Study on the Pore Structure Characterization of the Limestone Reservoir of the Taiyuan Formation in the Ordos Basin

Abstract

1. Introduction

2. Research Methods

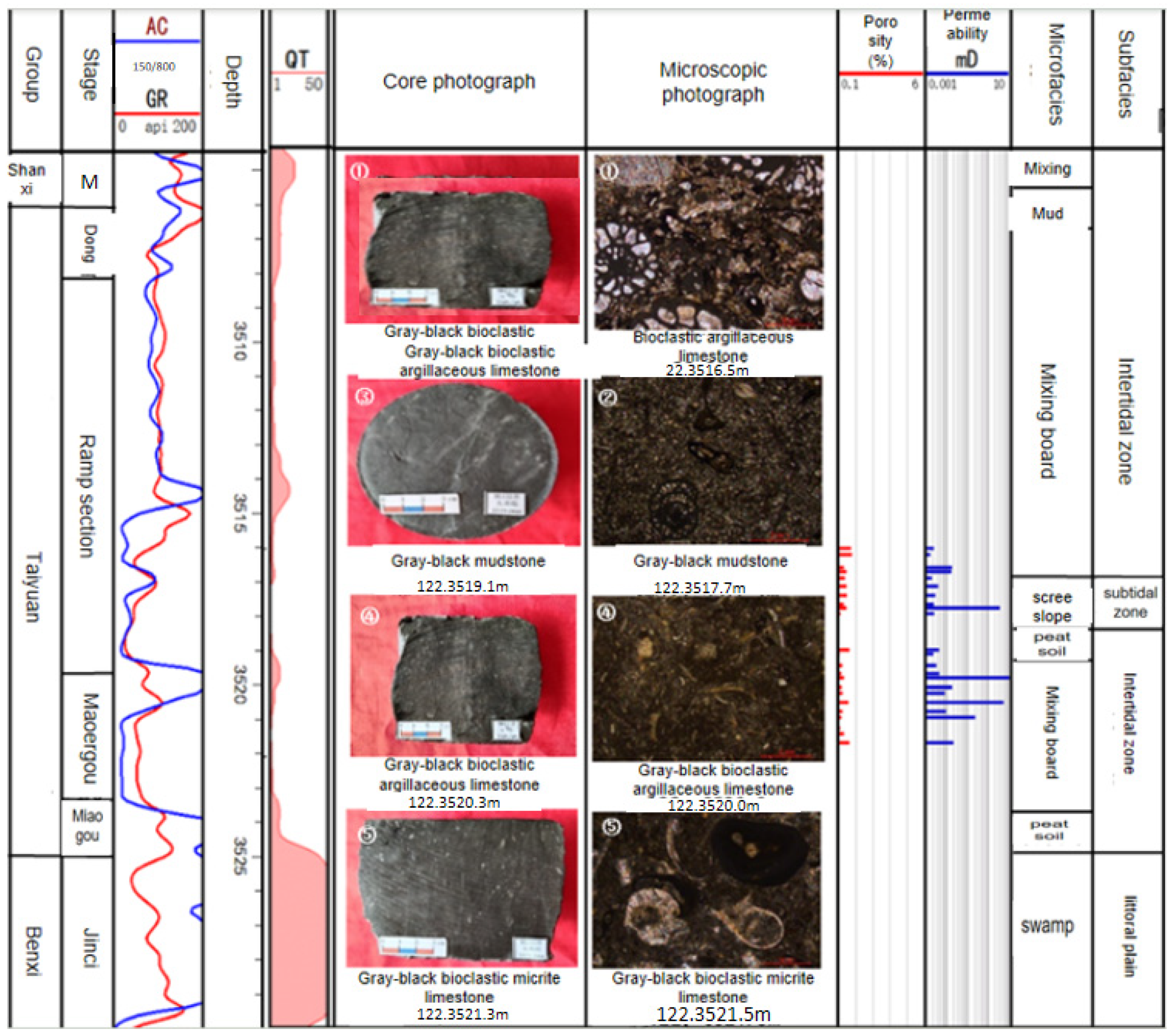

2.1. Geological Characteristics of the Study Area

2.2. Sample Preparation

2.3. Experimental Methods

- Thirty core samples with a smooth surface and no obvious defects were seletced, dried, and then vacuumed and pressurized to saturate the simulated formation water.

- The representative standard cores were tested using a Niumag Micro MR23-060H-1 nuclear magnetic resonance instrument (Niumag, Tianjin, China). The instrument frequency was set to 21 MHz, the magnetic field intensity was set to 0.5 T, the working temperature was kept at 30 °C, and the T2 spectrum was measured. During the test, the echo time was set to 0.07 ms, the number of scans was set to 32, and the echo number was 6000.

- The limestone sample was placed into a nuclear magnetic resonance instrument for testing and the nuclear magnetic resonance signal of the sample was obtained [17].

- After testing the nuclear magnetic resonance signal, signal enhancement, denoising, inversion, and other processes were carried out to extract the internal pore size distribution information of the sample.

- By analyzing the pore size distribution results, the pore size distribution characteristics of the limestone samples were evaluated.

- Select representative limestone samples with smooth surfaces and no obvious defects, cut them into 5 cm long samples, and place them in the sample cavity of the CT scanner.

- Adjust the position of the sample on the stage; turn on the X-ray source to detect and receive X-rays after absorption and attenuation; and rotate, transmit, and save the scanned two-dimensional image information. A two-dimensional slice of the test sample is obtained by each scan. By precisely rotating the stage, the sample is rotated at a small angle, and the previous scanning experiment is repeated many times until the 360 rotation and scanning are completed and the three-dimensional information of the entire sample is obtained.

- Using the GOM Volume Inspect software of a GOM Volume Inspect (ZEISS INSPECT X-ray, ZEISS, Oberkochen, Germany), the 3D image is generated by reconstructing the scanned original data. Select the appropriate reconstruction algorithm and filter to improve the image resolution. In this paper, in the process of image filtering and binarization, a sliding window was constructed, which was set to 5 pixels. When the window is in a certain position in the image, the pixel gray values are 50, 80, 100, 150, and 200, and the gray value of the window center is 100. After median filtering, the errors caused by system noise are eliminated. After filtering, the two-dimensional image is binarized, and the image only retains the skeleton and the hole [18].

- Use image analysis software to analyze the reconstructed 3D image, choose manual or automatic methods to identify and quantify the pores in limestone, determine the boundaries of the pores according to the gray value of the image, and calculate the porosity.

3. Experimental Results

3.1. Limestone Porosity Saturation State

3.2. NMR Aperture Distribution Characteristics

3.3. X-ray CT Scanning Aperture Distribution Characteristics

4. Conclusions

- (1)

- The accuracy of gas porosity measurement is based on the thermodynamic equilibrium of gas inside and outside the pore. During the thermodynamic experiment, the porosity of the sample will remain basically unchanged after 180 min. After 4 h of the experiment, the pressure in the sample was measured, and no gas leakage was found, indicating that the sample had reached the porosity saturation state.

- (2)

- The T2 spectrum of saturated marlite is in the form of three peaks, two peaks, and one peak. On the whole, the p1 peak of the T2 spectrum of limestone corresponds to micropores, and most of the p2 and p3 peaks correspond to mesopores–macropores. The average pore size of limestone is 120.86 nm, and the pore size of 10–300 nm is the highest, reaching 85.91%. The pore size of high-porosity samples is 150–350 nm, and the micropores are well developed. The pore size of medium porosity samples is 80–150 nm, and some samples are well developed. The pore size of low-porosity samples is mostly bimodal, with two peaks >> 300 nm and <<100 nm.

- (3)

- Through X-ray CT scanning, the reconstructed three-dimensional images were analyzed using image analysis software, and the pore distribution, pore characteristics, fractal dimension, and tortuosity characteristics of the different samples were obtained. With the increase in depth, the overall porosity decreases gradually, the fractal dimension decreases, and the tortuosity increases continuously.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kong, L.; Yin, Z.; Chen, Y.; Dong, Z.; Xu, J. Pore Structure Evolution and Failure Mechanism of Limestone in the Taiyuan Formation of the Ordos Basin under High Temperature. ACS Omega 2024, 9, 10177–10189. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Gui, H.; Wei, J.; Pang, Y.; Hu, M.; Zhang, Z.; Nie, F.; Hong, H.; Cui, Y.; Zhao, J. Hydrogeochemical evolution of Taiyuan Formation limestone water under the disturbance of water inrush from karst collapse column in Taoyuan Coal Mine, China. Water Supply 2022, 22, 8196–8210. [Google Scholar] [CrossRef]

- Lv, D.; Fan, W.; Ejembi, J.I.; Wu, D.; Wang, D.; Li, Z.; Li, J.; Li, P. Depositional environments of limestones from the Taiyuan Formation in the North China Block interpreted from REE proxies. Carbonates Evaporites 2020, 35, 363–372. [Google Scholar] [CrossRef]

- Wang, M.; Gui, H.; Hu, R.; Zhao, H.; Li, J.; Yu, H.; Fang, H. Hydrogeochemical Characteristics and Water Quality Evaluation of Carboniferous Taiyuan Formation Limestone Water in Sulin Mining Area in Northern Anhui, China. Int. J. Environ. Res. Public Health 2019, 16, 2512. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Gui, H. The geochemical (alkaline earth) characteristics of groundwater in the Taiyuan Formation limestone aquifer in Huaibei coalfield. Water Pract. Technol. 2019, 14, 217–228. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, G.; Sun, R.; Tang, Q.; Wu, D.; Wu, B.; Zhou, C. Geochemistry of rare earth elements in groundwater from the Taiyuan Formation limestone aquifer in the Wolonghu Coal Mine, Anhui province, China. J. Geochem. Explor. 2023, 135, 54–62. [Google Scholar] [CrossRef]

- Zhang, Z.; Lv, D.; Hower, J.C.; Wang, L.; Shen, Y.; Zhang, A.; Xu, J.; Gao, J. Geochronology, mineralogy, and geochemistry of tonsteins from the Pennsylvanian Taiyuan Formation of the Jungar Coalfield, Ordos Basin, North China. Int. J. Coal Geol. 2023, 267, 104183. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, Q.; Wu, C.; Qiu, Z.; Zhang, Q.; Wang, Y.; Liu, D.; Dong, D.; Zhou, S. Pore structures of the lower Permian Taiyuan shale and limestone in the Ordos Basin and the significance to unconventional natural gas generation and storage. Geofluids 2022, 2022, 3156547. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, L.; Zhao, Q.; Qiu, Z.; Liu, D.; Zhang, Q.; Wang, Y.; Dong, D. Reservoir characteristics of the lower permian marine-continental transitional shales: Example from the Shanxi Formation and Taiyuan Formation in the Ordos Basin. Geofluids 2021, 2021, 9373948. [Google Scholar] [CrossRef]

- Dong, G.; Liu, X.; Yin, L.; Fu, X.; Song, J.; Zhao, X.; Pei, W. Development characteristics and genetic analysis of dense limestone reservoirs in the Taiyuan Formation of the Ordos Basin, China. J. Nat. Gas Geosci. 2023, 8, 307–317. [Google Scholar] [CrossRef]

- Yin, J.; Hu, P.; Guo, Y.; Li, Y.; Luo, S. Petrological Characteristics and Hydrocarbon Generation of Carbonate Source Rocks of the Permian Taiyuan Formation in Central and Eastern Ordos Basin, China. Minerals 2023, 13, 1058. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Shen, Y.; Ji, W.; Wang, Q. Rock fabric of tight sandstone and its influence on irreducible water saturation in Eastern Ordos Basin. Energy Fuels 2023, 37, 3685–3696. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, D.; Qiu, Z.; Wu, C.; Zhang, Q.; Wang, Y.; Liu, D.; Deng, Z.; Zhou, S.; Pan, S. Sedimentology and geochemistry of Carboniferous-Permian marine-continental transitional shales in the eastern Ordos Basin, North China. Palaeogeogr. Palaeoclimatol. Palaeoecol. 2021, 571, 110389. [Google Scholar] [CrossRef]

- Liu, H.; Li, X.; Ma, Y.; Bai, Y.; Huang, J. The unconformity caused by the Huaiyuan movement and the deep natural gas exploration field in the Ordos Basin, China. Nat. Gas Ind. B 2021, 8, 539–551. [Google Scholar] [CrossRef]

- Shi, L.; Liu, T.; Zhang, X.; Huang, J.; Zhang, W.; Zhao, S. Origin type and generating mechanism of coal measure limestone gas: A case study of L1 limestone gas in the Taiyuan formation of the Shenzhou coal mine, Eastern edge of the ordos basin, China. Energy Fuels 2020, 34, 10904–10914. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Wu, P.; Meng, S. Paleoenvironment reconstruction of the upper Paleozoic in the Linxing area, northeastern Ordos Basin, China. AAPG Bull. 2021, 105, 2545–2574. [Google Scholar] [CrossRef]

- Li, G.; Qin, Y.; Shen, J. Geochemical characteristics of the Upper Paleozoic coal series shale in the Linxing area, Ordos Basin, China: Implications for paleoenvironment, provenance, and tectonic setting. Arab. J. Geosci. 2021, 14, 197. [Google Scholar] [CrossRef]

- Zhu, P.; Meng, X.; Wang, X.; Dong, Y.; Li, X.; Zhang, C.; Li, Z.; Ma, T.; Wei, W.; Guo, J. Geochemical characteristics of diagenetic fluid and densification model of tight gas sandstone reservoirs in Linxing area, eastern margin of Ordos Basin, China. Mar. Pet. Geol. 2022, 138, 105496. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, Y.; Wang, G.; Zhang, T.; He, W.; Ma, X.; Yu, X. Enrichment mechanism of the Upper Carboniferous-Lower Permian transitional shale in the east margin of the Ordos Basin, China: Evidence from geochemical proxies. Geofluids 2020, 2020, 8867140. [Google Scholar] [CrossRef]

- Deng, J.; Zeng, H.; Wu, P.; Du, J.; Gao, J.; Zhao, F.; Jiang, Z. Pore structure differentiation between deltaic and epicontinental tight sandstones of the upper Paleozoic in the eastern linxing area, ordos basin, China. Geofluids 2021, 2021, 9015041. [Google Scholar] [CrossRef]

- Yin, S.; Tian, T.; Wu, Z. Developmental characteristics and distribution law of fractures in a tight sandstone reservoir in a low-amplitude tectonic zone, eastern Ordos Basin, China. Geol. J. 2020, 55, 1546–1562. [Google Scholar] [CrossRef]

| Core Number | Number | Length (cm) | Diameter (cm) | Porosity (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 min | 15 min | 30 min | 60 min | 120 min | 180 min | 300 min | 420 min | ||||

| 3-49/55 | 3 | 3.61 | 2.51 | 1.17 | 1.22 | 1.32 | 1.45 | 1.64 | 1.72 | 1.77 | |

| 3-10/55 | 4 | 5.36 | 2.51 | 1.75 | 1.82 | 1.93 | 2.05 | 2.20 | 2.27 | 2.30 | |

| 3-36/55 | 5 | 2.68 | 2.51 | 1.71 | 1.82 | 1.94 | 2.13 | 2.28 | 2.38 | 2.43 | |

| 3-50/55 | 6 | 3.20 | 2.52 | 2.96 | 3.11 | 3.29 | 3.53 | 3.92 | 4.03 | 4.11 | |

| 4-35/50 | 7 | 5.48 | 2.51 | 0.62 | 0.68 | 0.80 | 0.97 | 1.25 | 1.35 | 1.39 | |

| 1-26/68 | 8 | 5.09 | 2.51 | 1.30 | 1.37 | 1.43 | 1.60 | 1.78 | 1.85 | 1.90 | |

| 1-35/68 | 9 | 5.61 | 2.51 | 1.68 | 1.78 | 1.92 | 2.09 | 2.19 | 2.27 | 2.32 | |

| 1-21/52 | 22 | 3.47 | 2.52 | 1.12 | 1.32 | 1.58 | 2.02 | 2.44 | 2.66 | 2.81 | 2.94 |

| 1-36/52 | 23 | 3.62 | 2.51 | 1.04 | 1.15 | 1.33 | 1.68 | 2.25 | 2.45 | 2.52 | |

| 1-43/52 | 25 | 3.51 | 2.53 | 2.18 | 2.31 | 2.47 | 2.76 | 3.10 | 3.28 | 3.37 | |

| 1-9/52 | 27 | 3.87 | 2.50 | 1.15 | 1.31 | 1.57 | 1.90 | 2.29 | 2.40 | 2.51 | |

| 1-36/127 | 101 | 2.23 | 2.50 | 1.02 | 1.12 | 1.25 | 1.49 | 1.71 | 1.83 | 1.98 | |

| 1-80/127 | 103 | 2.16 | 2.53 | 1.43 | 1.62 | 1.84 | 2.24 | 2.60 | 2.76 | 2.89 | |

| 5-95/99 | 104 | 1.89 | 2.50 | 0.90 | 1.08 | 1.30 | 1.73 | 2.32 | 2.51 | 2.63 | |

| 4-23/41 | 110 | 5.05 | 2.52 | 3.02 | 3.15 | 3.31 | 3.53 | 3.78 | 3.89 | 3.94 | |

| Core Number | Number | Depth (m) | Porosity (%) | Fractal Dimension | Tortuous Degree |

|---|---|---|---|---|---|

| 3-49/55 | 3 | 2655.9 | 1.21 | 1.99 | 3.87 |

| 1-26/68 | 4 | 2784.4 | 1.26 | 1.97 | 3.99 |

| 4-35/50 | 7 | 3343.0 | 0.52 | 1.78 | 19.4 |

| 1-21/52 | 22 | 2851.3 | 1.26 | 1.98 | 6.93 |

| 1-9/52 | 27 | 2916.0 | 1.26 | 1.79 | 13.75 |

| 1-36/127 | 101 | 3147.8 | 1.04 | 1.87 | 7.21 |

| 5-95/99 | 104 | 3167.4 | 1 | 1.95 | 8.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Liu, Y.; Dong, G.; Liu, B.; Li, C.; Zeng, X. Study on the Pore Structure Characterization of the Limestone Reservoir of the Taiyuan Formation in the Ordos Basin. Energies 2024, 17, 3275. https://doi.org/10.3390/en17133275

Zhang D, Liu Y, Dong G, Liu B, Li C, Zeng X. Study on the Pore Structure Characterization of the Limestone Reservoir of the Taiyuan Formation in the Ordos Basin. Energies. 2024; 17(13):3275. https://doi.org/10.3390/en17133275

Chicago/Turabian StyleZhang, Daofeng, Yan Liu, Guodong Dong, Baoxian Liu, Cheng Li, and Xu Zeng. 2024. "Study on the Pore Structure Characterization of the Limestone Reservoir of the Taiyuan Formation in the Ordos Basin" Energies 17, no. 13: 3275. https://doi.org/10.3390/en17133275

APA StyleZhang, D., Liu, Y., Dong, G., Liu, B., Li, C., & Zeng, X. (2024). Study on the Pore Structure Characterization of the Limestone Reservoir of the Taiyuan Formation in the Ordos Basin. Energies, 17(13), 3275. https://doi.org/10.3390/en17133275