Study on the Multiphase Flow Behavior in Jet Pump Drainage and Natural Gas Hydrate Production Wells with Combined Depressurization and Thermal Stimulation Method

Abstract

1. Introduction

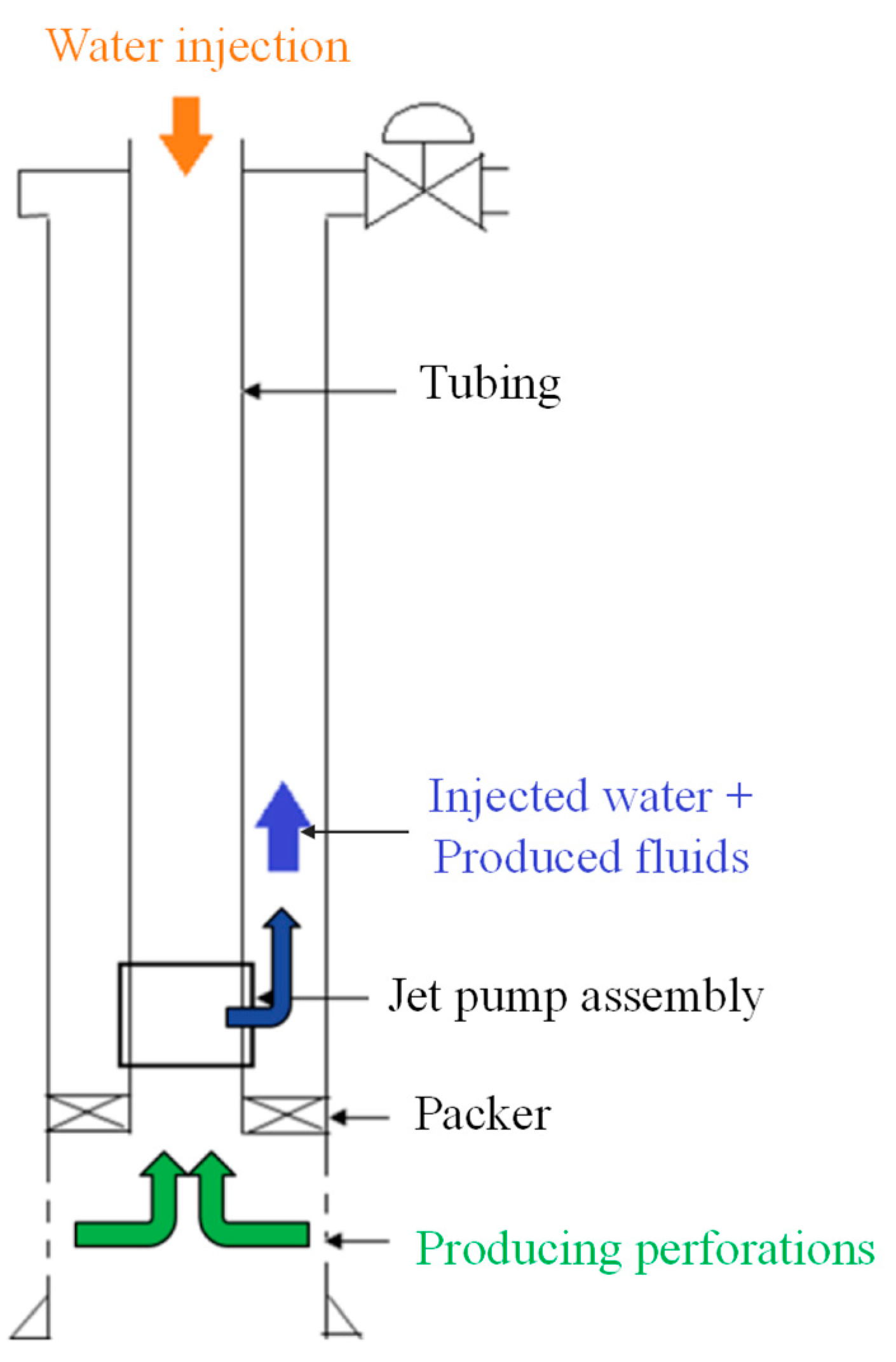

2. Feasibility Analysis and Mechanism Study of Jet-Pump-Lifted NGH Wells

2.1. Feasibility Analysis

2.2. Mechanism Study

3. Model Establishment and Solution

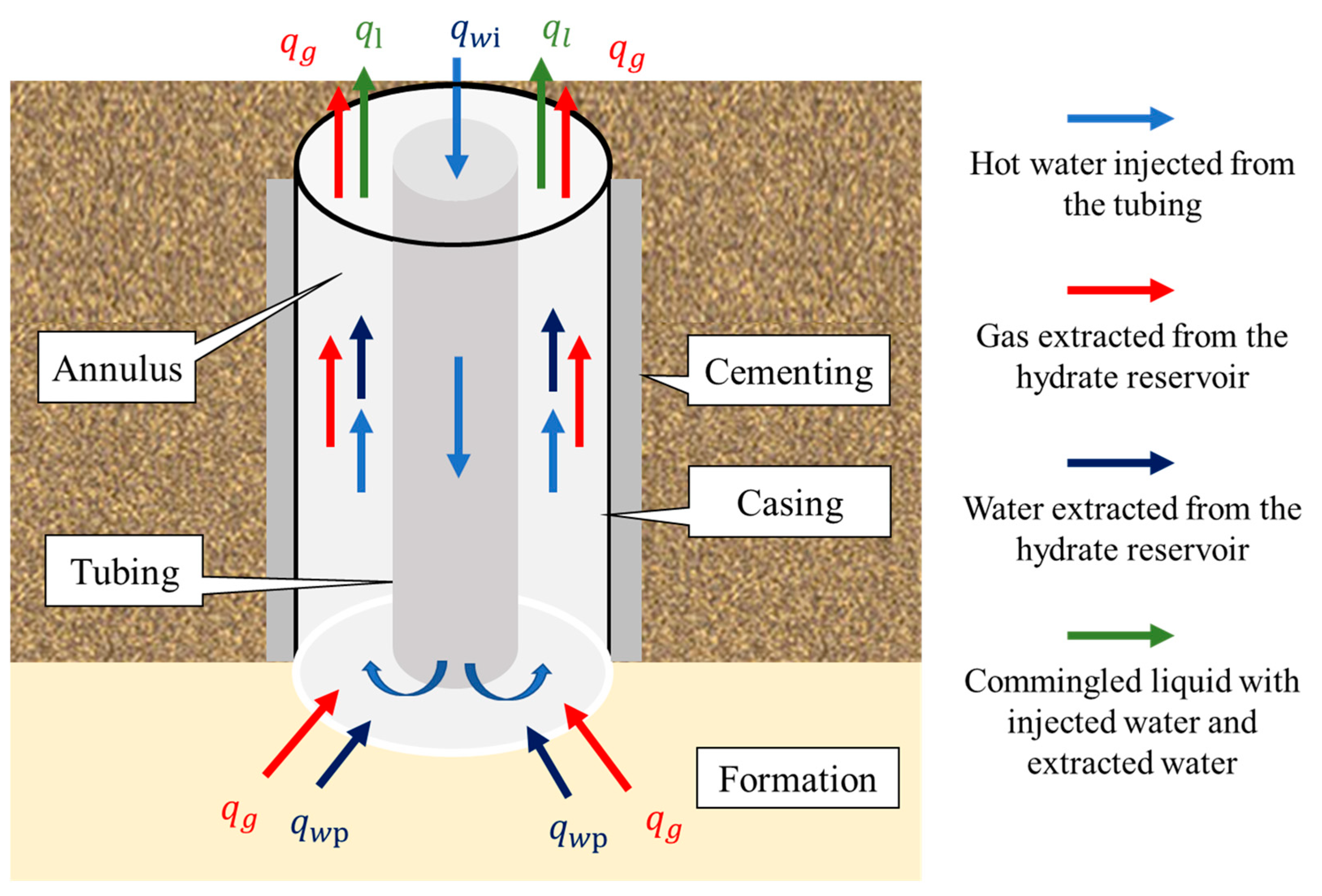

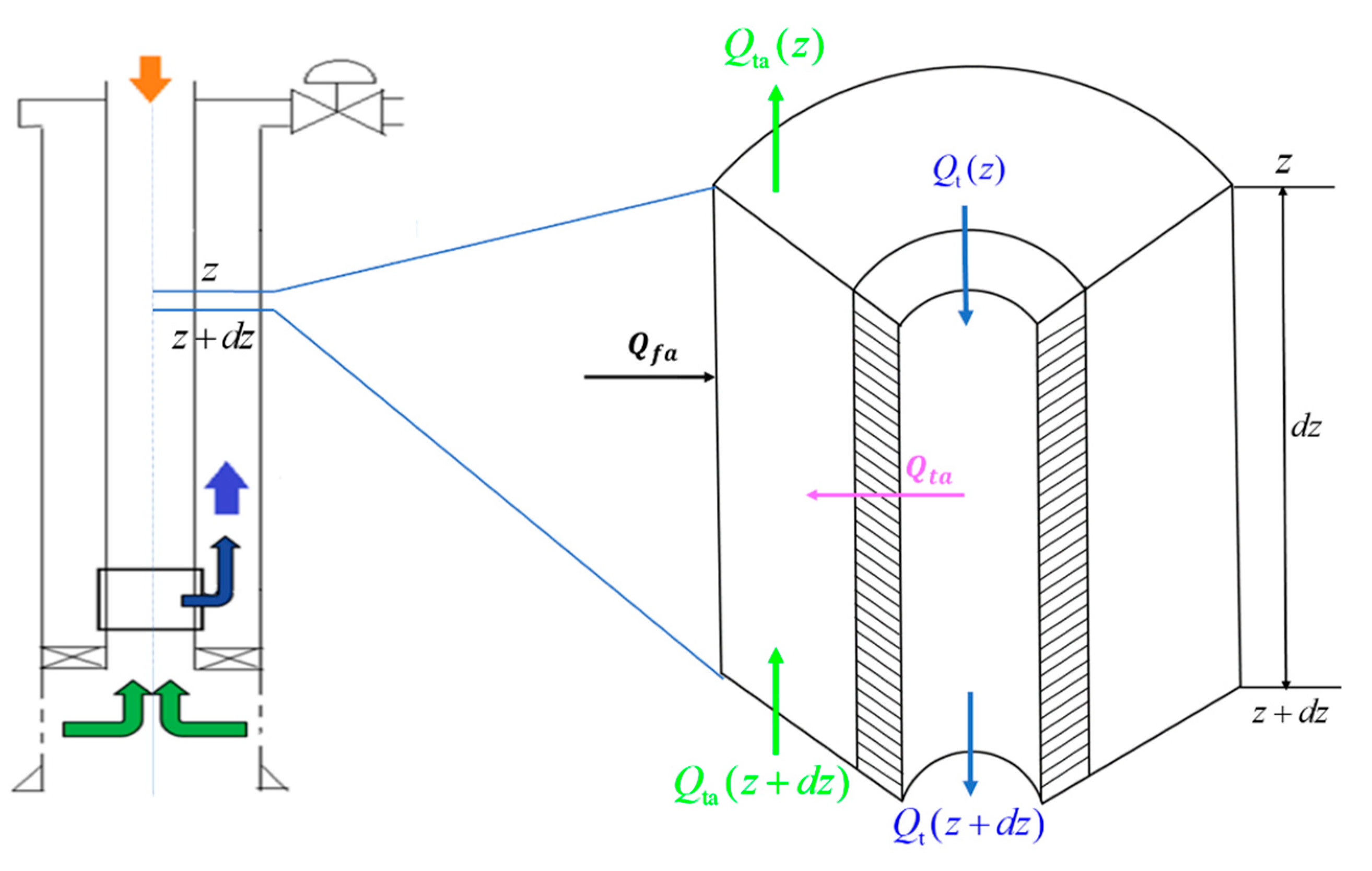

3.1. Establishment of Wellbore Flow Model of Jet-Pump-Lifted NGH Wells

3.1.1. Continuity Equation

3.1.2. Momentum Conservation Equation

3.1.3. Energy Conservation Equation

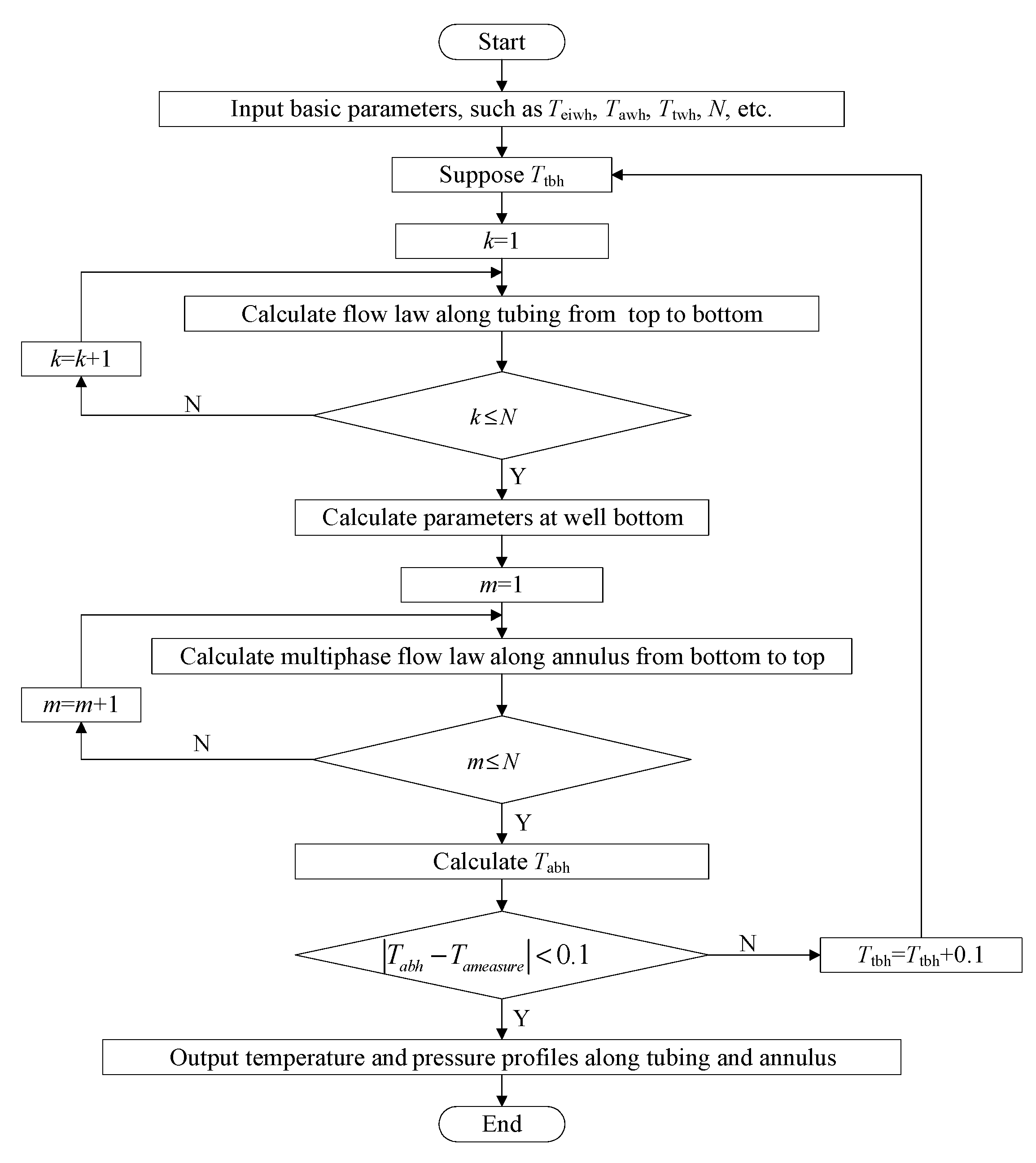

3.2. Model Solution

3.2.1. Boundary Conditions

3.2.2. Methodology

3.2.3. Solution Process

3.2.4. Model Validation

4. Results and Discussion

4.1. Basic Parameters for Simulations

4.2. Analysis of Multiphase Flow Behavior in Jet Pump Drainage and NGH Production Wells

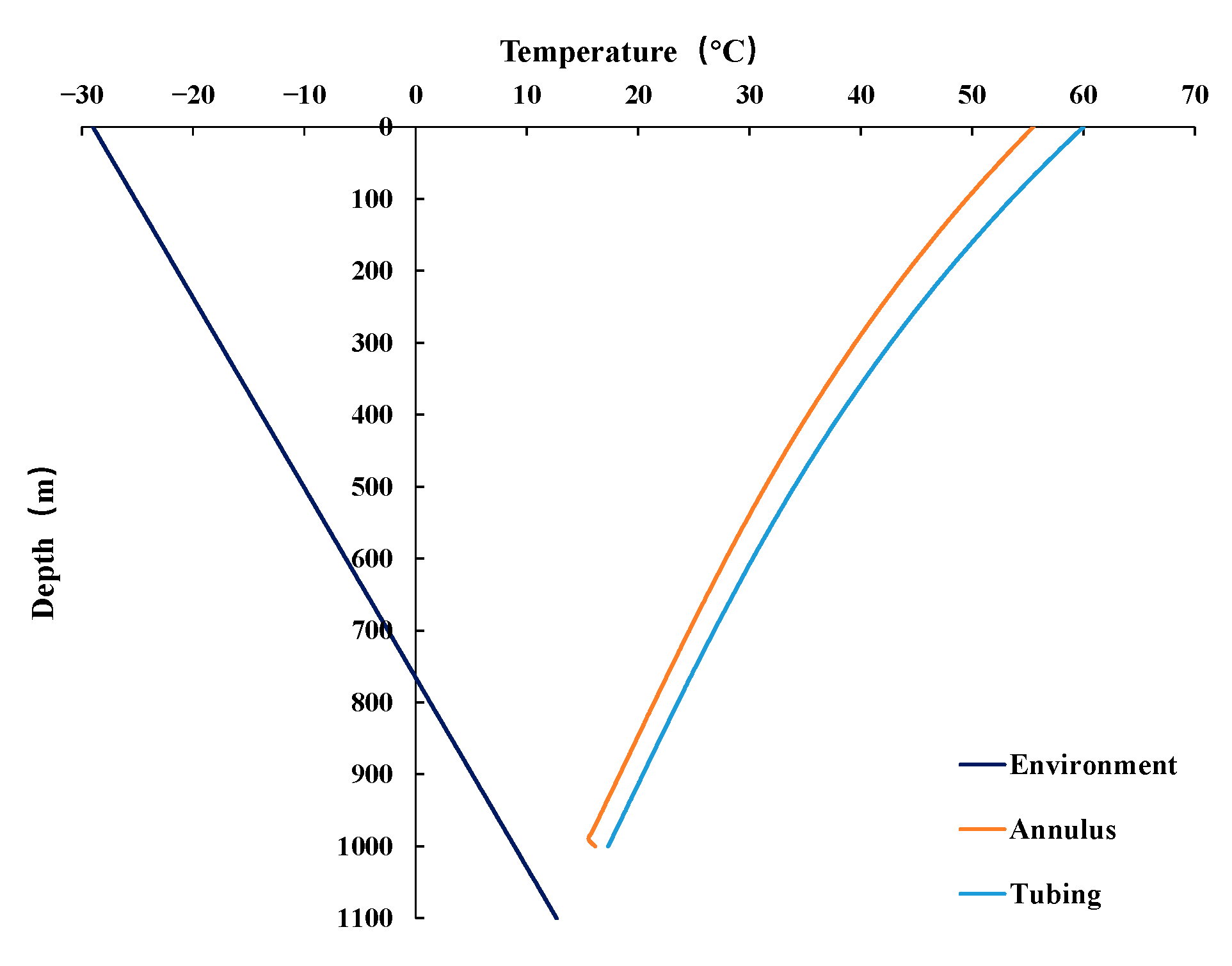

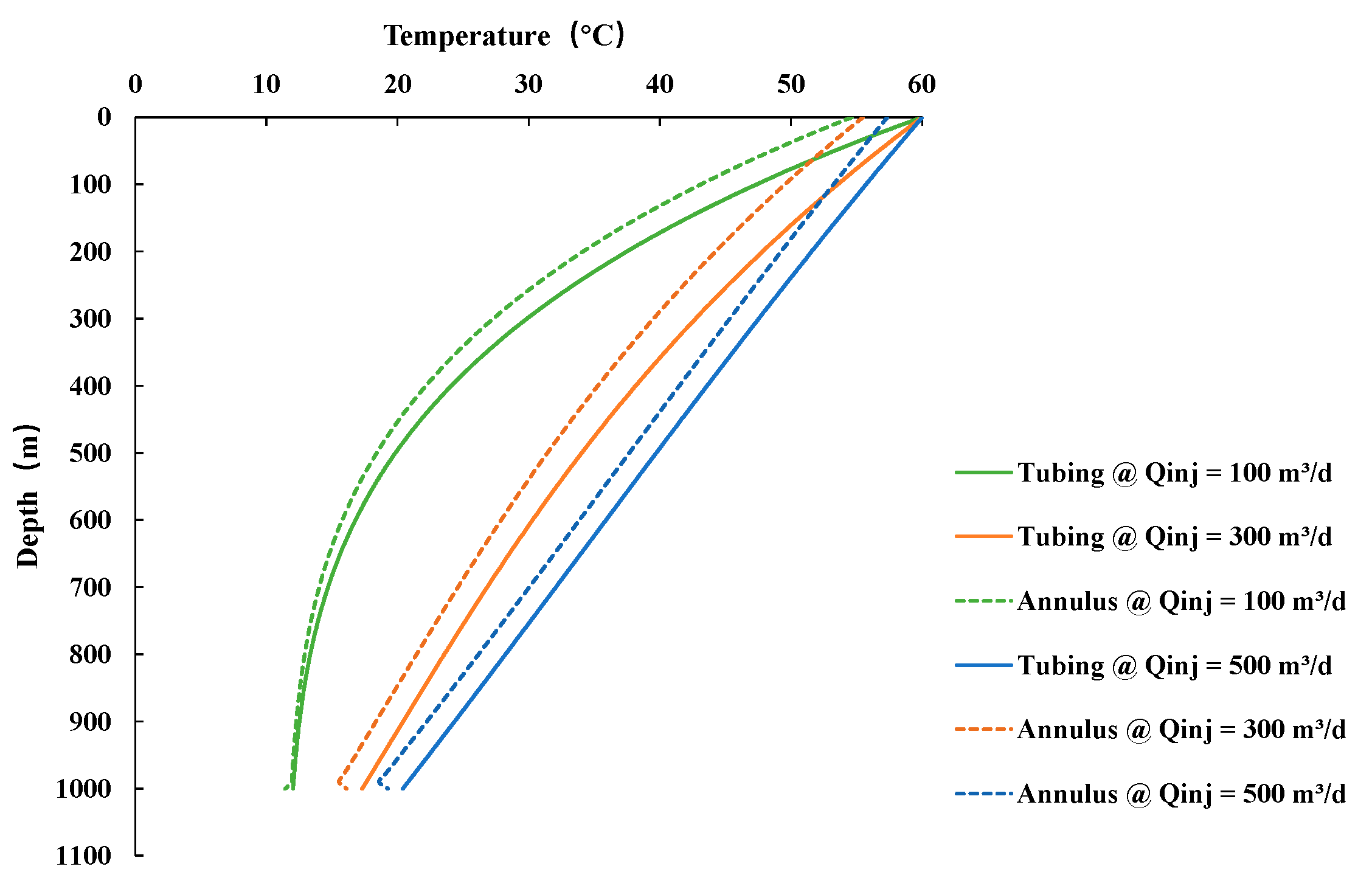

4.2.1. Temperature Profiles of Tubing and Annulus

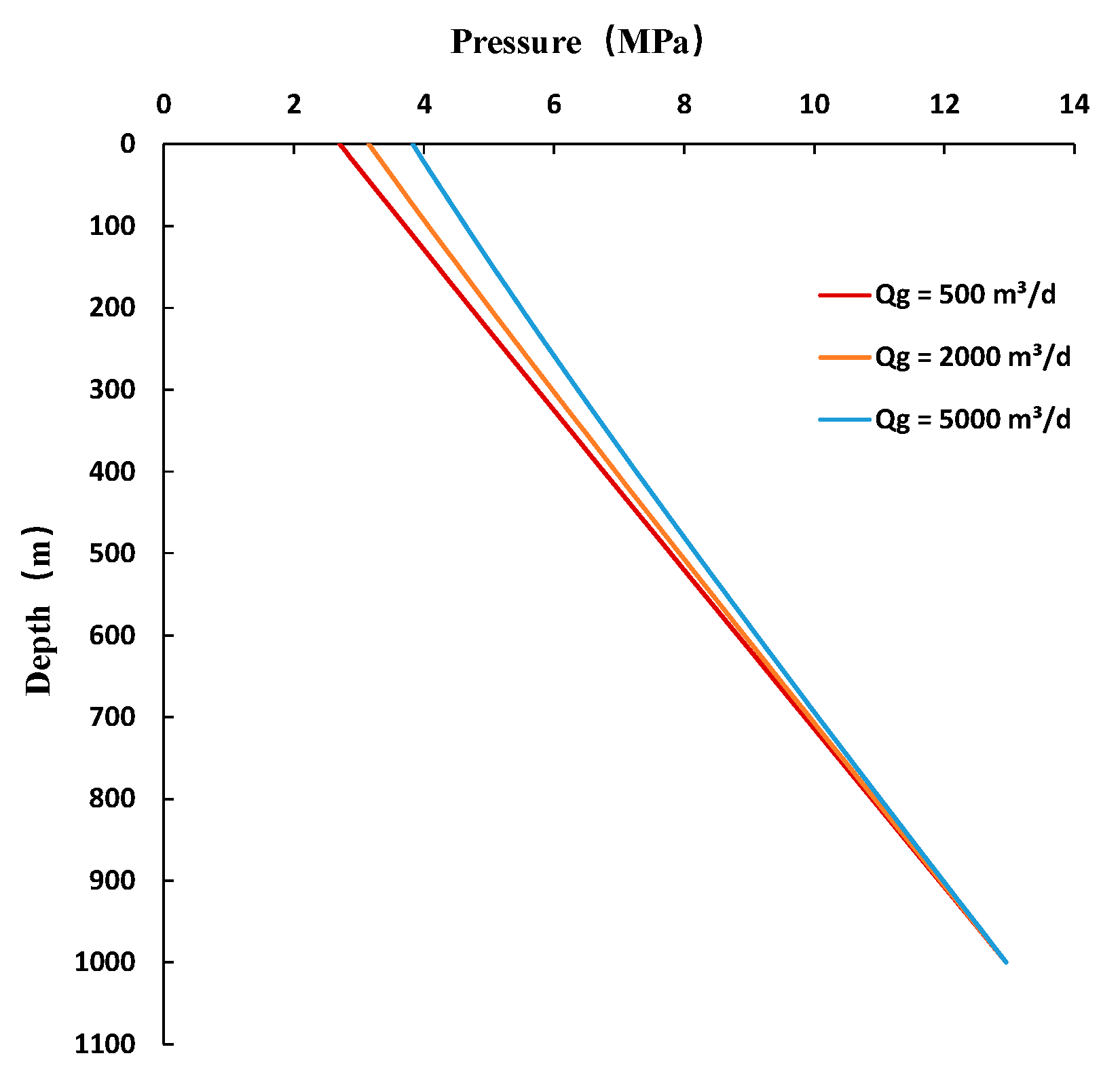

4.2.2. Pressure Profiles in Tubing and Annulus

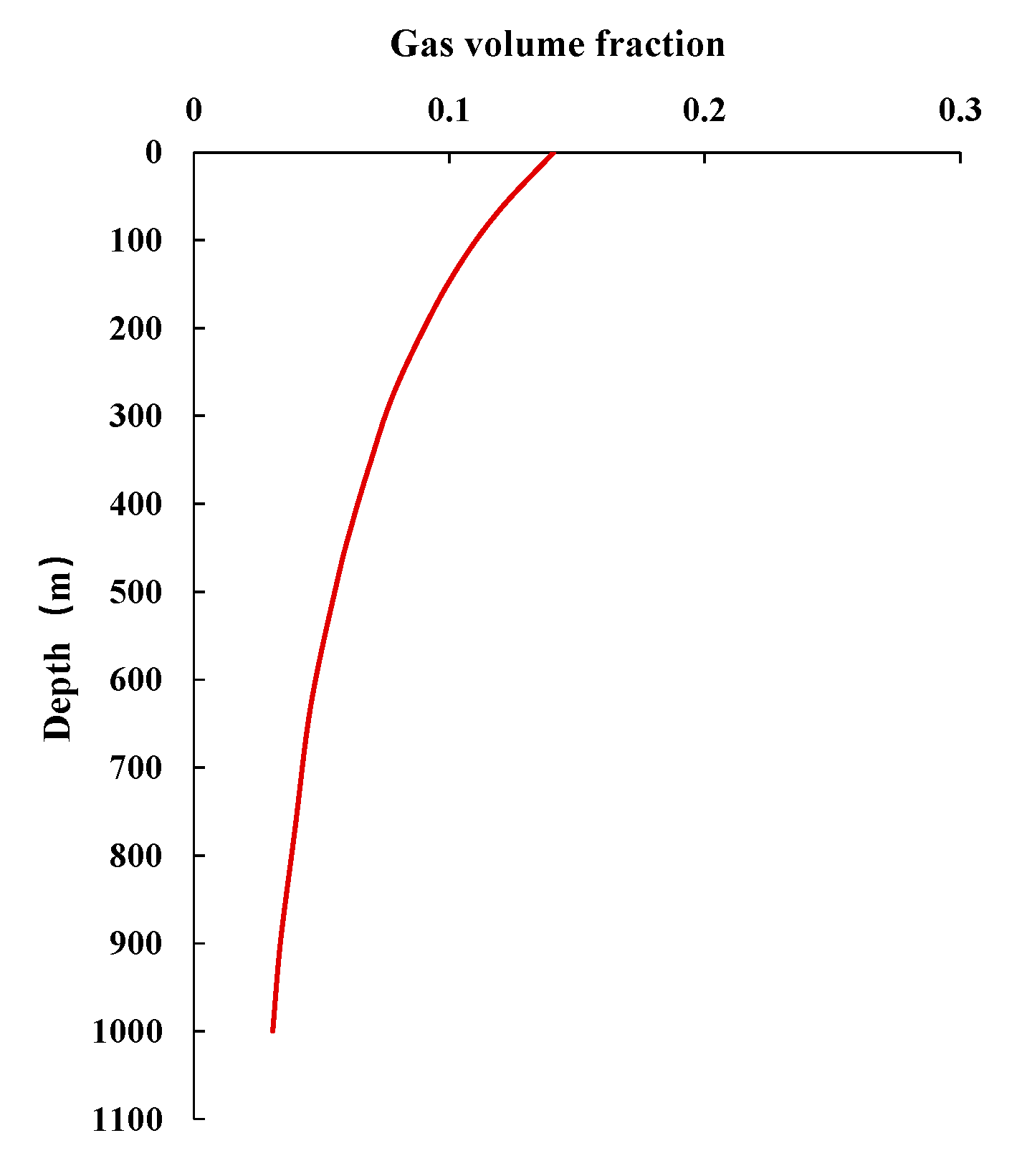

4.2.3. Gas Volume Fraction Profiles in Annulus

4.2.4. Effect of Production Parameters on Flow Behavior

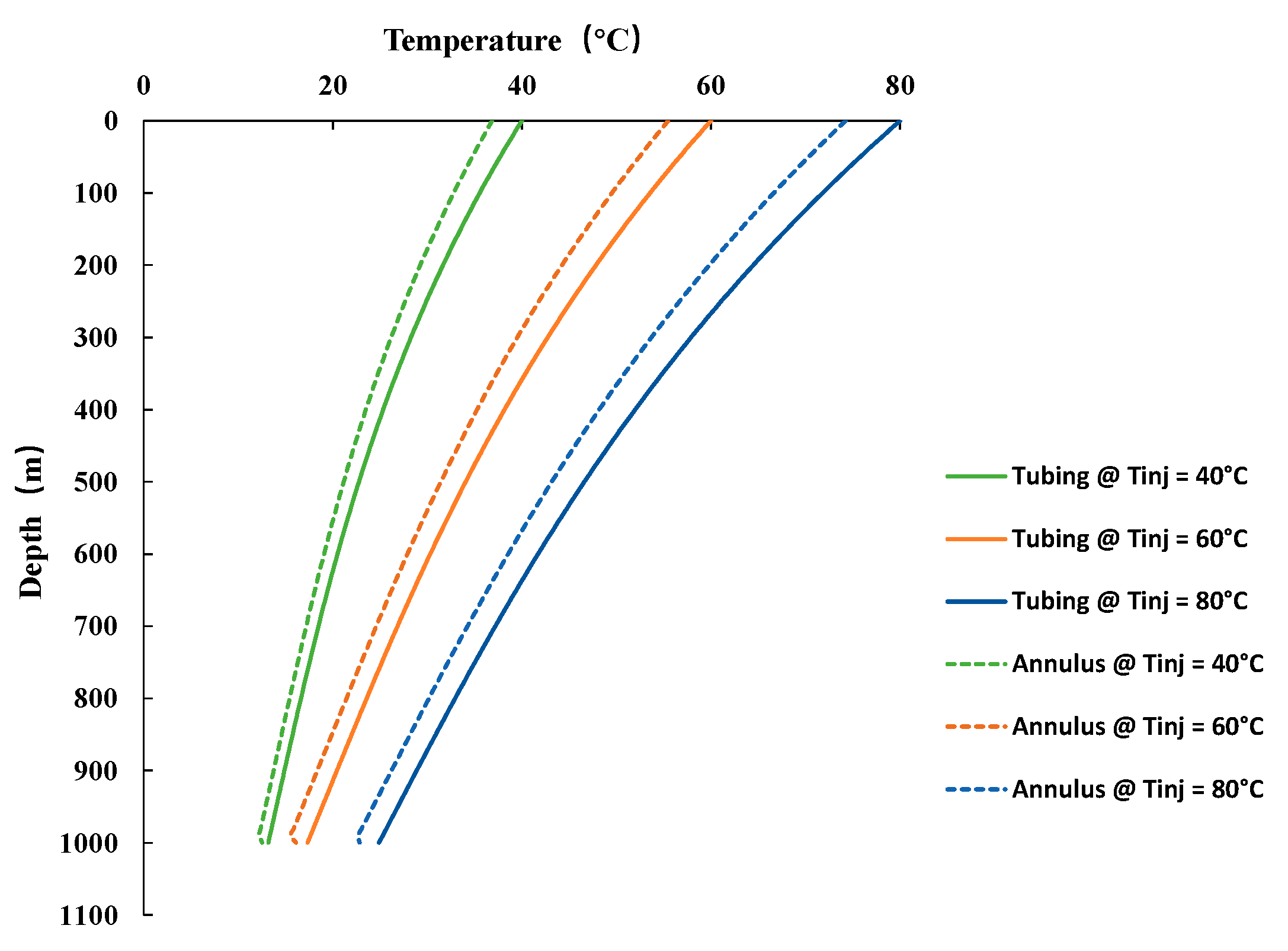

4.3. Optimization of Thermal Stimulation Parameters

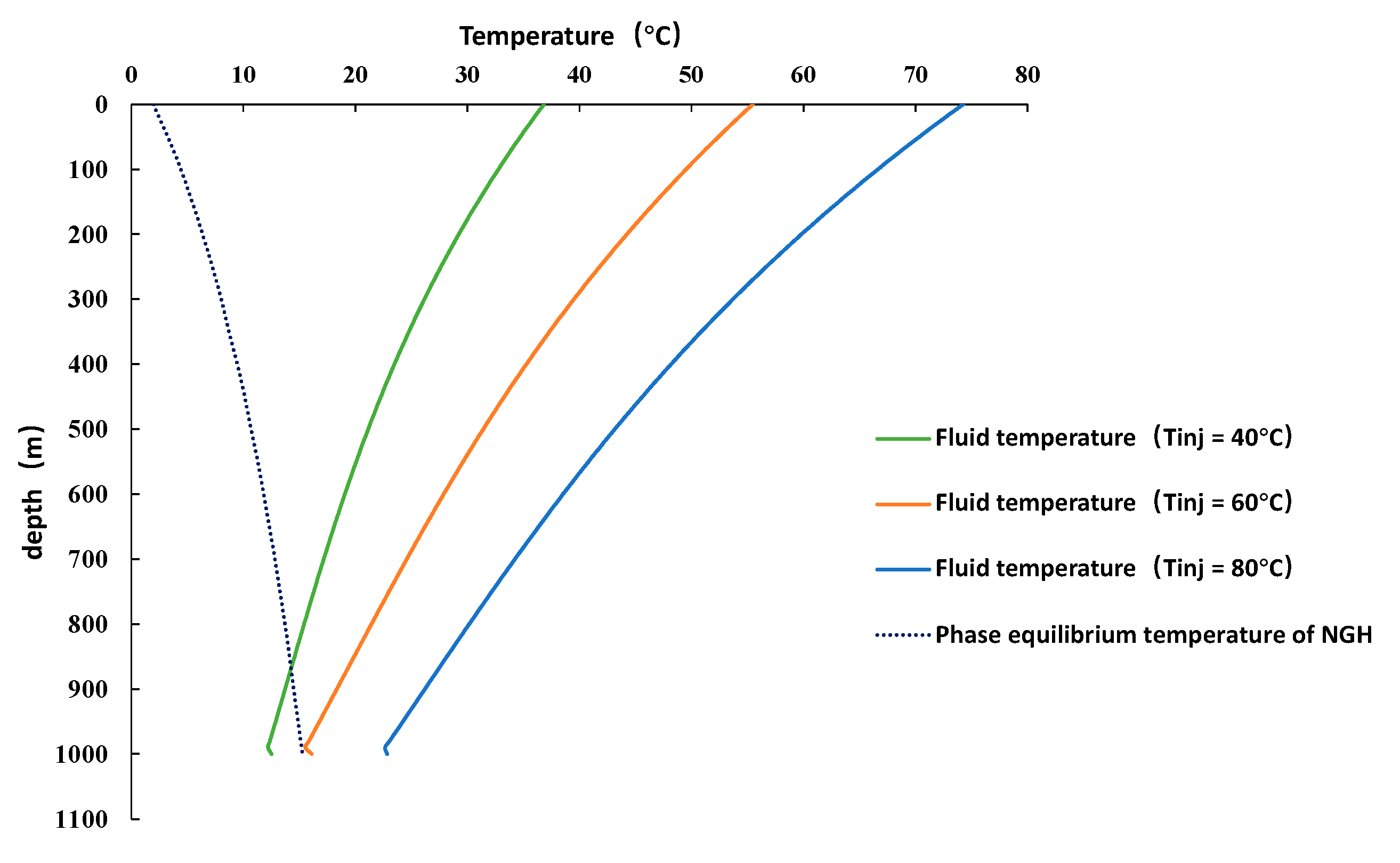

4.3.1. Injection Temperature

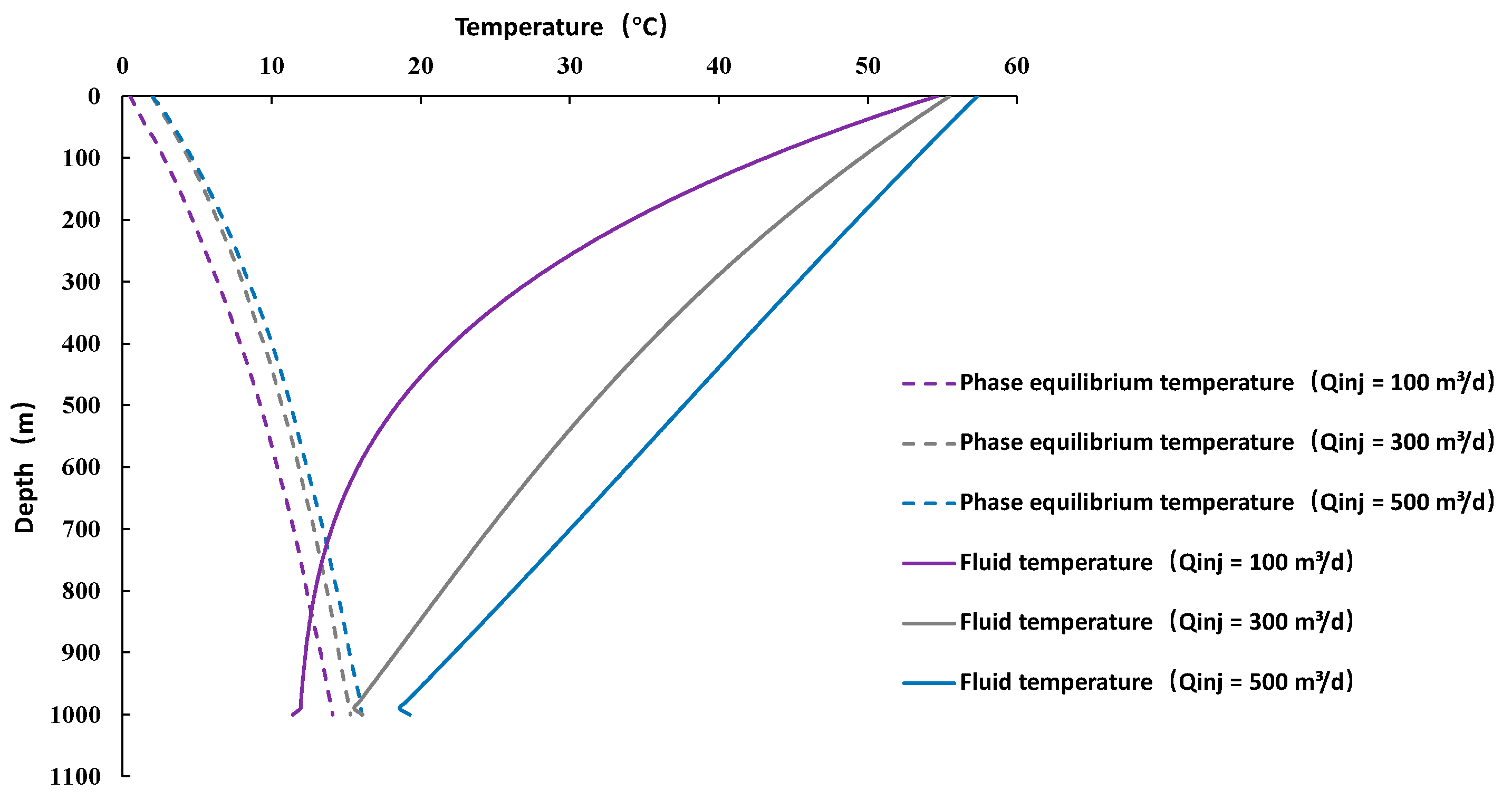

4.3.2. Injection Rate

4.3.3. Injection Pressure

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| density of the gas decomposed from the gas hydrate reservoir, kg/m3; | |

| density of the injected water, kg/m3; | |

| density of the water decomposed from the gas hydrate reservoir, kg/m3; | |

| mass flow rate of the gas extracted from the gas hydrate reservoir per unit volume, kg/(m3·s); | |

| mass flow rate of the water extracted from the gas hydrate reservoir per unit volume, kg/(m3·s); | |

| velocity of the injected water, m/s; | |

| velocity of the gas extracted from the gas hydrate reservoir, m/s; | |

| velocity of the water extracted from the gas hydrate reservoir, m/s; | |

| holdup of the injected water in the annulus, dimensionless; | |

| fraction of gas volume decomposed from the gas hydrate reservoir, dimensionless; | |

| holdup of the water decomposed from the gas hydrate reservoir, dimensionless; | |

| time, s; | |

| pipe length, m; | |

| pressure of the fluid in the tubing, Pa; | |

| pressure of the fluid in the annulus, Pa; | |

| gravitational constant, m/s2; | |

| inclination angle, rad; | |

| density of the mixed fluid, kg/m3; | |

| velocity of the mixed fluid, m/s; | |

| friction factor, dimensionless; | |

| diameter of the tubing, m; | |

| equivalent diameter of the annulus, m; | |

| surrounding environment temperature, °C; | |

| temperature of the fluid in the tubing, °C; | |

| temperature of the fluid in the annulus, °C; | |

| heat amount entering the element by conservation in the tubing, J; | |

| heat amount entering the element by conservation in the annulus, J; | |

| heat amount transferring from the annulus to the tubing, J; | |

| heat amount transferring from the formation by conduction, J; | |

| specific volume of the fluid in the tubing, J/(kg·°C); | |

| specific volume of the fluid in the annulus, J/(kg·°C); | |

| heat transfer coefficients of the tubing, W/(m2·K); | |

| heat transfer coefficients of the annulus, W/(m2·K); | |

| mass flow rate of the fluid in the tubing, kg/s; | |

| mass flow rate of the fluid in the annulus, kg/s; | |

| diameters of the tubing, m; | |

| diameters of the casing, m; | |

| thermal conductivity of the formation, W/(m·K); | |

| function of dimensionless time; | |

| temperature at the wellhead of the tubing, °C; | |

| injection temperature, °C; | |

| pressure at the wellhead of the tubing, Pa; | |

| injection pressure, Pa; | |

| flow rate of the fluid at the wellhead of the tubing, m3/s; | |

| injection rate, m3/s; | |

| temperature at the wellhead of the annulus, °C; | |

| measured temperature at the wellhead of the annulus, °C; | |

| environmental temperature at the bottom hole, °C; | |

| specific volume of the commingled fluid, J/(kg·°C); | |

| temperature at the bottom of the tubing, °C; | |

| temperature at the bottom of the annulus, °C; | |

| well depth, m; | |

| surface temperature, °C; | |

| geothermal gradient, °C/m. |

Abbreviations

| NGH | natural gas hydrate; |

| ESP | electric submersible pump; |

| GLR | gas–liquid–ratio; |

| GOR | gas–oil–ratio; |

| BHP | bottom head pressure. |

References

- Sakurai, S.; Nishioka, I.; Matsuzawa, M.; Matzain, B.; Goto, A.; Lee, J.E. Issues and Challenges with Controlling Large Drawdown in the First Offshore Methane-Hydrate Production Test. SPE Prod. Oper. 2017, 32, 500–516. [Google Scholar] [CrossRef]

- Yamamoto, K.; Wang, X.-X.; Tamaki, M.; Suzuki, K. The second offshore production of methane hydrate in the Nankai Trough and gas production behavior from a heterogeneous methane hydrate reservoir. RSC Adv. 2019, 9, 25987–26013. [Google Scholar] [CrossRef] [PubMed]

- Li, J.-F.; Ye, J.-L.; Qin, X.-W.; Qiu, H.-J.; Wu, N.-Y.; Lu, H.-L.; Xie, W.-W.; Lu, J.-A.; Peng, F.; Xu, Z.-Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Ye, J.L.; Qin, X.W.; Xie, W.W.; Lu, H.L.; Ma, B.J.; Qiu, H.J.; Liang, J.Q.; Lu, J.A.; Kuang, Z.G.; Lu, C.; et al. The second natural gas hydrate production test in the South China Sea. China Geol. 2020, 3, 197–209. [Google Scholar] [CrossRef]

- Ping, X.; Han, G.; Zhang, J.; Chang, J.; Cen, X.; Tang, H. Study on the Flow Behavior of Wellbore Fluids of a Natural Gas Hydrate Well with the Combined Depressurization and Heat Injection Method. Processes 2023, 11, 1625. [Google Scholar] [CrossRef]

- Petersen, J.; Bjørkevoll, K.S.; Lekvam, K. Computing the danger of hydrate formation using a modified dynamic kick simulator. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 27 February–1 March 2001. [Google Scholar]

- Fu, J.; Su, Y.; Jiang, W.; Xiang, X.; Li, B. Multiphase flow behavior in deep water drilling: The influence of gas hydrate. Energy Sci. Eng. 2020, 8, 1386–1403. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Y.; Sun, B.; Chen, L.; Zhang, J.; Wang, X. Modeling of Hydrate Blockage in Gas-Dominated Systems. Energy Fuels 2016, 30, 4653–4666. [Google Scholar] [CrossRef]

- Bassani, C.L.; Barbuto, F.A.; Sum, A.K.; Morales, R.E. Modeling the effects of hydrate wall deposition on slug flow hydrodynamics and heat transfer. Appl. Therm. Eng. 2017, 114, 245–254. [Google Scholar] [CrossRef]

- Wei, N.; Zhao, J.; Sun, W.; Zhou, S.; Zhang, L.; Li, Q.; Fu, Q.; Lü, X.; Zheng, L. Non-equilibrium multiphase wellbore flow characteristics in solid fluidization exploitation of marine gas hydrate reservoirs. Nat. Gas Ind. B 2019, 6, 282–292. [Google Scholar] [CrossRef]

- Merey, S.; Aydin, H.; Eren, T. Design of electrical submersible pumps in methane hydrate production wells: A case study in Nankai trough methane hydrates. Upstream Oil Gas Technol. 2020, 5, 100023. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, B.; Wang, Z.; Lou, W.; Zhang, J. Modeling of multiphase flow in marine gas hydrate production system and its application to control the production pressure difference. J. Nat. Gas Sci. Eng. 2020, 85, 103687. [Google Scholar] [CrossRef]

- Ping, X.; Han, G.; Cen, X.; Bai, Z.; Zhu, W.; Peng, L.; Ma, B. Prediction of Pressure and Temperature Profiles and Hydrate Formation Region in ESP-Lifted Natural Gas Hydrate Wells. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 26–28 April 2022. [Google Scholar]

- Liu, Z.; Zerpa, L.E. Preliminary Study of Liquid Loading Problems for Gas Hydrate Wells and Selection of Artificial Lift Methods. In Proceedings of the SPE Western Regional Meeting, Anchorage, AL, USA, 23–26 May 2016. [Google Scholar]

- Hasan, A.R.; Jang, M. An analytic model for computing the countercurrent flow of heat in tubing and annulus system and its application: Jet pump. J. Pet. Sci. Eng. 2021, 203, 108492. [Google Scholar] [CrossRef]

- Birkedal, K.A.; Hauge, L.P.; Graue, A.; Ersland, G. Transport Mechanisms for CO2-CH4 Exchange and Safe CO2 Storage in Hydrate-Bearing Sandstone. Energies 2015, 8, 4073–4095. [Google Scholar] [CrossRef]

- Jin, Y.; Li, S.; Yang, D.; Jiang, X. Determination of dissociation front and operational optimization for hydrate development by combining depressurization and hot brine stimulation. J. Nat. Gas Sci. Eng. 2018, 50, 215–230. [Google Scholar] [CrossRef]

- Uetani, T.; Furuichi, N.; Yorozu, H.; Sasaya, K.; Shibuya, T.; Kiminami, N.; Yonebayashi, H. Regaining Oil Production by Overcoming Emulsion Problems After Artificial Lift Installation. SPE Prod. Oper. 2017, 33, 300–312. [Google Scholar] [CrossRef]

- Kalwar, S.A.; Awan, A.Q.; Akhtar, M.S.; Hassan, R.U.; Khakwani, K.M. Successful Application of Jet Pump Technology for Production Optimization in a Brown Oil Field—A Case Study in Pakistan. SPE Middle East Artificial Lift Conference and Exhibition. In Proceedings of the SPE Middle East Artificial Lift Conference and Exhibition, Manama, Bahrain, 25–26 October 2022. [Google Scholar]

- Hasan, A.R.; Kabir, C.S. A Mechanistic Model for Computing Fluid Temperature Profiles in Gas-Lift Wells. SPE Prod. Facil. 1996, 11, 179–185. [Google Scholar] [CrossRef]

- Kurihara, M.; Sato, A.; Funatsu, K.; Ouchi, H.; Ashford, D. Analysis of Production Data for 2007/2008 Mallik Gas Hydrate Production Tests in Canada. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010. [Google Scholar]

| Parameter | Value |

|---|---|

| Well depth (m) | 5500 |

| Surface temperature (°C) | 20 |

| Geothermal gradient (°C/100 m) | 1.9 |

| Density of heavy oil (kg/m3) | 980 |

| Density of light oil (kg/m3) | 830 |

| GOR (m3/m3) | 25.3 |

| Injection temperature (°C) | 80 |

| Injection rate (m3/d) | 60 |

| Production rate (m3/d) | 75 |

| Injection pressure (MPa) | 3 |

| Temperature at well bottom (°C) | 123.4 |

| Parameter | Value |

|---|---|

| Top depth of reservoir (m) | 900 |

| Well depth (m) | 1110 |

| Initial pressure of reservoir (MPa) | 12.5 |

| Surface temperature (°C) | −29 |

| Gas specific gravity | 0.643 |

| Geothermal gradient (°C/m) | 0.0379 |

| Pump depth (m) | 1000 |

| Injection temperature (°C) | 60 |

| Injection rate (m3/d) | 100 |

| Gas flow rate (m3/d) | 2000 |

| Injection pressure (MPa) | 1 |

| Measured temperature at casing wellhead(°C) | 55.5 |

| Water flow rate (m3/d) | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ping, X.; Zhang, J.; Han, G.; Chang, J.; Wang, H. Study on the Multiphase Flow Behavior in Jet Pump Drainage and Natural Gas Hydrate Production Wells with Combined Depressurization and Thermal Stimulation Method. Energies 2024, 17, 3842. https://doi.org/10.3390/en17153842

Ping X, Zhang J, Han G, Chang J, Wang H. Study on the Multiphase Flow Behavior in Jet Pump Drainage and Natural Gas Hydrate Production Wells with Combined Depressurization and Thermal Stimulation Method. Energies. 2024; 17(15):3842. https://doi.org/10.3390/en17153842

Chicago/Turabian StylePing, Xiaolin, Jiqun Zhang, Guoqing Han, Junhua Chang, and Hongliang Wang. 2024. "Study on the Multiphase Flow Behavior in Jet Pump Drainage and Natural Gas Hydrate Production Wells with Combined Depressurization and Thermal Stimulation Method" Energies 17, no. 15: 3842. https://doi.org/10.3390/en17153842

APA StylePing, X., Zhang, J., Han, G., Chang, J., & Wang, H. (2024). Study on the Multiphase Flow Behavior in Jet Pump Drainage and Natural Gas Hydrate Production Wells with Combined Depressurization and Thermal Stimulation Method. Energies, 17(15), 3842. https://doi.org/10.3390/en17153842