1. Introduction

The normal operating temperature range of a lithium-ion battery (LiB) is between 273.15 and 318.15 K. The electrochemical performance in cold weather suffers from severe degradation, which has a negative influence when used in electric vehicles (EVs) in cold regions [

1]. At low temperatures, inactive positive and negative electrode materials can give rise to the slow kinetics of Li

+ intercalation/de-intercalation in the electrodes. Moreover, high electrolyte viscosity can cause slow Li

+ diffusion and low ionic electrical conductivity in the electrolyte, so the internal resistance of the LiB drastically increases, thereby leading to the significant loss of both the pulse power and usable energy, which can reduce the driving range and power performance of EVs [

1,

2,

3,

4,

5]. In addition, if an LiB is forcibly charged under low-temperature conditions, the Li

+ electrical deposition on the surface of the carbon electrode will replace the intercalation reaction [

1]. When a deposition interface appears, the obvious concentration gradient of the Li

+ lithium can be deposited on the graphite electrode’s surface in the form of undesirable dendrites, and the growth of a dendrite structure can cause substantial capacity loss and thermal runaway [

6,

7,

8]. Therefore, it is necessary for a battery thermal management system (BTMS) to heat the LiB to a reasonable operating temperature in order to improve the working ability and safety of LiBs at low temperatures.

Heating approaches can be divided into external and internal methods, depending on their thermal conduction paths [

9]. External heating, in which heat is transferred from the outside of the LiB’s modules to the inside by taking advantage of external heat sources, which include fluids, wild-line metal films, Peltier effect heaters, and others, can be safely and conveniently integrated with existing BTMSs and easily implemented. However, the external method exhibits a low heating velocity and efficiency because of the thermal dissipation required to cool the air in each intermediate path of the heat transfer process. It also exhibits a non-uniform temperature distribution in the interior of the LiB during the heating process, resulting in the degradation of the electrode materials and a localized heat-induced aging effect that reduces the LiB’s cycle lifetime [

9,

10,

11,

12,

13]. In contrast, the internal heating strategy implements the current excitation passing through the LiB to generate Joule heat due to the increasing internal resistance of the LiB in cold climates; such solutions include self-heating Li-ion battery (SHLB) structures [

14,

15,

16], electrically triggered heating [

17], alternating current heating [

8], and so on. The internal method achieves less energy loss, and there is a better heat generation rate and temperature gradient within the LiB than with the external method. However, the current excitation, which is similar to that in internal/external short circuits, can give rise to safety hazards and battery life degradation. Moreover, the selection rules for the current excitation parameters are still unknown, although there is substantial potential to warm LiBs to room temperature with high efficiency and a high heat production rate.

Table 1 shows the heating performance of the heating methods used in batteries. It can be seen from

Table 1 and Refs. [

18,

19,

20,

21,

22] that existing heating/preheating technologies can achieve a good effect for a certain target, such as the heat generation rate, safety, the recovery of the charging/discharging ability, and so on. However, it is difficult for BTMSs to balance the temperature rise, electrochemical performance, cycle lifetime, and safety. Thus, the development of a mature heating method is still a long-term goal for the application of LiBs in cold weather. To solve this, Xiong et al. [

12] proposed a hybrid heating strategy based on AC heating and wide-wire metal film heating methods. The technology led to 32% and 23% improvements in the heating rate and energy consumption compared to the AC heating method, respectively. Yang et al. [

4] introduced the multi-sheet battery design on the basis of an all-climate cell structure; this could achieve 25–30% improvements in both the energy consumption and activation time, as well as an improved cell lifetime compared with the one-sheet cell structure. Ruan et al. [

23] proposed an AC heating strategy with a constant sinusoidal alternating polarization voltage in order to balance the temperature rise and the health of the LiB. The heating rate and temperature difference inside the battery reached 3.73 K·min

−1 and 1.6 K, respectively, and the strategy caused less damage to the health state of the LiBs.

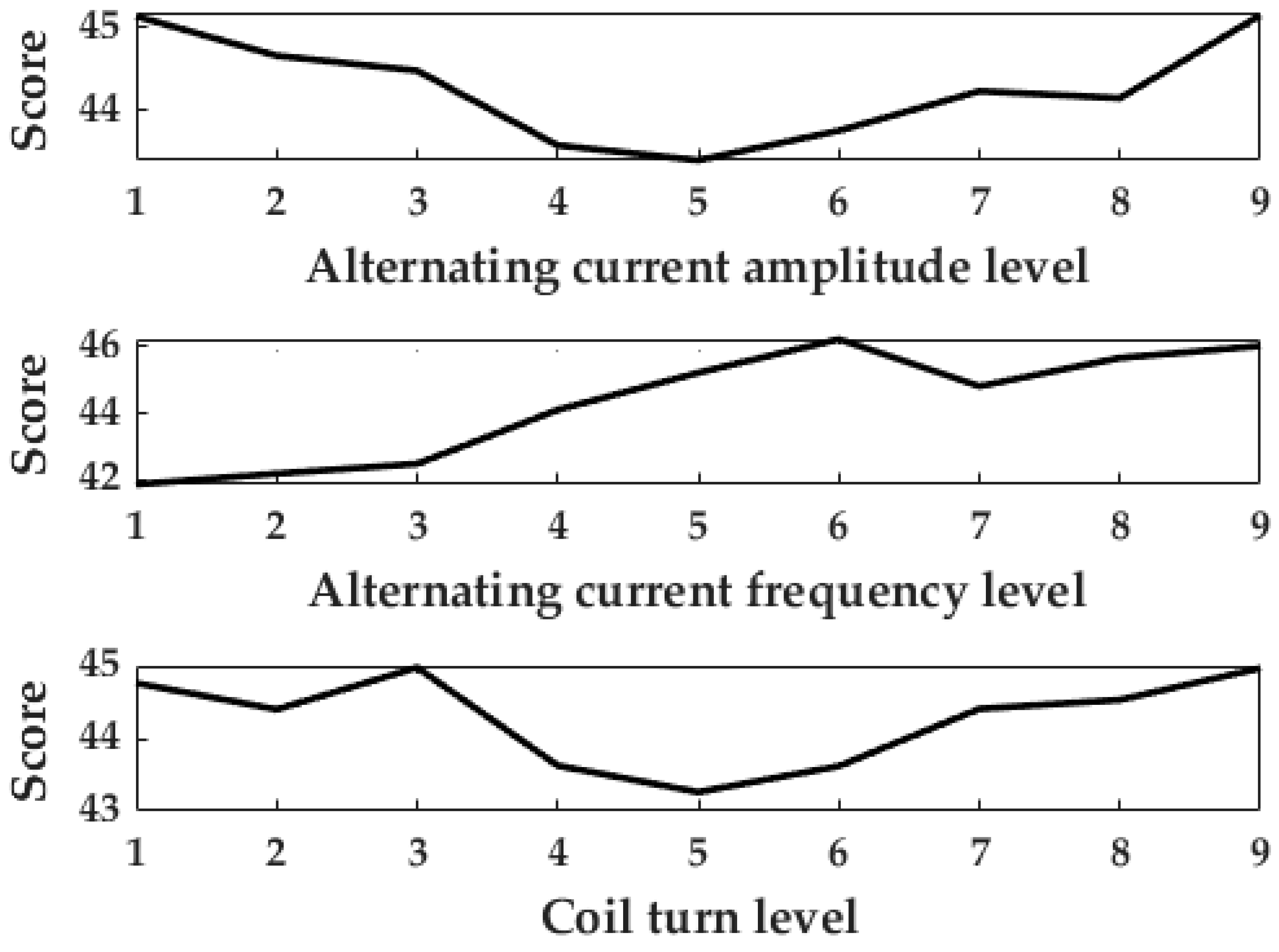

According to the above research, our academic team recently developed an extremely fast electromagnetic induction heating system (EIHS) so as to improve the working ability of LiBs. It applies the eddy current produced by the action of electromagnetic induction to realize conversion between electrical and thermal energy through the LiB’s resistance. In this way, the heating system can achieve a satisfactory average temperature rise rate (

ATR) and temperature difference at the end of the heating process, and the EIHS has no apparent effect on the LiB’s interior [

29]. Aiming to select the appropriate induction coil parameters for the optimization of the heating effect, our team developed the EIHS to explore the optimal parameter combination by designing an orthogonal test on the basis of the electrochemical–thermal coupling model (ETCM). Then, we studied the working performance of an LiB with this optimal combination. Based on the optimal parameter combination found in the orthogonal test, the heating strategy could achieve good temperature rise behavior by taking advantage of the eddy current passing through the heated LiB under the action of electromagnetic induction, which resembles internal alternating current heating. In the meantime, the heating method can avoid thermal runaway and other risks induced by self-discharging with a large current, so this heating strategy can achieve a trade-off among the heating rate, temperature distribution, and safety.

Firstly, based on porous electrode theory, lumped thermal energy conservation, and the electromagnetic induction heating principle, an ETCM was validated against the normal and pulse discharge experimental results at different temperatures and was used to research the terminal voltage output, temperature rise, and field performance during the heating process. Moreover, the induction heat production value was embedded into the thermal model in the form of an internal heat source. Secondly, the

ATR and temperature uniformity were adopted as the optimal targets, and we designed an orthogonal test to carry out multi-factor exploration. We took advantage of a range analysis to find the optimal copper coil parameter combination in order to improve the heating effect of the proposed EIHS. Thirdly, under the optimal parameter combination, the heating strategy could achieve a compromise between the heating rate and temperature difference inside the LiB. The temperature difference refers to the difference in temperature from the exterior of the shell to the mandrel after the heating process. The temperature difference inside the LiB mainly exists in the active material and mandrel and results from the fact that the skin depth of the shell is larger than the shell thickness. Moreover, the active material and mandrel are non-ferromagnetic materials that cannot be permeated by the eddy current. The temperature field is discussed in

Section 4.5. Furthermore, the significantly enhanced temperature rise performance can decrease the internal resistance to a quarter of the low-temperature level, hence improving the usable energy and charging/discharging pulse power. Additionally, the proposed EIHS causes less damage to the LiB’s cycle lifespan and exhibits no apparent energy degradation as compared to the normal situation at room temperature. Finally, under the comprehensive action of electromagnetic induction and heat conduction, the formation of a temperature field inside the LiB during the heating process was determined via the skin effect and material properties. We studied the relationship between the temperature gradient and electromagnetic field distribution within the LiB and the influence of the thermal conductivity of the active material of the LiB on the temperature uniformity inside the LiB during the heating process in order to analyze the decisive factors regarding temperature field generation. All of the parameters adopted in the study can be seen in the Nomenclature.

2. Electrochemical–Thermal Coupling Model

2.1. Model Structure

In this work, we established an ETCM to accurately characterize the voltage output of the LiB and the variation in the LiB’s temperature during the heating process.

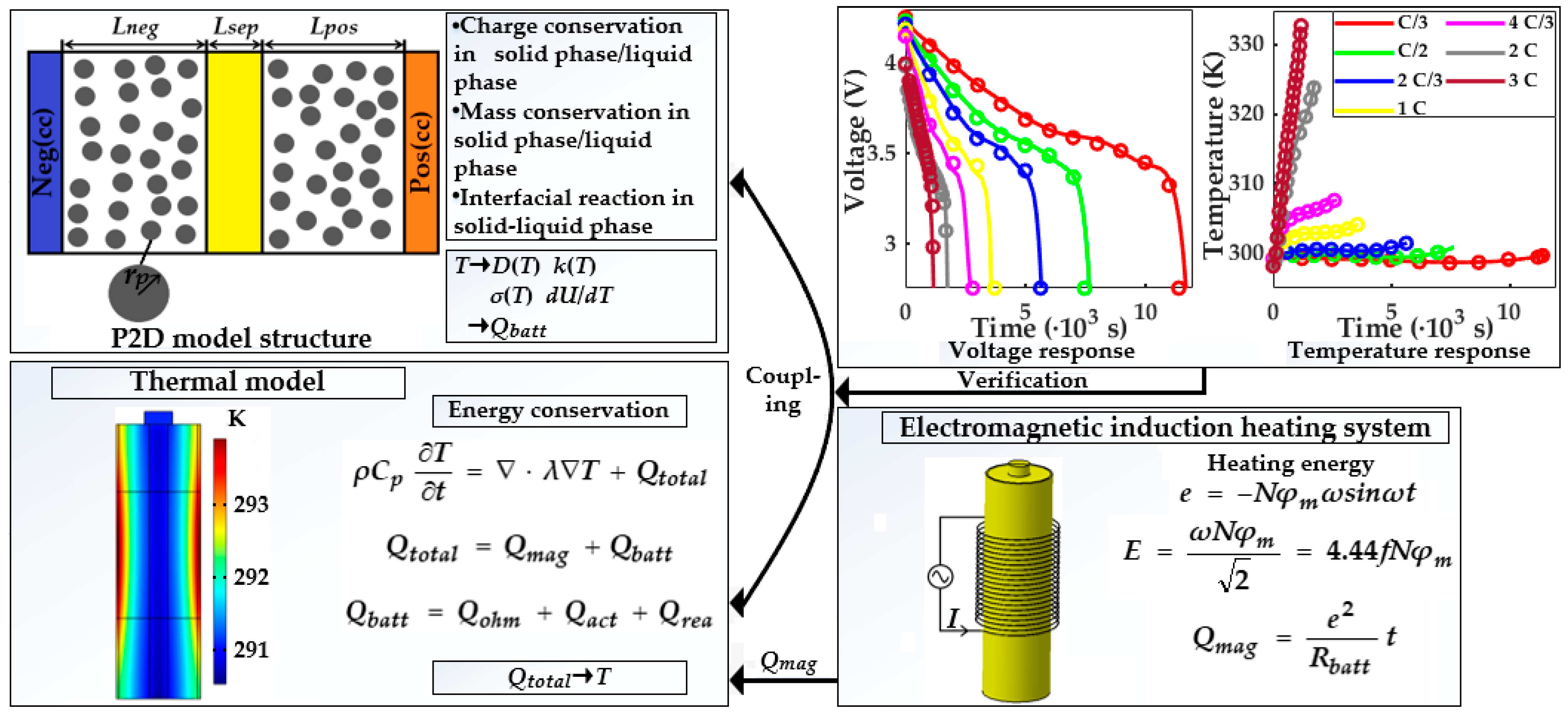

Figure 1 exhibits the ETCM’s structure, in which the heat generated by electromagnetic induction as part of the total heat generation of the LiB is input into the thermal model to reflect the temperature output. In the process of computation, the thermal production from the interior of the LiB and the electromagnetic induction heat are input into the governing equation in the thermal model as the total heat source. Then, the LiB temperature calculated in the thermal model is fed back to the electrochemical model in order to update the temperature-dependent parameters and hence the chemical reaction-induced heat generation inside the LiB. Thus, the electrochemical–thermal closed-loop feedback function can be realized by correcting the temperature-sensitive parameters in the electrochemical model on the basis of the computed temperature, such as the reaction rate constant, liquid-phase diffusivity, and so on. The response precision of the ETCM was studied through normal and pulse discharging experiments at various temperature conditions, which can be seen in

Section 4.1.

2.2. Electrochemical Model

As one of the most precise electrochemical models, based on the electrode kinetics, the Li

+ diffusion in the solid and liquid phases, concentrated solutions, and porous electrodes, the pseudo-two-dimensional (P2D) model introduced by Doyle and Newman has been applied in many commercialized simulation programs. Thus, the P2D model was adopted in this study to depict the internal state of the LiB according to the electrochemical reaction mechanism. The governing equations are shown in

Table 2 [

29,

30,

31].

As can be seen from the governing equations, the P2D model consists of four independent partial differential equations, which are associated via the electrochemical kinetic equation depicting the relationship between the net reaction rate and the electrode potential in the electrode reaction process [

32]. The model can describe the Li

+ diffusion in the solid phase, the mass transfer in the electrolyte, and the Li

+ intercalation/de-intercalation process at the solid–liquid phase interface.

2.3. Thermal Model

The P2D model is an isothermal model and cannot consider the interaction between a chemical reaction and heat generation. However, the accumulation of thermal energy during the heating and electrochemical reaction process inevitably gives rise to a change in the ionic transportation property and chemical reaction rate, which can be directly reflected in the variation in the reaction rate constant, the Li+ electrical conductivity and diffusivity, and other electrochemical parameters that are related to the operating temperature of the LiB. Thus, it is essential for the isothermal P2D model to be coupled with a heat generation model in order to ensure the computational accuracy of the operating state of the LiB at each temperature interval.

The heat generation during the charging/discharging process includes activation polarization, reaction, and ohmic heat, which represent the electrode polarization, enthalpy variation, and ohmic potential, respectively. Together, these constitute the total heat production with electromagnetic induction heat. Considering the consistency of the heat generation rate between the interior and the surface of an 18650 battery, the three-dimensional temperature distribution lumped heat generation model with an internal heat source was applied as the energy conservation equation in the three-dimensional cylindrical coordinate system. The boundary condition can be described by Newton’s law of cooling: when there is a temperature difference between the heated LiB and the environment, the LiB can transfer the heat energy to the air in the form of thermal convection during the heating process. The convention heat transfer coefficient was set as 20 W·m

−2·K

−1 in this study. The governing equations of the thermal model are shown in

Table 3.

According to the temperature-sensitive parameters updated in the electrochemical model, the heat production from the LiB itself was input in the energy conservation equation, which, together with the eddy current loss, determines the temperature rise at the current computation cycle by calculating the governing model in the thermal model.

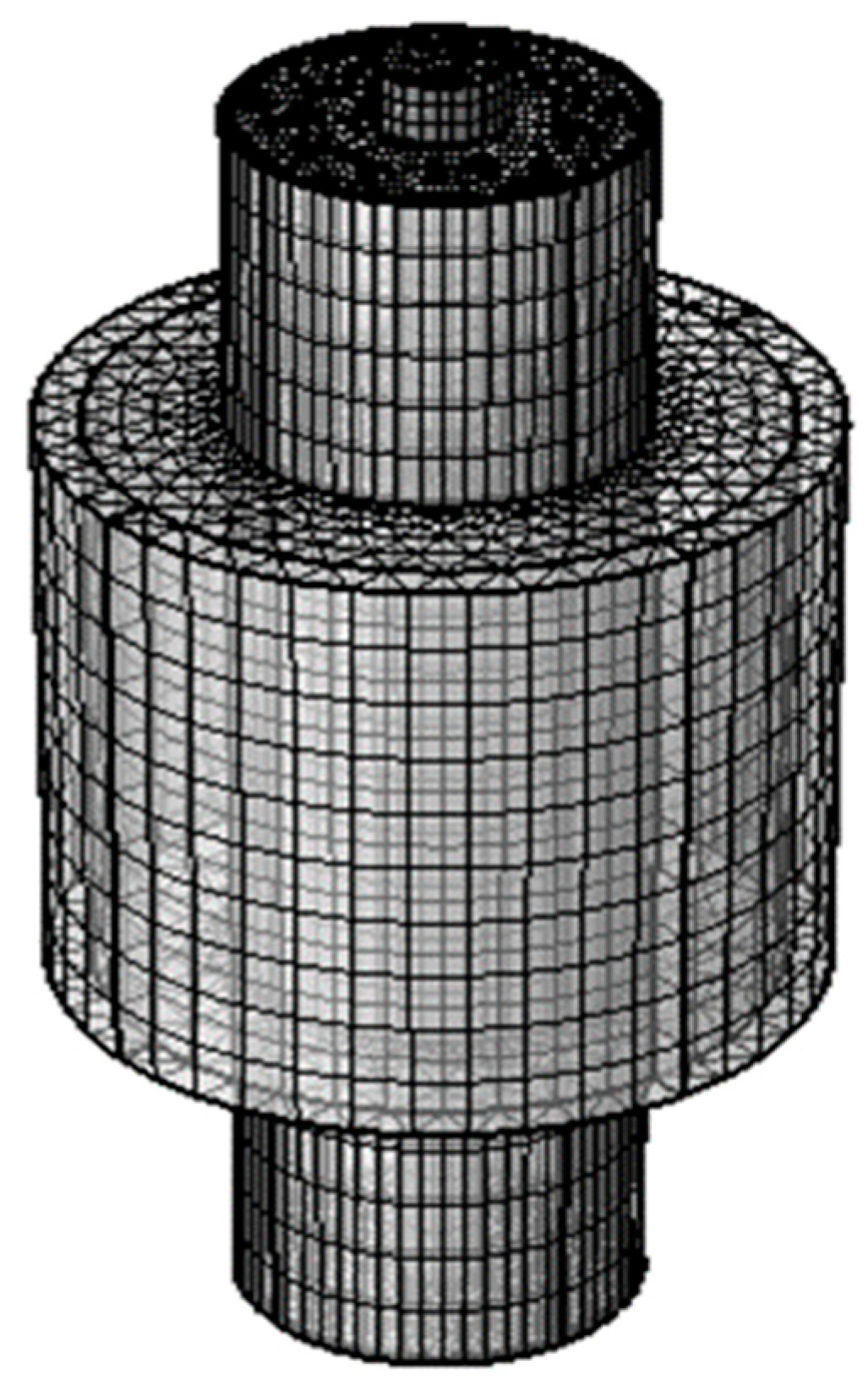

2.4. Electromagnetic Induction Heating Theory

Electromagnetic induction heating technology can excite the eddy current inside the conductor in order to cause the LiB temperature to rise in a short time through a series of energy conversions. This results in a high heating velocity and efficiency, excellent adaptability, and no pollution; the EIHS can be observed in

Figure 2.

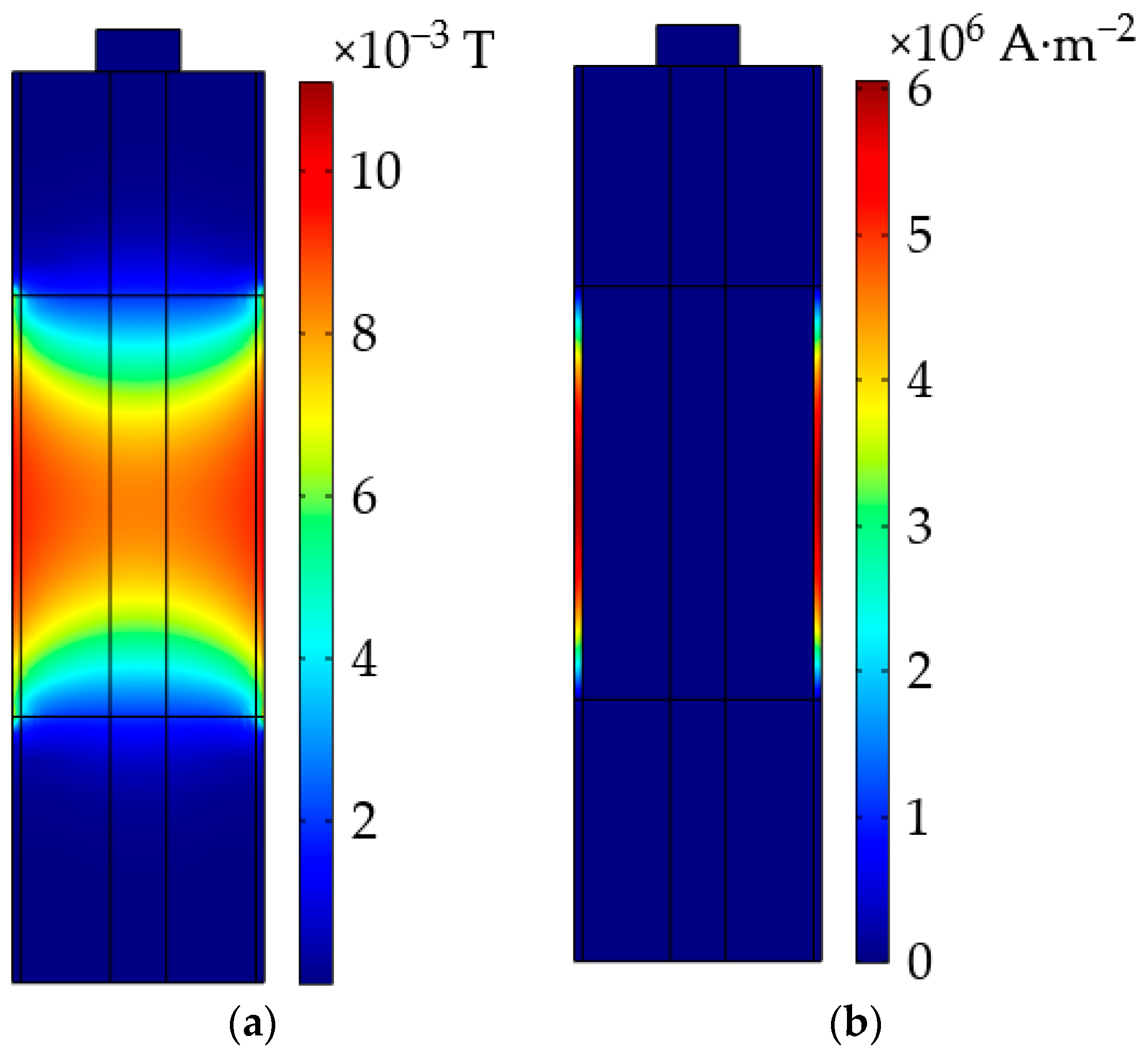

It can be seen from

Figure 2 that the proposed heating system is composed of an alternating power source, the heated LiB, and an induction copper coil. When the copper coil is subjected to an alternating current through the wire, the produced alternating magnetic field with the same frequency around the copper coil leads to a magnetic flux variation inside the LiB. Then, induction electromotive force (IEF) inside the LiB is produced, because the LiB in the closed loop can cut the magnetic induction line under the action of electromagnetic induction, which can cause the directional movement of the electrons in the interior of the LiB to generate an annular closed induction current inside the LiB due to the Lorentz force. Due to the impedance effect of the LiB, the induction current flowing through it can bring about an eddy current loss to realize the conversion from electrical to thermal energy so as to heat the LiB in the form of Joule heat. Furthermore, besides eddy current loss, the magnetic hysteresis heat effect, as part of the heat generation, is much lower, so it will be ignored in this study.

Besides the cylindrical battery, the proposed ETCM can be applied to other battery structures by adjusting the arrangement of the induction coils based on the shape of the heated battery. For example, for a square battery structure, the copper coil needs to be arranged around the battery in the form of a square cross-section, rather than the annular section adopted with the cylindrical battery.

According to Lenz’s law, the direction of the magnetic flux produced by the induction current prevents the variation of the original one inducing the eddy current; in other words, the induction current attempts to keep the original one constant, so the IEF can be written as

If the evolution of the magnetic flux exhibits a sinusoidal form, then

Thus, the effective value of the IEF can be expressed as

The Joule heat induced by the eddy current combined with the impedance effect of the conductor can be written as

Therefore, there are three energy conservations that occur in the electromagnetic induction heating process. First, the alternating current passing through the copper coil is converted into magnetic energy; then, the magnetic energy is converted into electrical energy because the LiB under the varying magnetic flux cuts the magnetic induction line to generate the induction current; finally, the induction current flowing through the interior of the LiB produces an eddy current loss through the resistance effect of the conductor, resulting in the conversion of electrical energy into Joule heat.

It is noted that the temperature rise is the combined action of electromagnetic induction and heat conduction, which results from the skin effect, and the electrical conductivity of the active material and mandrel in the interior of the LiB. The LiB shell has a high temperature rate, especially on the outer surface of the shell, which holds the majority of the eddy current loss. This transfers the heat energy to the interior of the LiB in the form of thermal conduction, so the induction heat has a direct impact on the thermal conduction. An analysis of the relation between the heat transfer mode and the temperature field is presented in

Section 4.5.

According to the skin effect, when the conductor is subjected to an alternating current, the free electrons in the cross-section of the conductor present a decreasing exponential distribution, so the eddy current distribution from the outer to the internal surface of the LiB and the skin depth can be expressed as

The skin effect shows a negative correlation between the eddy permeation depth and alternating current frequency, which can give rise to non-consistency of the eddy current distribution inside the LiB shell, leading to an inhomogeneous temperature rise during the heating process.

2.5. Electrochemical–Thermal Coupling Effect

Considering the temperature dependence of the chemical reaction inside the LiB, the coupling action between the electrochemical and thermal processes can be realized by correcting the temperature-sensitive parameters in the P2D model. Among these, the evolution of the reaction rate constant and the Li

+ electrical conductivity in the electrode can be expressed via the Arrhenius equation [

33].

Furthermore, the variations in the Li+ diffusivity and electrical conductivity in the liquid phase with the temperature can be approximately expressed in the form of the Arrhenius equation, in which the reference values of the parameters need to be achieved via interpolation on the basis of experimental data; they are not constant, as with the parameters mentioned in the previous paragraph.

The LiB temperature calculated in the thermal model can be fed back to the P2D model. It reflects the real-time electrochemical state, which, together with the induction heat, conversely affects the total heat generation related to the LiB temperature. Therefore, the output and input variables of the thermal model are the temperature and heat generation, which consists of the heat generated by the electrochemical reaction and the eddy current loss. Thus, the electrochemical and thermal coupling action can be realized by updating the temperature-sensitive parameters in real time and concurrently calculating the P2D and heat transfer models.

5. Conclusions

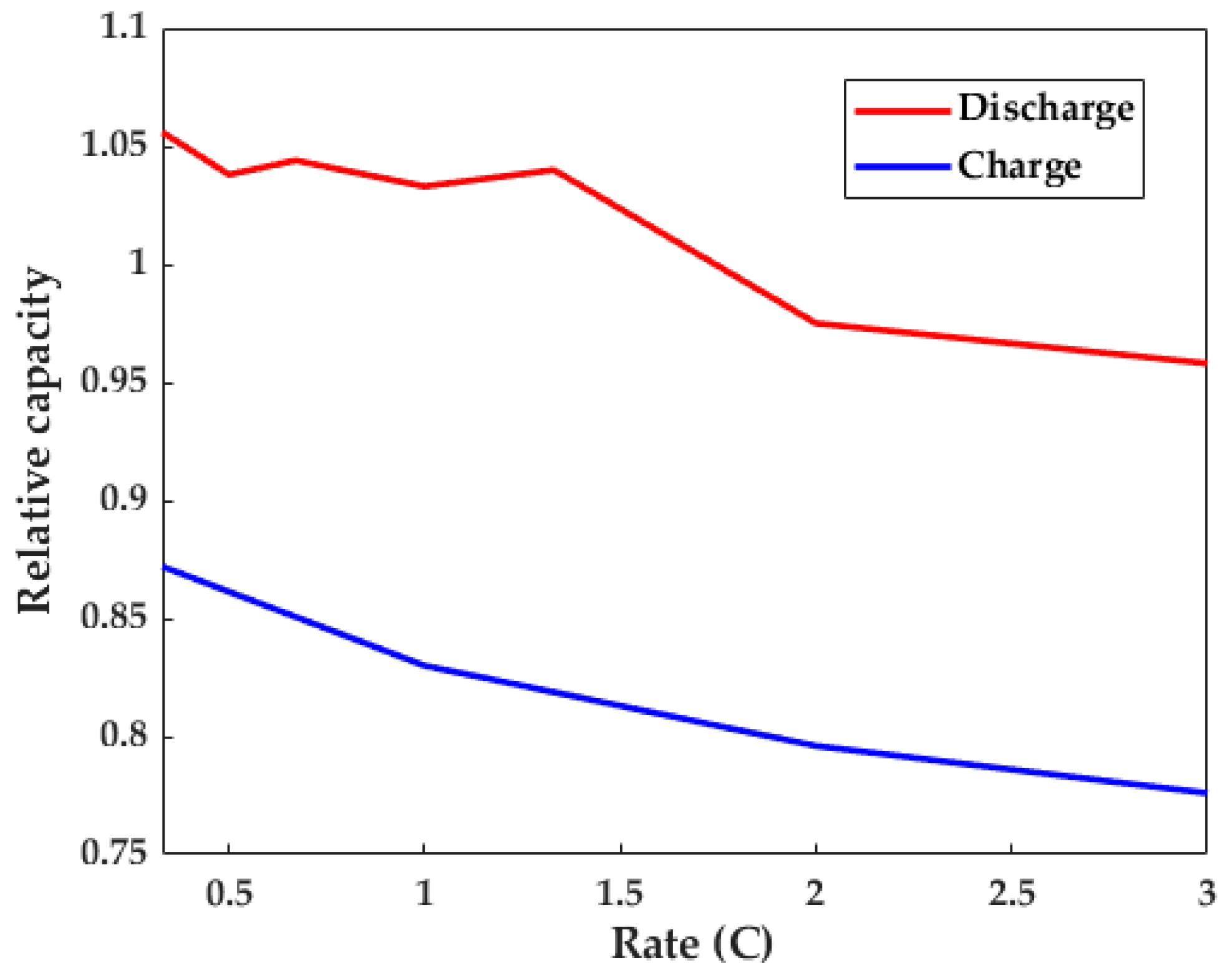

In this work, based on the EIHS with thermal energy generated by the induction current-induced eddy current loss, a “L8193” orthogonal test with three factors (copper coil turns, alternating current amplitude, and frequency) and nine levels was introduced to investigate the effect of the copper coil parameters on the temperature rise behavior so as to optimize the heating performance. Under the optimal parameter combination, the improvements in the electrochemical and thermal performance of the LiB through the proposed heating strategy were characterized by the proposed high-precision ETCM, which was validated against the CC discharge and HPPC test data at room and different low temperatures. The influencing factors and the formation of the temperature field inside the LiB during the heating process were also studied, revealing the following salient features.

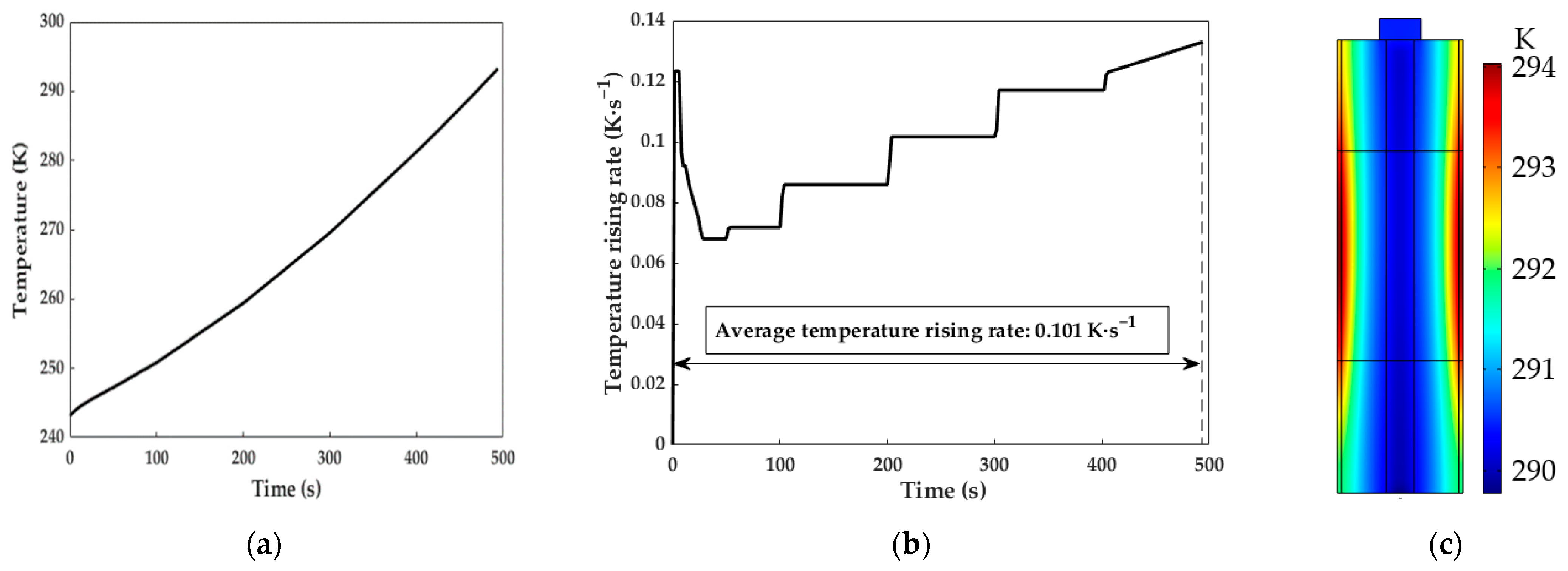

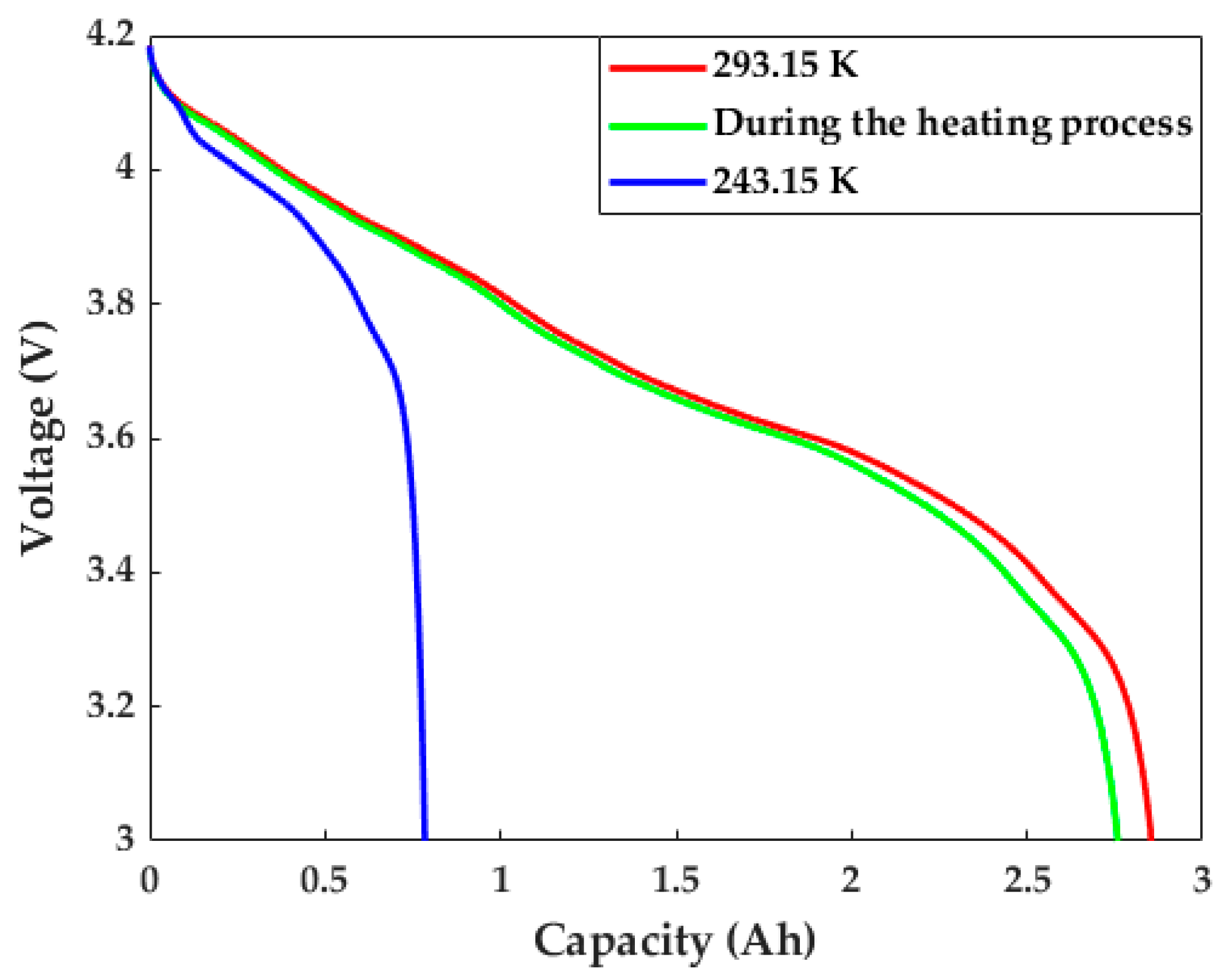

(a) A good compromise. Under the best parameter combination (alternating current = 12 A; frequency = 6 kHz; induction coil turns = 180), the LiB could be heated to 293.15 K from 243.15 K within 494 s, with a temperature difference of 4.21 K after the heating process, indicating that the heating strategy can achieve a balance between the heat generation velocity and temperature uniformity.

(b) The improvement of the energy output performance. Due to the internal resistance, which decreased to less than a quarter of that in the low-temperature situation, the enhancement of the terminal voltage output gave rise to a substantial improvement in both the pulse power and usable energy, which could provide a larger cruise range and better dynamics for EVs so as to enhance the practicability of EVs in cold weather.

(c) Almost no negative effect on LiB aging. After 120 heating cycles, the 1 C discharge capacity retention reached 96.39% of the initial level. Compared with the normal charge–discharge cycles at 293.15 K, there was only a 0.23% capacity retention loss, and the capacity calibration results were almost the same. This indicates that the EIHS did not give rise to an apparent capacity deterioration and had almost no impact on the LiB cycle lifetime.

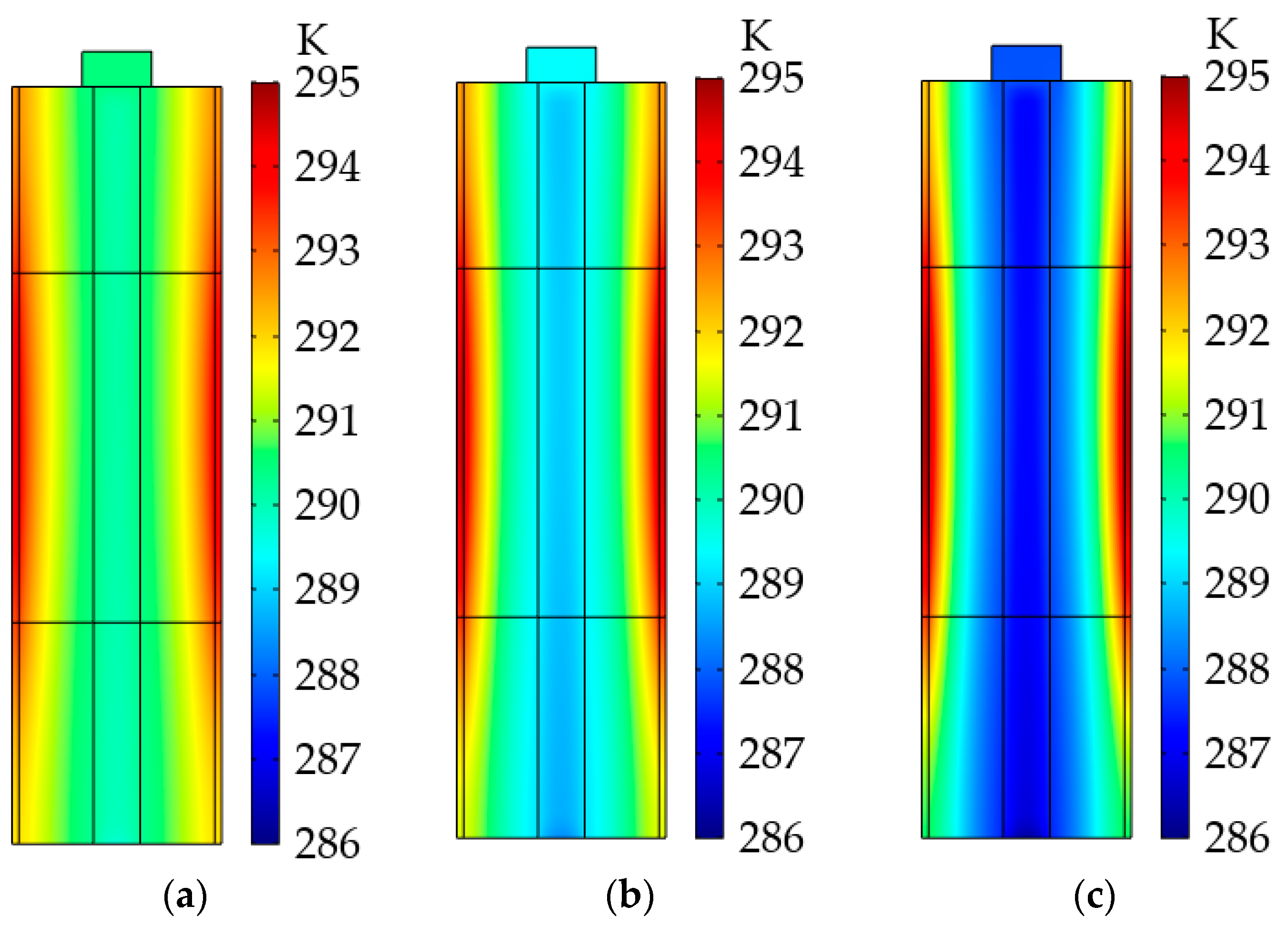

(d) The production of a temperature field. Based on the LiB material’s properties and the fact that the skin depth of the LiB shell was much greater than the thickness of the shell, the heat generation inside the shell showed homogeneous distribution. Moreover, the temperature difference during the heating process depended on the thermal conduction of the materials in the interior of the LiB. The temperature difference inside the LiB could be reduced with an increase in the radial thermal conductivity of the active material.

According to the above research, the EIHS under the optimal parameter combination found in the orthogonal test could achieve an excellent tradeoff among the temperature rise behavior, energy output, and state of health. The optimization of the heat conductivity of the LiB material with regard to safety and a satisfactory working ability is beneficial for the heating effect of the EIHS. In engineering applications, when an LiB operates at subzero temperatures, the heating system could be started automatically upon receiving a temperature signal from a sensor; thus, it could heat the LiB with a high temperature rise rate and uniform heat distribution. However, power batteries can exhibit irreversible aging effects during long-term operating processes, leading to variations in the heating effect of the proposed EIHS. The heating method based on the orthogonal test is only suitable for the current specific usage of LiBs, which does not reflect the LiB application requirements for all statuses and lifecycles. In other words, the optimal parameter combination determined by the heating strategy may not be the best combination for the LiB in each state. In order to further improve the heating performance of the proposed EIHS for various lifespan cycles and operating statuses, future research will focus on a heating strategy with alternating current parameters updated in real time on the basis of the proposed ETCM and an equivalent electrical circuit model for the real-time optimization of the induction coil parameters.