Assessing the Environmental Impact of Biobased Exterior Insulation Panel: A Focus on Carbon Uptake and Embodied Emissions

Abstract

1. Introduction

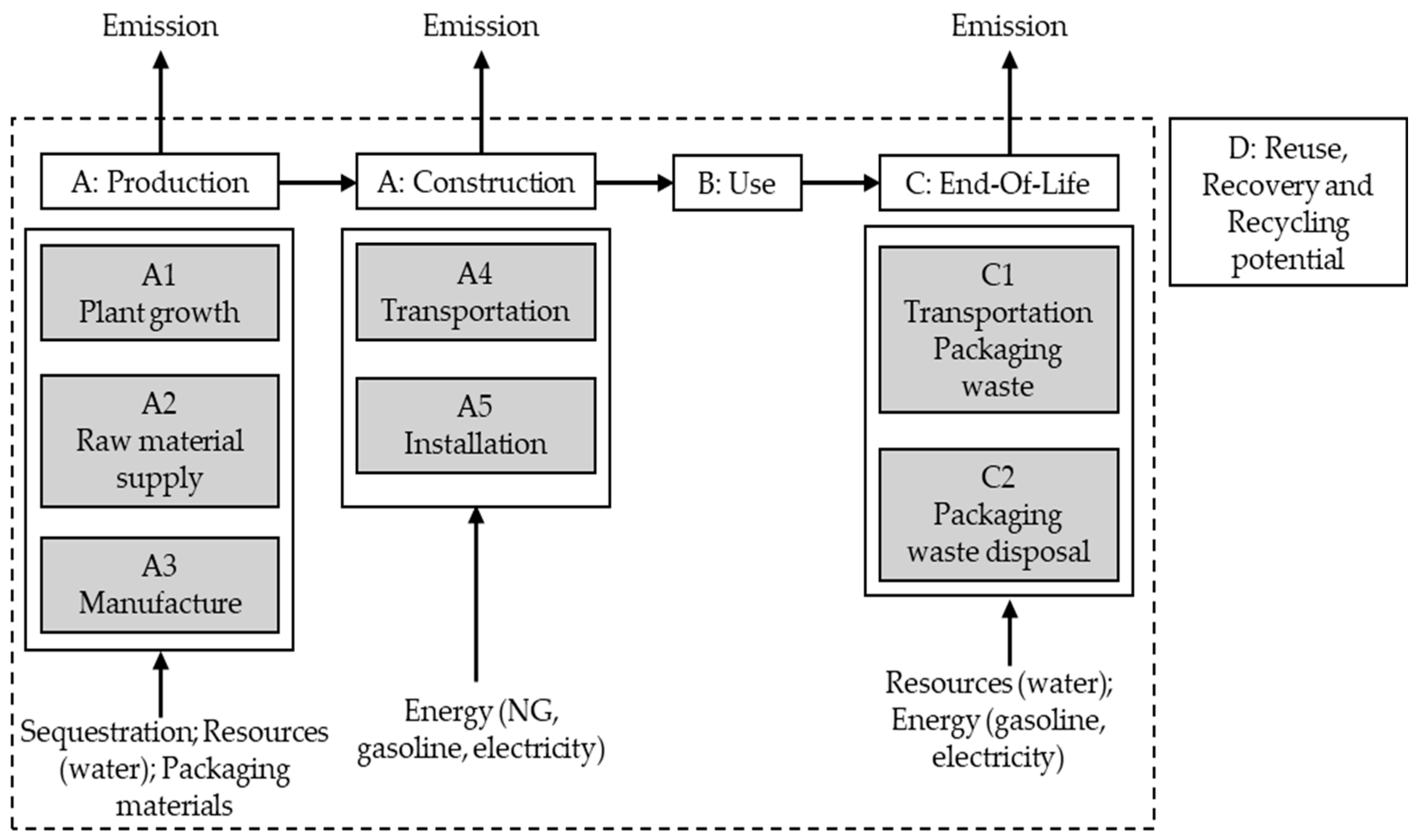

2. Materials and Methods

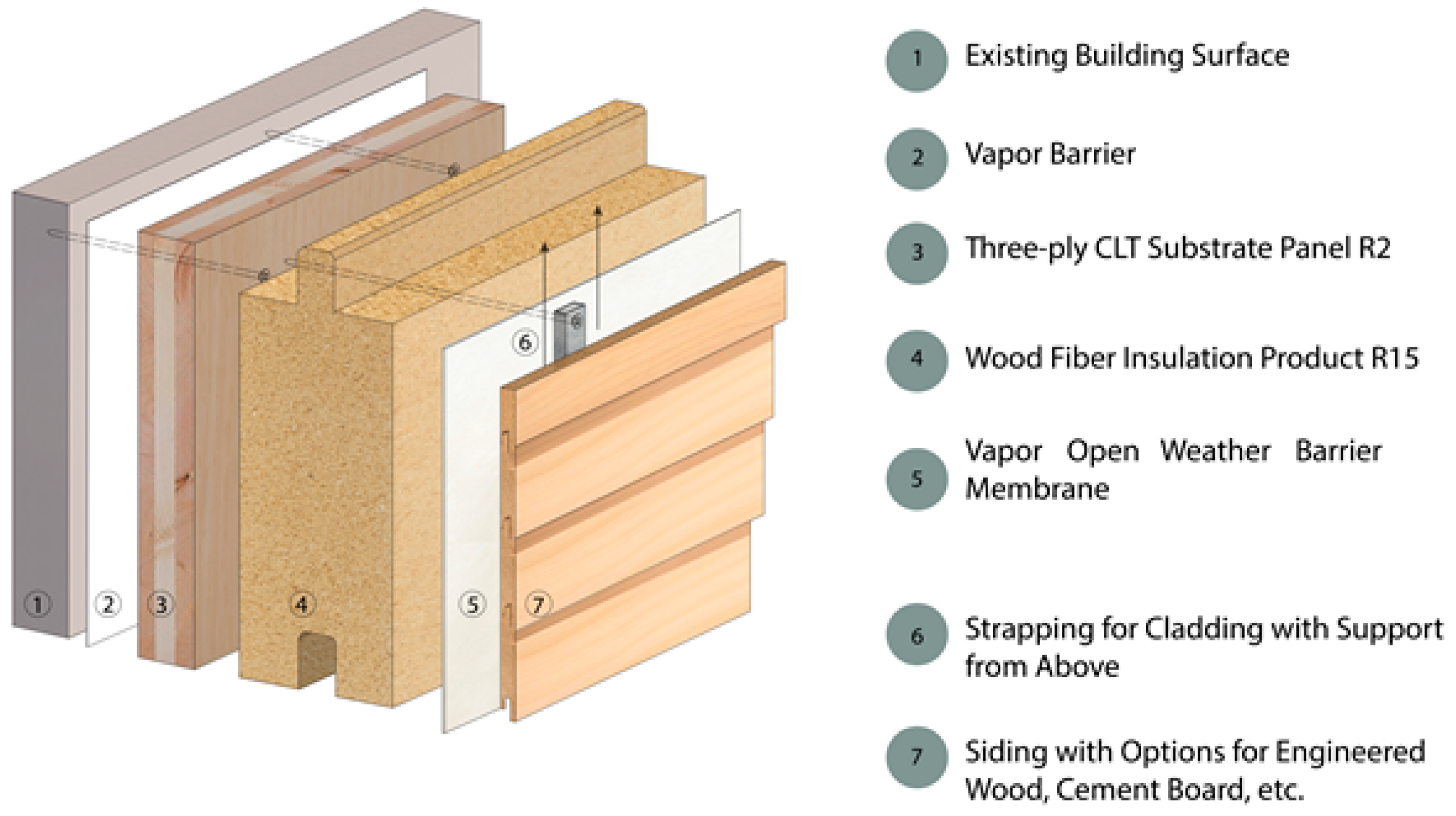

2.1. Goal and Scope

2.2. Life Cycle Inventory (LCI)

2.2.1. Sequestration and Embodied Carbon Estimation

2.2.2. Material Supply

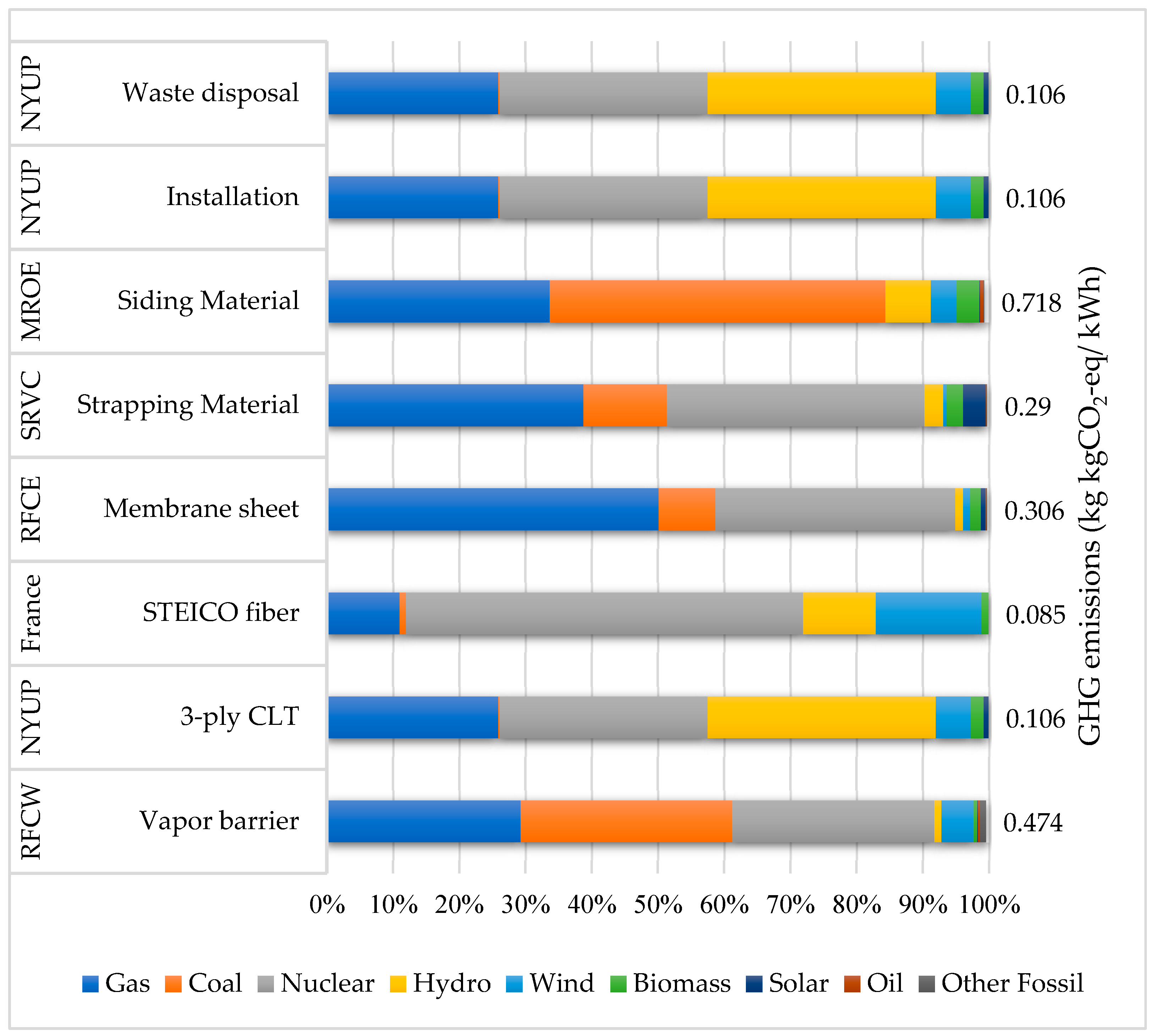

Vapor Barrier

Three-Ply CLT Substrate Panel

Wood Fiber Insulation Product

Membrane Sheet

Strapping Material

Siding Material

2.2.3. Energy Use for Material Manufacturing and Panel Installation

2.2.4. Packaging Waste Disposal

2.3. Life Cycle Impact Assessment

2.4. Uncertainty Analysis

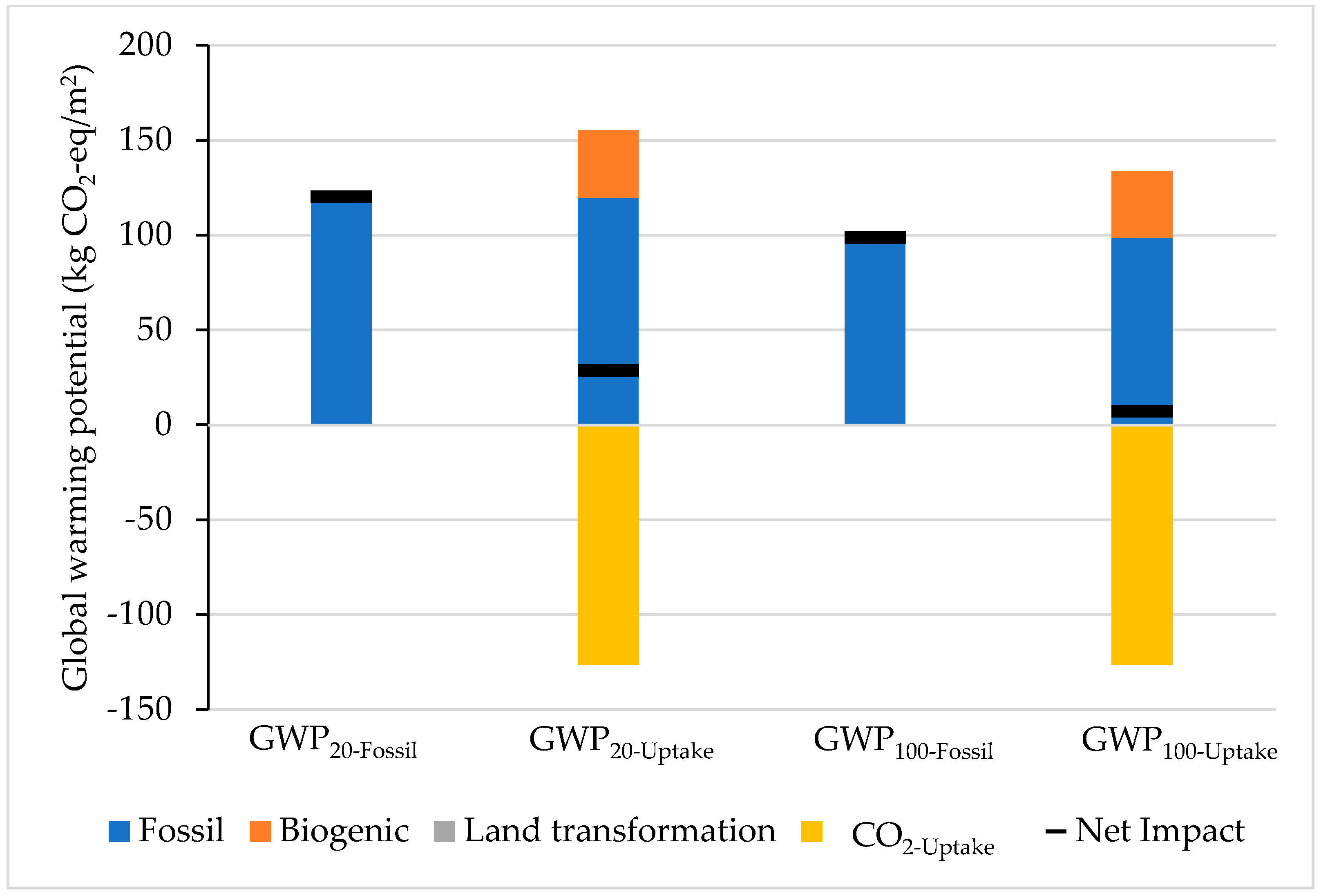

3. Results

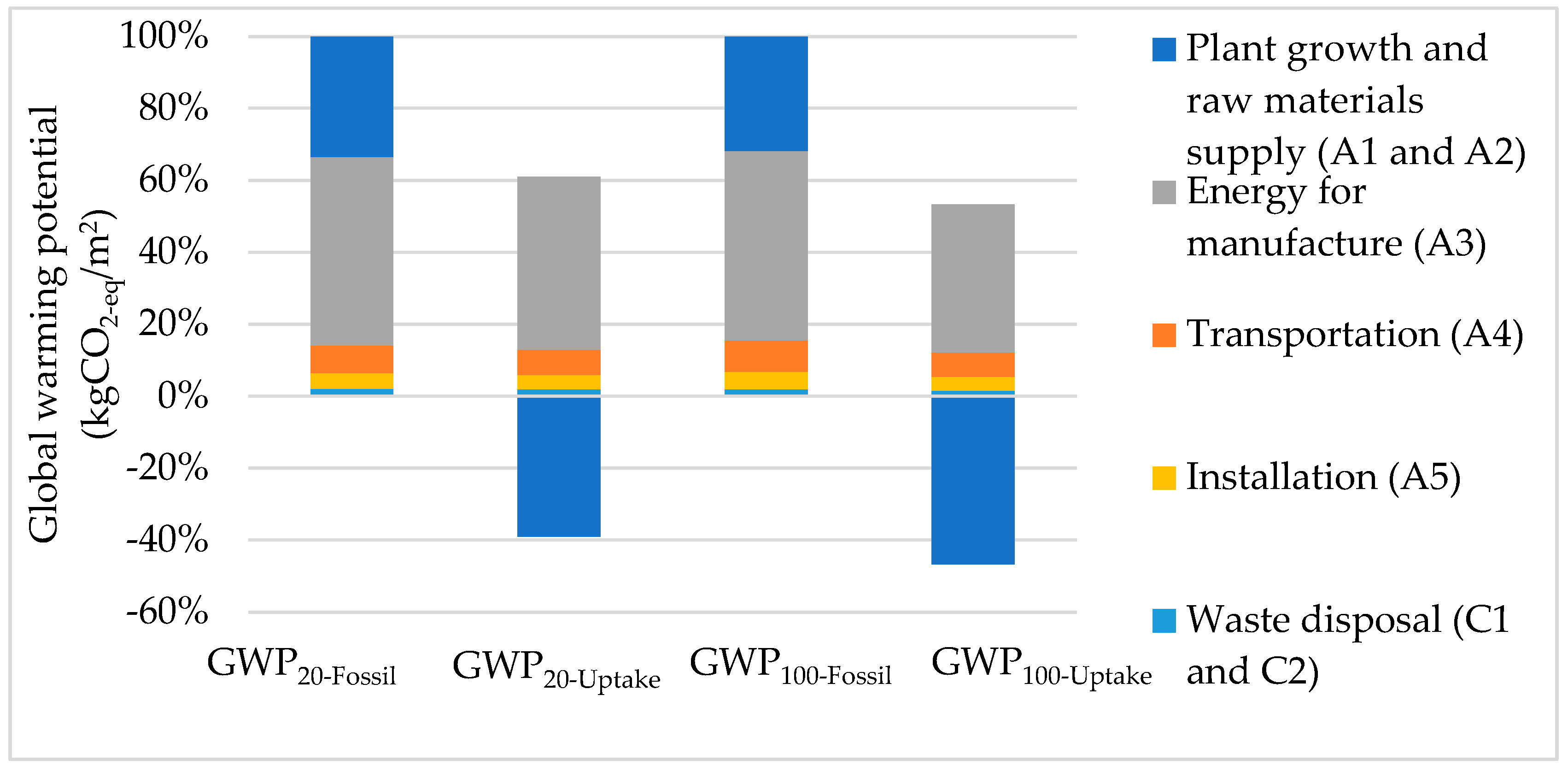

3.1. Impacts on Global Warming Potential

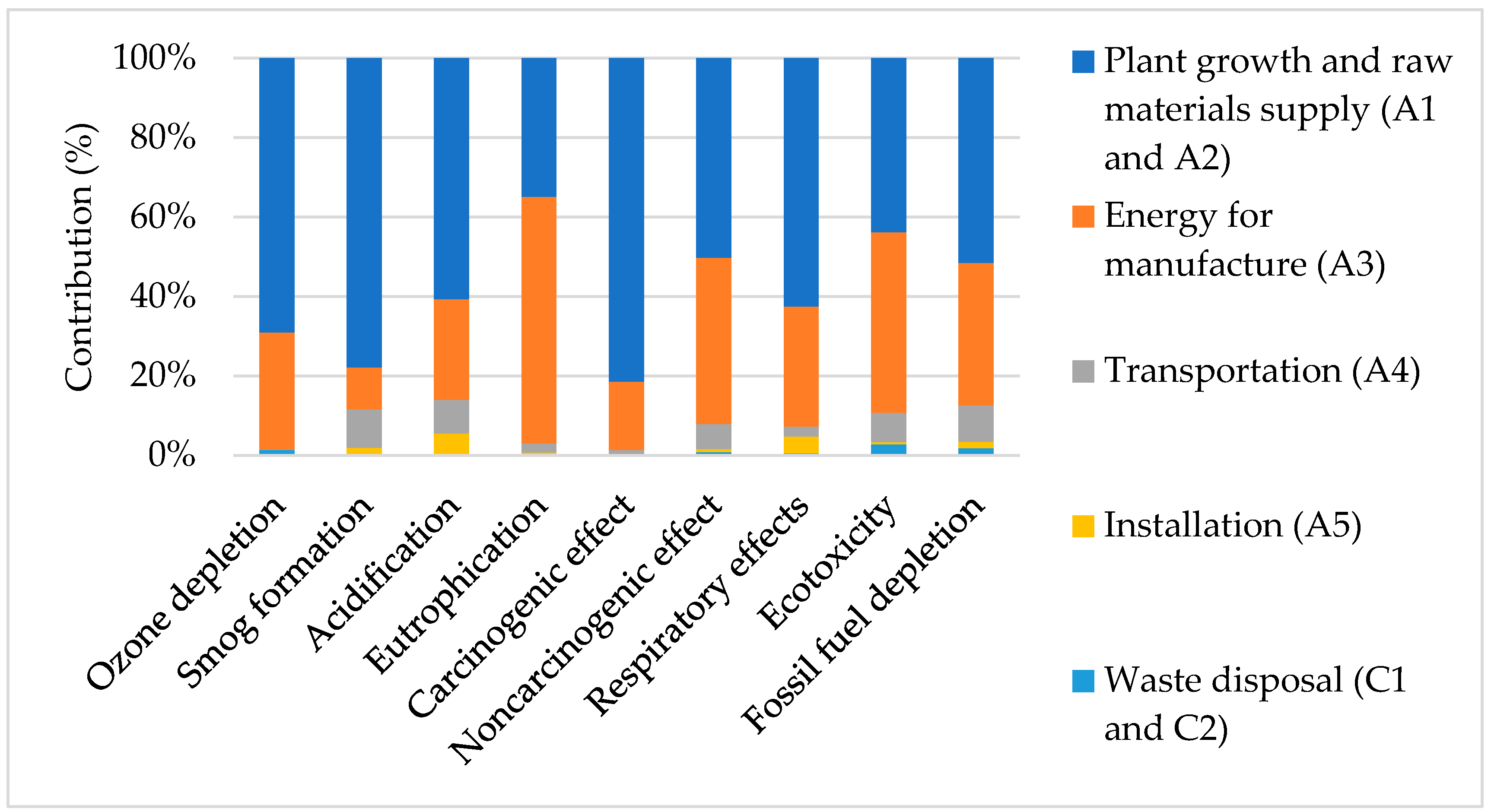

3.2. Other Impact Categories Results

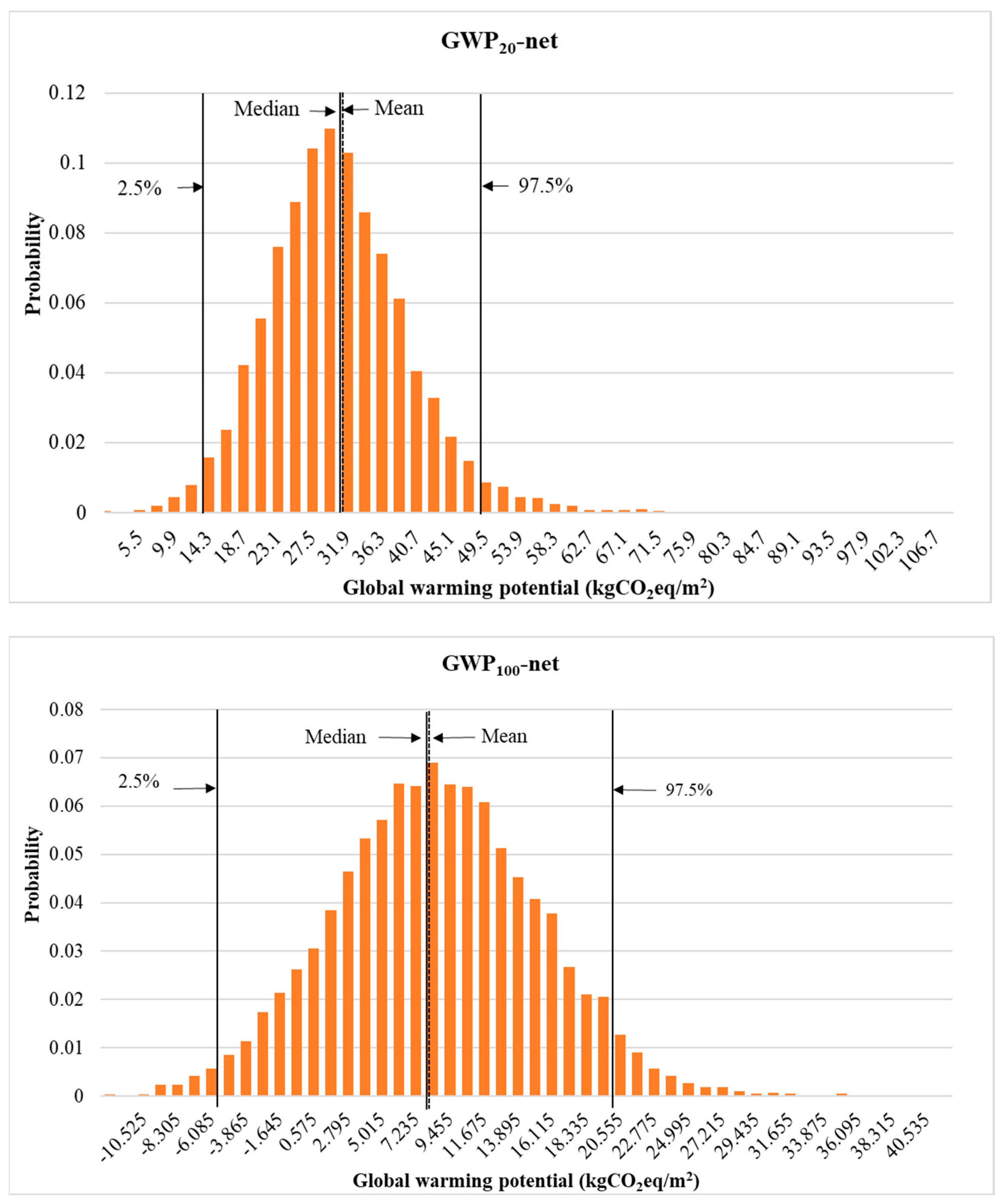

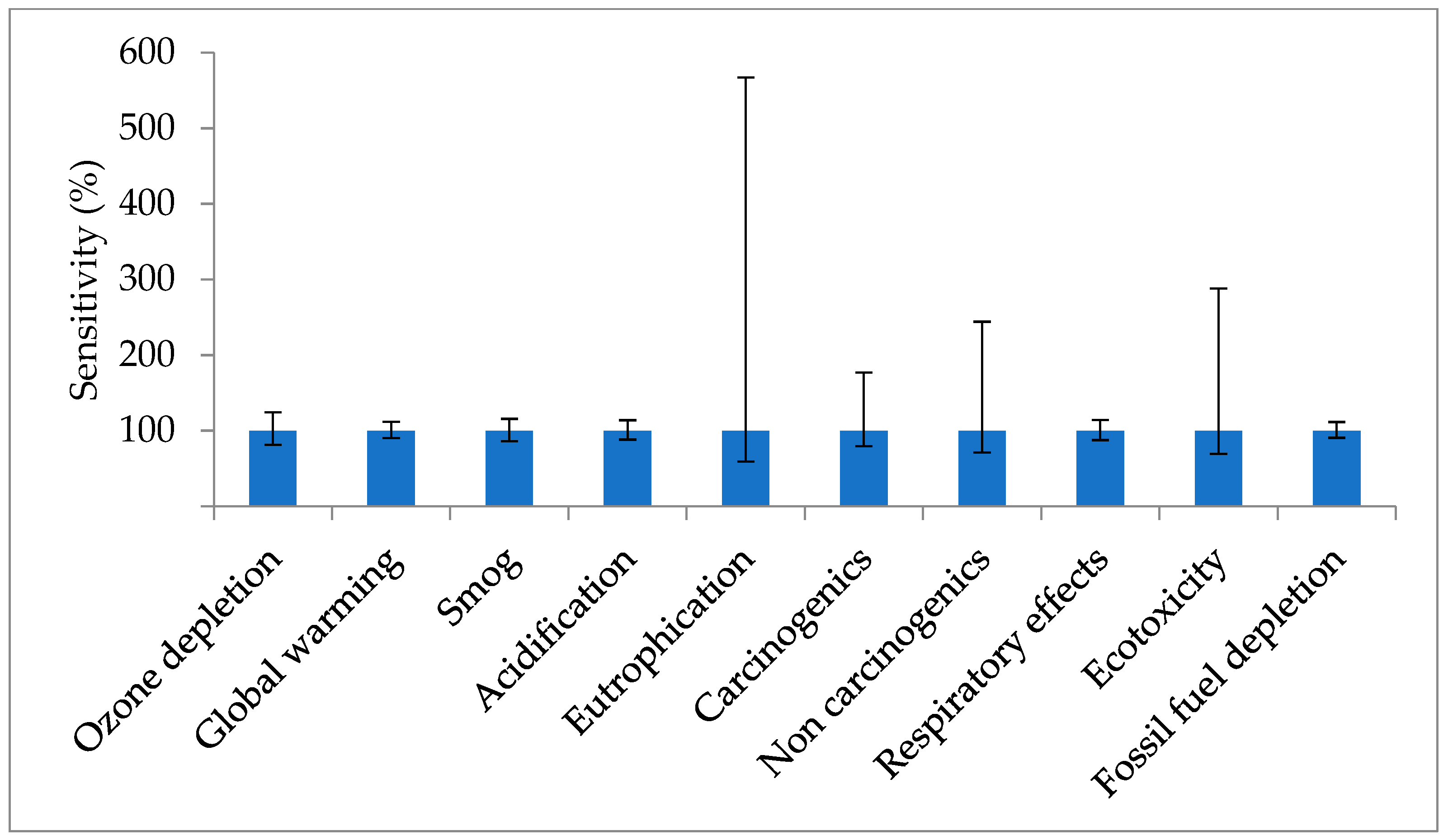

3.3. Uncertainty Analysis

4. Discussion

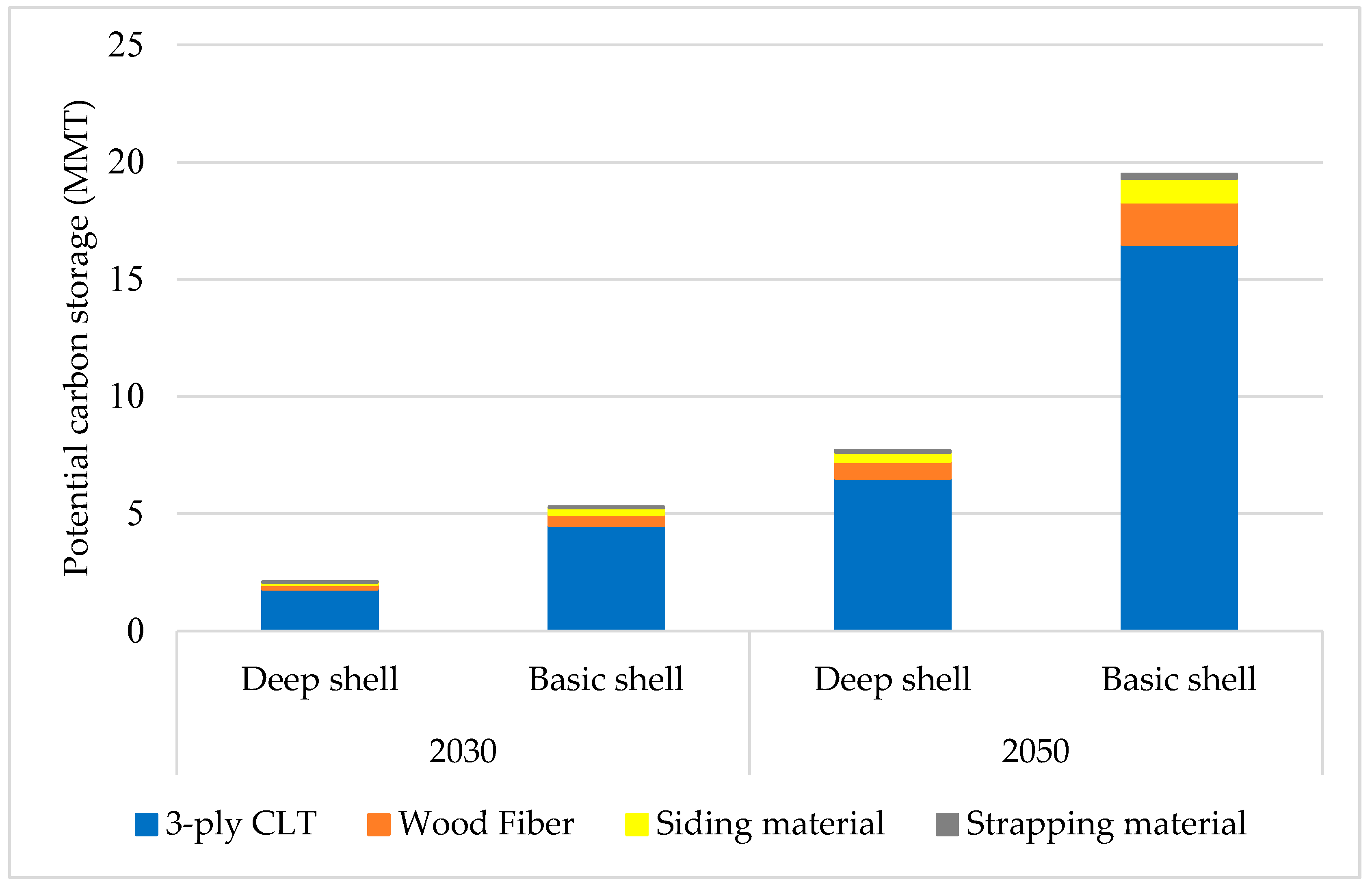

5. Implications

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Buildings; Net Zero by 2050 A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021; pp. 141–149.

- IEA. Global Status Report for Buildings and Construction 2019; International Energy Agency and United Nations Environment Programme: Paris, France, 2019; p. 39.

- González-Torres, M.; Pérez-Lombard, L.; Coronel, J.F.; Maestre, I.R.; Yan, D. A Review on Buildings Energy Information: Trends, End-Uses, Fuels and Drivers. Energy Rep. 2022, 8, 626–637. [Google Scholar] [CrossRef]

- EIA. Monthly Energy Review; Energy Information Administration: Washington, DC, USA, 2023.

- EIA. U.S. Energy-Related Carbon Dioxide Emissions, 2021; Energy Information Administration: Washington, DC, USA, 2022.

- U.S. Energy Information Administration. Annual Energy Outlook 2022; Independent Statistics and Analysis, U.S. Energy Information Administration: Washington, DC, USA, 2022; p. 38.

- Najjar, M.K.; Figueiredo, K.; Hammad, A.W.A.; Tam, V.W.Y.; Evangelista, A.C.J.; Haddad, A. A Framework to Estimate Heat Energy Loss in Building Operation. J. Clean. Prod. 2019, 235, 789–800. [Google Scholar] [CrossRef]

- U.S. Department of Housing. American Housing Survey (AHS) in 2021; American Housing Survey (AHS); Department of Housing and Urban Development (HUD) & U.S. Census Bureau: Washington, DC, USA, 2022; p. 1.

- IEA. Global Energy Review 2021: Analysis and Key Findings; International Energy Agency: Paris, France, 2021; p. 36.

- Harris, C. Opaque Envelopes: Pathway to Building Energy Efficiency and Demand Flexibility: Key to a Low-Carbon, Sustainable Future; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2021. [Google Scholar]

- U.S. Energy Information Administration. Annual Energy Outlook 2021 with Projection to 2050; Annual Energy Outlook; Independent Statistics & Analysis, U.S. Energy Information Administration (EIA), U.S. Department of Energy: Washington, DC, USA, 2021; p. 33.

- Pargana, N.; Pinheiro, M.D.; Silvestre, J.D.; De Brito, J. Comparative Environmental Life Cycle Assessment of Thermal Insulation Materials of Buildings. Energy Build. 2014, 82, 466–481. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.; Sanjayan, J.G.; Memon, R.A. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, F.; Wang, J. Design Optimization of Multi-Functional Building Envelope for Thermal Insulation and Exhaust Air Heat Recovery in Different Climates. J. Build. Eng. 2021, 43, 103151. [Google Scholar] [CrossRef]

- Blengini, G.A.; Di Carlo, T. The Changing Role of Life Cycle Phases, Subsystems and Materials in the LCA of Low Energy Buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- Zhao, J.R.; Zheng, R.; Tang, J.; Sun, H.J.; Wang, J. A Mini-Review on Building Insulation Materials from Perspective of Plastic Pollution: Current Issues and Natural Fibres as a Possible Solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef] [PubMed]

- Pescari, S.; Merea, M.; Pitroacă, A.; Vilceanu, C.-B. A Particular Case of Urban Sustainability: Comparison Study of the Efficiency of Multiple Thermal Insulations for Buildings. Sustainability 2022, 14, 16283. [Google Scholar] [CrossRef]

- Grazieschi, G.; Asdrubali, F.; Thomas, G. Embodied Energy and Carbon of Building Insulating Materials: A Critical Review. Clean. Environ. Syst. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Pavel, C.C. Competitive Landscape of the EU’s Insulation Materials Industry for Energy-Efficient Buildings; European Commission, Joint Research Centre; Publications Office of the European Union: Luxembourg, 2018; p. 24. [Google Scholar]

- Dickson, T.; Pavía, S. Energy Performance, Environmental Impact and Cost of a Range of Insulation Materials. Renew. Sustain. Energy Rev. 2021, 140, 110752. [Google Scholar] [CrossRef]

- Wi, S.; Park, J.H.; Kim, Y.U.; Kim, S. Evaluation of Environmental Impact on the Formaldehyde Emission and Flame-Retardant Performance of Thermal Insulation Materials. J. Hazard. Mater. 2021, 402, 123463. [Google Scholar] [CrossRef] [PubMed]

- Luangcharoenrat, C.; Intrachooto, S.; Peansupap, V.; Sutthinarakorn, W. Factors Influencing Construction Waste Generation in Building Construction: Thailand’s Perspective. Sustainability 2019, 11, 3638. [Google Scholar] [CrossRef]

- Lawrence, M. Reducing the Environmental Impact of Construction by Using Renewable Materials. J. Renew. Mater. 2015, 3, 163–174. [Google Scholar] [CrossRef]

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative Life Cycle Assessment of Bio-based Insulation Materials: Environmental and Economic Performances. GCB Bioenergy 2021, 13, 979–998. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Lazzaretto, A.; Manente, G.; Tong, C.; Liu, Q.; Li, N. The Development History and Prospects of Biomass-Based Insulation Materials for Buildings. Renew. Sustain. Energy Rev. 2017, 69, 912–932. [Google Scholar] [CrossRef]

- Sherwood, J.; Clark, J.H.; Farmer, T.J.; Herrero-Davila, L.; Moity, L. Recirculation: A New Concept to Drive Innovation in Sustainable Product Design for Bio-Based Products. Molecules 2016, 22, 48. [Google Scholar] [CrossRef] [PubMed]

- Kymäläinen, H.-R.; Sjöberg, A.-M. Flax and Hemp Fibres as Raw Materials for Thermal Insulations. Build. Environ. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

- Mnasri, F.; Abahri, K.; El Ganaoui, M.; Gabsi, S. Numerical Investigation of Hygrothermal Behavior on Porous Building Materials. Int. J. Civ. Environ. Eng. 2016, 10, 789–793. [Google Scholar]

- El Faridy, Z.F.; Trabelsi, A.; Kuznik, F. A Picture on Bio-Based Building Materials as Thermal Insulation for Sustainable Buildings. Acad. J. Civ. Eng. 2019, 37, 634–641. [Google Scholar]

- Romano, A.; Bras, A.; Grammatikos, S.; Shaw, A.; Riley, M. Dynamic Behaviour of Bio-Based and Recycled Materials for Indoor Environmental Comfort. Constr. Build. Mater. 2019, 211, 730–743. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.; Schellnhuber, H.J. Buildings as a Global Carbon Sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene. Buildings 2020, 10, 81. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood Waste as an Alternative Thermal Insulation for Buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.; Rismanchi, B.; Ng, H.; Hasan, M.; Metselaar, H.; Muraza, O.; Aditiya, H. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Li, T.-T.; Chuang, Y.-C.; Huang, C.-H.; Lou, C.-W.; Lin, J.-H. Applying vermiculite and perlite fillers to sound-absorbing/thermal-insulating resilient PU foam composites. Fibers Polym. 2015, 16, 691–698. [Google Scholar] [CrossRef]

- Berardi, U.; Madzarevic, J. Microstructural analysis and blowing agent concentration in aged polyurethane and polyisocyanurate foams. Appl. Therm. Eng. 2020, 164, 114440. [Google Scholar] [CrossRef]

- Tingley, D.D.; Hathway, A.; Davison, B.; Allwood, D. The environmental impact of phenolic foam insulation boards. Proc. Inst. Civ. Eng.-Constr. Mater. 2017, 170, 91–103. [Google Scholar] [CrossRef]

- Yang, W.; Li, Y. Sound absorption performance of natural fibers and their composites. Sci. China Technol. Sci. 2012, 55, 2278–2283. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Samar, M.; Saxena, S. Study of chemical and physical properties of perlite and its application in India. Int. J. Sci. Technol. Manag. 2016, 5, 70–80. [Google Scholar]

- Muthukumar, K.; Sabariraj, R.; Kumar, S.D.; Sathish, T. Investigation of thermal conductivity and thermal resistance analysis on different combination of natural fiber composites of banana, pineapple and jute. Mater. Today Proc. 2020, 21, 976–980. [Google Scholar] [CrossRef]

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite materials based on hemp and flax for low-energy buildings. Materials 2017, 10, 510. [Google Scholar] [CrossRef] [PubMed]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: Elaboration and performances evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Sierra-Pérez, J.; Boschmonart-Rives, J.; Gabarrell, X. Environmental assessment of façade-building systems and thermal insulation materials for different climatic conditions. J. Clean. Prod. 2016, 113, 102–113. [Google Scholar] [CrossRef]

- Gonzalez, D. Life Cycle Assessment of a Hybrid Biobased Panel for Insulated Concrete Forms Used in Residential Buildings. Master Thesis, University of Waterloo, Waterloo, ON, Canada, 2021. [Google Scholar]

- Ingrao, C.; Scrucca, F.; Tricase, C.; Asdrubali, F. A comparative Life Cycle Assessment of external wall-compositions for cleaner construction solutions in buildings. J. Clean. Prod. 2016, 124, 283–298. [Google Scholar] [CrossRef]

- Zieger, V. Dynamic life cycle assessment to compare conventional and bio-based building construction impact on global warming. Master Thesis, Aalto University, Lorient, France, 2019. [Google Scholar]

- Guggemos, A.A.; Horvath, A. Comparison of environmental effects of steel-and concrete-framed buildings. J. Infrastruct. Syst. 2005, 11, 93–101. [Google Scholar] [CrossRef]

- CWC. Comparing the Environmental Effects of Building Systems: A Case Study; Canadian Wood Council (CWC): Ottawa, ON, Canada, 1997; pp. 1–11. [Google Scholar]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S.S. Comparative Life-Cycle Assessment of a Mass Timber Building and Concrete Alternative. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- Krogmann, U.; Minderman, N.; Senick, J.; Andrews, C. Life-Cycle Assessment of New Jersey Meadowlands Commission Center for Environmental and Scientific Education Building; Rutgers Center for Green Building: New Brunswick, NJ, USA, 2008. [Google Scholar]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A Comparative Cradle-to-Gate Life Cycle Assessment of Mid-Rise Office Building Construction Alternatives: Laminated Timber or Reinforced Concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Mouton, L.; Allacker, K.; Röck, M. Bio-Based Building Material Solutions for Environmental Benefits over Conventional Construction Products—Life Cycle Assessment of Regenerative Design Strategies (1/2). Energy Build. 2023, 282, 112767. [Google Scholar] [CrossRef]

- Thomson, A.; Walker, P. Durability Characteristics of Straw Bales in Building Envelopes. Constr. Build. Mater. 2014, 68, 135–141. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Bianchi, F.; Baldinelli, G.; Rotili, A.; Schiavoni, S. Straw Bale Constructions: Laboratory, in Field and Numerical Assessment of Energy and Environmental Performance. J. Build. Eng. 2017, 11, 56–68. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Experimental Study on the Physical–Mechanical Durability of Innovative Hemp-Based Composites for the Building Industry. Energy Build. 2015, 104, 316–322. [Google Scholar] [CrossRef]

- El Hajj, N.; Mboumba-Mamboundou, B.; Dheilly, R.-M.; Aboura, Z.; Benzeggagh, M.; Queneudec, M. Development of Thermal Insulating and Sound Absorbing Agro-Sourced Materials from Auto Linked Flax-Tows. Ind. Crop. Prod. 2011, 34, 921–928. [Google Scholar] [CrossRef]

- Zhou, X.; Zheng, F.; Li, H.; Lu, C. An Environment-Friendly Thermal Insulation Material from Cotton Stalk Fibers. Energy Build. 2010, 42, 1070–1074. [Google Scholar] [CrossRef]

- da Rosa, L.C.; Santor, C.G.; Lovato, A.; da Rosa, C.S.; Güths, S. Use of Rice Husk and Sunflower Stalk as a Substitute for Glass Wool in Thermal Insulation of Solar Collector. J. Clean. Prod. 2015, 104, 90–97. [Google Scholar] [CrossRef]

- Huang, P.; Zeidler, A.; Chang, W.; Ansell, M.P.; Chew, Y.J.; Shea, A. Specific Heat Capacity Measurement of Phyllostachys Edulis (Moso Bamboo) by Differential Scanning Calorimetry. Constr. Build. Mater. 2016, 125, 821–831. [Google Scholar] [CrossRef]

- Pongon, R.S.; Aranico, E.C.; Dagoc, F.L.S.; Amparado, R.F., Jr. Carbon Stock Assessment of Bamboo Plantations in Northern Mindanao, Philippines. J. Biodivers. Environ. Sci. 2016, 9, 97–112. [Google Scholar]

- Binici, H.; Eken, M.; Kara, M.; Dolaz, M. An Environment-Friendly Thermal Insulation Material from Sunflower Stalk, Textile Waste and Stubble Fibers. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications (ICRERA), Madrid, Spain, 20–23 October 2013; pp. 833–846. [Google Scholar]

- Pinto, J.; Paiva, A.; Varum, H.; Costa, A.; Cruz, D.; Pereira, S.; Fernandes, L.; Tavares, P.; Agarwal, J. Corn’s Cob as a Potential Ecological Thermal Insulation Material. Energy Build. 2011, 43, 1985–1990. [Google Scholar] [CrossRef]

- Charca, S.; Noel, J.; Andia, D.; Flores, J.; Guzman, A.; Renteros, C.; Tumialan, J. Assessment of Ichu Fibers as Non-Expensive Thermal Insulation System for the Andean Regions. Energy Build. 2015, 108, 55–60. [Google Scholar] [CrossRef]

- Wagner, M.; Kiesel, A.; Hastings, A.; Iqbal, Y.; Lewandowski, I. Novel Miscanthus Germplasm-Based Value Chains: A Life Cycle Assessment. Front. Plant Sci. 2017, 8, 990. [Google Scholar] [CrossRef] [PubMed]

- Vay, O.; De Borst, K.; Hansmann, C.; Teischinger, A.; Müller, U. Thermal Conductivity of Wood at Angles to the Principal Anatomical Directions. Wood Sci. Technol. 2015, 49, 577–589. [Google Scholar] [CrossRef]

- Kawasaki, T.; Kawai, S. Thermal Insulation Properties of Wood-Based Sandwich Panel for Use as Structural Insulated Walls and Floors. J. Wood Sci. 2006, 52, 75–83. [Google Scholar] [CrossRef]

- Cherki, A.; Remy, B.; Khabbazi, A.; Jannot, Y.; Baillis, D. Experimental Thermal Properties Characterization of Insulating Cork–Gypsum Composite. Constr. Build. Mater. 2014, 54, 202–209. [Google Scholar] [CrossRef]

- Chikhi, M.; Agoudjil, B.; Boudenne, A.; Gherabli, A. Experimental Investigation of New Biocomposite with Low Cost for Thermal Insulation. Energy Build. 2013, 66, 267–273. [Google Scholar] [CrossRef]

- Alavez-Ramirez, R.; Chiñas-Castillo, F.; Morales-Dominguez, V.; Ortiz-Guzman, M. Thermal Conductivity of Coconut Fibre Filled Ferrocement Sandwich Panels. Constr. Build. Mater. 2012, 37, 425–431. [Google Scholar] [CrossRef]

- Panyakaew, S.; Fotios, S. New Thermal Insulation Boards Made from Coconut Husk and Bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Pavelek, M.; Adamová, T. Bio-Waste Thermal Insulation Panel for Sustainable Building Construction in Steady and Unsteady-State Conditions. Materials 2019, 12, 2004. [Google Scholar] [CrossRef]

- Wei, K.; Lv, C.; Chen, M.; Zhou, X.; Dai, Z.; Shen, D. Development and Performance Evaluation of a New Thermal Insulation Material from Rice Straw Using High Frequency Hot-Pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Torres-Rivas, A.; Palumbo, M.; Haddad, A.; Cabeza, L.F.; Jiménez, L.; Boer, D. Multi-Objective Optimisation of Bio-Based Thermal Insulation Materials in Building Envelopes Considering Condensation Risk. Appl. Energy 2018, 224, 602–614. [Google Scholar] [CrossRef]

- Vink, E.T.; Rabago, K.R.; Glassner, D.A.; Gruber, P.R. Applications of Life Cycle Assessment to NatureWorksTM Polylactide (PLA) Production. Polym. Degrad. Stab. 2003, 80, 403–419. [Google Scholar] [CrossRef]

- Lukić, I.; Premrov, M.; Leskovar, Ž.V.; Passer, A. Assessment of the Environmental Impact of Timber and Its Potential to Mitigate Embodied GHG Emissions. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 022068. [Google Scholar] [CrossRef]

- Skullestad, J.L.; Bohne, R.A.; Lohne, J. High-Rise Timber Buildings as a Climate Change Mitigation Measure—A Comparative LCA of Structural System Alternatives. Energy Procedia 2016, 96, 112–123. [Google Scholar] [CrossRef]

- Podesto, L.; Breneman, S. CLT Research: Available and Accessible to North American Designers. Wood Des. Focus 2016, 26, 3–7. [Google Scholar]

- Gu, H.; Bergman, R. Life Cycle Assessment and Environmental Building Declaration for the Design Building at the University of Massachusetts; Gen. Tech. Rep. FPL-GTR-255; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2018; pp. 1–73. [Google Scholar]

- Bowick, M. Brock Commons Tallwood House, University of British Columbia an Environmental Building Declaration According to EN 15978 Standard; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2018. [Google Scholar]

- Hammond, G.P.; Jones, C.I. Embodied Energy and Carbon in Construction Materials. Proc. Inst. Civ. Eng.-Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life Cycle Assessment (LCA) of Cross-Laminated Timber (CLT) Produced in Western Washington: The Role of Logistics and Wood Species Mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef]

- Connolly, T.; Loss, C.; Iqbal, A.; Tannert, T. Feasibility Study of Mass-Timber Cores for the UBC Tall Wood Building. Buildings 2018, 8, 98. [Google Scholar] [CrossRef]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross Laminated Timber (CLT): Overview and Development. Eur. J. Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Lehmann, S. Sustainable Construction for Urban Infill Development Using Engineered Massive Wood Panel Systems. Sustainability 2012, 4, 2707–2742. [Google Scholar] [CrossRef]

- Dong, Y.; Cui, X.; Yin, X.; Chen, Y.; Guo, H. Assessment of Energy Saving Potential by Replacing Conventional Materials by Cross Laminated Timber (CLT)—A Case Study of Office Buildings in China. Appl. Sci. 2019, 9, 858. [Google Scholar] [CrossRef]

- Silva, C.V.; Branco, J.M.; Lourenço, P.B. A Project Contribution to the Development of Sustainable Multi-Storey Timber Buildings. In Chapter 5—Innovative Construction Systems; MULTICOMP—Artes Gráficas, Lda: Guimarães, Portugal, 2013; pp. 379–386. [Google Scholar]

- Mallo, M.F.L.; Espinoza, O. Awareness, Perceptions and Willingness to Adopt Cross-Laminated Timber by the Architecture Community in the United States. J. Clean. Prod. 2015, 94, 198–210. [Google Scholar] [CrossRef]

- Van De Kuilen, J.; Ceccotti, A.; Xia, Z.; He, M. Very Tall Wooden Buildings with Cross Laminated Timber. Procedia Eng. 2011, 14, 1621–1628. [Google Scholar] [CrossRef]

- Younis, A.; Dodoo, A. Cross-Laminated Timber for Building Construction: A Life-Cycle-Assessment Overview. J. Build. Eng. 2022, 52, 104482. [Google Scholar] [CrossRef]

- Frangi, A.; Fontana, M.; Hugi, E.; Jübstl, R. Experimental Analysis of Cross-Laminated Timber Panels in Fire. Fire Saf. J. 2009, 44, 1078–1087. [Google Scholar] [CrossRef]

- Klippel, M.; Schmid, J. Design of Cross-Laminated Timber in Fire. Struct. Eng. Int. 2017, 27, 224–230. [Google Scholar] [CrossRef]

- Dsilva, J.; Zarmukhambetova, S.; Locke, J. Assessment of Building Materials in the Construction Sector: A Case Study Using Life Cycle Assessment Approach to Achieve the Circular Economy. Heliyon 2023, 9, e20404. [Google Scholar] [CrossRef]

- Guest, G.; Cherubini, F.; Strømman, A.H. Global Warming Potential of Carbon Dioxide Emissions from Biomass Stored in the Anthroposphere and Used for Bioenergy at End of Life. J. Ind. Ecol. 2013, 17, 20–30. [Google Scholar] [CrossRef]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental Benefits of Using Hybrid CLT Structure in Midrise Non-Residential Construction: An LCA Based Comparative Case Study in the US Pacific Northwest. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Cadorel, X.; Crawford, R. Life Cycle Analysis of Cross Laminated Timber in Buildings: A Review; The Architectural Science Association and RMIT University Melbourne: Melbourne, Australia, 2018; pp. 107–114. [Google Scholar]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG Emissions of Buildings–The Hidden Challenge for Effective Climate Change Mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Carcassi, O.B.; Minotti, P.; Habert, G.; Paoletti, I.; Claude, S.; Pittau, F. Carbon Footprint Assessment of a Novel Bio-Based Composite for Building Insulation. Sustainability 2022, 14, 1384. [Google Scholar] [CrossRef]

- Lan, K.; Kelley, S.S.; Nepal, P.; Yao, Y. Dynamic Life Cycle Carbon and Energy Analysis for Cross-Laminated Timber in the Southeastern United States. Environ. Res. Lett. 2020, 15, 124036. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W. Comparative Sustainability Evaluation of Two Engineered Wood-Based Construction Materials: Life Cycle Analysis of CLT versus GLT. Build. Environ. 2021, 204, 108112. [Google Scholar] [CrossRef]

- De Rosa, M.; Pizzol, M.; Schmidt, J. How Methodological Choices Affect LCA Climate Impact Results: The Case of Structural Timber. Int. J. Life Cycle Assess. 2018, 23, 147–158. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Samson, R. Biogenic Carbon and Temporary Storage Addressed with Dynamic Life Cycle Assessment. J. Ind. Ecol. 2013, 17, 117–128. [Google Scholar] [CrossRef]

- Brandão, M.; Levasseur, A.; Kirschbaum, M.U.; Weidema, B.P.; Cowie, A.L.; Jørgensen, S.V.; Hauschild, M.Z.; Pennington, D.W.; Chomkhamsri, K. Key Issues and Options in Accounting for Carbon Sequestration and Temporary Storage in Life Cycle Assessment and Carbon Footprinting. Int. J. Life Cycle Assess. 2013, 18, 230–240. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment: Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 21930:2017; Sustainability in Buildings and Civil Engineering Works–Core Rules for Environmental Product Declarations of Construction Products and Services. International Organization for Standardization (ISO): Geneva, Switzerland, 2017; p. 25.

- Crovella, P.; Tom, K.; Mohamad, R.; William, S. A Zero-Carbon Energy Retrofit Solution for NYS Buildings from NYS Forests; SUNY College of Environmental Science and Forestry: New York, NY, USA, 2021; p. 41. [Google Scholar]

- International Code Council (ICC). 2009 International Energy Conservation Code; International Code Council (ICC): Washington, DC, USA, 2009; Volume 2009, p. 93.

- ACLCA. ACLCA Guidance to Calculating Non-LCIA Inventory Metrics in Accordance with ISO 21930:2017; Product Category Rule (PCR) Committee of the American Center for Life Cycle Assessment: Philadelphia, PA, USA, 2019; p. 70. [Google Scholar]

- De Serres-Lafontaine, C.; Blanchet, P.; Charron, S.; Delem, L.; Wastiels, L. Bio-Based Innovations in Cross-Laminated Timber (CLT) Envelopes: A Hygrothermal and Life Cycle Analysis (LCA) Study. Build. Environ. 2024, 256, 111499. [Google Scholar] [CrossRef]

- Ecoinvent. Ecoinvent Life Cycle Assessment Database; Ecoinvent: Zurich, Switzerland, 2023; Available online: https://ecoinvent.org/database/ (accessed on 10 September 2023).

- NREL U.S. Life Cycle Inventory (USLCI) Database. The Federal LCA Commons (FLCAC), National Renewable Energy Laboratory. 2012. Available online: https://www.lcacommons.gov/ (accessed on 20 November 2023).

- Puettmann, M.E.; Wagner, F.G.; Johnson, L. Life Cycle Inventory of Softwood Lumber from the Inland Northwest US. Wood Fiber Sci. 2010, 42, 52–66. [Google Scholar]

- GCP Applied Technologies Inc. Environmental Product Declaration of GCP Applied Technologies Inc. Perm-A-Barrier® Air Barriers; GCP Applied Technologies Inc.: Alpharetta, GA, USA, 2017. [Google Scholar]

- GCP Applied Technologies Inc. PERM-A-BARRIER® NPL 10/ NPL 10 LT Data Sheet: Fluid-Applied Impermeable Air and Vapor Barrier Membrane; GCP Applied Technologies Inc.: Alpharetta, GA, USA, 2023. [Google Scholar]

- Structurlam. EPD for Cross Laminated Timber Produced by Structurlam in Okanagan Falls, BC; Structurlam Mass Timber Corporation: Penticton, BC, Canada, 2020; p. 15. [Google Scholar]

- STEICO. EPD for Wood Fibre Insulation Boards Manufactured in a Dry Process; Institut Bauen und Umwelt: Berlin, Germany, 2020; p. 10. [Google Scholar]

- DuPont. Environmental Product Declaration: Tyvek® Mechanically Fastened Air and Water Barrier Systems; DuPont: Wilmington, IL, USA, 2017; p. 18. [Google Scholar]

- Aro, M.D. Life-Cycle Assessment of Thermally-Modified Southern Pine Decking. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 2018. [Google Scholar]

- SFPA. Pressure-Treated Southern Pine; Southern Forest Products Association: Metairie, LA, USA, 2019; p. 24. [Google Scholar]

- SFPA. Southern Pine Use Guide; Southern Forest Products Association: Metairie, LA, USA, 2018; p. 20. [Google Scholar]

- LP SmartSide. LP® SmartSide® Environmental Product Declaration; Louisiana-Pacific Corporation: Nashville, TN, USA, 2021; p. 21. [Google Scholar]

- Puettmann, M.; Pierobon, F.; Ganguly, I.; Gu, H.; Chen, C.; Liang, S.; Jones, S.; Maples, I.; Wishnie, M. Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration. Sustainability 2021, 13, 13987. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration (EIA). New York: State Profiles and Energy Estimates. Monthly 2022, 1. Available online: https://www.eia.gov/state/data.php?sid=NY (accessed on 27 July 2023).

- Spillane, K. 2021 Annual Report on Recyclables Recovered & Updated Comprehensive Recycling Analysis; Onondaga County Resource Recovery Agency (OCRRA): Syracuse, NY, USA, 2022; p. 11. [Google Scholar]

- Glance, D. 2019 Annual Report on Recyclables Recovered; Onondaga County Resource Recovery Agency (OCRRA): Syracuse, NY, USA, 2020; p. 20. [Google Scholar]

- Bare, J. TRACI 2.0: The Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts 2.0. Clean Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

- Guo, M.; Murphy, R.J. LCA Data Quality: Sensitivity and Uncertainty Analysis. Sci. Total Environ. 2012, 435–436, 230–243. [Google Scholar] [CrossRef]

- Marcea, R.; Lau, K. Carbon Dioxide Implications of Building Materials. J. For. Eng. 1992, 3, 37–43. [Google Scholar] [CrossRef]

- Lechón, Y.; La Rúa, C.D.; Lechón, J.I. Environmental Footprint and Life Cycle Costing of a Family House Built on CLT Structure. Analysis of Hotspots and Improvement Measures. J. Build. Eng. 2021, 39, 102239. [Google Scholar] [CrossRef]

- Peñaloza, D.; Erlandsson, M.; Falk, A. Exploring the Climate Impact Effects of Increased Use of Bio-Based Materials in Buildings. Constr. Build. Mater. 2016, 125, 219–226. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life Cycle Primary Energy Use and Carbon Emission of an Eight-Storey Wood-Framed Apartment Building. Energy Build. 2010, 42, 230–242. [Google Scholar] [CrossRef]

- Chaudhary, A.; Messer, A. Life Cycle Assessment of Adhesives Used in Wood Constructions Life Cycle Assessment (LCA) of Adhesives Used in Wood Constructions; ETH: Zurich, Switzerland, 2015. [Google Scholar]

- Liu, W.; Zhang, Z.; Xie, X.; Yu, Z.; von Gadow, K.; Xu, J.; Zhao, S.; Yang, Y. Analysis of the Global Warming Potential of Biogenic CO2 Emission in Life Cycle Assessments. Sci. Rep. 2017, 7, 39857. [Google Scholar] [CrossRef]

- Andersen, J.H.; Rasmussen, N.L.; Ryberg, M.W. Comparative Life Cycle Assessment of Cross Laminated Timber Building and Concrete Building with Special Focus on Biogenic Carbon. Energy Build. 2022, 254, 111604. [Google Scholar] [CrossRef]

- Breton, C.; Blanchet, P.; Amor, B.; Beauregard, R.; Chang, W.-S. Assessing the Climate Change Impacts of Biogenic Carbon in Buildings: A Critical Review of Two Main Dynamic Approaches. Sustainability 2018, 10, 2020. [Google Scholar] [CrossRef]

- Hubbard, S.S.; Bergman, R.D.; Sahoo, K.; Bowe, S.A. A Life Cycle Assessment of Hardwood Lumber Production in the Northeast and North Central United States; CORRIM Report; Consortium for Research on Renewable Industrial Materials (CORRIM): Corvallis, OR, USA, 2020; 45p. [Google Scholar]

- Hosseini, S.S.; Yaghmaeian, K.; Yousefi, N.; Mahvi, A.H. Estimation of Landfill Gas Generation in a Municipal Solid Waste Disposal Site by LandGEM Mathematical Model. Glob. J. Environ. Sci. Manag. 2018, 4, 493–506. [Google Scholar] [CrossRef]

- Head, M.; Magnan, M.; Kurz, W.A.; Levasseur, A.; Beauregard, R.; Margni, M. Temporally-Differentiated Biogenic Carbon Accounting of Wood Building Product Life Cycles. SN Appl. Sci. 2021, 3, 62. [Google Scholar] [CrossRef]

- Gonçalves, D.; Bordado, J.M.; Marques, A.C.; Galhano dos Santos, R. Non-Formaldehyde, Bio-Based Adhesives for Use in Wood-Based Panel Manufacturing Industry—A Review. Polymers 2021, 13, 4086. [Google Scholar] [CrossRef] [PubMed]

- González-García, S.; Feijoo, G.; Heathcote, C.; Kandelbauer, A.; Moreira, M.T. Environmental Assessment of Green Hardboard Production Coupled with a Laccase Activated System. J. Clean. Prod. 2011, 19, 445–453. [Google Scholar] [CrossRef]

- Chen, L.; Miller, S.A.; Ellis, B.R. Comparative Human Toxicity Impact of Electricity Produced from Shale Gas and Coal. Environ. Sci. Technol. 2017, 51, 13018–13027. [Google Scholar] [CrossRef] [PubMed]

- Burchart-Korol, D.; Pustejovska, P.; Blaut, A.; Jursova, S.; Korol, J. Comparative Life Cycle Assessment of Current and Future Electricity Generation Systems in the Czech Republic and Poland. Int. J. Life Cycle Assess. 2018, 23, 2165–2177. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.A.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated Life-Cycle Assessment of Electricity-Supply Scenarios Confirms Global Environmental Benefit of Low-Carbon Technologies. Proc. Natl. Acad. Sci. USA 2015, 112, 6277–6282. [Google Scholar] [CrossRef] [PubMed]

- Poinssot, C.; Bourg, S.; Ouvrier, N.; Combernoux, N.; Rostaing, C.; Vargas-Gonzalez, M.; Bruno, J. Assessment of the Environmental Footprint of Nuclear Energy Systems. Comparison between Closed and Open Fuel Cycles. Energy 2014, 69, 199–211. [Google Scholar] [CrossRef]

- Atilgan, B.; Azapagic, A. Life Cycle Environmental Impacts of Electricity from Fossil Fuels in Turkey. J. Clean. Prod. 2015, 106, 555–564. [Google Scholar] [CrossRef]

- Levasseur, A.; Brandão, M.; Lesage, P.; Margni, M.; Pennington, D.; Clift, R.; Samson, R. Valuing Temporary Carbon Storage. Nat. Clim. Chang. 2012, 2, 6–8. [Google Scholar] [CrossRef]

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 Emissions from Biomass Combustion for Bioenergy: Atmospheric Decay and Contribution to Global Warming. GCB Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef]

- Holtsmark, B. Quantifying the Global Warming Potential of CO2 Emissions from Wood Fuels. GCB Bioenergy 2015, 7, 195–206. [Google Scholar] [CrossRef]

- Holtsmark, B. A Comparison of the Global Warming Effects of Wood Fuels and Fossil Fuels Taking Albedo into Account. GCB Bioenergy 2015, 7, 984–997. [Google Scholar] [CrossRef]

- Lenton, T.M. Early Warning of Climate Tipping Points. Nat. Clim. Chang. 2011, 1, 201–209. [Google Scholar] [CrossRef]

- Ximenes, F.A.; Cowie, A.L.; Barlaz, M.A. The Decay of Engineered Wood Products and Paper Excavated from Landfills in Australia. Waste Manag. 2018, 74, 312–322. [Google Scholar] [CrossRef] [PubMed]

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological Challenges and Developments in LCA of Low Energy Buildings: Application to Biogenic Carbon and Global Warming Assessment. Build. Environ. 2015, 90, 51–59. [Google Scholar] [CrossRef]

- Garcia, R.; Alvarenga, R.A.F.; Huysveld, S.; Dewulf, J.; Allacker, K. Accounting for Biogenic Carbon and End-of-Life Allocation in Life Cycle Assessment of Multi-Output Wood Cascade Systems. J. Clean. Prod. 2020, 275, 122795. [Google Scholar] [CrossRef]

- Castellano, G.; Paoletti, I.M.; Malighetti, L.E.; Carcassi, O.B.; Pradella, F.; Pittau, F. Bio-Based Solutions for the Retrofit of the Existing Building Stock: A Systematic Review. In Bio-Based Building Materials; Amziane, S., Merta, I., Page, J., Eds.; RILEM Bookseries; Springer Nature: Cham, Switzerland, 2023; Volume 45, pp. 399–419. ISBN 978-3-031-33464-1. [Google Scholar]

- NYSCAC. Scoping Plan; New York State Climate Action Council: Albany, NY, USA, 2022; p. 433. [Google Scholar]

- Wilcox, J.; Hammer, H.; Patane, N. Appendix G: Integration Analysis Technical Supplement New York State Climate Action Council Scoping Plan; New York State Energy Research & Development Authority (NYSERDA) and New York State Department of Environmental Conservation (NYSDEC): New York, NY, USA, 2022; p. 184. [Google Scholar]

- NYSERDA. Market Characterization Study: Building Stock Assessment and Architectural Profiles of Predominant New York State Multifamily Building Types; NYSERDA RetrofitNY; New York State Energy Research and Development Authority, Pratt Institute School of Architecture, Syracuse University School of Architecture: Albany, NY, USA, 2020; p. 118. [Google Scholar]

- Reyna, J.; Wilson, E.; Parker, A.; Satre-Meloy, A.; Egerter, A.; Bianchi, C.; Praprost, M.; Speake, A.; Liu, L.; Horsey, R. US Building Stock Characterization Study: A National Typology for Decarbonizing US Buildings; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2022; p. 93. [Google Scholar]

| Phases | Vapor Barrier | 3-Ply CLT | Wood Fiber | Membrane Sheet | Strapping Material | Siding Material | |

|---|---|---|---|---|---|---|---|

| Plant growth (kgCO2-eq) (A1) | — a | −89 | −22.7 | — | −1.11 | −11.2 | |

| Raw materials (kg), (A2) b | 2.14 | 94.2 | 12.7 | 8.82 × 10−5 | 1.59 | 7.32 | |

| Transportation (A3) | On road (km) | 694 | 439 | 384 | 437 | 739 | |

| Barge (km) | — | — | 6610 | — | — | ||

| Energy use (A4) | Electricity (kWh) | 5.0 | 30.8 | 30.1 | 1.27 × 10−2 | 33.9 | 29.0 |

| Natural gas (MJ) | 3.60 | 26.5 | — | — | — | — | |

| Installation (A5) | Electricity (kWh) | 0.278 | 1.39 | 1.39 | 0.278 | 0.278 | 1.39 |

| Packaging waste (kg) (C1 and C2) | 9.77 × 10−2 | 3.81 × 10−2 | 3.81 × 10−2 | 1.00 × 10−4 | 9.77 × 10−2 | 3.61 × 10−4 | |

| Impact Category | Unit | Vapor Barrier | Three-Ply CLT | Wood Fiber | Membrane Sheet | Strapping Material | Siding Material | Installation | Waste Treatment | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Ozone depletion | kg CFC-11 eq | 3.92 × 10−7 | 6.41 × 10−6 | 1.93 × 10−7 | 3.85 × 10−10 | 1.14 × 10−6 | 5.35 × 10−7 | 8.63 × 10−11 | 1.27 × 10−7 | 8.79 × 10−6 |

| Smog formation | kg O3 eq | 0.345 | 3.80 | 1.40 | 1.75 × 10−4 | 0.626 | 11.5 | 0.320 | 3.03 × 10−2 | 18.1 |

| Acidification | kg SO2 eq | 2.87 × 10−2 | 1.37 × 10−1 | 8.11 × 10−2 | 1.66 × 10−5 | 5.53 × 10−2 | 4.38 × 10−1 | 4.10 × 10−2 | 2.38 × 10−3 | 0.783 |

| Eutrophication | kg N eq | 1.01 × 10−2 | 2.74 × 10−2 | 1.30 × 10−2 | 5.71 × 10−6 | 2.44 × 10−2 | 9.27 × 10−2 | 5.80 × 10−4 | 7.64 × 10−4 | 0.169 |

| Carcinogenic effect | CTUh | 2.14 × 10−7 | 8.36 × 10−6 | 3.77 × 10−7 | 2.12 × 10−10 | 4.54 × 10−7 | 1.41 × 10−6 | 8.83 × 10−9 | 2.92 × 10−8 | 1.08 × 10−5 |

| Noncarcinogenic effect | CTUh | 1.15 × 10−6 | 4.08 × 10−6 | 2.15 × 10−6 | 5.78 × 10−10 | 4.44 × 10−6 | 6.21 × 10−6 | 1.52 × 10−7 | 1.51 × 10−7 | 1.83 × 10−5 |

| Respiratory effects | kg PM2.5 eq | 1.78 × 10−3 | 2.34 × 10−2 | 4.25 × 10−3 | 1.21 × 10−6 | 3.93 × 10−3 | 1.13 × 10−2 | 1.99 × 10−3 | 2.51 × 10−4 | 4.69 × 10−2 |

| Ecotoxicity | CTUe | 24.9 | 52.9 | 39.5 | 1.15 × 10−2 | 49.3 | 158 | 1.85 | 9.43 | 336 |

| Fossil fuel depletion | MJ surplus | 16.7 | 51.4 | 19.2 | 1.36 × 10−2 | 26.0 | 59.6 | 3.00 | 3.24 | 179 |

| Studies on Biobased Building Materials | GWP100 Impacts (kgCO2-eq/m2) | Materials Studied |

|---|---|---|

| Marcea and Lau [131] | 40.7 | Wood compared to non-wood building materials in North American context. |

| Mouton et al. [55] | 68.22 | Timber-, straw- and hemp-based materials in European context. |

| Liang et al. [52] | 193 | Mass timber (CLT and glued laminated timber (glulam)) and associated materials in the U.S. context. |

| CWC [51] | 159 | Mass timber (nail-laminated timber (NLT), glulam, and CLT) in Canadian context. |

| Pierobon et al. [97] | 327.53 | Hybrid CLT structure (CLT and gypsum as wallboard) in the U.S. Pacific Northwest context. |

| Gustavsson et al. [134] | 89 * | Wood residues (branches, foliage, bark, construction, and demolition wood) in Swedish context. |

| Robertson et al. [54] | 126 * | CLT and glulam in Canadian context. |

| Lechon et al. [132] | 34 | Cross-laminated timber (CLT) in Spanish context. |

| Penaloza et al. [133] | 5 * | CLT and cellulose fiber insulation material in Swedish context. |

| Penaloza et al. [133] | 197 | |

| This study | 98.7 | CLT and associated materials for installation (vapor barrier, wood fiber, membrane sheet, and strapping and siding materials). |

| This study | 7.2 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, M.S.; Therasme, O.; Crovella, P.; Volk, T.A. Assessing the Environmental Impact of Biobased Exterior Insulation Panel: A Focus on Carbon Uptake and Embodied Emissions. Energies 2024, 17, 3406. https://doi.org/10.3390/en17143406

Hossain MS, Therasme O, Crovella P, Volk TA. Assessing the Environmental Impact of Biobased Exterior Insulation Panel: A Focus on Carbon Uptake and Embodied Emissions. Energies. 2024; 17(14):3406. https://doi.org/10.3390/en17143406

Chicago/Turabian StyleHossain, Md Sahadat, Obste Therasme, Paul Crovella, and Timothy A. Volk. 2024. "Assessing the Environmental Impact of Biobased Exterior Insulation Panel: A Focus on Carbon Uptake and Embodied Emissions" Energies 17, no. 14: 3406. https://doi.org/10.3390/en17143406

APA StyleHossain, M. S., Therasme, O., Crovella, P., & Volk, T. A. (2024). Assessing the Environmental Impact of Biobased Exterior Insulation Panel: A Focus on Carbon Uptake and Embodied Emissions. Energies, 17(14), 3406. https://doi.org/10.3390/en17143406