001 | |

| Parameter | Hazelnut Variety | p-Value | |||

|---|---|---|---|---|---|

| ‘Kataloński’ | ‘Olbrzymi z Halle’ | ‘Olga’ | ‘Webba Cenny’ | ||

| LHV (MJ·kg−1) | 17.35 ± 0.08 a * | 17.40 ± 0.03 a | 17.39 ± 0.02 a | 17.33 ± 0.05 a | 0.3328 |

| HHV (MJ·kg−1) | 18.63 ± 0.08 a | 18.68 ± 0.03 a | 18.68 ± 0.02 a | 18.61 ± 0.05 a | 0.3235 |

| M (%) | 8.64 ± 0.04 b | 8.85 ± 0.02 ab | 8.9 ± 0.12 a | 9.01 ± 0.12 a | 0.0064 |

| V (%) | 68.28 ± 0.10 ab | 68.54 ± 0.08 a | 67.96 ± 0.18 b | 67.2 ± 0.37 c | 0.0004 |

| A (V%) | 0.73 ± 0.09 b | 0.77 ± 0.02 b | 0.79 ± 0.06 b | 0.99 ± 0.05 a | 0.0005 |

| FC (V%) | 23.85 ± 2.68 a | 21.83 ± 0.06 a | 22.34 ± 0.12 a | 22.8 ± 0.2000 a | 0.3625 |

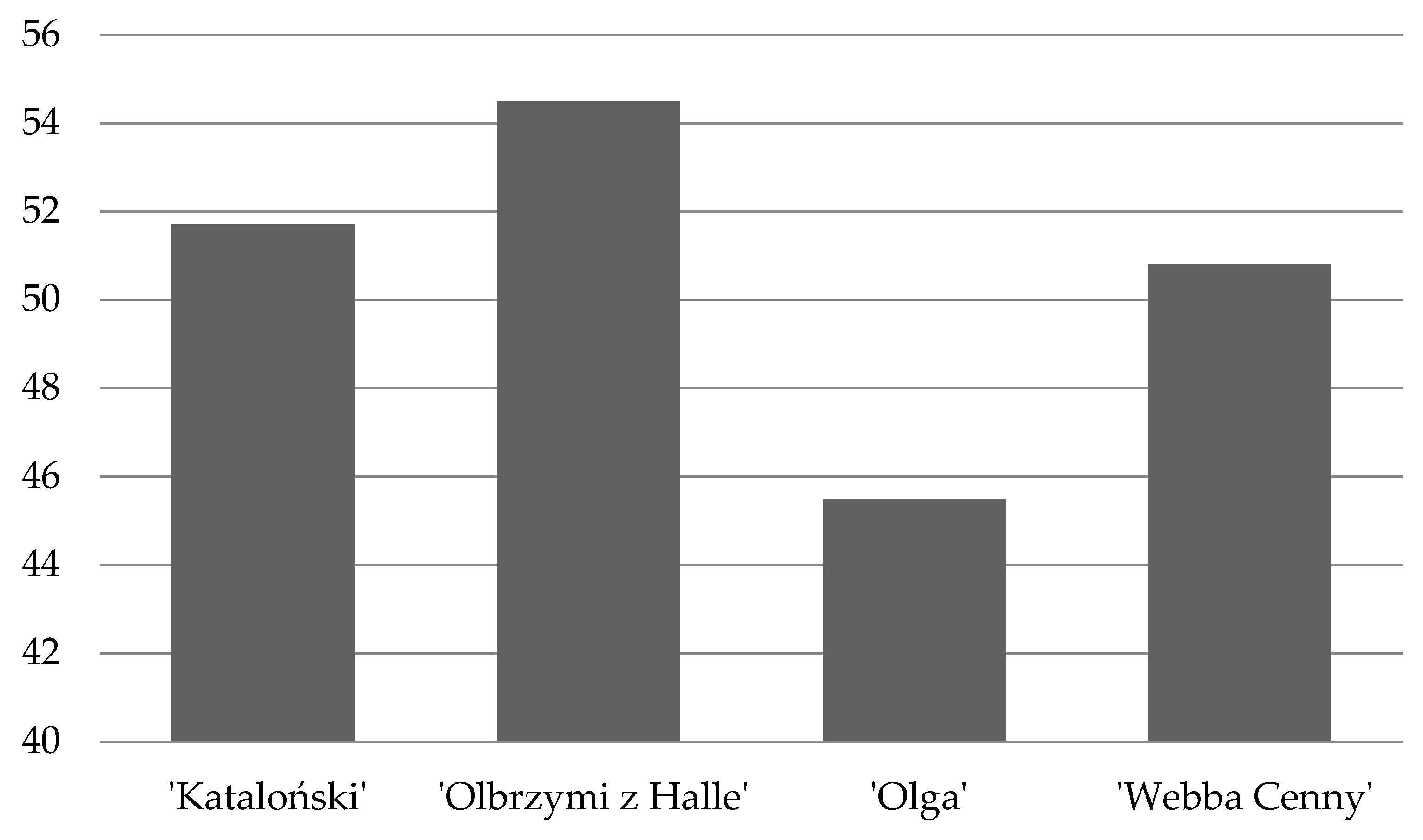

| C (V%) | 46.23 ± 0.09 ab | 47.03 ± 0.61 a | 46.55 ± 0.12 ab | 46.17 ± 0.06 b | 0.0372 |

| H (V%) | 7.52 ± 0.02 a | 7.25 ± 0.36 a | 7.58 ± 0.02 a | 7.5 ± 0.01 a | 0.2098 |

| N (V%) | 0.30 ± 0.01 a | 0.35 ± 0.08 a | 0.29 ± 0.06 a | 0.36 ± 0.02 a | 0.3243 |

| S (V%) | 0.01 ± 0 ab | 0.01 ± 0.00 b | 0.01 ± 0.00 ab | 0.02 ± 0.00 a | 0.0421 |

| O (V%) | 45.19 ± 0.06 a | 44.58 ± 0.42 a | 44.77 ± 0.24 a | 44.97 ± 0.10 a | 0.0776 |

| H/C | 1.63 ± 0.0008 a | 1.54 ± 0.0937 a | 1.63 ± 0.0017 a | 1.62 ± 0.0022 a | 0.149 |

| N/C | 0.01 ± 0.0001 a | 0.01 ± 0.0016 a | 0.01 ± 0.0012 a | 0.01 ± 0.0003 a | 0.2986 |

| O/C | 0.73 ± 0.0021 a | 0.71 ± 0.0156 a | 0.72 ± 0.0057 a | 0.73 ± 0.0024 a | 0.0474 |

| Parameter | Hazelnut Variety | p-Value | |||

|---|---|---|---|---|---|

| ‘Kataloński’ | ‘Olbrzymi z Halle’ | ‘Olga’ | ‘Webba Cenny’ | ||

| CO (kg·Mg−1) | 56.96 ± 0.11 ab * | 57.94 ± 0.75 a | 57.35 ± 0.15 ab | 56.88 ± 0.07 b | 0.0372 |

| CO2 (kg·Mg−1) | 1394.78 ± 2.74 ab | 1418.83 ± 18.46 a | 1404.48 ± 3.67 ab | 1392.97 ± 1.67 b | 0.0372 |

| NOx (kg·Mg−1) | 1.08 ± 0.02 a | 1.23 ± 0.28 a | 1.02 ± 0.20 a | 1.26 ± 0.05 a | 0.3243 |

| SO2 (kg·Mg−1) | 0.03 ± 0.00 ab | 0.02 ± 0.00 b | 0.03 ± 0.01 ab | 0.03 ± 0.001 a | 0.0421 |

| Dust (kg·Mg−1) | 0.93 ± 0.12 b | 0.98 ± 0.03 b | 1.00 ± 0.08 b | 1.25 ± 0.07 a | 0.0051 |

| Parameter | Hazelnut Variety | p-Value | |||

|---|---|---|---|---|---|

| ‘Kataloński’ | ‘Olbrzymi z Halle’ | ‘Olga’ | ‘Webba Cenny’ | ||

| VoO2 (Nm3·kg−1) | 0.97 ± 0.003 a * | 0.97 ± 0.013 a | 0.98 ± 0.005 a | 0.97 ± 0.002 a | 0.1894 |

| Voa (Nm3·kg−1) | 4.61 ± 0.01 a | 4.63 ± 0.06 a | 4.67 ± 0.02 a | 4.61 ± 0.01 a | 0.1894 |

| VCO2 (Nm3·kg−1) | 0.86 ± 0.002 ab | 0.88 ± 0.011 a | 0.87 ± 0.002 ab | 0.86 ± 0.001 b | 0.0002 |

| VSO2 (Nm3·kg−1) | 0.00 ± 0.00 a | 0.00 ± 0.00 b | 0.00 ± 0.00 a | 0.00 ± 0.00 a | 0.0001 |

| VH2O (Nm3·kg−1) | 0.95 ± 0.002 a | 0.92 ± 0.04 a | 0.96 ± 0.001 a | 0.95 ± 0.001 a | 0.2074 |

| VN2 (Nm3·kg−1) | 3.89 ± 0.01 a | 3.94 ± 0.07 a | 3.92 ± 0.06 a | 3.93 ± 0.02 a | 0.3386 |

| Vgu (Nm3·kg−1) | 4.75 ± 0.02 a | 4.81 ± 0.10 a | 4.79 ± 0.07 a | 4.79 ± 0.02 a | 0.2082 |

| Vga (Nm3·kg−1) | 6.44 ± 0.03 a | 6.48 ± 0.15 a | 6.50 ± 0.08 a | 6.48 ± 0.03 a | 0.5286 |

| Parameter | Hazelnut Variety | |||

|---|---|---|---|---|

| ‘Kataloński’ | ‘Olbrzymi z Halle’ | ‘Olga’ | ‘Webba Cenny’ | |

| HHV (MJ·kg−1) | −0.35714 | 0.91813 | −0.73876 | 0.86603 |

| LHV (MJ·kg−1) | −0.35692 | 0.91214 | −0.79127 | 0.86184 |

| C (%) | −0.66684 | 0.44676 | 0.09095 | −0.65616 |

| H (%) | −0.59002 | −0.8783 | −0.32791 | 0.67284 |

| N (%) | −0.12064 | 0.5402 | 0.20129 | −0.96555 |

| S (%) | 0.3459 | 0.4789 | 0.5 | 0.3376 |

| M (%) | −0.93089 | −0.8417 | −0.35473 | −0.78611 |

| O (%) | 0.96336 | 0.02192 | 0.11973 | 0.96259 |

| A (%) | 0.16935 | −0.43984 | −0.77592 | −0.89492 |

| V (%) | 0.94095 | 0.42984 | 0.18228 | 0.76962 |

| FC | 0.83929 | −0.21254 | 0.48755 | −0.72882 |

| WEc | −0.66684 | 0.44676 | 0.09095 | −0.65616 |

| WEco | −0.66684 | 0.44676 | 0.09095 | −0.65616 |

| WNOx | −0.12064 | 0.5402 | 0.20129 | −0.96555 |

| WECO2 | −0.66684 | 0.44676 | 0.09095 | −0.65616 |

| WESO2 | 0.3698 | 0.2874 | 0.5 | 0.3376 |

| WEdust | 0.16935 | −0.43984 | −0.77592 | −0.89492 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borkowska, A.; Klimek, K.; Maj, G.; Kapłan, M. Analysis of the Energy Potential of Hazelnut Husk Depending on the Variety. Energies 2024, 17, 3933. https://doi.org/10.3390/en17163933

Borkowska A, Klimek K, Maj G, Kapłan M. Analysis of the Energy Potential of Hazelnut Husk Depending on the Variety. Energies. 2024; 17(16):3933. https://doi.org/10.3390/en17163933

Chicago/Turabian StyleBorkowska, Anna, Kamila Klimek, Grzegorz Maj, and Magdalena Kapłan. 2024. "Analysis of the Energy Potential of Hazelnut Husk Depending on the Variety" Energies 17, no. 16: 3933. https://doi.org/10.3390/en17163933

APA StyleBorkowska, A., Klimek, K., Maj, G., & Kapłan, M. (2024). Analysis of the Energy Potential of Hazelnut Husk Depending on the Variety. Energies, 17(16), 3933. https://doi.org/10.3390/en17163933