A Dynamic Analysis of Biomethane Reforming for a Solid Oxide Fuel Cell Operating in a Power-to-Heat System Integrated into a Renewable Energy Community

Abstract

1. Introduction

2. Methodology

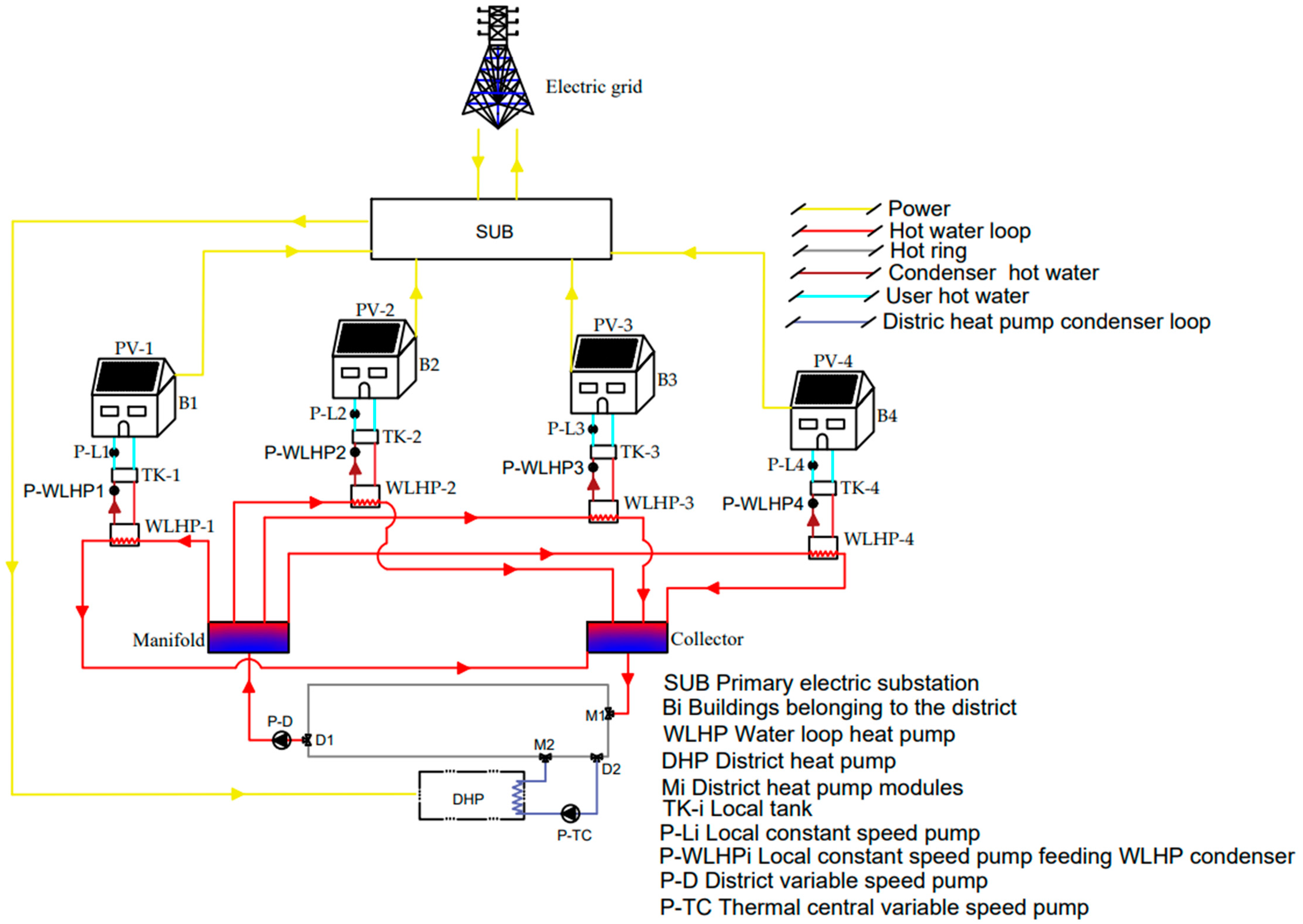

3. System Layout

4. System Model

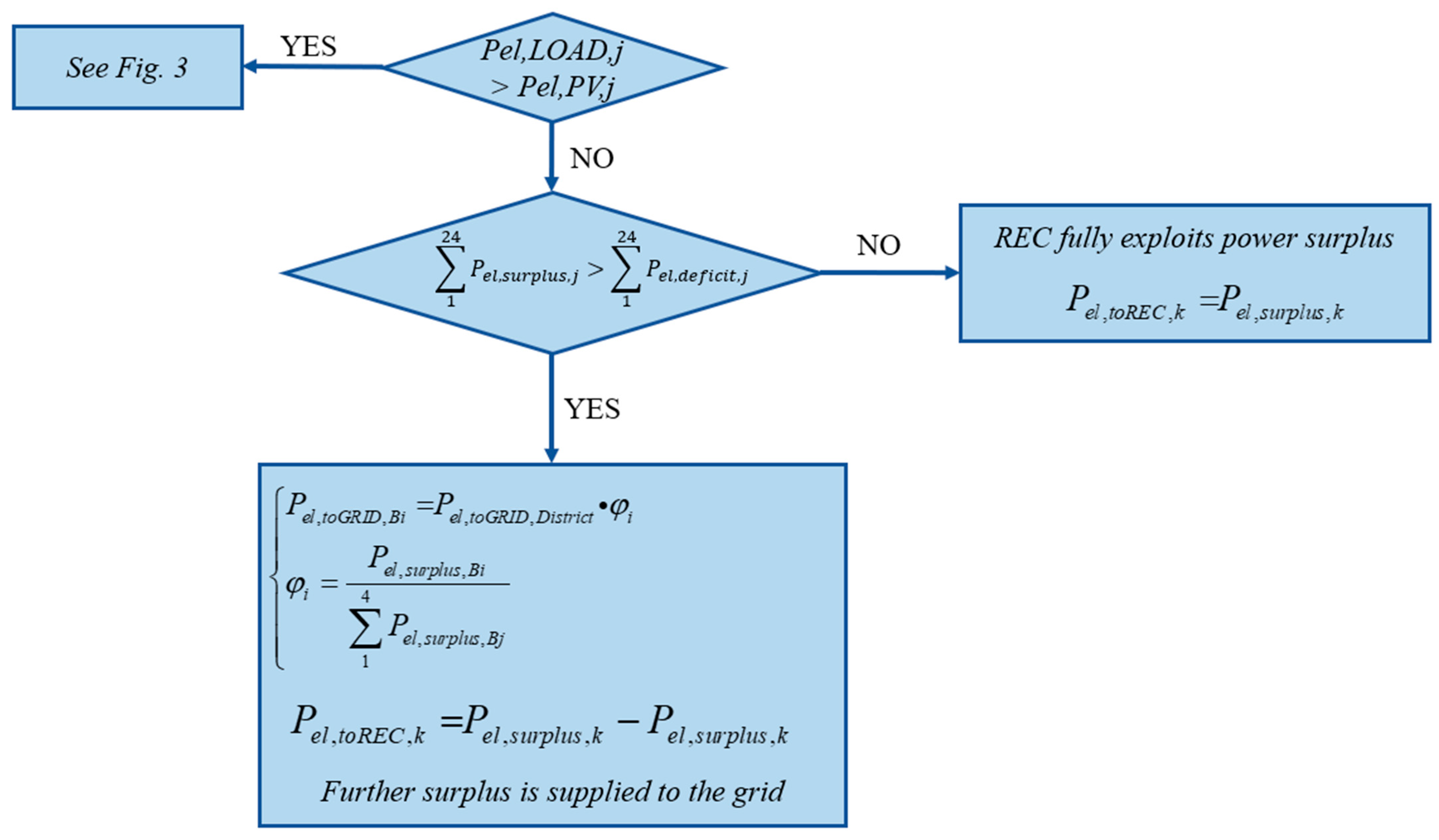

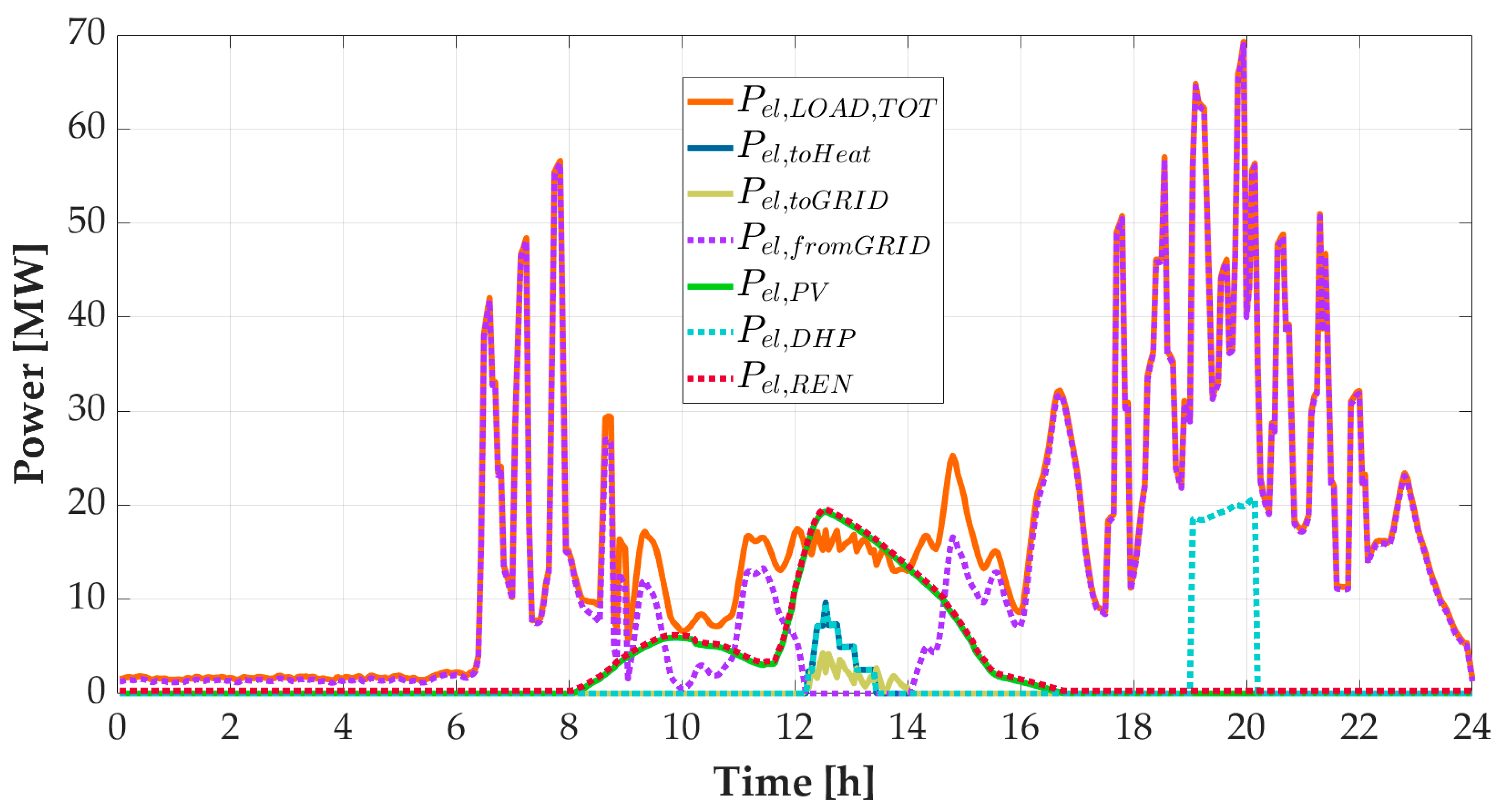

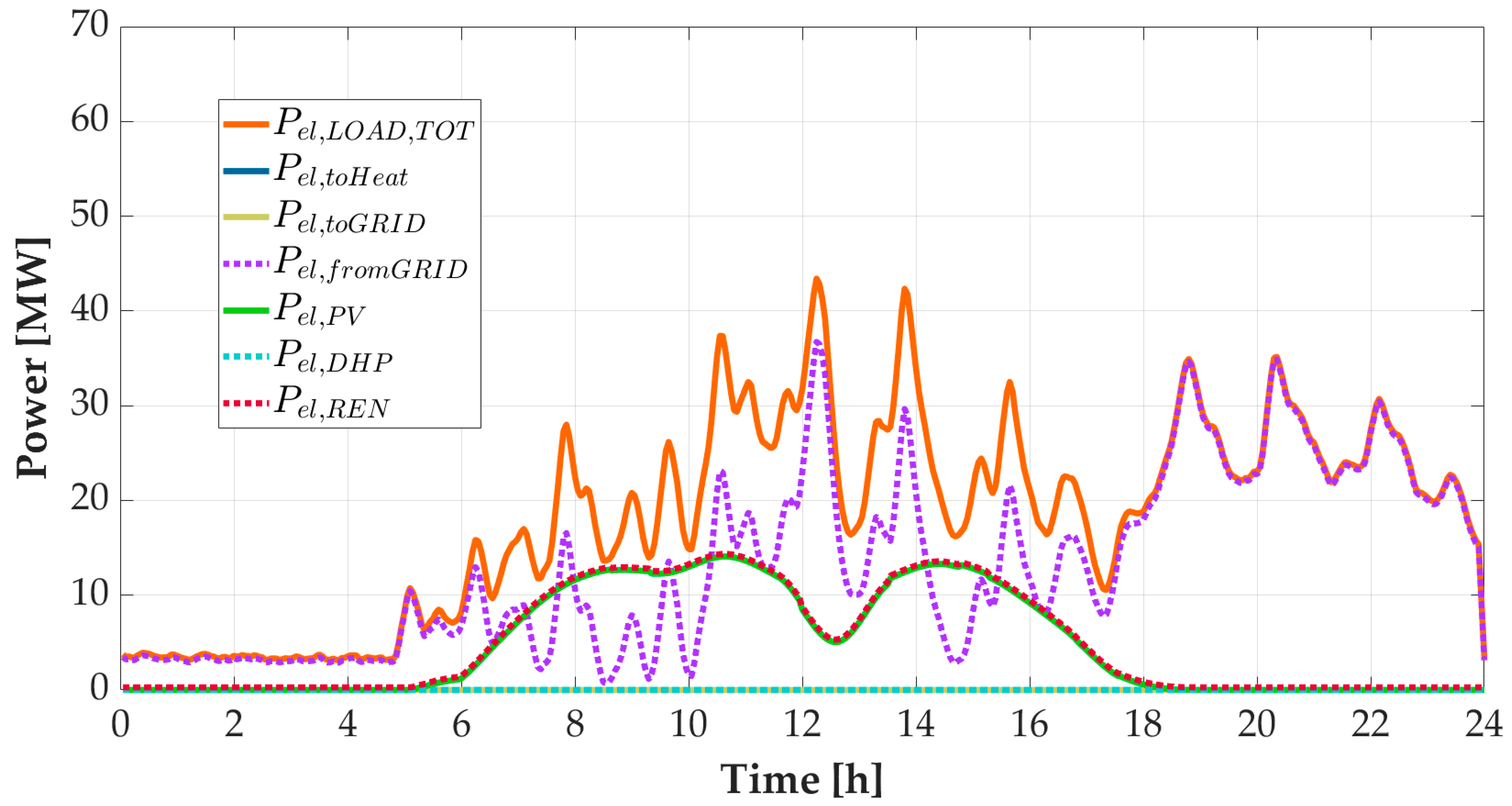

4.1. Renewable Energy Community Model

4.2. Thermoeconomic Model

| Parameter | Description | Value | Unit | |

|---|---|---|---|---|

| jel,fromGRID | Electricity purchasing cost | 0.25 | €/kWh | |

| jel,toGRID | Electricity energy exporting cost | 0.05 | €/kWh | |

| jel,fromREC | Local electricity purchasing cost | 0.15 | €/kWh | |

| jel,toREC | Local electricity exporting cost | 0.15 | €/kWh | |

| jNG | Natural gas purchasing price | 1.50 | €/Sm3 | |

| LHVCH4 | Natural gas lower heating value | 9.59 | kWh/Sm3 | |

| JPV | PV cost | 1000 [41] | €/kW | |

| Jpiping | Piping specific cost | 72.20 [4] | €/m | |

| Jexcavation | Excavation specific cost | 12.68 | €/m3 | |

| d | Discount | 25 | % | |

| Jpump | 108 m3/h | Cost of Salmson 108 m3/h pump | 2.66 [5] | k€/pump |

| 110 m3/h | Cost of Salmson 110 m3/h pump | 2.88 [5] | k€/pump | |

| 20 m3/h | Cost of Salmson 20 m3/h pump | 0.61 [5] | k€/pump | |

| 14 m3/h | Cost of Salmson 14 m3/h pump | 0.68 [5] | k€/pump | |

| JLHP | Water loop heat pump-specific cost | 150 [42] | €/kW | |

| JDHP | District heat pump-specific cost | 150 [42] | €/kW | |

| JSOFC | Solid oxide fuel cell cost | 2500 [43] | €/kW | |

| JAD | Anaerobic digestion plant cost | 800 [32] | €/m3 | |

| ηel | Electric grid efficiency | 46 | % | |

| ηB | Boiler efficiency | 75 | % | |

| mPV | PV yearly maintenance cost | 0.5 | %/year | |

| mplant | Plant yearly maintenance cost | 1.0 | %/year | |

5. Case Study

6. Results

7. Discussion

8. Conclusions

- The bio-REC system achieves a primary energy saving slightly higher than a conventional REC system, despite the small size of the solid oxide fuel cell (SOFC) selected based on the available OFMSW from the district. This indicates that the integration of biogas production can enhance energy efficiency.

- The self-consumption to load ratio increases from 33% to 35% due to reduced energy withdrawal from the grid during night hours. This suggests that even a small-sized SOFC can significantly improve grid independence and energy self-sufficiency.

- The profitability of the proposed bio-REC plant is extremely good with and without the adoption of incentives. This highlights the financial benefits of investing in bio-REC systems, which can be an attractive option for stakeholders even without government subsidies.

- The proposed bio-REC system resulted in an interesting solution for pushing towards the development of smart and sustainable cities. It efficiently integrates renewable energy technologies to match the energy demand of grouped users, suggesting that similar systems can be replicated in other urban areas to enhance sustainability and resilience.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sorknæs, P. Hybrid energy networks and electrification of district heating under different energy system conditions. Energy Rep. 2021, 7, 222–236. [Google Scholar] [CrossRef]

- Izzeldin, M.; Muradoğlu, Y.G.; Pappas, V.; Petropoulou, A.; Sivaprasad, S. The impact of the Russian-Ukrainian war on global financial markets. Int. Rev. Financ. Anal. 2023, 87, 102598. [Google Scholar] [CrossRef]

- Pörtner, H.O.; Roberts, D.C.; Adams, H.; Adler, C.; Aldunce, P.; Ali, E.; Ara Begum, R.; Betts, R.; Bezner Kerr, R.; Biesbroek, R.; et al. (Eds.) Summary for Policymakers. In IPCC Report, Climate Change 2022: Impacts, Adaptation and Vulnerability; Cambridge University Press: Cambridge, UK, 2022; pp. 3–33. [Google Scholar] [CrossRef]

- Zhou, E.; Wang, X. Dynamics of systemic risk in European gas and oil markets under the Russia–Ukraine conflict: A quantile regression neural network approach. Energy Rep. 2023, 9, 3956–3966. [Google Scholar] [CrossRef]

- Lamioni, R.; Bronzoni, C.; Folli, M.; Tognotti, L.; Galletti, C. Impact of H2-enriched natural gas on pollutant emissions from domestic condensing boilers: Numerical simulations of the combustion chamber. Int. J. Hydrogen Energy 2023, 48, 19686–19699. [Google Scholar] [CrossRef]

- Di Giulio, E.; Napolitano, M.; Di Meglio, A.; Romano, R.A.; Dragonetti, R. Low frequency acoustic method to measure the complex density of porous materials. J. Acoust. Soc. Am. 2022, 152, 2220–2226. [Google Scholar] [CrossRef]

- Sanongboon, P.; Pettigrew, T. Hybrid energy system optimization model: Electrification of Ontario’s residential space and water heating case study. Energy Clim. Chang. 2022, 3, 100070. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; d’Accadia, M.D.; Vicidomini, M. A hybrid renewable system based on wind and solar energy coupled with an electrical storage: Dynamic simulation and economic assessment. Energy 2018, 155, 174–189. [Google Scholar] [CrossRef]

- De Miranda, P.E.V. Hydrogen energy: Sustainable and perennial. In Science and Engineering of Hydrogen-Based Energy Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–38. [Google Scholar]

- Napolitano, M.; Di Giulio, E.; Auriemma, F.; Romano, R.A.; Dragonetti, R. Low frequency acoustic method to measure the complex bulk modulus of porous materials. J. Acoust. Soc. Am. 2022, 151, 1545–1556. [Google Scholar] [CrossRef]

- Di Giulio, E.; Di Meglio, A.; Massarotti, N.; Dragonetti, R. Effective Thermal Conductivity Model for Tetragonal Pin Array Stack. J. Fluid Flow Heat Mass Transf. 2022, 9, 38–42. [Google Scholar] [CrossRef]

- Testasecca, T.; Catrini, P.; Beccali, M.; Piacentino, A. Dynamic simulation of a 4th generation district heating network with the presence of prosumers. Energy Convers. Manag. X 2023, 20, 100480. [Google Scholar] [CrossRef]

- Liu, D.-x.; Lei, H.-Y.; Li, J.-S.; Dai, C.-s.; Xue, R.; Liu, X. Optimization of a district heating system coupled with a deep open-loop geothermal well and heat pumps. Renew. Energy 2024, 223, 119991. [Google Scholar] [CrossRef]

- Volpato, G.; Carraro, G.; Cont, M.; Danieli, P.; Rech, S.; Lazzaretto, A. General guidelines for the optimal economic aggregation of prosumers in energy communities. Energy 2022, 258, 124800. [Google Scholar] [CrossRef]

- Smirnova, E.; Kot, S.; Kolpak, E.; Shestak, V. Governmental support and renewable energy production: A cross-country review. Energy 2021, 230, 120903. [Google Scholar] [CrossRef]

- Directive (EU) 2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG (accessed on 1 March 2024).

- Fouladvand, J.; Aranguren Rojas, M.; Hoppe, T.; Ghorbani, A. Simulating thermal energy community formation: Institutional enablers outplaying technological choice. Appl. Energy 2022, 306, 117897. [Google Scholar] [CrossRef]

- Petrucci, A.; Barone, G.; Buonomano, A.; Athienitis, A. Modelling of a multi-stage energy management control routine for energy demand forecasting, flexibility, and optimization of smart communities using a Recurrent Neural Network. Energy Convers. Manag. 2022, 268, 115995. [Google Scholar] [CrossRef]

- Hachem-Vermette, C.; Guarino, F.; La Rocca, V.; Cellura, M. Towards achieving net-zero energy communities: Investigation of design strategies and seasonal solar collection and storage net-zero. Sol. Energy 2019, 192, 169–185. [Google Scholar] [CrossRef]

- Gjorgievski, V.Z.; Cundeva, S.; Georghiou, G.E. Social arrangements, technical designs and impacts of energy communities: A review. Renew. Energy 2021, 169, 1138–1156. [Google Scholar] [CrossRef]

- Gul, E.; Baldinelli, G.; Bartocci, P.; Bianchi, F.; Piergiovanni, D.; Cotana, F.; Wang, J. A techno-economic analysis of a solar PV and DC battery storage system for a community energy sharing. Energy 2022, 244, 123191. [Google Scholar] [CrossRef]

- Fouladvand, J.; Ghorbani, A.; Mouter, N.; Herder, P. Analysing community-based initiatives for heating and cooling: A systematic and critical review. Energy Res. Soc. Sci. 2022, 88, 102507. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, M.; Liu, Y.; Wang, D.; Zhuang, Z.; Quan, M. Energy, exergy, and economic analysis of a centralized solar and biogas hybrid heating system for rural areas. Energy Convers. Manag. 2023, 276, 116591. [Google Scholar] [CrossRef]

- Zwickl-Bernhard, S.; Auer, H. Demystifying natural gas distribution grid decommissioning: An open-source approach to local deep decarbonization of urban neighborhoods. Energy 2022, 238, 121805. [Google Scholar] [CrossRef]

- Vivian, J.; Chinello, M.; Zarrella, A.; De Carli, M. Investigation on Individual and Collective PV Self-Consumption for a Fifth Generation District Heating Network. Energies 2022, 15, 1022. [Google Scholar] [CrossRef]

- Bartolini, A.; Carducci, F.; Muñoz, C.B.; Comodi, G. Energy storage and multi energy systems in local energy communities with high renewable energy penetration. Renew. Energy 2020, 159, 595–609. [Google Scholar] [CrossRef]

- Ancona, M.A.; Baldi, F.; Branchini, L.; De Pascale, A.; Gianaroli, F.; Melino, F.; Ricci, M. Comparative Analysis of Renewable Energy Community Designs for District Heating Networks: Case Study of Corticella (Italy). Energies 2022, 15, 5248. [Google Scholar] [CrossRef]

- Ceglia, F.; Marrasso, E.; Roselli, C.; Sasso, M.; Coletta, G.; Pellegrino, L. Biomass-Based Renewable Energy Community: Economic Analysis of a Real Case Study. Energies 2022, 15, 5655. [Google Scholar] [CrossRef]

- Babu, R.; Prieto Veramendi, P.M.; Rene, E.R. Strategies for resource recovery from the organic fraction of municipal solid waste. Case Stud. Chem. Environ. Eng. 2021, 3, 100098. [Google Scholar] [CrossRef]

- Di Fraia, S.; Di Meglio, A.; Massarotti, N.; Vanoli, L.; Bentivoglio, R.; Volpecina, V. Energy recovery and waste valorization in a frozen food processing facility: A case study from Lazio, Italy. Energy Effic. 2024, 17, 13. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Sadeghzadeh Hemayati, S.; Tabatabaei, M.; Aghbashlo, M.; Mahmoudi, S.B. A review on beet sugar industry with a focus on implementation of waste-to-energy strategy for power supply. Renew. Sustain. Energy Rev. 2019, 103, 423–442. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; d’Accadia, M.D.; Vicidomini, M. Concentrating photovoltaic/thermal collectors coupled with an anaerobic digestion process: Dynamic simulation and energy and economic analysis. J. Clean. Prod. 2021, 311, 127363. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Cimmino, L.; d’Accadia, M.D.; Vicidomini, M. A Novel Layout for Combined Heat and Power Production for a Hospital Based on a Solid Oxide Fuel Cell. Energies 2024, 17, 979. [Google Scholar] [CrossRef]

- Di Meglio, A.; Massarotti, N.; Nithiarasu, P. A physics-driven and machine learning-based digital twinning approach to transient thermal systems. Int. J. Numer. Methods Heat Fluid Flow 2024. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Cimmino, L.; Dentice d’Accadia, M.; Vicidomini, M. Dynamic simulation and thermoeconomic analysis of a power to gas system. Renew. Sustain. Energy Rev. 2023, 187, 113759. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Cimmino, L.; Dentice d’Accadia, M.; Vicidomini, M. Novel paradigm for renewable energy communities: A techno-economic analysis of a renewable energy community in Italy. In Proceedings of the 18th Conference on Sustainable Development of Energy, Water and Environment Systems–SDEWES 2023, Dubrovnik, Croatia, 24–29 September 2023. [Google Scholar]

- Calise, F.; Cappiello, F.L.; Dentice d’Accadia, M.; Vicidomini, M. Energy efficiency in small districts: Dynamic simulation and technoeconomic analysis. Energy Convers. Manag. 2020, 220, 113022. [Google Scholar] [CrossRef]

- GSE. Biomethane Decree. Discount in Capital Costs for New Installation Anaerobic Digesters. 2022. Available online: https://www.gse.it/servizi-per-te/attuazione-misure-pnrr/produzione-di-biometano/accesso-agli-incentivi (accessed on 1 March 2024).

- ISPRAmbiente. Regional Costs for Waste Disposal. Available online: https://www.catasto-rifiuti.isprambiente.it/index.php?pg=costiregione&width=1536&height=864&advice=si (accessed on 1 March 2024).

- Calise, F.; Cappiello, F.L.; Cimmino, L.; Dentice d’Accadia, M.; Vicidomini, M. A comparative thermoeconomic analysis of fourth generation and fifth generation district heating and cooling networks. Energy 2023, 284, 128561. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; d’Accadia, M.D.; Vicidomini, M. A novel smart energy network paradigm integrating combined heat and power, photovoltaic and electric vehicles. Energy Convers. Manag. 2022, 260, 115599. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; d’Accadia, M.D.; Petrakopoulou, F.; Vicidomini, M. A solar-driven 5th generation district heating and cooling network with ground-source heat pumps: A thermo-economic analysis. Sustain. Cities Soc. 2022, 76, 103438. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Cimmino, L.; Vicidomini, M. Dynamic simulation modelling of reversible solid oxide fuel cells for energy storage purpose. Energy 2022, 260, 124893. [Google Scholar] [CrossRef]

- The American Society of Heating, Refrigerating and Air-Conditioning Engineers. 1993 ASHRAE Handbook: Fundamentals; ASHRAE: Atlanta, GA, USA, 1993. [Google Scholar]

- ENEA. Agenzia Nazionale per le Nuove Tecnologie, L’energia e lo Sviluppo Economico Sostenibile. 2019. Available online: http://www.enea.it/it (accessed on 1 March 2024).

- Available online: https://global.aermec.com/it/ (accessed on 1 March 2024).

- Zhang, M.; Yu, S.; Li, H. Inter-Zone Optimal Scheduling of Rural Wind–Biomass-Hydrogen Integrated Energy System. Energies 2023, 16, 6202. [Google Scholar] [CrossRef]

- Thiruselvi, D.; Kumar, P.S.; Kumar, M.A.; Lay, C.-H.; Aathika, S.; Mani, Y.; Jagadiswary, D.; Dhanasekaran, A.; Shanmugam, P.; Sivanesan, S.; et al. A critical review on global trends in biogas scenario with its up-gradation techniques for fuel cell and future perspectives. Int. J. Hydrogen Energy 2021, 46, 16734–16750. [Google Scholar] [CrossRef]

- Mittal, S.; Ahlgren, E.O.; Shukla, P.R. Barriers to biogas dissemination in India: A review. Energy Policy 2018, 112, 361–370. [Google Scholar] [CrossRef]

- Medina, M.S.G.; Aguilar, J.; Rodríguez-Moreno, M.D. A Bioinspired Emergent Control for Smart Grids. IEEE Access 2023, 11, 7503–7520. [Google Scholar] [CrossRef]

- Cowley, T.; Hutty, T.; Hammond, J.; Brown, S. Achieving emission reduction through the utilisation of local low-grade heat sources in district heating networks. Appl. Therm. Eng. 2024, 242, 122381. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Chacón-Pérez, Y.; Cardona-Alzate, C.A. Evaluation of biogas and syngas as energy vectors for heat and power generation using lignocellulosic biomass as raw material. Electron. J. Biotechnol. 2018, 33, 52–62. [Google Scholar] [CrossRef]

| Component | Parameter | Value | Unit |

|---|---|---|---|

| PV Field | Module efficiency | 0.18 | - |

| PV field-rated power per building | 36.40 | kW | |

| PV field area | 3033.3 | m2 | |

| PV field overall power | 2.18 | MW | |

| AD | Capacity | 800 | m3 |

| Input biomass flow rate | 626.4 | kg/h | |

| Output-rated biogas flow rate | 87 | Sm3/h | |

| Operating temperature | 37 | °C | |

| Upgrading rated power | 120 | kWel | |

| SOFC | Rated electric power | 288 | kWel |

| Rated thermal power | 523 | kWth | |

| Electric efficiency | 0.502 | - | |

| Flow rate of exhaust gases | 2005 | Kg/h | |

| Temperature of exhaust gases | 822 | °C | |

| Operating pressure of cell | 1 | bar | |

| WLHP (WWB-0700 [46]) | Battery charging efficiency | 90 | % |

| Maximum allowed discharging/charging power | 1.25 | MW | |

| Rated coefficient of performance (COP) | 4.14 | - | |

| Rated water flow rate (load side) | 19,977 | kg/h | |

| Rated water flow rate (source side) | 14,835 | kg/h | |

| Rated load temperature | 80 | °C | |

| Source side temperature | 25–45 | °C | |

| DHP (NRB-HA-2200 [46]) | Rated heat transfer rate | 620 | kW |

| Rated power demand | 193.5 | kW | |

| Rated coefficient of performance (COP) | 3.20 | - | |

| Rated water flow rate (load side) | 107,669 | kg/h | |

| Rated air flow rate (source side) | 180,000 | m3/h | |

| Rated load temperature | 35 | °C |

| Parameter | Description | Value | Unit | |

|---|---|---|---|---|

| REC (PS1) | Bio-REC (PS2) | |||

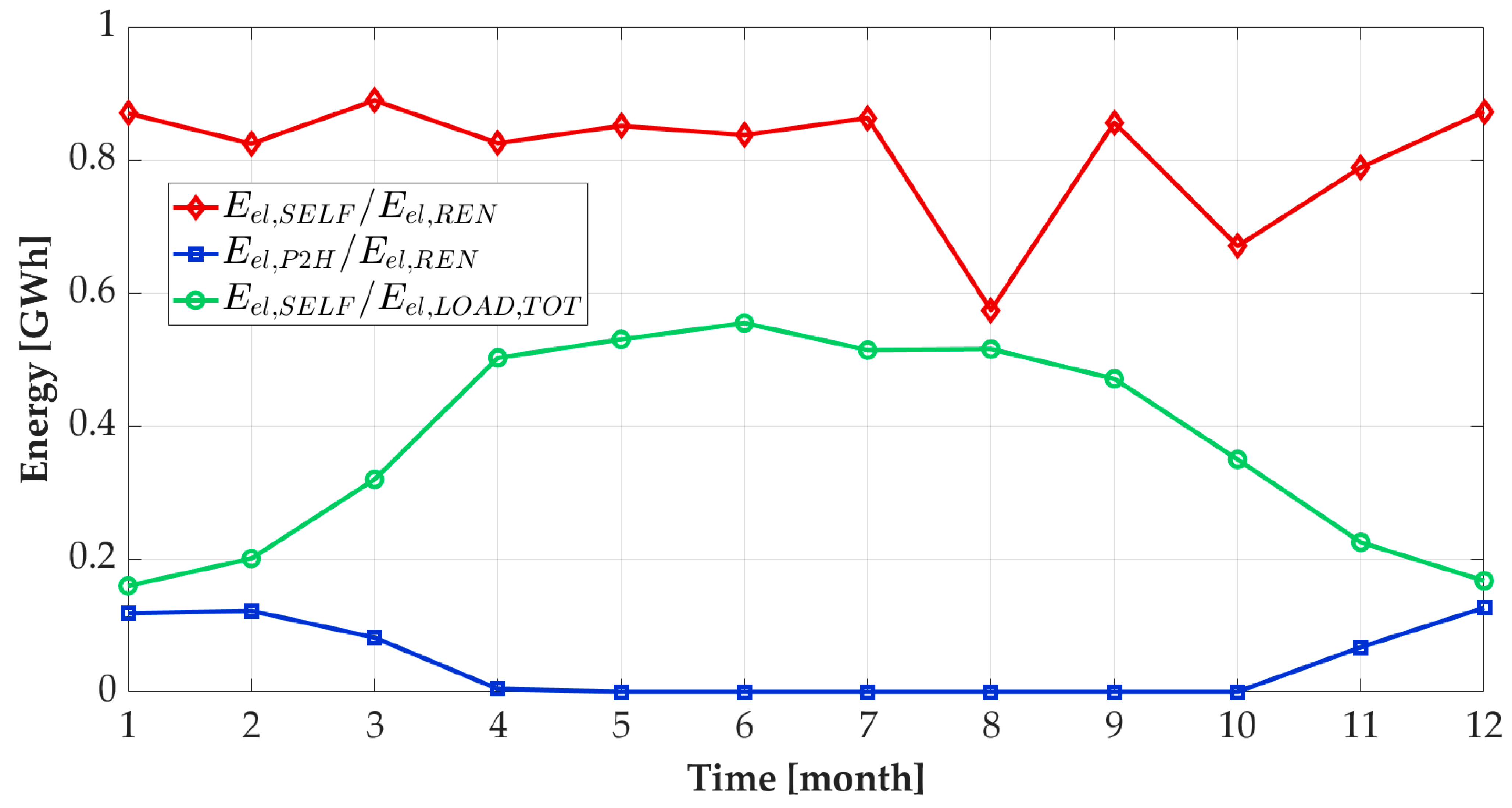

| Eel,toGRID | Electricity supplied to the grid | 10.68 | 10.94 | GWh/year |

| Eel,fromGRID | Electricity withdrawn from the grid | 86.44 | 85.22 | GWh/year |

| Eel,LOAD | Electricity load of the district | 129.1 | 128.4 | GWh/year |

| Eel,PV | Electricity produced by the PV fields | 53.33 | 53.33 | GWh/year |

| Eel,P2H | Electricity supplied to the DH system | 1.65 | 1.63 | GWh/year |

| Eel,SELF | Electricity self-consumed | 42.66 | 43.31 | GWh/year |

| Eth,DHW | Thermal energy demand for DHW | 37.05 | 37.05 | GWh/year |

| Eth,demandH | Thermal energy demand for space heating | 71.49 | 71.49 | GWh/year |

| Eel,SELF/Eel,LOAD | Self-consumption to load ratio | 0.33 | 0.35 | - |

| Eel,SELF/Eel,PV | Self-consumption to PV production ratio | 0.80 | 0.82 | - |

| PEtot | Total primary energy consumption | 214.11 | 210.88 | GWh/year |

| ΔPE | Difference in primary energy consumption | 58.91 | 62.14 | GWh/year |

| PES | Primary energy saving | 22 | 23 | % |

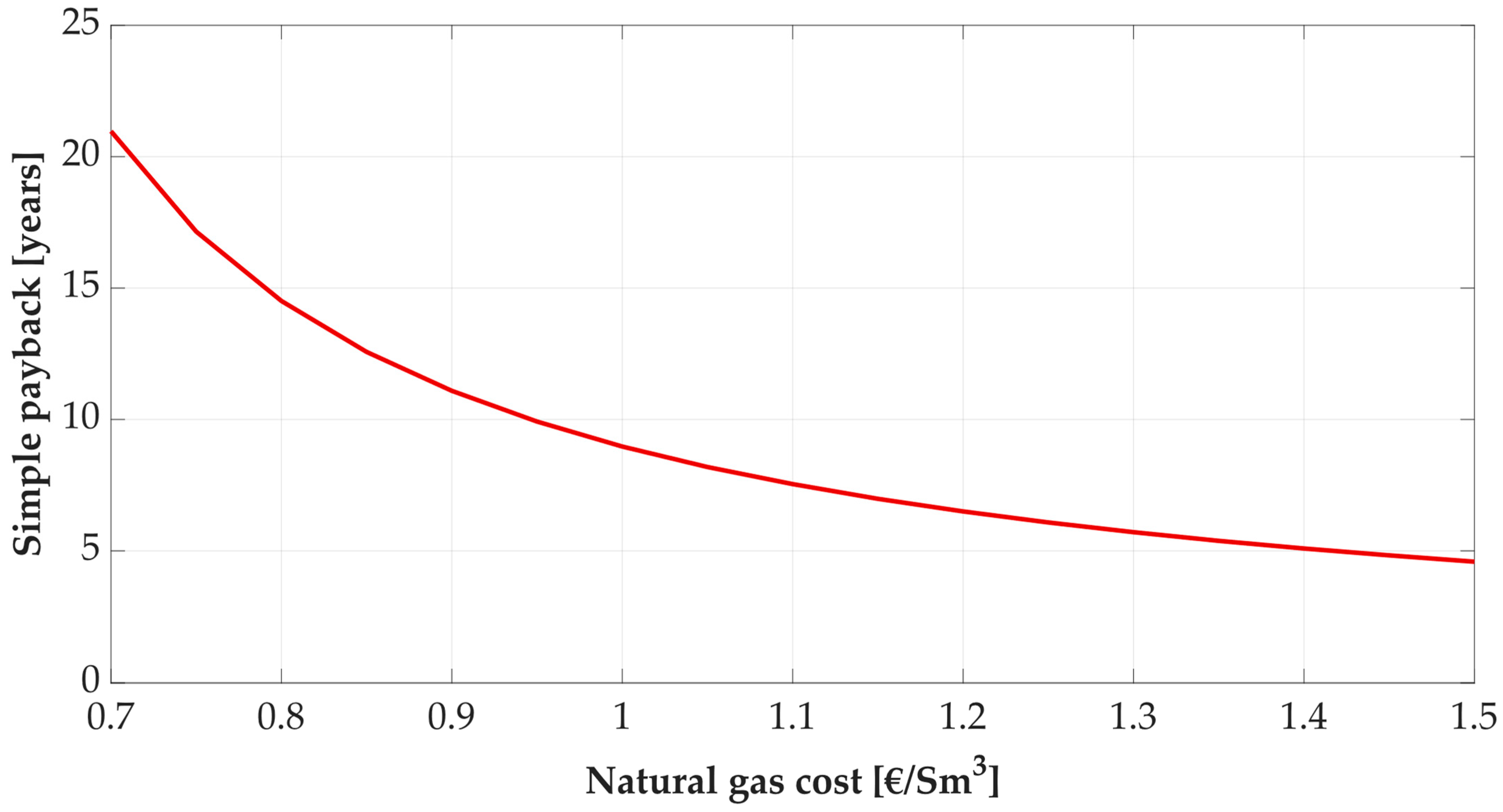

| ΔC | Operating costs difference | 14.86 | 15.18 | M€/year |

| C | Capital cost of investment | 69.9 | 71.2 | M€ |

| SPB | Simple payback | 4.7 | 4.7 | years |

| PI | Profit index | 1.21 | 1.22 | - |

| NPV | Net present value | 84.7 | 86.7 | M€ |

| ΔCinc | Operating costs difference with incentives | 14.86 | 15.46 | M€/year |

| Cinc | Capital cost of investment with incentives | 69.9 | 70.9 | M€ |

| SPBinc | Simple payback with incentives | 4.7 | 4.5 | years |

| PIinc | Profit index with incentives | 1.21 | 1.26 | - |

| NPVinc | Net present value with incentives | 84.7 | 89.8 | M€ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calise, F.; Cappiello, F.L.; Cimmino, L.; Vicidomini, M. A Dynamic Analysis of Biomethane Reforming for a Solid Oxide Fuel Cell Operating in a Power-to-Heat System Integrated into a Renewable Energy Community. Energies 2024, 17, 3160. https://doi.org/10.3390/en17133160

Calise F, Cappiello FL, Cimmino L, Vicidomini M. A Dynamic Analysis of Biomethane Reforming for a Solid Oxide Fuel Cell Operating in a Power-to-Heat System Integrated into a Renewable Energy Community. Energies. 2024; 17(13):3160. https://doi.org/10.3390/en17133160

Chicago/Turabian StyleCalise, Francesco, Francesco Liberato Cappiello, Luca Cimmino, and Maria Vicidomini. 2024. "A Dynamic Analysis of Biomethane Reforming for a Solid Oxide Fuel Cell Operating in a Power-to-Heat System Integrated into a Renewable Energy Community" Energies 17, no. 13: 3160. https://doi.org/10.3390/en17133160

APA StyleCalise, F., Cappiello, F. L., Cimmino, L., & Vicidomini, M. (2024). A Dynamic Analysis of Biomethane Reforming for a Solid Oxide Fuel Cell Operating in a Power-to-Heat System Integrated into a Renewable Energy Community. Energies, 17(13), 3160. https://doi.org/10.3390/en17133160