Pipeline Infrastructure for CO2 Transport: Cost Analysis and Design Optimization

Abstract

1. Introduction

2. Methodology

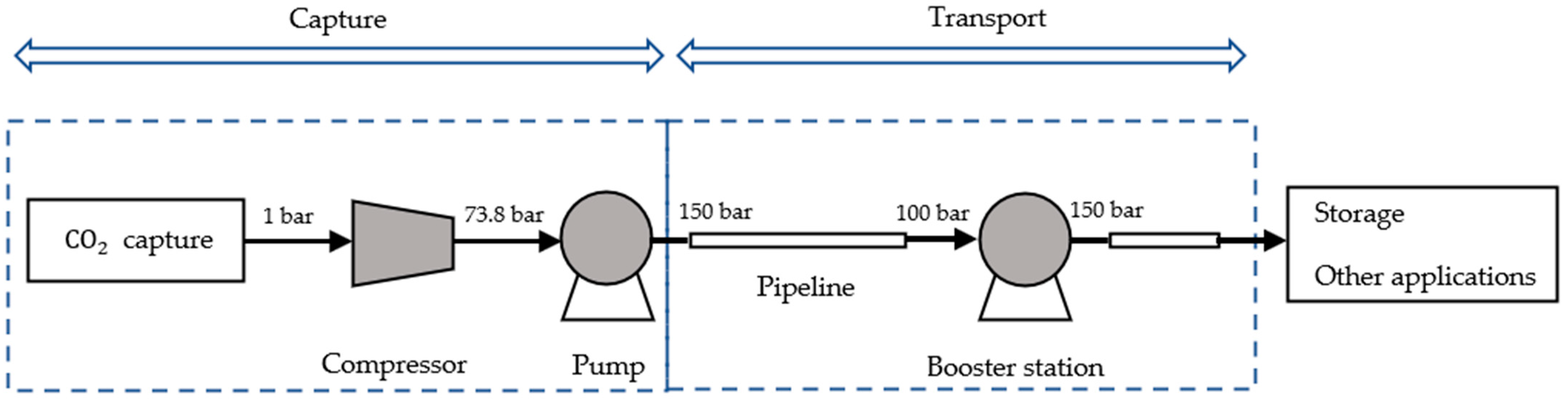

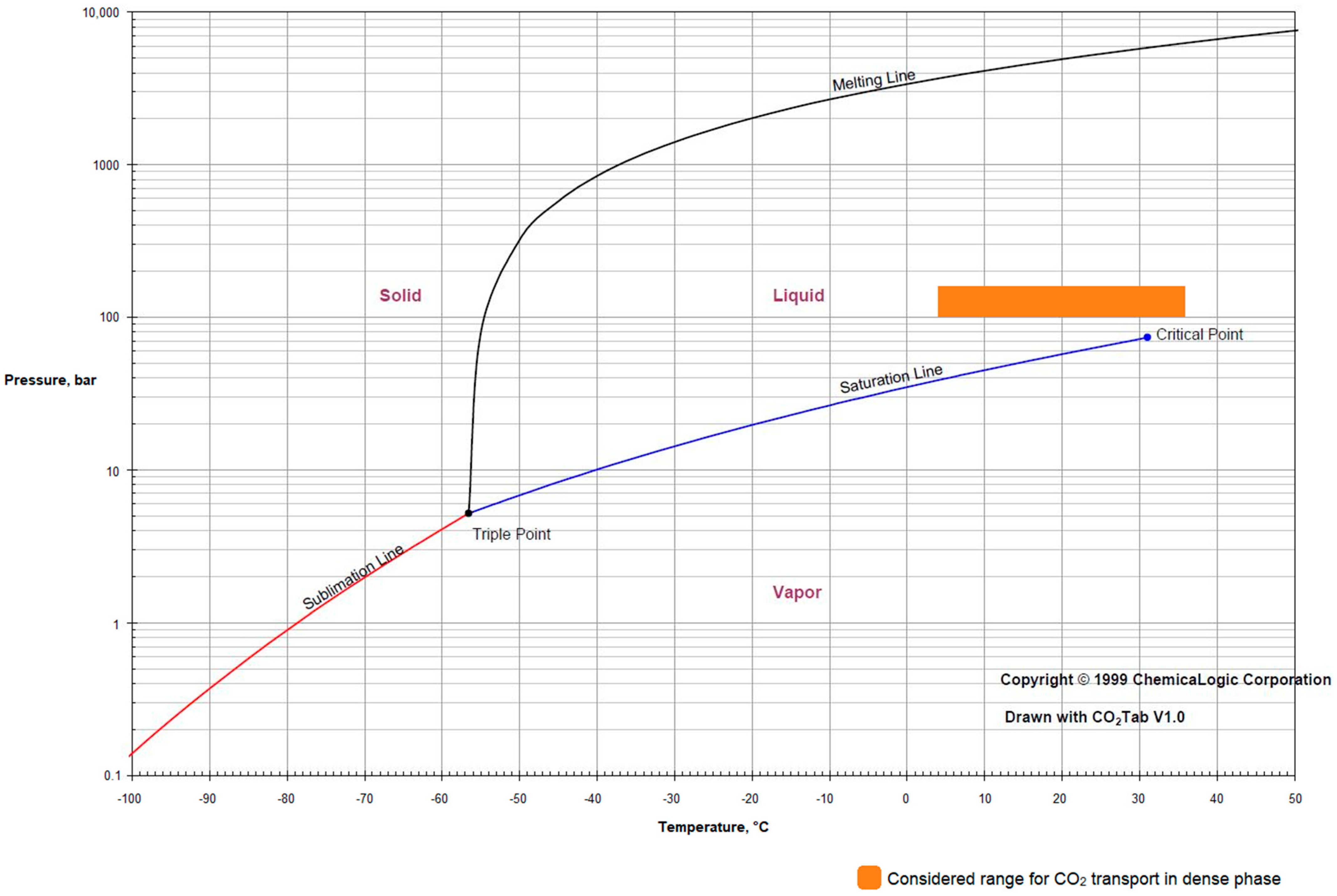

2.1. Pipeline

2.2. Compressor and Pump

2.3. Booster Stations

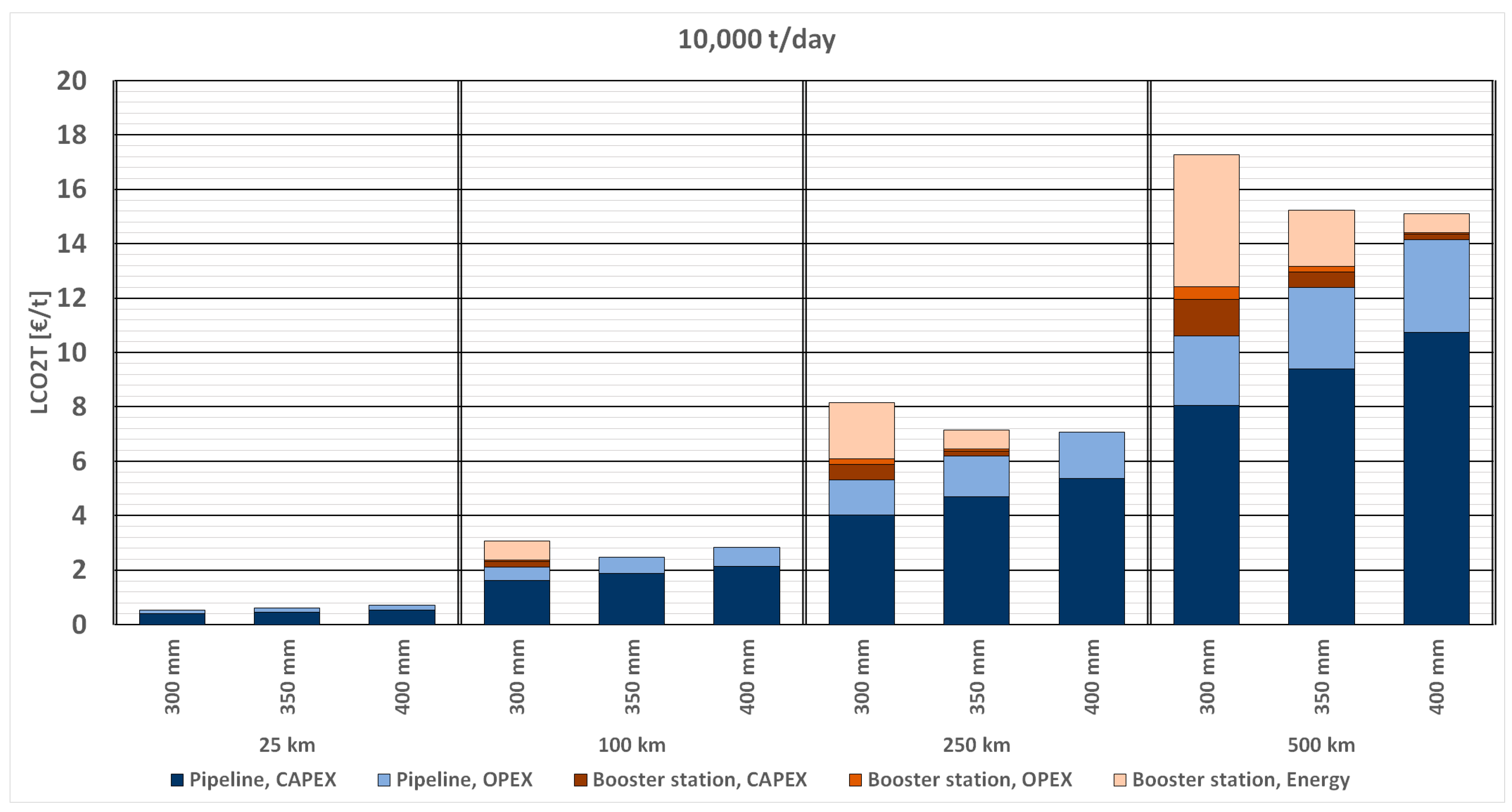

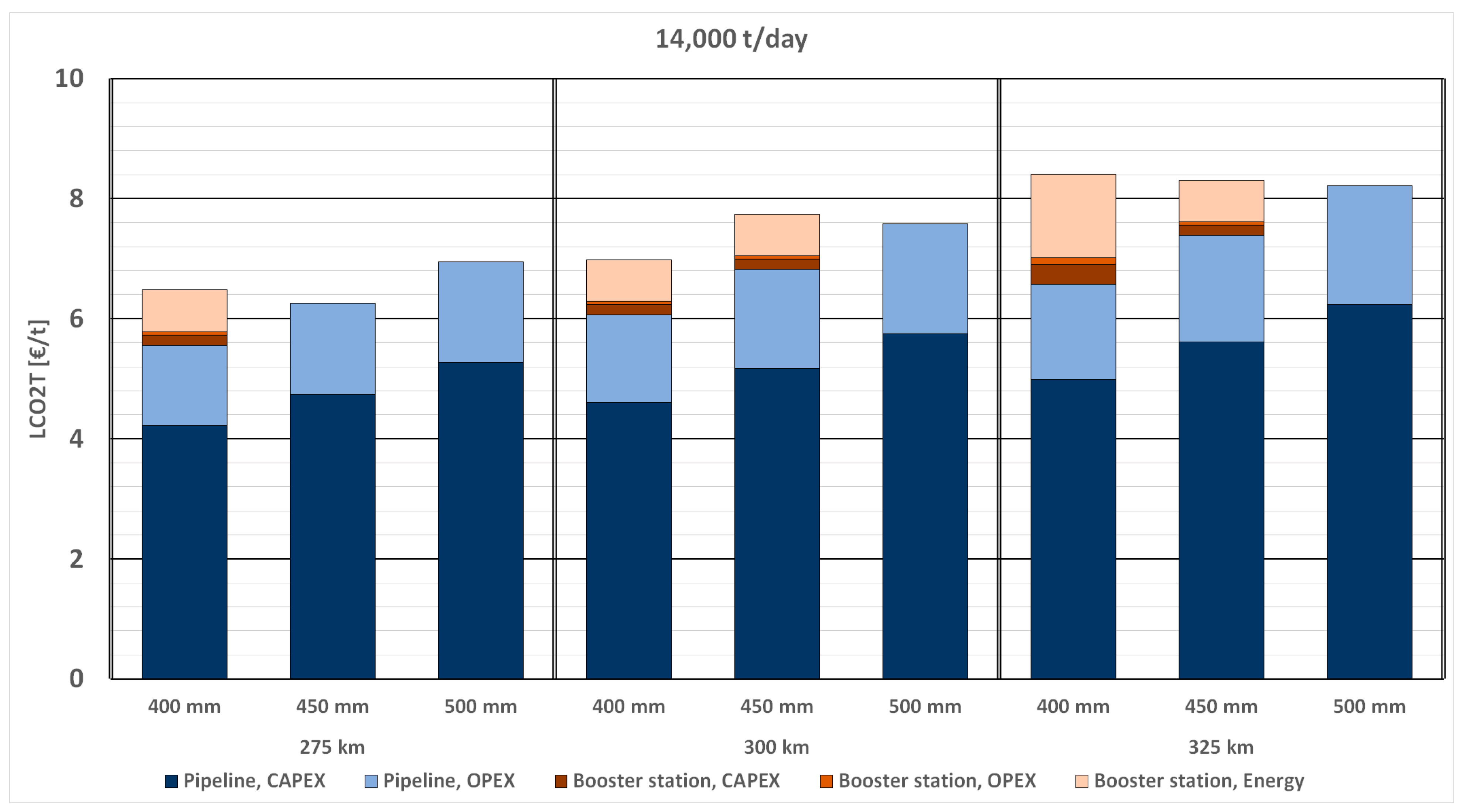

3. Results & Discussion

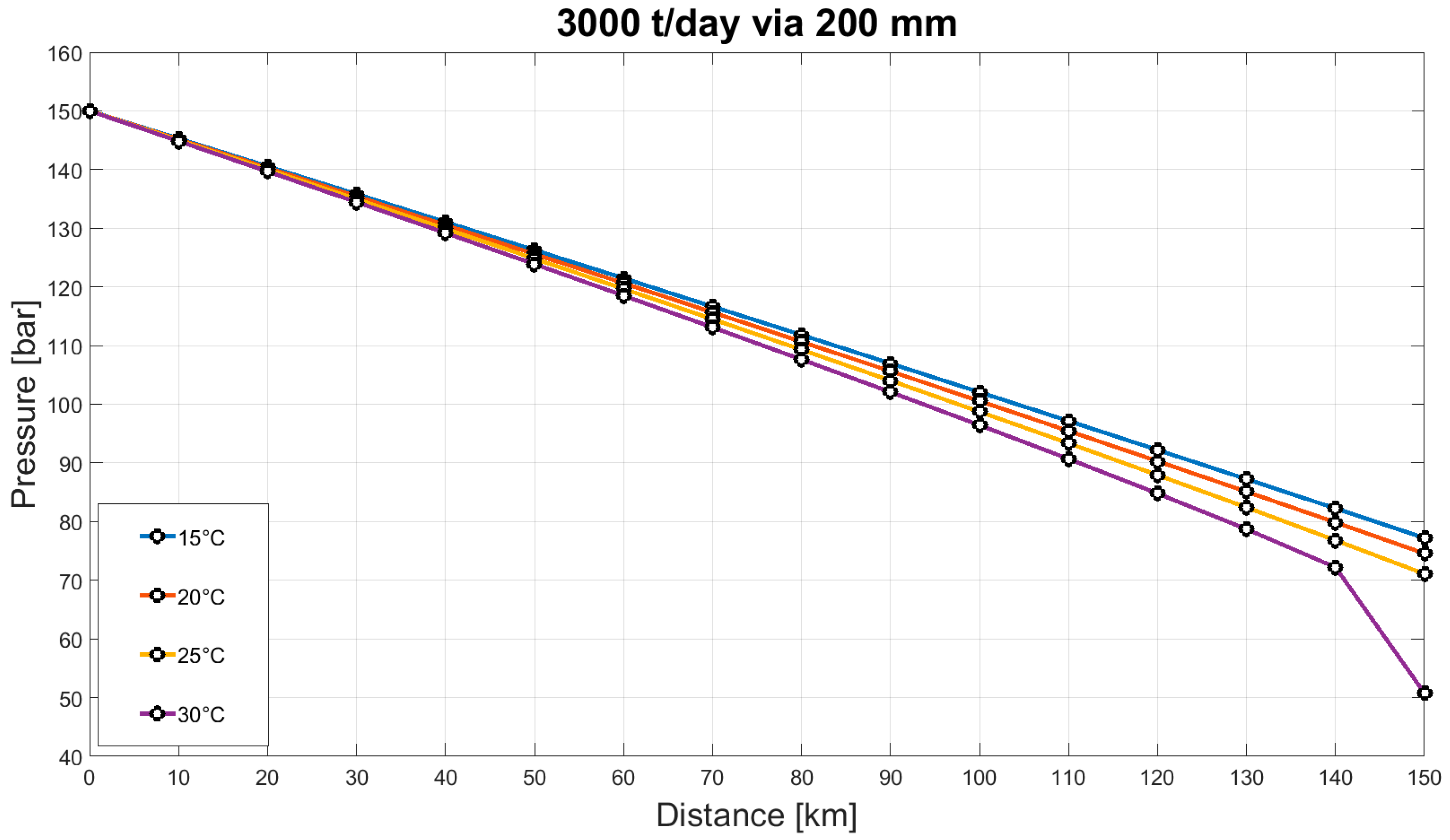

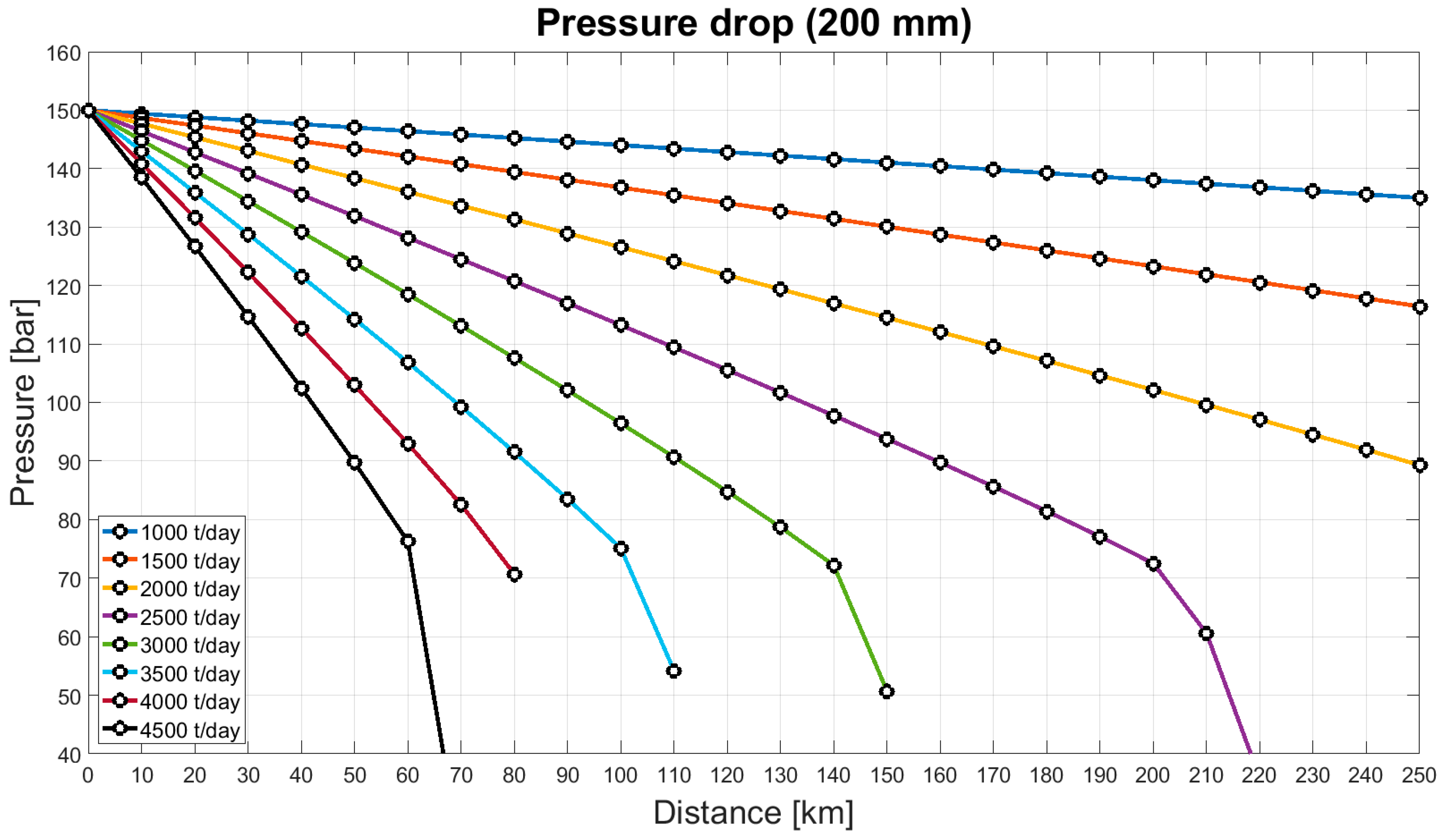

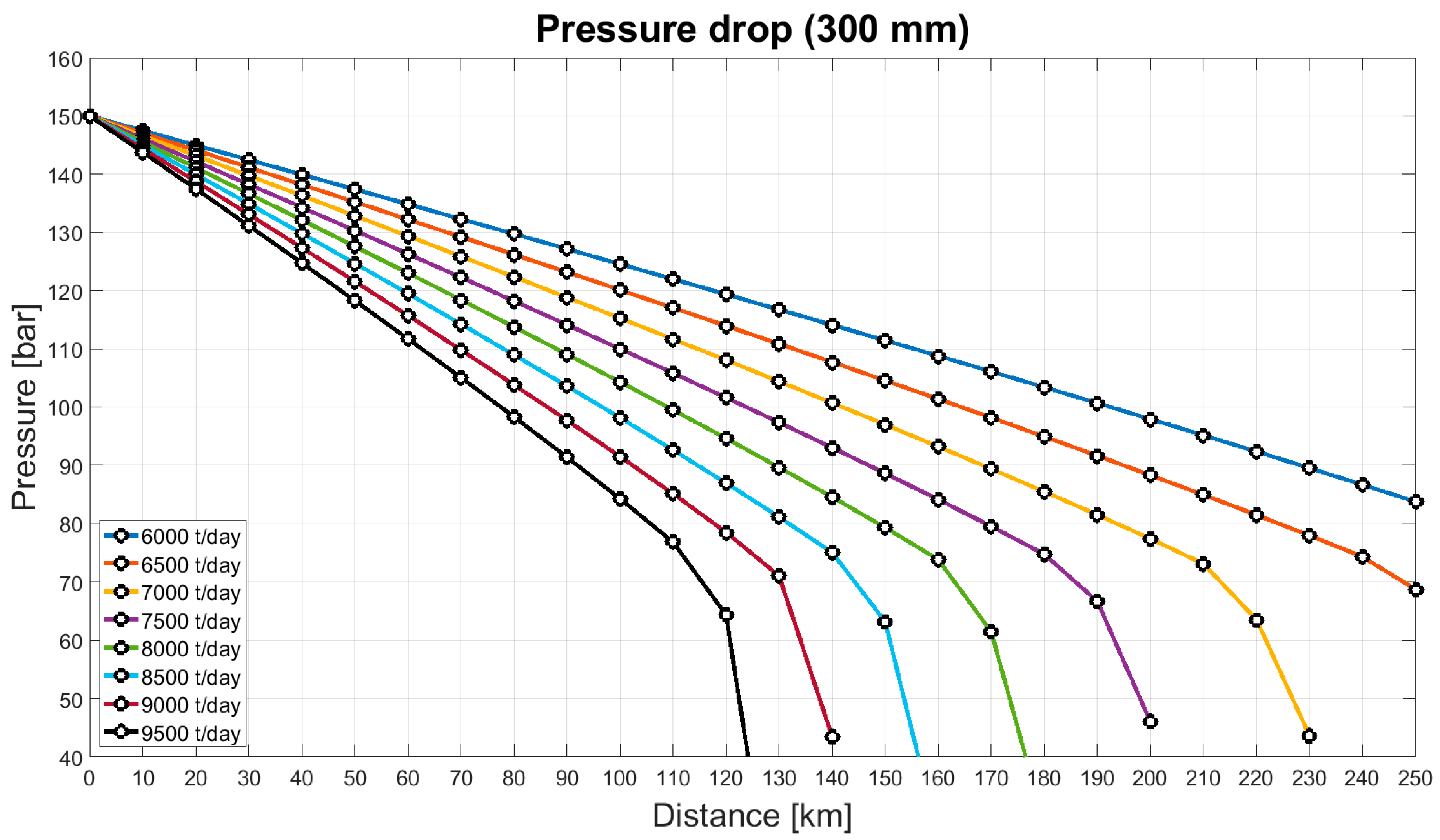

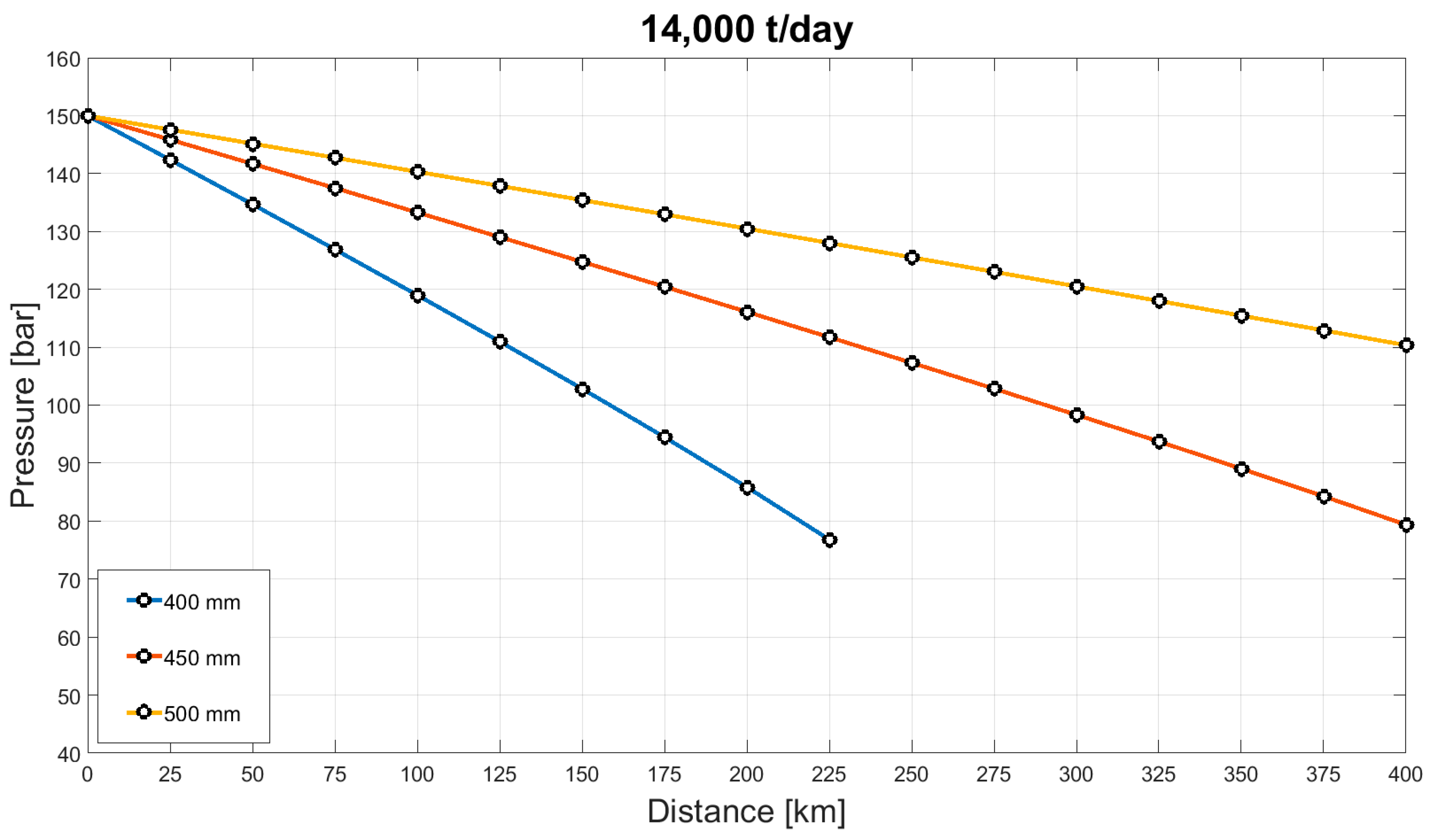

3.1. Pressure Drop

3.2. Pipeline

3.3. Anomalies

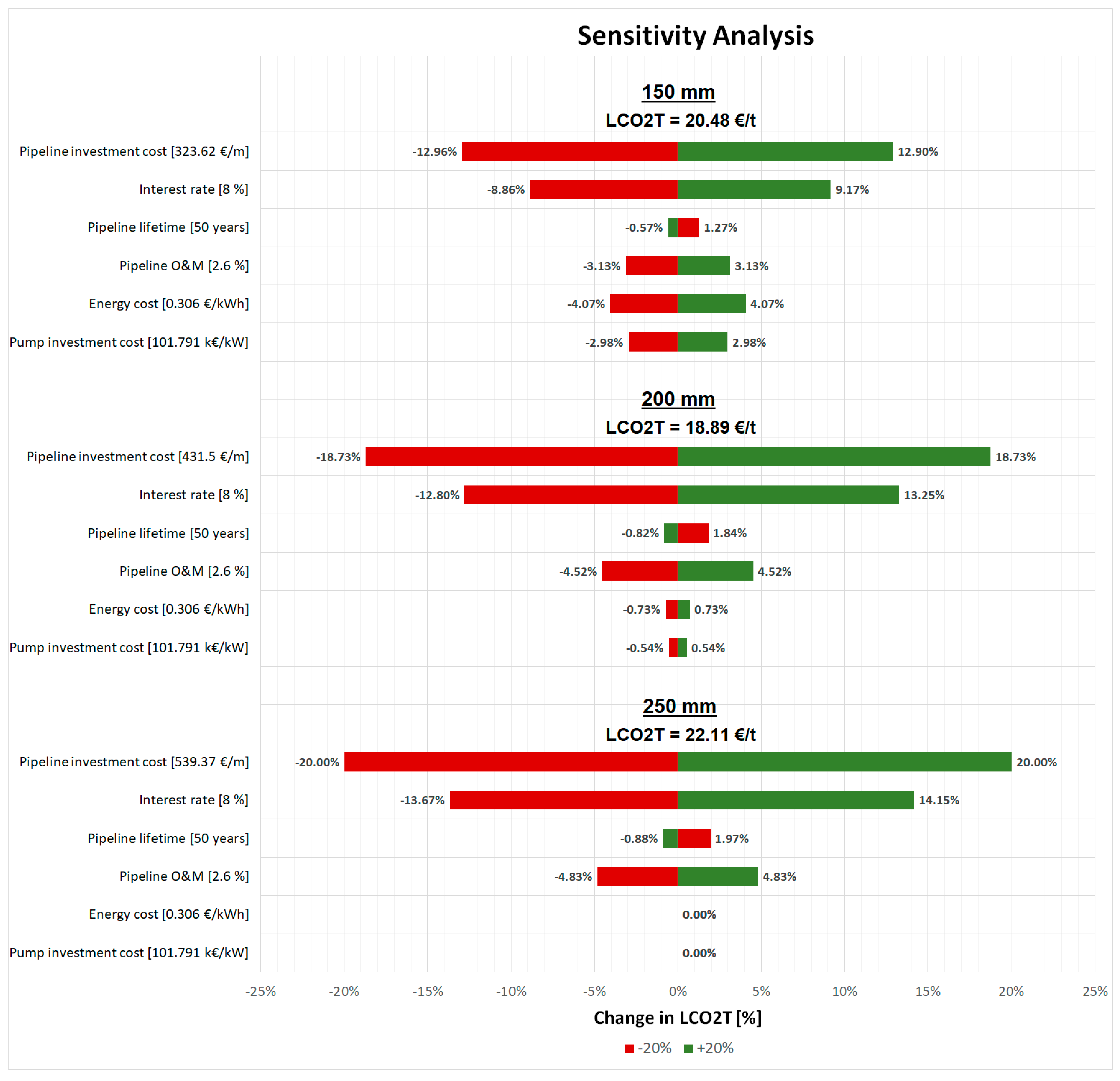

3.4. Sensitivity Analysis

4. Conclusions

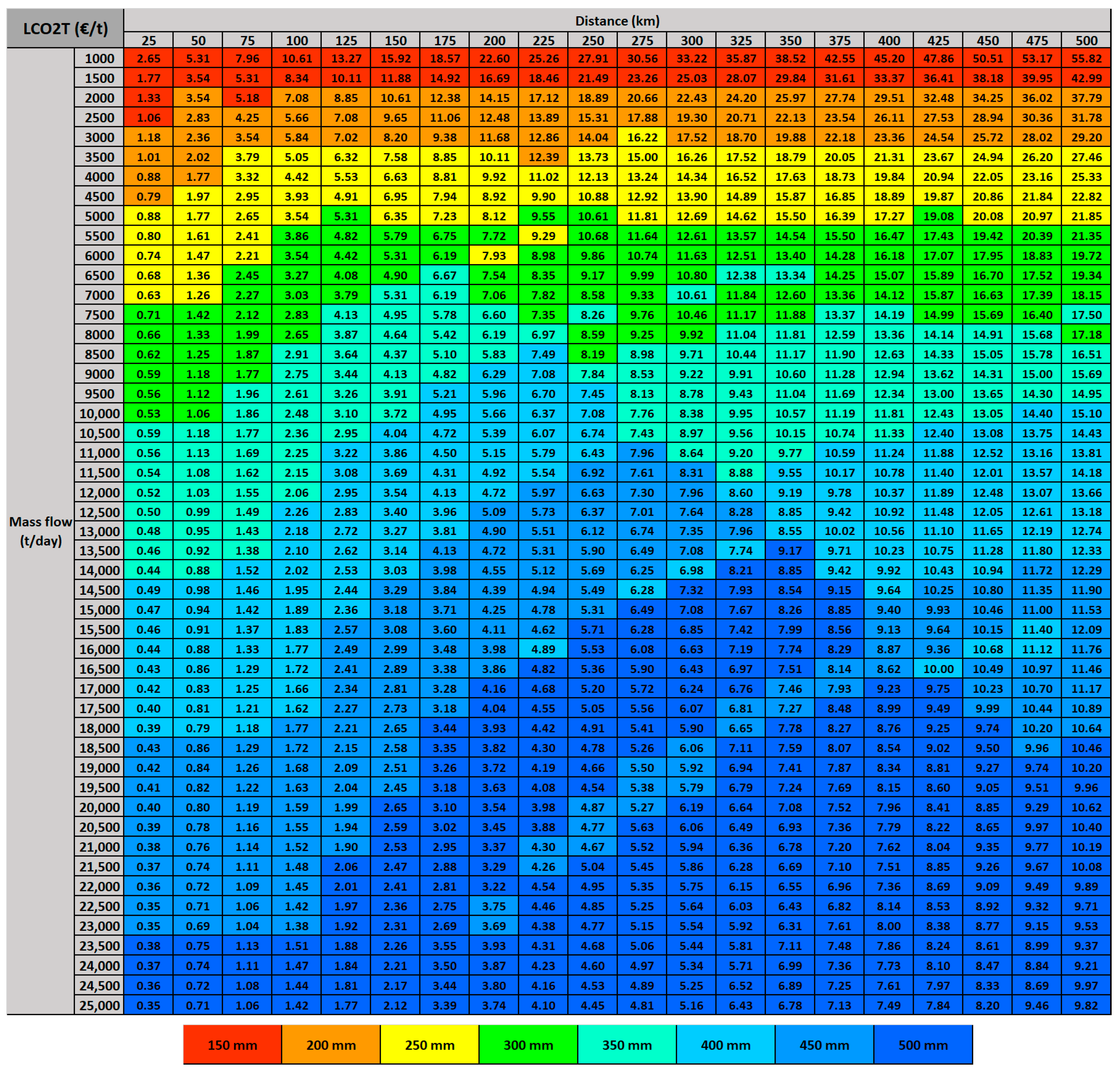

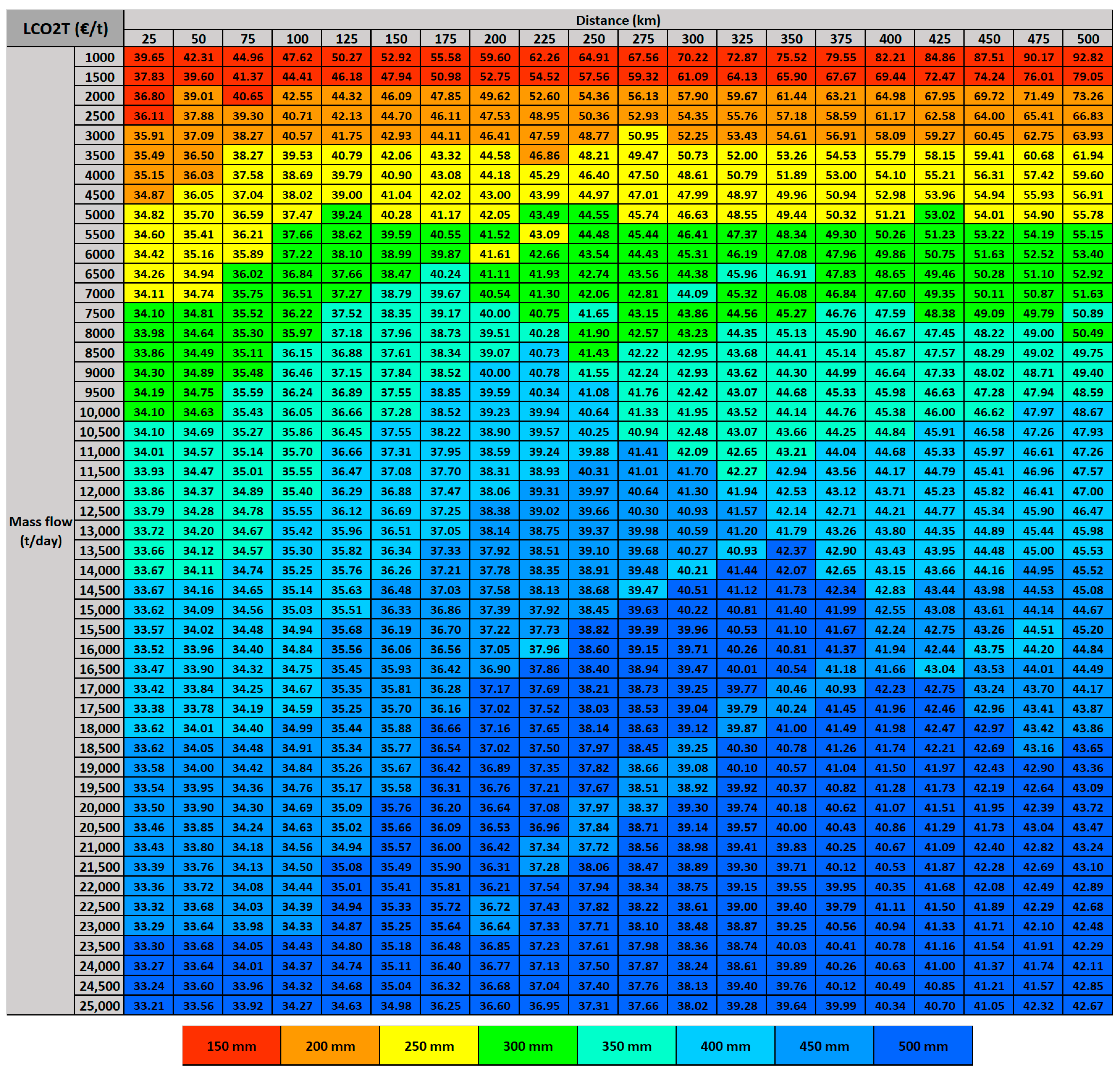

- Costs: The estimated levelized transport costs span a wide range, from 0.25 €/t to 55.82 €/t, depending on the transported mass, which varies from 1000 t/day to 25,000 t/day, and transport distances ranging from 25 km to 500 km. When factoring in initial compression costs, the LCO2T extends from 33.21 €/t to as high as 92.82 €/t for the same parameters. The calculated costs are based on various assumptions and serve as fundamental reference points for infrastructure planning.

- Pipeline diameter: An analysis was conducted on eight different pipeline diameters, spanning from 150 mm to 500 mm. The resulting LCO2T calculations play a pivotal role in identifying the optimal pipeline diameter tailored to specific mass flow requirements and transport distances.

- Flow temperature: This research emphasizes the impact of CO2 flow temperature within the pipeline. Elevated temperatures cause higher pressure loss, emphasizing the influence of environmental conditions on pipeline performance.

- Booster stations: Determining the exact distance at which a booster pump should be placed is one of the key highlights of this study. It is clear from the results that the number of booster stations plays a key role in determining the optimal diameter size, as it significantly impacts the total LCO2T.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations and Notations

| Symbols | Unit | Meaning |

| M€ | Base cost of compressor | |

| k€ | Base cost of pump | |

| M€ | Compressor investment cost | |

| J/kg/K | Specific heat under constant pressure | |

| k€ | Pump investment cost | |

| € | Total investment cost of compressor and pump | |

| J/kg/K | Specific heat under constant volume | |

| - | Capacity factor for compressor and pump | |

| - | Capacity factor for pipeline | |

| - | Compression ratio | |

| - | Capital recovery factor for compressor and pump | |

| - | Capital recovery factor for pipeline | |

| m | Diameter of pipeline | |

| €/year | Annual energy cost of compression and pumping | |

| - | Friction factor | |

| - | Interest rate | |

| - | Cumulative inflation rate from 2010 to 2024 | |

| €/m | Pipeline investment cost | |

| € | Total investment cost for pipeline | |

| - | Ratio of specific heat under constant pressure to specific heat under constant volume | |

| m | Length of pipeline | |

| €/t | Levelized cost of compressor and pump energy | |

| €/t | Levelized cost of initial compressor and pump investment | |

| €/t | Levelized cost of compressor and pump O&M | |

| €/t | Levelized cost of pipeline transport | |

| €/t | Levelized cost of pipeline investment | |

| €/t | Levelized cost of pipeline O&M | |

| t/day | CO2 mass flow rate per day | |

| kg/kmol | Molecular weight of CO2 | |

| t/year | Mass of CO2 transported per year | |

| - | Multiplication exponent | |

| years | Lifetime | |

| - | Number of compressor stages | |

| - | Number of parallel compressor units | |

| - | Number of parallel pump units | |

| €/year | Operations and maintenance costs for compressor and pumps | |

| €/year | Operations and maintenance costs for pipeline | |

| bar | Base pressure | |

| bar | Critical pressure/Outlet pressure of compressor | |

| €/kWh | Electricity cost | |

| bar | Final pressure of pump | |

| bar | Inlet pressure of pump | |

| bar | Inlet pressure of compressor | |

| Sm3/day | Standard volume flow rate | |

| kJ/kmol/K | Universal gas constant | |

| - | Reynolds number | |

| K | Base temperature | |

| K | Flow temperature | |

| K | CO2 temperature at compressor inlet | |

| m/s | Velocity of CO2 in pipeline | |

| kW | Base scale of compressor | |

| kW | Total compression power | |

| kW | Maximum capacity of compressor unit | |

| kW | Pumping power per unit | |

| kW | Maximum capacity of pump unit | |

| kW | Compressor power per stage | |

| - | Compressor scaling factor | |

| - | Pump scaling factor | |

| - | Compressibility factor | |

| - | Average CO2 compressibility factor | |

| Greek symbols | Unit | Meaning |

| bar | Pressure drop | |

| mm | Pipe roughness | |

| - | Isentropic efficiency | |

| - | Pump efficiency | |

| kg/m3 | Density of CO2 at average pressure and temperature | |

| kg/m3 | Density of CO2 at base temperature and pressure | |

| kg/m/s | Dynamic viscosity | |

| Abbreviations | Meaning | |

| CAPEX | Capital expenditure | |

| CCUS | Carbon capture, utilization, and storage | |

| LCO2T | Levelized cost of carbon dioxide transport | |

| O&M | Operation and maintenance | |

| OPEX | Operational expenditure | |

References

- BMWK. Kriterien zur Festlegung des Wasserstoff-Kernnetz Szenarios. Available online: https://www.bmwk.de/Redaktion/DE/Downloads/E/240226-eckpunkte-cms.pdf?__blob=publicationFile&v=8 (accessed on 17 May 2024).

- Dalheimer. 20240226-Referentenentwurf-cms. Available online: https://www.bmwk.de/Redaktion/DE/Downloads/Gesetz/20240226-referentenentwurf-cms.pdf?__blob=publicationFile&v=10 (accessed on 17 May 2024).

- Rüger, J.; Busse, A., Dr.; Röhrkasten, S., Dr. Eckpunkte Langzeitstrategie Negativemissionen. Available online: https://www.bmwk.de/Redaktion/DE/Downloads/E/240226-eckpunkte-negativemissionen.pdf?__blob=publicationFile&v=8 (accessed on 17 May 2024).

- Wirtschaft und Klimaschutz, BMWK—Bundesministerium für. Bundesminister Habeck Will den Einsatz von CCS Ermöglichen: “Ohne CCS Können wir Unmöglich die Klimaziele Erreichen”. Available online: https://www.bmwk.de/Redaktion/DE/Pressemitteilungen/2024/02/20240226-habeck-will-den-einsatz-von-ccs-ermoeglichen.html (accessed on 17 May 2024).

- IEA. Putting CO2 to Use. Available online: https://iea.blob.core.windows.net/assets/50652405-26db-4c41-82dc-c23657893059/Putting_CO2_to_Use.pdf (accessed on 17 May 2024).

- Global Status of CCS 2021. Available online: https://ukccsrc.ac.uk/wp-content/uploads/2024/04/guloren-turan-global-status-of-ccs-2023.pdf (accessed on 17 May 2024).

- Simonsen, K.R.; Hansen, D.S.; Pedersen, S. Challenges in CO2 transportation: Trends and perspectives. Renew. Sustain. Energy Rev. 2024, 191, 114149. [Google Scholar] [CrossRef]

- Liu, E.; Lu, X.; Wang, D. A Systematic Review of Carbon Capture, Utilization and Storage: Status, Progress and Challenges. Energies 2023, 16, 2865. [Google Scholar] [CrossRef]

- Lu, H.; Ma, X.; Huang, K.; Fu, L.; Azimi, M. Carbon dioxide transport via pipelines: A systematic review. J. Clean. Prod. 2020, 266, 121994. [Google Scholar] [CrossRef]

- Wang, H.; Chen, J.; Li, Q. A Review of Pipeline Transportation Technology of Carbon Dioxide. IOP Conf. Ser. Earth Environ. Sci. 2019, 310, 32033. [Google Scholar] [CrossRef]

- Onyebuchi, V.E.; Kolios, A.; Hanak, D.P.; Biliyok, C.; Manovic, V. A systematic review of key challenges of CO2 transport via pipelines. Renew. Sustain. Energy Rev. 2018, 81, 2563–2583. [Google Scholar] [CrossRef]

- Peletiri, S.; Rahmanian, N.; Mujtaba, I. CO2 Pipeline Design: A Review. Energies 2018, 11, 2184. [Google Scholar] [CrossRef]

- Hoa, L.Q.; Baessler, R.; Bettge, D. On the Corrosion Mechanism of CO2 Transport Pipeline Steel Caused by Condensate: Synergistic Effects of NO2 and SO2. Materials 2019, 12, 364. [Google Scholar] [CrossRef] [PubMed]

- Porter, R.T.; Fairweather, M.; Pourkashanian, M.; Woolley, R.M. The range and level of impurities in CO2 streams from different carbon capture sources. Int. J. Greenh. Gas Control 2015, 36, 161–174. [Google Scholar] [CrossRef]

- Zhao, Q.; Li, Y.-X. The influence of impurities on the transportation safety of an anthropogenic CO2 pipeline. Process Saf. Environ. Prot. 2014, 92, 80–92. [Google Scholar] [CrossRef]

- Knoope, M.; Guijt, W.; Ramírez, A.; Faaij, A. Improved cost models for optimizing CO2 pipeline configuration for point-to-point pipelines and simple networks. Int. J. Greenh. Gas Control 2014, 22, 25–46. [Google Scholar] [CrossRef]

- Grant, T.; Morgan, D.; Gerdes, K. Quality Guidelines for Energy System Studies: Carbon Dioxide Transport and Storage Costs in NETL Studies; DOE/NETL-2013/1614; National Energy Technology Laboratory (NETL): Pittsburgh, PA, USA; Morgantown, WV, USA; Albany, OR, USA, 2017. Available online: https://www.osti.gov/biblio/1557135 (accessed on 17 May 2024).

- Mohammadi, M.; Hourfar, F.; Elkamel, A.; Leonenko, Y. Economic Optimization Design of CO2 Pipeline Transportation with Booster Stations. Ind. Eng. Chem. Res. 2019, 58, 16730–16742. [Google Scholar] [CrossRef]

- Rubin, E.S.; Davison, J.E.; Herzog, H.J. The cost of CO2 capture and storage. Int. J. Greenh. Gas Control 2015, 40, 378–400. [Google Scholar] [CrossRef]

- Grant, T.; Poe, A.; Valenstein, J.; Guinan, A.; Shih, C.; Lin, S. Quality Guidelines for Energy System Studies: Carbon Dioxide Transport and Storage Costs in NETL Studies; National Energy Technology Laboratory (NETL): Pittsburgh, PA, USA; Morgantown, WV, USA, 2019. Available online: https://www.osti.gov/biblio/1567735 (accessed on 17 May 2024).

- Mallon, W.; Buit, L.; van Wingerden, J.; Lemmens, H.; Eldrup, N.H. Costs of CO2 Transportation Infrastructures. Energy Procedia 2013, 37, 2969–2980. [Google Scholar] [CrossRef]

- Global CCS Institute. The Costs of CO2 Transport: Post-Demonstration CCS in the EU—Global CCS Institute. Available online: https://www.globalccsinstitute.com/resources/publications-reports-research/the-costs-of-co2-transport-post-demonstration-ccs-in-the-eu/ (accessed on 26 March 2024).

- Correia, S.d.S.J.; Morbee, J.; Tzimas, E. Technical and Economic Characteristics of a CO2 Transmission Pipeline Infrastructure; Publications Office of the European Union: Luxembourg, 2011; ISNN 1018-5593. [Google Scholar] [CrossRef]

- Knoope, M.; Ramírez, A.; Faaij, A. A state-of-the-art review of techno-economic models predicting the costs of CO2 pipeline transport. Int. J. Greenh. Gas Control 2013, 16, 241–270. [Google Scholar] [CrossRef]

- Hydrogen Delivery Scenario Analysis Model. Available online: https://hdsam.es.anl.gov/index.php?content=hdsam (accessed on 26 March 2024).

- Solomon, M.D.; Heineken, W.; Scheffler, M.; Birth-Reichert, T. Cost Optimization of Compressed Hydrogen Gas Transport via Trucks and Pipelines. Energy Technol. 2024, 12, 2300785. [Google Scholar] [CrossRef]

- Witkowski, A.; Majkut, M.; Rulik, S. Analysis of pipeline transportation systems for carbon dioxide sequestration. Arch. Thermodyn. 2014, 35, 117–140. [Google Scholar] [CrossRef]

- Jackson, S. Development of a Model for the Estimation of the Energy Consumption Associated with the Transportation of CO2 in Pipelines. Energies 2020, 13, 2427. [Google Scholar] [CrossRef]

- McCollum, D.L.; Ogden, J.M. Techno-Economic Models for Carbon Dioxide Compression, Transport, and Storage & Correlations for Estimating Carbon Dioxide Density and Viscosity; Institute of Transportation Studies: Davis, CA, USA, 2006. [Google Scholar]

- Deng, H.; Roussanaly, S.; Skaugen, G. Techno-economic analyses of CO2 liquefaction: Impact of product pressure and impurities. Int. J. Refrig. 2019, 103, 301–315. [Google Scholar] [CrossRef]

- Bell, I.H.; Wronski, J.; Quoilin, S.; Lemort, V. Pure and Pseudo-pure Fluid Thermophysical Property Evaluation and the Open-Source Thermophysical Property Library CoolProp. Ind. Eng. Chem. Res. 2014, 53, 2498–2508. [Google Scholar] [CrossRef] [PubMed]

- CO2Tab Downloads. Available online: http://www.chemicalogic.com/Pages/CO2TabDownloads.html (accessed on 6 May 2024).

- Kreutz, T.; Williams, R.; Consonni, S.; Chiesa, P. Co-production of hydrogen, electricity and CO from coal with commercially ready technology. Part B: Economic analysis. Int. J. Hydrog. Energy 2005, 30, 769–784. [Google Scholar] [CrossRef]

- €1 in 2010 → 2024|Germany Inflation Calculator. Available online: https://www.officialdata.org/germany/inflation/2010?amount=1 (accessed on 6 May 2024).

- Pipeline Transmission of CO2 and Energy Transmission Study–Report; IEA Greenhouse Gas R&D Programme: Cheltenham, UK, 2002.

- The Danish Energy Agency. Technology Data for Carbon Capture, Transport and Storage. Available online: https://ens.dk/en/our-services/projections-and-models/technology-data/technology-data-carbon-capture-transport-and (accessed on 26 March 2024).

- Wildenborg, T.; Gale, J.; Hendriks, C.; Holloway, S.; Brandsma, R.; Kreft, E.; Lokhorst, A. Cost curves for CO2 storage: European sector. In Greenhouse Gas Control Technologies 7; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2005; pp. 603–610. [Google Scholar] [CrossRef]

- Heddle, G.; Herzog, H.; Klett, M. The Economics of CO2 Storage; Massachusetts Institute of Technology, Laboratory for Energy and the Environment: Cambridge, MA, USA, 2003. [Google Scholar]

- Piessens, K.; Laenen, B.; Nijs, W.; Mathieu, P.; Baele, J.M.; Hendriks, C.; Bertrand, E.; Bierkens, J.; Brandsma, R.; Broothaers, M.; et al. Policy Support System for Carbon Capture and Storage; Relatório final para a Science for a Sustainable Development (SSD), 2008; Available online: https://www.belspo.be/belspo/SSD/science/Reports/PSS-CCS_FinRep_2008.DEF.pdf (accessed on 17 May 2024).

- Turgut, O.E.; Asker, M.; Çoban, M.T. A review of non iterative friction factor correlations for the calculation of pressure drop in pipes. Bitlis Eren Univ. J. Sci. Technol. 2014, 4, 1–8. [Google Scholar] [CrossRef]

- Solomon, M.D.; Heineken, W.; Scheffler, M.; Birth-Reichert, T. Pressure Drop In Pipelines Transporting Compressed Hydrogen Gas. Energy Technol. 2023, 12, 2300785. [Google Scholar] [CrossRef]

| Diameter [mm] | Investment Cost () [€/m] |

|---|---|

| 150 | 323.62 |

| 200 | 431.5 |

| 250 | 539.37 |

| 300 | 647.24 |

| 350 | 755.12 |

| 400 | 862.99 |

| 450 | 970.86 |

| 500 | 1078.74 |

| Assumption | Value | Unit |

|---|---|---|

| [26] | 90% | |

| 8% | ||

| 50 | years | |

| Fix O&M factor [25] | 2.6% |

| Stage | Pressure Range [bar] | Average Temperature [K] [29] | ||

|---|---|---|---|---|

| 1 | 0.995 | 1.27 | 1.0–2.36 | 356 |

| 2 | 0.989 | 1.28 | 2.36–5.59 | 356 |

| 3 | 0.974 | 1.30 | 5.59–13.21 | 356 |

| 4 | 0.937 | 1.35 | 13.21–31.22 | 356 |

| 5 | 0.846 | 1.52 | 31.22–73.80 | 356 |

| Assumption | Value | Unit |

|---|---|---|

| 8% | ||

| 15 | years | |

| 90% | ||

| 0.306 | €/kWh | |

| [16] | 0.9 | |

| [34] | 36.55% | |

| Universal gas constant (R) | 8.314 | kJ/(kmolK) |

| Molecular weight of CO2 (M) | 44.01 | kg/kmol |

| Compressor | ||

| [30] | 313.15 | K |

| 1 | bar | |

| 73.8 | bar | |

| [29] | 5 | |

| [16] | 80% | |

| [16,33] | 21.9 | M€ |

| [16] | 13,000 | kW |

| [16] | 0.67 | |

| [16] | 35,000 | kW |

| Pump | ||

| [16] | 303.15 | K |

| 73.8 | bar | |

| 150 | bar | |

| [16] | 75% | |

| [16] | 74.3 | k€ |

| [16] | 0.58 | |

| [16,35] | 2000 | kW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solomon, M.D.; Scheffler, M.; Heineken, W.; Ashkavand, M.; Birth-Reichert, T. Pipeline Infrastructure for CO2 Transport: Cost Analysis and Design Optimization. Energies 2024, 17, 2911. https://doi.org/10.3390/en17122911

Solomon MD, Scheffler M, Heineken W, Ashkavand M, Birth-Reichert T. Pipeline Infrastructure for CO2 Transport: Cost Analysis and Design Optimization. Energies. 2024; 17(12):2911. https://doi.org/10.3390/en17122911

Chicago/Turabian StyleSolomon, Mithran Daniel, Marcel Scheffler, Wolfram Heineken, Mostafa Ashkavand, and Torsten Birth-Reichert. 2024. "Pipeline Infrastructure for CO2 Transport: Cost Analysis and Design Optimization" Energies 17, no. 12: 2911. https://doi.org/10.3390/en17122911

APA StyleSolomon, M. D., Scheffler, M., Heineken, W., Ashkavand, M., & Birth-Reichert, T. (2024). Pipeline Infrastructure for CO2 Transport: Cost Analysis and Design Optimization. Energies, 17(12), 2911. https://doi.org/10.3390/en17122911