Life Cycle Assessment of Piezoelectric Devices Implemented in Wind Turbine Condition Monitoring Systems

Abstract

1. Introduction

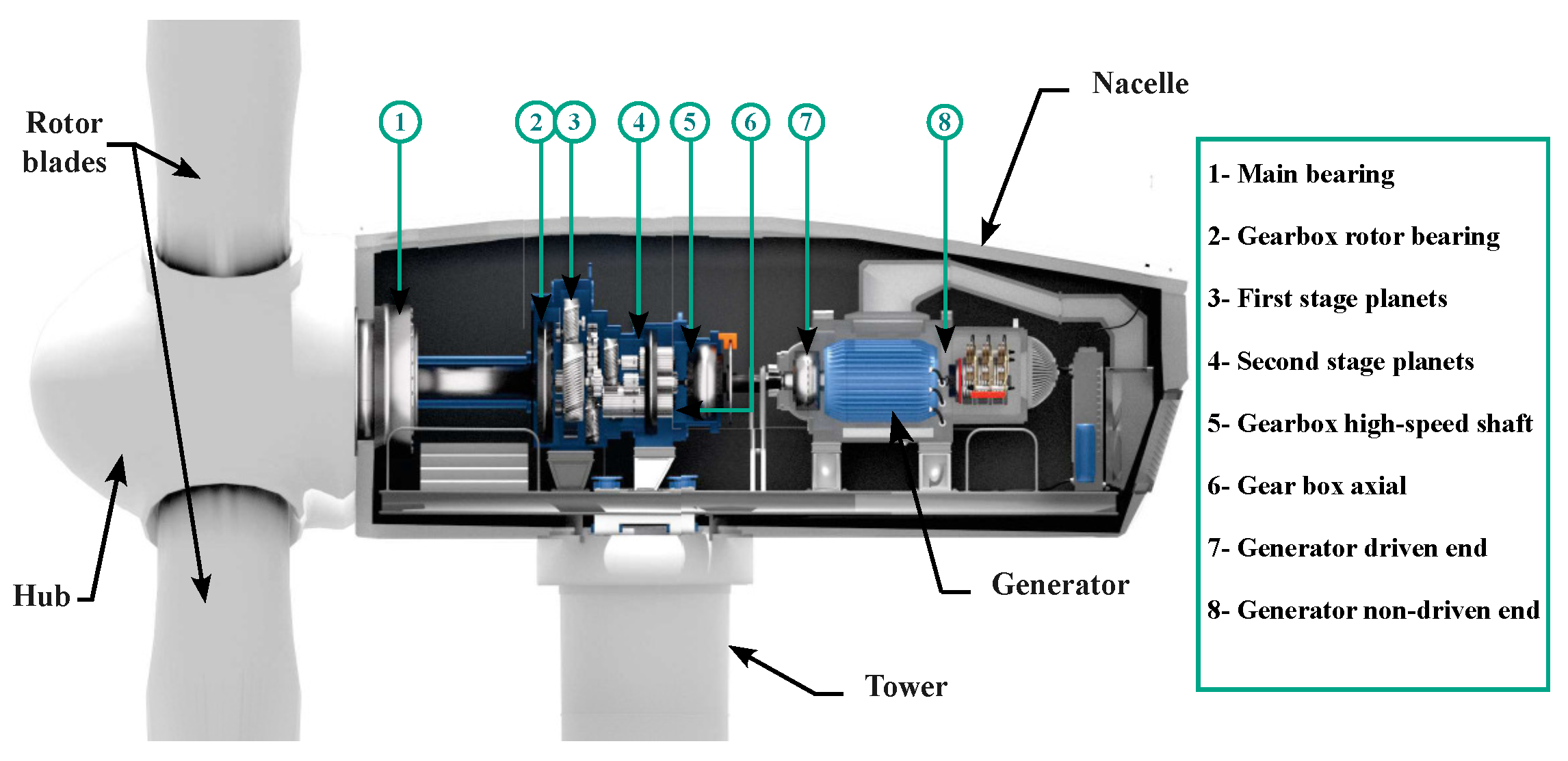

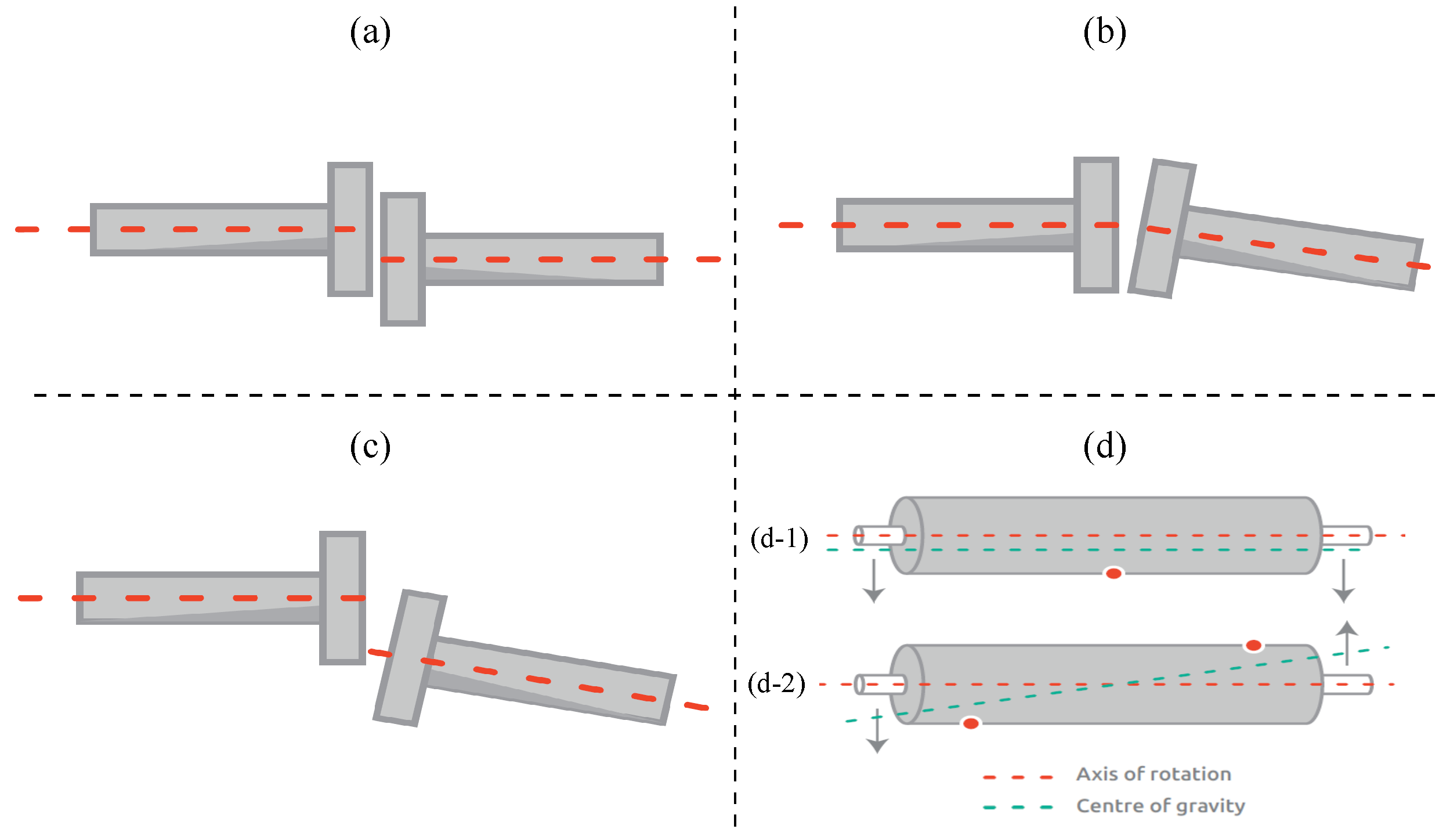

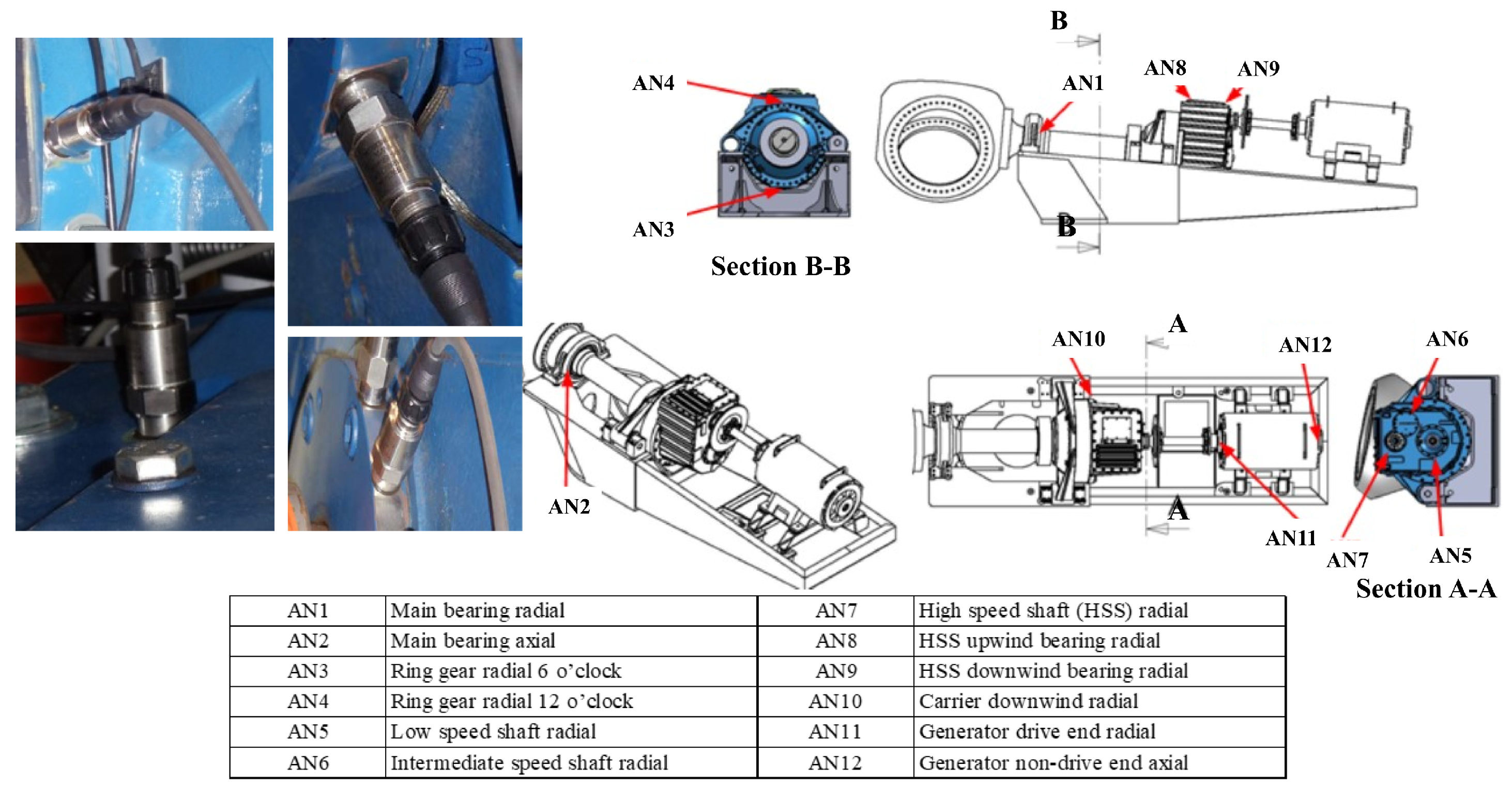

1.1. Ecodesign and Sustainability of Wind Turbines Based on Condition Monitoring and Predictive Maintenance

1.2. Condition Monitoring Systems Based on Piezoelectric Devices

- Piezoelectric sensors (PEs);

- Integrated Electronics Piezoelectric (IEPE);

- Micro electromechanical systems (MEMSs).

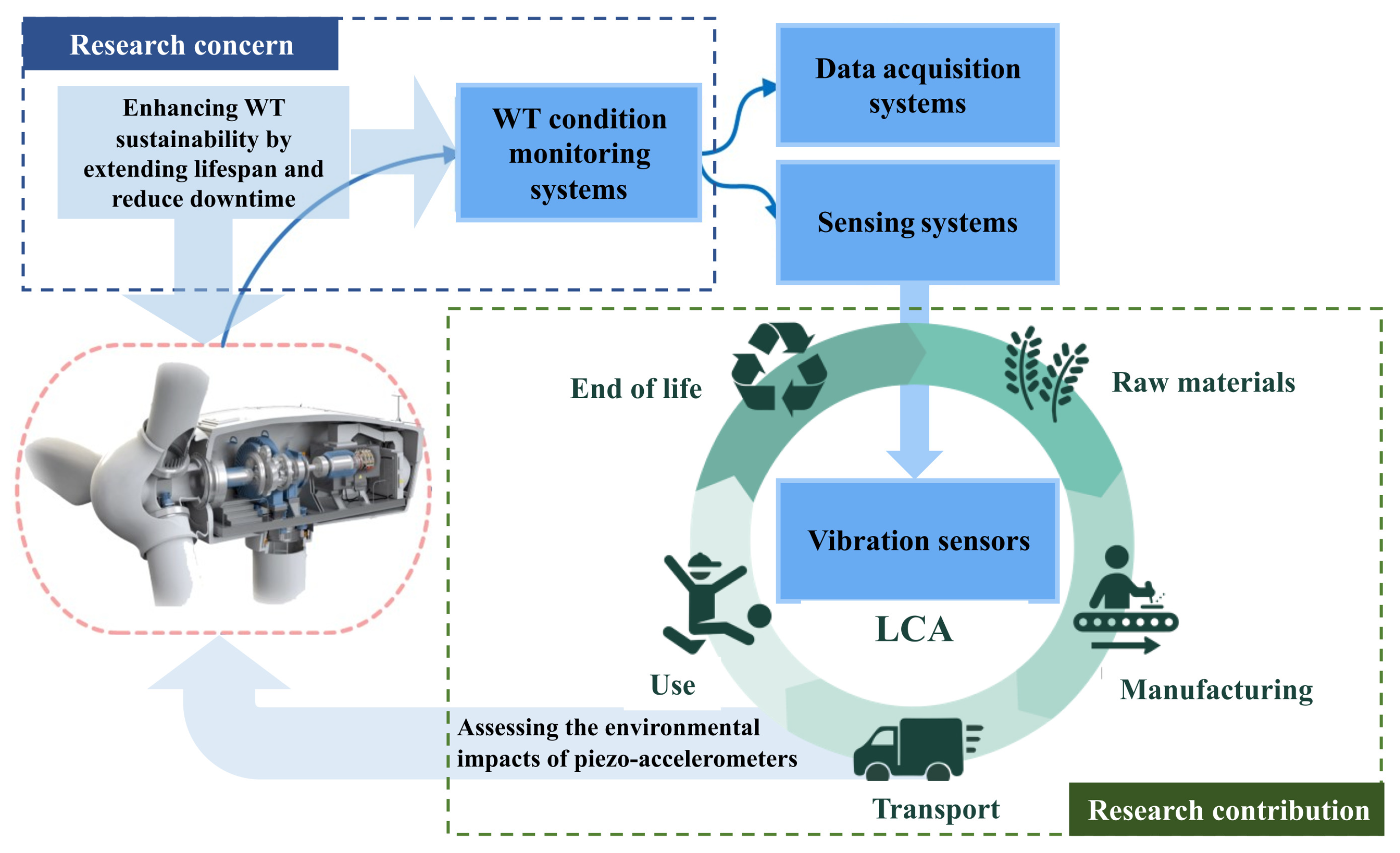

1.3. Scientific Contribution and Manuscript Structure

- (1)

- Providing more complete data, which have never been gathered, on how these sensors impact the environment by conducting an LCA of a commonly used piezoelectric accelerometer in wind turbine CMSs.

- (2)

- Highlighting the utility of LCA results in better guide decision-making and drive the ecodesign of monitoring systems and vibration sensors, thereby improving the sustainability of wind turbines.

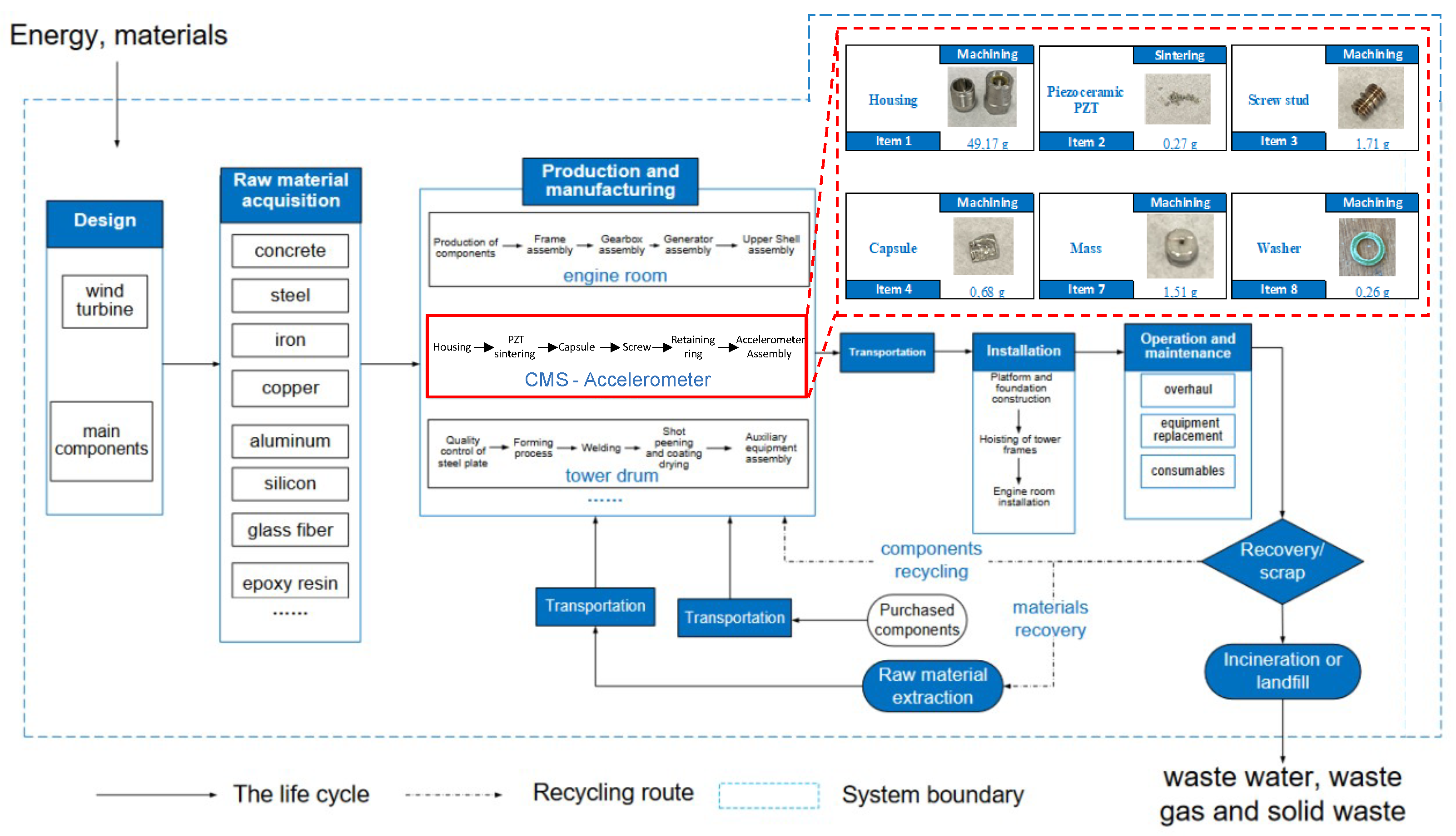

2. Materials and Methods

2.1. Goal and Scope Definition

- Understand the environmental impacts associated with the production and disposal of the accelerometer.

- Identify the stages in the life cycle that contribute most significantly to the overall environmental burden.

- Provide data to inform design improvements or decision-making for reducing the environmental impact.

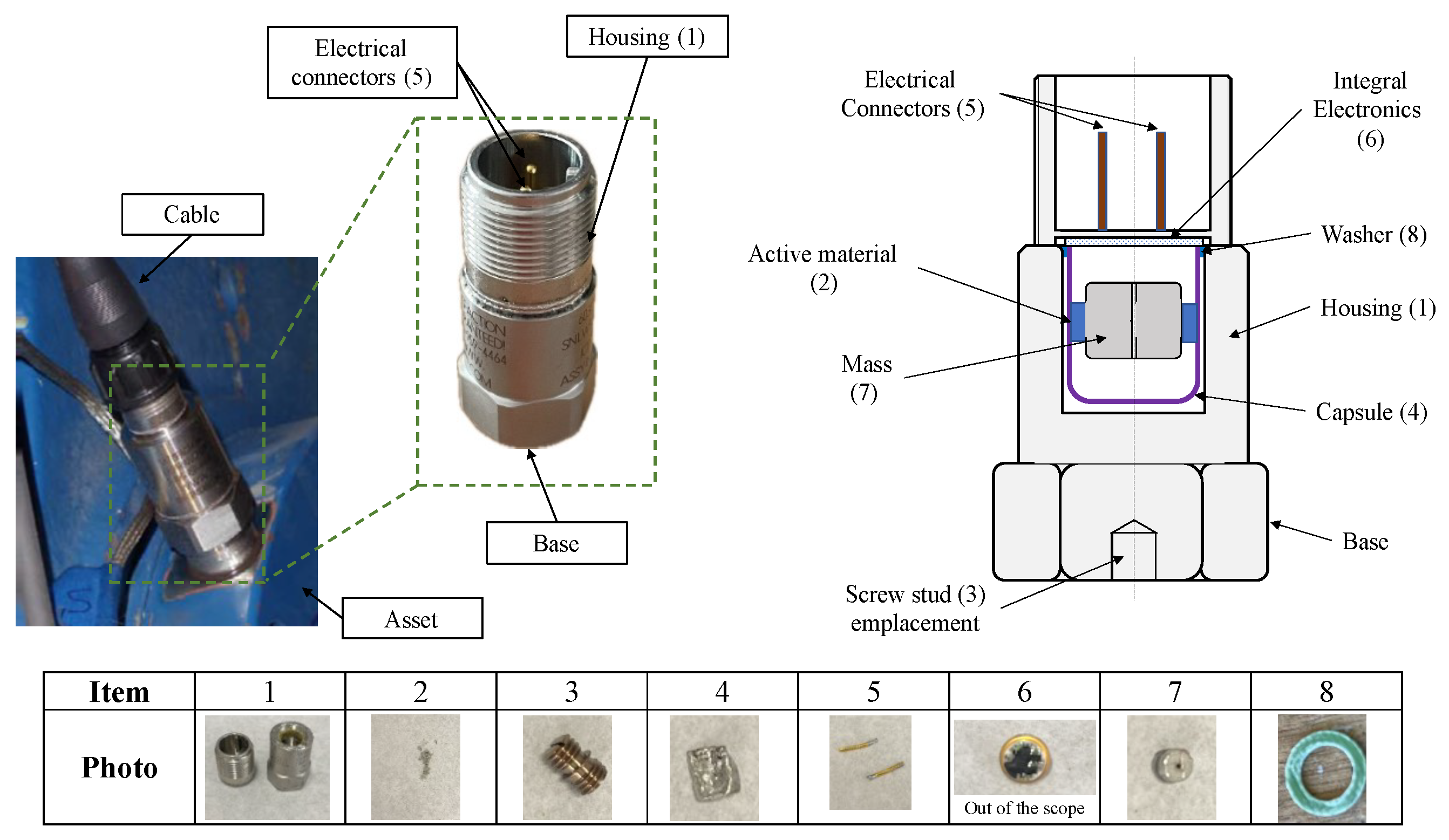

2.2. Life Cycle Inventory Analysis

3. Results and Discussion

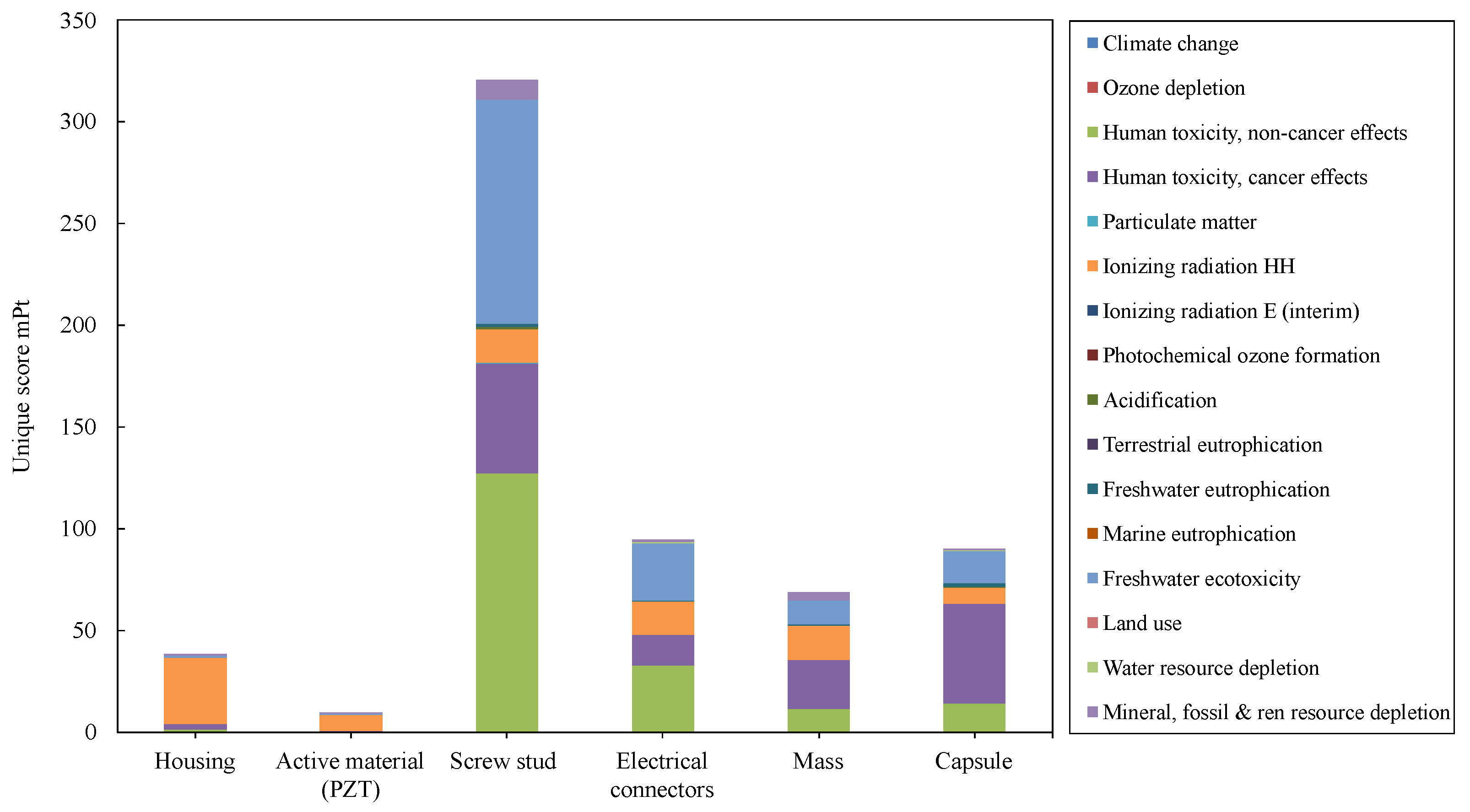

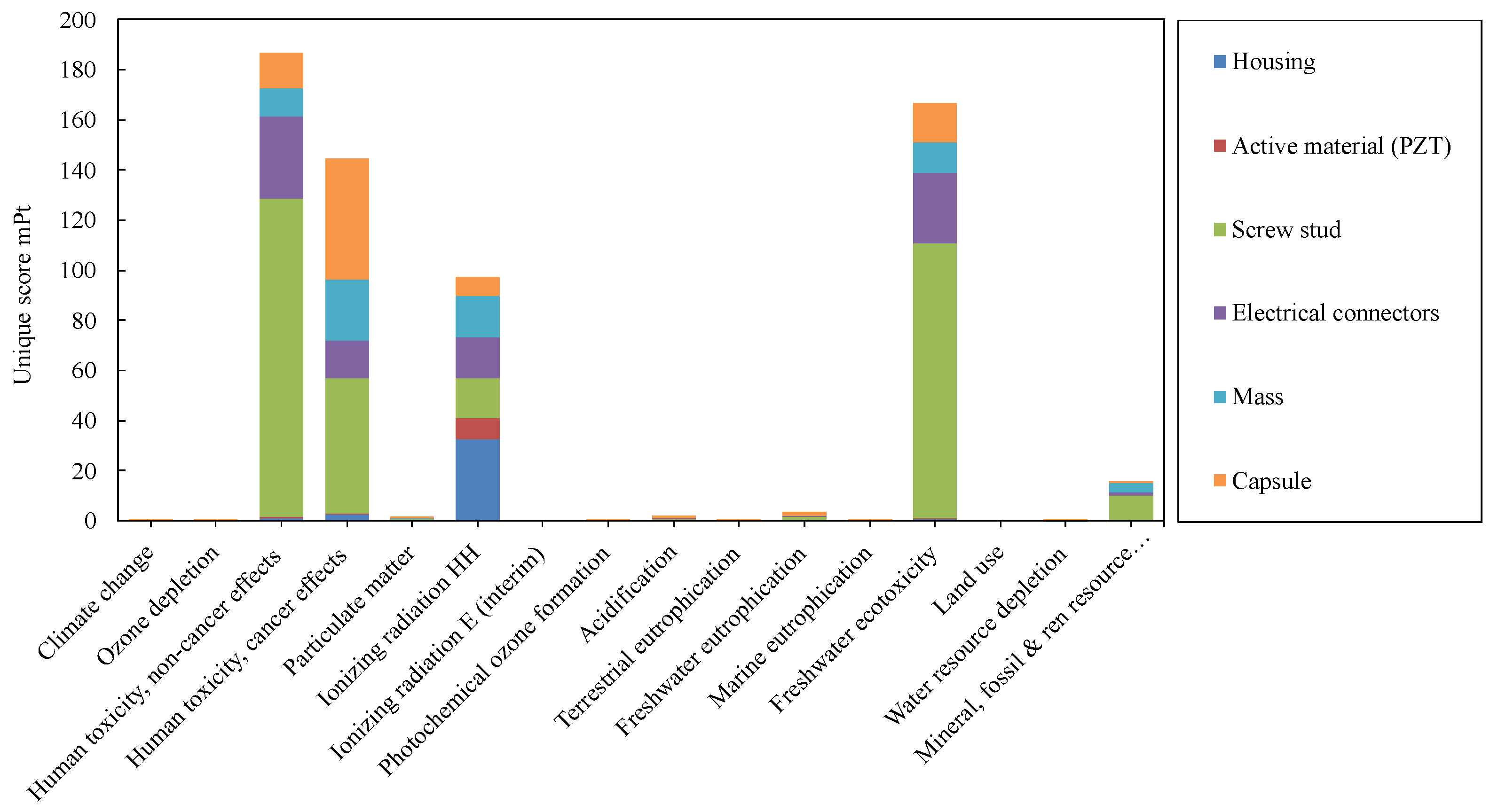

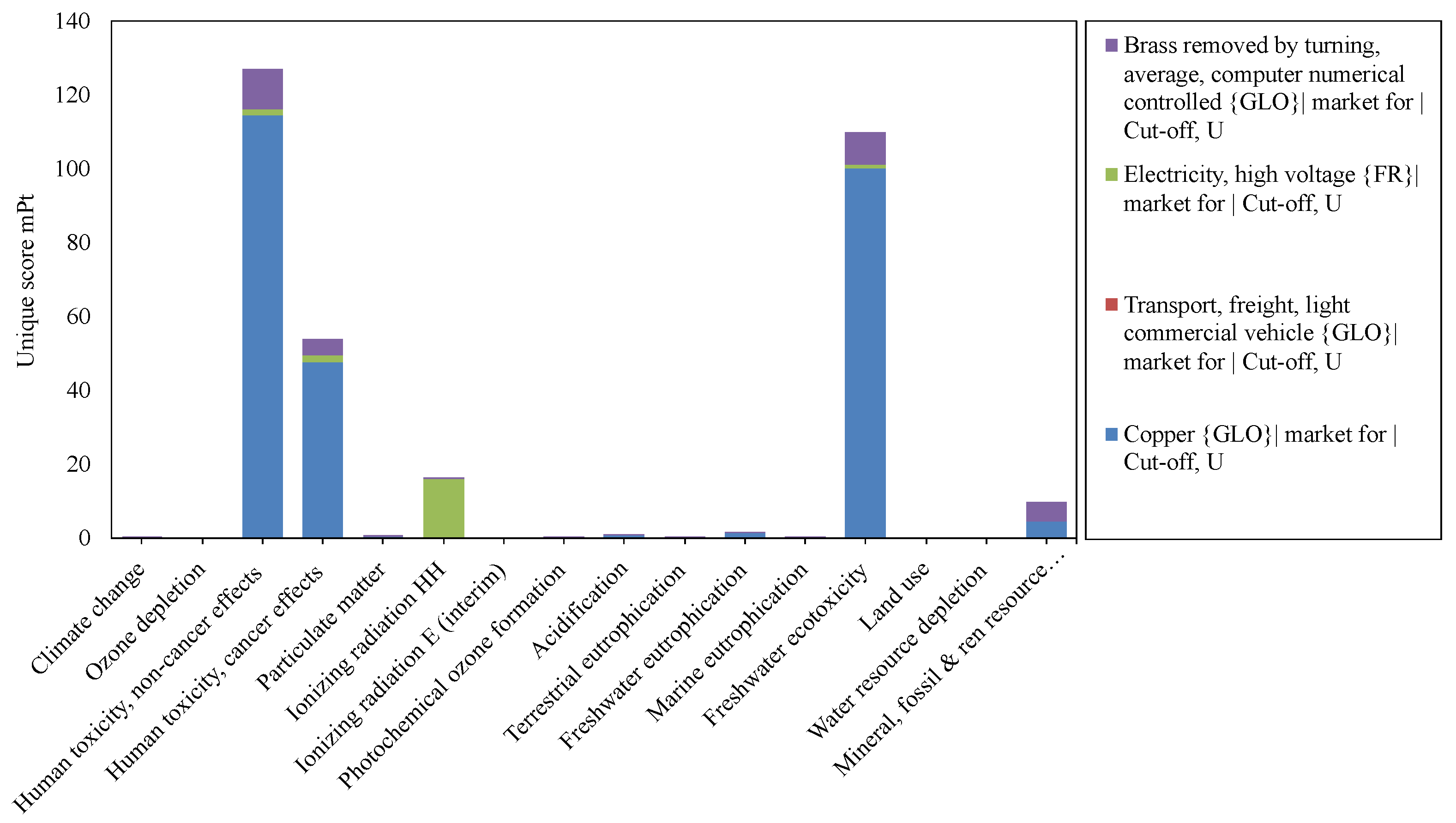

3.1. Life Cycle Impact Assessment

3.2. Interpretation of Results

4. Conclusions

- (1)

- Parts made from copper have the most significant impact on the environment, so changing materials or manufacturing processes and practices can mitigate this impact. It is also possible to change the architecture of the accelerometer by eliminating the screw stud while favoring another type of fastening (e.g., mounting with a magnet or by structural bonding).

- (2)

- The Piezoceramic PZT element has the least impact on the environment; however, there are regulatory restrictions on its use due to the dominant presence of lead in its chemical composition. This means that its substitution with another alternative lead-free material is always preferable.

- (3)

- The study highlights that ionizing radiation and human toxicity are major environmental concerns, particularly due to the heavy reliance on nuclear energy in France. This underscores the importance of considering energy sources in the ecodesign to minimize environmental and health risks.

- Our study employs a partial LCA due to the difficulty of obtaining comprehensive data for all life cycle stages. Detailed information on materials, manufacturing processes, and end-of-life treatments are very limited in the literature; additionally, the Ecoinvent database provides generic data that can potentially skew the results. In addition, assumptions and simplifications might not accurately reflect real conditions.

- The initial phase of our inventory involves disassembling the accelerometer, as shown in Section 2.2, to identify the materials and manufacturing processes used. Variations in manufacturing practices among different suppliers or production batches, along with the absence of specific data, can result in variability in environmental impacts. Consequently, the available data may be uncertain or variable, potentially leading to inaccuracies in the LCA results.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| TDS | Technical Data Sheet |

| EF | Environmental Footprint |

| CMS | Condition Monitoring Systems |

| BOM | Bill Of Materials |

| EDXS | Energy-Dispersive X-ray Spectroscopy |

References

- Desalegn, B.; Gebeyehu, D.; Tamrat, B. Wind energy conversion technologies and engineering approaches to enhancing wind power generation: A review. Heliyon 2022, 8, e11263. [Google Scholar] [CrossRef] [PubMed]

- Pourrajabian, A.; Afshar, P.A.N.; Ahmadizadeh, M.; Wood, D. Aero-structural design and optimization of a small wind turbine blade. Renew. Energy 2016, 87, 837–848. [Google Scholar] [CrossRef]

- Muhsen, H.; Al-Kouz, W.; Khan, W. Small Wind Turbine Blade Design and Optimization. Symmetry 2019, 12, 18. [Google Scholar] [CrossRef]

- Hasan, M.; El-Shahat, A.; Rahman, M. Performance Investigation of Three Combined Airfoils Bladed Small Scale Horizontal Axis wind Turbine by BEM and CFD Analysis. J. Power Energy Eng. 2017, 5, 14–27. [Google Scholar] [CrossRef]

- Rehman, S.; Alam, M.; Alhems, L.; Rafique, M. Horizontal Axis Wind Turbine Blade Design Methodologies for Efficiency Enhancement—A Review. Energies 2018, 11, 506. [Google Scholar] [CrossRef]

- Sethuraman, L.; Dykes, K. GeneratorSE: A Sizing Tool for Variable-Speed Wind Turbine Generators; Technical Report; National Renewable Energy Laboratory: Washington, DC, USA, 2017; Volume 9. Available online: http://www.osti.gov/servlets/purl/1395455/ (accessed on 2 July 2024).

- Li, D.; Zhang, Z.; Zhou, X.; Zhang, Z.; Yang, X. Cross-wind dynamic response of concrete-filled double-skin wind turbine towers: Theoretical modelling and experimental investigation. J. Vib. Control. 2023, 30, 2881–2893. [Google Scholar] [CrossRef]

- Kouloumpis, V.; Azapagic, A. A model for estimating life cycle environmental impacts of offshore wind electricity considering specific characteristics of wind farms. Sustain. Prod. Consum. 2022, 29, 495–506. [Google Scholar] [CrossRef]

- Rueda-Bayona, J.G.; Eras, J.J.C.; Chaparro, T.R. Impacts generated by the materials used in offshore wind technology on Human Health, Natural Environment and Resources. Energy 2022, 261, 125223. [Google Scholar] [CrossRef]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life cycle assessment of a multi-megawatt wind turbine. Renew. Energy 2009, 34, 667–673. [Google Scholar] [CrossRef]

- Martínez, E.; Jiménez, E.; Blanco, J.; Sanz, F. LCA sensitivity analysis of a multi-megawatt wind turbine. Appl. Energy 2010, 87, 2293–2303. [Google Scholar] [CrossRef]

- Tremeac, B.; Meunier, F. Life cycle analysis of 4.5 MW and 250 W wind turbines. Renew. Sustain. Energy Rev. 2009, 13, 2104–2110. [Google Scholar] [CrossRef]

- Gaha, R.; Benamara, A.; Yannou, B. Eco-Design of a Basin Mixer in Geometric Modeling Phase. Key Eng. Mater. 2014, 572, 7–11. [Google Scholar] [CrossRef]

- Canet, H.; Guilloré, A.; Bottasso, C. The eco-conscious wind turbine: Design beyond purely economic metrics. Wind. Energy Sci. 2023, 8, 1029–1047. [Google Scholar] [CrossRef]

- Guilloré, A.; Canet, H.; Bottasso, C. Life Cycle Environmental Impact of Wind Turbines: What are the Possible Improvement Pathways? J. Phys. Conf. Ser. 2022, 2265, 042033. [Google Scholar] [CrossRef]

- Bonou, A.; Skelton, K.; Olsen, S. Ecodesign framework for developing wind turbines. J. Clean. Prod. 2016, 126, 643–653. [Google Scholar] [CrossRef]

- Martinez-Marquez, D.; Florin, N.; Hall, W.; Majewski, P.; Wang, H.; Stewart, R. State-of-the-art review of product stewardship strategies for large composite wind turbine blades. Resour. Conserv. Recycl. Adv. 2022, 15, 200109. [Google Scholar] [CrossRef]

- Chu, W.; Lin, C.; Li, M. Active multimode vibration control of a smart structure using macro fiber composite actuators based on ANFIS. J. Low Freq. Noise Vib. Act. Control. 2020, 39, 1187–1203. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, W.; Luo, H.; Zhang, R. Modeling and active control of geometrically nonlinear vibration of composite laminates with macro fiber composite. Compos. Struct. 2023, 321, 117292. [Google Scholar] [CrossRef]

- Zhou, X.; Ke, Y.; Zhu, J.; Cui, W. Sustainable Operation and Maintenance of Offshore Wind Farms Based on the Deep Wind Forecasting. Sustainability 2023, 16, 333. [Google Scholar] [CrossRef]

- Yildirim, M.; Sun, X.; Gebraeel, N. Sensor-Driven Condition-Based Generator Maintenance Scheduling—Part I: Maintenance Problem. IEEE Trans. Power Syst. 2016, 31, 4253–4262. [Google Scholar] [CrossRef]

- Tian, Z.; Wang, H. Wind power system reliability and maintenance optimization considering turbine and wind uncertainty. J. Qual. Maint. Eng. 2022, 28, 252–273. [Google Scholar] [CrossRef]

- Gaha, R.; Benamara, A.; Yannou, B. An Environmental Impact/Cost Model for Evaluating Multiple Feature-Based Machining Methods. In Design and Modeling of Mechanical Systems—II. Lecture Notes in Mechanical Engineering; Chouchane, M., Fakhfakh, T., Daly, H., Aifaoui, N., Chaari, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 21–27. [Google Scholar]

- ISTEC International. E-book: Optimizing WTG Availability and Maintenance Efficiency. Available online: https://www.istec.com/en/ebook-wtg/ (accessed on 2 July 2024).

- Vishwakarma, M.; Purohit, R.; Harshlata, V.; Rajput, P. Vibration Analysis & Condition Monitoring for Rotating Machines: A Review. Mater. Today Proc. 2017, 4, 2659–2664. [Google Scholar]

- Piotrowski, J. Shaft Alignment Handbook; Taylor & Francis Group: Oxfordshire, UK, 2006. [Google Scholar]

- Jalan, A.; Mohanty, A. Model based fault diagnosis of a rotor–bearing system for misalignment and unbalance under steady-state condition. J. Sound Vib. 2009, 327, 604–622. [Google Scholar] [CrossRef]

- Tahir, M.; Hussain, A.; Badshah, S.; Khan, A.; Iqbal, N. Classification of unbalance and misalignment faults in rotor using multi-axis time domain features. In Proceedings of the 2016 International Conference On Emerging Technologies (ICET), Islamabad, Pakistan, 18–19 October 2016; pp. 1–4. [Google Scholar]

- Yamamoto, G.; Da Costa, C.; Da Silva Sousa, J.S. A smart experimental setup for vibration measurement and imbalance fault detection in rotating machinery. Case Stud. Mech. Syst. Signal Process. 2016, 4, 8–18. [Google Scholar] [CrossRef]

- Mathew, J.; Alfredson, R. The Condition Monitoring of Rolling Element Bearings Using Vibration Analysis. J. Vib. Acoust. Stress. Reliab. Des. 1984, 106, 447–453. [Google Scholar] [CrossRef]

- Dalpiaz, G.; Rivola, A. Condition Monitoring and Diagnostics in Automatic Machines: Comparison of Vibration Analysis Techniques. Mech. Syst. Signal Process. 1997, 11, 53–73. [Google Scholar] [CrossRef][Green Version]

- KiranKumar, M.; Lokesha, M.; Kumar, S.; Kumar, A. Review on Condition Monitoring of Bearings using vibration analysis techniques. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 012110. [Google Scholar] [CrossRef]

- Malla, C.; Panigrahi, I. Review of Condition Monitoring of Rolling Element Bearing Using Vibration Analysis and Other Techniques. J. Vib. Eng. Technol. 2019, 7, 407–414. [Google Scholar] [CrossRef]

- Sheng, S. Wind Turbine Gearbox Condition Monitoring Round Robin Study—Vibration Analysis; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2012; Volume 7. Available online: https://www.osti.gov/biblio/1048981 (accessed on 2 July 2024).

- Jonas, S.; Anagnostos, D.; Brodbeck, B.; Meyer, A. Vibration Fault Detection in Wind Turbines Based on Normal Behaviour Models without Feature Engineering. Energies 2023, 16, 1760. [Google Scholar] [CrossRef]

- Li, D.; Ho, S.; Song, G.; Ren, L.; Li, H. A review of damage detection methods for wind turbine blades. Smart Mater. Struct. 2015, 24, 033001. [Google Scholar] [CrossRef]

- Metra Mess und Frequenztechnik. Piezoelectric Accelerometers Theory and Application; Metra Mess und Frequenztechnik: Radebeul, Germany, 2001. [Google Scholar]

- Aloui, R.; Larbi, W.; Chouchane, M. Finite Element Modeling and Analysis of a Bimorph Piezoelectric Energy Harvester. In Design and Modeling of Mechanical Systems—III; Haddar, M., Chaari, F., Benamara, A., Chouchane, M., Karra, C., Aifaoui, N., Eds.; Springer: Cham, Switzerland, 2018; pp. 1205–1214. [Google Scholar]

- Aloui, R.; Larbi, W.; Chouchane, M. Sensitivity Analysis of Frequency Response Functions for Load Resistance of Piezoelectric Energy Harvesters. In Advances in Acoustics and Vibration II; Fakhfakh, T., Karra, C., Bouaziz, S., Chaari, F., Haddar, M., Eds.; Springer: Cham, Switzerland, 2018; pp. 136–148. [Google Scholar]

- Aloui, R.; Larbi, W.; Chouchane, M. Metamodeling and Sensitivity Analysis of a Piezoelectric Energy Harvester Based on Polynomial Chaos Expansions. In Advances in Nonlinear Dynamics and Control of Mechanical and Physical Systems; Belhaq, M., Ed.; Springer: Singapore, 2024; pp. 165–176. [Google Scholar]

- Varanis, M.; Silva, A.; Mereles, A.; Pederiva, R. MEMS accelerometers for mechanical vibrations analysis: A comprehensive review with applications. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 527. [Google Scholar] [CrossRef]

- Laine, J.; Mougenot, D. A high-sensitivity MEMS-based accelerometer. Lead. Edge 2014, 33, 1234–1242. [Google Scholar] [CrossRef]

- Sheng, S.; Yang, W. Wind Turbine Drivetrain Condition Monitoring—An Overview (Presentation); National Renewable Energy Lab. (NREL): Golden, CO, USA, 2013; Volume 7. Available online: https://www.osti.gov/biblio/1087787 (accessed on 2 July 2024).

- Le, T.; Luu, T.; Nguyen, H.; Nguyen, T.; Ho, D.; Huynh, T. Piezoelectric Impedance-Based Structural Health Monitoring of Wind Turbine Structures: Current Status and Future Perspectives. Energies 2022, 15, 5459. [Google Scholar] [CrossRef]

- Rödel, J.; Jo, W.; Seifert, K.; Anton, E.; Granzow, T.; Damjanovic, D. Perspective on the Development of Lead-free Piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Bell, A.; Deubzer, O. Lead-free piezoelectrics—The environmental and regulatory issues. MRS Bull. 2018, 43, 581–587. [Google Scholar] [CrossRef]

- Orlik, K.; Lorgouilloux, Y.; Marchet, P.; Thuault, A.; Jean, F.; Rguiti, M.; Courtois, C. Influence of microwave sintering on electrical properties of BCTZ lead free piezoelectric ceramics. J. Eur. Ceram. Soc. 2020, 40, 1212–1216. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Koh, S.; Reaney, I.; Sinclair, D.; Mustapha, K.; Acquaye, A.; Wang, D. Are lead-free piezoelectrics more environmentally friendly? MRS Commun. 2017, 7, 1–7. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Reaney, I.; Koh, S.; Acquaye, A.; Sinclair, D.; Randall, C.A.; Abubakar, F.H.; Smith, L.; Schileo, G.; Ozawa-Meida, L. Life cycle assessment and environmental profile evaluation of lead-free piezoelectrics in comparison with lead zirconate titanate. J. Eur. Ceram. Soc. 2018, 38, 4922–4938. [Google Scholar] [CrossRef]

- Pender, K.; Bacharoudis, K.; Romoli, F.; Greaves, P.; Fuller, J. Feasibility of Natural Fibre Usage for Wind Turbine Blade Components: A Structural and Environmental Assessment. Sustainability 2024, 16, 5533. [Google Scholar] [CrossRef]

- Atilgan Turkmen, B.; Germirli Babuna, F. Life Cycle Environmental Impacts of Wind Turbines: A Path to Sustainability with Challenges. Sustainability 2024, 16, 5365. [Google Scholar] [CrossRef]

- Gkantou, M.; Rebelo, C.; Baniotopoulos, C. Life Cycle Assessment of Tall Onshore Hybrid Steel Wind Turbine Towers. Energies 2020, 13, 3950. [Google Scholar] [CrossRef]

- Chang, C.C.W.; Ding, T.J.; Han, W.; Chai, C.C.; Bhuiyan, M.A.; Choon-Yian, H.; Song, T.C. Recent advancements in condition monitoring systems for wind turbines: A review. Energy Rep. 2023, 9, 22–27. [Google Scholar]

- Jin, X.; Xu, Z.; Qiao, W. Condition Monitoring of Wind Turbine Generators Using SCADA Data Analysis. IEEE Trans. Sustain. Energy 2021, 12, 202–210. [Google Scholar] [CrossRef]

- Leung, D.; Yang, Y. Wind energy development and its environmental impact: A review. Renew. Sustain. Energy Rev. 2012, 16, 1031–1039. [Google Scholar] [CrossRef]

- Nazir, M.; Ali, N.; Bilal, M.; Iqbal, H. Potential environmental impacts of wind energy development: A global perspective. Curr. Opin. Environ. Sci. Health 2020, 13, 85–90. [Google Scholar] [CrossRef]

- An, J.; Zou, Z.; Chen, G.; Sun, Y.; Liu, R.; Zheng, L. An IoT-Based Life Cycle Assessment Platform of Wind Turbines. Sensors 2021, 21, 1233. [Google Scholar] [CrossRef] [PubMed]

- Hagen, L.; Petrick, K.; Wilhelm, S.; Schmehl, R. Life-Cycle Assessment of a Multi-Megawatt Airborne Wind Energy System. Energies 2023, 16, 1750. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Treyer, K.; Bauer, C. Life cycle inventories of electricity generation and power supply in version 3 of the ecoinvent database—part II: Electricity markets. Int. J. Life Cycle Assess. 2016, 21, 1255–1268. [Google Scholar] [CrossRef]

- System Models. Available online: https://support.ecoinvent.org/system-models (accessed on 30 May 2024).

- Piezotronics, P. Model M603C01—Platinum Low-Cost Industrial ICP® Accelerometer—Installation and Operating Manual. Available online: https://www.pcb.com/products?m=m603c01 (accessed on 2 July 2024).

- JRC International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Provisions and Action Steps. JRC Public Repository. 2010. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC58190 (accessed on 2 July 2024).

- Shrout, T.; Zhang, S. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Nomel, I.; Lelievre, J.; Boyer, L.; Durand-Panteix, O.; Marchet, P. Synthesis of 0.94 Na0.5Bi0.5TiO3–0.06 BaTiO3 (NBT-6BT) lead-free piezoelectric powder suitable for aerosol deposition (AD). Ceram. Int. 2022, 48, 14697–14707. [Google Scholar] [CrossRef]

- Naumann, G.; Famiglietti, J.; Schropp, E.; Motta, M.; Gaderer, M. Dynamic life cycle assessment of European electricity generation based on a retrospective approach. Energy Convers. Manag. 2024, 311, 118520. [Google Scholar] [CrossRef]

| Sensor Type | Temperature Range | Size of the Sensor Casing | Frequency Response | Measurement Range | Sensitivity |

|---|---|---|---|---|---|

| PE | Cryo up to >+300 °C | Very small | DC to 10 kHz+ | 2 g to 50 × 103 g | Very high |

| IEPE | −50 °C to +200 °C, Cryo possible | normal | Typically 0.5 Hz to 10 kHz | 10 g to 10 × 103 g | normal |

| MEMS | −50 °C to 120 °C | normal | DC to 3 kHz | 0 g to 250 g | high |

| Performance | SI Unit | Value |

|---|---|---|

| Sensitivity (±10%) | mV (m/s2) | 10.2 |

| Measurement range | m/s2 | ±490 |

| Frequency range (±3 dB) | Hz | 0.5 to 104 |

| Resonant frequency | Hz | 25 |

| Broadband resolution (1 to 104 Hz) | m/s2 | 3434 |

| Non-linearity | – | ±1% |

| Transverse sensitivity | – | ≤7% |

| LCA Keys | Accelerometer M603C01 |

|---|---|

| Functional unit | One accelerometer that transmits the vibration signal to the processing unit during MTBF of the asset |

| Lifespan | It is assumed to be 3 years |

| System Boundaries | Cradle to gate: From raw material extraction to manufacturing stage |

| Method/Normalization/Ponderation | European, ILCD 2011 Midpoint+ [63]/EC-JRC Global, Equal weighting |

| Environmental impact categories | 16 indicators of Midpoint |

| Item | Designation | Quantity | Weight (g) | Material | Manufacturing Process | SimaPro Database |

|---|---|---|---|---|---|---|

| 1 | Housing | 1 | 49.17 | Stainless steel | Machining | Available |

| 2 | Active material | 1 | 0.27 | Piezoceramic PZT | Sintering | Not available |

| 3 | Screw stud | 1 | 1.71 | Copper | Machining | Available |

| 4 | Capsule | 1 | 0.68 | Tungsten | Machining | Available |

| 5 | Electrical connectors | 1 | 0.45 | Copper | Extrusion | Available |

| 6 | Integral electronics | 1 | 0.71 | Cu/Al/Polymer ⋯ | Electronics processes | Not available |

| 7 | Mass | 1 | 1.51 | Tungsten | Machining | Available |

| 8 | Washer | 1 | 0.26 | Epoxy | Cutting/drilling | Available |

| PZT Material Composition | Weight % | Measured Weight % |

|---|---|---|

| Lead Oxide | 50–70 | 56.31 |

| Zirconium Oxide | 10–30 | 11.19 |

| Titanium Oxide | 5–20 | 4.89 |

| Niobium Oxide | 0–10 | 0.52 |

| Strontium Oxide | 0–5 | 2.54 |

| Barium Oxide | 0–5 | 3.13 |

| Magnesium Oxide | 0–5 | 0.13 |

| Nickel Oxide | 0–5 | 0.00 |

| Iron Oxide | 0–5 | 0.00 |

| Manganese Oxide | 0–5 | 0.00 |

| Silver | 0–25 | 0.38 |

| Impact Categories | Unity | Housing | Active Material (PZT) | Screw Stud | Electrical Connectors | Mass | Capsule |

|---|---|---|---|---|---|---|---|

| Total | mPt | 38.0447 | 9.4441 | 320.9638 | 94.8215 | 68.6894 | 89.8220 |

| Climate change | mPt | 0.0149 | 0.0032 | 0.1248 | 0.0661 | 0.1988 | 0.5869 |

| Ozone depletion | mPt | 0.0584 | 0.0146 | 0.0518 | 0.0499 | 0.0537 | 0.0237 |

| Human toxicity non-cancer effects | mPt | 1.3712 | 0.3964 | 127.0123 | 32.6856 | 11.3865 | 14.0418 |

| Human toxicity, cancer effects | mPt | 2.6875 | 0.4209 | 53.8915 | 15.1196 | 24.1430 | 48.3682 |

| Particulate matter | mPt | 0.0344 | 0.0074 | 0.6841 | 0.2032 | 0.2492 | 0.4781 |

| Ionizing radiation HH | mPt | 32.7833 | 8.1954 | 16.2180 | 16.0857 | 16.4121 | 7.6362 |

| Ionizing radiation E (interim) | mPt | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| Photochemical ozone formation | mPt | 0.0088 | 0.0022 | 0.2130 | 0.0676 | 0.1007 | 0.1761 |

| Acidification | mPt | 0.0114 | 0.0026 | 0.9561 | 0.2664 | 0.1983 | 0.5215 |

| Terrestrial eutrophication | mPt | 0.0092 | 0.0024 | 0.2172 | 0.0719 | 0.1125 | 0.1685 |

| Freshwater eutrophication | mPt | 0.102 | 0.0034 | 1.5706 | 0.4074 | 0.1925 | 1.3022 |

| Marine eutrophication | mPt | 0.0138 | 0.0034 | 0.1483 | 0.0498 | 0.0622 | 0.1406 |

| Freshwater ecotoxicity | mPt | 0.7847 | 0.2373 | 109.8026 | 28.2726 | 12.1544 | 15.5745 |

| Land use | mPt | 0.0000 | 0.0000 | 0.0005 | 0.0002 | 0.0002 | 0.0001 |

| Water resource depletion | mPt | 0.0357 | 0.0090 | 0.0819 | 0.0809 | −0.0145 | 0.7068 |

| Mineral, fossil and renewable resource depletion | mPt | 0.2214 | 0.1459 | 9.9912 | 1.3946 | 3.4398 | 0.0967 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aloui, R.; Gaha, R.; Lafarge, B.; Celik, B.; Verdari, C. Life Cycle Assessment of Piezoelectric Devices Implemented in Wind Turbine Condition Monitoring Systems. Energies 2024, 17, 3928. https://doi.org/10.3390/en17163928

Aloui R, Gaha R, Lafarge B, Celik B, Verdari C. Life Cycle Assessment of Piezoelectric Devices Implemented in Wind Turbine Condition Monitoring Systems. Energies. 2024; 17(16):3928. https://doi.org/10.3390/en17163928

Chicago/Turabian StyleAloui, Rabie, Raoudha Gaha, Barbara Lafarge, Berk Celik, and Caroline Verdari. 2024. "Life Cycle Assessment of Piezoelectric Devices Implemented in Wind Turbine Condition Monitoring Systems" Energies 17, no. 16: 3928. https://doi.org/10.3390/en17163928

APA StyleAloui, R., Gaha, R., Lafarge, B., Celik, B., & Verdari, C. (2024). Life Cycle Assessment of Piezoelectric Devices Implemented in Wind Turbine Condition Monitoring Systems. Energies, 17(16), 3928. https://doi.org/10.3390/en17163928