1. Introduction

Gas turbines are key units in aviation propulsion, electricity generation, and other industrial applications. Their critical role in all applications makes it essential to ensure high reliability and operational safety, a task that may be challenging due to the harsh working environment at high speeds and under high temperatures and pressures. This increases the risk of malfunction or performance degradation of any of the gas turbine components.

To ensure high availability, reliability, and efficient operation throughout the gas turbine lifecycle, faults must be detected and identified early so that appropriate maintenance actions can be taken. This fact has been recognized early in the development of gas turbines and has led to the appearance of engine health monitoring and diagnostic methods.

Although mechanical faults, such as shaft misalignment, imbalance, bearing faults, etc., are encountered in gas turbines, there is a group of faults that is particular to this type of engine, namely those related to the aerothermodynamics of the gas path components, compressors, and turbines. Typical faults in this category are compressor and turbine fouling, excessive blade-tip clearance, erosion, variable geometry system malfunction, and foreign object damage (FOD). There is a special research interest in investigating and developing methods to diagnose these types of faults. Such methods are known as performance diagnostic methods. Such methods have already been reviewed by several authors in recent years (e.g., [

1,

2]), while subsequent evolution has led to the appearance of related reviews even more recently [

3,

4,

5,

6].

Early methods used model-based approaches, where diagnostic reasoning is based on a physical representation of the engine through thermodynamic models; examples of such methods were presented in [

7,

8,

9] in the early 1990s. Approaches relying on statistical principles, when a large number of historical records is available or when various health conditions of engines can be simulated through an engine performance model, have also been developed, for example, the methods proposed in [

10,

11,

12].

When a physical model is not available, Artificial Intelligence (AI) approaches offer an alternative, as they can reason and uncover the cause–effect relationship between observable measurements and non-observable health parameters, even when the functional relationship between them is unknown or incomplete. AI-based methods are also attractive because they can handle large systems with multiple parameters and manage stochastic phenomena like those encountered in diagnostic problems. A review of such methods was included in [

6], while some examples of such early methods were presented in [

13,

14,

15]. It is noted here that the importance of combining multiple sources of information has been recognized and given rise to the use of approaches known as “information fusion”. Such approaches were recently reviewed in [

16], while early related efforts can be found in [

17,

18].

Both statistical and AI approaches depend on the availability of data, i.e., they are “data-driven”. Data-driven methods require the collection of extensive data sets, which should cover a large variety of faulty conditions if detailed fault identification is desired. By their nature, they are most suitable for the particular gas turbine from which the data come, with the need for another extensive corresponding data set when a new application engine is targeted. These drawbacks can be alleviated using physics-based methods. Parameters related to the physics of engine operation are then monitored to detect and identify the presence of abnormal conditions in one or more of the gas turbine components as early and as accurately as possible.

Performance diagnostic methods aim to represent physical faults through component performance parameter deviations, leading to the need to estimate these parameters to solve the diagnostic problem. Determining such parameters and their inter-relation with operational abnormalities is, thus, a critical element of an efficient diagnostic method. While many researchers have provided relevant information, there are still questions today as to its general validity, while in some cases, it is confusing. It would, thus, be valuable to provide such information in an organized manner and to clarify the features that relate it to the physical situations at hand. It can be understood from the discussion of the works reviewed herein that apparent inconsistencies can be found in published information.

The present paper reviews works that provide information on how appropriate engine performance parameters represent physical faults of gas turbines. We start by providing an overview of the literature discussing the most common gas turbine faults. We then summarize the way of representing faults related to the aerothermodynamics of the gas turbine. Works that represent these gas turbine faults in terms of appropriate engine parameters are then reviewed. An interpretation of the gathered information useful for adopting the correct correlation of faults and parameter deviations is also presented. It is noted that to the authors’ knowledge, the present review is the first of its kind.

2. Overview of Literature on Compressor and Turbine Faults

The need for knowledge of the effects of faults on the performance of a gas turbine and its components has motivated researchers to investigate the nature, mechanism, and effect of faults on the values of performance parameters. Such investigations first appeared a long time ago during the early stages of the development of performance diagnostic methods. The main abnormalities investigated are fouling, erosion and corrosion, tip-clearance increase, variable geometry system faults, and foreign object damage.

Works investigating the effect of the presence of these faults on the performance parameters of engine components, compressors or turbines, have already appeared in the 80’s and early 90’s, for example [

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29].

An overview of developments to date, including experiences with gas turbine faults and their damage effects, was included in a specialized publication of the AGARD conference proceedings from April 1994 [

30]. Reviews of developments to the time of publication have then been provided by several authors. In the years that followed, several authors reviewed developments in fault identification techniques, focusing on the effects of faults on performance.

In [

31], Meher-Homji et al. reviewed the area of gas turbine recoverable and non-recoverable performance deterioration. Deterioration mechanisms, including compressor and turbine fouling, erosion, increased clearances, and seal distress, were covered, along with their manifestations, rules of thumb, and mitigation approaches. Permanent deterioration was also covered. Because of the importance of compressor fouling, gas turbine inlet filtration, fouling mechanisms, and compressor washing were covered in detail.

In [

32], Burnes and Kurz provided a detailed analysis and simulation of the effect of component deterioration (increased tip clearance, erosion, and fouling) on overall engine performance. Emphasis was placed on recoverable and non-recoverable degradation of specific components affecting gas turbine system performance and operation. The interaction of degraded components was studied in detail.

In [

33], Kurz and Brun discussed the effect of degradation on gas turbines as part of a complex system (e.g., a pipeline, a reinjection station, etc.). Treating the gas turbine package as a system reveals the degradation effects on the components’ match and the driven equipment’s match. Based on some detailed studies on the mechanisms that cause engine degradation—namely, changes in blade surfaces due to erosion or fouling and the effect on blade aerodynamics; changes in seal geometries and clearances and the effect on parasitic flows; and changes in the combustion system (e.g., which result in different pattern factors)—the effects of degradation were discussed.

In [

34], Kurz et al. provided a discussion on how degradation develops and affects the performance of gas turbines. Because the function of a gas turbine is the result of the fine-tuned cooperation of many different components, the emphasis of this work was on a gas turbine and its components as a system.

Details on the effect of fouling on gas turbine performance were provided by Meher-Homji et al. [

35] and Kurz and Brun [

36]. An extensive review of works on fouling presented at the yearly conferences of ASME was presented relatively recently in [

37].

In [

38], Bons reviewed the effects of surface roughness on gas turbine performance based on publications in the open literature over the past 60 years. Empirical roughness correlations routinely employed for drag and heat transfer estimates were summarized. Roughness influences engine performance by causing earlier boundary-layer transition, increased boundary-layer momentum loss (i.e., thickness), and/or flow separation.

Damage caused by the impact of objects on the blading of compressors or turbines is also a source of malfunctions. Failures in compressor and turbine blades were reviewed in [

39]. The geometry changes and structural aspects of failing blades due to different reasons were summarized. A similar type of information discussing the physical aspects of the various fault mechanisms that alter blade shape was presented by Aust and Pons in [

40]. Such information is useful when detailed computations of the flow inside faulty components are performed.

A discussion on performance-related faults was published by Fentaye et al. [

4], while references to the way faults influence the performance of components was included in [

6].

Information on faulty situations has been included in recently published textbooks on gas turbines. For example, Giampaolo, 2014 [

41] refers to fouling, erosion, and FOD, with comments on the way they affect performance. El-Sayed, 2017 [

42] examined erosion in gas turbines and reviewed approaches for its theoretical estimation, while reference to FOD was also made.

3. Representation of Faults Related to Gas Turbine Aerothermodynamics

The occurrence of a fault in gas turbines causes changes in the values of characteristic parameters that represent the condition of its components. A scalar can be used to characterize such changes. For any parameter (

), the scalar (factor) (

) that shows how it stands with respect to the reference condition is defined as follows:

A value equal to 1 indicates that the component is in its intact condition, termed “healthy” for the purpose of fault diagnostics.

Aerothermodynamic faults affect the aerothermodynamic processes within the gas turbine. Two such major processes are compression and expansion, which are materialized by turbomachinery components, namely compressors and turbines, respectively. The two quantities characterizing how these components operate are mass flow capacity and efficiency. The parameters related to these quantities can, thus, be used as “health parameters” and are defined as follows:

where

is the gas mass flow rate,

is the total temperature,

is the total pressure at station

i along the engine’s gas path (usually according to the AS755 standard of SAE [

43]),

is the efficiency of the component with entrance at station i, and subscript

, indicates reference values, i.e., values of a healthy engine.

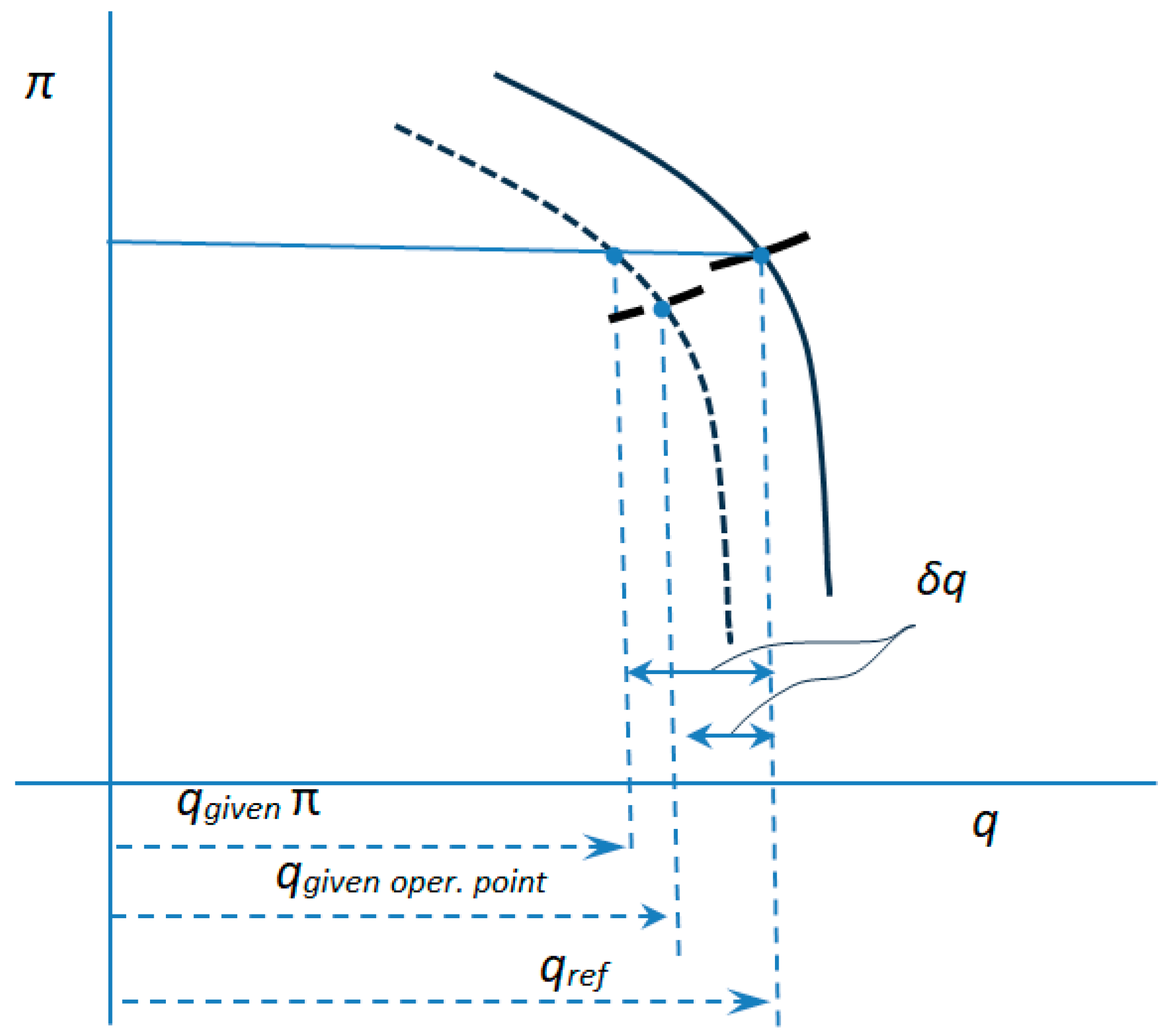

A comment that can be made here is about the way the corresponding points are defined. Although scalars are used by practically all researchers, few define them precisely because the correspondence of operating points is not specified. It can be seen, for example, that for the corresponding operating points of a compressor, conditions could be defined for a given rotational speed at a constant pressure ratio (e.g., [

9]) or the point along an operating line, as, for example, shown in

Figure 1. The two definitions would provide the same value if the characteristic were perpendicular to the abscissa. Other ways may also be used, such as a setting defined through another parameter, for example, the load. Other assumptions may also be used; for example in [

44], the pressure ratio and mass flow characteristics were assumed to be shifted by equal percentages along both axes.

The use of those factors to describe the health condition of engine components was introduced by Stamatis et al. [

9,

45]. The deviation of an engine component’s health parameter from its nominal value indicates that the component has suffered an alteration and can, thus, be used to indicate the presence of a fault. The percentage deviation (“Delta”) of a health parameter (

) is defined as follows:

where

is the value of the health parameter and

is its nominal value, which is equal to unity for the reference condition. From Equations (1) and (4), it is obvious that

.

The more severe the fault, the greater the magnitude of the deviation. However, the magnitude is not sufficient for characterizing the fault. The combination of the deviations of both health parameters characterizes the fault. As stated by many researchers (see, for example, [

46,

47,

48,

49]), specific physical faults located in an engine component lead to specific deviations of both of its health parameters. An approach commonly followed by many researchers is to use the ratio of the two deviations to characterize a specific fault in a component. In other words, the ratio of deviations of an engine component’s health indices shows the kind of fault present in a component.

This ratio is, thus, also be referred to as the “fault ratio” of the fault of a component and can serve as its signature. In the following, the way this ratio corresponds to faults is discussed. When appropriate, the “factor pair” (Δ(SW), Δ(SE)) is also be used (for example, when Δ(SE) ≈ 0).

4. Sources of Information for Signatures

In order to produce a diagnosis with respect to the existence and kind of a fault, its signature should be known. The generation of signatures for the faults of interest in this paper can be achieved through different types of approaches, which produce and compare parameters from a healthy component with the corresponding parameters of a faulty one. They may use the following:

- (a)

Ad hoc testing or field operation data: This approach comprises experimental investigations, where stand-alone components or components within an engine are experimentally investigated. Faults are artificially created to represent the actual ones expected to happen in the field. The performance of the intact component is established, then compared to the one with a fault implanted. Test data can also originate from engines operating in the field, where periods of intact and faulty operation can occur.

- (b)

Detailed fluid mechanics computations: Computational Fluid Dynamic (CFD) methods can produce the flow field in turbomachines and determine their overall performance thereafter. Flows with geometries under intact and faulty conditions are computed, and the corresponding performances are deduced. A comparison of the two produces the corresponding health indices.

- (c)

Low-fidelity computations: Methods that use a representation of the performance of turbomachinery elements (e.g., blade rows pr entire stages) to synthesize the overall performance can be used for the same purpose. A well-known method that has been used in many cases for the derivation of fault signatures is the stage-stacking method.

It is straightforward to understand that obtaining data from ad hoc testing is the most cumbersome (and possibly least general) approach. CFD approaches, on the other hand, can produce very detailed information that would be difficult or even impossible to produce by testing. Such methods have become more accessible and reliable in recent years, and this is why fault information from simulations has been produced by many investigators, as indicated in the following sections. Applying CFD to complicated geometries, such as those of multi-stage turbomachines, still requires strong computational resources and considerable computational time. An effective way to face this disadvantage is to follow approach (c) using data derived for simpler elements with approach (b). For example, the performance of a single stage can be established for healthy and faulty conditions, and stage stacking can then be used to derive the performance of a multi-stage component. It is noteworthy that approach (c) can also be combined with approach (a) in the same way.

It is noted here that applying CFD requires that the possibility of physically mapping the geometry changes corresponding to faults exist. Thus, information about depicting faults is essential. Such information has been included in several publications, including CFD studies or low-fidelity computations. Physical descriptions of faults in gas turbines have been the subject of publications, such as, for example, [

39,

40], while a comprehensive description of the physics of FOD, erosion, and corrosion from the point of view of engine safety is provided in Sections 5.2–5.4 of [

50].

The first to provide a systematic set of fault ratios for performance faults in gas turbines were Zwebeck and Plidis [

51], as shown in

Table 1. The values they provided were then used by numerous researchers in the following years. The authors did not provide hard evidence for the origin of the values, which were, to a large extent, based on their experience and judgement.

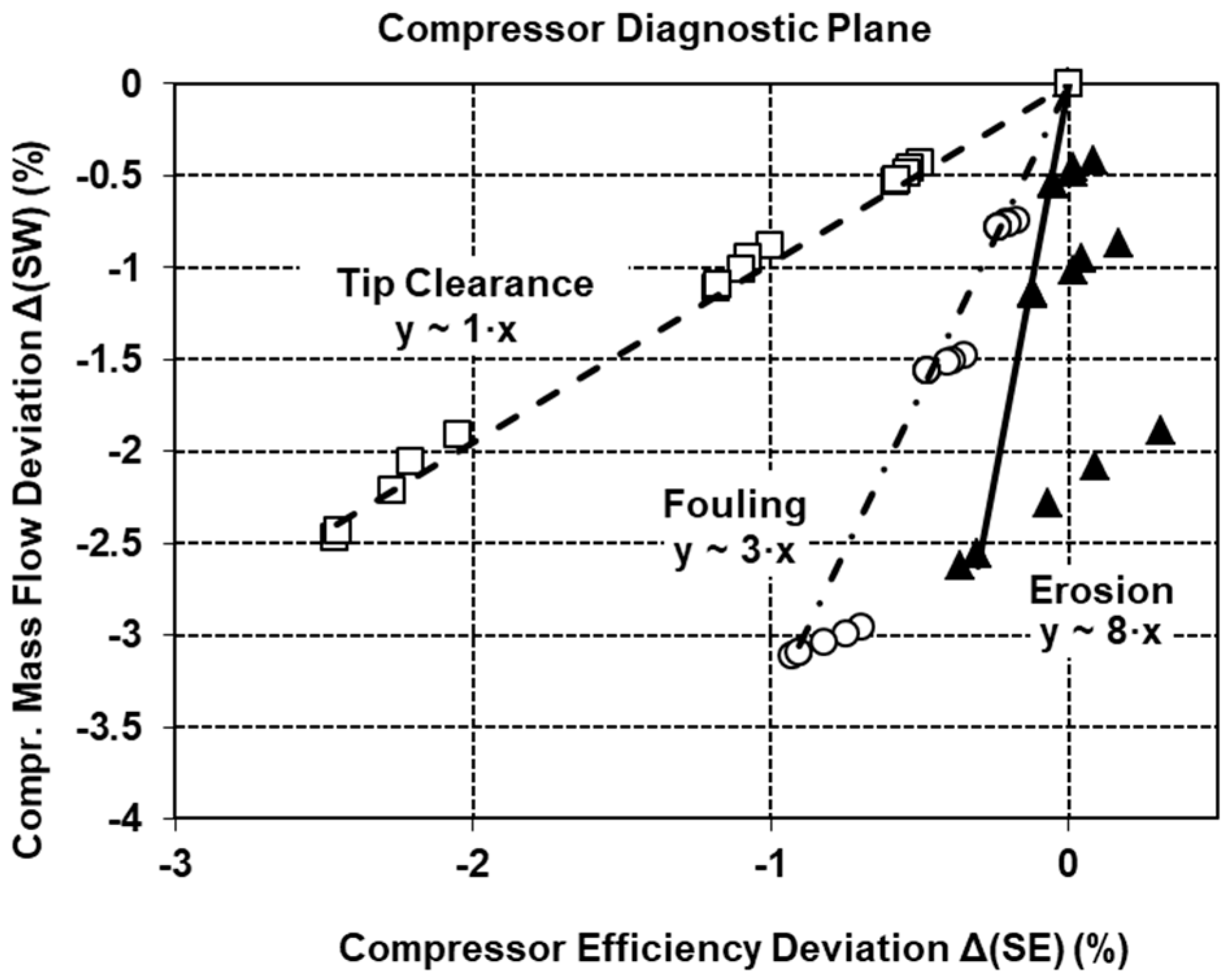

Another example of a set of faults, each linked to another ratio of deviations, is shown in

Figure 2. This information was derived and published by the group of the present authors, Aretakis et al. [

47], following a type (c) approach. Their analysis presents the effects of common simulated fault, on the 15-stage compressor of a 6 MW single-shaft engine in terms of a cross plot of compressor Δ(SW) versus Δ(SE), as shown in

Figure 2.

In this figure, points corresponding to the same fault are grouped along a trend line. In the considered tip clearance faults, Δ(SW) and Δ(SE) follow a ratio close to 1, while fouling follows a ratio close to 3 and erosion follows a ratio larger than 8.

In the following, information for individual faults is reviewed in light of the situation outlined above. The review concludes with an analysis that aims to elucidate fault signature behavior observed by different investigators and, hopefully, shed some light on the correct employment of fault signature information in performance diagnostic methods.

Before proceeding, it should be noted that existing published information on the signatures of different faults is not always coherent, and the findings of different researchers may appear, at first glance, contradictory. On the other hand, many researchers have used ratios they borrowed from previously published works, and when the information chain is traced, the initial source may include values with no reference to hard evidence. The propagation of spurious information can, thus, be continued until the latest work, possibly putting in question the method that uses it.

The resolution of such apparent inconsistencies is one of the motives for carrying out the present review.

5. Fouling

Fouling is the deposition of particles over flow-path surfaces, blades, and end walls, creating a layer that alters their geometry and roughness. It exhibits different characteristics in compressors and turbines. The fault ratios connected to this effect are discussed in the following for both types of components.

5.1. Compressors

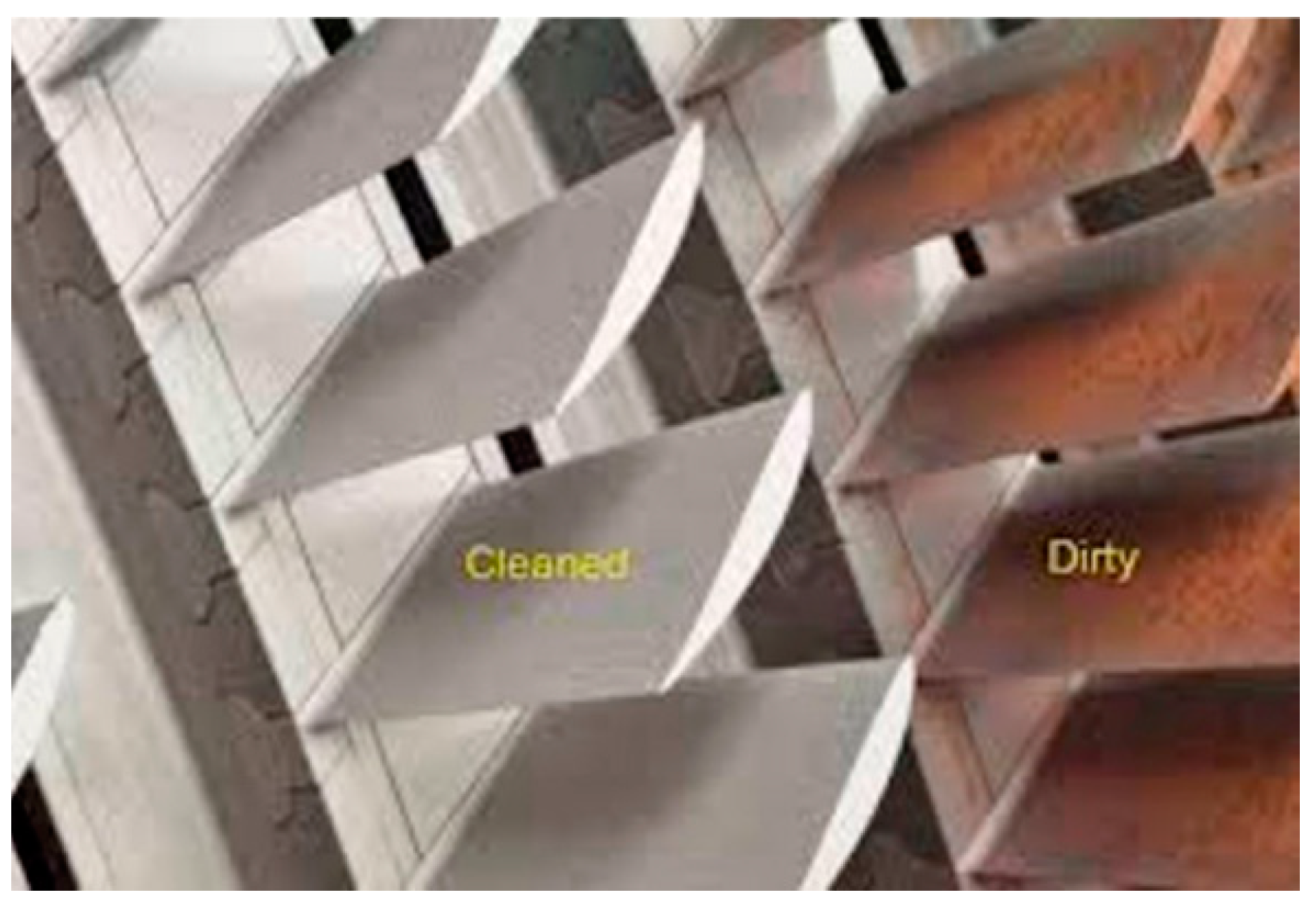

Compressor fouling is a condition that affects the everyday operation of all gas turbines and, due to its importance, has attracted interest from the early years in the development of monitoring techniques. It happens when sticky particulate matter is deposited on the compressor’s annulus passage, including rotors and stators [

52]. Smoke, oil mists, carbon, and sea salts are common examples. The effect of compressor fouling comprises drops in airflow and compressor isentropic efficiency, manifesting as drops in engine output and thermal efficiency. In some cases, fouling can also result in surge problems, as it moves the compressor surge line to the right, closer to the operating line. Details on the effect of fouling on gas turbine performance can also be found in [

35,

36]. An example picture of a fouled compressor is shown in

Figure 3.

Fouling has been investigated thoroughly, and many researchers have reported the effects on the corresponding health parameters. Experimental studies were published as early as 1976 [

54]. The importance of using the relationship of mass flow-to-efficiency deviations was understood very early and presented as a figure in [

24], where test data from a fouled industrial gas turbine were presented. These data were used in many publications after that. The effect of the extent and magnitude of fouling over the stages of a multi-stage compressor was investigated early in [

55], where the dependence of overall characteristics on these local changes was proposed as a different ratio for the overall performance depending on the number of stages affected. A comprehensive assessment of work on fouling up to the time of publication was reported in [

56], where the use of the ratio of health parameters was discussed. A similar review of all aspects, including the ratio, was presented in [

57].

An overview of values obtained by various investigators is compiled in

Table 2. The sources (bibliographic references) in this table provide results from base studies, which were either experimental or computational (low- or high-fidelity fluid dynamics computations). In some of the references, fault ratios were not provided but performance maps of intact and fouled components were presented. The present authors used those maps to deduce ratios. The notation (DR) is used to indicate such cases in this and subsequent tables.

The fouling fault ratio has been used by investigators presenting diagnostic methods. Such values are shown in

Table 3. Although not constituting source material, it is useful to include them as an indication of the usefulness of this quantity, especially since those diagnostic methods have been successfully applied to operational cases (e.g., [

49]).

Observing the values of the fault ratio in the tables above, it is noted that they show a variability from about 1 to 3.5. A question that reasonably arises then is whether one signature can be assigned to this fault. It is noted here that fouling may occur in different possible ways. First, the nature of fouling particles and their intensity, whether light or severe, change its effect. Such aspects have been extensively discussed by various investigators (for example, [

21]). Operating conditions may be another factor. For example, data from the operation of a jet engine at a range of speeds indicate that the ratio remains almost constant at different rotational speeds [

58]. Finally, an important factor is the overall compressor layout and fouling scheme. For example, if one stage is fouled, the ratio takes a value close to one. If this same stage is the first stage of a multi-stage compressor, then the ratio for the entire compressor may reach much larger values, as discussed later in the paper. Early investigations (for example, [

21,

67]) seem to have captured this aspect. However, it is disregarded in many recent studies, where a value is chosen without any particular reference to the studied compressor configuration.

5.2. Turbines

While compressor fouling is an effect that influences virtually all operating gas turbines, turbine fouling does not occur to the same extent. Particles contained in the air entering the gas turbine are mostly destroyed in the high-temperature environment of the combustion chamber to the point that gas turbine operation is considered to affect some air cleaning [

69]! There are, however, situations resulting in turbine fouling, such as operation with heavy fuels, operation in environments with high contents of particular constituents, fuels with additives, jet engines operating in volcanic clouds, etc. A picture of a fouled turbine is shown in

Figure 4.

Again, this was understood early in gas turbine development. Studies of the effect of fouling on turbines started very early, e.g., [

54,

70,

71], and effect has been of interest and studied until recently (e.g., [

72,

73,

74,

75]). An early, thorough review of tests related to turbine fouling was presented in [

76], covering all aspects of particle interaction with turbomachinery blading. A more recent review focusing on turbine fouling was presented in [

77]. However, both reviews focused on the mechanisms of fouling through particle interaction with the blading and not on the effect on performance characteristics.

An overview of deviation values obtained by different investigators is presented in

Table 4 and

Table 5. Variability can also be observed here, and comments similar to those for the compressor case apply.

6. Tip Clearance

The size of blade tip clearance is an important design feature that affects operating behavior, performance output, and fuel consumption ([

50]). It affects the magnitude of flow pressure loss and is usually desired to be as small as possible. Other requirements dictate larger sizes, however, such as the need to avoid rubs caused by differential expansion of blades and casing or having sufficient tolerance to avoid contact due to rotating assembly vibrations. During service, clearances may increase in the process of engine aging, but they may also suffer from accelerated deterioration due to factors such as erosion or even sudden modifications due to incidents such as blade-tip rub.

Investigations on the effects of tip clearance gap size on compressor and turbine performance appear early in the literature, since this gap is also a design feature of turbomachinery components. Computational efforts started as soon as CFD was applied to turbomachinery. Indicative of the importance of this type of computation is reference [

79], while modeling tip clearance effects in multi-stage environments is a current ability (e.g., [

80]).

An overview of deviation values obtained by different investigators is presented in

Table 6 and

Table 7. The comments made above for fouling also apply here.

A significant variability is observed in these tables, as was the case above for compressor fouling. Again, the way clearance increases may play a role, especially when a multi-stage environment is addressed.

The effect of tip clearance in turbines has also been investigated very early. Studies appeared as early as in 1969 [

86], when the effects of different tip clearances of a single-stage turbine were investigated and Deltas were reported. A summary of previous works was presented by Hourmouziadis in 1987 [

87], where efficiency drop was presented, with no mention of mass flow effect. An overview of deviation values obtained by different investigators is presented in

Table 8 and

Table 9, organized in the same way as the previous tables. Even though the matter has received considerable attention in design studies, not much has been published in terms of performance deviations from which fault ratios could be extracted.

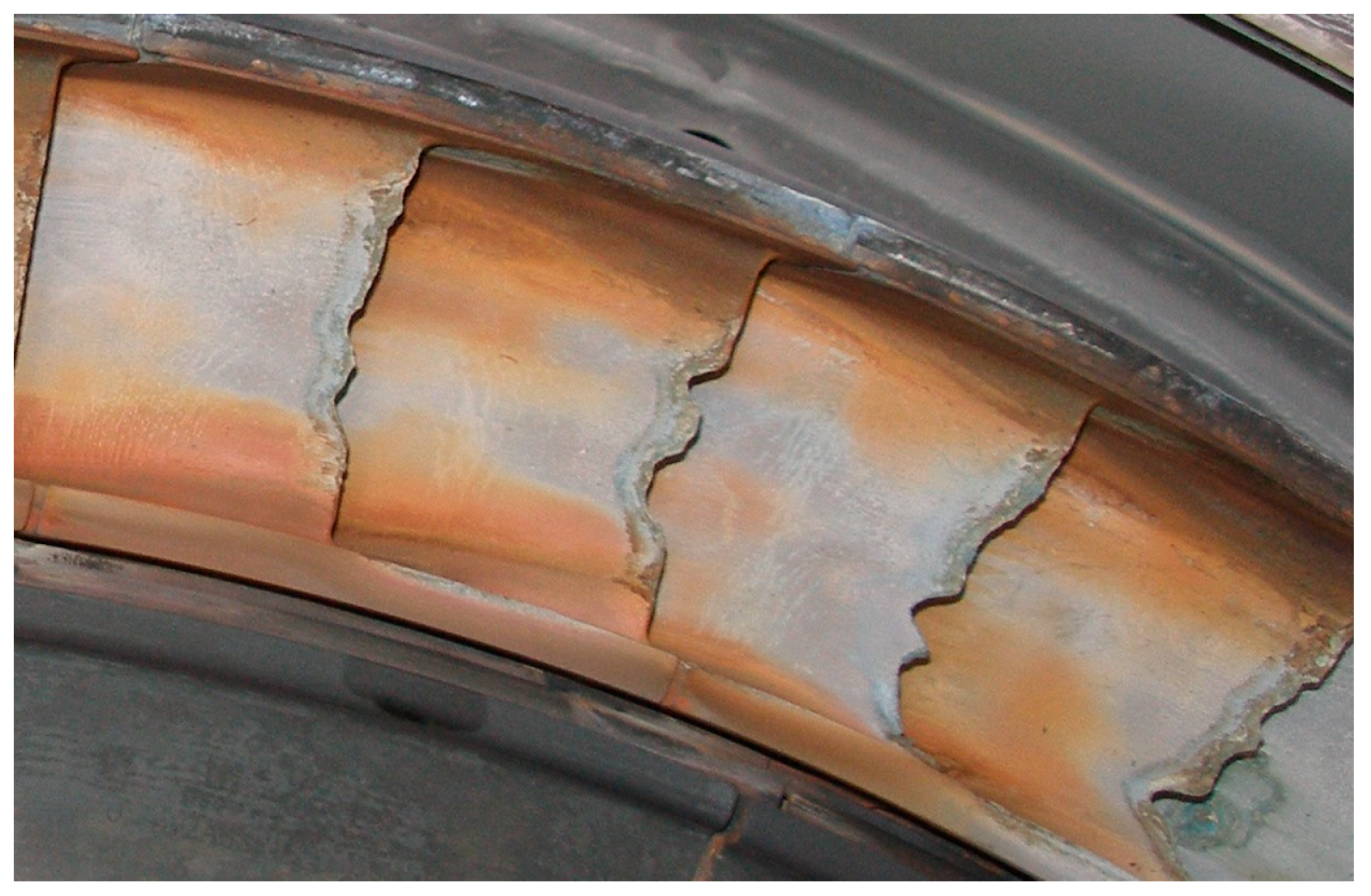

7. Erosion

Erosion is a type of abrasive wear in which solid particles flowing in the gas impact surfaces and wear engine parts. Erosion acts in two main ways on the blades. The first is by reducing their length by removing material from the blade tip, altering its shape and increasing the tip clearance. The second is by altering the shape and the surface roughness of the blade airfoils. The two effects are combined, leading to performance deterioration. Only a few publications have shown that the two mechanisms are separated. Usually, the effect of erosion is reported without distinguishing between the two.

It should be commented here that material loss can also be caused by chemical reaction of the blade surface with constituents or contaminants of the gas flowing through the engine. In this case, the wear is termed corrosion, and its effects are similar to those of erosion, even though the degree of influence may differ (

Figure 5).

Erosion can occur in gas turbine compressors and turbines ([

50]). Since the effects of the different mechanisms on compressor and turbine blades may widely differ and the location of the eroded parts of the components may vary, it becomes apparent that the effect on engine performance may be altered accordingly.

The mechanisms that contribute to the effects of erosion on turbomachinery blading and their influence on performance were thoroughly reviewed by Hamed et al. [

76], while the effects of deterioration due to operation in a particulate environment were reviewed earlier by Tabakof [

90]. Their group extensively studied particle trajectories and the subsequent erosion or deposition effects. Surface roughness effects were reviewed by Bons [

38], who provided some detailed information about the effect of erosion on blade surfaces. An early work that presented data from the operating experience of an aircraft engine manufacturer is that of Richardson et al. [

85]. Erosion effects were also included in a review of compressor fouling by Suman et al. [

37]. A very recent and extensive review of compressor erosion research focusing mainly on Russian studies was presented by Blinov et al. [

91]. The condition monitoring point of view was especially commented on.

A realistic approach for studying leading-edge erosion of fan blades was presented by Hergt et al. [

92]. Continuing efforts to conduct realistic studies of erosion problems in turbofan engines at DLR were also referenced in this study.

Deviation values obtained for compressor erosion by different investigators are presented in

Table 10 and

Table 11.

A very recent numerical study of the effect of turbine erosion on performance was presented by Zhang [

95]. It is indicative of what can be achieved today, even though the effects on performance are not in the form of fault ratios. In this case, not much has been published in terms of performance deviations from which fault ratios could be extracted.

An overview of deviation values obtained by different investigators for turbine erosion is presented in

Table 12 and

Table 13.

8. Variable Geometry System Faults

A variable geometry system is susceptible to faulty operation, which is desired to be detected as early as possible [

97]. A summary of possible malfunctions was provided by Hashmi et al. [

98]. They studied the effect and possibility of detecting faults in the placement of the entire set of blades of a variable stator due to drifts in the VGV schedule using an engine model. Variations on the compressor map were shown by presenting different maps for different schedules, but they were not expressed in terms of diagnostic indices. Deviations can be positive or negative for both mass flow and efficiency, depending on the direction of VGV drift. A similar result was obtained in tests performed on a twin-spool gas turbine on an LP compressor [

99]. Tests were also conducted by Cruz-Manzo et al. [

53,

100], who reported deviations in efficiency but not in mass flow. Studies of the problem have also been very recently presented, for example, by Zheng et al. [

101], who computed the performance of a four-stage low-pressure compressor when one of the IGVs was misplaced. Although they observed shifts in mass flow and efficiency, differences were of a small magnitude and could hardly be used to estimate fault ratios reliably. VGV faults on a single-spool test engine were also reported by Kim et al. [

102]. They observed flow capacity shifts that were larger than shifts in efficiency. The shifts showed some dependence on engine operating conditions.

Deviation values obtained by different investigators are presented in

Table 14 and

Table 15.

9. Blade Impact Damage (FOD and DOD)

When an object accidentally flowing through an engine impacts its blades, it damages them, altering their shape through deformation or loss of material (

Figure 6). When the object originates from the outside, typically, in the case of a compressor, the term foreign object damage (FOD) is used. Such objects can be birds, ice or hail, or solid objects that accidentally happen to be present close to the engine inlet. If the object originates from the engine itself, for example, loose mechanical parts that are detached, the term domestic object damage (DOD) is used. Impact damage of turbines is usually of this type.

FOD incidents and methods for their detection have been described in a number of publications. FOD identification is a current problem, and several methods have been proposed for this purpose, mostly unrelated to performance alterations [

50]. Recently, Voight et al. [

104] proposed such a method. In their paper, an account of recent efforts was also presented. Mishra et al. [

105] described the investigation of FOD in an aero gas turbine and presented the details of the conducted investigation to assess the extent of damage and its root cause. Hussin et al. [

106] discussed FOD and techniques to prevent it. Throughout this research, information related to FOD problems and their impact on the aviation industry was gathered and presented. Since FOD is an incident marked in time, instantaneous changes are used for its detection. Fusion of information from different sensors and processing methods is applied (e.g., Turso et al. [

107] and Strack et al. [

108]).

Performance deviations related to the loss of blade area due to FOD and blade rework were experimentally derived for a six-stage axial compressor by Schmücker and Schäffler [

25]. A fault ratio of about 1 was found (

Table 16). Developers of diagnostic methods use values such as those reported in

Table 17. It is worth noting that the authors of [

49] reported successful detection of compressor FOD from field data using the corresponding values in their diagnostic method.

Turbine blade damage cases have been much less frequently reported. A physical description of such damage, as well as its effect on turbine performance, was reported in [

53]. An example of damaged blading is shown in

Figure 7, while deviations in turbine health indices from four incidents are shown in

Table 18. It is observed that the fault ratios vary, depending on the incident. This is expected, since the irregularities caused by individual incidents are not necessarily of the same form or nature. What all four cases have in common is an increase in flow and a decrease in efficiency. Values that have been employed by developers of diagnostic methods are shown in

Table 19.

10. Discussion

Understanding fault ratios is crucial because their assumed values are fundamental to different types of diagnostic methods. Above, we pointed out many such methods [

19,

44,

48,

49,

51,

65,

66,

67,

68,

96]. Certain features of existing information have become apparent, and discussing them is useful to guide developers of diagnostic method, ensuring efficient implementation of the appropriate fault ratio values.

First, it was shown that even though faults are referenced through a simple designation such as “fouling”, ”erosion”, FOD, etc., the actual effect is not uniquely specified. A typical example is FOD, which refers to deformations of quite different forms, depending on the location, strength, and form of the impact that occurred. Variability can also be observed in other malfunctions, such as fouling, depending on the nature of deposits and their locations within the components.

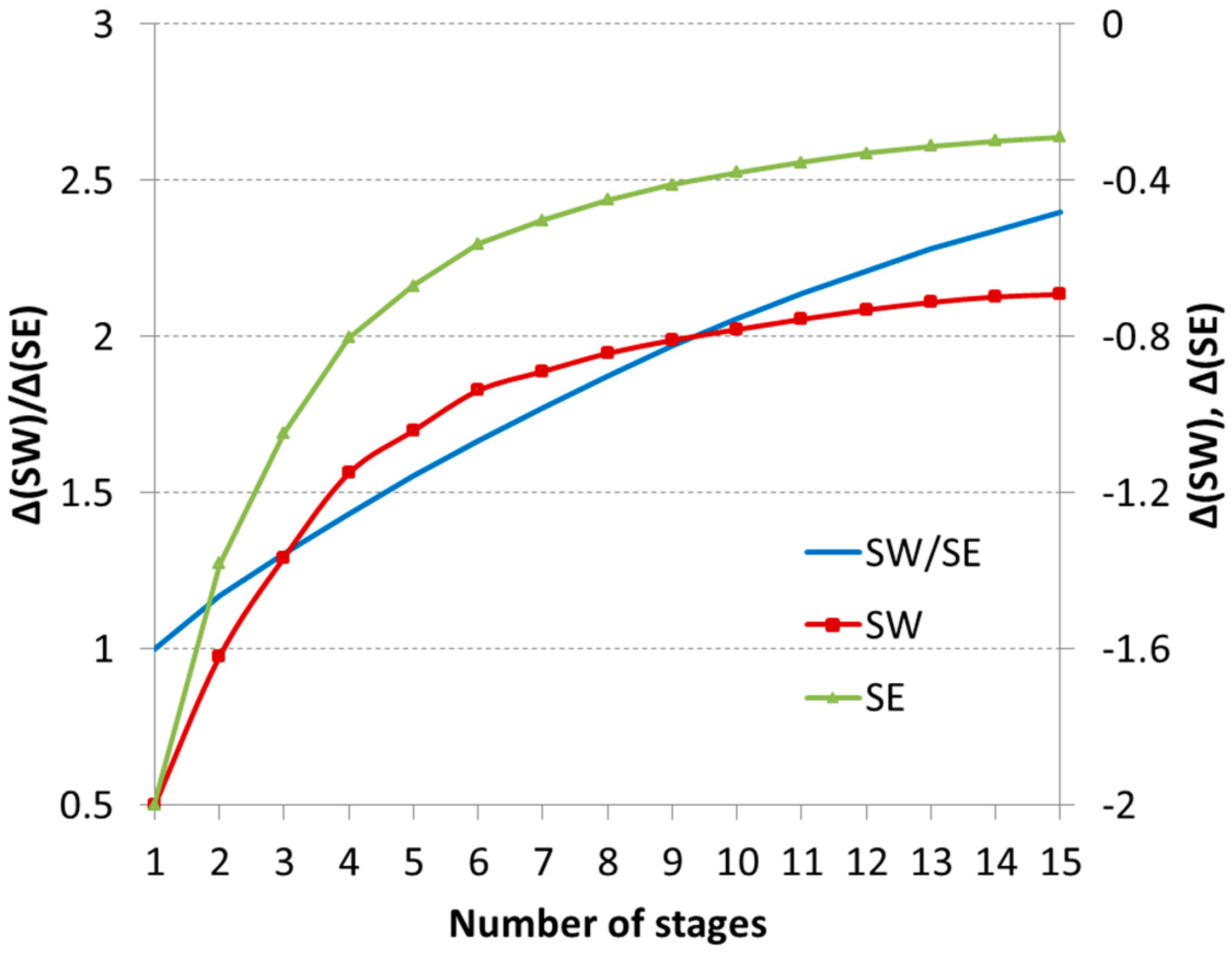

When referring to multi-stage axial compressors, an alteration happening in a stage or group of stages will have a different effect, depending on the location, whether the front or the rear of the compressor. This has already been observed by investigators in the past, but here, we demonstrate an example effect. The fault ratio of a multi-stage compressor containing one faulty stage with a fault pair (−2, −2) was evaluated and is shown in

Figure 8. The stage-stacking technique, as developed by the authors of [

109,

110], was used. The 15-stage multi-stage compressor presented in [

109] was used as a test case. It is observed that the compressor performance is characterized by a fault ratio of 2.4 when the faulty stage is the first one (something that would correspond to a case of fouling), and it drops to a value of 0.1 when the faulty stage is the last one (something that corresponds to erosion). Note that both situations come from a stage that suffers a fault with a fault ratio equal to 1.

The fact that a stage that forms a part of a multi-stage environment will produce a different fault ratio, depending on the total number of compressor stages, is demonstrated in

Figure 9. The fault ratio of different compressors, by combining the first and subsequent stages of the compressor of the previous case, is shown. This is a figure that corresponds to 15 compressors (the first one comprising one stage, the second one from two stages, the third one from three stages, etc.), with each set being a subset of the 15-stage case compressor. It is observed that while the single stage, which is the first stage of every compressor considered, has a fault ratio of 1, this ratio for the entire compressor increases with the number of stages that follow. For our example case, it starts from a value of 1, reaching 2.4 for a 15-stage compressor.

This observation may be useful in interpreting the variability of fault ratios observed in some cases presented in

Table 2.

A question arising in diagnostic methods development is the capability of precise fault identification. When gas path analysis-based methods are employed, this capability is linked to the distinction of signatures of the different malfunctions. For the specific case of the multi-stage compressor examined in [

47], for example, this distinction can occur as shown in

Figure 2. Examining the data of the tables presented above, however, it is observed that apart from the fact that each designated fault corresponds to a range of fault ratios, as already commented, overlapping of values also exists. It is interesting to observe that the fault ratios for three compressor faults that were reported in the early method proposed in [

51] were identical.

These results suggest that while qualitative trends are unique to different types of faults, their quantitative signatures must be specific to the particular case at hand. Conventional methods of deriving signatures through experimentation or analysis of fault incidents if and when they occur are no longer necessary. This is due to the emergence of a reliable alternative, namely the ability to perform accurate flow-field computations for virtually any geometry change within the gas path of an engine. With the computational abilities existing today, CFD can be used to produce signatures for specific engine components that represent the case of interest, and fault signatures that will certainly reflect that particular case will be produced. Researchers aware of this fact pay particular attention so that a representation matching the features for the case of interest is used (e.g., [

92]).

The present authors believe that a new horizon is emerging for determining fault ratio values through precise flow computations for gas path geometries modified by the occurrence of faults. Such studies enable not only the determination of values for specific gas turbines and faults but also the exploration of parameter interdependencies and the creation of rules for deriving signatures for engines with different characteristics and operating conditions.

11. Conclusions

This paper aimed to gather relevant information on how the most common aero-thermal faults of gas turbine compressors and turbines can be represented in terms of appropriate health parameters. Information was extracted from existing publications, either directly referenced or deduced by the present authors from results presented in the corresponding publications, typically component maps for healthy and faulty operation.

The choice and definition of appropriate health parameters and the use of their ratios, termed fault ratios here, for characterization of faults were discussed. Tables of values of parameters and fault ratios for individual faults were compiled. Existing literature was found to be much richer for the case of situations encountered in everyday operation, namely compressor fouling, while information for other faults was limited or even scarce.

The sources of information, namely test data or calculations, were commented upon, and it was pointed out that current-day computational fluid dynamics capabilities offer an attractive means of producing fault signatures.

The variability of signatures for the same fault, as well as for different faults, was discussed, and ways of interpreting it for multi-stage compressor environments were presented. It was commented that even though a general term can be used for one type of faulty condition, it can correspond to different actual physical situations, leading to the observed variability.

A final conclusion is that when a diagnostic method is set up for a particular gas turbine, although published information is a useful guideline for establishing fault signatures, the features of the particular test case should be taken into account, and corresponding signatures should be used. Computational methods existing today offer a valuable tool for establishing such information.