Importance of Fluid/Fluid Interactions in Enhancing Oil Recovery by Optimizing Low-Salinity Waterflooding in Sandstones

Abstract

1. Introduction

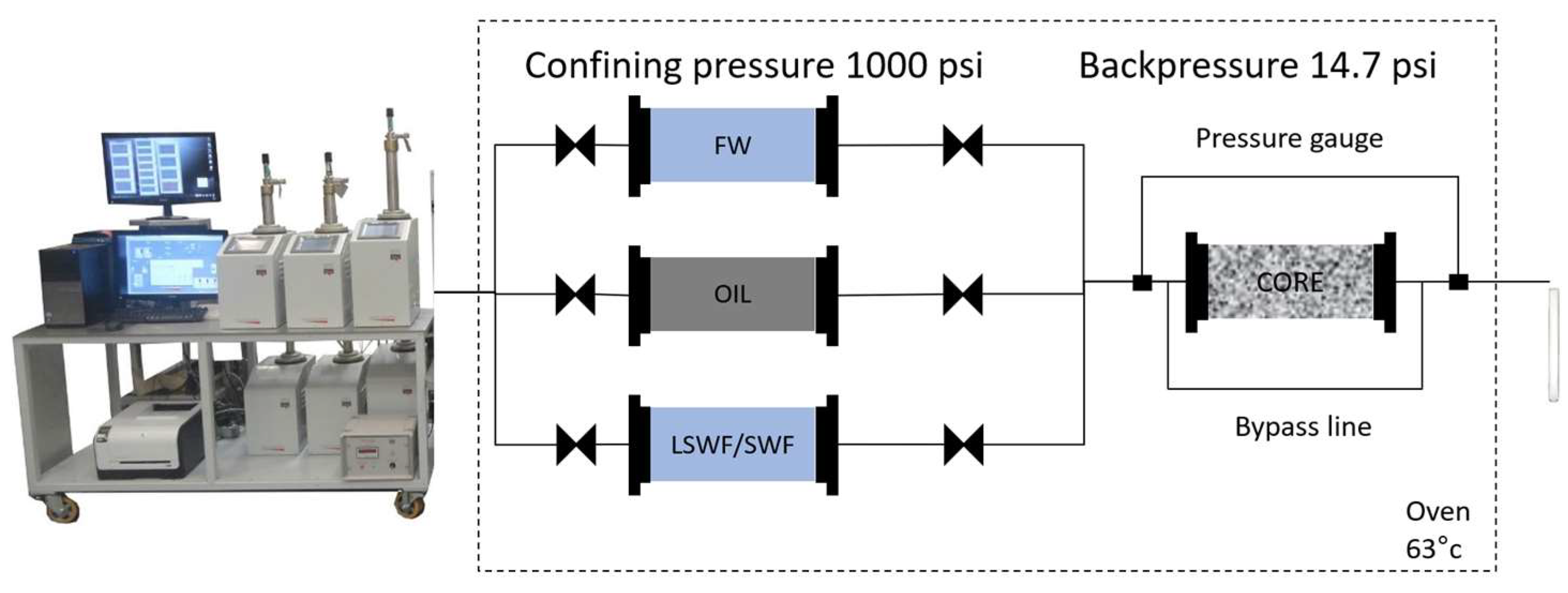

2. Materials and Methods

2.1. Fluids and Rock

2.2. Experiments Methodology

- = Porous volume.

- = Total produced water volume during oil flooding stage.

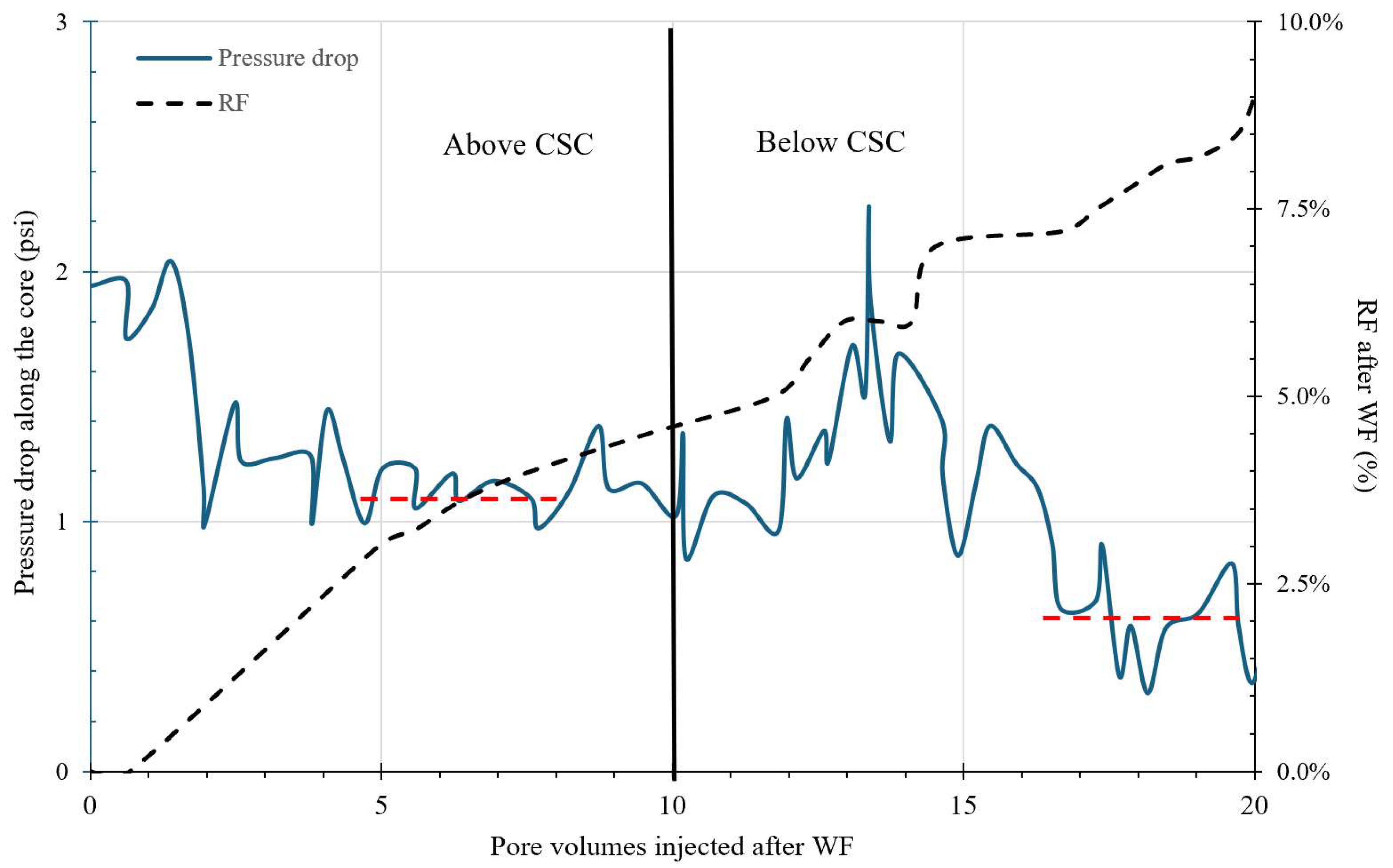

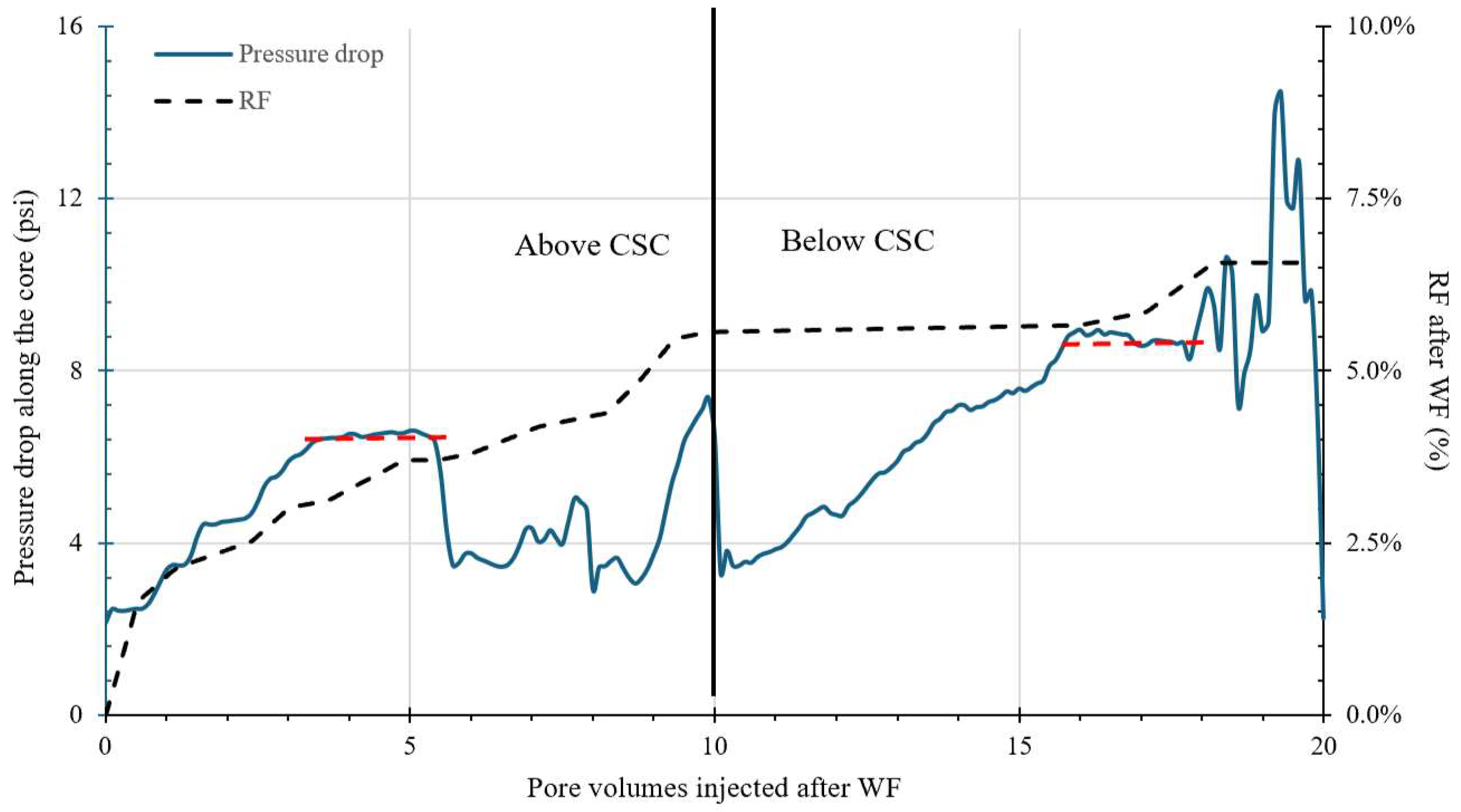

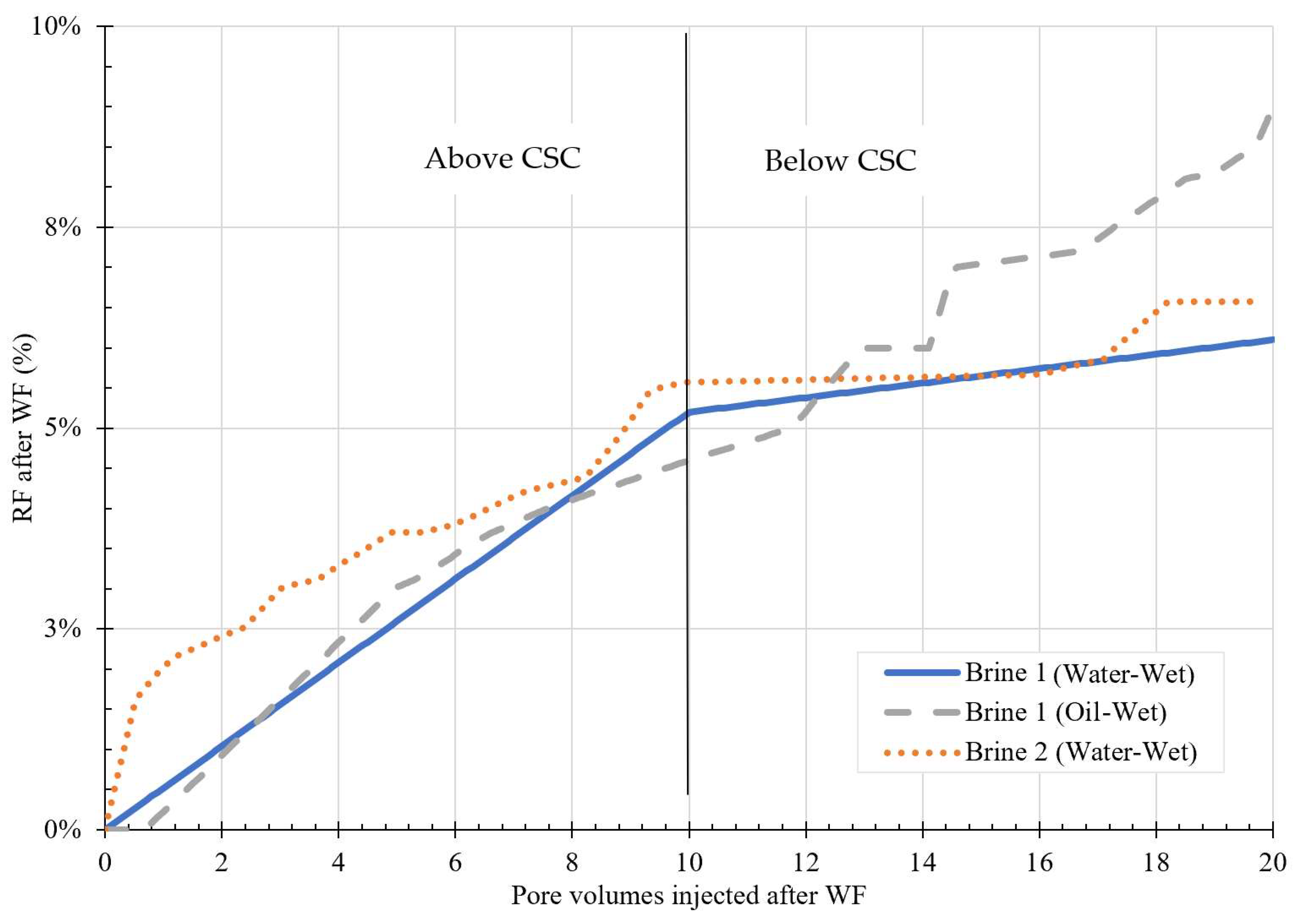

3. Results and Discussion

4. Conclusions

- Wettability alteration was found to be the most effective mechanism, leading to enhanced oil recovery even in cases where fluid/fluid interactions were negligible. For the oil-wet case, 40% recovery was observed, which was more than the 25% recovery in the water-wet state.

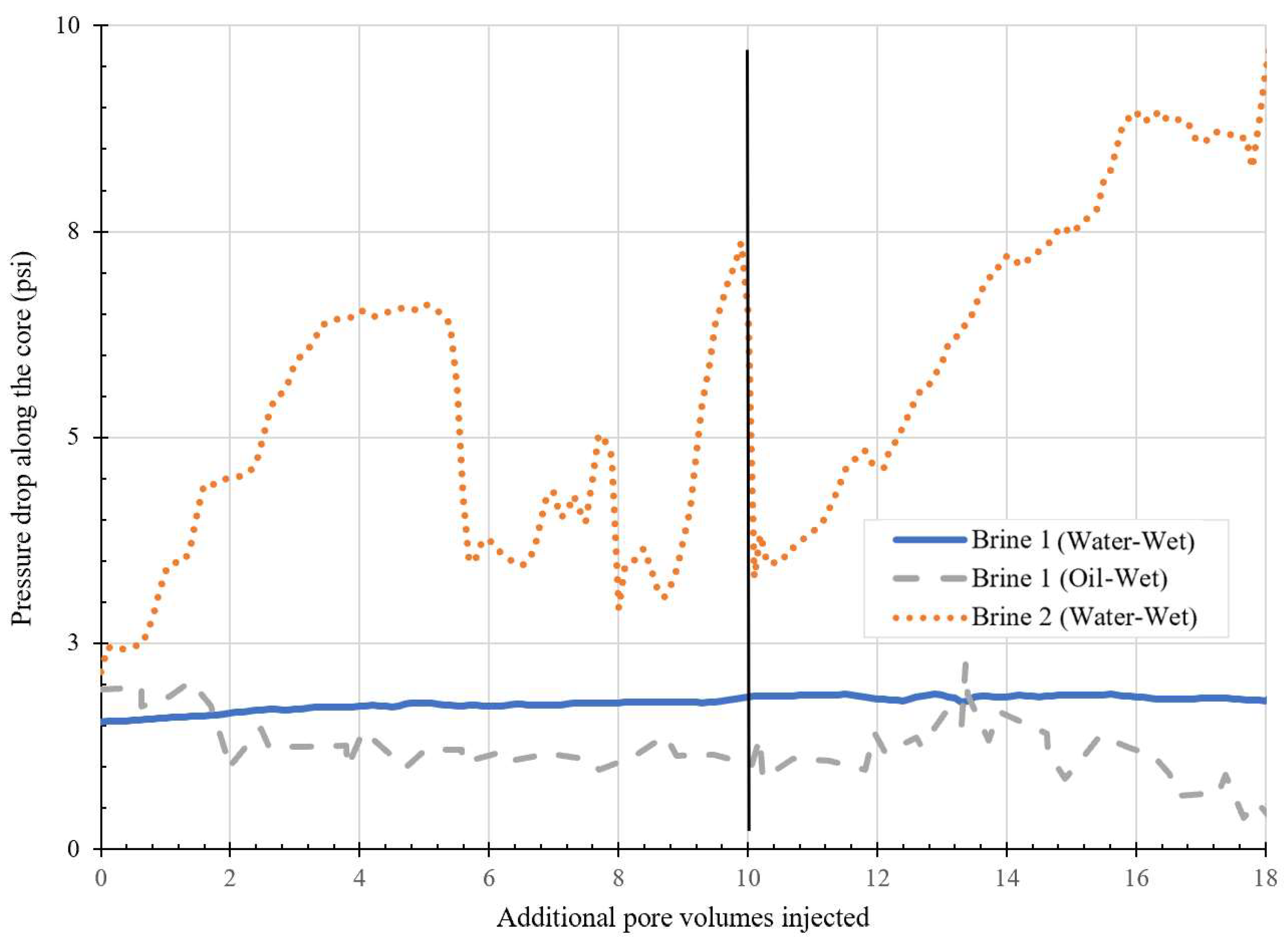

- In water-wet cores, optimizing the injection brine to activate fluid/fluid mechanisms led to a high recovery factor due to the enhanced elasticity of the interface and the formation of micro-dispersions. This was confirmed by the change in pressure drop and mobility.

- Fluid diversion due to fines migration is not a strong mechanism during LSWF/SWF and cannot be considered the dominant reason for incremental oil production below the CSC in water-wet sandstones.

- The MRF results indicated that the sulfate content in the brine significantly influenced the stability of the interface by reducing snap-off, which is particularly beneficial for high-paraffin-content oil in sandstones.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Morrow, N.R. Comparison of Secondary and Tertiary Recovery with Change in Injection Brine Composition for Crude Oil/Sandstone Combinations. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2006. [Google Scholar] [CrossRef]

- Rivet, S.M.; Lake, L.W.; Pope, G.A. A Coreflood Investigation of Low-Salinity Enhanced Oil Recovery. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar] [CrossRef]

- Rock, A.; Hincapie, R.E.; Hoffmann, E.; Ganzer, L. Tertiary Low Salinity Waterflooding LSWF in Sandstone Reservoirs: Mechanisms, Synergies and Potentials in EOR Applications. In Proceedings of the SPE Europec Featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018. [Google Scholar] [CrossRef]

- Austad, T. Chapter 13—Water-Based EOR in Carbonates and Sandstones: New Chemical Understanding of the EOR Potential Using “Smart Water”. In Enhanced Oil Recovery Field Case Studies; Sheng, J.J., Ed.; Gulf Professional Publishing: Oxford, UK, 2013; pp. 301–335. [Google Scholar] [CrossRef]

- Austad, T.; RezaeiDoust, A.; Puntervold, T. Chemical Mechanism of Low Salinity Water Flooding in Sandstone Reservoirs. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. SPE-129767-MS. [Google Scholar] [CrossRef]

- Nguyen, N.; Dang, C.; Gorucu, S.E.; Nghiem, L.; Chen, Z. The role of fines transport in low salinity waterflooding and hybrid recovery processes. Fuel 2020, 263, 116542. [Google Scholar] [CrossRef]

- Takeya, M.; Shimokawara, M.; Elakneswaran, Y.; Nawa, T.; Takahashi, S. Predicting the electrokinetic properties of the crude oil/brine interface for enhanced oil recovery in low salinity water flooding. Fuel 2019, 235, 822–831. [Google Scholar] [CrossRef]

- Wang, X.; Liu, W.; Shi, L.; Zou, Z.; Ye, Z.; Wang, H.; Han, L. A comprehensive insight on the impact of individual ions on Engineered Waterflood: With already strongly water-wet sandstone. J. Pet. Sci. Eng. 2021, 207, 109153. [Google Scholar] [CrossRef]

- Salehpour, M.; Riazi, M.; Malayeri, M.R.; Seyyedi, M. CO2-saturated brine injection into heavy oil carbonate reservoirs: Investigation of enhanced oil recovery and carbon storage. J. Pet. Sci. Eng. 2020, 195, 107663. [Google Scholar] [CrossRef]

- Tagavifar, M.; Jang, S.H.; Chang, L.; Mohanty, K.; Pope, G. Controlling the composition, phase volume, and viscosity of microemulsions with cosolvent. Fuel 2017, 211, 214–222. [Google Scholar] [CrossRef]

- Patil, S.; Dandekar, A.; Patil, S.; Khataniar, S. Low Salinity Brine Injection for EOR on Alaska North Slope (ANS). In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 3–5 December 2008. [Google Scholar] [CrossRef]

- Law, S.; Sutcliffe, P.; Fellows, S. Secondary Application of Low Salinity Waterflooding to Forties Sandstone Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar] [CrossRef]

- Nasralla, R.A.; Alotaibi, M.B.; Nasr-El-Din, H.A. Efficiency of Oil Recovery by Low Salinity Water Flooding in Sandstone Reservoirs. In Proceedings of the SPE Western North American Region Meeting, Anchorage, AK, USA, 7–11 May 2011. [Google Scholar] [CrossRef]

- Romero, M.I.; Gamage, P.; Jiang, H.; Chopping, C.; Thyne, G. Study of low-salinity waterflooding for single- and two-phase experiments in Berea sandstone cores. J. Pet. Sci. Eng. 2013, 110, 149–154. [Google Scholar] [CrossRef]

- Garcia-Olvera, G.; Alvarado, V. Interfacial rheological insights of sulfate-enriched smart-water at low and high-salinity in carbonates. Fuel 2017, 207, 402–412. [Google Scholar] [CrossRef]

- Mohamed, M.I.; Alvarado, V. Smart Water Flooding in Berea Sandstone at Low Temperature: Is Wettability Alteration the Sole Mechanism at Play? In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar] [CrossRef]

- Smith, E.R.; Medina-Rodríguez, B.X.; Alvarado, V. Influence of interfacial responses of Berea Sandstone in low-salinity waterflooding environments. Fuel 2022, 311, 121712. [Google Scholar] [CrossRef]

- Al-Nofli, K.; Pourafshary, P.; Mosavat, N.; Shafiei, A. Effect of Initial Wettability on Performance of Smart Water Flooding in Carbonate Reservoirs—An Experimental Investigation with IOR Implications. Energies 2018, 11, 1394. [Google Scholar] [CrossRef]

- Villero-Mandon, J.; Pourafshary, P.; Riazi, M. Oil/Brine Screening for Improved Fluid/Fluid Interactions during Low-Salinity Water Flooding. Colloids Interfaces 2024, 8, 23. [Google Scholar] [CrossRef]

- Bidhendi, M.M.; Garcia-Olvera, G.; Morin, B.; Oakey, J.S.; Alvarado, V. Interfacial Viscoelasticity of Crude Oil/Brine: An Alternative Enhanced-Oil-Recovery Mechanism in Smart Waterflooding. SPE J. 2018, 23, 803–818. [Google Scholar] [CrossRef]

- Chai, R.; Liu, Y.; He, Y.; Cai, M.; Zhang, J.; Liu, F.; Xue, L. Effects and Mechanisms of Acidic Crude Oil–Aqueous Solution Interaction in Low-Salinity Waterflooding. Energy Fuels 2021, 35, 9860–9872. [Google Scholar] [CrossRef]

- Tang, G.Q.; Morrow, N.R. Influence of brine composition and fines migration on crude oil brine rock interactions and oil recovery. J. Pet. Sci. Technol. 1999, 24, 99–111. [Google Scholar] [CrossRef]

- Harvey, D. 2.2: Concentration. Chemistry LibreTexts. 15 June 2020. Available online: https://chem.libretexts.org/Courses/Montana_State_University/MSU%3A_CHMY311_Fundamental_Analytical_Chemistry/02%3A_Basic_Tools_of_Analytical_Chemistry/2.02%3A_Concentration (accessed on 27 June 2024).

- Research Triangle Park. ‘Amount Concentration’ in IUPAC Compendium of Chemical Terminology, 3rd ed.; International Union of Pure and Applied Chemistry: Research Triangle Park, NC, USA, 2006. [Google Scholar]

- Shakeel, M.; Samanova, A.; Pourafshary, P.; Hashmet, M.R. Optimization of Low Salinity Water/Surfactant Flooding Design for Oil-Wet Carbonate Reservoirs by Introducing a Negative Salinity Gradient. Energies 2022, 15, 9400. [Google Scholar] [CrossRef]

- Muneer, R.; Pourafshary, P.; Rehan Hashmet, M. An integrated modeling approach to predict critical flow rate for fines migration initiation in sandstone reservoirs and water-bearing formations. J. Mol. Liq. 2023, 376, 121462. [Google Scholar] [CrossRef]

- Kakati, A.; Jha, N.K.; Kumar, G.; Sangwai, J.S. Application of Low Salinity Water Flooding for Light Paraffinic Crude Oil Reservoir. In Proceedings of the SPE Symposium: Production Enhancement and Cost Optimisation, Kuala Lumpur, Malaysia, 7–8 November 2017. [Google Scholar] [CrossRef]

- Thyne, G.; Gamage, P. Evaluation of the Effect of Low Salinity Waterflooding for 26 Fields in Wyoming. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar] [CrossRef]

| Oil | Density (g/cc) | Kinematic Viscosity (cst) | Dynamic Viscosity (cP) |

|---|---|---|---|

| oil sample | 0.8225 | 11.4 | 9.41 |

| @ 11,500 ppm | @ 8500 ppm | @ 1000 ppm | |||||

|---|---|---|---|---|---|---|---|

| Type of Brine | Brine Composition | Molarity (M) | Density (g/cc) | Molarity (M) | Density (g/cc) | Molarity (M) | Density (g/cc) |

| Brine 1 | 100% NaCl | 0.33 | 1.0038 | 0.29 | 1.0028 | 0.22 | 1.002 |

| Brine 2 | 50% Na2SO4, 25% MgCl2 6H2O 25% NaCl | 0.57 | 1.0027 | 0.53 | 1.0019 | 0.47 | 1.001 |

| Ions | Concentration (ppm) |

|---|---|

| Na+, K+ | 81,600 |

| Ca2+ | 9540 |

| Mg2+ | 1470 |

| Cl− | 90,370 |

| Total | 182,980 |

| Core | L (cm) | D (cm) | Φ (%) | Kgas (mD) | |

|---|---|---|---|---|---|

| 1 | 7.70 | 3.80 | 19.5 | 339.9 | 28 |

| 2 | 7.57 | 3.80 | 21.8 | 329.9 | 35 |

| 3 | 7.50 | 3.81 | 21.0 | 349.9 | 24 |

| Initial Wettability | Core Used | Brine Used | LSW Injection Stage 1 | LSW Injection Stage 2 | LSW Injection Stage 3 |

|---|---|---|---|---|---|

| Water-wet | Core 1 | Brine 1 | 11,500 ppm | 8500 ppm | 1000 ppm |

| Oil-wet | Core 2 | Brine 1 | 11,500 ppm | 8500 ppm | 1000 ppm |

| Water-wet | Core 3 | Brine 2 | 11,500 ppm | 8500 ppm | 1000 ppm |

| Mechanism at Play | |||

|---|---|---|---|

| Studied Scenarios | Type of Ions | Above CSC (8500 ppm) | Below CSC (1000 ppm) |

| Water-wet (Core 1) | Brine 1 | Fluid/fluid (weak) | Fluid/fluid (weak) + fines migration (strong) |

| Oil-wet (Core 2) | Brine 1 | Fluid/fluid (weak) + wettability alteration (strong) | Fluid/fluid (weak) + wettability alteration (strong) + fines migration (strong) |

| Water-wet (Core 3) | Brine 2 | Fluid/fluid (strong) | Fluid/fluid (strong) + fines migration (strong) |

| RF after WF (%) | |||

|---|---|---|---|

| Studied Scenarios | Type of Ions | Above CSC | Below CSC |

| Water-wet | Brine 1 | 5.2 | 0.9 |

| Oil-wet | Brine 1 | 5.0 | 4.0 |

| Water-wet | Brine 2 | 5.8 | 1.1 |

| MRF | ||

|---|---|---|

| Studied Scenarios | Above CSC | Below CSC |

| Brine 1 | 1.14 | 1.23 |

| Brine 2 | 1.52 | 1.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villero-Mandon, J.; Askar, N.; Pourafshary, P.; Riazi, M. Importance of Fluid/Fluid Interactions in Enhancing Oil Recovery by Optimizing Low-Salinity Waterflooding in Sandstones. Energies 2024, 17, 3315. https://doi.org/10.3390/en17133315

Villero-Mandon J, Askar N, Pourafshary P, Riazi M. Importance of Fluid/Fluid Interactions in Enhancing Oil Recovery by Optimizing Low-Salinity Waterflooding in Sandstones. Energies. 2024; 17(13):3315. https://doi.org/10.3390/en17133315

Chicago/Turabian StyleVillero-Mandon, Jose, Nurzhan Askar, Peyman Pourafshary, and Masoud Riazi. 2024. "Importance of Fluid/Fluid Interactions in Enhancing Oil Recovery by Optimizing Low-Salinity Waterflooding in Sandstones" Energies 17, no. 13: 3315. https://doi.org/10.3390/en17133315

APA StyleVillero-Mandon, J., Askar, N., Pourafshary, P., & Riazi, M. (2024). Importance of Fluid/Fluid Interactions in Enhancing Oil Recovery by Optimizing Low-Salinity Waterflooding in Sandstones. Energies, 17(13), 3315. https://doi.org/10.3390/en17133315