Abstract

The reservoir properties of super-heavy oil reservoirs in fluvial sedimentation are relatively poor, with high heterogeneity directly affecting the steam injection rate and expansion velocity of the steam chamber in the SAGD process. In order to significantly improve SAGD production performance, a combination of laboratory testing and physical simulation experiments was used to analyze the changes in reservoir-rock structure, rock geomechanical characteristics, and porosity and permeability during high-pressure injection, through rock geomechanics testing, core-flood experiment, and SEM scanning analysis. Large-scale two-dimensional physical simulation experiments were designed to analyze the effect of different injection agents in assisting the expansion of steam chambers. The experimental results showed that, with the increase in injection pore pressure, the reservoir permeability increased from 2.74 D to 4.56 D, and the contact between rock particles became looser after expansion, indicating a significant improvement in reservoir properties through high-pressure-injection-induced dilation. The results of the two-dimensional physical simulation experiments demonstrated that the solvent-assisted steam-chamber dilation speed was further increased compared with the conventional huff-n-puff dilation. Cyclic gas-injection volume can be increased from 0.16 PV in pure-steam injection cases to 0.32 PV. The hybrid-agent system of solvent-plus-gas can produce the dual positive effect of solvent dissolution and gas diffusion, more effectively improve the steam-chamber expansion speed, enhance the phased oil-recovery degree by 23.41%, and increase the oil/steam ratio from 0.27 to 0.33, indicating encouraging potentials in improving heavy oil and bitumen production performance by the dilation strategy.

1. Introduction

The SAGD (steam assisted gravity drainage) process, which is one of the most commonly used heavy-oil and oil-sand recovery methods, was invented by R.G Butler approximately 40 years ago and been commercialized for 25 years. The downhole temperature surveillance and simulation results indicate that the steam chamber non-uniform development is a common phenomenon, which limits the production performance and steam chamber expansion rate. The main reason for this conformance evolution is the fluvial sedimentation environment, which has overlapped sand bodies with different permeability and fluid flow mobility.

Aimed at improving the steam conformance, extensive studies have been carried out during past years, mainly focused on the mechanisms of different methods, operational strategies, change in injection fluids, and a hybrid process of the methods above, and obtained different results.

Among various methods, the hydraulic dilation to improve the porous media permeability is one of the most effective strategies. The hydraulic connection model was produced for the squeeze-preprocessing SAGD start-up [1]. The geomechanical and thermal-reservoir simulation has been carried out to demonstrates SAGD enhancement due to shear dilation [2]. High-pressure start-up SAGD with geomechanics [3], geomechanical treatment in the numerical simulation of SAGD [4], fluid flow–thermoplastic deformation of oil sand and hydraulic fracture propagation of land facies ultra-heavy oil sands were investigated by numerical simulation [5,6], to demonstrate the mechanism of dilation process.

The treatment of inter-well formation can be started during the SAGD preheating process. Zhang, J., et al. have validated the effectiveness of steam circulation strategies for SAGD wells after geomechanical dilation start-up [7]. Sun, X., et al. introduced the SAGD dilation start-up and its applications in China [8]. An experimental investigation method was used to study the SAGD dilation start-up in shallow heavy-oil reservoirs, which received positive results [7,8,9,10].

As the common process of dilation is to inject water, the reservoir deformation, constitutive model of oil sands, and the stress-dependent model for permeability changes are the focus of this treatment. The permeability enhancement, geomechanical characterization of inclined heterolithic stratification, and its permeability evolution, were also analyzed by experiment and numerical simulation [11,12,13,14,15]. Moreover, the alteration of stress as the operational strategy is also validated [16].

As most heterogeneous reservoirs have the mudstone or shale barriers [17], Gao, Y., et al. studied the evaluation of influences of mudstone barriers under hot-water injection using coupled geomechanical–thermal simulation [18], which validated that the hot-water dilation can effectively break the mud barriers and improve the steam conformance.

Apart from the hot-water injection, the solvent has good oil-dissolution effect, which is able to massively reduce the oil viscosity. Abbasi-Asl, Y. et al. studied the role of reservoir dilation on solvent-assisted SAGD (SA-SAGD) performance [19]. The in situ dilation affects solvent-assisted SAGD performance, and the solvent-assisted start-up of SAGD in shallow heavy-oil reservoirs, and the effect of geomechanics on optimization of solvent-assisted SAGD/SA-SAGD were also investigated, which shows that the hybrid process combining solvent and hot water or steam could further improve the dilation performance [20,21,22,23,24].

Other approaches including injecting oil-in-water emulsions [25], in situ catalytic aquathermolysis combined with geomechanical dilation [26], herringbone injector–horizontal-producer–steam-assisted gravity drainage (HI-SAGD) were also alternatives to further enhance the dilation performance [27,28].

The pure-steam dilation method has been applied in SAGD reservoirs in Xinjiang oilfield and showed encouraging performance [29,30], which validates the effectiveness of this method from laboratory to oilfield. However, the geomechanical properties of rock under high-temperature–high-pressure (HTHP) conditions have not been quantified. Considering the field conditions, the non-condensable gas is more largely available and less expensive than solvent for dilation injection, while the combined mechanism of NCG and solvent is unclear; it is also necessary for their contribution to the steam chamber volume and SAGD production performance to be analyzed in detail. Furthermore, most SAGD well pairs have entered into the production stage, and the effectiveness of dilation in already developed steam chambers needs in-depth study.

To this end, this work is mainly focused on the rock HTHP geomechanics characteristics, and scaled physical experiments were designed and used to study the effectiveness of hybrid fluid of NCG and solvent on the SAGD steam-chamber growth, production dynamics and oil recovery factor [31].

2. Methodology

2.1. Rock Geomechanical Properties Test

- (1)

- Triaxial test under different confining pressures

A triaxial test under different confining pressures was carried out to acquire the geomechanical properties of the core samples, which are crucial for mechanism investigation and guidance of the following two-dimensional physical modelling. The core samples are obtained from the typical oil-sand formation of FC oilfield, Xinjiang province, China. The triaxial test apparatus was used to test the core sample geomechanical properties with the varied confining pressures from 1 to 6 MPa. The Young’s modulus, Poisson’s ratio, stress, and strain were recorded systematically.

Tracking software was used to assist the analysis of the rock failure mechanism; the vector direction means the direction of the force on different parts of the rock, and the overall shape of the vector field is based on the change of core shape, to quantify and match the failure position and dynamics.

- (2)

- Petrophysical property test at elevated injection pressures

A one-dimensional core-flooding apparatus was used to test the permeability and porosity of the core under different timed injection pressure. The dimension of the core holder is Φ2.54 cm × 10 cm, the pressure limit is 0.1–20 MPa, and the temperature limit is 0–230 °C.

The test scheme increases the injection pressure from 100 psi to 700 psi, and the permeability and porosity at different cycles of injection and production periods were tested and recorded.

- (3)

- SEM image analysis after dilation test

After the core-flood test, the core samples were taken out and slides were prepared to take the SEM images, to analyze the micro-structures after dilation by injection.

2.2. Two-Dimensional Scaled Physical Experiments

2.2.1. Experiment Apparatus

The steam-chamber expansion characteristics and mechanisms of conventional SAGD production, dilation by pure steam huff-n-puff, solvent-assisted huff-n-puff, non-condensate gas-assisted huff-n-puff, and solvent-assisted plus non-condensate gas-assisted huff-n-puff were carried under heterogeneous reservoir conditions. Through comparative experiments, the improvement effect of different injection agents on chamber expansion was investigated, and the variation characteristics of chamber expansion at different treatment cycles were revealed, which provided a key basis for the optimization of key parameters of steam-chamber dilation. The oil sample is from Z18 of the FC oilfield, and dewatered before experiments.

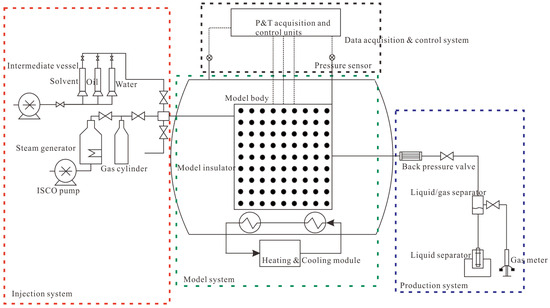

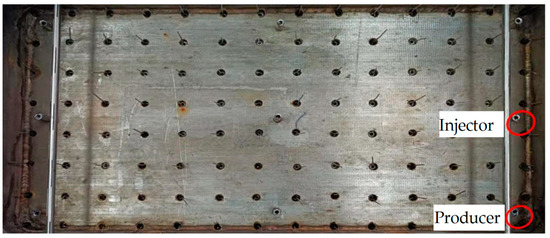

In this experiment, a two-dimensional scaled physical system was utilized under high-temperature and high-pressure conditions. The system consisted of an injection module, model body, monitoring module, and production-measurement module. The experimental flow chart can be seen in Figure 1. Well points, temperature, and pressure-data surveillance points within the model are illustrated in Figure 2. The temperature-field surveillance and inversion software can be viewed in Figure 3.

Figure 1.

Flow chart of two dimensional scaled physical experiment system.

Figure 2.

Well points and thermocouple points.

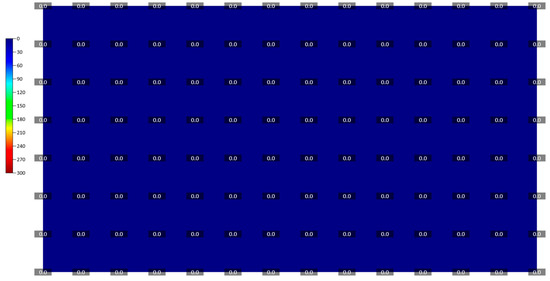

Figure 3.

Surveillance software for the physical system.

The two-dimensional physical model device is a crucial tool for studying enhanced thermal oil recovery in heavy-oil reservoirs. By applying similarity theory, researchers can explore the mechanisms of different recovery methods and optimize key operating parameters with flexibility. The device exhibits the following technical characteristics:

- (1)

- Modularization of experimental model: the high-pressure and high-temperature model is equipped with an automatic data-collection function for pressure data and temperature data from thermocouples.

- (2)

- Integral operation control panel: the temperature, pressure and other parameters of the model can be displayed and controlled by the modules, and can be recorded, and controlled by the computer; The model body-heat insulation and injection and production well-heat insulation structure are innovative design in this system.

- (3)

- Diversification of experimental schemes: the model can be designed to simulate various conditions of injecting agents, operational parameters and well patterns.

The well points are shown in Figure 2, which simulates the semi SAGD well pair. The temperature surveillance software is show in Figure 3, which shows the temperature point data and the pump injection pressures can be controlled.

The physical simulation experimental system has the following technical parameters:

- (1)

- Working pressure: 0–10 MPa;

- (2)

- Working temperature: room temperature—270 °C;

- (3)

- Core specification: 400 mm × 200 mm × 70 mm, flexible graphite seal;

- (4)

- Steam displacement: 12 L/h, maximum working output temperature 350 °C;

- (5)

- Software: automatic data gathering of temperature, pressure, saturation point, flow and other data;

- (6)

- Measuring points: the temperature field is 14 × 8 = 112; the number of pressure measuring points is 9;

- (7)

- Two vertical wells; three SAGD pairs.

2.2.2. Design of the Experiment

The similarity criterion of large-scale two-dimensional SAGD physical simulation is carried out according to Butler’s SAGD similarity criterion. The designed results according to the reservoir data are listed in Table 1:

Table 1.

Comparison of the reservoir and model parameters based on similarity design.

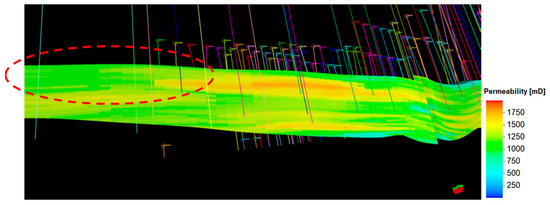

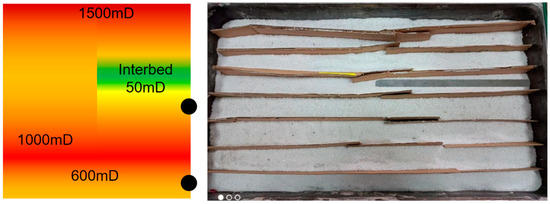

2.2.3. Sand-Pack Design Based on Heterogeneous Formation Characteristics

According to the characteristics of reservoir longitudinal heterogeneity in SAGD area of double horizontal wells, the interlayer/low permeability layer can be divided into two cases: above well I and between well IP; among them, the interlayer above well I is very important to open the steam chamber and use the reserves above the interlayer (Figure 4). The interlayer between IP wells is greatly affected by sedimentation rhythm. In order to fully cover the influence of different interlayers and optimize the operating parameters, physical simulation of interlayers above well I and numerical simulation of interlayers above well I and between IP wells are adopted, as shown in Figure 5.

Figure 4.

Cross-section map of permeability (red circle: low temperature/interbeded zone).

Figure 5.

Vertical sand-pack design.

According to the similarity, the field permeability of 807 mD corresponds to 602 D in the physical model. For the heterogeneous reservoir condition, the filling sand is 600 mD, 1000 mD and 1500 mD, respectively, and the permeability of the corresponding physical model is 448 D, 746 D and 1119 D, respectively. The corresponding particle sizes are 1000 μm, 1400 μm and 1600 μm, respectively, and the corresponding quartz sand mesh numbers are 15 mesh, 10.7 mesh and 9.4 mesh, respectively. Finally, stratified heterogeneous filling sand was determined according to the above mesh numbers. The weight of quartz sand used in this filling is 6.19 kg.

Low-strength cement (sand-to-mud ratio 2:1) was used to simulate the muddy interlayer. The sand-containing cement board was prefabricated first, and then interlayer strips of different thickness and length were cut according to the interlayer thickness, which was used for the interlayer setting in each experiment. According to the thickness of the model, the actual reservoir thickness and the actual interlayer thickness of the reservoir, the designed interlayer thickness is 3 cm, interlayer distribution is 1/2 the well-group spacing, and the shear dilation strength of the interlayer is 7–8 MPa.

2.2.4. Experimental Schemes and Methodology

In order to compare the effect of steam stimulation and the effect of different agents on this process, a total of 5 sets of physical experiments were designed and carried out to reveal the characteristics of steam-chamber and production performance under different injection agents and different operation strategies. The parameters of different cases are listed in Table 2:

Table 2.

Technical parameters of each scheme.

- (1)

- Conventional dual-horizontal well SAGD;

- (2)

- Conventional steam huff-n-puff dilation—SAGD;

- (3)

- Solvent-assisted steam huff-n-puff dilation—SAGD;

- (4)

- Non-condensate gas-assisted steam huff-n-puff dilation—SAGD;

- (5)

- Solvent plus non-condensate gas-assisted steam huff-n-puff dilation—SAGD.

3. Results and Discussion

3.1. Rock Geomechanical-Properties Test

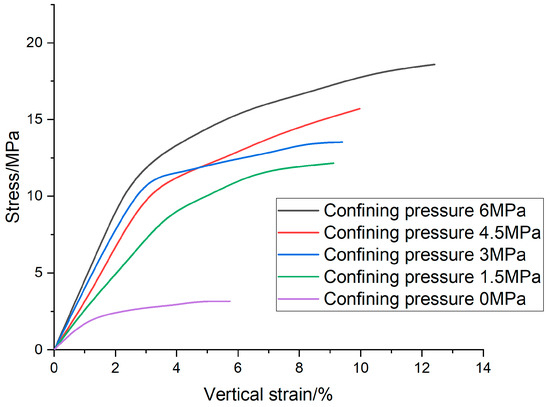

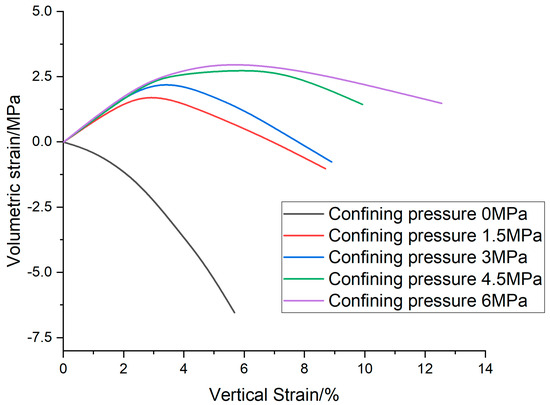

3.1.1. Triaxial Test under Different Confining Pressures

Through the core triaxial test, the stress–strain curves and volumetric expansion curves of different rocks in the study area are measured, and the key rock mechanics parameters are calculated. By increasing the confining pressure from 0 to 6 MPa, the effective stress increases dramatically under the same vertical strain (Figure 6). The volumetric strain also increases with confining pressure (Figure 7). From the results, the rock of the super-heavy oil reservoir in Fengcheng oilfield has strong dilatancy effect under low confining pressure, and the volume expansion capacity is more than 3%.

Figure 6.

Stress–strain curves under different confining pressures.

Figure 7.

Volumetric strain curves under different confining pressures.

From the change characteristics of the force diagram of the triaxial mechanics, using the tracking software to simulate the rock failure process, the results show that under the combined action of overlying formation pressure plus the expansion of the pore-injection pressure, the rock is squeezed by expansion and failure at the middle section, and the main failure mechanism is dilation failure, which is different from the shear failure of rapid-preheating SAGD process. The core image after the test is similar to the simulation results, in which it is also fractured in the middle section of the core.

3.1.2. Petrophysical Property Test at Elevated Injection Pressures

The porosity and permeability test results after one-dimensional cyclic steam stimulation shows that the porosity and permeability increase with injection pressure (Table 3). The main reason for this enhancement is that the increase in pore pressure promotes the rock dilatation.

Table 3.

Comparison of core permeability and porosity at different cycles.

When the injection pressure increases from 5.73 MPa to 7.52 MPa, the permeability of the core increases from 2.74 D to 4.56 D. By contrast, the porosity increases from 34.31% to 36.77%, correspondingly, while the increment in the first three cycles is lower than that in the fourth-to-seventh cycle, which means that the expansion takes effect with more than three cycles. After multi-cycles of treatment, the petrophysical properties can be effectively improved.

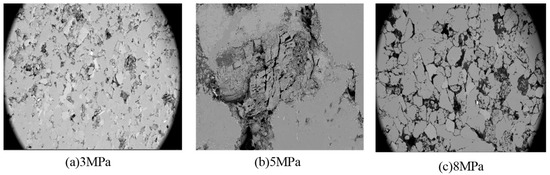

3.1.3. SEM Image Analysis after Dilation Test

SEM images before and after the dilation of the core shown in Figure 8 demonstrate that after 1 h of steam injection at conventional pressure of 3 MPa (no dilation phenomenon), the sandstone particles are tightly distributed and mainly filled by crude oil and clay minerals. After 1 h of steam injection at a normal medium pressure of 5 MPa, clay falls off and micro-cracks appear between particles. After 1 h steam injection at a high pressure of 8 MPa, the gap between particles increases and the dilation phenomenon is obvious.

Figure 8.

Microscopic images of core dilatation under different injection pressures.

3.2. Two-Dimensional Scaled Physical Experiments

- (1)

- Temperature field

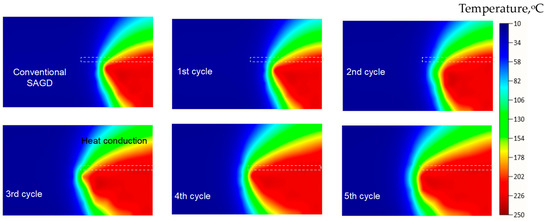

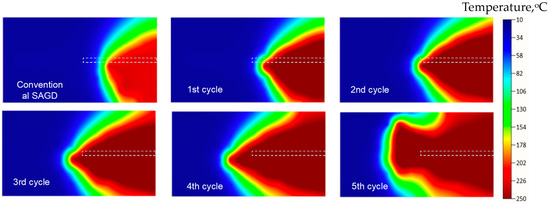

① Conventional SAGD. From the comparison of temperature fields at different times in Figure 9, there is an interlayer above the steam injection well and the planar range is 1/2 the well-pair spacing, that is, the interlayer closure degree is 50%. Under this condition, the steam chamber cannot break through the interlayer to develop upwards, but keeps expanding horizontally. The oil layer above the interlayer mainly relies on heat conduction to heat up, and the steam chamber bypasses the interlayer and develops upward in the later stage.

Figure 9.

Temperature distribution of conventional dual-horizontal well SAGD.

② Conventional steam-dilatation–SAGD: after the 51 min of SAGD, 5 cycles of steam huff-n-puff were carried out. As can be seen from the temperature-change characteristics in Figure 10, there is no obvious breakthrough on the interlayer. However, compared with conventional SAGD, the temperature is increased by 20 °C, which promotes the transverse expansion of the steam chamber and accelerates the development of the steam chamber bypassing the interlayer.

Figure 10.

SAGD temperature field at different stages of dilation by conventional steam.

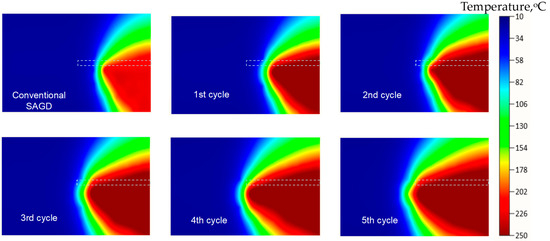

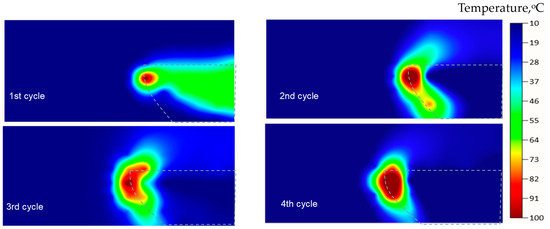

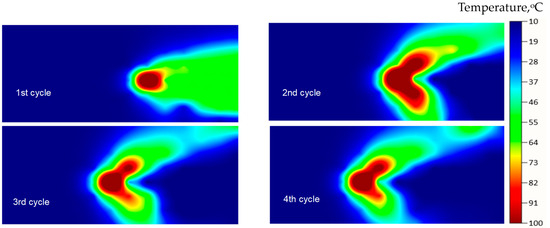

③ Solvent-assisted huff-n-puff dilatation–SAGD: from the temperature field in Figure 11, the molecular diffusion of solvent in crude oil promotes the rapid lateral expansion of the steam chamber, but the longitudinal expansion effect is weaker than that of non-condensate gas due to the limited injection of solvent, considering the high solvent price.

Figure 11.

Solvent-assisted dilation—SAGD temperature field at different stages.

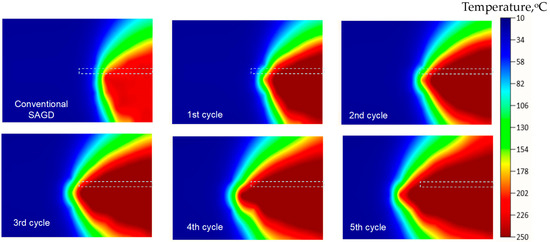

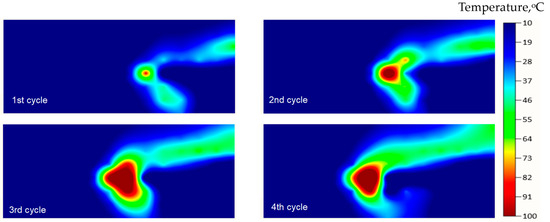

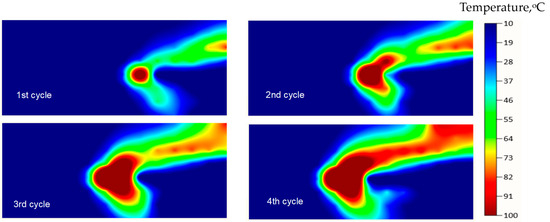

④ Non-condensate gas-assisted huff-n-puff dilation—SAGD: differently from conventional steam and solvent, the diffusion of gas promotes the diffusion of the steam chamber above the interlayer, and the range is larger than that of pure steam. As shown in Figure 12, the steam chamber breaks through the interlayer and begins to expand upwards at the fifth cycle, indicating that the addition of non-condensate gas is conducive to huff-n-puff dilation.

Figure 12.

NCG-assisted dilation—SAGD temperature field at different stages.

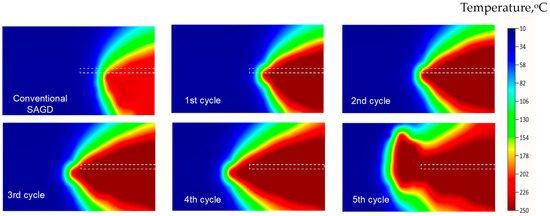

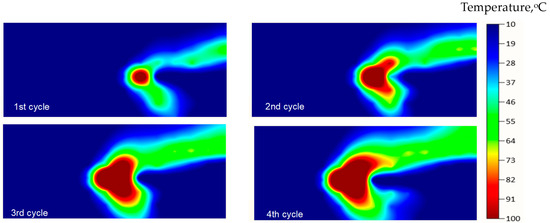

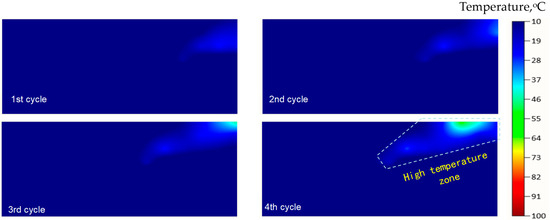

⑤ Non-condensate gas plus solvent-assisted huff-n-puff expansion—SAGD: huff-n-puff under multi-agent synergistic action can have a hybrid effect of different agents. Among these in Figure 13, the horizontal expansion of the steam chamber is promoted by solvent and the longitudinal expansion is promoted by non-condensate gas, and the influence of the interlayer on the longitudinal development of the steam chamber is gradually weakened after the fifth huff-n-puff cycle.

Figure 13.

NCG plus solvent-assisted dilation—SAGD temperature field at different stages.

- (2)

- Steam-chamber comparison for different cycles

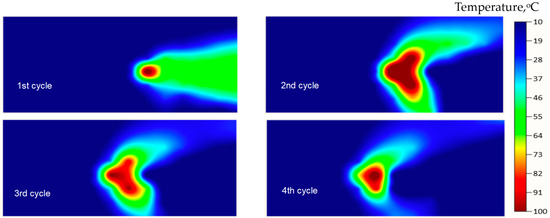

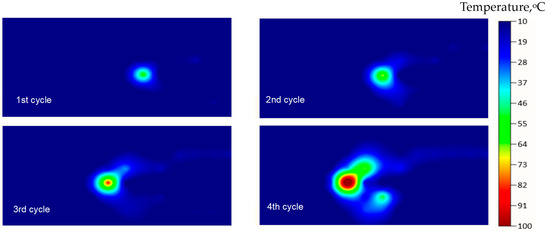

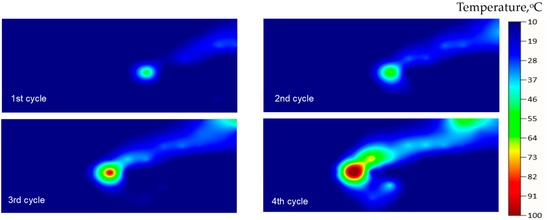

① Conventional steam expansion—SAGD: by comparing the temperature variation of different huff-n-puff cycles under the same injection agent and drawing it onto an isoline map, it is shown in Figure 14 that in the expansion stage, the steam chamber mainly expands horizontally, and it is difficult to break through the vertical development of the upper layer. The temperature change above the interlayer mainly depends on heat conduction.

Figure 14.

Temperature variation of different stimulation cycles (conventional steam).

② Solvent-assisted dilation—SAGD: from the temperature-field changes of different huff-n-puff cycles, it can be seen in Figure 15 that the solvent mainly promotes the transverse expansion of the steam chamber. From the temperature-field changes, the temperature of the transverse steam-chamber edge changes greatly. Furthermore, there is also an obvious temperature variation zone in the longitudinal direction, indicating that the solvent mainly expands horizontally, while the vertical expansion is, comparatively, much less.

Figure 15.

Temperature variation of different stimulation cycles (solvent-assisted steam).

③ Non-condensate gas-assisted dilatation–SAGD: the effect of non-condensate gas is obvious in the first and second cycles in Figure 16. The main reason is that the non-condensate gas has a better penetration effect, which mainly promotes the temperature-field development above the interlayer and the form of the steam chamber. The lateral dilatation is affected by the high temperature of the steam.

Figure 16.

Temperature variation of different stimulation cycles (NCG-assisted steam).

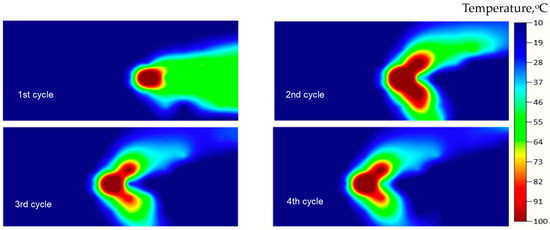

④ Non-condensate gas plus solvent-assisted dilation—SAGD: this strategy can play the dual role of horizontal solvent expansion plus vertical penetration of non-condensate gas, which would greatly improve the expansion range. As shown in Figure 17, the combination of the two can effectively break through the interlayer, and realize the upward development of the steam chamber in the expansion stage. However, it is necessary to consider the difference between the experiment and the field, and the recommended cycles of implementation are more than those in the laboratory.

Figure 17.

Temperature variation of different stimulation cycles (NCG plus solvent-assisted steam).

- (3)

- Steam-chamber comparison for different injection agents

① solvent vs. steam: from Figure 18, compared with the conventional steam huff-n-puff expansion, the solvent mainly takes effect on the front edge of the steam chamber and expands the huff-n-puff chamber boundary more effectively than the steam; the third cycle is the most obvious.

Figure 18.

Temperature difference of solvent vs. steam between different cycles.

② NCG vs. steam: as shown in Figure 19, the non-condensate gas has good penetration effect and the injected volume is larger than that of pure steam. because the steam will condense in situ and the actual volume shrinks, so the effected range of NCG is correspondingly larger. Unlike the effect of solvents, the dilation range includes both lateral-edge and top direction.

Figure 19.

Temperature difference of NCG vs. steam between different cycles.

③ NCG vs. solvent: from Figure 20, compared with the solvent, the advantage of non-condensate gas is mainly in the boundary of the steam chamber, in extending the transverse range of the steam chamber, while the longitudinal amplitude is slightly smaller.

Figure 20.

Temperature difference of NCG vs. solvent between different cycles.

④ Solvent-plus-NCG vs. steam: from Figure 21, the dual function of horizontal solvent expansion plus longitudinal penetration of non-condensate gas greatly improves the expansion range.

Figure 21.

Temperature difference of solvent-plus-NCG vs. steam between different cycles.

⑤ Solvent-plus-NCG vs. solvent: from Figure 22, compared with the solvent, the advantage of non-condensate gas is mainly in the boundary of the steam chamber, in extending the transverse range of the steam chamber, and the longitudinal amplitude is slightly smaller. However, with the help of the solvent, the effect is better than that of pure non-condensate gas.

Figure 22.

Temperature difference of solvent-plus-NCG vs. solvent between different cycles.

⑥ solvent-plus-NCG vs. NCG: Due to the small amount of solvent, the effect is not particularly obvious. Figure 23 indicates that the role of the solvent is mainly to reduce the oil viscosity and resistance of the crude oil, assist the non-condensate gas to penetrate outwards, which is validated by a small temperature zone above the reservoir.

Figure 23.

Temperature difference of solvent-plus-NCG vs. NCG between different cycles.

- (4)

- SAGD production dynamics

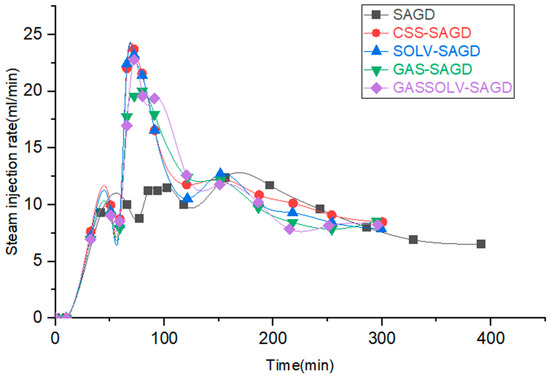

Steam injection speed: blocked by the interlayer, the conventional SAGD steam chamber expands slowly, and the steam-injection speed reduces correspondingly, to only 11.2 mL/min during the plateau period, as shown in Figure 24. Through the huff-n-puff dilation by forced injection of steam, the injection speed in the steam-chamber expansion stage is increased to 23 mL/min, which is doubled, and the steam chamber volume is greatly increased. Meanwhile, gas breakthrough is prevented through the well-soak measure.

Figure 24.

Comparison of steam injection rate.

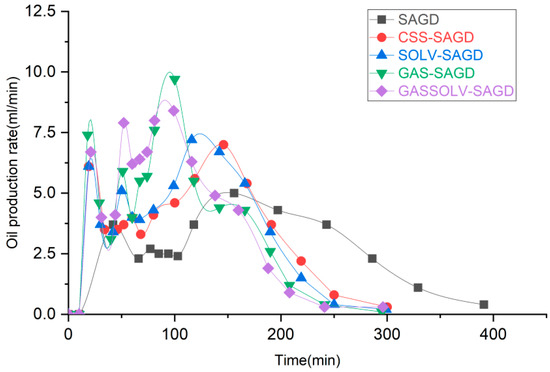

Oil production rate: as shown in Figure 25, the conventional SAGD steam chamber is blocked by interlayers, and the oil production speed is low, and difficult to massively improve. However, the four expansion methods can effectively improve the oil production speed and shorten the SAGD production time by increasing the steam injection speed.

Figure 25.

Comparison of oil production rate.

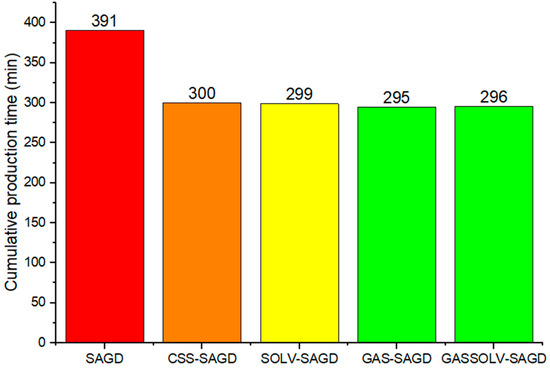

Production time: it can be seen in Figure 26 that the conventional SAGD ends at 391 min, while the dilation-assisted SAGD ends at about 296 min, and the production time is shortened by 24.3%. It is further proved that huff-n-puff expansion has the good effect of accelerating steam-chamber expansion, accelerating oil drainage, increasing oil recovery speed and shortening production time.

Figure 26.

Comparison of production time.

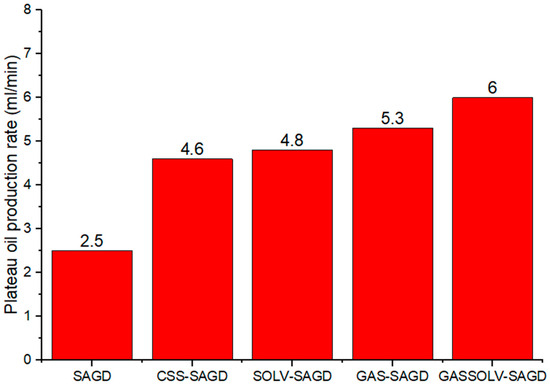

Oil production rate during the plateau period: as shown in Figure 27, the average oil production rate of conventional SAGD during the plateau period is only 2.5 mL/min; the oil production rate is increased to more than 4.6 mL/min through four expansion methods, which is an increase of more than 84%. Among these methods, the oil production rate increases to 6 mL/min by the solvent-plus-non-condensate-gas hybrid method, which increases by 1.4 times.

Figure 27.

Comparison of average oil-production rate during plateau period.

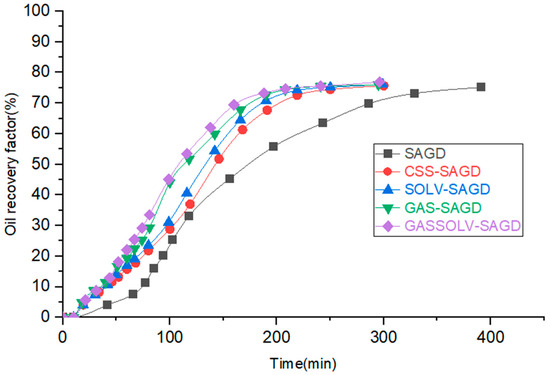

Recovery factor: the difference in the final recovery factor is small, mainly because at 50% interlayer closure, steam can bypass the interlayer and continue to develop the steam chamber, and eventually tap the reserves above; but the production time of conventional SAGD is the longest, with the lowest oil-recovery rate.

As shown in Figure 28, although the final oil recovery factor of different cases is similar, the difference in oil recovery degree at 162 min is significant. As the huff-n-puff expansion accelerated the development of the steam chamber upwards, the maximum difference in recovery degree was 23.41% during the same period, which was mainly affected by the injected agents. Compared to the conventional SAGD case, the cases of SAGD dilation by cyclic injection of pure steam, solvent + steam, gas + steam, and gas plus solvent +steam enhanced the oil recovery degree by 11.01%, 15.46%, 19.89%, and 23.41%, respectively. The multi-functional combination of gas plus solvent +steam can further improve the oil recovery degree by 12.4%, compared to pure steam dilation. Based on the economic evaluation, as the cost of the dilation process only involves five cycles of stimulation and the payback is the higher oil-output rate and shortened life time, the input–output ratio for the cases of SAGD dilation by cyclic injection of pure steam, solvent + steam, gas + steam, and gas plus solvent +steam was calculated. The prices of steam, solvent, and gas are CNY 0.14/L (CWE), CNY 0.8/L, and CNY 0.007/L, respectively. The injected volume of stimulated steam is 229 mL, 229 mL, 239 mL, and 252 mL, respectively. The injected volume of gas is 207 mL and 152 mL for case 3 and 4, respectively. Taking the oil price as CNY 2555/ton, and the oil density at 0.91 g/mL, the cumulative cost for each case is CNY 32, CNY 34, CNY 84, and CNY 75, and the incremental oil is CNY 328, CNY 461, CNY 593, and CNY 698. Based on the detailed calculation above, the input–output ratio for the four cases of stimulation is 10.22, 13.69, 7.04, and 9.35, respectively.

Figure 28.

Comparison of oil recovery factor.

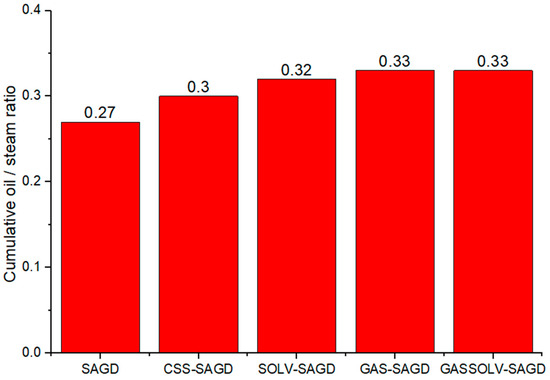

Accumulative oil/steam ratio: Figure 29 demonstrates that the accumulative oil/steam ratio of agent-assisted expansion SAGD is above 0.3, while that of conventional SAGD is 0.27, indicating that accelerating the development of the steam chamber by huff-n-puff expansion can effectively improve the steam utilization efficiency. Among the ratios, the non-condensate gas-assisted oil/steam ratio has the best improvement effect.

Figure 29.

Comparison of cumulative oil/steam ratio.

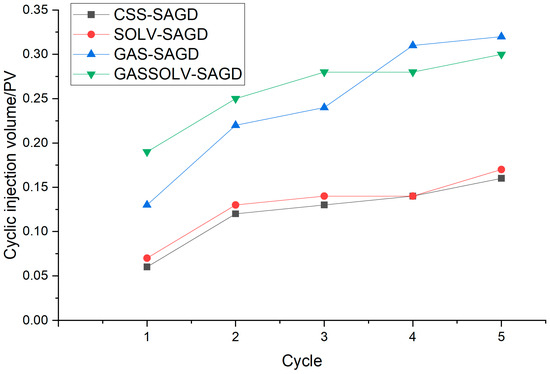

Non-condensate gas mechanism: compared with water steam and solvent plus steam in Figure 30, non-condensate gas (methane) can significantly improve the cyclic-injection amount of huff-n-puff. The cyclic-injection amount of non-condensate gas-assisted steam huff-n-puff expansion can reach 0.32 PV, while the former two are difficult to achieve. The analysis indicates that the high diffusivity and dispersibility of non-condensing gas is the main reason for the injection enhancement.

Figure 30.

Comparison of the cumulative oil/steam ratio.

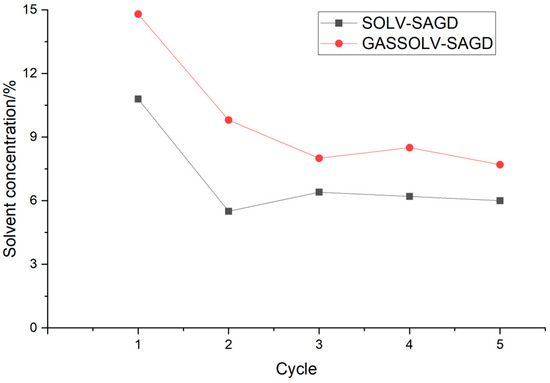

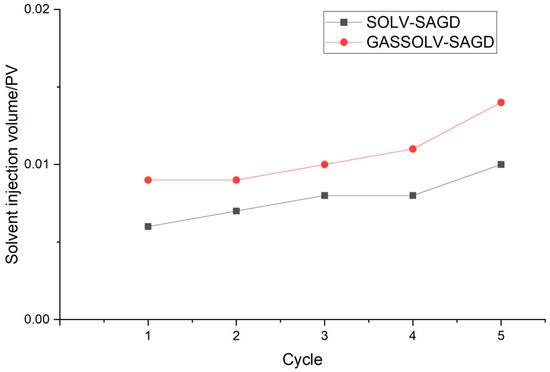

Mechanism of solvent: as shown in Figure 31 and Figure 32, the addition of solvent can significantly improve the effect of simple steam huff-n-puff expansion, mainly because the solvent is distributed in the front edge of the steam chamber, dissolves and reduces the viscosity of crude oil, and plays a role in reducing the expansion resistance. However, the addition of 5–10% solvent is limited, and it is recommended that it should be combined with gas, to further improve the effect of huff-n-puff dilation effect by increasing the injected PV number.

Figure 31.

Injected solvent concentration at different cycles.

Figure 32.

Injected solvent PV at different cycles.

4. Conclusions

Through physical simulation experiments, it is indicated that the SAGD steam chamber in heterogeneous reservoirs develops slowly, and it is difficult to further improve steam injection speed and chamber development speed when large continuous physical interlayers exist. Huff-n-puff dilation can improve steam injection capacity, accelerate steam breakthrough through interlayers/low permeability bands to develop upwards and outwards, increase oil production speed and shorten production time. Therefore, it has important application potential in fluvial sedimental heterogeneous SAGD reservoirs.

The solvent-assisted experiment shows that the solvent mainly takes effect on the edge of the steam chamber, and the steam-chamber dilation speed is further increased by 5 percentage points compared with the conventional huff-n-puff dilation.

The gas-assisted experiment shows that this method has the advantages of gas dissolution into oil, and high dispersion and high diffusivity of gas through gas injection, and that the cyclic gas-injection volume can be greatly increased from 0.16 PV in the steam injection case to 0.32 PV. It should be noted that, considering that N2 has the side effect of thermal insulation, methane or CO2 is recommended, but in the case of steam injection, CO2 is highly corrosive, so methane is preferred.

The experiment of solvent plus gas-assisted huff-n-puff dilation shows that the hybrid-agent system can play the dual role of solvent and gas, more effectively improve the steam-chamber expansion speed, enhance the oil recovery rate by 23.41%, and increase the oil/steam ratio from 0.27 to 0.33.

The reduced steam is 291 mL, 455 mL, 545 mL, and 518 mL (CWE) for four cases of stimulation. Taking the CO2 emission intensity of 0.28 tCO2/t steam (CWE), the reduced GHG emissions of the four cases is 81.4 mL, 127.4 mL, 152.6 mL, and 144.9 mL, respectively. Compared with conventional SAGD with no stimulation, the GHG emission can be reduced by 8.3%, 12.9%, 15.5%, and 14.7% in real-world applications.

The implications of this study are significant for the field SAGD production performance improvement, with respect to the conventional operations.

Author Contributions

Conceptualization, Y.W.; methodology, writing, review and editing, Q.L.; investigation, Y.X., Y.Y., X.M., L.C. and G.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work received the financial support of the Science and Technology Project of CNPC (2023ZZ0405).

Data Availability Statement

The data of this article are available on request through e-mail.

Acknowledgments

The valuable comments made by the anonymous reviewers are sincerely appreciated.

Conflicts of Interest

Authors Qijun Lv, Guo Yang, Yangbo Xie, Xiaomei Ma and Yongbin Wu were employed by the company Petrochina. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhang, L.; Wu, W.; Chen, S.; You, H.; Lin, B. Hydraulic Connection Model in Squeeze Preprocessing SAGD Start-Up. In Proceedings of the International Field Exploration and Development Conference 2017; Springer: Singapore, 2019; pp. 466–474. [Google Scholar]

- Collins, P.M.; Carlson, M.R.; Walters, D.A.; Settari, A. Geomechanical and thermal reservoir simulation demonstrates SAGD enhancement due to shear dilation. In SPE/ISRM Rock Mechanics Conference; SPE: Kuala Lumpur, Malaysia, 2002; p. SPE–78237. [Google Scholar]

- Mojarad, R.S.; Tran, D. Coupled Modeling of High Pressure Start-Up SAGD with Geomechanics; U.S. Department of Energy, Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2010.

- Rivero, J.A.; Li, Q. Modeling the Effects of Reservoir Deformation during Steam Injection Operations: From Empirical Models to a More Rigorous Geomechanical Treatment in the Numerical Simulation of SAGD. In SPE Canada Heavy Oil Conference; SPE: Kuala Lumpur, Malaysia, 2020; p. D051S010R003. [Google Scholar]

- Gong, X.; Wan, R.; Mohamadi, M. Coupled fluid flow-thermoplastic deformation of oil sand and shale in SAGD process. In SPE Canada Heavy Oil Conference; SPE: Kuala Lumpur, Malaysia, 2013; p. SPE–165501. [Google Scholar]

- Pang, H.; Lin, B.; Chen, M.; Jin, Y.; Chen, S.; You, H. Numerical simulation of hydraulic fracture propagation of landfacies ultra-heavy oilsands in Xinjiang Oilfield. In ISRM Congress; ISRM: Salzburg, Austria, 2015; p. ISRM–13CONGRESS. [Google Scholar]

- Zhang, J.; Fan, Y.; Xu, B.; Yang, B.; Yuan, Y.; Yu, Y. Steam circulation strategies for SAGD wells after geomechanical dilation start-up. In SPE Canada Heavy Oil Conference; SPE: Kuala Lumpur, Malaysia, 2016; p. D011S002R002. [Google Scholar]

- Sun, X.; Qian, G.; Xu, B.; Li, B.; Du, J. SAGD dilation startup and its applications in a shallow super heavy-oil reservoir in Xinjiang Oil Field, China. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Sydney, Australia, 2020; p. ARMA–2020. [Google Scholar]

- Wang, X.; Zhang, F.; Sun, J.; Xu, B. Experimental investigation on the SAGD dilation start-up in shallow heavy oil reservoirs. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 570, p. 032046. [Google Scholar]

- Pinto, H.; Wang, X.; Gates, I. On the ratio of energy produced to energy injected in SAGD: Long-term consequences of early stage operational decisions. J. Pet. Sci. Eng. 2021, 199, 108271. [Google Scholar] [CrossRef]

- Lin, B.; Chen, S.; Jin, Y. Evaluation of reservoir deformation induced by water injection in SAGD wells considering formation anisotropy, heterogeneity and thermal effect. J. Pet. Sci. Eng. 2017, 157, 767–779. [Google Scholar] [CrossRef]

- Kashihara, K.; Okamoto, N. Thought about Constitutive Model of Oil Sands during SAGD Process. In SPWLA Formation Evaluation Symposium of Japan; SPWLA: Houston, TX, USA, 2015; p. SPWLA–JFES. [Google Scholar]

- Nassir, M.; Walters, D. Permeability enhancement of oil sands. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Sydney, Australia, 2018; p. ARMA–2018. [Google Scholar]

- Khademi, M.; Chalaturnyk, R. Geomechanical Characterization of Inclined Heterolithic Stratification Lithosome and Its Permeability Evolution under SAGD Stress Paths. In SPE Annual Technical Conference and Exhibition? SPE: Kuala Lumpur, Malaysia, 2019; p. D011S007R001. [Google Scholar]

- Wong RC, K.; Li, Y. A stress-dependent model for permeability changes in oil sand due to shear dilation. In PETSOC Canadian International Petroleum Conference; PETSOC: Mumbai, India, 2000; p. PETSOC–2000. [Google Scholar]

- Chen, S.; Xiang, H.; Li, B.; Xu, B. Geomechanical dilation assisted VHSD process in altered-stress mature oilsands reservoir: Geomechanical studies and field experiences. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Sydney, Australia, 2022; p. ARMA–2022. [Google Scholar]

- Meng, H.; Jin, Y.; Lin, B.T.; Wang, P.F.; Lyu, Z.L.; Liu, X. Evaluation of influences of mudstone barriers on the water injection performance in SAGD wells. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Sydney, Australia, 2019; p. ARMA–2019. [Google Scholar]

- Gao, Y.; Ren, Z.; Chen, M.; Jiang, H.; Ding, S. Coupled geomechanical-thermal simulation for oil sand reservoirs with shale barriers under hot water injection in vertical well-assisted SAGD wells. J. Pet. Sci. Eng. 2022, 208, 109644. [Google Scholar] [CrossRef]

- Abbasi-Asl, Y.; Chalaturnyk, R.J. Understanding the Role of Reservoir Dilation on Solvent Assisted SAGD (SA-SAGD) Performance in Oil Sands Reservoirs; a Semi-Analytical Study. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Sydney, Australia, 2017; p. ARMA–2017. [Google Scholar]

- Abbasi Asl, Y.; Chalaturnyk, R.J. In–Situ Dilation Affects Solvent–Assisted Steam–Assisted–Gravity–Drainage Performance: The Case of a Shallow Athabasca–Type Oil–Sands Reservoir. SPE Reserv. Eval. Eng. 2018, 21, 418–432. [Google Scholar] [CrossRef]

- Garipov, T.T.; Voskov, D.V.; Tchelepi, H.A. Rigorous coupling of geomechanics and thermal-compositional flow for SAGD and ES-SAGD operations. In SPE Canada Heavy Oil Conference; SPE: Kuala Lumpur, Malaysia, 2015; p. SPE–174508. [Google Scholar]

- Wu, Y.; Li, X.; Shen, D.; He, W.; Liu, X. Solvent-assisted start-up of SAGD in shallow heavy oil reservoirs. In SPE Asia Pacific Enhanced Oil Recovery Conference; SPE: Kuala Lumpur, Malaysia, 2015; p. D031S014R005. [Google Scholar]

- Shokri, A.R.; Hosseini, B.K. Contribution of Geomechanics in Evaluation of Heat Transfer Mechanisms at Mobile Zone of SAGD and ES-SAGD. In SPE Canada Heavy Oil Conference; SPE: Kuala Lumpur, Malaysia, 2014; p. D021S010R001. [Google Scholar]

- Abbasi Asl, Y.; Chalaturnyk, R. Effect of Geomechanics on Optimization of Solvent Assisted SAGD SA-SAGD in Oil Sands Reservoirs. In SPE Canada Heavy Oil Conference; SPE: Kuala Lumpur, Malaysia, 2016; p. D021S008R001. [Google Scholar]

- Ni, Y.; Ding, B.; Yu, L.; Dong, M.; Gates, I.D.; Yuan, Y. Conformance control for SAGD using oil-in-water emulsions in heterogeneous oil sands reservoirs. In International Petroleum Technology Conference; IPTC: Kuala Lumpur, Malaysia, 2019; p. D021S037R001. [Google Scholar]

- Fan, Y.; Sun, X.; Mai, X.; Xu, B.; Dong, M.; Yuan, Y. In-situ catalytic aquathermolysis combined with geomechanical dilation to enhance thermal heavy-oil production. In SPE Canada Heavy Oil Conference; SPE: Kuala Lumpur, Malaysia, 2017; p. D021S007R001. [Google Scholar]

- Gao, Y.; Chen, M.; Li, W. Coupled 3D thermo-hydro-mechanical-chemical analysis of Karamay oil sand reservoirs under hot water injection in SAGD wells considering formation heterogeneity. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Sydney, Australia, 2020; p. ARMA–2020. [Google Scholar]

- Liu, P.; Zhou, Y.; Liu, P.; Shi, L.; Li, X.; Li, L. Numerical study of herringbone injector-horizontal producer steam assisted gravity drainage (HI-SAGD) for extra-heavy oil recovery. J. Pet. Sci. Eng. 2019, 181, 106227. [Google Scholar] [CrossRef]

- Sun, X.; Xu, B.; Qian, G.; Li, B. The application of geomechanical SAGD dilation startup in a Xinjiang oil field heavy-oil reservoir. J. Pet. Sci. Eng. 2021, 196, 107670. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, B.; Yang, B. Application of Geomechanics in Heavy Oil Production-Advanced Canadian Experience. In ISRM International Symposium Geomechanics; ISRM: Salzburg, Austria, 2017; p. ISRM–ISG. [Google Scholar]

- Kostina, A.; Zhelnin, M.; Plekhov, O. Study of Rock Dilation Effect on Oil Recovery during Steam-Assisted Gravity Drainage. Procedia Struct. Integr. 2022, 37, 431–438. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).