Co-Pyrolysis of Sewage Sludge, Two-Component Special Municipal Waste and Plastic Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Pyrolysis Process

2.3. Analysis

2.4. Calculation Methods

3. Results

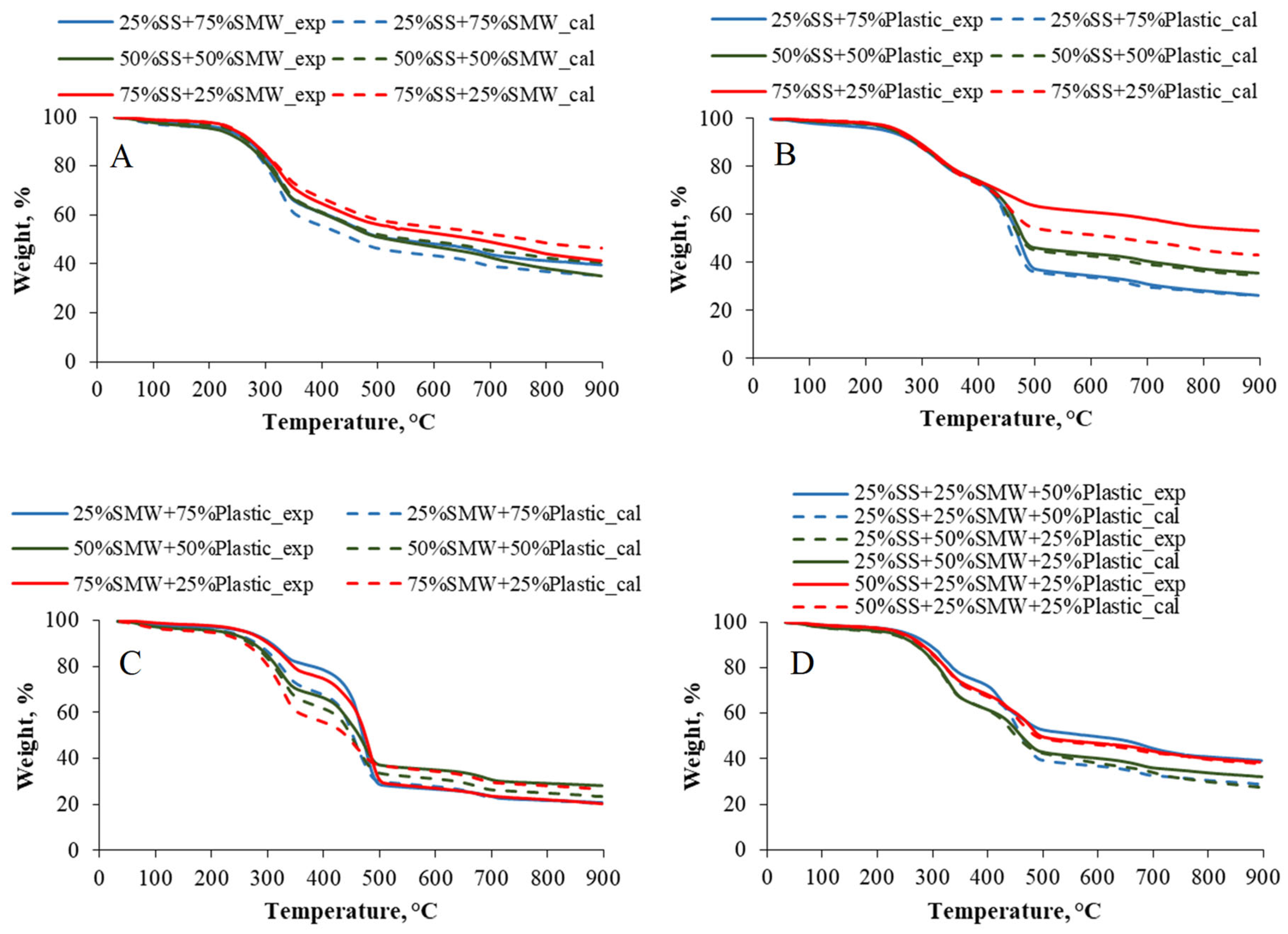

3.1. Thermogravimetric Experiments

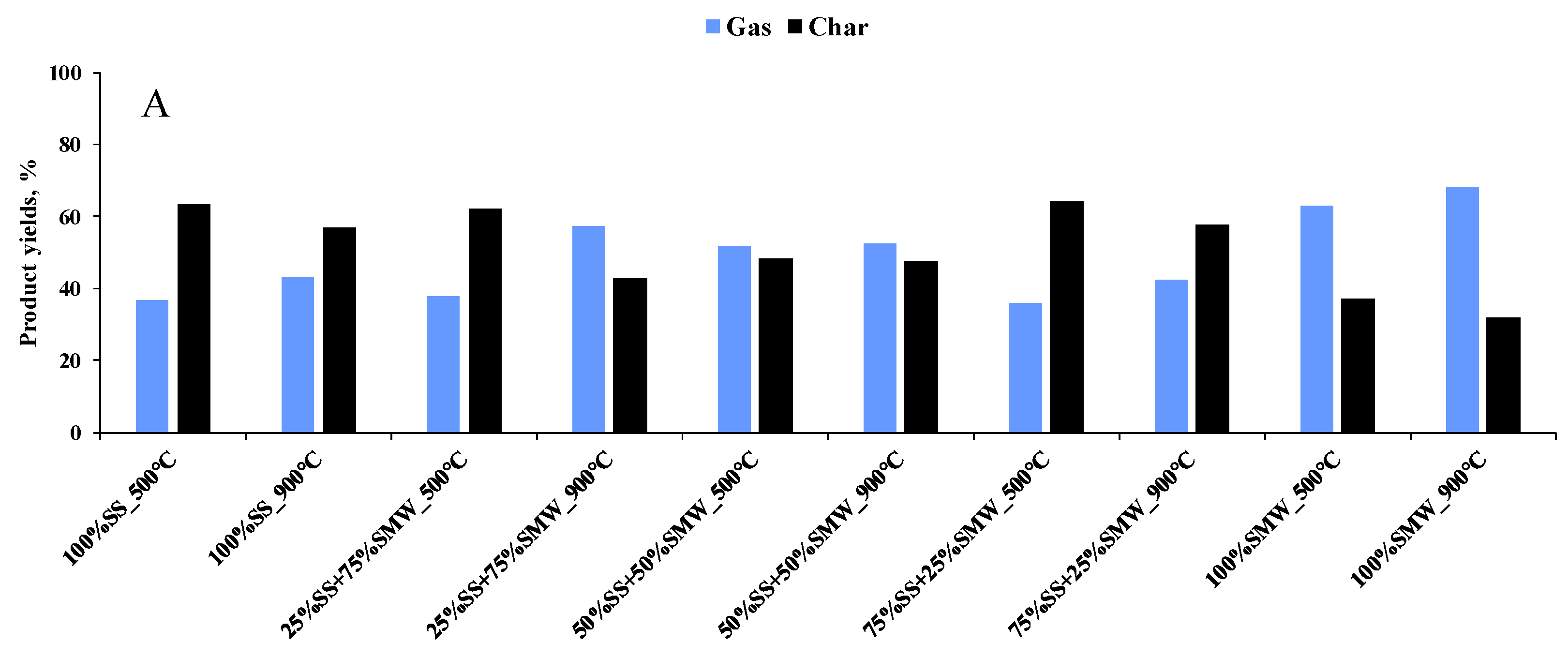

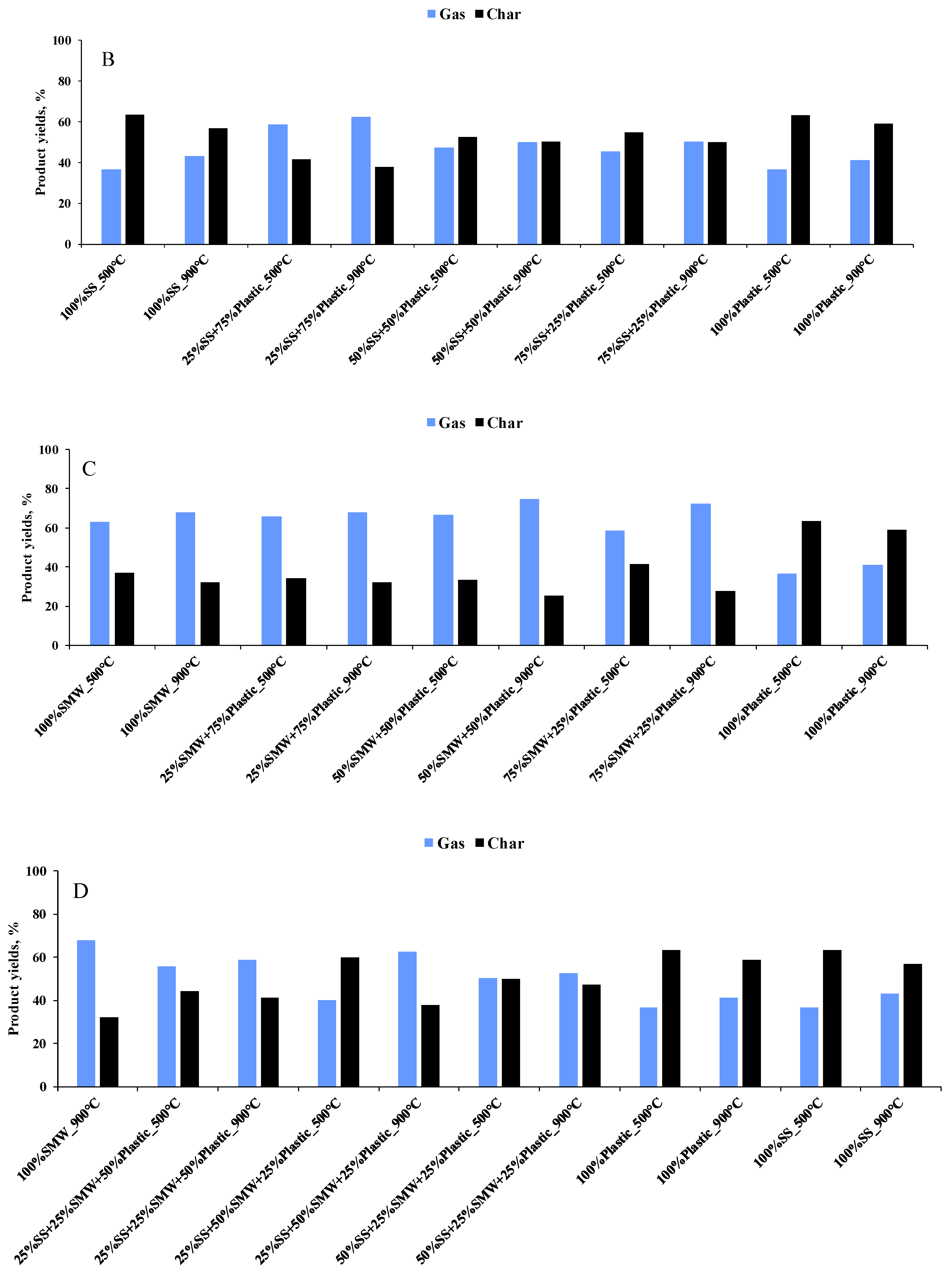

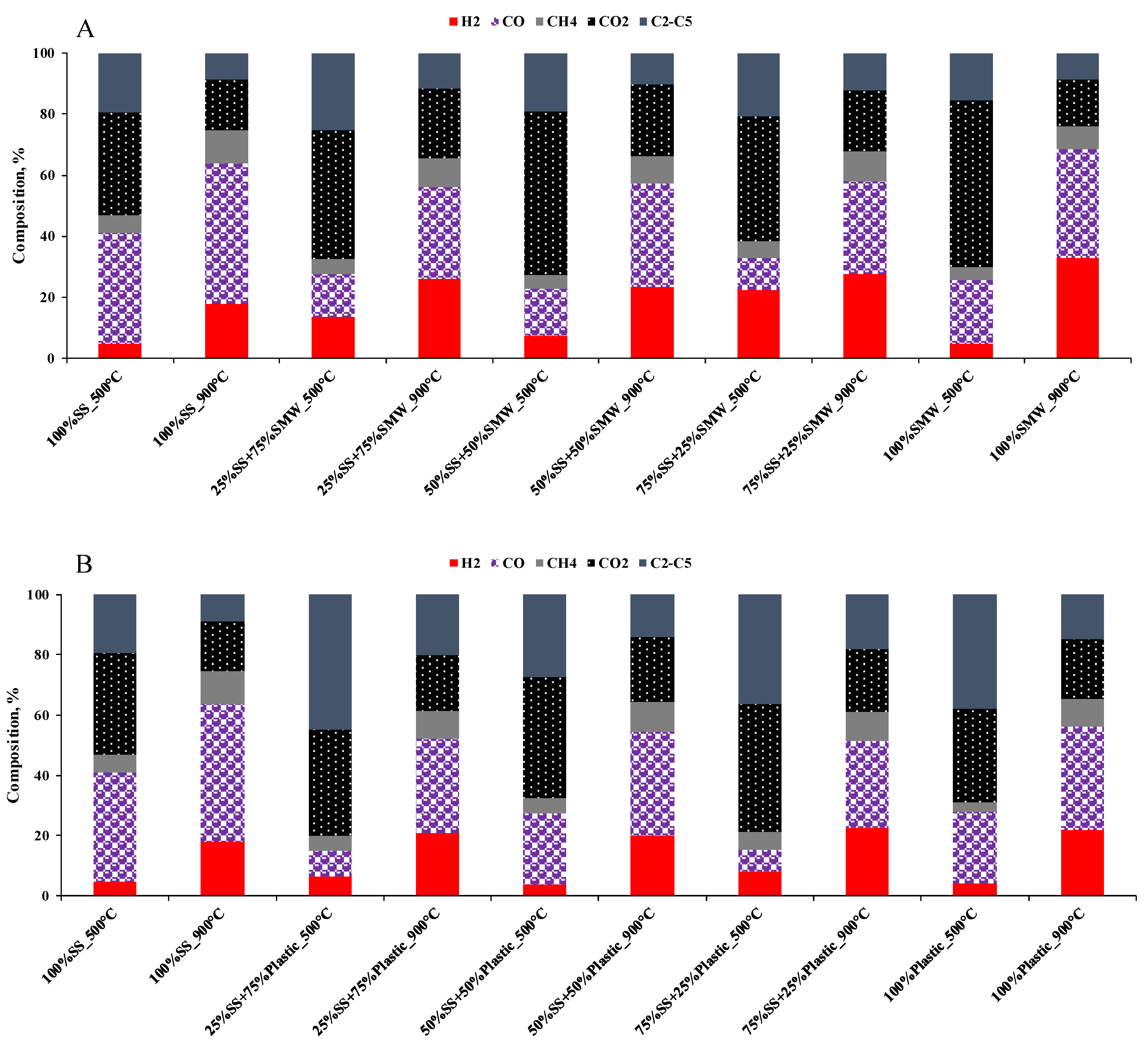

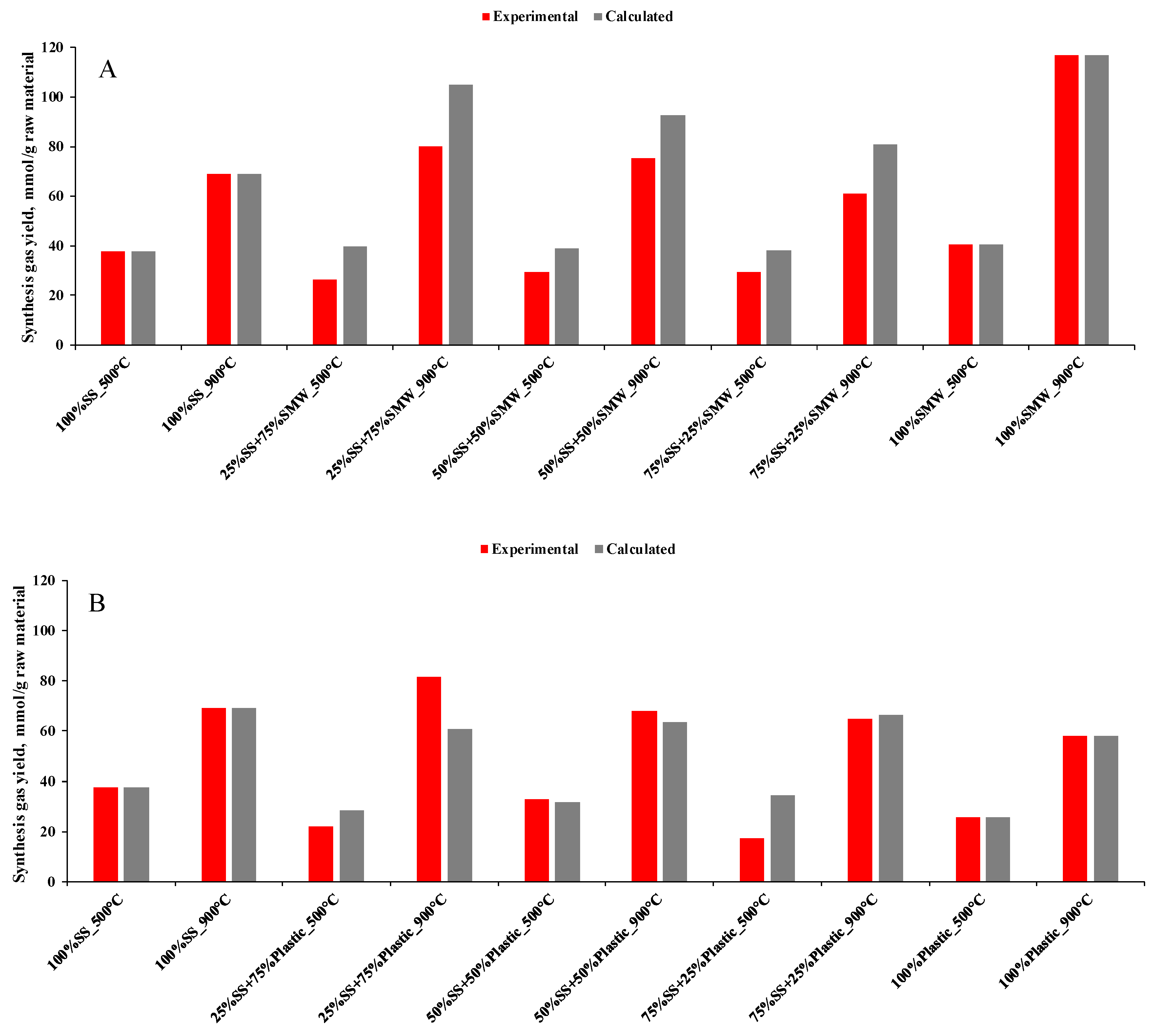

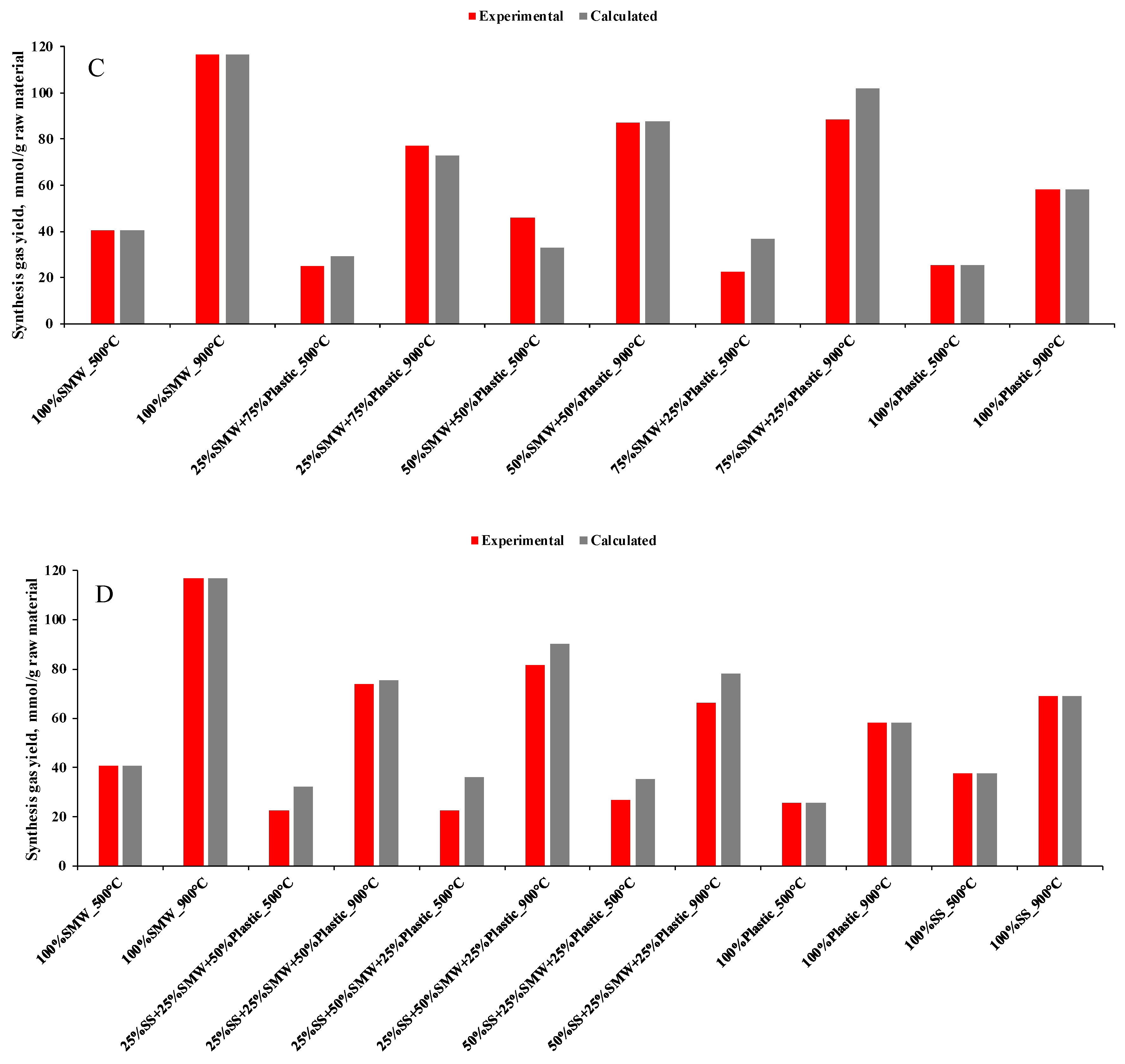

3.2. Scaled-Up Experiments

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations/Acronyms

| DTG | derivative thermogravimetric |

| FID | flame ionization detector |

| HDPE | high-density polyethylene |

| LDPE | low-density polyethylene |

| PET | polyethylene terephthalate |

| PP | polypropylene |

| PUR | polyurethane |

| PVC | polyvinylchloride |

| SMW | two-component special municipal waste |

| SS | sewage sludge |

| TCD | thermal conductivity detector |

| TG | thermogravimetric |

References

- Lee, S.; Kim, Y.-M.; Siddiqui, M.Z.; Park, Y.-K. Different pyrolysis kinetics and product distribution of municipal and livestock manure sewage sludge. Environ. Pollut. 2021, 285, 117197. [Google Scholar] [CrossRef] [PubMed]

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Lamastra, L.; Suciu, N.A.; Trevisan, M. Sewage sludge for sustainable agriculture: Contaminants’ contents and potential use as a fertilizer. Chem. Biol. Technol. Agric. 2018, 5, 10. [Google Scholar] [CrossRef]

- López, A.; Rodrígez-Chueca, J.; Mosteo, R.; Gómez, J.; Ormad, M.P. Microbiological quality of sewage sludge after digestion treatment: A pilot scale case of study. J. Clean. Prod. 2020, 254, 120101. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Tariq, R.; Hameed, Z.; Ali, I.; Naqvi, M.; Chen, W.-H.; Ceylan, S.; Rashid, H.; Ahmad, J.; Taqvi, S.A.; et al. Pyrolysis of high ash sewage sludge: Kinetics and thermodynamic analysis using Coats-Redfern method. Renew. Sustain. Energy Rev. 2009, 131, 854–860. [Google Scholar] [CrossRef]

- Liu, H.; Xu, G.; Li, G. Pyrolysis characteristic and kinetic analysis of sewage sludge using model-free and master plots methods. Process. Saf. Environ. Prot. 2021, 149, 48–55. [Google Scholar] [CrossRef]

- Gao, N.; Li, J.; Qi, B.; Li, A.; Duan, Y.; Wang, Z. Thermal analysis and products distribution of dried sewage sludge pyrolysis. J. Anal. Appl. Pyrolysis 2014, 105, 43–48. [Google Scholar] [CrossRef]

- Nowicki, L.; Ledakowicz, S. Comprehensive characterization of thermal decomposition of sewage sludge by TG–MS. J. Anal. Appl. Pyrolysis 2014, 110, 220–228. [Google Scholar] [CrossRef]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, R.; Man, Y.; Ren, J. Recent developments of hydrogen production from sewage sludge by biological and thermochemical process. Int. J. Hydrogen Energy 2019, 44, 19676–19697. [Google Scholar] [CrossRef]

- Mosko, J.; Pohorely, M.; Skoblia, S.; Beno, Z.; Jeremias, S. Detailed analysis of sewage sludge pyrolysis gas: Effect of pyrolysis temperature. Energies 2020, 13, 4087. [Google Scholar] [CrossRef]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Iwuchukwu, F.U.; Eyankware, O.E.; Iwuozor, K.O.; Olotu, K.; Bright, O.C.; Igwegbe, C.A. Flash pyrolysis of biomass: A review of recent advances. Clean Technol. Environ. Policy 2022, 2, 2349–2363. [Google Scholar] [CrossRef]

- Gao, N.; Quan, C.; Liu, B.; Li, Z.; Wu, C.; Li, A. Continuous pyrolysis of sewage sludge in a screw-feeding reactor: Products characterization and ecological risk assessment of heavy metals. Energy Fuels 2017, 31, 5063–5072. [Google Scholar] [CrossRef]

- Xin, C.; Zhao, J.; Ruan, R.; Addy, M.M.; Liu, S.; Mu, D. Economical feasibility of bio-oil production from sewage sludge through pyrolysis. Thermal Sci. 2018, 22, 459–467. [Google Scholar] [CrossRef]

- Kim, Y.; Parker, W. A technical and economic evaluation of the pyrolysis of sewage sludge for the production of bio-oil. Bioresour. Technol. 2008, 99, 1409–1416. [Google Scholar] [CrossRef] [PubMed]

- Haghighat, M.; Majidian, N.; Hallajisani, A.; Samipourgiri, M. Production of bio-oil from sewage sludge: A review on the thermal and catalytic conversion by pyrolysis. Sustain. Energy Technol. Assess. 2020, 42, 100870. [Google Scholar] [CrossRef]

- Tomasek, S.; Bárkányi, Á.; Egedy, A.; Miskolczi, N. Model-based determination of optimal operating parameters for different solid waste gasification. Chem. Eng. J. Adv. 2024, 17, 100586. [Google Scholar] [CrossRef]

- Umana, B.; Shoaib, A.; Zhang, N.; Smith, R. Integrating hydroprocessors in refinery hydrogen network optimisation. Appl Energy 2014, 133, 169–182. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Q.; Chen, M.; Ma, L.; Yand, B.; Chen, J.; Lv, Z.; Liang, Q.; Yang, P. Evaluation of migration of heavy metals and performance of product during co-pyrolysis process of municipal sewage sludge and walnut shell. Environ. Sci. Pollut. Res. 2017, 24, 22082–22090. [Google Scholar] [CrossRef]

- Amin, R.A.; Huang, Y.; He, Y.; Zhang, R.; Liu, G.; Chen, C. Biochar applications and modern techniques for characterization. Clean Technol. Environ. Policy 2016, 18, 1457–1473. [Google Scholar] [CrossRef]

- Yue, Y.; Cui, L.; Lin, Q.; Li, G.; Zhao, X. Efficiency of sewage sludge biochar in improving urban soil properties and promoting grass growth. Chemosphere 2017, 173, 551–556. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Garg, A. Primary sewage sludge-derived activated carbon: Characterisation and application in wastewater treatment. Clean Technol. Environ. Policy 2015, 17, 1619–1631. [Google Scholar] [CrossRef]

- Sizmur, T.; Fresno, T.; Akgül, G.; Frost, H.; Moreno-Jiménez, E. Biochar modification to enhance sorption of inorganics from water. Bioresour. Technol. 2017, 246, 34–47. [Google Scholar] [CrossRef]

- Mohamed, B.A.; Ruan, R.; Bilal, M.; Periyasamy, S.; Awasthi, M.K.; Rajamohan, N.; Leng, L. Sewage sludge co-pyrolysis with agricultural/forest residues: A comparative life-cycle assessment. Renew. Sustain. Energy Rev. 2024, 192, 114168. [Google Scholar] [CrossRef]

- Lin, B.; Huang, Q.; Chi, Y. Co-pyrolysis of oily sludge and rice husk for improving pyrolysis oil quality. Fuel Process. Technol. 2018, 177, 275–282. [Google Scholar] [CrossRef]

- Wang, X.; Deng, S.; Tan, H.; Adeosun, A.; Vujanović, M.; Yang, F.; Duić, N. Synergetic effect of sewage sludge and biomass co-pyrolysis: A combined study in a thermogravimetric analyser and a fixed bed reactor. Energy Convers. Manag. 2016, 118, 399–405. [Google Scholar] [CrossRef]

- Zhang, W.; Yuan, C.; Xu, J.; Yang, X. Beneficial synergetic effect on gas production during co-pyrolysis of sewage sludge and biomass in a vacuum reactor. Bioresour. Technol. 2015, 183, 255–258. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, Y.; Yang, L.; Zhu, Y. High quality syngas produced from the co-pyrolysis of wet sewage sludge with sawdust. Int. J. Hydrogen Energy 2018, 43, 5463–5472. [Google Scholar] [CrossRef]

- Singh, S.V.; Ming, Z.; Fennel, P.S.; Shah, N.; Anthony, E.J. Progress in biofuel production from gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Dong, Q.; Zhang, S.; Wu, B.; Pi, M.; Xiong, Y.; Zhang, H. Co-pyrolysis of sewage sludge and rice straw: Thermal behavior and char characteristic evaluation. Energy Fuels 2019, 34, 607–615. [Google Scholar] [CrossRef]

- Ling, C.C.Y.; Li, S.F.Y. Synergistic interactions between sewage sludge, polypropylene, and high-density polyethylene during co-pyrolysis: An investigation based on iso-conversional model-free methods and master plot analysis. J. Hazard. Mater. 2023, 455, 131600. [Google Scholar] [CrossRef]

- Zaker, A.; Chen, Z.; Zaheer-Uddin, M.; Guo, J. Co-pyrolysis of sewage sludge and low-density polyethylene—A thermogravimetric study of thermo-kinetics and thermodynamic parameters. J. Environ. Chem. Eng. 2021, 9, 104554. [Google Scholar] [CrossRef]

- Azizi, K.; Haghighi, A.M.; Moraveji, M.K.; Olazar, M.; Lopez, G. Co-pyrolysis of binary and ternary mixtures of microalgae, wood and waste tires through TGA. Renew. Energy 2019, 142, 264–271. [Google Scholar] [CrossRef]

- Batuer, A.; Long, J.; Du, H.; Chen, D. Multi-products oriented co-pyrolysis of papers, plastics, and textiles in MSW and the synergistic effects. J. Anal. Appl. Pyrolysis 2022, 163, 105478. [Google Scholar] [CrossRef]

- Tomasek, S.; Miskolczi, N. Investigation of pyrolysis behavior of sewage sludge by thermogravimetric analysis coupled with Fourier Transform Infrared Spectrometry using different heating rates. Energies 2022, 15, 5116. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T. Effect of the heating rate on the thermochemical behavior and biofuel properties of sewage sludge pyrolysis. Energy Fuels 2016, 30, 1564–1570. [Google Scholar] [CrossRef]

- Tomaszewska, K.; Kaluzna-Czapliñska, J.; Józwiak, K. Thermal and thermo-catalytic degradation of polyolefins as a simple and efficient method of landfill clearing. Pol. J. Chem. Technol. 2010, 12, 50–57. [Google Scholar] [CrossRef]

- Adnan, A.; Shah, J.; Rasul, J.M. Thermo-catalytic pyrolysis of polystyrene in the presence of zinc bulk catalysts. J. Taiwan Inst. Chem. Eng. 2014, 45, 2494–2500. [Google Scholar] [CrossRef]

- Bermudez, J.M.; Fidalgo, B. Production of bio-syngas and bio-hydrogen via gasification. In Handbook of Biofuels Production, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Chen, G.-B.; Huang, K.-C. A study of copyrolysis characteristics of sewage sludge and waste polypropylene. Int. J. Energy Res. 2023, 2023, 1406397. [Google Scholar] [CrossRef]

- Almeida, D.; de Fátima Marques, M. Thermal and catalytic pyrolysis of plastic waste. Polimeros 2016, 26, 44–51. [Google Scholar] [CrossRef]

- Özsin, G.; Pütün, A.E. An investigation on pyrolysis of textile wastes: Kinetics, thermodynamics, in-situ monitoring of evolved gasses and analysis of the char reaidue. J. Environ. Chem. Eng. 2022, 10, 107748. [Google Scholar] [CrossRef]

- Lim, J.Y.; McGregor, J.; Sederman, A.J.; Dennis, J.S. The role of the Boudouard and water-gas shift reactions in the methanation of CO or CO2 over Ni/γ-Al2O3 catalyst. Chem. Eng. Sci. 2016, 152, 754–766. [Google Scholar] [CrossRef]

- Muhiiwa, R.F.; Sempuga, B.; Hildebrandt, D.; Van Der Walt, J. Study the effects of temperature on syngas composition from pyrolysis of wood pellets using a nitrogen plasma torch reactor. J. Anal. Appl. Pyrolysis 2018, 130, 159–168. [Google Scholar] [CrossRef]

- Lahijani, P.; Zainal, Z.A.; Mohammadi, M.; Mohamed, A.R. Conversion of the greenhouse gas CO2 to the fuel gas CO via the Boudouard reaction: A review. Renew. Sustain. Energy Rev. 2015, 41, 615–632. [Google Scholar] [CrossRef]

- Gunasee, S.D.; Danon, B.; Görgens, J.F.; Mohee, R. Co-pyrolysis of LDPE and cellulose: Synergies during devolatilization and condensation. J. Anal. Appl. Pyrolysis 2017, 126, 307–314. [Google Scholar] [CrossRef]

- Kim, S.S.; Agblevor, F.A.; Lim, J. Fast pyrolysis of chicken litter and turkey litter in a fluidized bed reactor. J. Ind. Eng. Chem. 2009, 15, 247–252. [Google Scholar] [CrossRef]

| Amount, % | SS | SMW | Plastic |

|---|---|---|---|

| C | 31.2 | 39.1 | 38.8 |

| H | 4.0 | 6.3 | 5.8 |

| N | 4.4 | 1.2 | 1.7 |

| S | 1.4 | 0.4 | 0.0 |

| O + other elements | 59.0 | 53.0 | 53.7 |

| Raw Materials | H2/CO Ratios 500 °C/900 °C | LHV, MJ/Nm3 500 °C/900 °C |

|---|---|---|

| 100%SS | 0.1/0.4 | 20.8/17.6 |

| 100%SMW | 0.2/0.9 | 15.5/16.8 |

| 100%Plastic | 0.2/0.6 | 31.0/20.3 |

| 25%SS + 75%SMW | 1.0/0.9 | 22.7/18.1 |

| 50%SS + 50%SMW | 0.5/0.7 | 17.8/17.3 |

| 75%SS + 25%SMW | 2.1/0.9 | 20.2/19.0 |

| 25%SS + 75%Plastic | 0.7/0.7 | 35.0/23.6 |

| 50%SS + 50%Plastic | 0.2/0.6 | 24.3/20.0 |

| 75%SS + 25%Plastic | 1.1/0.8 | 29.3/22.1 |

| 25% SMW + 75%Plastic | 0.7/0.8 | 31.3/26.6 |

| 50%SMW + 50%Plastic | 0.2/0.9 | 28.4/28.0 |

| 75%SMW + 25%Plastic | 1.1/0.7 | 26.4/21.6 |

| 25%SS + 25%SMW + 50%Plastic | 0.5/0.8 | 32.1/23.0 |

| 25%SS + 50%SMW + 25%Plastic | 0.8/0.9 | 28.5/20.8 |

| 50%SS + 25%SMW + 25%Plastic | 0.4/0.9 | 24.0/20.3 |

| Raw Materials | 500 °C | 900 °C | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | S | C/N | H/C | C | H | N | S | C/N | H/C | |

| 100%SS | 21.4 | 1.3 | 2.4 | 0.4 | 8.8 | 0.06 | 12.4 | 0.4 | 0.6 | 0.4 | 21.7 | 0.03 |

| 100%SMW | 37.8 | 1.7 | 1.7 | 0.0 | 21.8 | 0.04 | 28.6 | 2.9 | 1.6 | 0.0 | 18.3 | 0.10 |

| 100%Plastic | 25.3 | 1.2 | 1.5 | 0.0 | 17.1 | 0.05 | 27.7 | 3.1 | 2.2 | 0.2 | 12.8 | 0.11 |

| 25%SS + 75%SMW | 37.0 | 4.0 | 2.0 | 0.0 | 19.0 | 0.11 | 23.3 | 0.4 | 0.7 | 1.3 | 32.8 | 0.02 |

| 50%SS + 50%SMW | 34.3 | 2.8 | 1.9 | 0.4 | 18.5 | 0.08 | 20.3 | 0.5 | 0.7 | 1.2 | 27.8 | 0.02 |

| 75%SS + 25%SMW | 37.9 | 2.2 | 2.5 | 0.42 | 15.3 | 0.06 | 22.3 | 0.6 | 1.0 | 0.7 | 22.5 | 0.03 |

| 25%SS + 75%Plastic | 24.2 | 1.4 | 1.5 | 0.0 | 16.2 | 0.06 | 14.6 | 0.6 | 0.8 | 0.7 | 18.7 | 0.04 |

| 50%SS + 50%Plastic | 20.3 | 1.1 | 1.2 | 0.0 | 17.1 | 0.05 | 8.8 | 0.3 | 0.5 | 0.8 | 17.0 | 0.03 |

| 75%SS + 25%Plastic | 23.6 | 1.6 | 1.9 | 0.3 | 12.2 | 0.07 | 14.7 | 0.4 | 0.8 | 0.5 | 19.1 | 0.03 |

| 25%SMW + 75%Plastic | 33.7 | 1.1 | 1.2 | 0.0 | 28.3 | 0.03 | 21.8 | 0.4 | 0.7 | 2.4 | 31.6 | 0.02 |

| 50%SMW + 50%Plastic | 29.3 | 1.6 | 1.4 | 0.0 | 21.2 | 0.05 | 19.6 | 0.5 | 0.6 | 2.3 | 31.1 | 0.02 |

| 75%SMW + 25%Plastic | 25.2 | 1.3 | 1.2 | 0.0 | 21.3 | 0.0 | 26.5 | 0.6 | 0.5 | 1.4 | 49.0 | 0.02 |

| 25%SS + 25%SMW + 50%Plastic | 23.7 | 2.2 | 1.1 | 0.55 | 22.0 | 0.09 | 14.8 | 0.4 | 0.5 | 0.8 | 30.2 | 0.02 |

| 25%SS + 50%SMW + 25%Plastic | 38.6 | 3.5 | 1.6 | 1.80 | 24.1 | 0.09 | 24.2 | 0.6 | 0.7 | 2.1 | 33.1 | 0.02 |

| 50%SS + 25%SMW + 25%Plastic | 24.5 | 2.2 | 1.1 | 0.88 | 23.2 | 0.09 | 15.3 | 0.4 | 0.5 | 1.1 | 31.9 | 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomasek, S.; Miskolczi, N. Co-Pyrolysis of Sewage Sludge, Two-Component Special Municipal Waste and Plastic Waste. Energies 2024, 17, 3696. https://doi.org/10.3390/en17153696

Tomasek S, Miskolczi N. Co-Pyrolysis of Sewage Sludge, Two-Component Special Municipal Waste and Plastic Waste. Energies. 2024; 17(15):3696. https://doi.org/10.3390/en17153696

Chicago/Turabian StyleTomasek, Szabina, and Norbert Miskolczi. 2024. "Co-Pyrolysis of Sewage Sludge, Two-Component Special Municipal Waste and Plastic Waste" Energies 17, no. 15: 3696. https://doi.org/10.3390/en17153696

APA StyleTomasek, S., & Miskolczi, N. (2024). Co-Pyrolysis of Sewage Sludge, Two-Component Special Municipal Waste and Plastic Waste. Energies, 17(15), 3696. https://doi.org/10.3390/en17153696