Joint Deployment of Sensors and Chargers in Wireless Rechargeable Sensor Networks

Abstract

1. Introduction

- (1)

- We present a new problem of joint deployment of sensors and chargers in a two-dimensional plane with the constraints of deployment cost.

- (2)

- We propose a strategy for deploying static sensors and chargers in a two-dimensional plane by scheduling the working state and the charging state of the sensors to realize the real-time monitoring of PoIs. The target is to reduce the deployment cost of WSNs. We formulate the above problem and conclude two progressive problems, P1 and P2, to analyze the impact of sensor and charger deployment on deployment network costs and prove their NP-hardness.

- (3)

- The aggregation effect of sensors is revealed to effectively reduce the number of deployed chargers, and thus, the greedy heuristic approximate solution for deploying sensors by using the aggregation effect (GHDSAE) is proposed. Then, the greedy heuristic (GH) solution and the particle swarm optimization (PSO) solution are proposed for the deployment of chargers. The accuracy and efficiency of the solutions are evaluated through a large number of simulations at different computational scales.

2. Related Work

3. Model and Problem Statement

3.1. Network Model

3.2. Sensor Perception Model

3.3. Charging Model

3.4. Problem Formulation

4. Solutions

4.1. Hardness Analysis

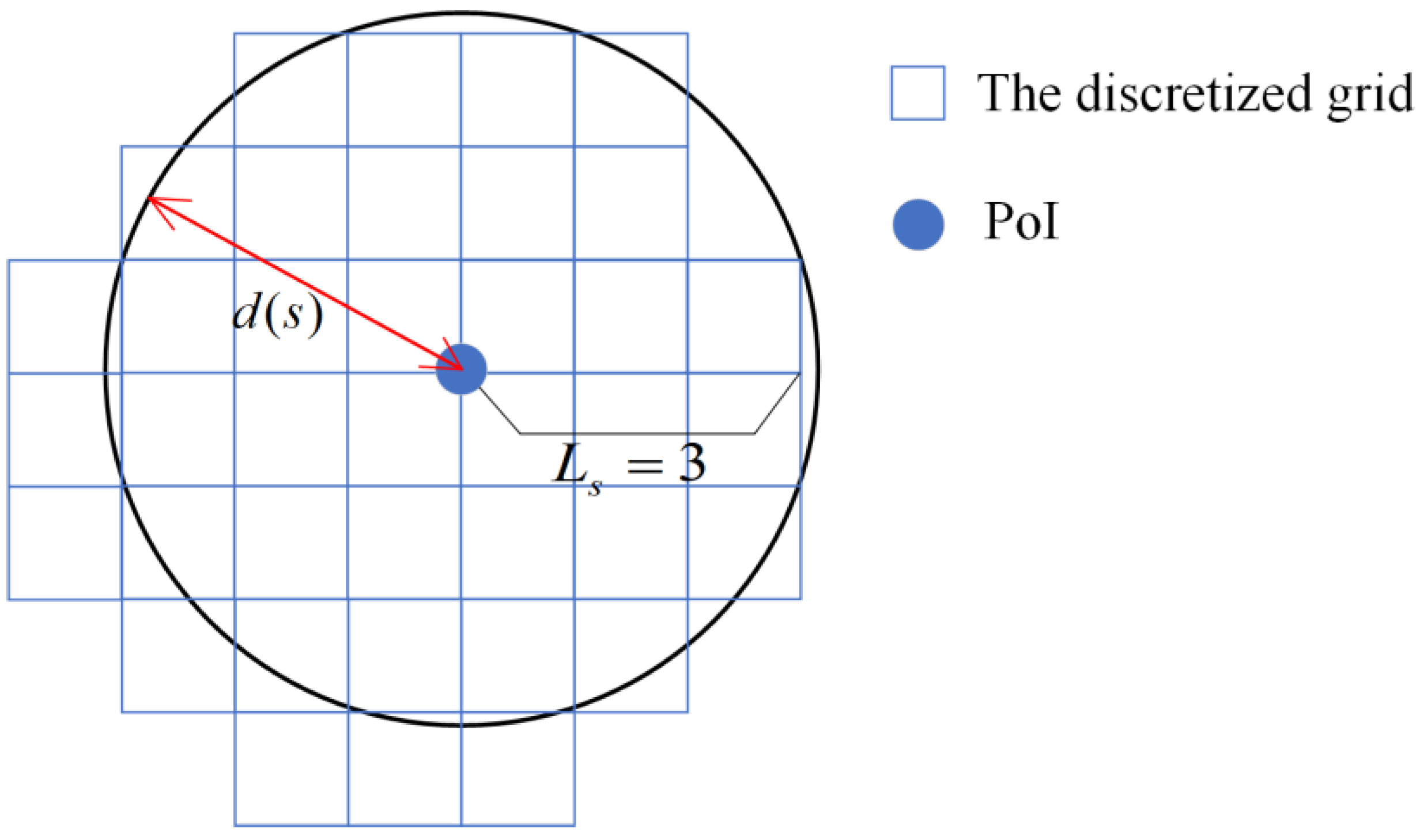

4.2. Area Discretization

4.3. Approximate Algorithms for Deploying Sensors

| Algorithm 1: Details of the GHDSAE for sensor deployment |

| Input: , Output: 1: ; 2 3 do 4: For do 5: slots; 6: End for 7: with the largest number of effectively covering PoIs and the smallest distance to already deployed sensors; 8: ; 9: End while 10 |

4.4. Approximate Algorithm for Deploying Chargers

| Algorithm 2: Details of GH for charger deployment |

| Input Output ; ; in descending order; do ; && do ; ; 9: End While 10: End For |

| Algorithm 3: Details of PSO for charger deployment |

| Input Output ; in descending order; do ; && do of each particle; 8: End While 9: End for |

5. Simulation Evaluation

5.1. Simulation Setup

5.2. Solution of the Sensor Deployment

5.2.1. Varying the Number of PoIs

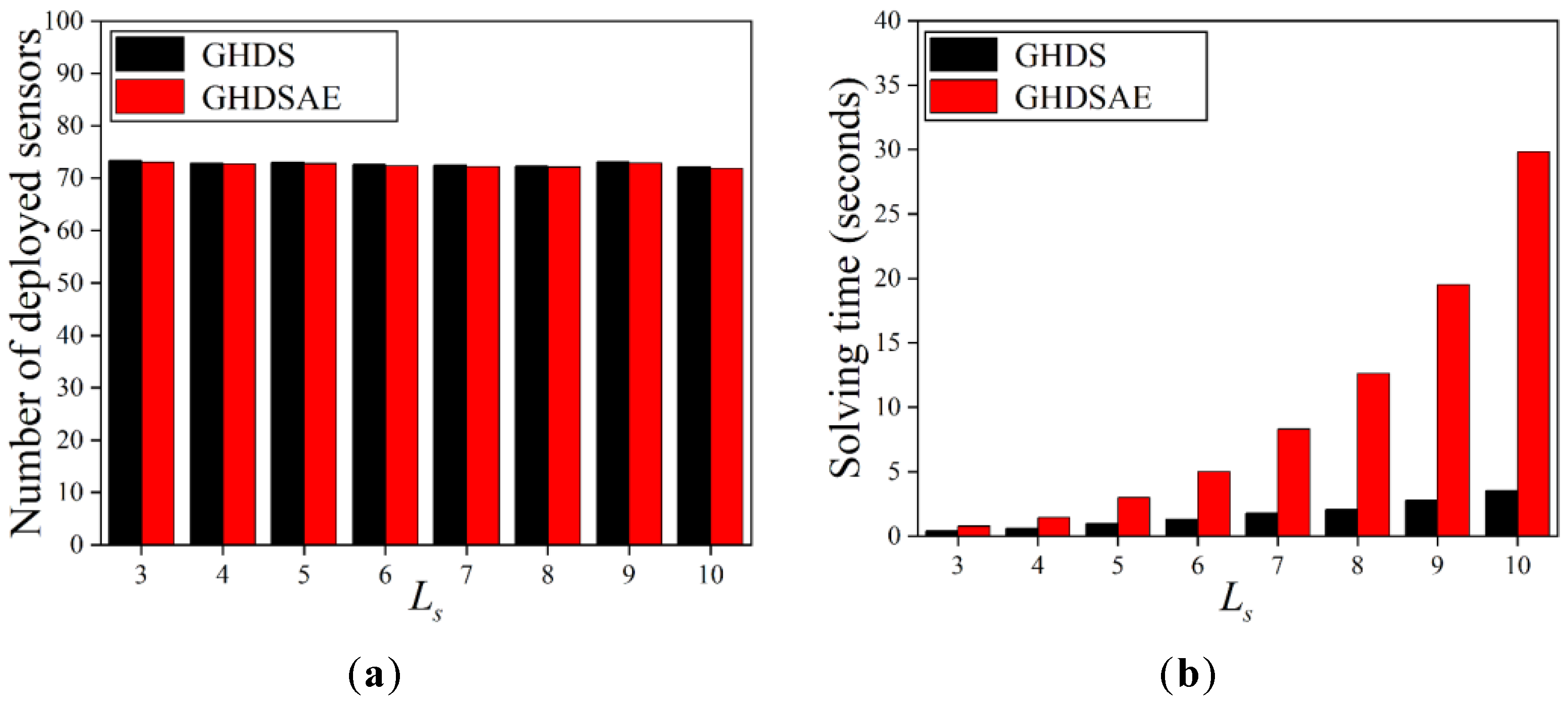

5.2.2. Varying the Number of

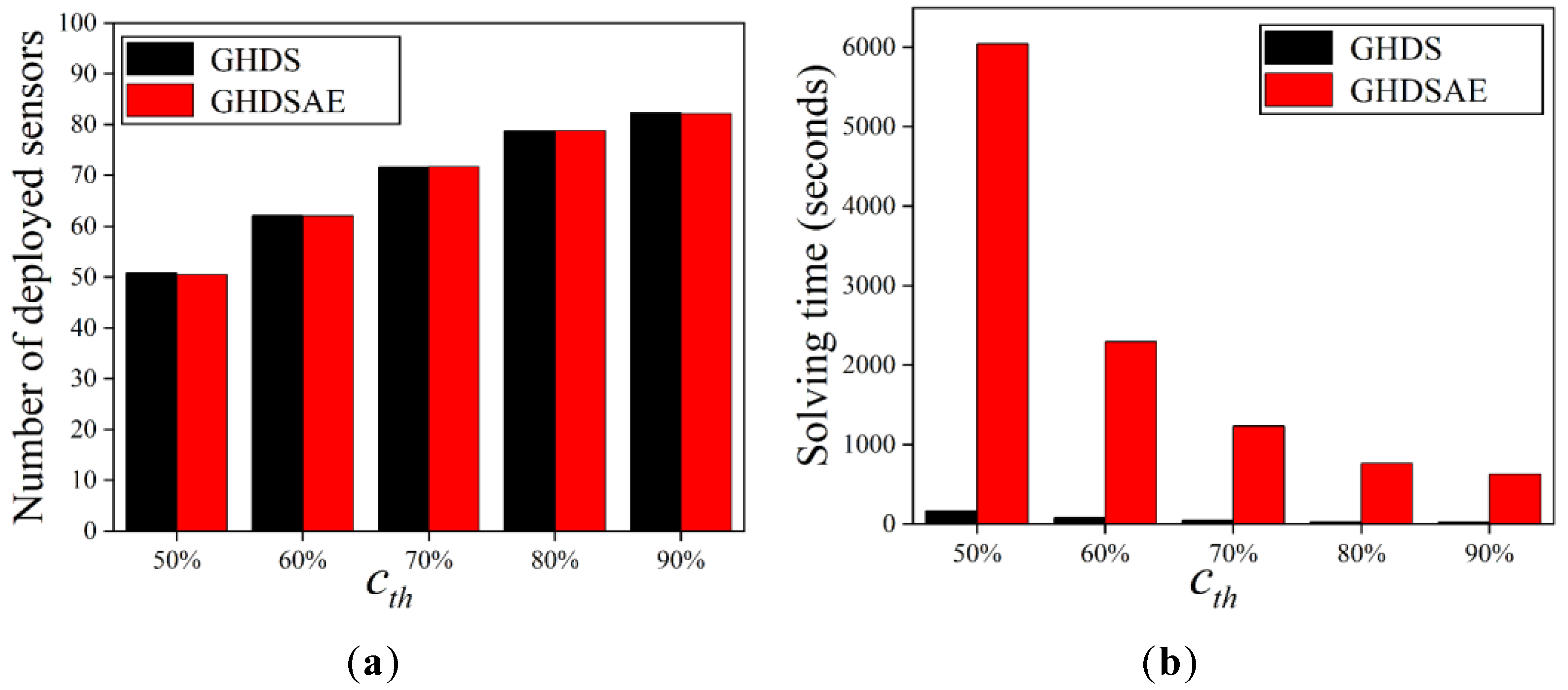

5.2.3. Varying the Perception Probability of Sensors

5.3. Solution of the Charger Deployment

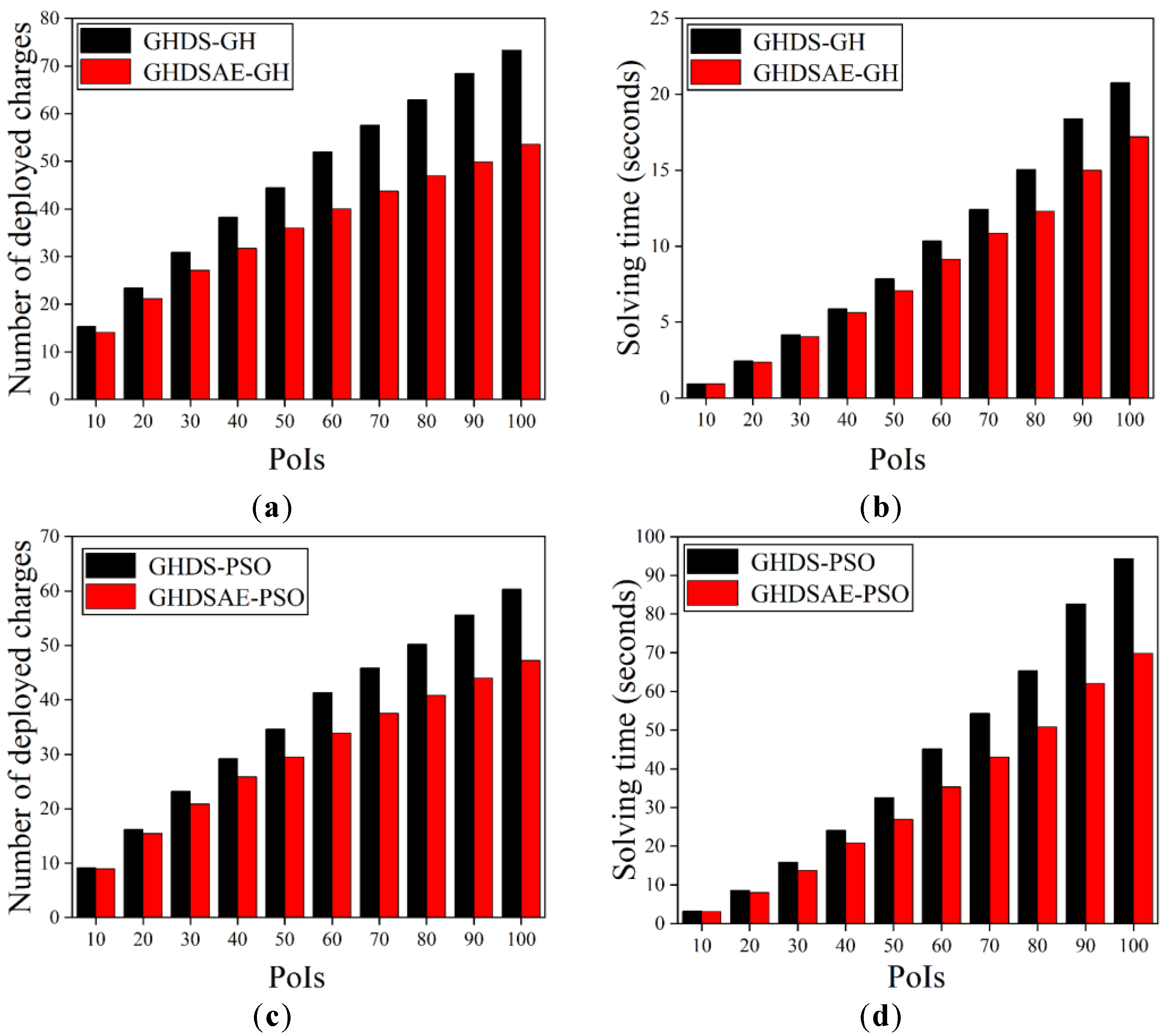

5.3.1. Varying the Number of PoIs

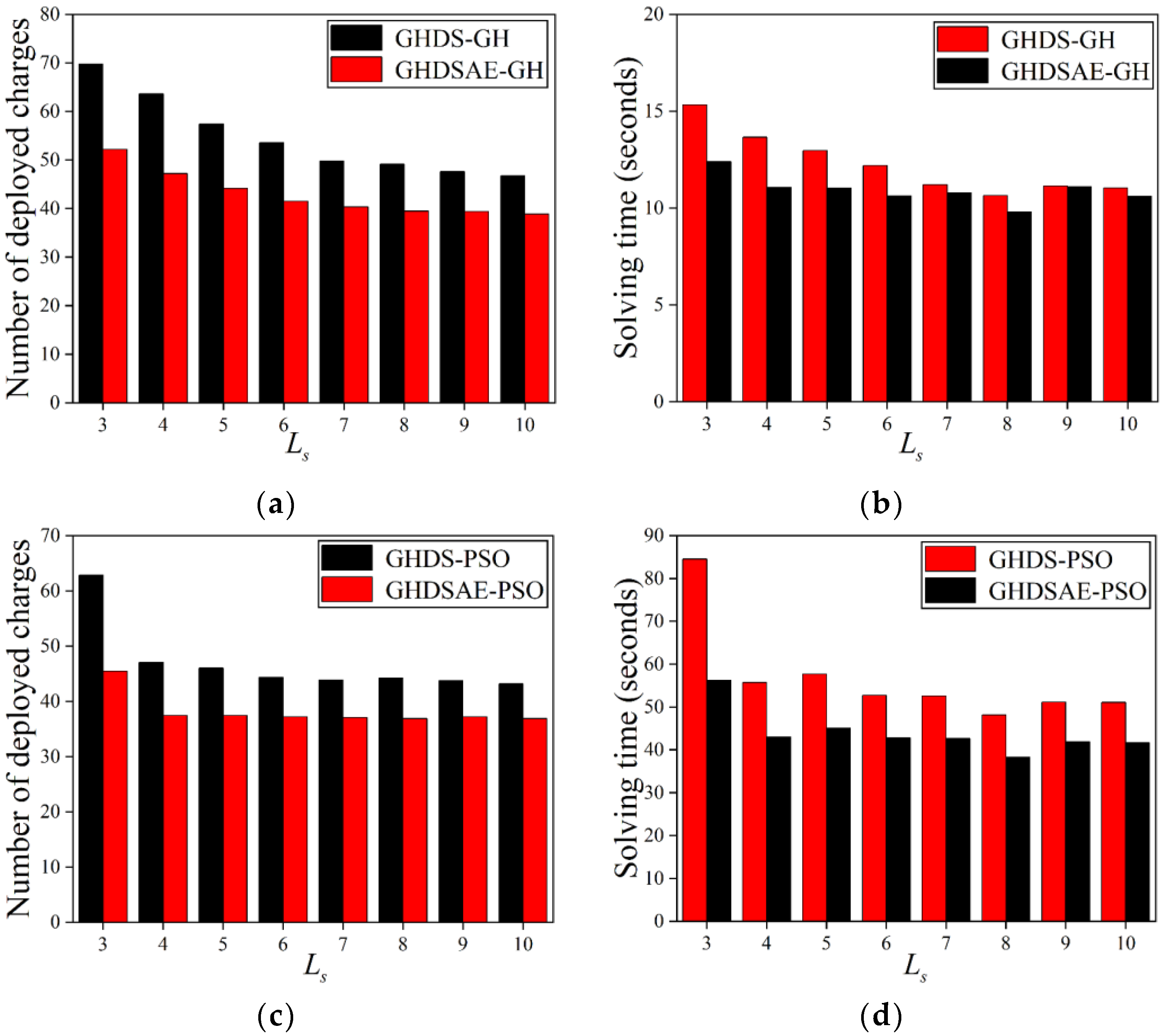

5.3.2. Varying the Number of

5.3.3. Varying the Perception Probability of Sensors

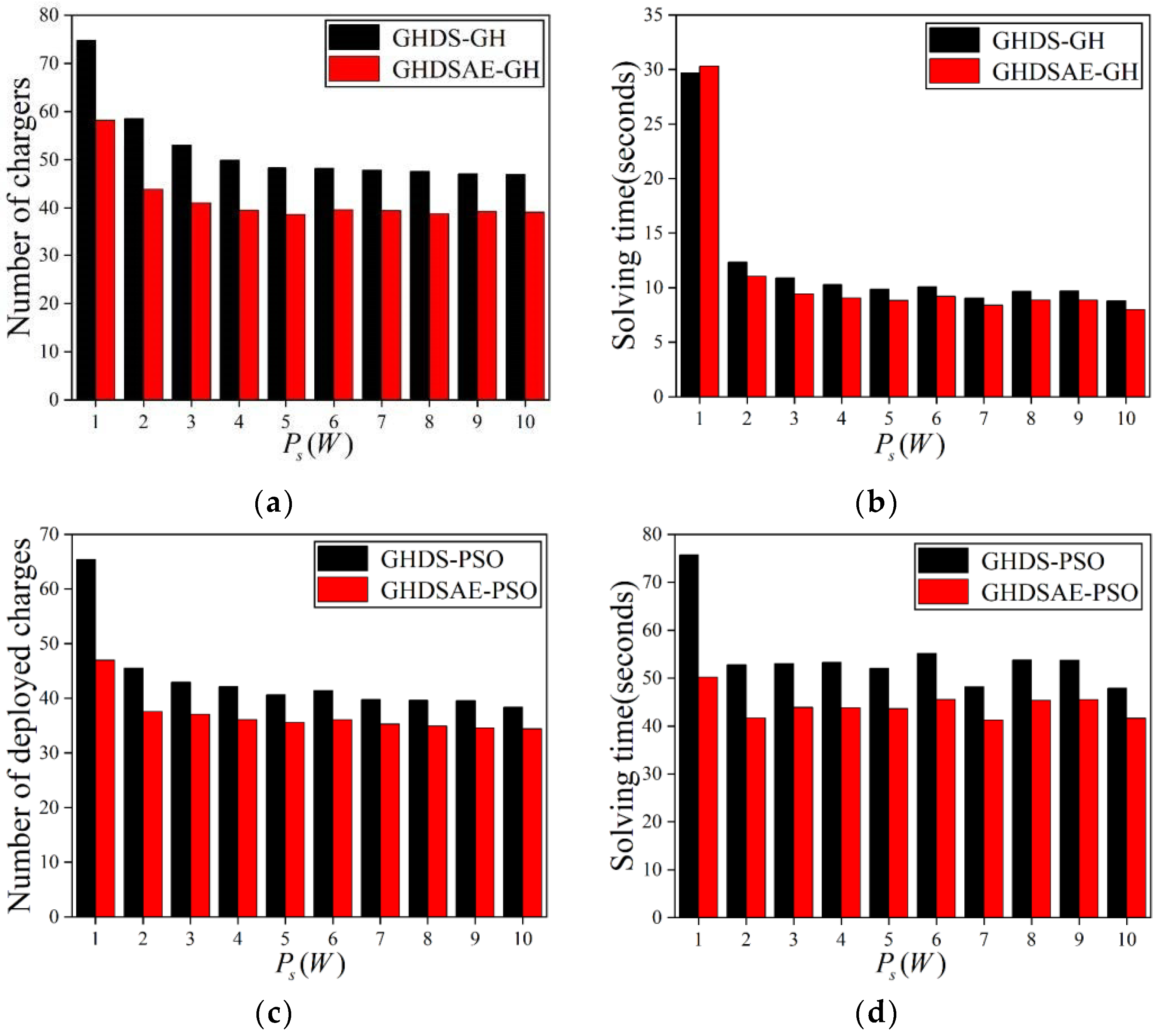

5.3.4. Varying the Transmitting Power of Chargers

5.3.5. Varying the Number of

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Royer, L.; Terray, L.; Rubéo-Lisa, M.; Sudre, J.; Gauthier, P.J.; Claude, A.; Giammanco, S.; Pecora, E.; Principato, P.; Breton, V. Lessons Learnt from Monitoring the Etna Volcano Using an IoT Sensor Network through a Period of Intense Eruptive Activity. Sensors 2024, 24, 1577. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cui, Y.; Wang, C.; Song, X.; Pei, Y.; Yuan, Z. Rotating permanent magnet antenna array for directional communication in pipeline monitoring system. AEU-Int. J. Electron. Commun. 2024, 177, 155210. [Google Scholar] [CrossRef]

- Armijo, A.; Zamora-Sánchez, D. Integration of Railway Bridge Structural Health Monitoring into the Internet of Things with a Digital Twin: A Case Study. Sensors 2024, 24, 2115. [Google Scholar] [CrossRef] [PubMed]

- Guetta, Y.; Shapiro, A. On-board physical battery replacement system and procedure for drones during flight. IEEE Robot. Autom. Lett. 2022, 7, 9755–9762. [Google Scholar] [CrossRef]

- Karamov, D.N.; Suslov, K.V. Structural optimization of autonomous photovoltaic systems with storage battery replacements. Energy Rep. 2021, 7, 349–358. [Google Scholar] [CrossRef]

- Sharma, P.; Holla, V.V.; Gurram, S.; Kamble, N.; Yadav, R.; Srinivas, D.; Pal, P.K. A Study of Battery Replacement Characteristics of Patients with Parkinson’s Disease and Factors Influencing Battery Drain. Mov. Disord. 2023, 26, 580–583. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Song, T. Energy-efficient cooperative caching for information-centric wireless sensor networking. IEEE Internet Things J. 2021, 9, 846–857. [Google Scholar] [CrossRef]

- Sudha, M.; Chandrakala, D.; Sreethar, S.; Shrivindhya, A. Energy Efficient Spiking Deep Residual Network and Binary Horse Herd Optimization Espoused clustering Protocol for Wireless Sensor Networks. Appl. Soft Comput. 2024, 157, 111456. [Google Scholar] [CrossRef]

- Nguyen, P.D.; Kim, L.W. Sensor system: A Survey of sensor Type, Ad Hoc network Topology and energy harvesting techniques. Electronics 2021, 10, 219. [Google Scholar] [CrossRef]

- Dziurdzia, P.; Bratek, P.; Markiewicz, M. An Efficient Electrothermal Model of a Thermoelectric Converter for a Thermal Energy Harvesting Process Simulation and Electronic Circuits Powering. Energies 2023, 17, 204. [Google Scholar] [CrossRef]

- Dhurgadevi, M.; Sakthivel, P. An Analysis of Wind Energy Generation by Opting the Better Placement of Wind Turbine by Artificial Neural Network and to Improve the Energy Efficiency of Wireless Sensor Network. Wirel. Pers. Commun. 2022, 123, 2607–2624. [Google Scholar] [CrossRef]

- Zheng, J.; Li, Z.; Zhang, H. Low-Wind-Speed Galloping Wind Energy Harvester Based on a W-Shaped Bluff Body. Energies 2024, 17, 958. [Google Scholar] [CrossRef]

- Makhetha, M.J.; Markus, E.D.; Abu-Mahfouz, A.M. Efficient wireless power transfer via self-resonant Conformal Strongly Coupled Magnetic Resonance for wireless sensor networks. Energy Rep. 2022, 8, 1358–1367. [Google Scholar] [CrossRef]

- Kuthadi, V.M.; Selvaraj, R.; Baskar, S.; Shakeel, P.M. Data security tolerance and portable based energy-efficient framework in sensor networks for smart grid environments. Sustain. Energy Technol. Assess. 2022, 52, 102184. [Google Scholar]

- Qiu, S.; Hao, Z.; Wang, Z.; Liu, L.; Liu, J.; Zhao, H.; Fortino, G. Sensor combination selection strategy for kayak cycle phase segmentation based on body sensor networks. IEEE Internet Things J. 2021, 9, 4190–4201. [Google Scholar] [CrossRef]

- Yuan, S. High-rise building deformation monitoring based on remote wireless sensor network. IEEE Sens. J. 2021, 21, 25133–25141. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, X.; Wu, C.; Chen, S.; Chen, F. Design of optimal utility of wireless rechargeable sensor networks via joint spatiotemporal scheduling. Appl. Math. Model. 2020, 86, 54–73. [Google Scholar] [CrossRef]

- Tita, E.D.; Nwadiugwu, W.P.; Lee, J.M.; Kim, D.S. Real-time optimizations in energy profiles and end-to-end delay in WSN using two-hop information. Comput. Commun. 2021, 172, 169–182. [Google Scholar] [CrossRef]

- Huang, S.C. A Charging-Aware Multi-Mode Routing Protocol for Data Collection in Wireless Rechargeable Sensor Networks. Sensors 2019, 19, 3338. [Google Scholar] [CrossRef]

- Malebary, S. Wireless mobile charger excursion optimization algorithm in wireless rechargeable sensor networks. IEEE Sens. J. 2020, 20, 13842–13848. [Google Scholar] [CrossRef]

- Zhang, P.; Ding, X.; Xu, J.; Wang, J.; Shi, L. Successive interference cancellation based throughput optimization for multi-hop wireless rechargeable sensor networks. Sensors 2020, 20, 327. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Lin, C.; Dai, H.; Wang, P.; Wang, L.; Wu, G.; Zhang, Q. Trading off charging and sensing for stochastic events monitoring in WRSNs. IEEE/ACM Trans. Netw. 2021, 30, 557–571. [Google Scholar] [CrossRef]

- Dhanvijay, M.M.; Patil, S.C. Internet of Things: A survey of enabling technologies in healthcare and its applications. Comput. Netw. 2019, 153, 113–131. [Google Scholar] [CrossRef]

- Ding, X.; Wang, Y.; Sun, G.; Luo, C.; Li, D.; Chen, W.; Hu, Q. Optimal charger placement for wireless power transfer. Comput. Netw. 2020, 170, 107123. [Google Scholar] [CrossRef]

- Wu, S.; Dai, H.; Xu, L.; Liu, L.; Xiao, F.; Xu, J. Comprehensive cost optimization for charger deployment in multi-hop wireless charging. IEEE Trans. Mob. Comput. 2022, 22, 4563–4577. [Google Scholar] [CrossRef]

- Fang, Z.; Chien, W.-C.; Zhang, C.; Hang, N.T.; Chen, W.M. GA-based Charger Deployment Algorithm in Indoor Wireless Rechargeable Sensor Networks. J. Internet Technol. 2023, 24, 487–494. [Google Scholar]

- Yu, N.; Dai, H.; Chen, G.; Liu, A.X.; Tian, B.; He, T. Connectivity-constrained placement of wireless chargers. IEEE Trans. Mob. Comput. 2019, 20, 909–927. [Google Scholar] [CrossRef]

- Wang, X.; Dai, H.; Wang, W.; Zheng, J.; Yu, N.; Chen, G.; Dou, W.; Wu, X. Practical heterogeneous wireless charger placement with obstacles. IEEE Trans. Mob. Comput. 2019, 19, 1910–1927. [Google Scholar] [CrossRef]

- Lin, T.L.; Chang, H.Y.; Wang, Y.H. A novel hybrid search and remove strategy for power balance wireless charger deployment in wireless rechargeable sensor networks. Energies 2020, 13, 2661. [Google Scholar] [CrossRef]

- You, W.; Ren, M.; Ma, Y.; Wu, D.; Yang, J.; Liu, X.; Liu, T. Practical charger placement scheme for wireless rechargeable sensor networks with obstacles. ACM Trans. Sens. Netw. 2023, 20, 11. [Google Scholar] [CrossRef]

- Yang, M.; Wang, A.; Sun, G.; Zhang, Y.; Engineering, E. Deploying charging nodes in wireless rechargeable sensor networks based on improved firefly algorithm. Comput. Electr. Eng. 2018, 72, 719–731. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.; Zhu, Y.; Liu, Y.; Zhao, C. Optimization strategy of wireless charger node deployment based on improved cuckoo search algorithm. EURASIP J. Wirel. Commun. Netw. 2021, 2021, 74. [Google Scholar] [CrossRef]

- Gong, C.; Guo, C.; Xu, H.; Zhou, C.; Yuan, X. A joint optimization strategy of coverage planning and energy scheduling for wireless rechargeable sensor networks. Processes 2020, 8, 1324. [Google Scholar] [CrossRef]

- Xu, P.; Wu, J.; Chang, C.-Y.; Shang, C.; Roy, D.S. MCDP: Maximizing cooperative detection probability for barrier coverage in rechargeable wireless sensor networks. IEEE Sens. J. 2020, 21, 7080–7092. [Google Scholar] [CrossRef]

- He, S.; Chen, J.; Jiang, F.; Yau, D.K.; Xing, G.; Sun, Y. Energy provisioning in wireless rechargeable sensor networks. IEEE Trans. Mob. Comput. 2012, 12, 1931–1942. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Chen, C.S.; Wang, Z.; Zhu, Y.H. Charging while moving: Deploying wireless chargers for powering wearable devices. IEEE Trans. Veh. Technol. 2018, 67, 11575–11586. [Google Scholar] [CrossRef]

- Power Over Distance, Powercast. Available online: http://www.powercastco.com (accessed on 25 May 2024).

- Yao, H.; Zheng, C.; Fu, X.; Yang, Y.; Ungurean, I. Charger and receiver deployment with delay constraint in mobile wireless rechargeable sensor networks. Ad Hoc Netw. 2022, 126, 102756. [Google Scholar] [CrossRef]

| Paper | Deployment Objective | Coverage Objective | Optimization Objective | Approaches | |||

|---|---|---|---|---|---|---|---|

| CU | DC | CR | ECC | ||||

| [27] | SC | SS | √ | GH | |||

| [24] | SC | SS | √ | √ | GH | ||

| [28] | SC | SS | √ | GH | |||

| [29] | SC | SS | √ | GH | |||

| [25] | SC | SS | √ | GH | |||

| [30] | SC | SS | √ | GH | |||

| [31] | SC | SS | √ | IFA | |||

| [32] | SC | SS | √ | ICS | |||

| [26] | SC | SS | √ | GA | |||

| [33] | SC | SS | √ | √ | GH & PSO | ||

| Our | SS & SC | SS & PoIs | √ | GH & PSO | |||

| Parameters | Description |

|---|---|

| A two-dimensional plane used to define the problem | |

| Sensor’s life cycle | |

| The number of time slots in a life cycle of the sensor | |

| The wireless charging efficiency | |

| The maximum charging distance of the charger | |

| The maximum charging power of the sensor | |

| The maximum operating time slot of the sensor | |

| The average power consumption of the sensor | |

| A continuous variable. The sensing probability the sensor perceives the PoIs | |

| A continuous variable. The maximum transmitting power of the charger | |

| Variables | Description |

| A two-dimensional continuous variable. The location of the i-th deployed PoI, and is the set of all deployed PoIs, and oi also refers to the PoIs itself for simplicity | |

| A two-dimensional continuous variable. The location of the j-th deployed sensor, and is the set of all deployed sensors, and sj also refers to the sensor itself for simplicity | |

| also refers to the charger itself for simplicity | |

| in one cycle | |

| The scheduling scheme of all sensors | |

| by a sensor . |

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Side length of the square | 50 (m) | 0.5 | |

| 5 | 0.5 | ||

| 5 (W) | 5.6 | ||

| 0.012 (W) | 3.4 | ||

| 0.04 (W) | 70% | ||

| 15 (m) | 5 | ||

| 0.003 | 1 (m) | ||

| 0.2316 | PoIs | 70 | |

| 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lian, J.; Yao, H. Joint Deployment of Sensors and Chargers in Wireless Rechargeable Sensor Networks. Energies 2024, 17, 3130. https://doi.org/10.3390/en17133130

Lian J, Yao H. Joint Deployment of Sensors and Chargers in Wireless Rechargeable Sensor Networks. Energies. 2024; 17(13):3130. https://doi.org/10.3390/en17133130

Chicago/Turabian StyleLian, Jie, and Haiqing Yao. 2024. "Joint Deployment of Sensors and Chargers in Wireless Rechargeable Sensor Networks" Energies 17, no. 13: 3130. https://doi.org/10.3390/en17133130

APA StyleLian, J., & Yao, H. (2024). Joint Deployment of Sensors and Chargers in Wireless Rechargeable Sensor Networks. Energies, 17(13), 3130. https://doi.org/10.3390/en17133130