Closing the Loop between Waste-to-Energy Technologies: A Holistic Assessment Based on Multiple Criteria

Abstract

1. Introduction

2. Methods

2.1. PROMETHEE Method

- Calculation of preference degrees for each pair of alternatives.

- Calculation of unicriterion flows.

- Calculation of global flows.

2.2. Criteria and Data Collection

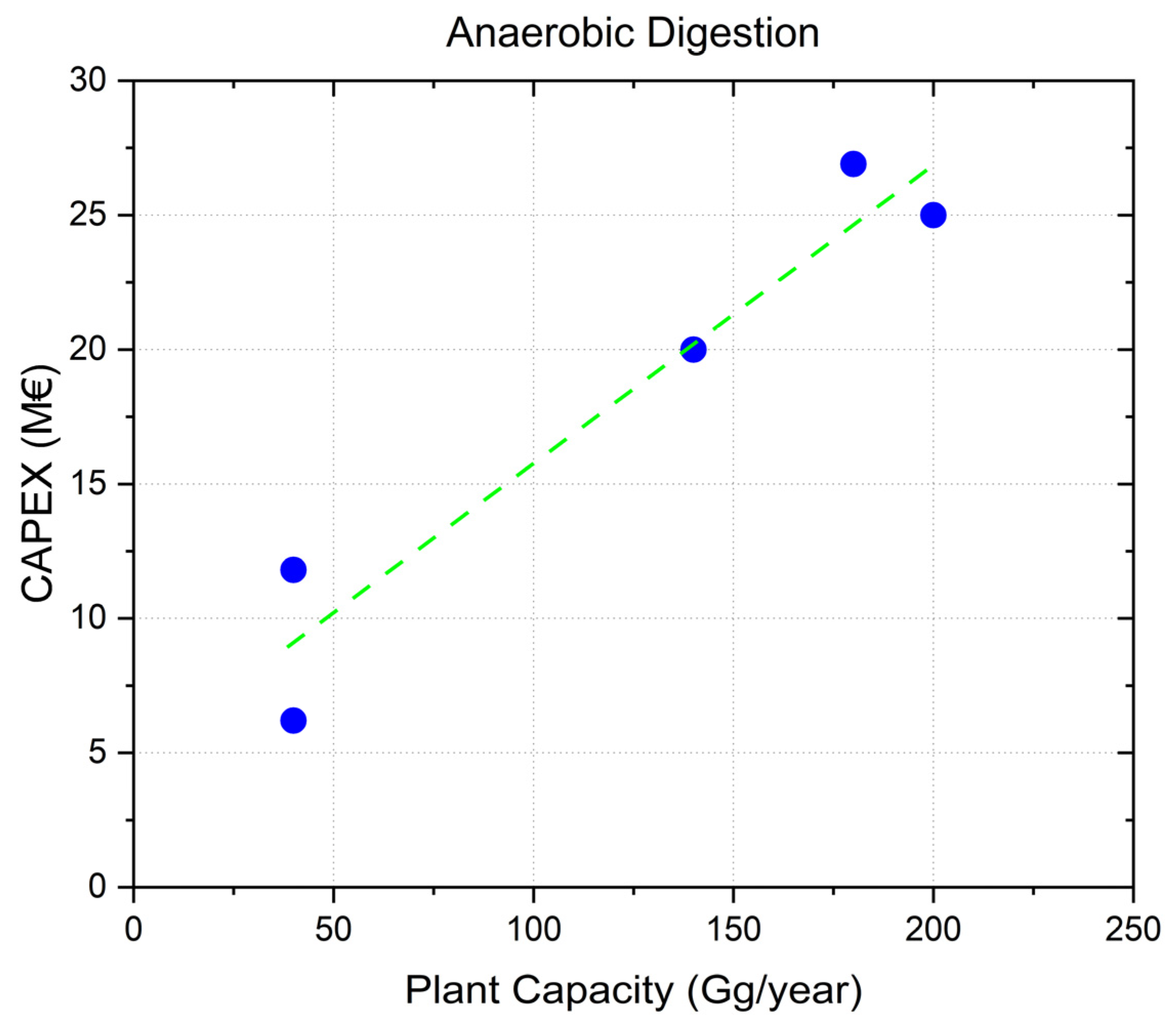

2.2.1. Economic Criterion

2.2.2. Environmental Criterion

| Study | Feedstock | Functional Unit | Technology | GWP (kg CO2 eq./Functional Unit) |

|---|---|---|---|---|

| [30] | MSW | 1 Mg of waste | Pyrolysis–Gasification | 1017 |

| [31] | Mixture of waste | 1 kg of waste | Incineration | 1.91 |

| Gasification | 0.94 | |||

| Anaerobic digestion | 1.7 | |||

| [32] | MSW | 1 kg of waste | Incineration | 0.7 |

| Pyrolysis | 0.6 | |||

| Gasification | 0.55 | |||

| [44] | MSW | 1 Mg of waste | Gasification | −96 |

| [45] | MSW | 1 Mg of waste | Incineration | 496 |

| [46] | MSW | 1 Mg of waste | Incineration | 593 |

| [27] | MSW | 1 Mg of waste | Incineration | 372 |

| Anaerobic digestion | 324 | |||

| Gasification | 376 | |||

| [33] | MSW Refuse | 1 Mg of waste | Incineration | −725 |

| [34] | MSW | 1 Mg of waste | Incineration | 430 |

| Gasification | 27 | |||

| [47] | MSW | 1 Mg of waste | Incineration | 271 |

| Anaerobic digestion | −164 | |||

| [48] | MSW | 1 Mg of waste | Pyrolysis | 250 |

| [49] | MSW | 1 Mg of waste | Gasification | 566 |

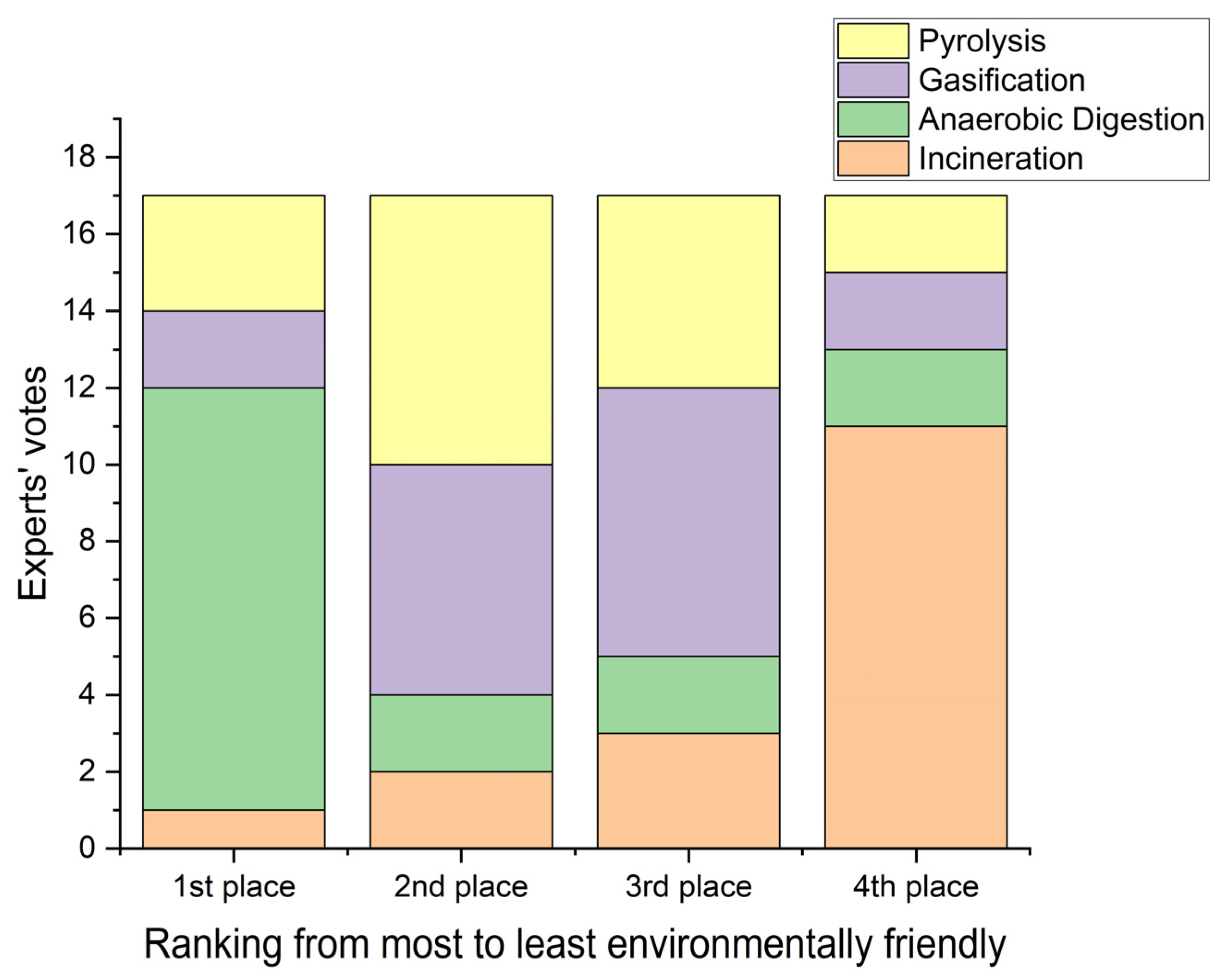

2.2.3. Social Criterion

2.2.4. Technological Criterion and Alternative Economic and Environmental Indices

2.3. Current State of MSW Management in Greece

2.4. Waste-to-Energy Technologies

2.4.1. Incineration

2.4.2. Gasification

2.4.3. Pyrolysis

2.4.4. Anaerobic Digestion

2.4.5. Other Technologies

3. Results

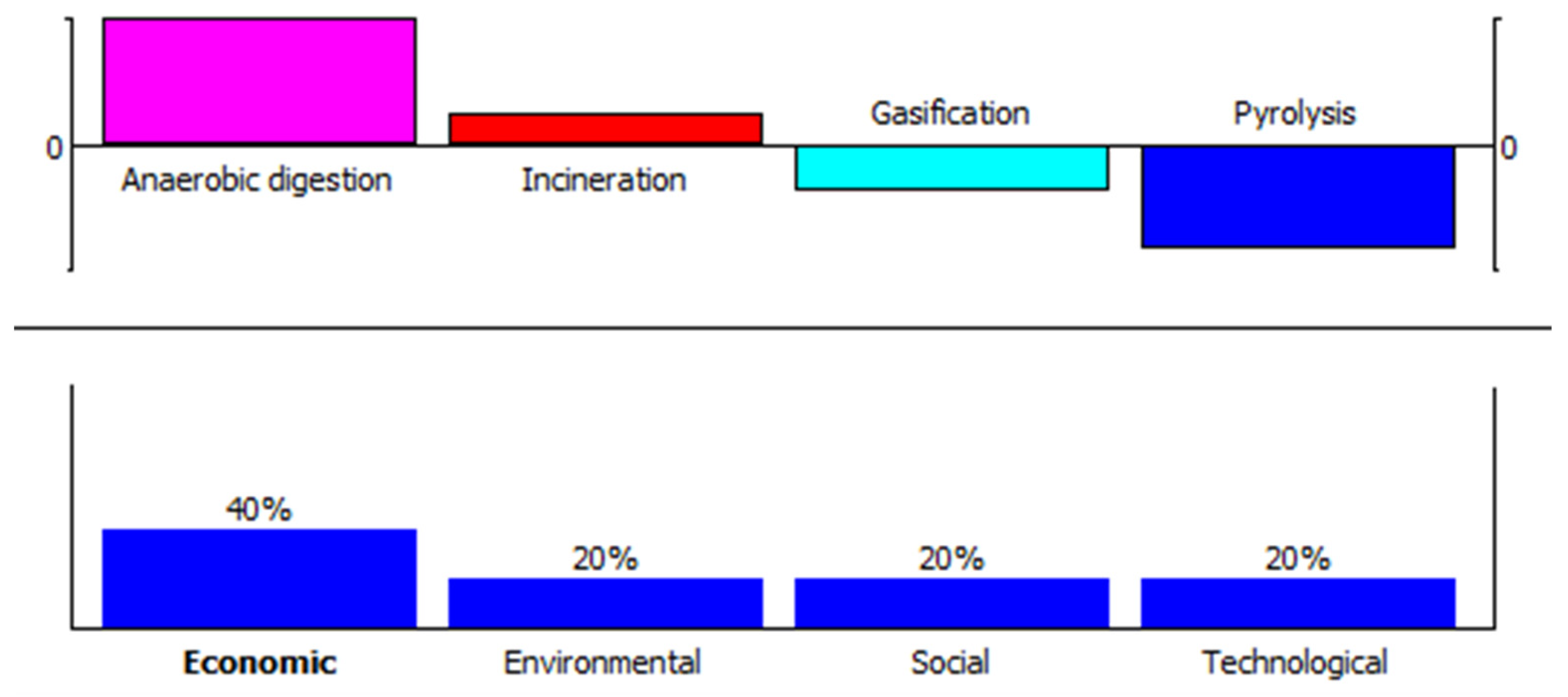

3.1. Scenario 1

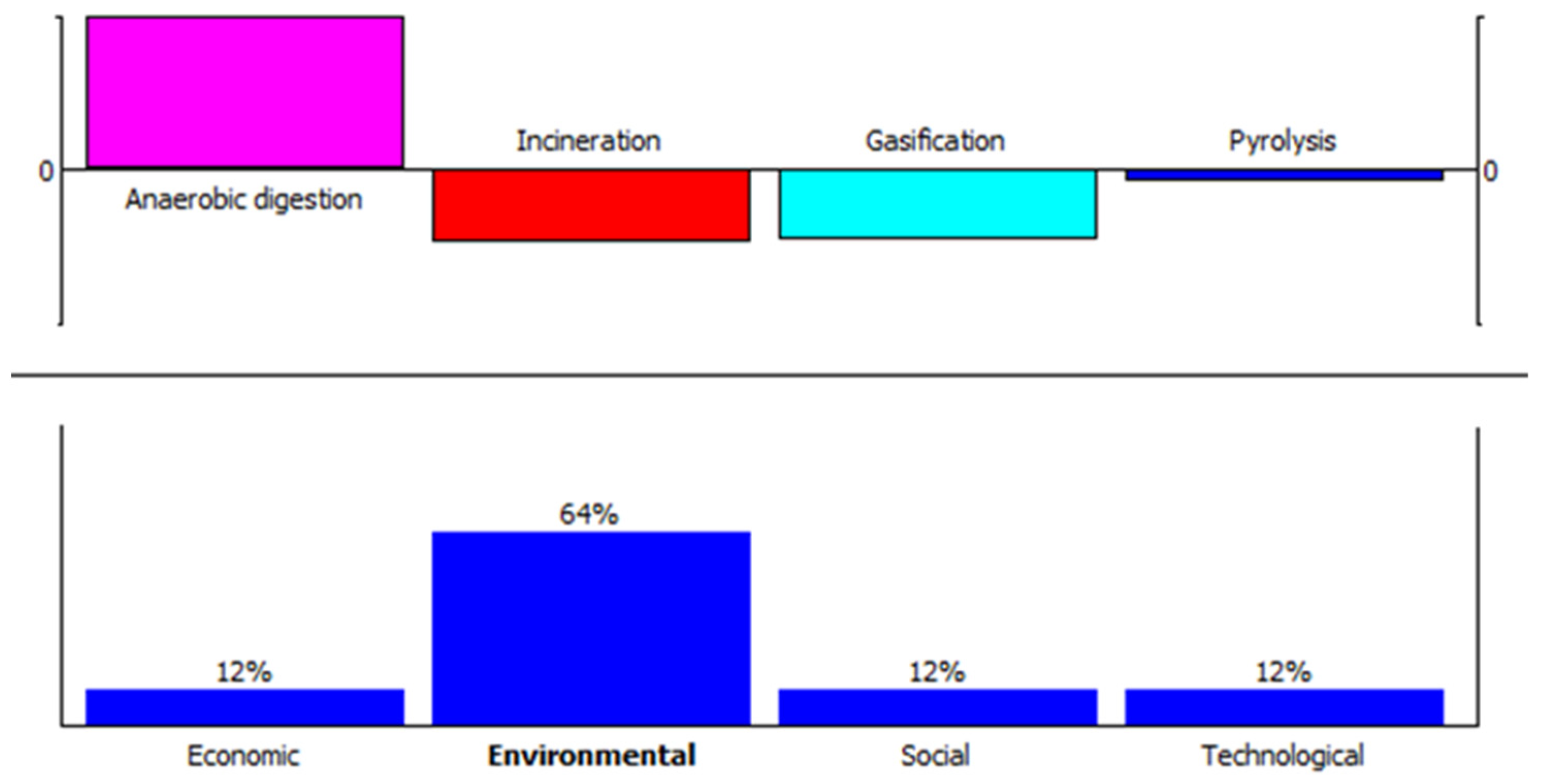

3.2. Scenario 2

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Chicago, IL, USA, 2018. [Google Scholar]

- Abdallah, M.; Shanableh, A.; Arab, M.; Shabib, A.; Adghim, M.; El-Sherbiny, R. Waste to energy potential in middle income countries of MENA region based on multi-scenario analysis for Kafr El-Sheikh Governorate, Egypt. J. Environ. Manag. 2019, 232, 58–65. [Google Scholar] [CrossRef] [PubMed]

- Klinghoffer, N.B.; Castaldi, M.J. Gasification and pyrolysis of municipal solid waste (MSW). In Waste to Energy Conversion Technology; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; pp. 146–176. [Google Scholar] [CrossRef]

- Vlachokostas, C.; Michailidou, A.V.; Achillas, C. Multi-Criteria Decision Analysis towards promoting Waste-to-Energy Management Strategies: A critical review. Renew. Sustain. Energy Rev. 2021, 138, 110563. [Google Scholar] [CrossRef]

- Almanaseer, N.; Abbassi, B.; Dunlop, C.; Friesen, K.; Nestico-Semianiw, E. Multi-Criteria Analysis of Waste-to-Energy Technologies in Developed and Developing Countries. Environ. Res. Eng. Manag. 2020, 76, 32–43. [Google Scholar] [CrossRef]

- Hoang, N.H.; Fogarassy, C. Sustainability Evaluation of Municipal Solid Waste Management System for Hanoi (Vietnam)—Why to Choose the ‘Waste-to-Energy’ Concept. Sustainability 2020, 12, 1085. [Google Scholar] [CrossRef]

- Hoang, G.M.; Fujiwara, T.; Phu, T.S.P.; Nguyen, L.D. Sustainable solid waste management system using multi-objective decision-making model: A method for maximizing social acceptance in Hoi An city, Vietnam. Environ. Sci. Pollut. Res. 2018, 26, 34137–34147. [Google Scholar] [CrossRef] [PubMed]

- Coban, A.; Ertis, I.F.; Cavdaroglu, N.A. Municipal solid waste management via multi-criteria decision making methods: A case study in Istanbul, Turkey. J. Clean. Prod. 2018, 180, 159–167. [Google Scholar] [CrossRef]

- Inglezakis, V.J.; Moustakas, K.; Khamitova, G.; Tokmurzin, D.; Sarbassov, Y.; Rakhmatulina, R.; Serik, B.; Abikak, Y.; Poulopoulos, S.G. Current municipal solid waste management in the cities of Astana and Almaty of Kazakhstan and evaluation of alternative management scenarios. Clean Technol. Environ. Policy 2018, 20, 503–516. [Google Scholar] [CrossRef]

- Tan, S.T.; Ho, W.S.; Hashim, H.; Lee, C.T.; Taib, M.R.; Ho, C.S. Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia. Energy Convers. Manag. 2015, 102, 111–120. [Google Scholar] [CrossRef]

- Afgan, N.H.; Carvalho, M.G. Multi-Criteria Assessment of New and Renewable Energy Power Plants. 2002. Available online: www.elsevier.com/locate/energy (accessed on 3 April 2024).

- Kheybari, S.; Rezaie, F.M.; Naji, S.A.; Najafi, F. Evaluation of energy production technologies from biomass using analytical hierarchy process: The case of Iran. J. Clean. Prod. 2019, 232, 257–265. [Google Scholar] [CrossRef]

- Thengane, S.K. Assessment of Different Technologies for Managing Yard Waste Using Analytic Hierarchy Process. Process Integr. Optim. Sustain. 2019, 3, 255–272. [Google Scholar] [CrossRef]

- Fetanat, A.; Mofid, H.; Mehrannia, M.; Shafipour, G. Informing energy justice based decision-making framework for waste-to-energy technologies selection in sustainable waste management: A case of Iran. J. Clean. Prod. 2019, 228, 1377–1390. [Google Scholar] [CrossRef]

- Alsabbagh, M. Mitigation of CO2e Emissions from the Municipal Solid Waste Sector in the Kingdom of Bahrain. Climate 2019, 7, 100. [Google Scholar] [CrossRef]

- Khan, I.; Kabir, Z. Waste-to-energy generation technologies and the developing economies: A multi-criteria analysis for sustainability assessment. Renew. Energy 2020, 150, 320–333. [Google Scholar] [CrossRef]

- Khoshand, A.; Kamalan, H.; Rezaei, H. Application of analytical hierarchy process (AHP) to assess options of energy recovery from municipal solid waste: A case study in Tehran, Iran. J. Mater. Cycles Waste Manag. 2018, 20, 1689–1700. [Google Scholar] [CrossRef]

- Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Banias, G.; Kafetzopoulos, G.; Karagiannidis, A. Social acceptance for the development of a waste-to-energy plant in an urban area. Resour. Conserv. Recycl. 2011, 55, 857–863. [Google Scholar] [CrossRef]

- Brans, J.P.; Vincke, P. Note—A Preference Ranking Organisation Method. Manag. Sci. 1985, 31, 647–656. [Google Scholar] [CrossRef]

- Ishizaka, A.; Nemery, P. Multi-Criteria Decision Analysis: Methods and Software; Wiley: Chichester, UK, 2013. [Google Scholar]

- Taherdoost, H. Using PROMETHEE Method for Multi-Criteria Decision Making: Applications and Procedures. Iris J. Econ. Bus. Manag. 2023, 1. [Google Scholar] [CrossRef]

- Aleluia, J.; Ferrão, P. Assessing the costs of municipal solid waste treatment technologies in developing Asian countries. Waste Manag. 2017, 69, 592–608. [Google Scholar] [CrossRef] [PubMed]

- Katsanevakis, I.; Malamakis, A.; Perkoulidis, G.; Tsatsarelis, T. Evaluation of Municipal Solid Waste by Energy Point of View and the Perspectives of Application in Region of Central Macedonia; Technical Chamber of Greece: Thessaloniki, Greece, 2010; pp. 31, 55. [Google Scholar]

- Langen, M.; Mitchinson, J. Processing of municipal solid waste before anaerobic digestion—Qualities, capex and OPEX of case studies. In Proceedings of the 15th European Biosolids and Organic Resources Conference, Leeds, UK, 15–17 November 2010. [Google Scholar]

- Mckendry, P. Overview of Anaerobic Digestion and Power and Gas to Grid Plant CAPEX and OPEX Costs. Int. J. Bioprocess. Biotech. 2018, 2, 109. [Google Scholar] [CrossRef]

- Fernández-González, J.M.; Grindlay, A.L.; Serrano-Bernardo, F.; Rodríguez-Rojas, M.I.; Zamorano, M. Economic and environmental review of Waste-to-Energy systems for municipal solid waste management in medium and small municipalities. Waste Manag. 2017, 67, 360–374. [Google Scholar] [CrossRef]

- Aracil, C.; Haro, P.; Fuentes-Cano, D.; Gómez-Barea, A. Implementation of waste-to-energy options in landfill-dominated countries: Economic evaluation and GHG impact. Waste Manag. 2018, 76, 443–456. [Google Scholar] [CrossRef] [PubMed]

- Panepinto, D.; Zanetti, M. Technical and environmental comparison among different municipal solid waste management scenarios. Sustainability 2021, 13, 3167. [Google Scholar] [CrossRef]

- Satiada, M.A.; Calderon, A. Comparative analysis of existing waste-to-energy reference plants for municipal solid waste. Clean. Environ. Syst. 2021, 3, 100063. [Google Scholar] [CrossRef]

- Zaman, A.U. Life cycle assessment of pyrolysis-gasification as an emerging municipal solid waste treatment technology. Int. J. Environ. Sci. Technol. 2013, 10, 1029–1038. [Google Scholar] [CrossRef]

- Arafat, H.A.; Jijakli, K.; Ahsan, A. Environmental performance and energy recovery potential of five processes for municipal solid waste treatment. J. Clean. Prod. 2015, 105, 233–240. [Google Scholar] [CrossRef]

- Evangelisti, S.; Tagliaferri, C.; Clift, R.; Lettieri, P.; Taylor, R.; Chapman, C. Life cycle assessment of conventional and two-stage advanced energy-from-waste technologies for municipal solid waste treatment. J. Clean. Prod. 2015, 100, 212–223. [Google Scholar] [CrossRef]

- Ramos, A.; Teixeira, C.A.; Rouboa, A. Assessment study of an advanced gasification strategy at low temperature for syngas generation. Int. J. Hydrogen Energy 2018, 43, 10155–10166. [Google Scholar] [CrossRef]

- Zhou, Z.; Tang, Y.; Dong, J.; Chi, Y.; Ni, M.; Li, N.; Zhang, Y. Environmental performance evolution of municipal solid waste management by life cycle assessment in Hangzhou, China. J. Environ. Manag. 2018, 227, 23–33. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: Theoretical analysis and case study of commercial plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef]

- Ahamed, A.; Yin, K.; Ng, B.J.H.; Ren, F.; Chang, V.W.-C.; Wang, J.-Y. Life cycle assessment of the present and proposed food waste management technologies from environmental and economic impact perspectives. J. Clean. Prod. 2016, 131, 607–614. [Google Scholar] [CrossRef]

- Khoo, H.H. Life cycle impact assessment of various waste conversion technologies. Waste Manag. 2009, 29, 1892–1900. [Google Scholar] [CrossRef] [PubMed]

- Mayer, F.; Bhandari, R.; Gäth, S.A. Life cycle assessment on the treatment of organic waste streams by anaerobic digestion, hydrothermal carbonization and incineration. Waste Manag. 2021, 130, 93–106. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principle and Framework. International Standard: Geneva, Switzerland, 2006.

- Leme, M.M.V.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Lopes, B.M.; Ferreira, C.H. Techno-economic analysis and environmental impact assessment of energy recovery from Municipal Solid Waste (MSW) in Brazil. Resour. Conserv. Recycl. 2014, 87, 8–20. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S. Critical review on life cycle assessment of conventional and innovative waste-to-energy technologies. Sci. Total Environ. 2019, 672, 708–721. [Google Scholar] [CrossRef] [PubMed]

- Dastjerdi, B.; Strezov, V.; Rajaeifar, M.A.; Kumar, R.; Behnia, M. A systematic review on life cycle assessment of different waste to energy valorization technologies. J. Clean. Prod. 2021, 290, 25. [Google Scholar] [CrossRef]

- Houghton, J.T. Climate Change 1995: The Science of Climate Change; Cambridge University Press: Cambridge, UK, 1996. [Google Scholar]

- Coventry, Z.A.; Tize, R.; Karunanithi, A.T. Comparative life cycle assessment of solid waste management strategies. Clean. Technol. Environ. Policy 2016, 18, 1515–1524. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Azapagic, A. Assessing the environmental sustainability of energy recovery from municipal solid waste in the UK. Waste Manag. 2016, 50, 346–363. [Google Scholar] [CrossRef]

- Menikpura, S.N.M.; Sang-Arun, J.; Bengtsson, M. Assessment of environmental and economic performance of Waste-to-Energy facilities in Thai cities. Renew. Energy 2016, 86, 576–584. [Google Scholar] [CrossRef]

- Chhabra, V.; Parashar, A.; Shastri, Y.; Bhattacharya, S. Techno-economic and life cycle assessment of pyrolysis of unsegregated urban municipal solid waste in India. Ind. Eng. Chem. Res. 2021, 60, 1473–1482. [Google Scholar] [CrossRef]

- Ouedraogo, A.S.; Frazier, R.S.; Kumar, A. Comparative life cycle assessment of gasification and landfilling for disposal of municipal solid wastes. Energies 2021, 14, 7032. [Google Scholar] [CrossRef]

- Wang, J.; Okopi, S.I.; Ma, H.; Wang, M.; Chen, R.; Tian, W.; Xu, F. Life cycle assessment of the integration of anaerobic digestion and pyrolysis for treatment of municipal solid waste. Bioresour. Technol. 2021, 338, 125486. [Google Scholar] [CrossRef] [PubMed]

- Assefa, G.; Frostell, B. Social sustainability and social acceptance in technology assessment: A case study of energy technologies. Technol. Soc. 2007, 29, 63–78. [Google Scholar] [CrossRef]

- OECD. Environmental Performance Reviews: Greece 2020. In OECD Environmental Performance Reviews; OECD: Paris, France, 2020. [Google Scholar] [CrossRef]

- DIRECTIVE (EU) 2018/851 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 30 May 2018 Amending Directive 2008/98/EC on Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0851 (accessed on 27 March 2024).

- Vlachokostas, C. Closing the Loop Between Energy Production and Waste Management: A Conceptual Approach Towards Sustainable Development. Sustainability 2020, 12, 5995. [Google Scholar] [CrossRef]

- ISWA. White Book on Energy-from-Waste (EfW); ISWA: Rotterdam, NL, USA, 2022. [Google Scholar]

- Silva, M.G.; Przybysz, A.L.; Piekarski, C.M. Location as a key factor for waste to energy plants. J. Clean. Prod. 2022, 379, 134386. [Google Scholar] [CrossRef]

- Manousaki, I.; Konstandakopoulou, F. Environmental appraisal of alternative municipal solid waste management scenarios: The case of Chania, Greece. Prog. Ind. Ecol. Int. J. 2018, 12, 345–360. [Google Scholar] [CrossRef]

- Zitouni-Petrogianni, A.; Voutsas, E. Modeling, Optimization and Cost Analysis of Municipal Solid Waste Treatment with Plasma Gasification. Environ. Process. 2021, 8, 747–767. [Google Scholar] [CrossRef]

- Alatzas, S.; Moustakas, K.; Malamis, D.; Vakalis, S. Biomass potential from agricultural waste for energetic utilization in Greece. Energies 2019, 12, 1095. [Google Scholar] [CrossRef]

- Aravani, V.P.; Papadakis, V.G. Technoeconomic assessment for the viable exploitation of biomass residues by an innovative pyrolysis-anaerobic digestion processing plant. Environ Res 2024, 243, 117835. [Google Scholar] [CrossRef]

- Moya, D.; Aldás, C.; López, G.; Kaparaju, P. Municipal solid waste as a valuable renewable energy resource: A worldwide opportunity of energy recovery by using Waste-To-Energy Technologies. Energy Procedia 2017, 134, 286–295. [Google Scholar] [CrossRef]

- Singh, R.P.; Tyagi, V.V.; Allen, T.; Ibrahim, M.H.; Kothari, R. An overview for exploring the possibilities of energy generation from municipal solid waste (MSW) in Indian scenario. Renew. Sustain. Energy Rev. 2011, 15, 4797–4808. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Lombardi, L.; Carnevale, E.; Corti, A. A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef] [PubMed]

- Sipra, A.T.; Gao, N.; Sarwar, H. Municipal solid waste (MSW) pyrolysis for bio-fuel production: A review of effects of MSW components and catalysts. Fuel Process. Technol. 2018, 175, 131–147. [Google Scholar] [CrossRef]

- Rulkens, W. Sewage sludge as a biomass resource for the production of energy: Overview and assessment of the various options. Energy Fuels 2008, 22, 9–15. [Google Scholar] [CrossRef]

- Surendra, K.C.; Takara, D.; Hashimoto, A.G.; Khanal, S.K. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sustain. Energy Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Sevillano, C.A.; Pesantes, A.A.; Carpio, E.P.; Martínez, E.J.; Gómez, X. Anaerobic digestion for producing renewable energy-the evolution of this technology in a new uncertain scenario. Entropy 2021, 23, 145. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y. A review on hydrothermal carbonization of biomass and plastic wastes to energy products. Biomass Bioenergy 2020, 134, 105479. [Google Scholar] [CrossRef]

- Yu, S.; He, J.; Zhang, Z.; Sun, Z.; Xie, M.; Xu, Y.; Bie, X.; Li, Q.; Zhang, Y.; Sevilla, M.; et al. Towards Negative Emissions: Hydrothermal Carbonization of Biomass for Sustainable Carbon Materials. Adv. Mater. 2024, 36, 2307412. [Google Scholar] [CrossRef]

- Yu, S.; Zhao, P.; Liu, M.-Q.; Gao, Y.; Li, Q.-H.; Zhang, Y.-G.; Zhou, H. Effects of decoupled temperature and pressure on the hydrothermal process of lignin. RanliaoHuaxueXuebao/J. Fuel Chem. Technol. 2023, 51, 1106–1113. [Google Scholar] [CrossRef]

- Vlachokostas, C.; Achillas, C.; Michailidou, A.V.; Tsegas, G.; Moussiopoulos, N. Externalities of energy sources: The operation of a municipal solid waste-to-energy incineration facility in the greater Thessaloniki area, Greece. Waste Manag. 2020, 113, 351–358. [Google Scholar] [CrossRef]

- Yu, S.; Li, Q.; Zhang, Y.; Zhou, H. New possibility for PET plastic recycling by a tailored hydrolytic enzyme. Green Energy Environ. 2024, 9, 163–195. [Google Scholar] [CrossRef]

| Incineration | Gasification | Pyrolysis | Anaerobic Digestion | |

|---|---|---|---|---|

| Scenario 1 | ||||

| CAPEX (EUR/Mg feedstock) | 610 | 705 | 800 | 113 |

| GWP (kg CO2/Mg feedstock) | 584 | 443 | 482 | 360 |

| Scenario 2 | ||||

| Economic criterion (1–4 scale) | 2.06 | 2.7 | 3.6 | 1.65 |

| Environmental criterion (1–4 scale) | 3.41 | 2.53 | 2.35 | 1.70 |

| Scenario 1 and 2 | ||||

| Public preference (1–5 scale) | 4.31 | 4.05 | 4.07 | 4.16 |

| Large-scale applicability in Greece (1–5 scale) | 3.80 | 3.10 | 2.50 | 4.60 |

| Technology | Phi | Phi+ | Phi− | Ranking |

|---|---|---|---|---|

| Anaerobic digestion | 0.8333 | 0.9167 | 0.0833 | 1 |

| Incineration | 0.1667 | 0.5833 | 0.4167 | 2 |

| Gasification | −0.3333 | 0.3333 | 0.6667 | 3 |

| Pyrolysis | −0.6667 | 0.1667 | 0.8333 | 4 |

| Technology | Phi | Phi+ | Phi− | Ranking |

|---|---|---|---|---|

| Anaerobic digestion | 0.8333 | 0.9167 | 0.0833 | 1 |

| Incineration | 0.1667 | 0.5833 | 0.4167 | 2 |

| Gasification | −0.5 | 0.25 | 0.75 | 3 |

| Pyrolysis | −0.5 | 0.25 | 0.75 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mertzanakis, C.; Vlachokostas, C.; Toufexis, C.; Michailidou, A.V. Closing the Loop between Waste-to-Energy Technologies: A Holistic Assessment Based on Multiple Criteria. Energies 2024, 17, 2971. https://doi.org/10.3390/en17122971

Mertzanakis C, Vlachokostas C, Toufexis C, Michailidou AV. Closing the Loop between Waste-to-Energy Technologies: A Holistic Assessment Based on Multiple Criteria. Energies. 2024; 17(12):2971. https://doi.org/10.3390/en17122971

Chicago/Turabian StyleMertzanakis, Christos, Christos Vlachokostas, Charalampos Toufexis, and Alexandra V. Michailidou. 2024. "Closing the Loop between Waste-to-Energy Technologies: A Holistic Assessment Based on Multiple Criteria" Energies 17, no. 12: 2971. https://doi.org/10.3390/en17122971

APA StyleMertzanakis, C., Vlachokostas, C., Toufexis, C., & Michailidou, A. V. (2024). Closing the Loop between Waste-to-Energy Technologies: A Holistic Assessment Based on Multiple Criteria. Energies, 17(12), 2971. https://doi.org/10.3390/en17122971